Glue pouring and packaging equipment for lamp production and technological method thereof

A process method and technology of packaging equipment, which are applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., can solve the problems of defective products, cannot be repaired in time, and low efficiency, and are easy to install and disassemble. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

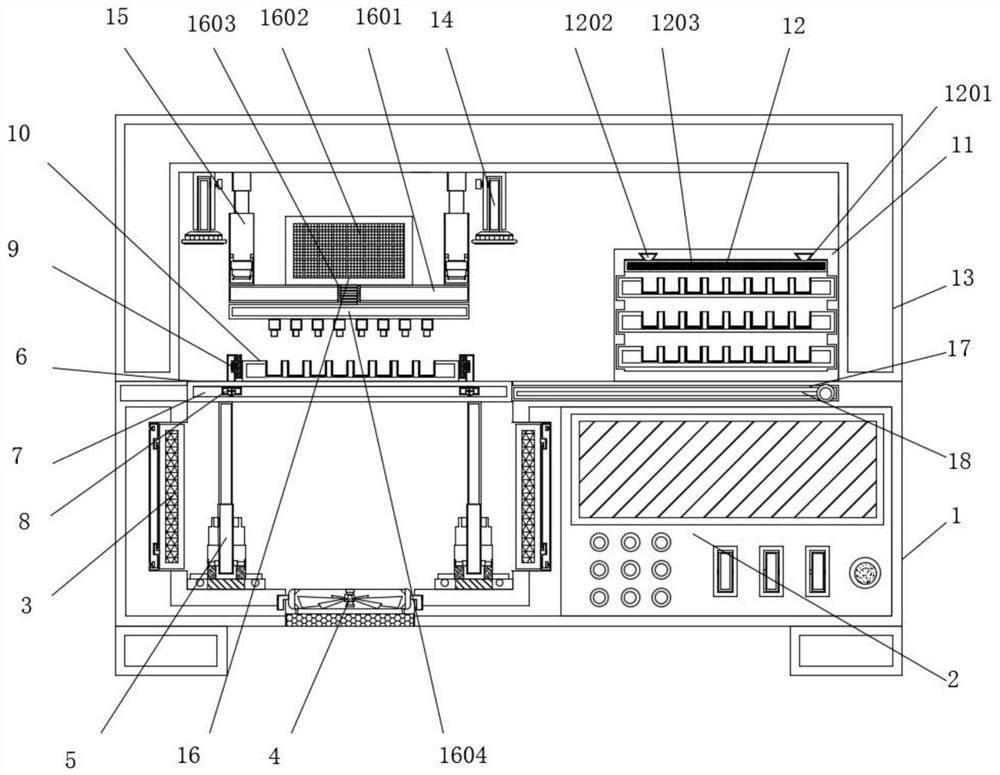

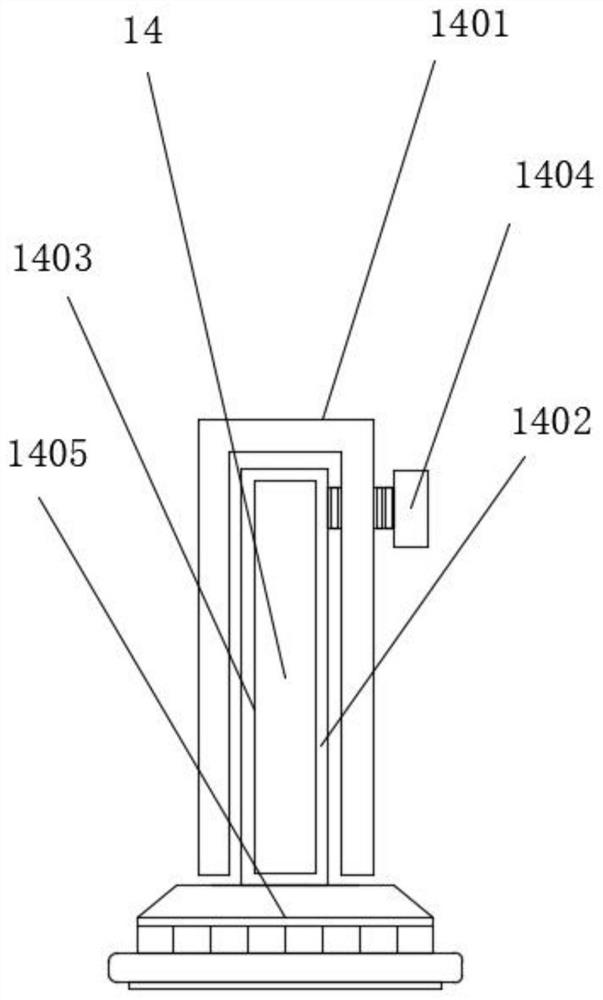

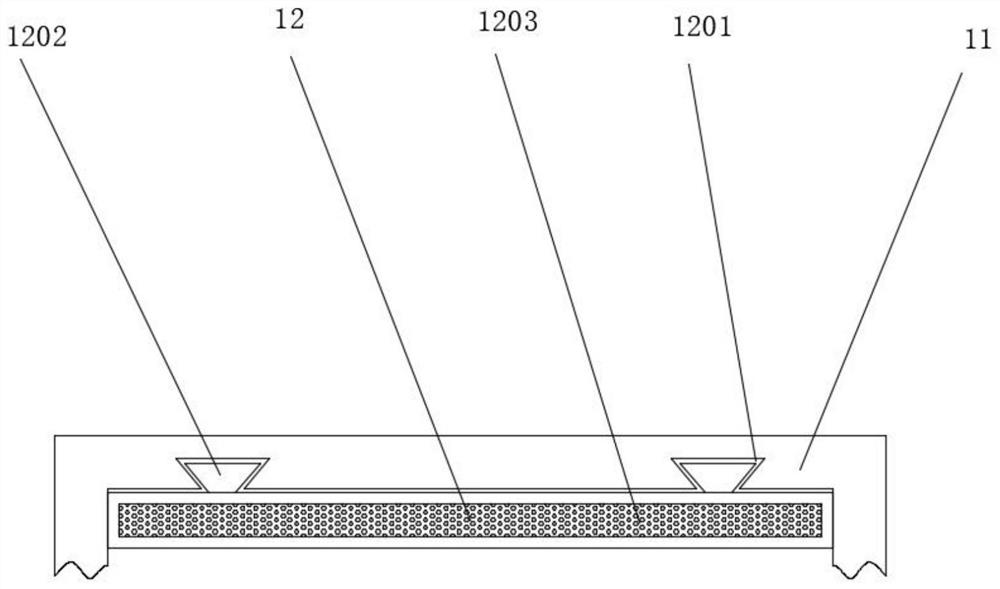

[0041] see Figure 1-6 , in this embodiment: a glue filling and encapsulating equipment for lamp production and its process method, comprising a bottom box 1; an electrical box 2 is threadedly connected to the inner side of the bottom box 1, and a heating mechanism 3 is installed on the inner side wall of the bottom box 1, and the bottom box 1 1. A heat dissipation mechanism 4 is installed under the inner side. An electric telescopic rod 5 is welded above the outer side of the bottom box 1, and the upper end of the electric telescopic rod 5 is connected to a processing table 6. At the same time, a chute 7 is opened on the inside of the processing table 6, and the inside of the chute 7 is set. There is a slider 8, and a clamping mechanism 9 is connected above the outer side of the slider 8, a material tray 10 is arranged above the outer side of the processing table 6, a material storage box 11 is arranged above the outer side of the bottom box 1, and a material storage box 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com