Heating board structure

A heating plate and fixing plate technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of complex structure of the heating device and unsatisfactory heating and drying effect, and achieve the effect of simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

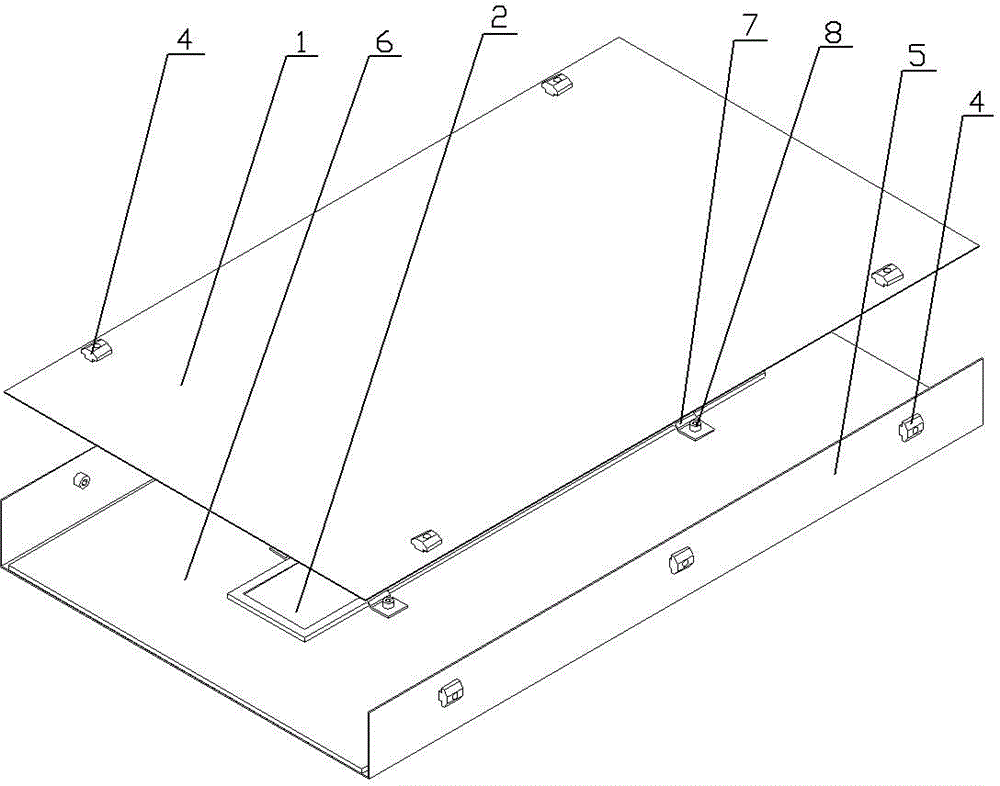

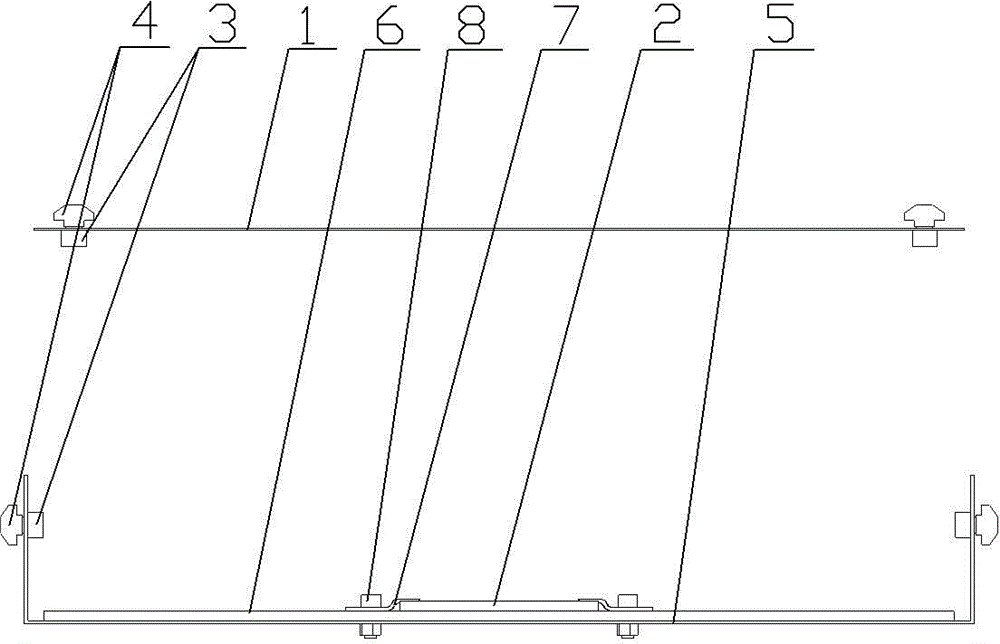

[0010] See figure 1 , figure 2 As shown, a heating plate structure includes a heating upper plate 1 and a heating lower plate 2, the upper end of the heating upper plate 1 is installed with a fixing block 4 through bolts 3, the heating lower plate 2 is installed on a U-shaped fixing plate 5, and the U-shaped fixing plate 5. Fixing blocks 4 are respectively installed on the outside of both sides through bolts 3. The fixing block 4 is in the shape of a plane with a plane on the upper end. There is a gap between the two sides of the fixing block 4 and the heating upper plate 1 and the U-shaped fixing plate 5, which is convenient. It is embedded in the T-shaped card slot of the profile or in the T-shaped guide rail; the upper end of the heating upper plate 1 is evenly installed with four fixing blocks 4 through bolts 3, and the outer sides of the U-shaped fixing plate 5 are respectively installed with three bolts 3 in a straight line The fixed block 4 arranged can realize better...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com