Patents

Literature

1322results about "Liquid/gas/vapor removal by gas jets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FET-based sensor for detecting ionic material, ionic material detecting device using the FET-based sensor, and method of detecting ionic material using the FET-based sensor

ActiveUS7859029B2Reduce concentrationHigh sensitivityDrying solid materials without heatSolid-state devicesEngineeringElectric current

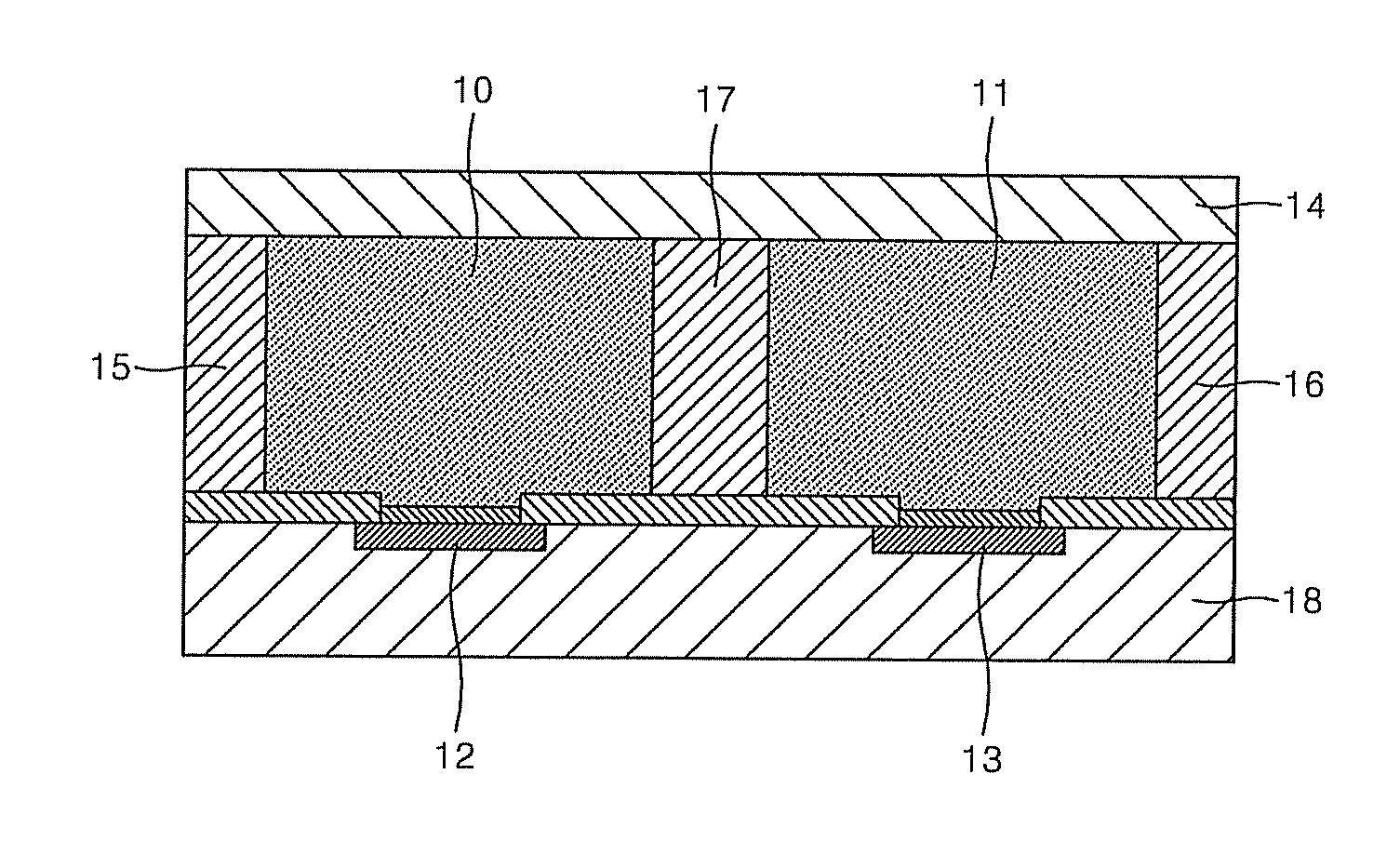

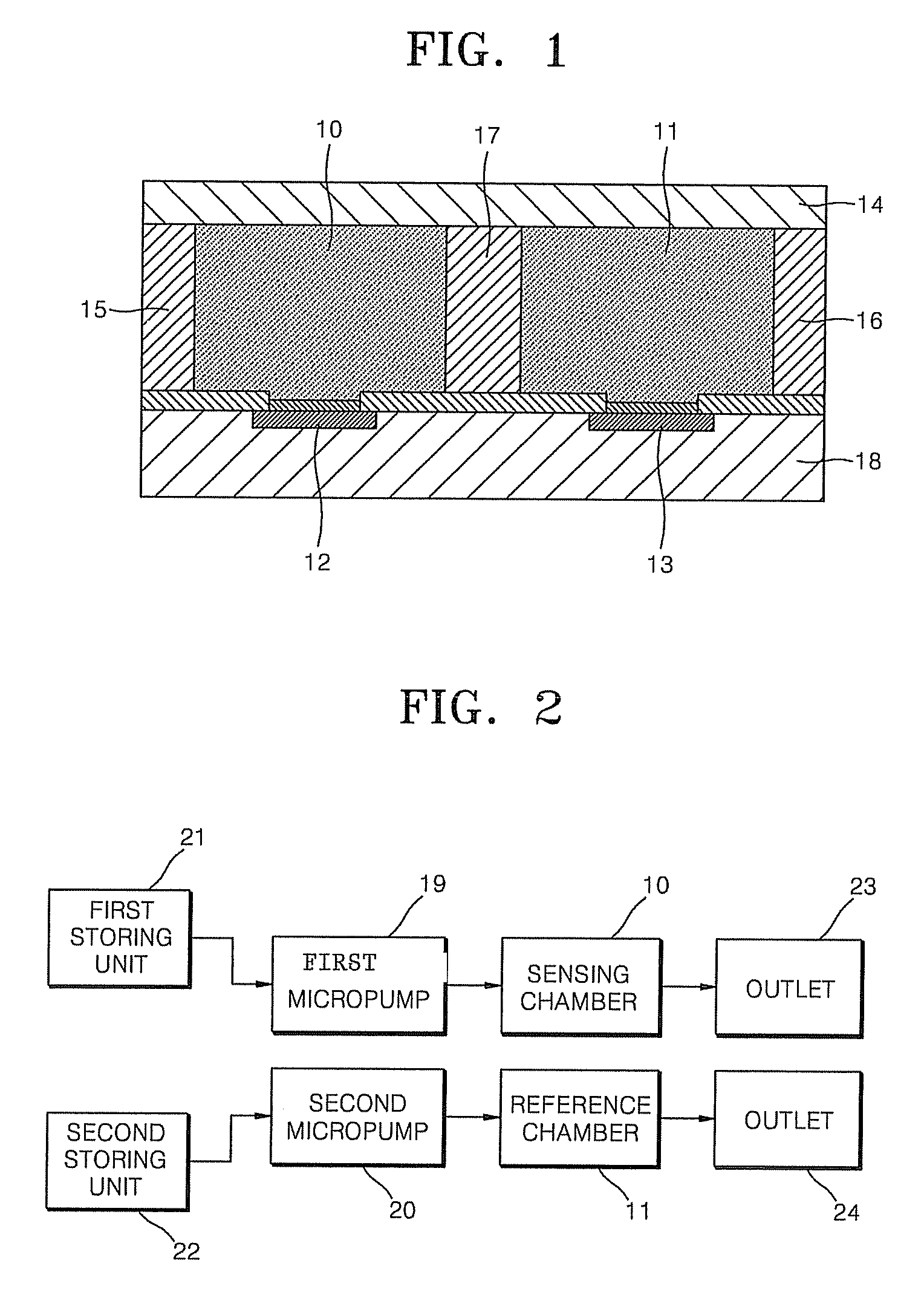

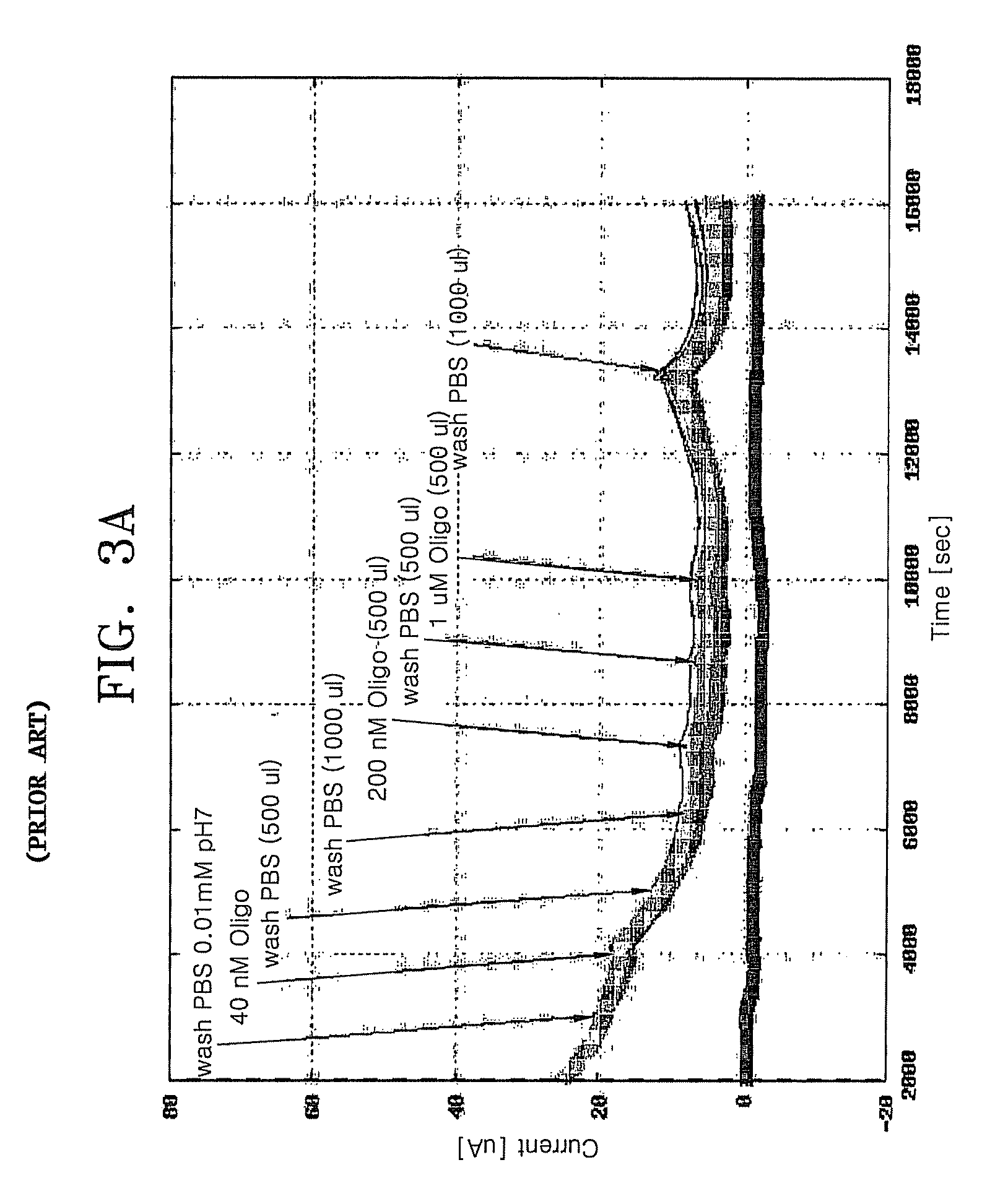

Provided are a FET-based sensor for detecting an ionic material, an ionic material detecting device including the FET-based sensor, and a method of detecting an ionic material using the FET-based sensor. The FET-based sensor includes: a sensing chamber including a reference electrode and a plurality of sensing FETs; and a reference chamber including a reference electrode and a plurality of reference FETs. The method includes: flowing a first solution into and out of the sensing chamber and the reference chamber of the FET-based sensor; flowing a second solution expected to contain an ionic material into and out of the sensing chamber while continuously flowing the first solution into and out of the reference chamber; measuring a current in a channel region between the source and drain of each of the sensing and reference FETs; and correcting the current of the sensing FETs.

Owner:SAMSUNG ELECTRONICS CO LTD

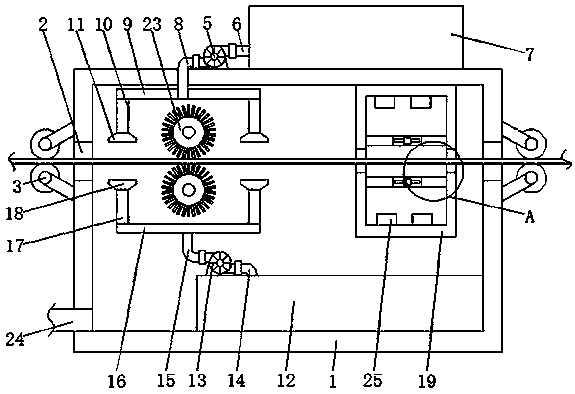

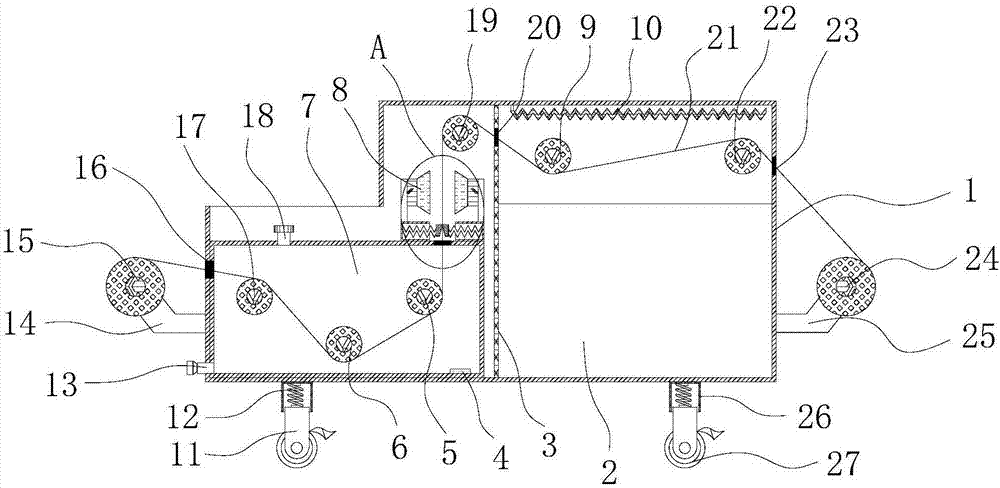

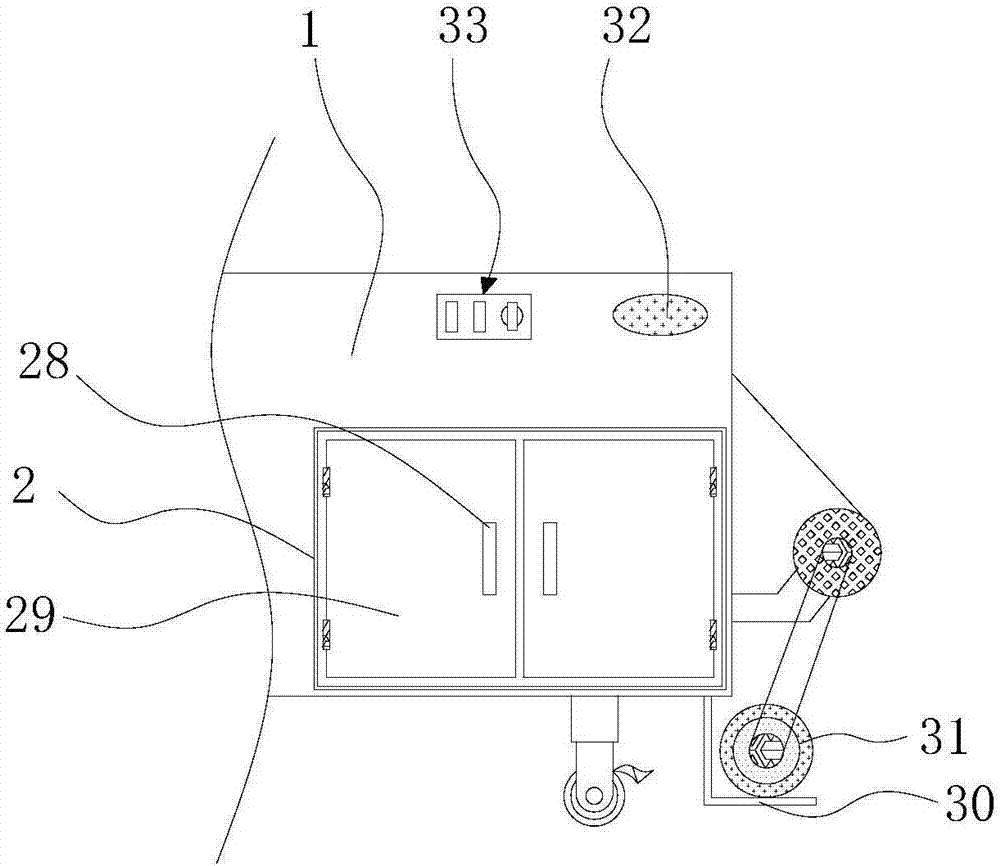

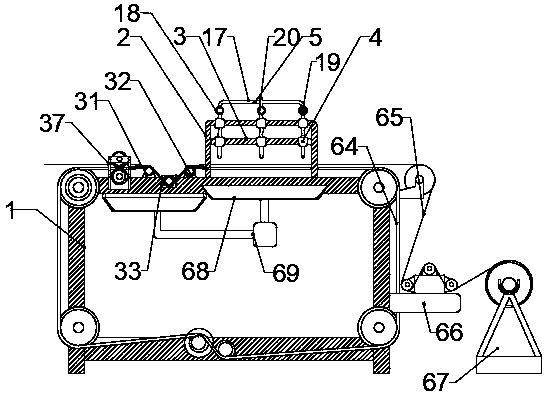

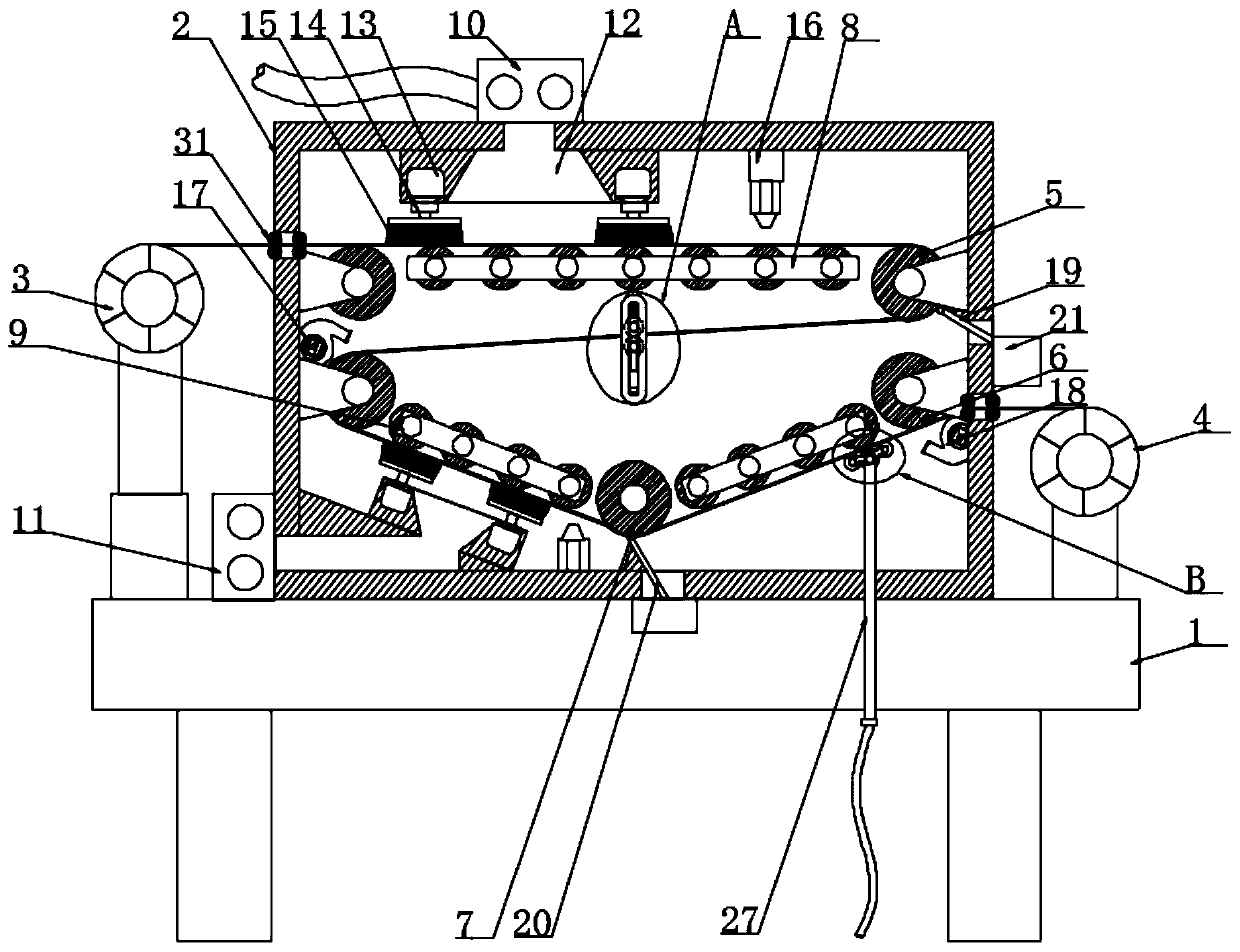

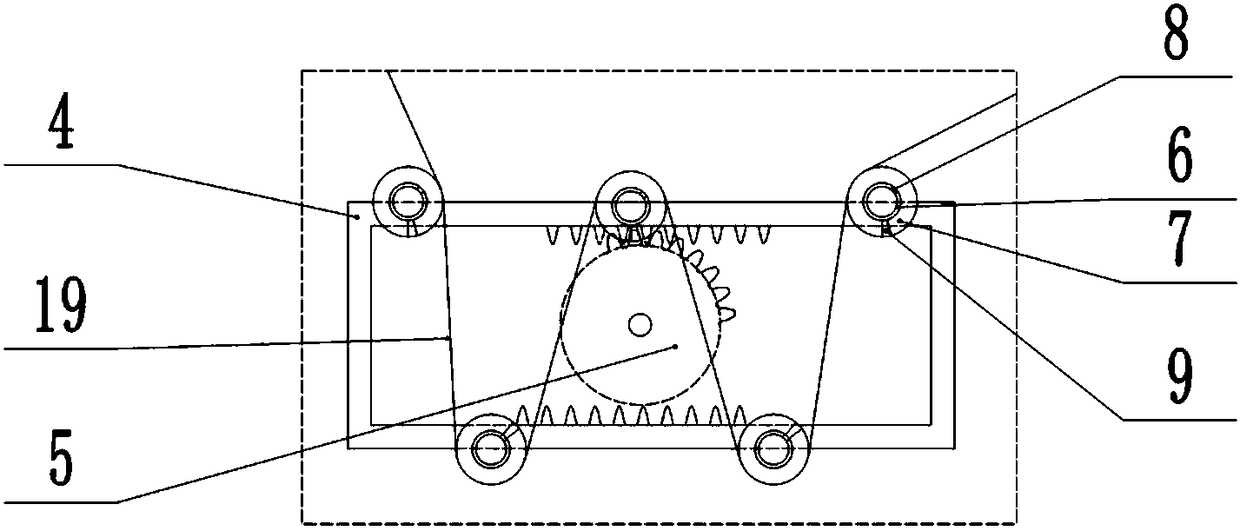

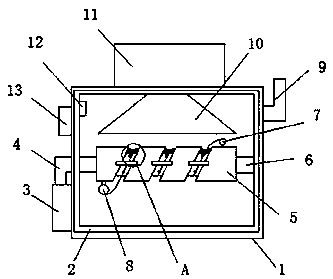

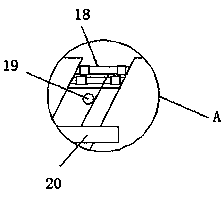

Cleaning equipment for spinning

InactiveCN107938211AWash thoroughlyEffective flushingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringAirflow

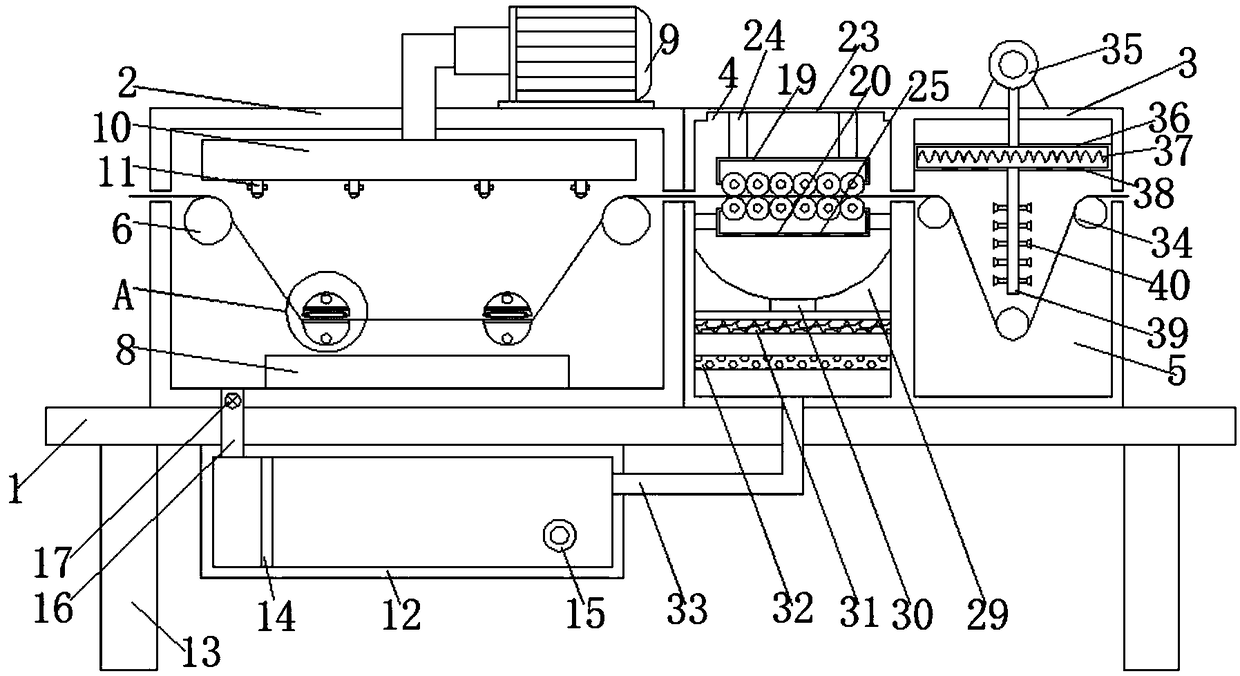

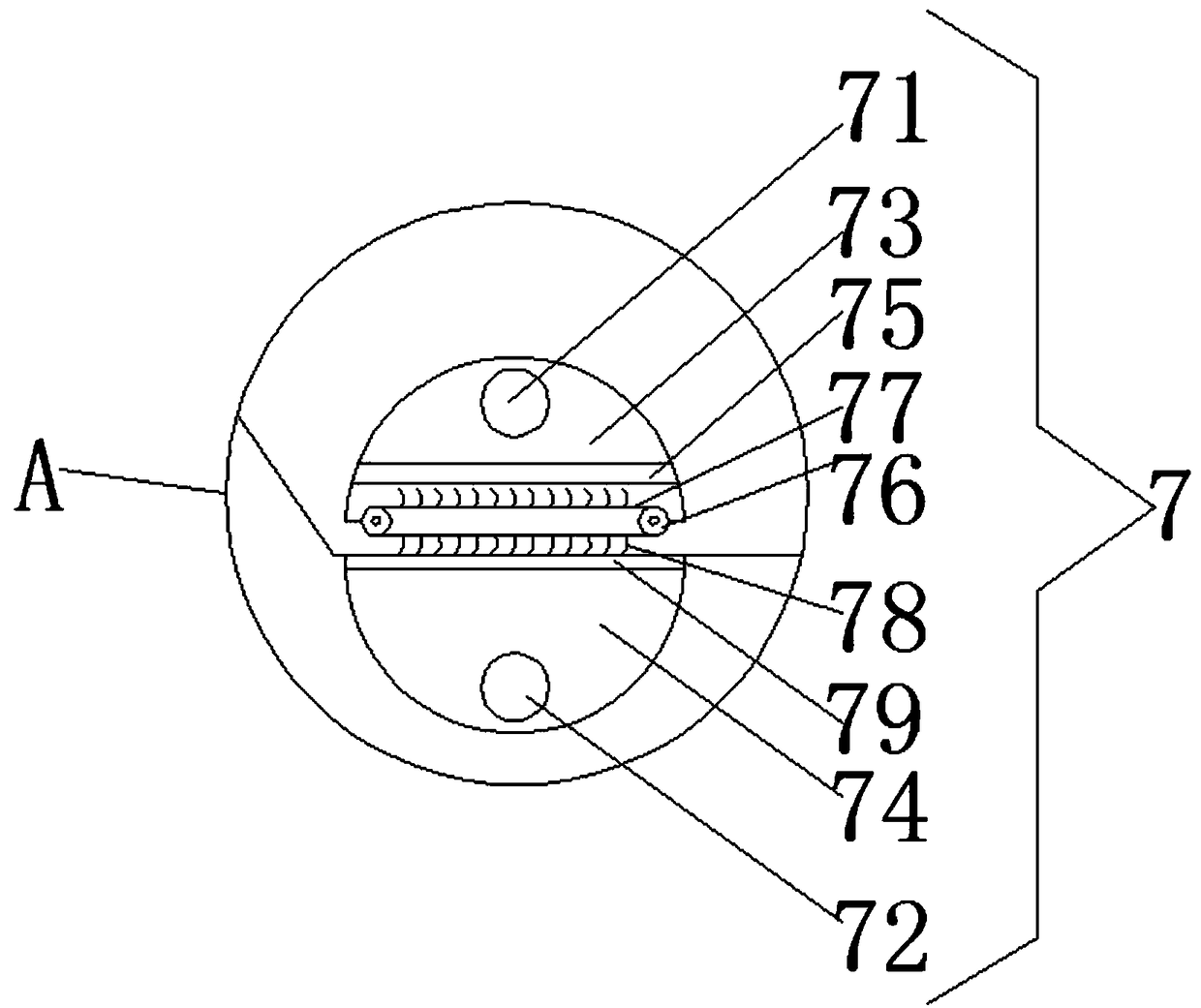

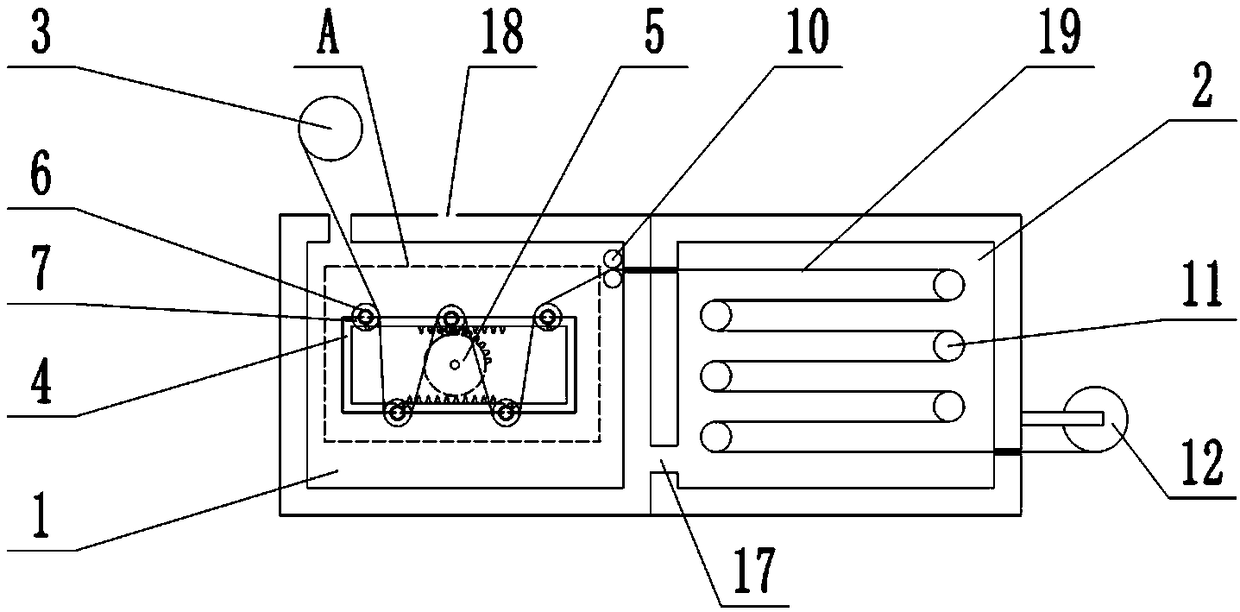

The invention relates to the technical field of cleaning equipment for spinning and discloses cleaning equipment for spinning. The cleaning equipment comprises an equipment body; two sides of the equipment body are symmetrically provided with first openings; two symmetrical rollers are fixedly installed on upper ends of the two sides of the equipment body; spinning fabric is stitched between the two rollers. By means of the cleaning equipment for spinning, under the effect of a first water pump and a second water pump, fabric can be effectively washed; a first nozzle and a second nozzle at theleft end can be used for washing before brushing to clean dust on the fabric; a first nozzle and a second nozzle at the right end can be used for effectively washing off the dust after the cleaning of electric rollers so as to guarantee that the fabric can be cleaned thoroughly; by means of two fans at up and down, hot air flow in a drying box can be blown to the fabric so that two sides of the fabric can be uniformly heated to accelerate drying and guarantee the drying efficiency.

Owner:胡和萍

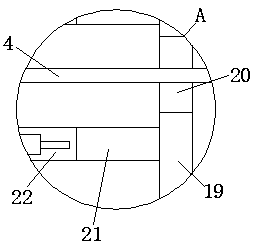

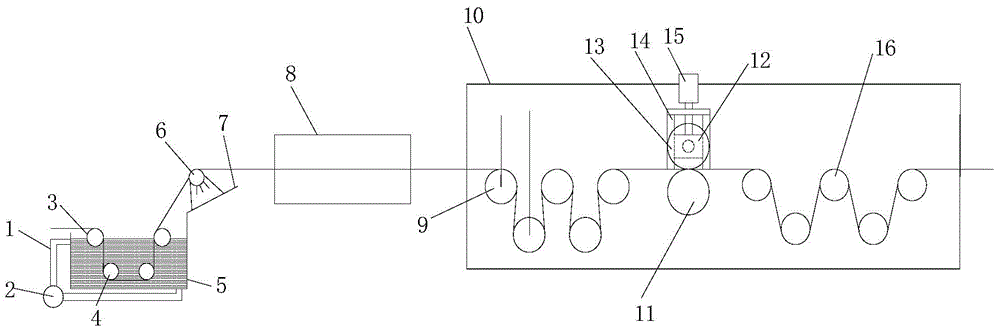

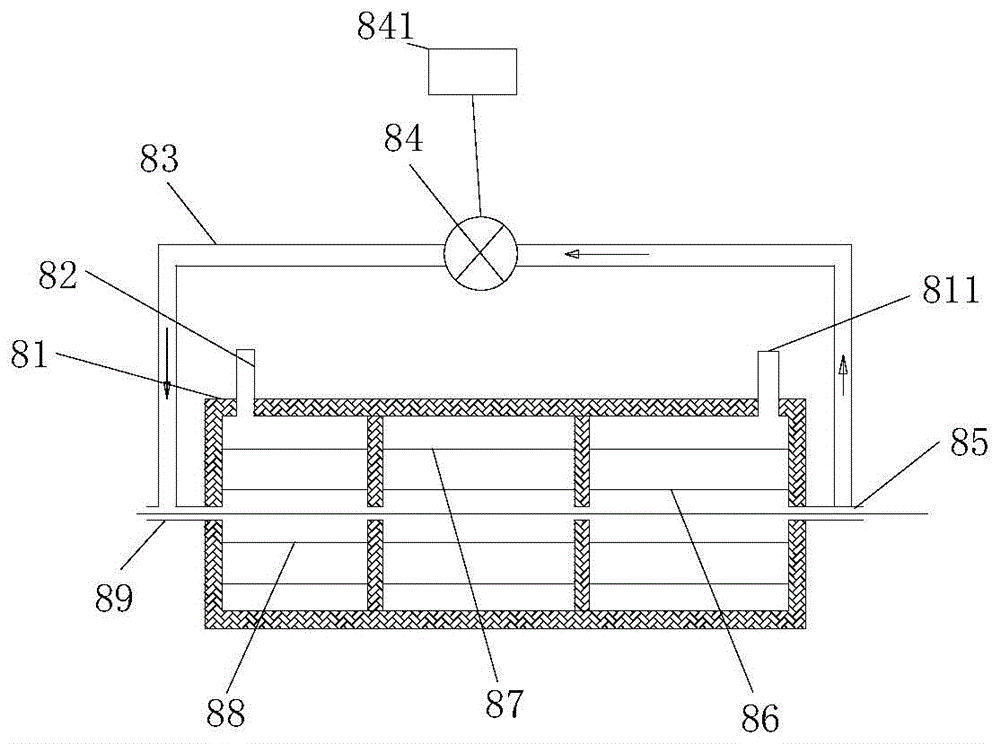

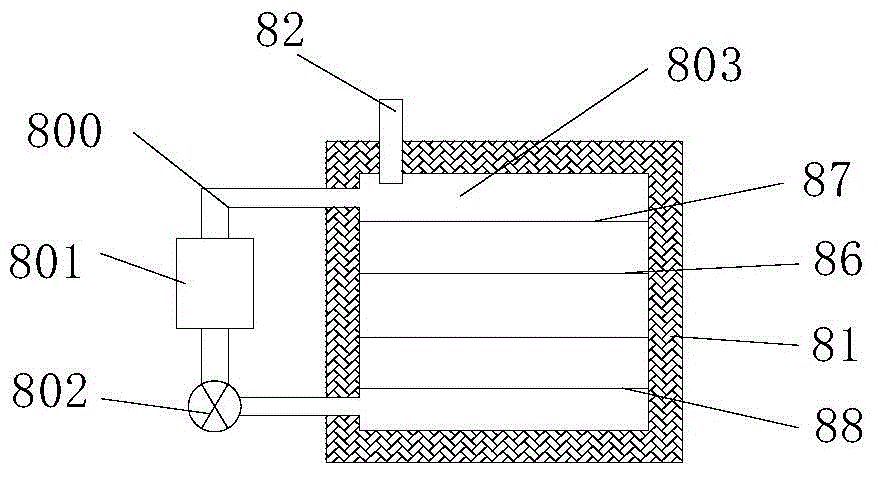

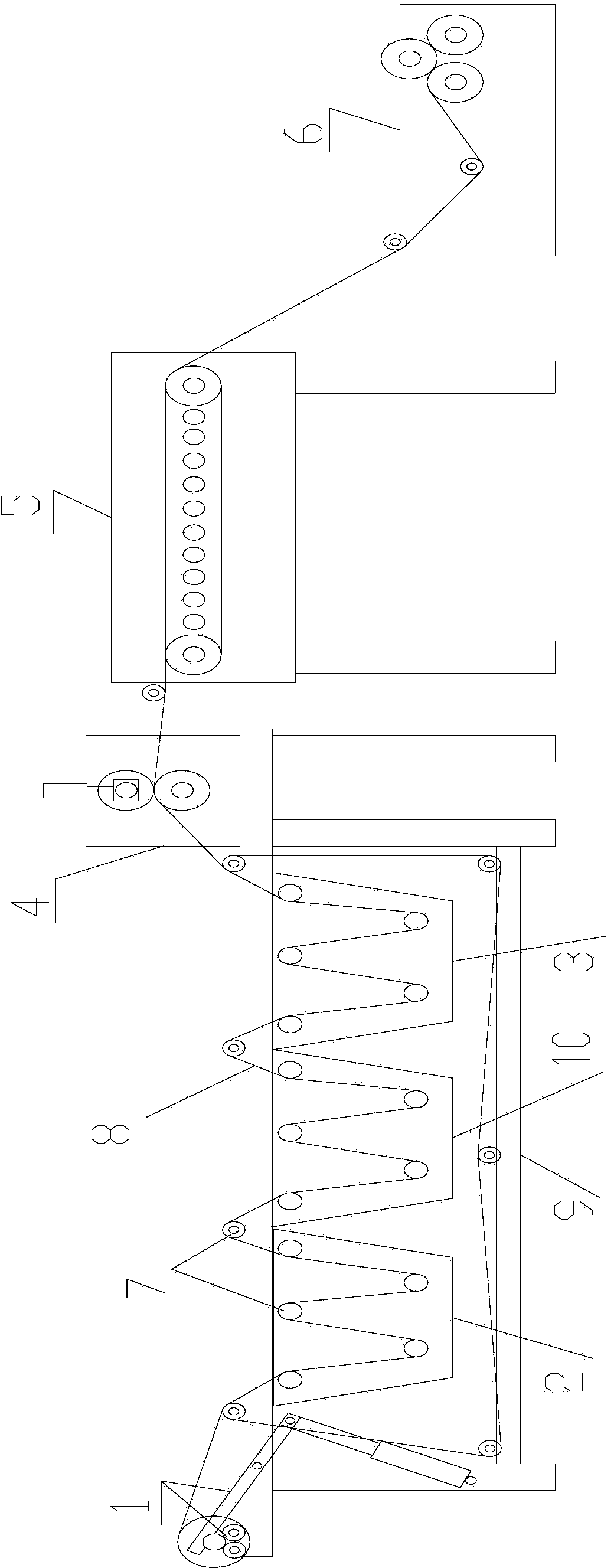

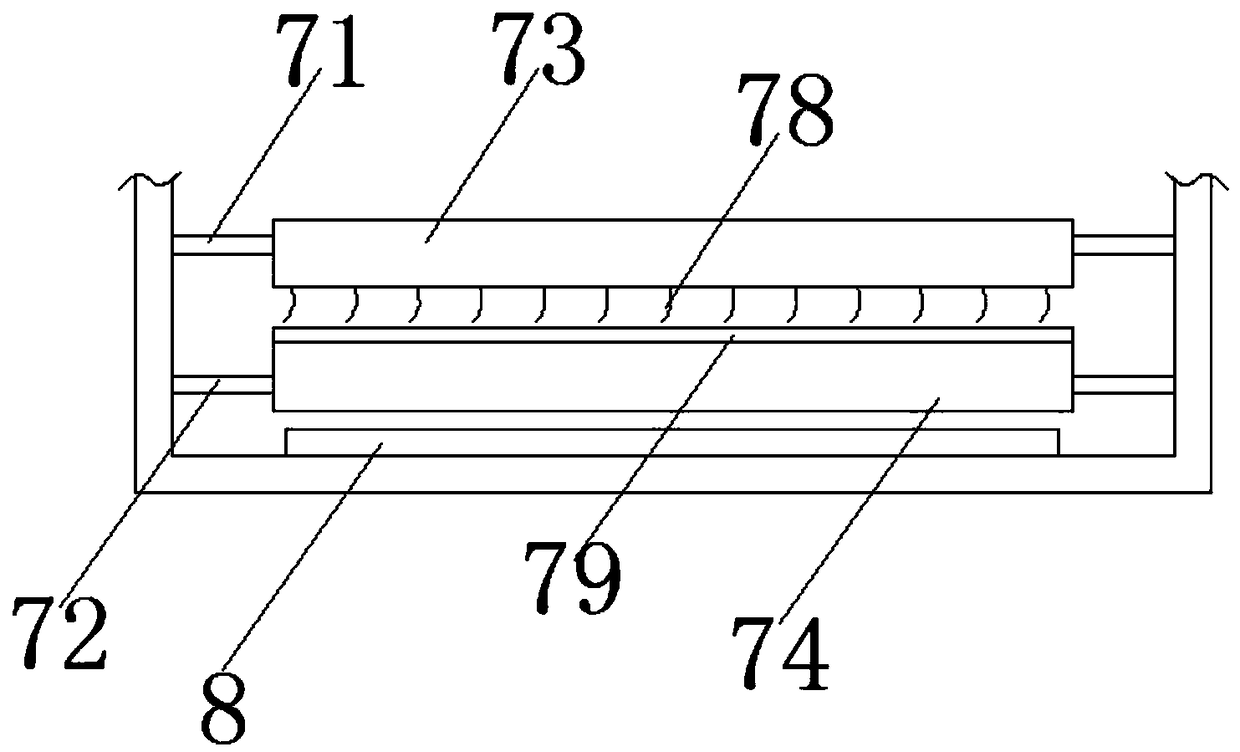

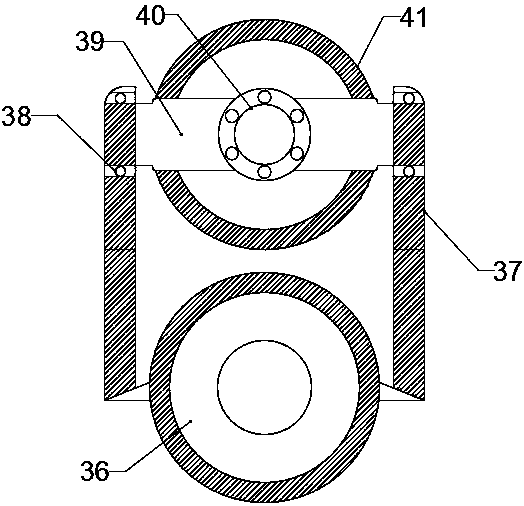

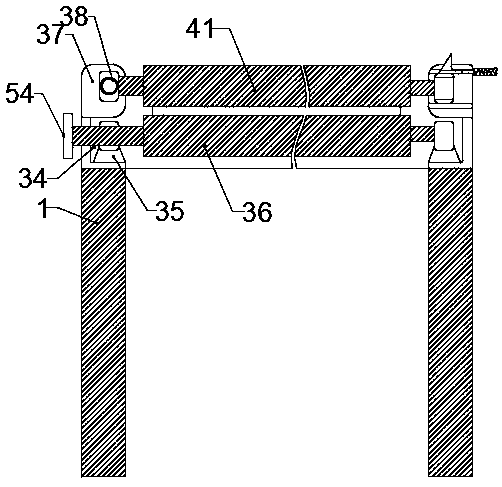

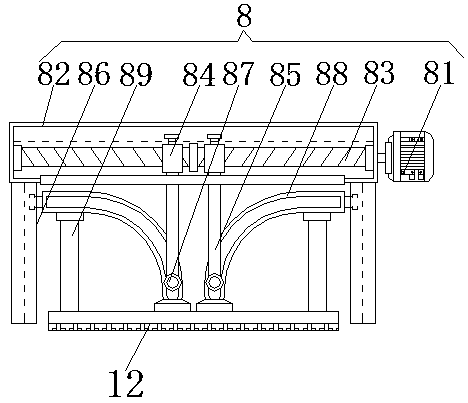

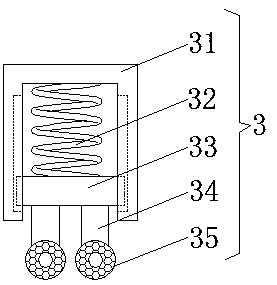

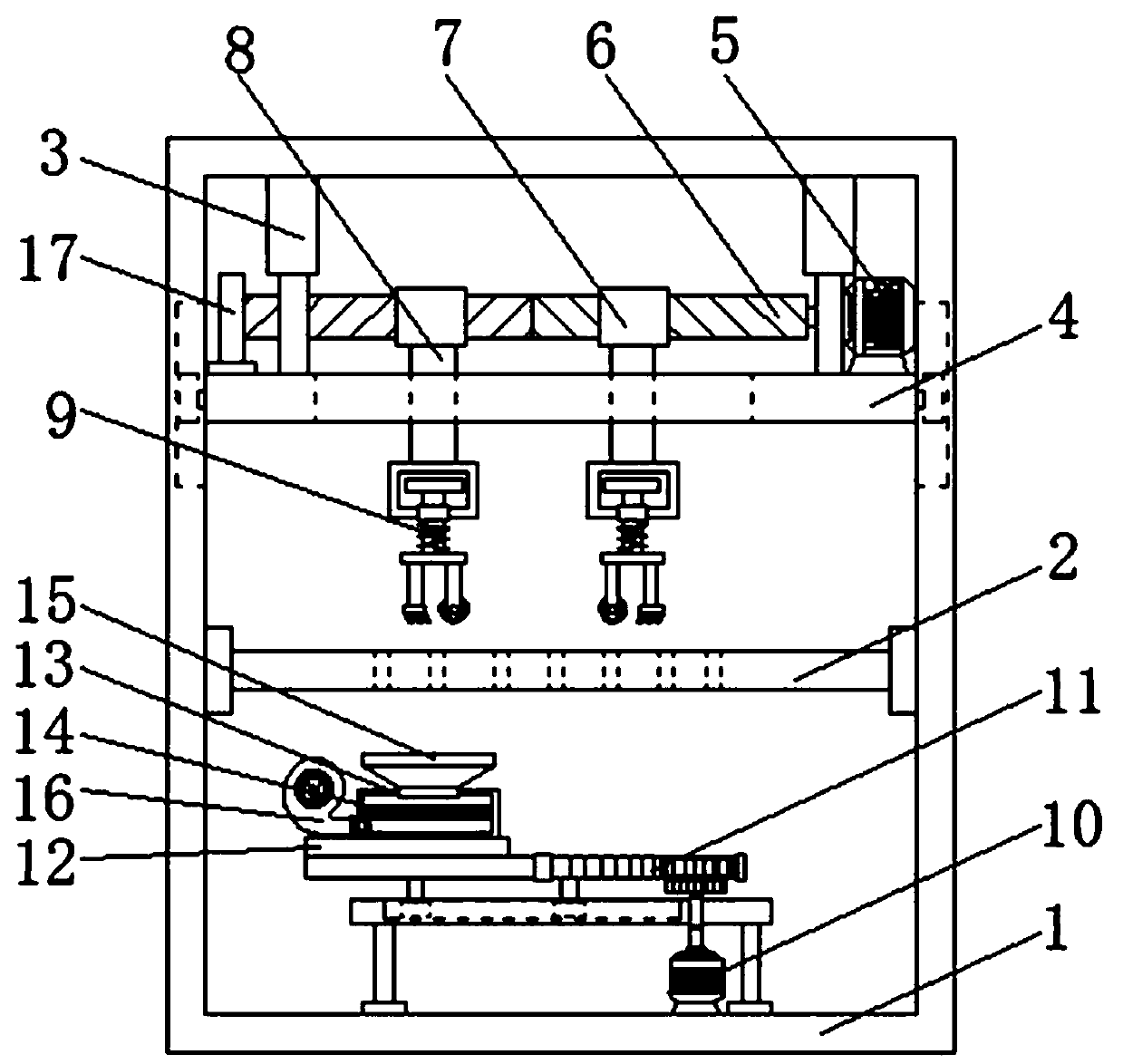

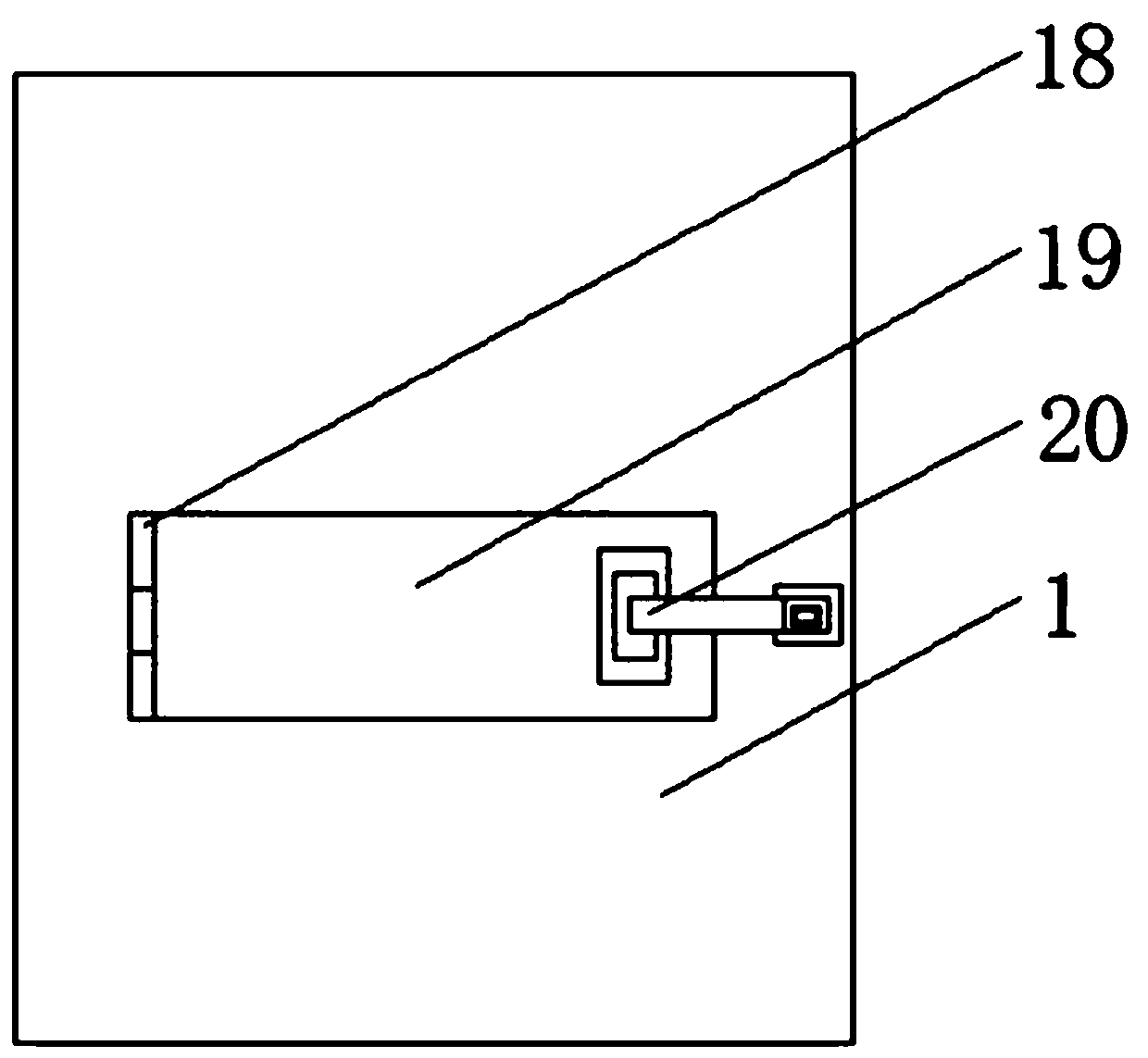

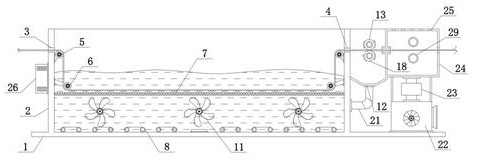

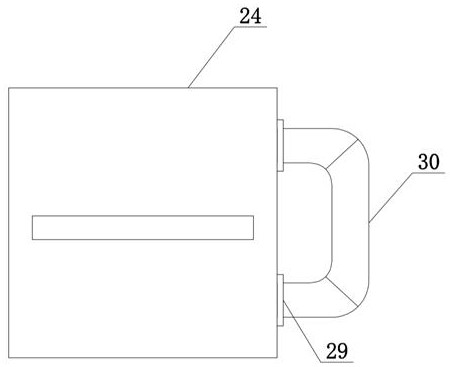

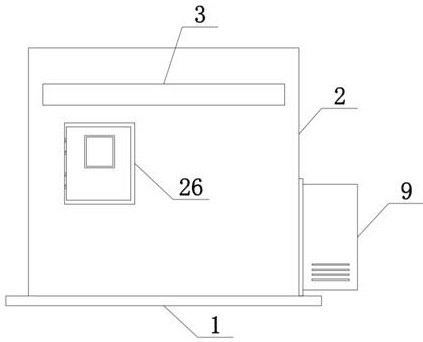

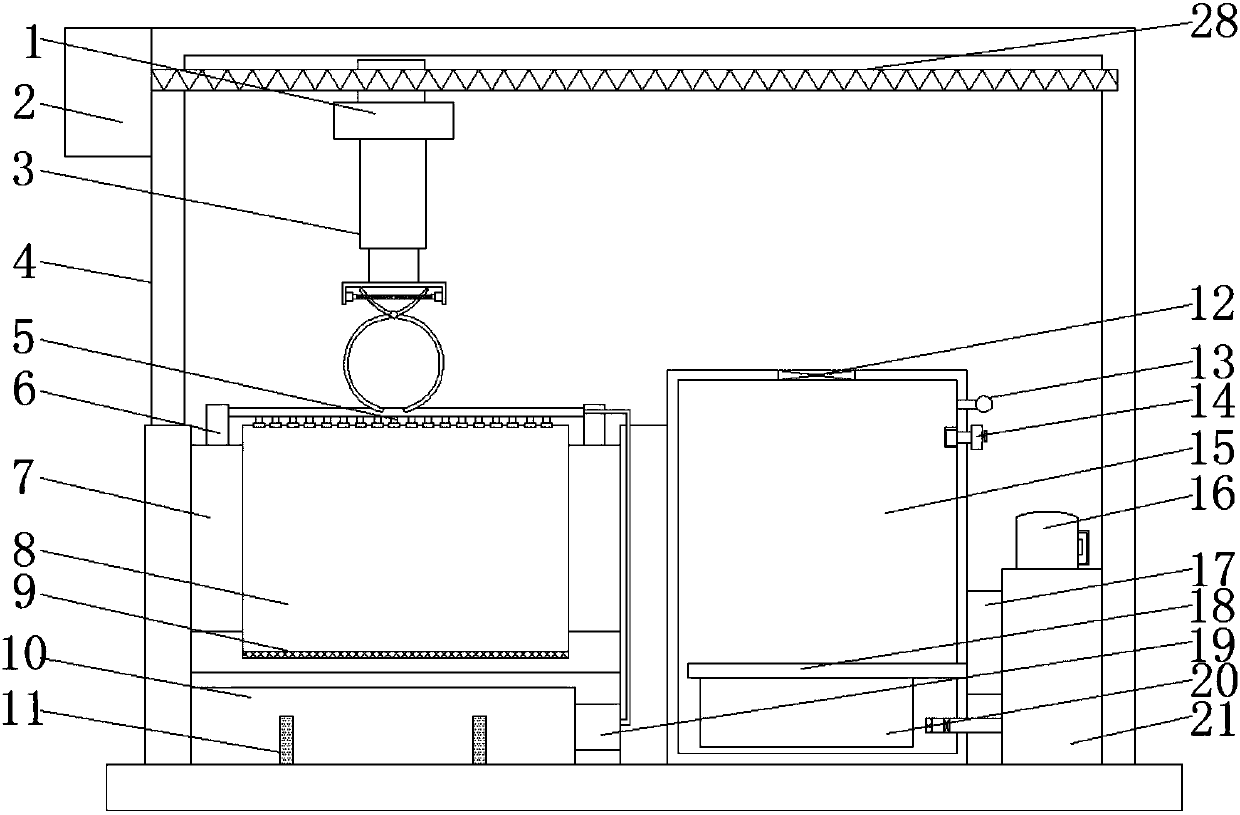

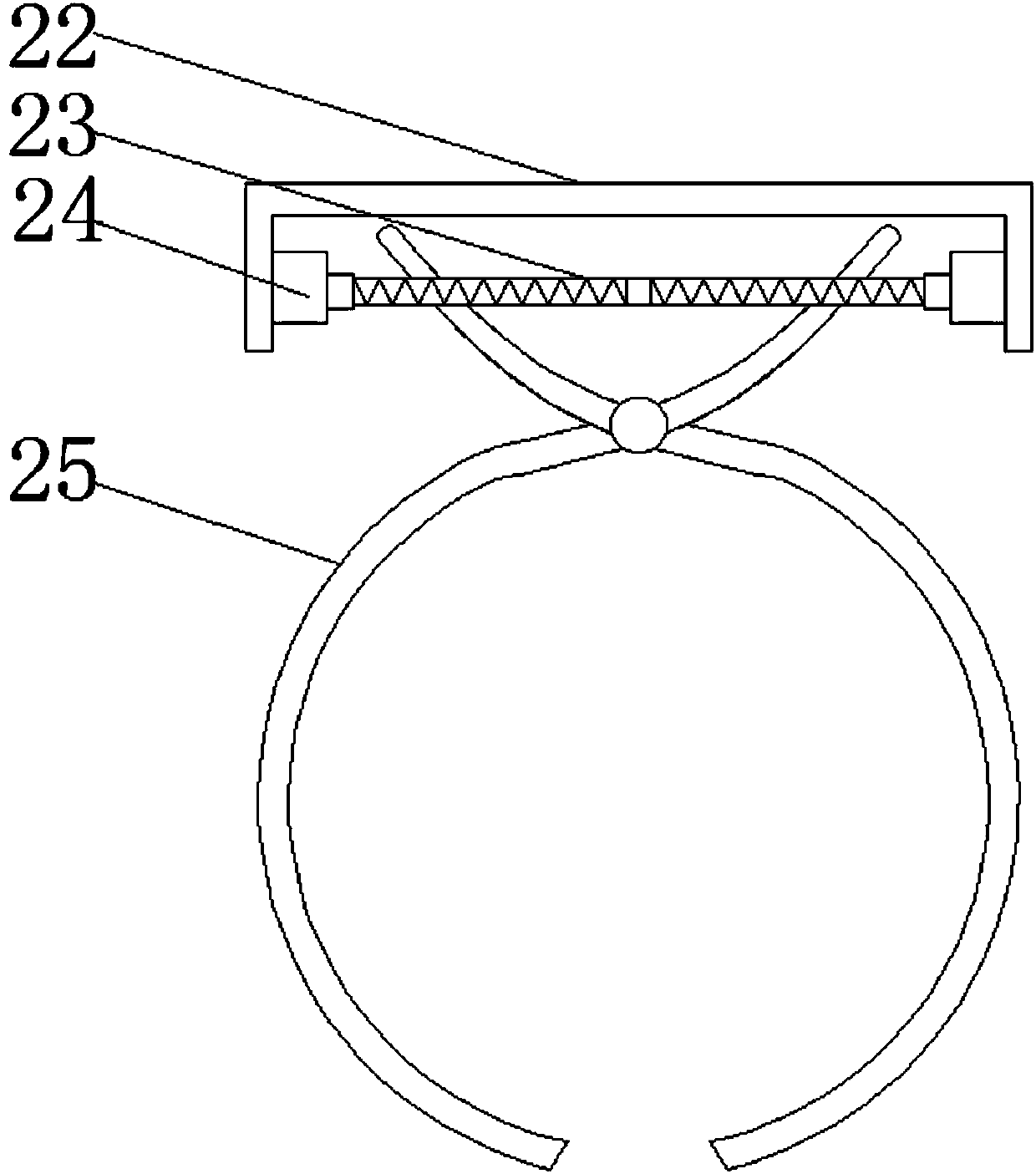

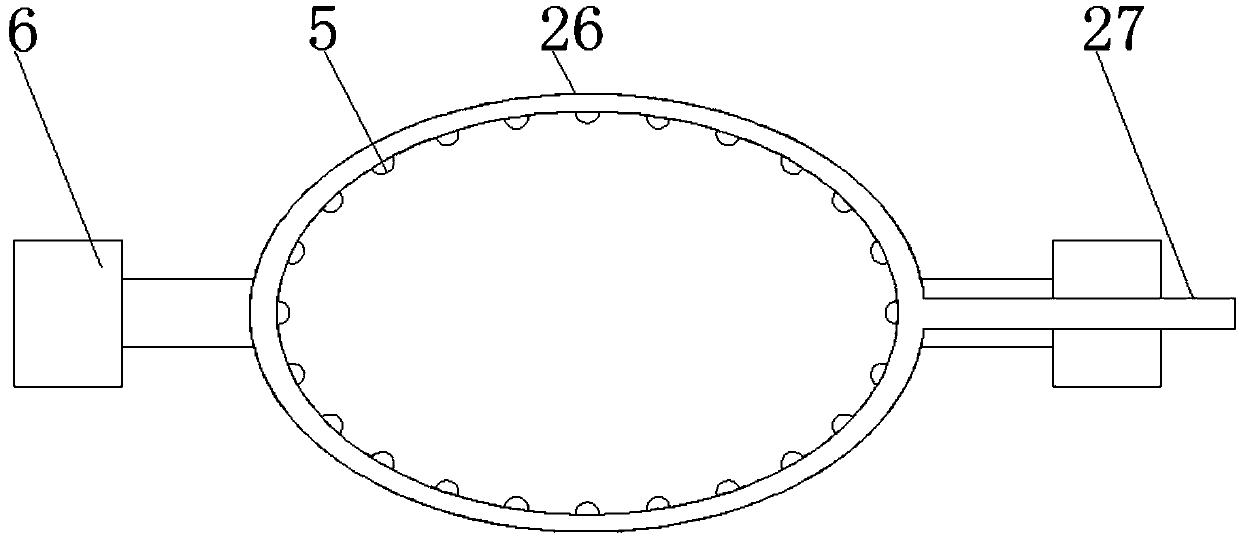

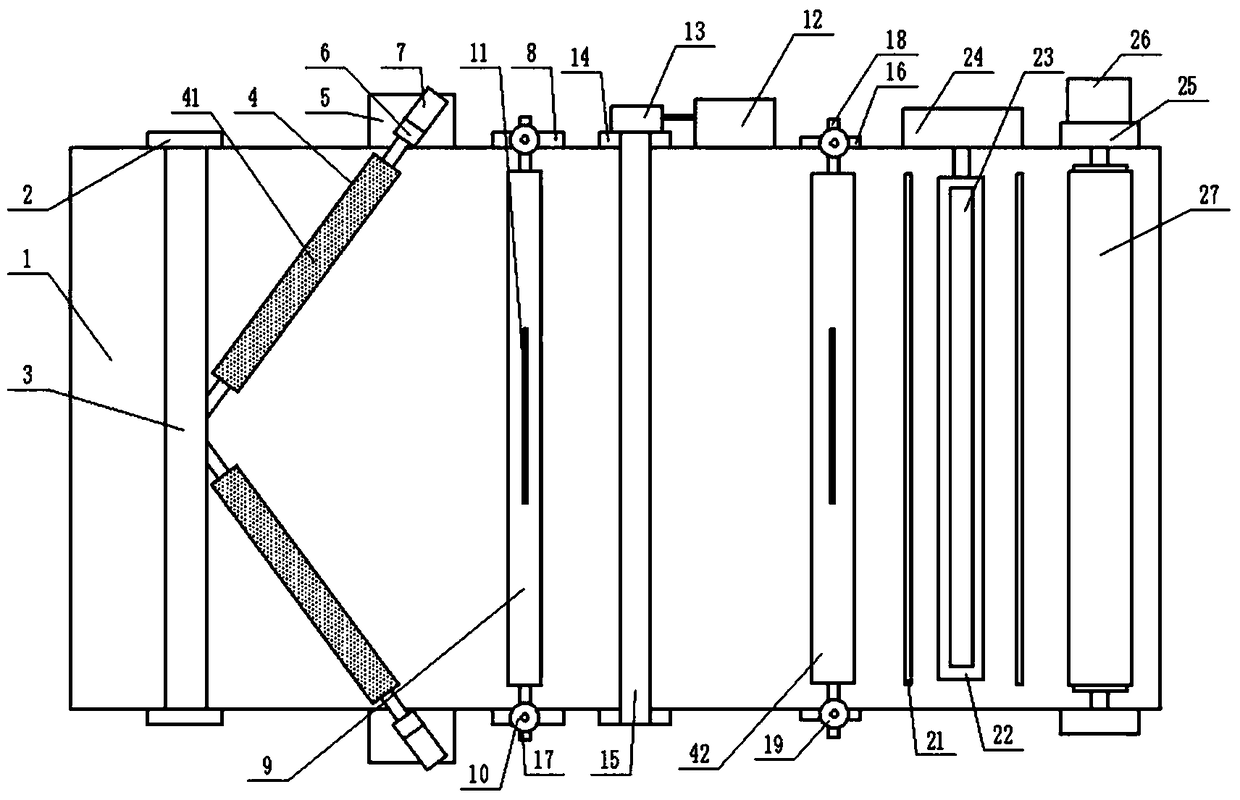

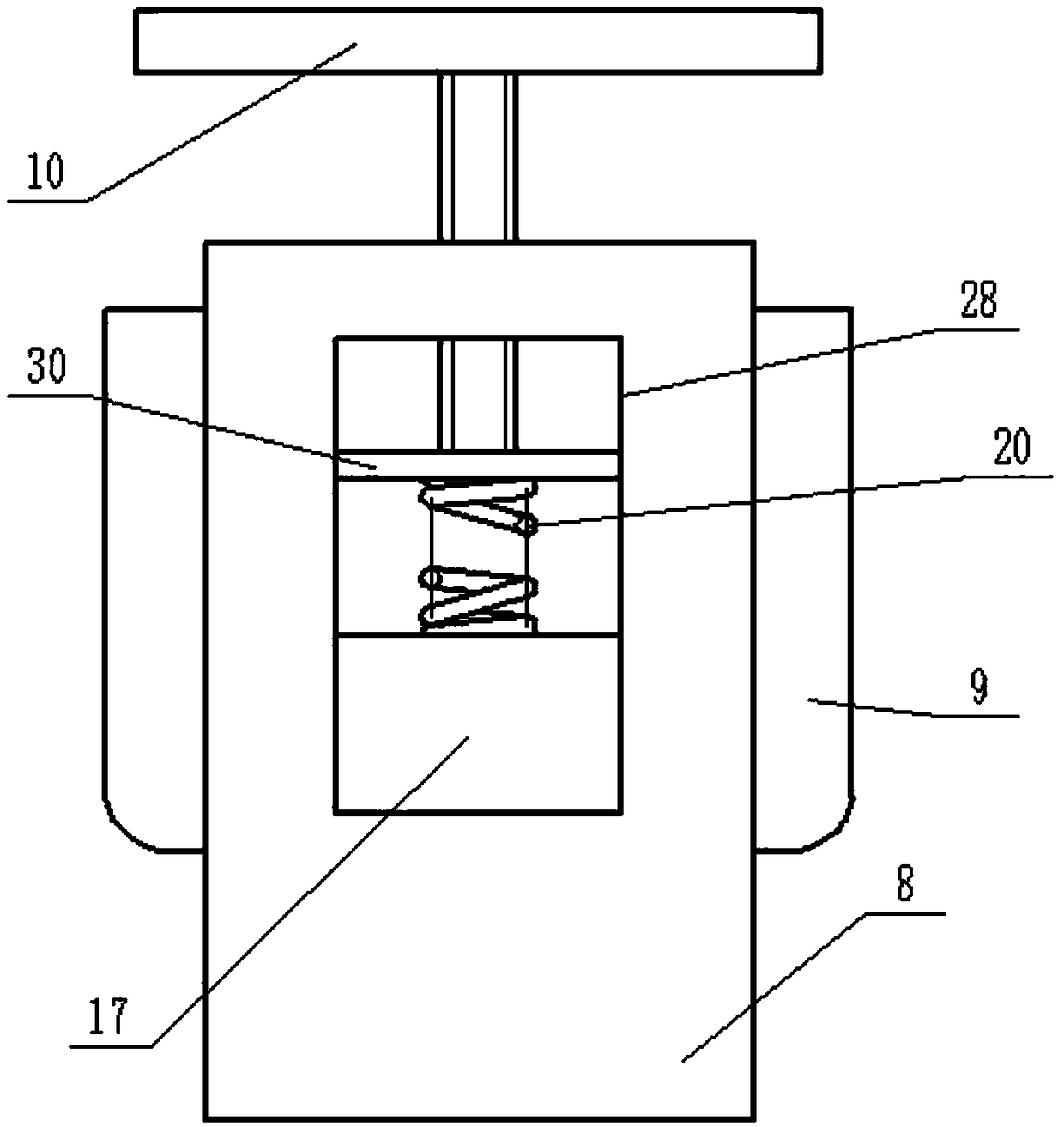

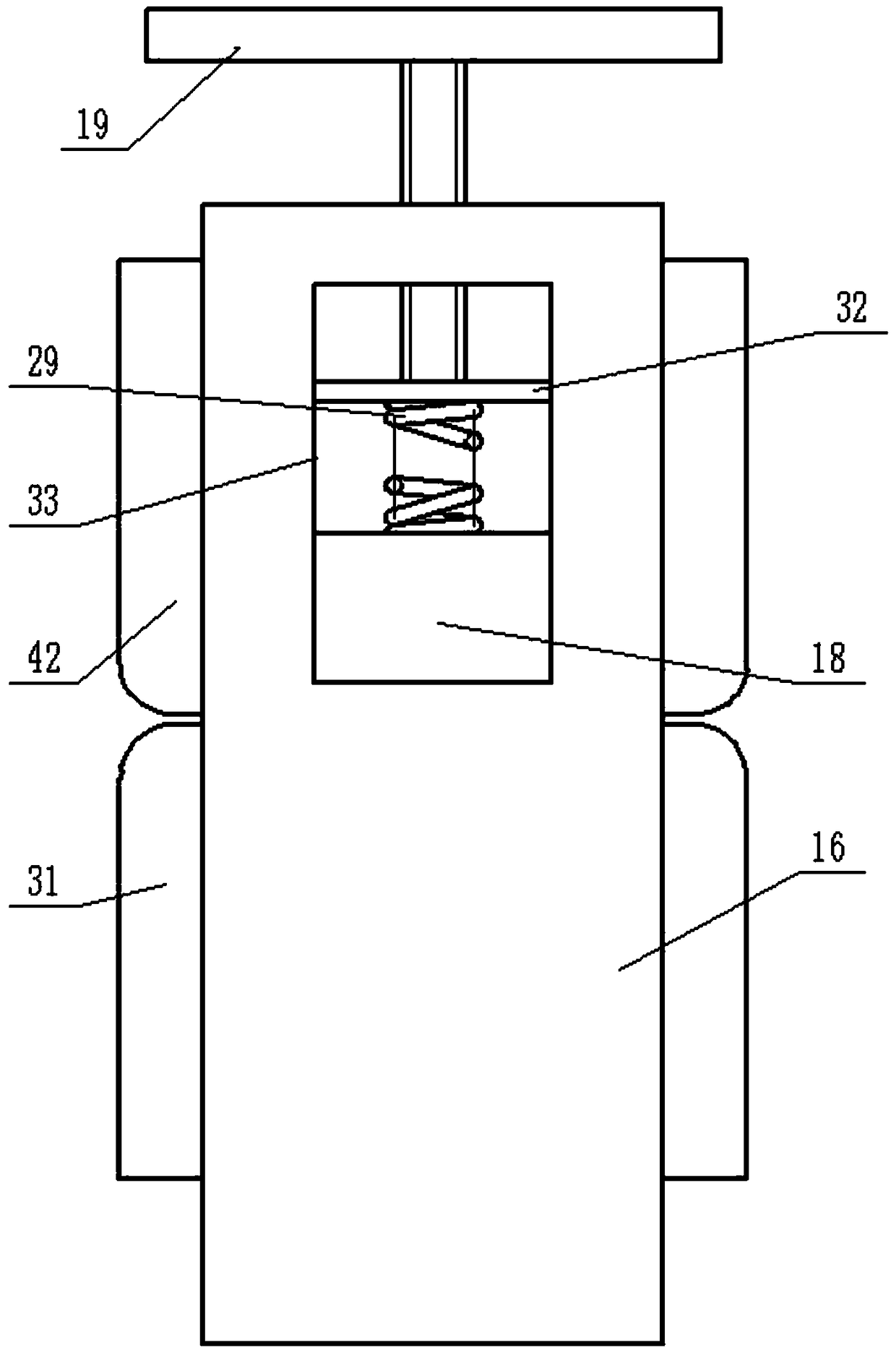

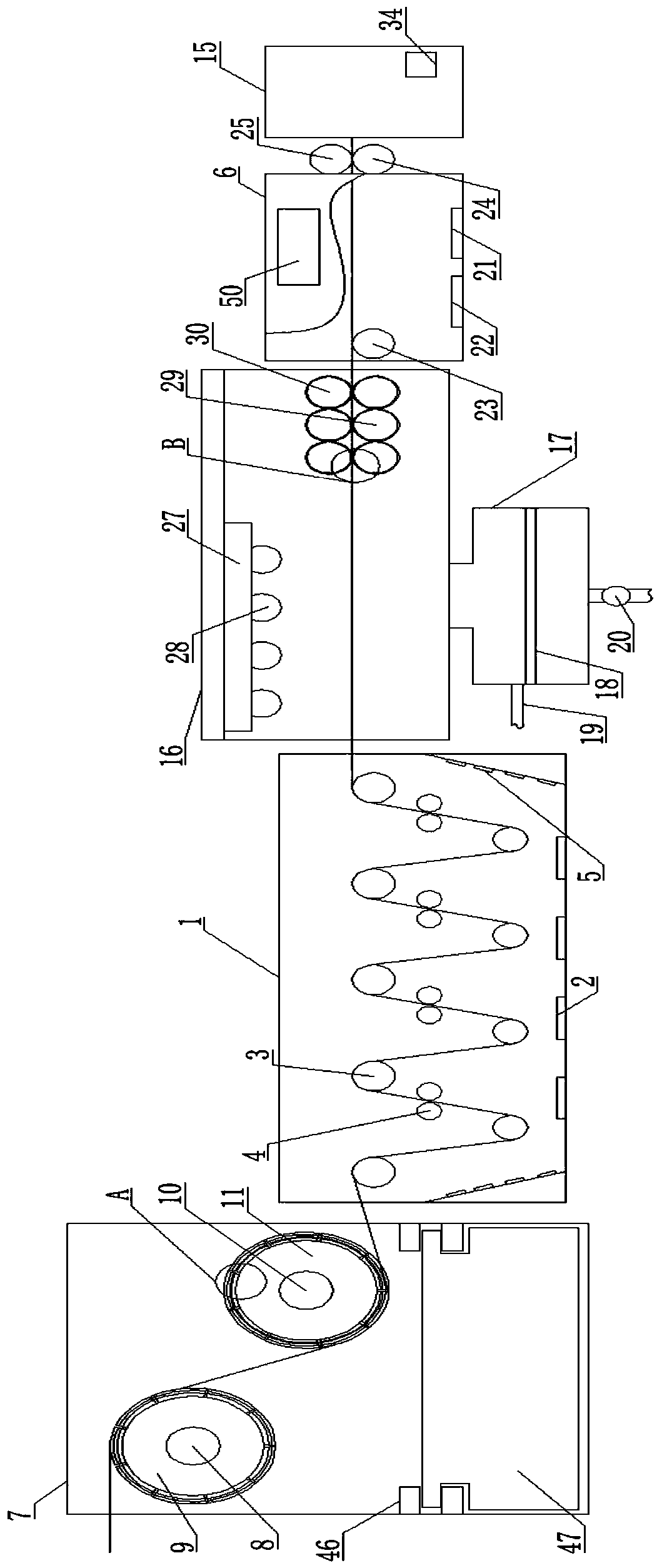

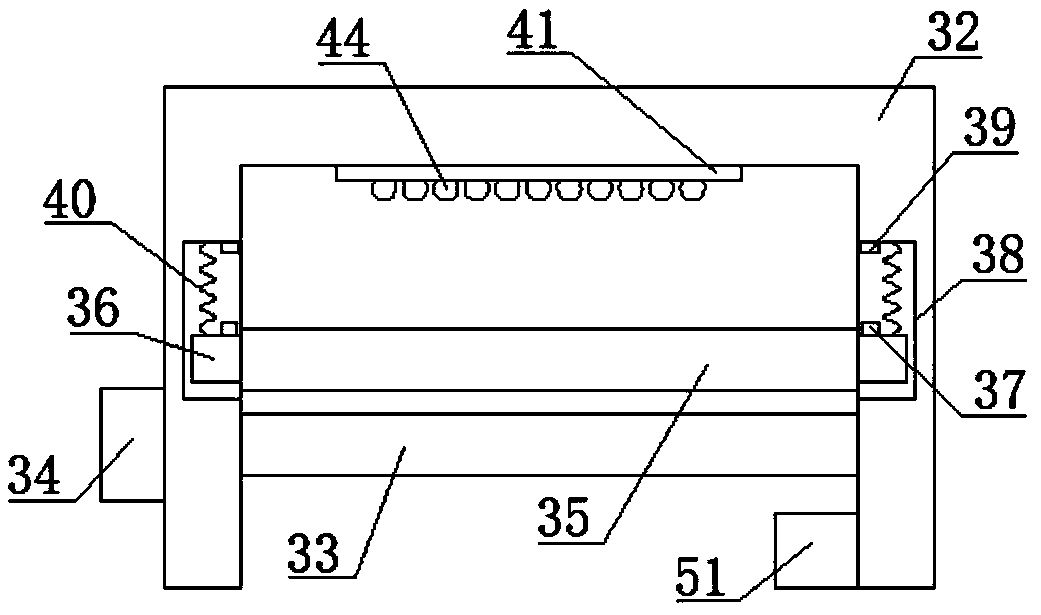

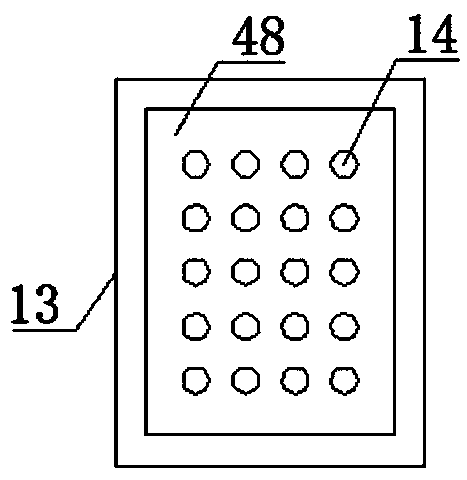

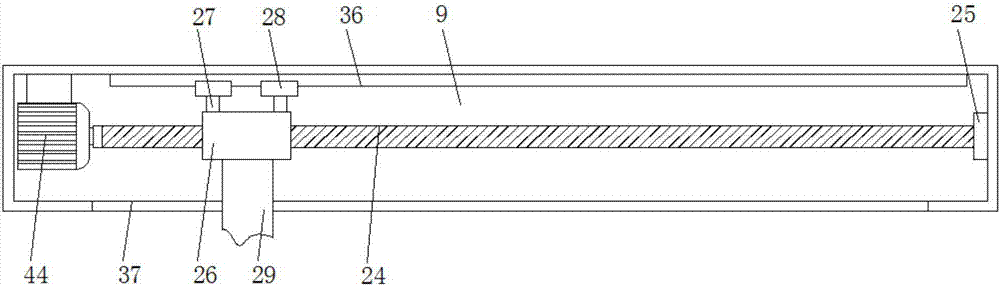

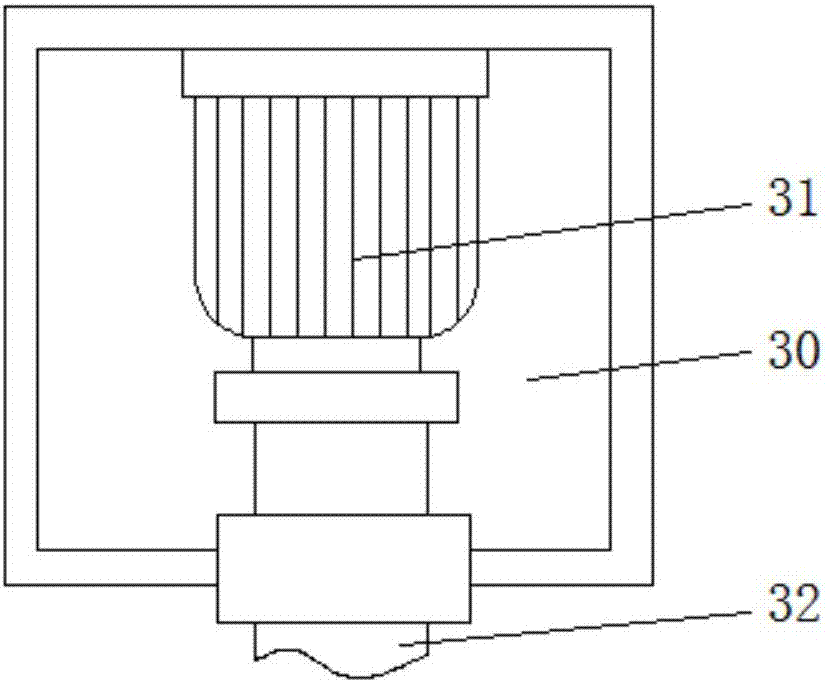

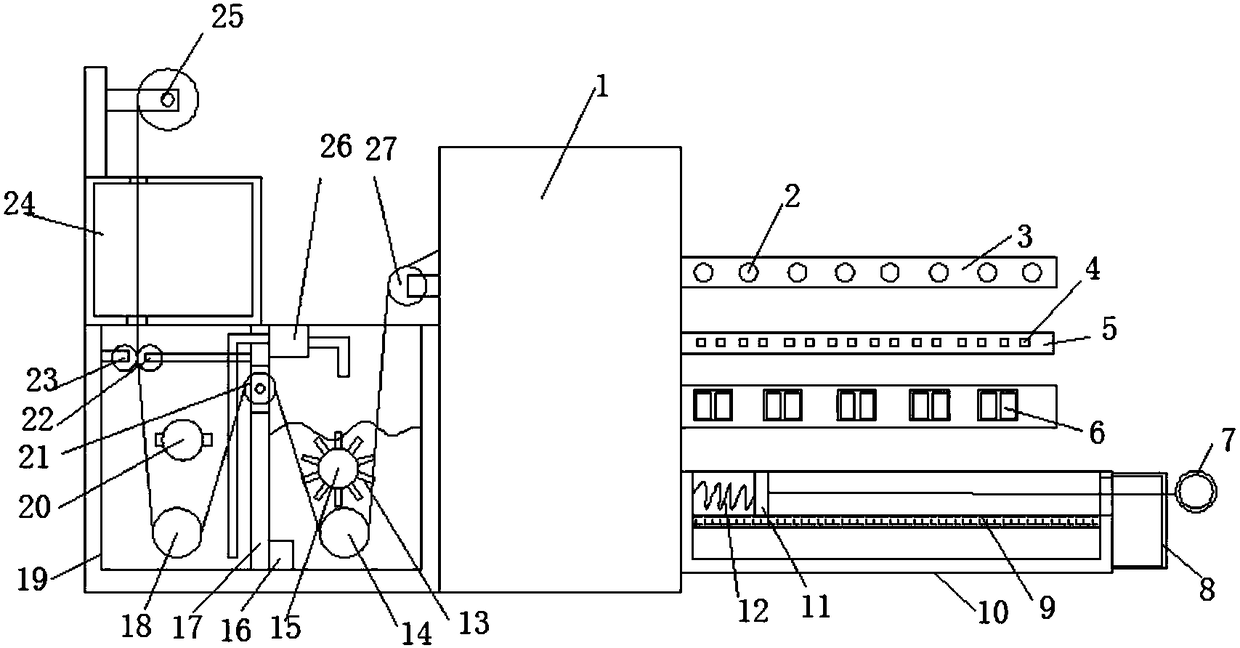

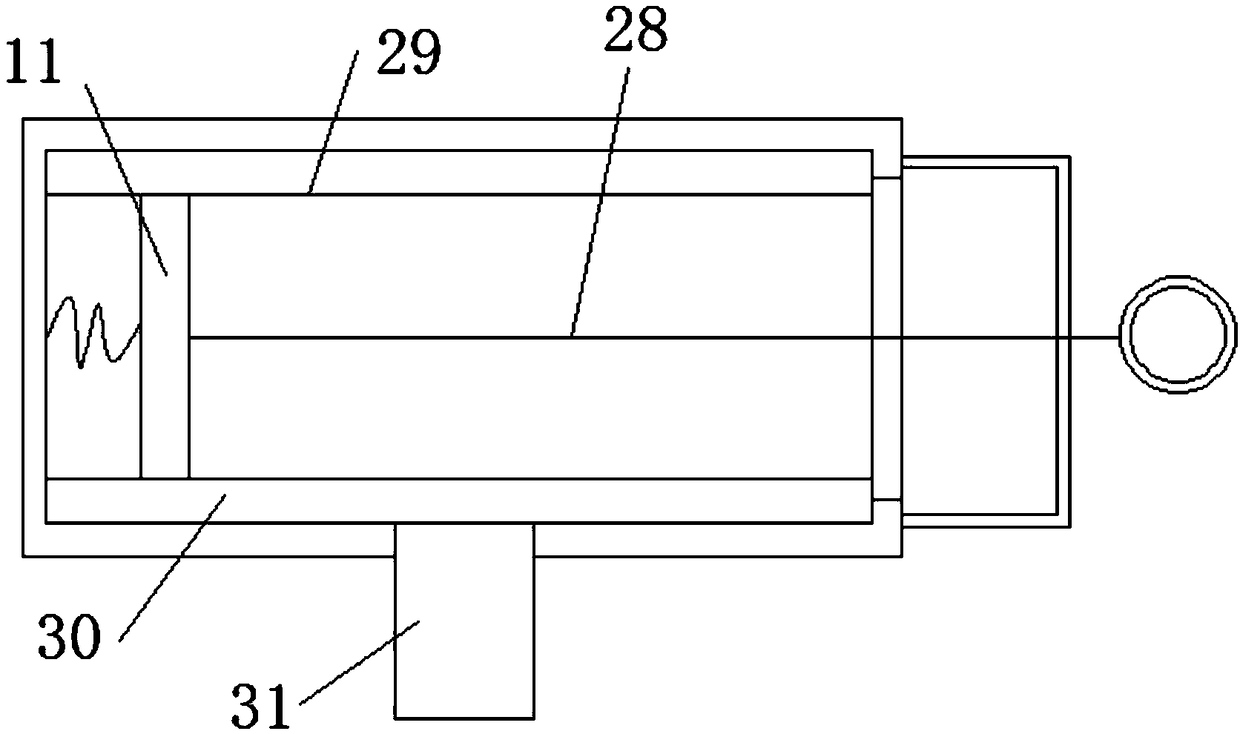

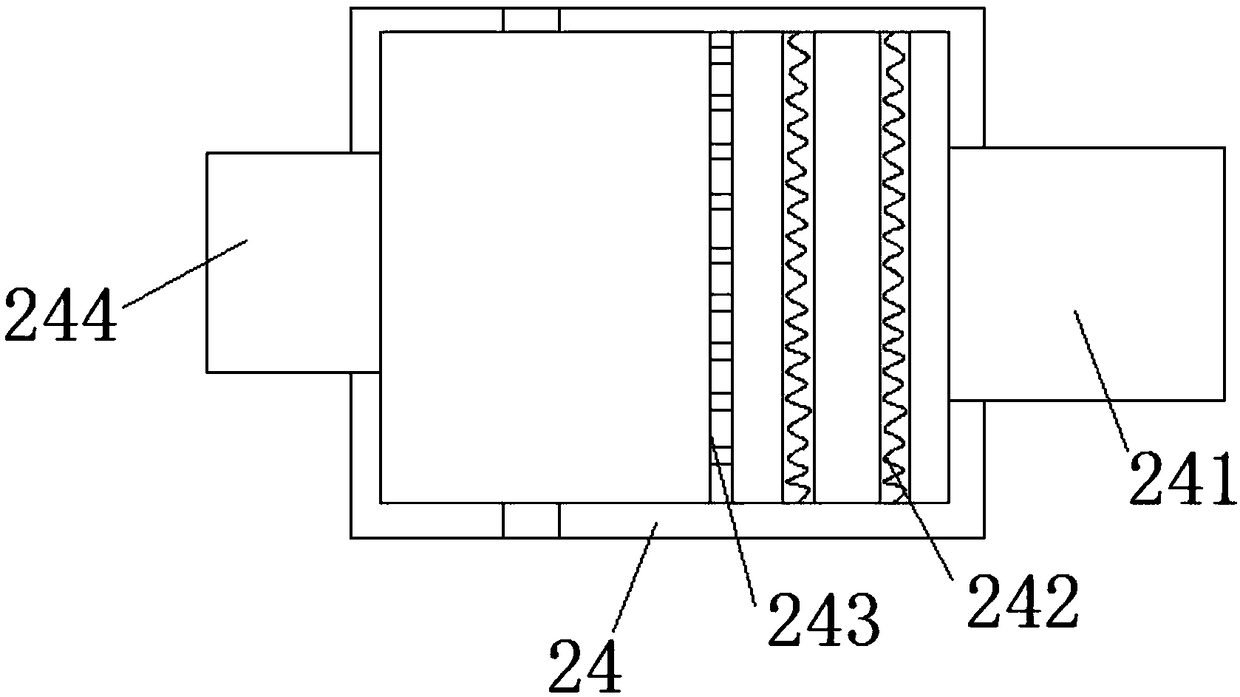

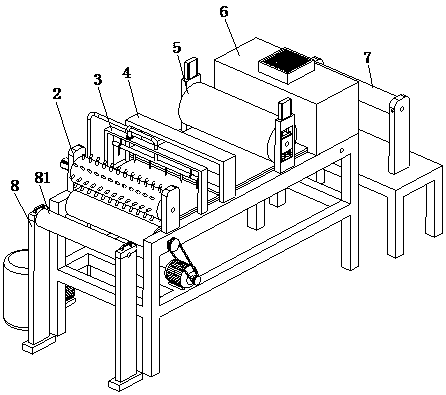

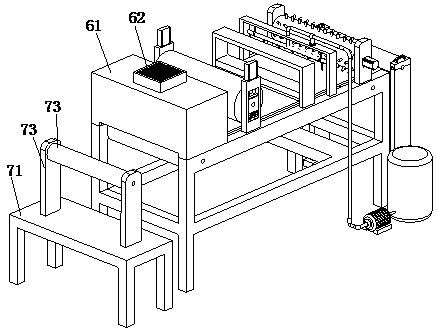

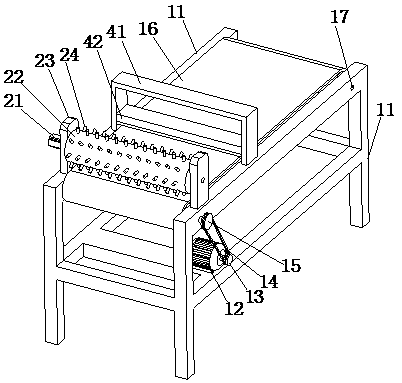

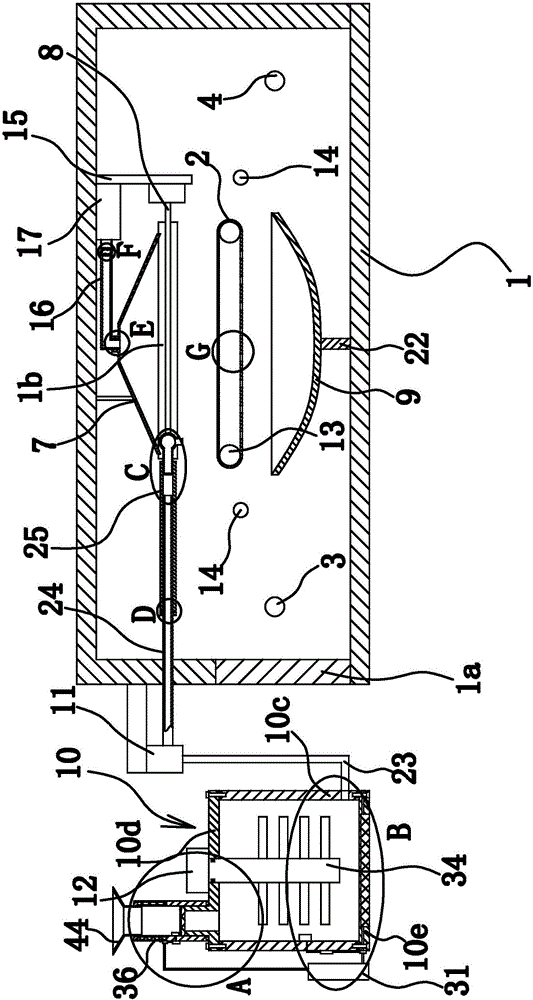

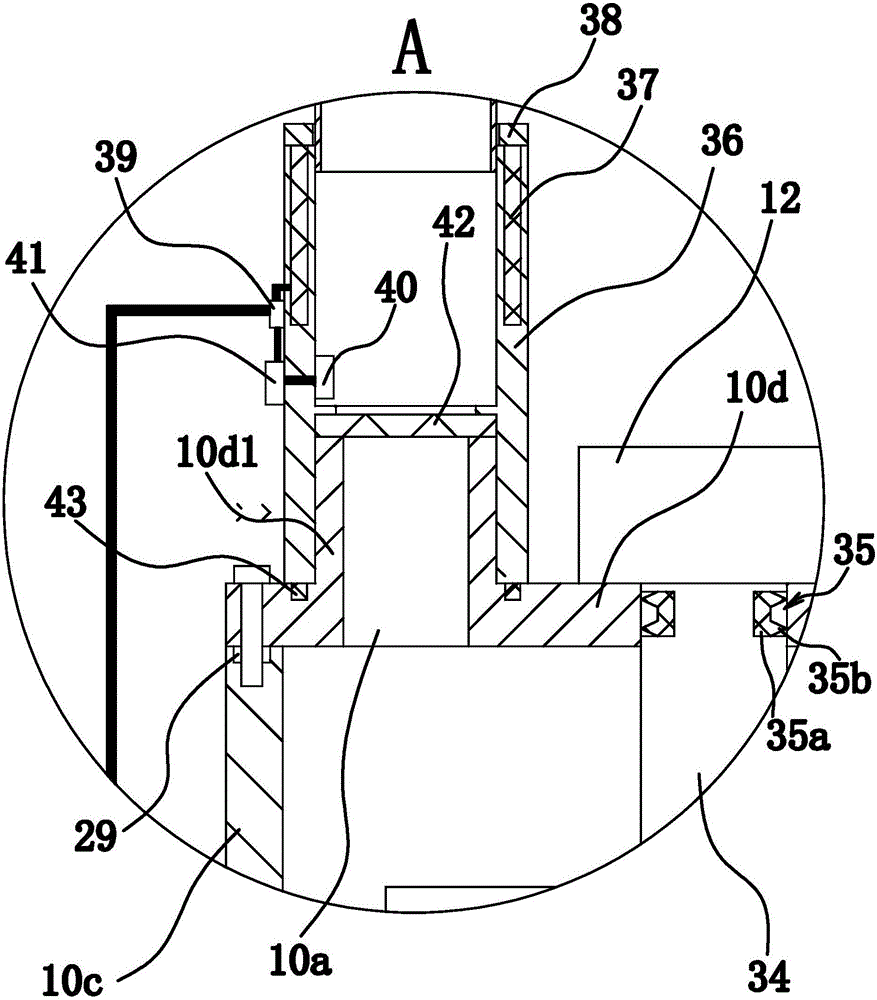

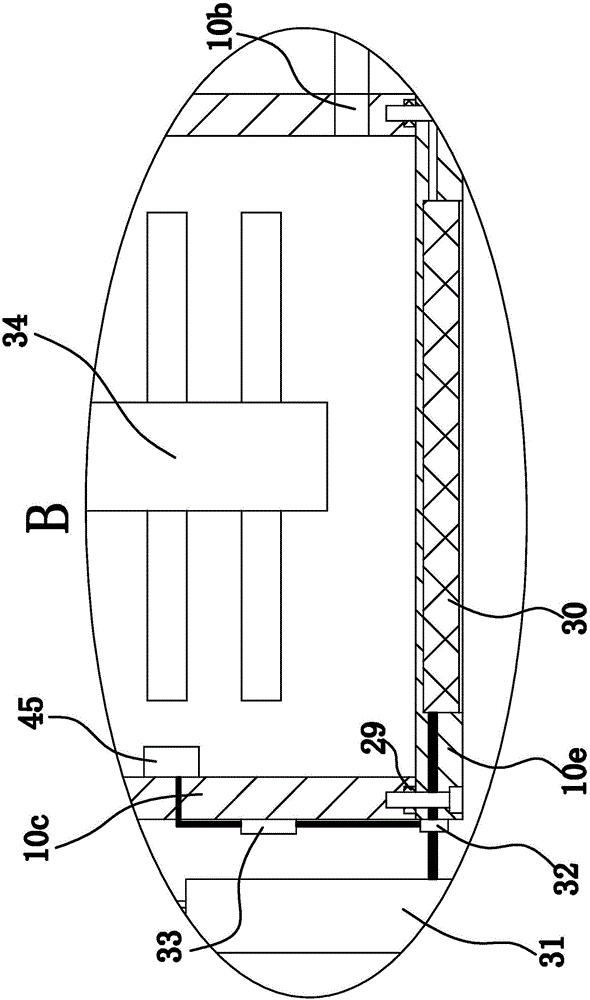

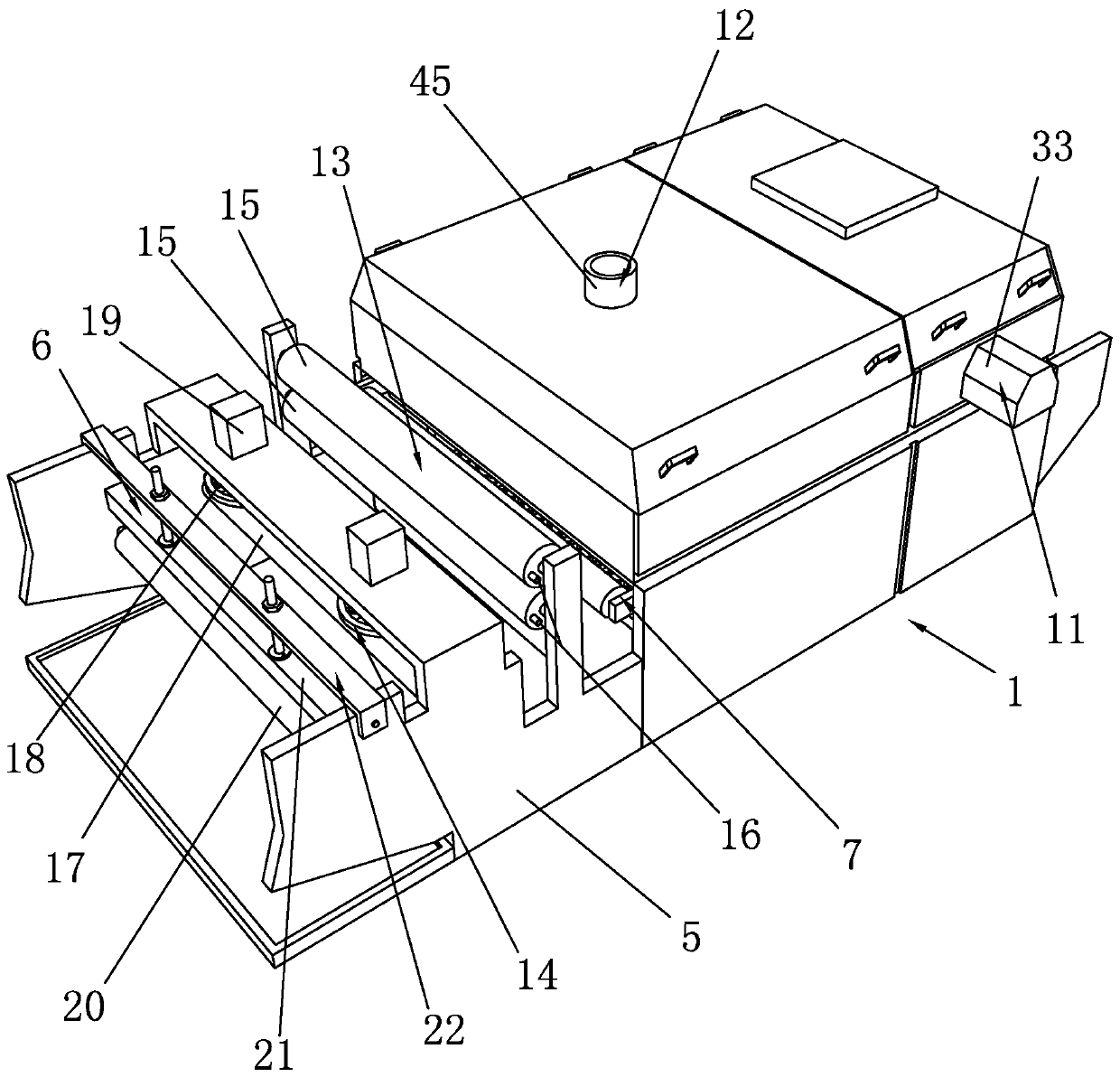

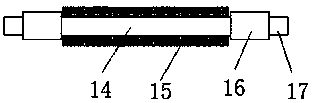

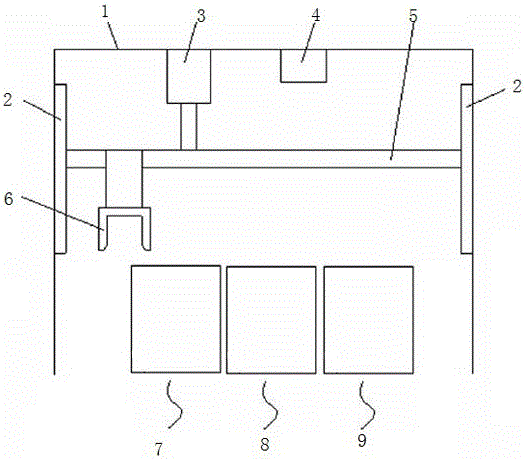

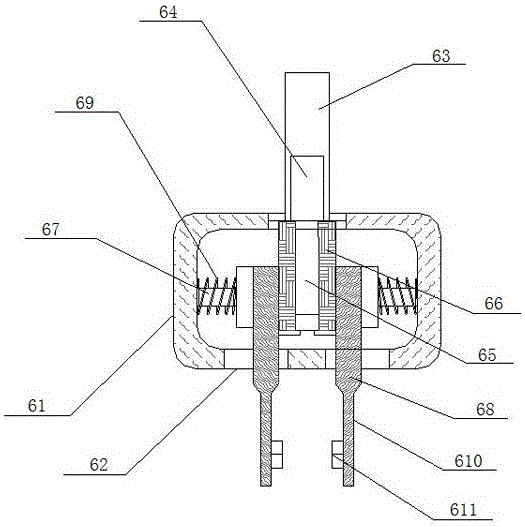

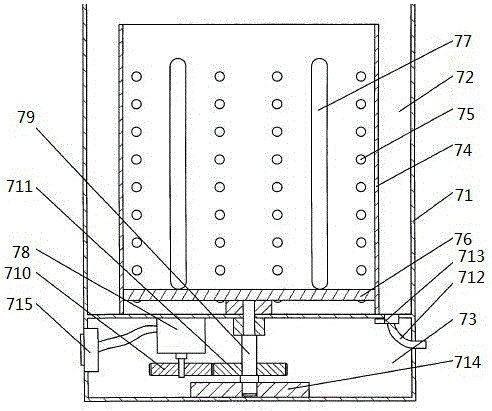

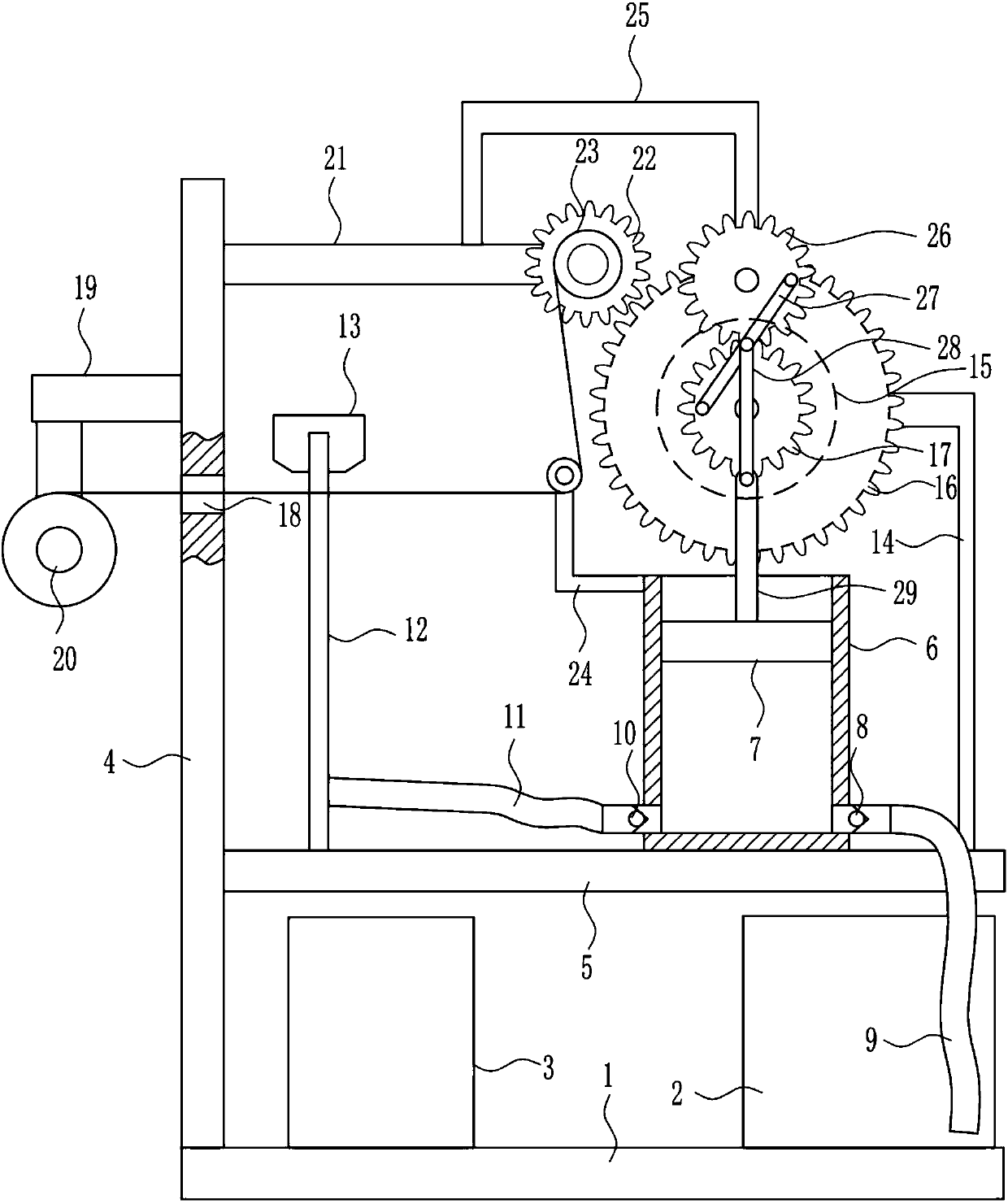

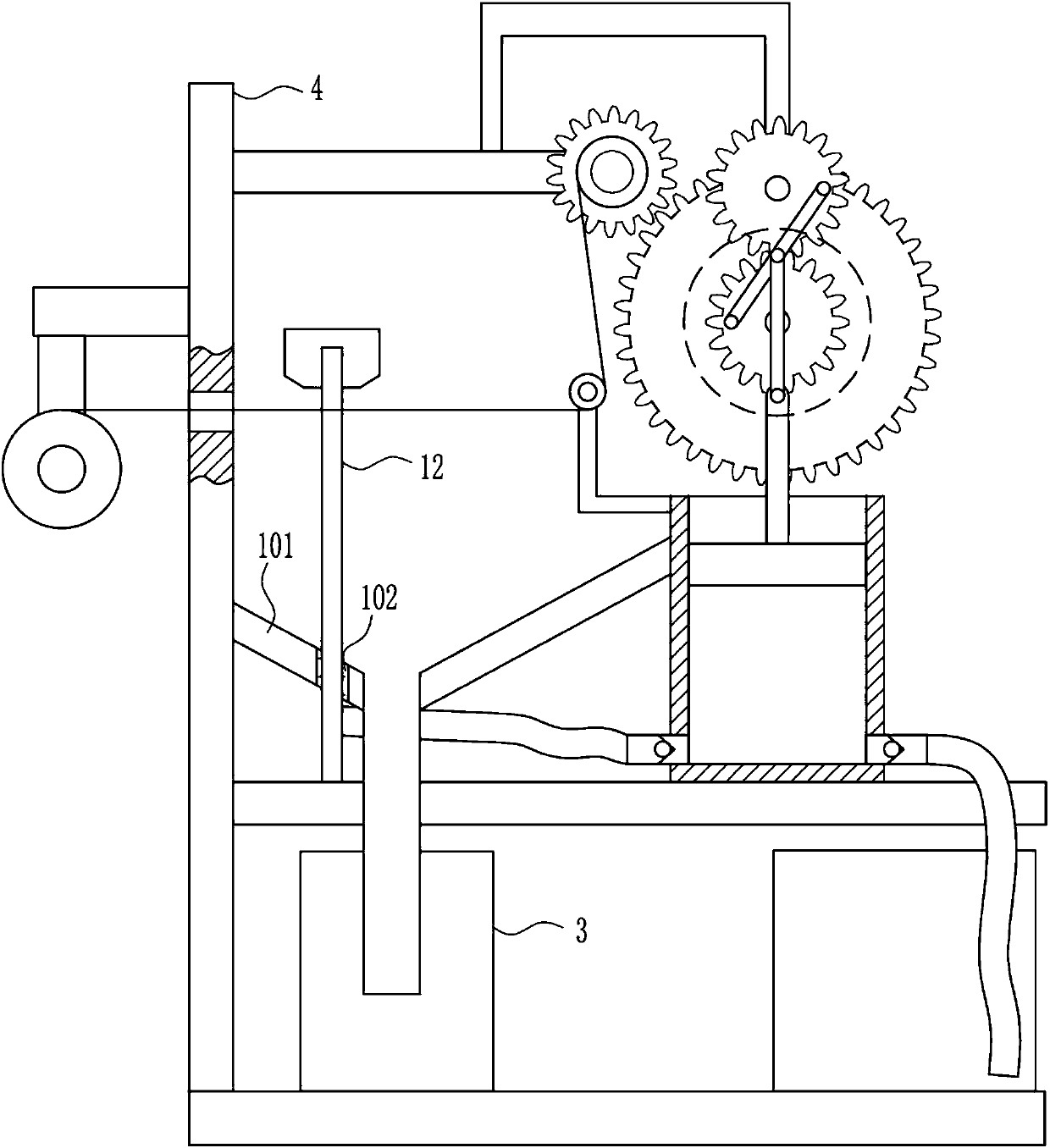

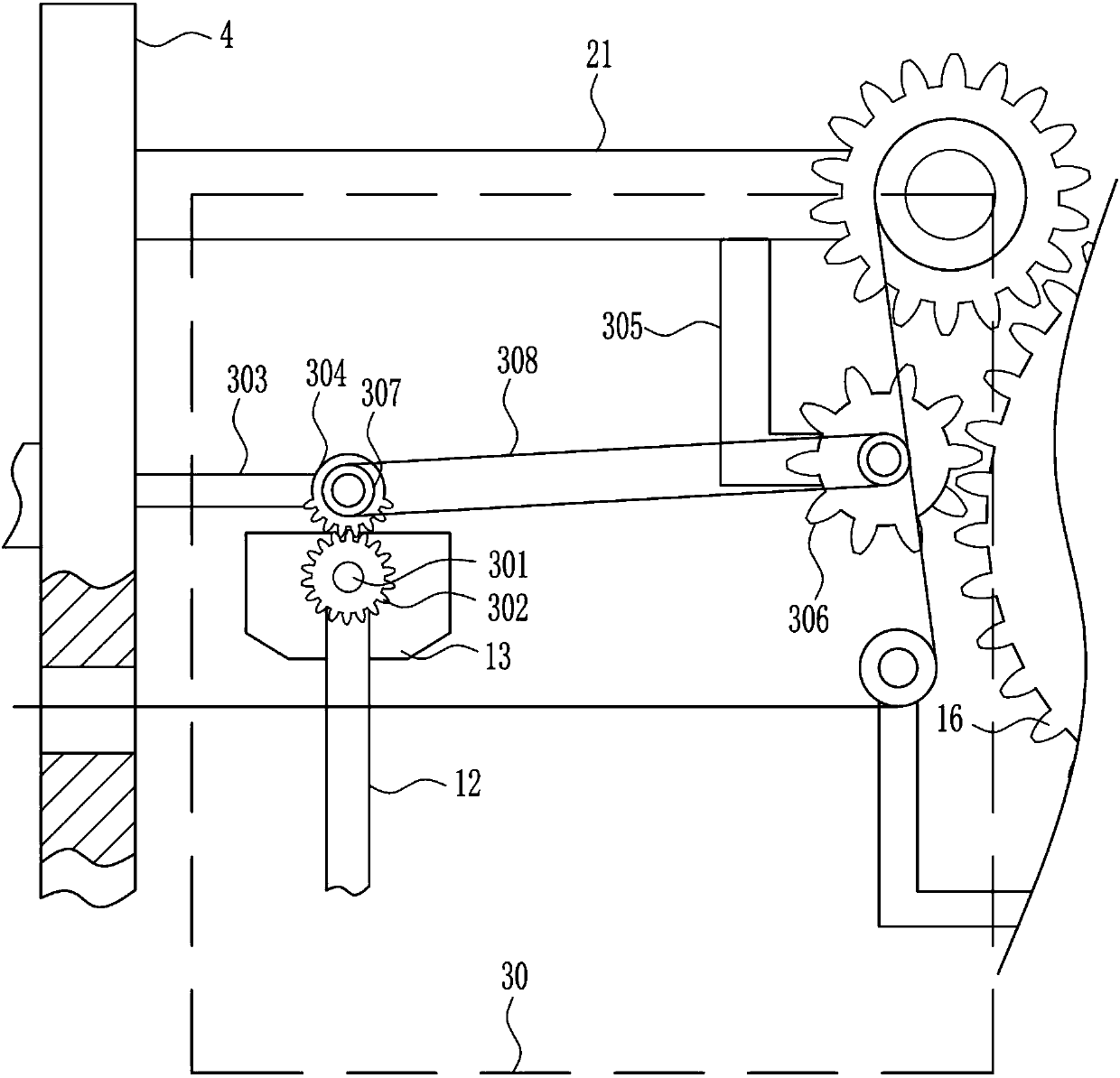

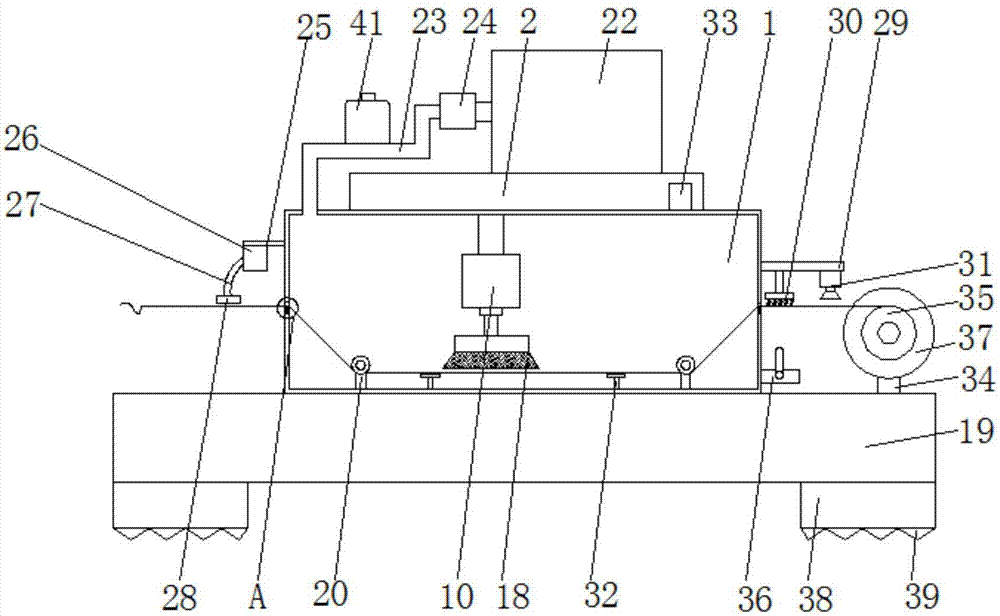

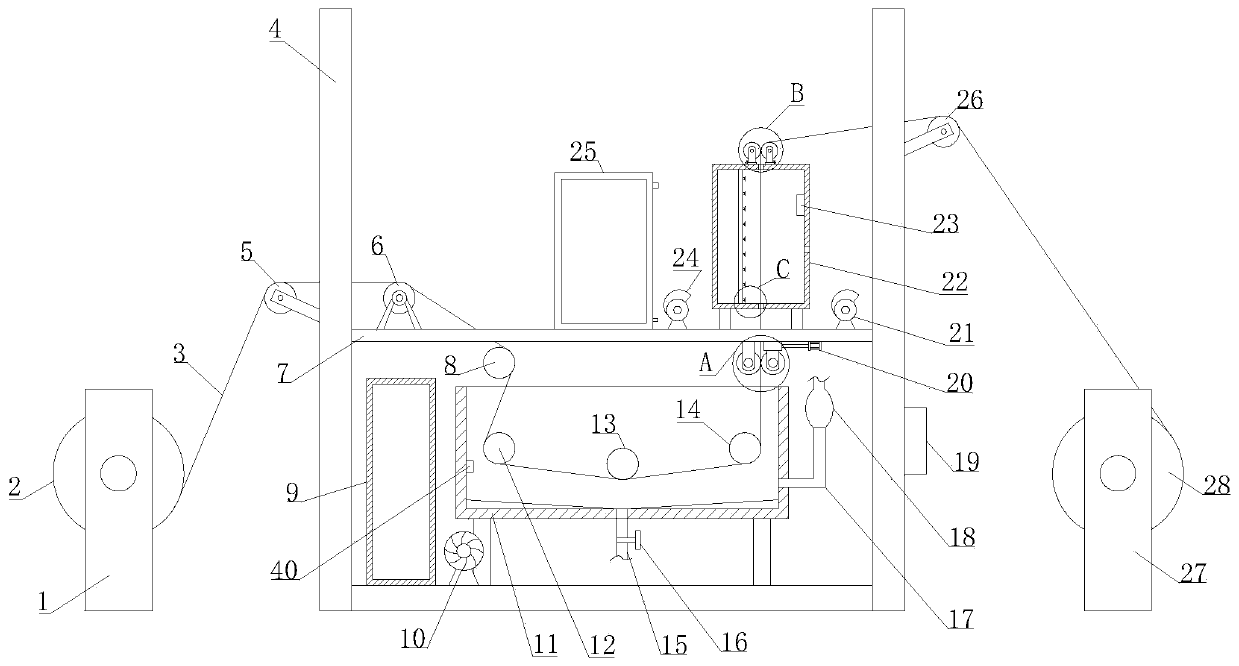

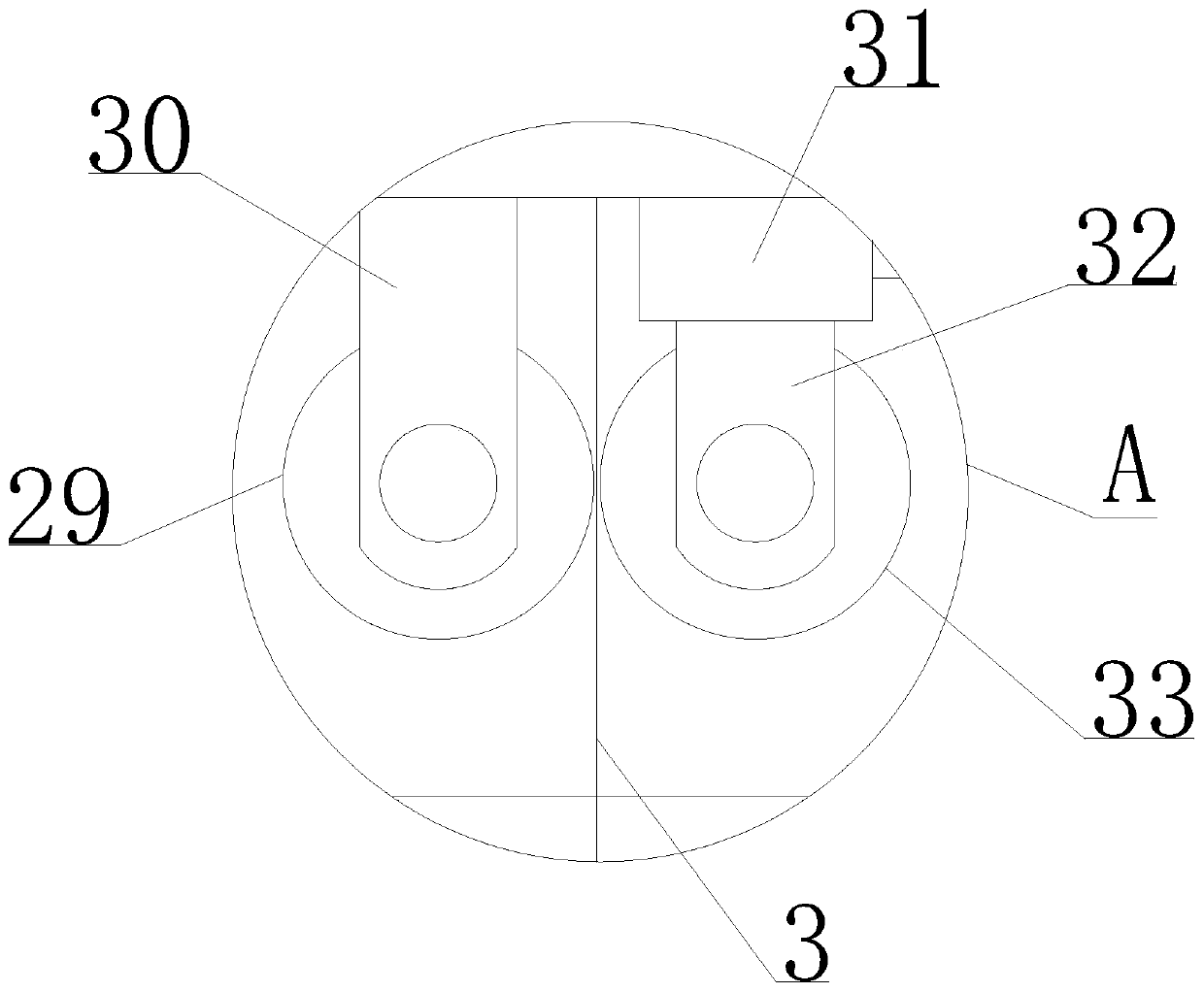

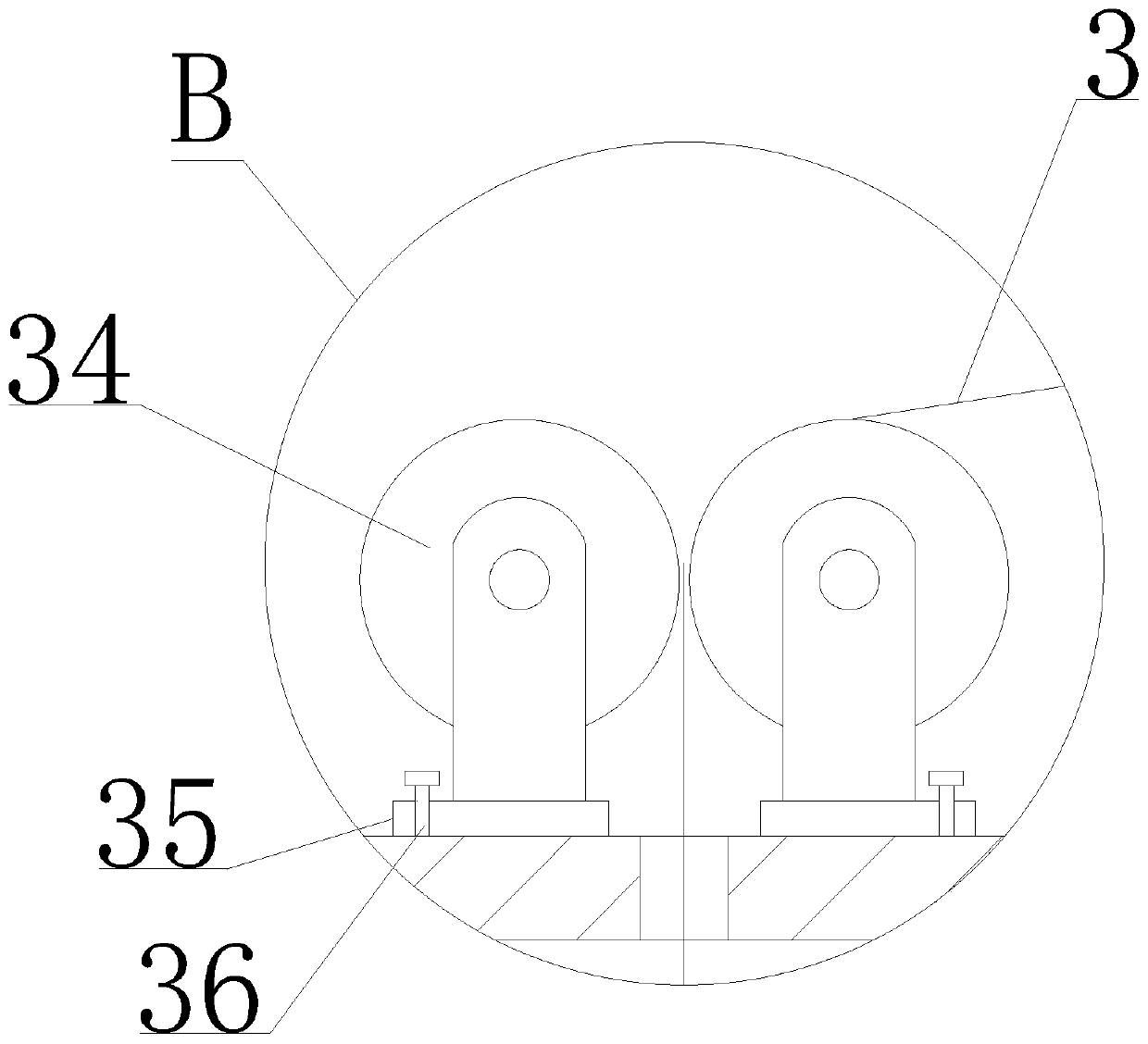

Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

ActiveCN103334246AGuaranteed uniformityImprove uniformityHeating/cooling textile fabricsLiquid/gas/vapor removal by gas jetsCarbon fibersWorking environment

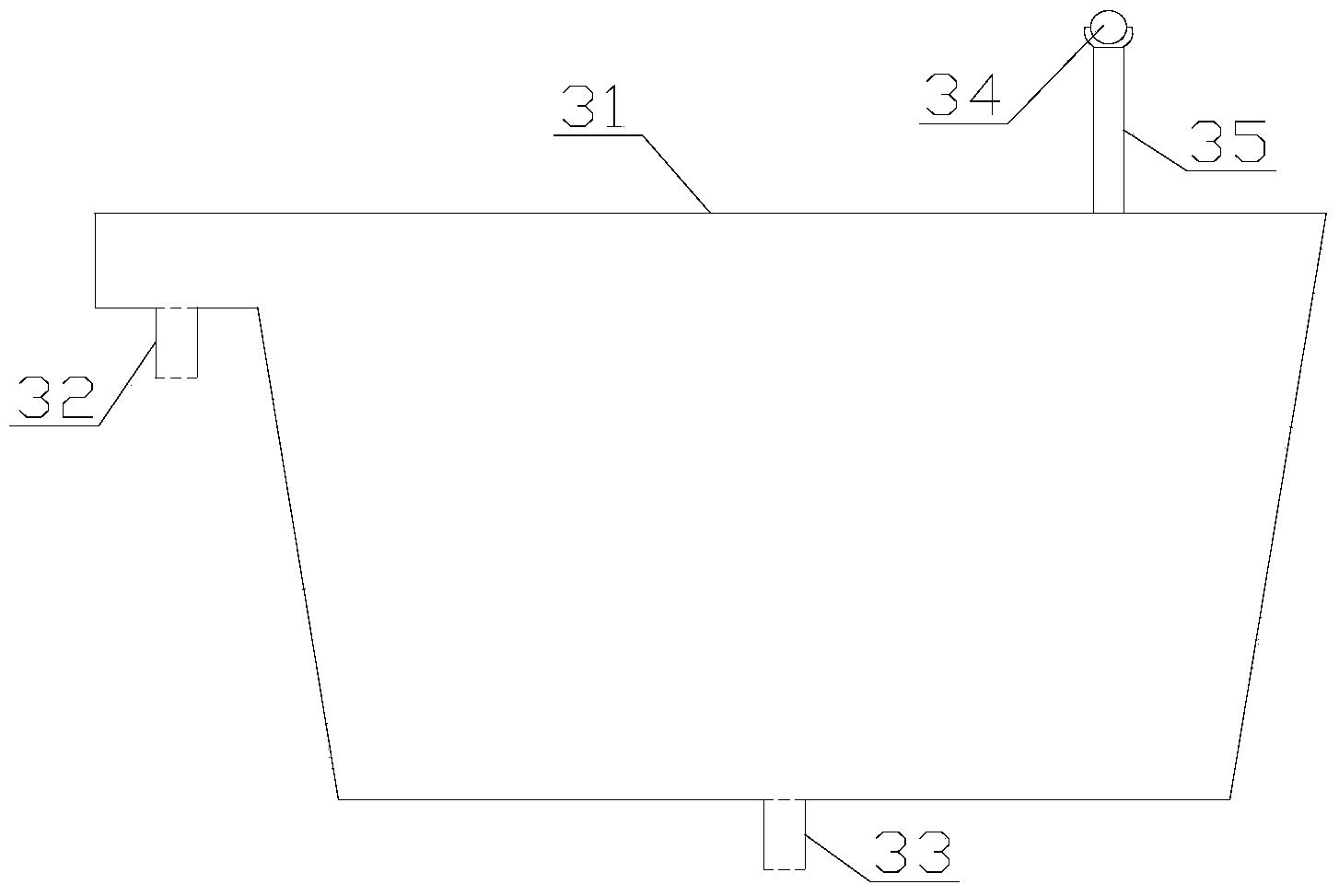

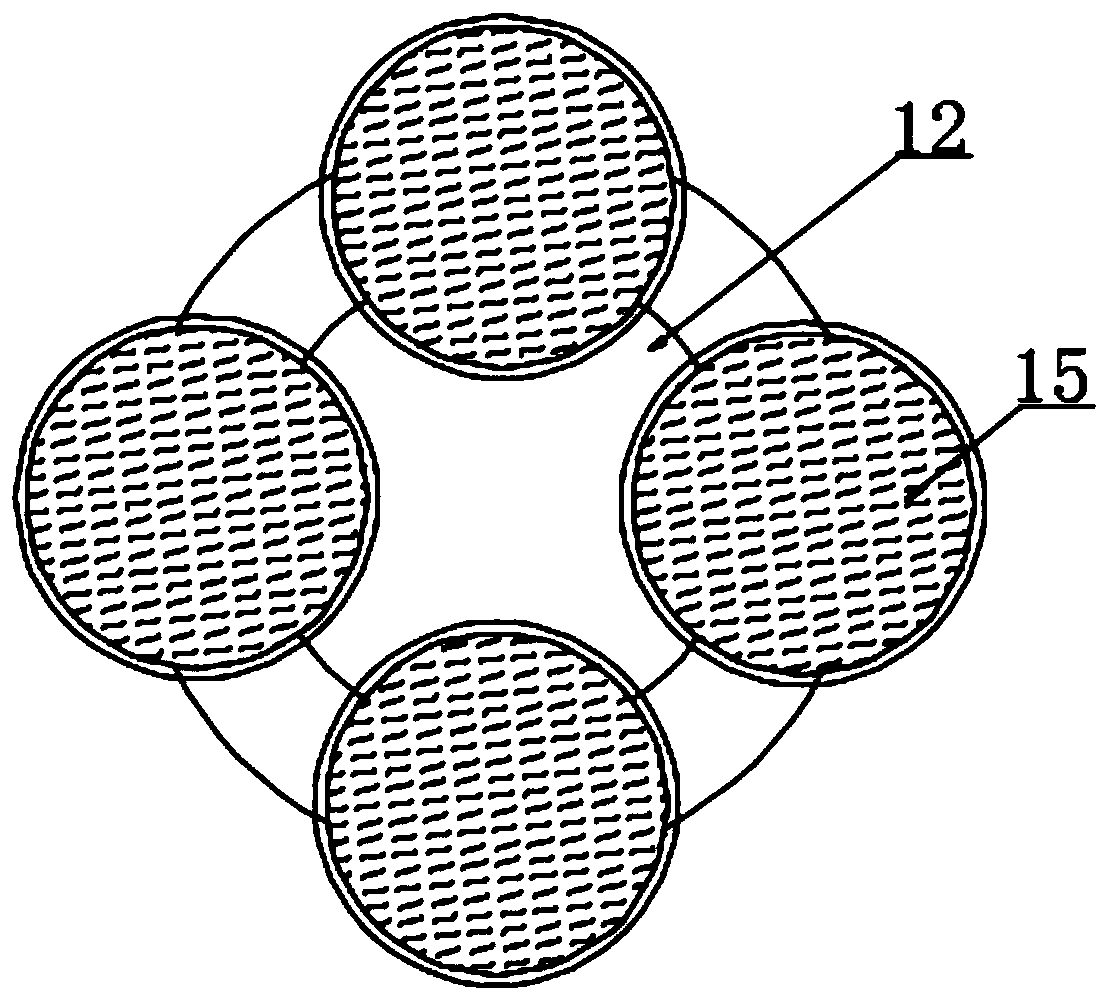

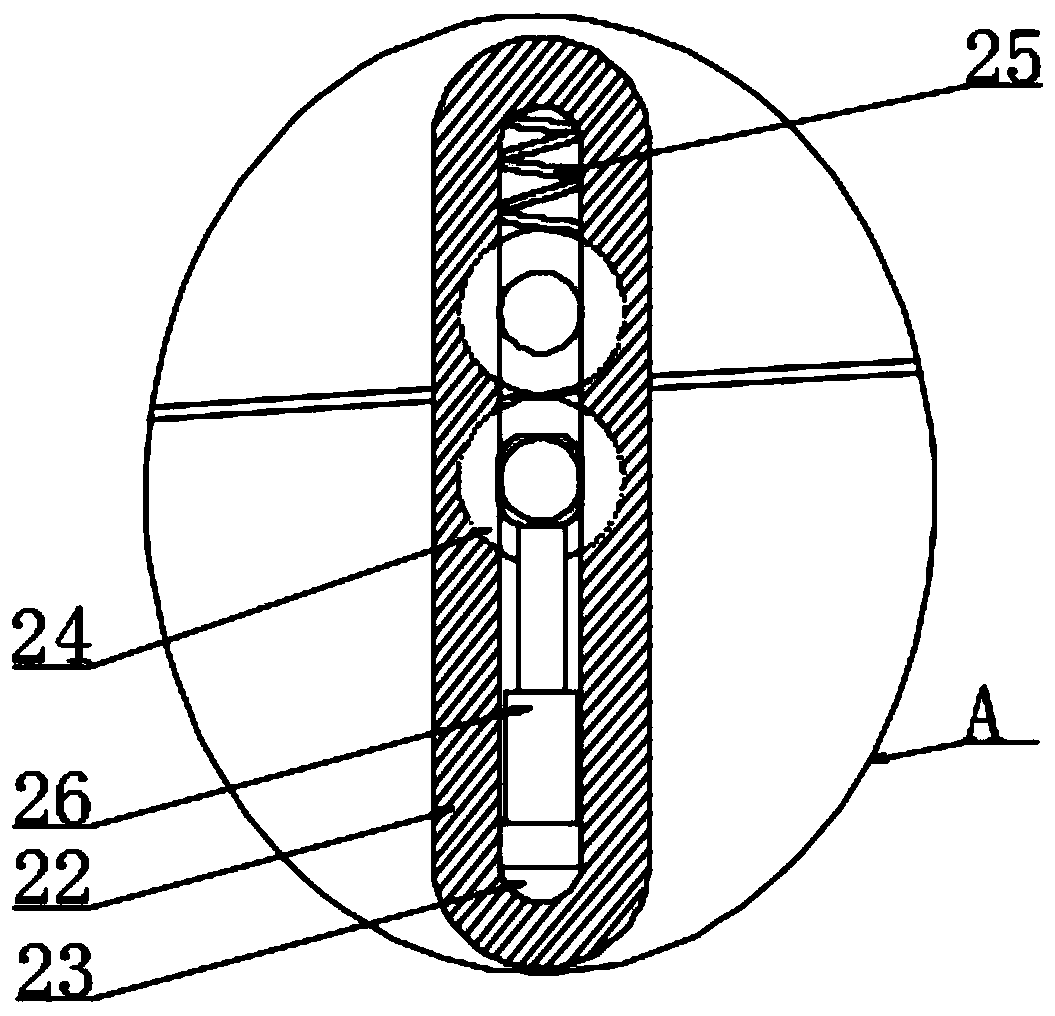

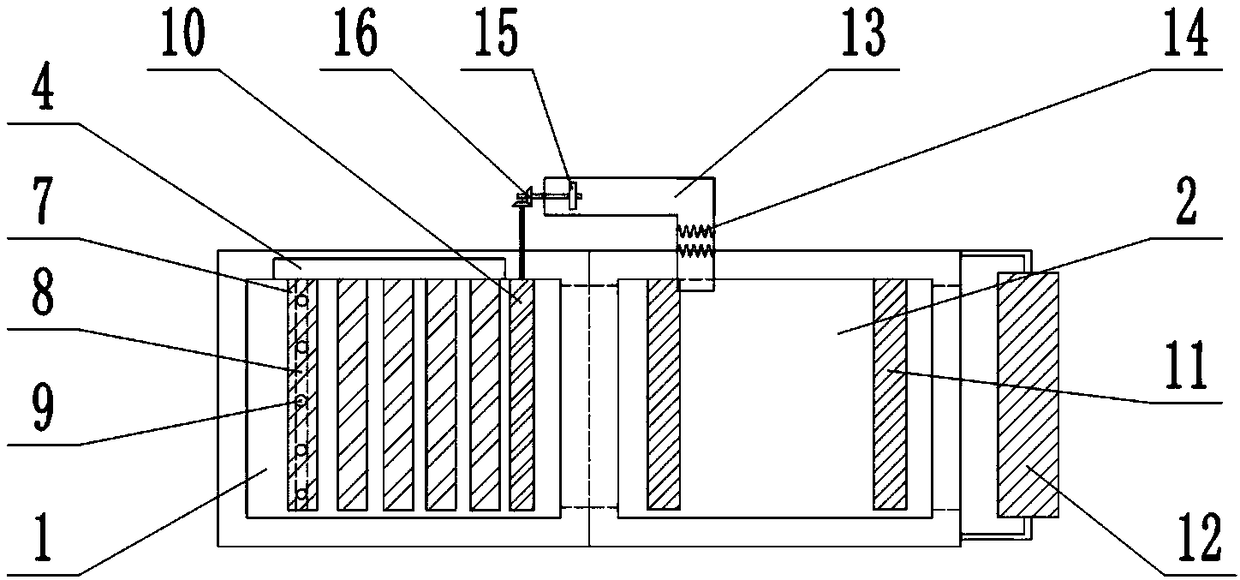

The invention belongs to a generation device for a polyacrylonitrile-based carbon fiber and particularly relates to a sizing, drying and shaping device for the polyacrylonitrile-based carbon fiber. The sizing, drying and shaping device comprises a sizing device for sizing a carbon fiber, a drying device for the sized carbon fiber as well as a shaping device for shaping the dried carbon fiber, wherein the sizing device comprises a sizing groove for accommodating slurry; a circulating pipeline is arranged on the outer side of the sizing groove; one end of the circulating pipeline is connected with the bottom of the sizing groove; the other end of the circulating pipeline is connected with the upper edge of the sizing groove; a circulating pump is arranged on the circulating pipeline; a guiding roller which is partially immersed in the slurry and an immersing roller which is completely immersed in the slurry are arranged in the sizing groove; a reflowing plate which is arranged in an extending manner is arranged on the outlet edge of the sizing groove; and an air purge device is fixedly arranged above the reflowing plate. According to the sizing, drying and shaping device disclosed by the invention, the sizing is uniform, the shape of tows is good; the pollution of air to the carbon fiber is reduced in the sizing and drying; and meanwhile, the work environment is improved and the work comfortableness of workers is improved.

Owner:ZHONGJIAN TECH CO LTD

Textile dyeing device

InactiveCN106968069AExtended drying timeGuarantee normal dyeing workTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringDrying time

The invention discloses a textile dyeing device, comprising a box body, a dye box is fixedly installed at the left end of the bottom of the inner cavity of the box, and a first drive roller is movably installed at the upper left end of the inner cavity of the dye box. The lower end of the cavity is movably installed with a second transmission roller, the upper right end of the inner cavity of the dye box is movably installed with a third transmission roller, the right end of the upper surface of the dye box is provided with a second through hole, and the right end of the bottom of the inner cavity of the dye box is provided with a second through hole. A pressure sensor is fixedly installed. In the invention, the scraper is movably connected to the inner cavity of the second sleeve through the second spring, which can scrape off the dye adhering to the surface of the dyed fabric after dyeing. The fabric is air-dried, which solves the problem that a large amount of dye will adhere to the surface of the fabric during the dyeing process of the existing fabric dyeing machine, which not only prolongs the drying time of the fabric after dyeing, but also causes the waste of dye.

Owner:湖州梦源环保科技有限公司

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Cleaning drying device used for gauze production

ActiveCN108930110AImprove product qualityAvoid secondary adsorptionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryImpurity

The invention provides a cleaning drying device used for gauze production, and relates to the technical field of gauze production and manufacturing equipment. The cleaning drying device used for gauzeproduction comprises a base. The top of the base is fixedly provided with a cleaning box and a drying box. The drying box is divided into a dehydration chamber and a drying chamber. The cleaning boxis internally provided with a first cloth guide roller and a cleaning device. The cleaning device comprises an upper supporting rod and a lower supporting rod. Using the leaning drying device used forgauze production, through cooperation of an upper supporting rod, a lower supporting rod, an upper cleaning roll, a lower cleaning roll, a scraper blade, a rotating disk, and a banister brush, gauzedrives a driving belt to drive on the rotating disk, and the banister brush on the driving belt cleans the surface of the gauze. Under operation of the driving belt, the banister brush drives impurities into the upper cleaning roll, and the impurities on the banister brush are removed through the scraper blade. Impurities pass through the scraper blade and enter into the upper cleaning roll, and the impurities on the surface of the gauze are removed in cleaning, so that product quality of the gauze is improved.

Owner:陈剑璋

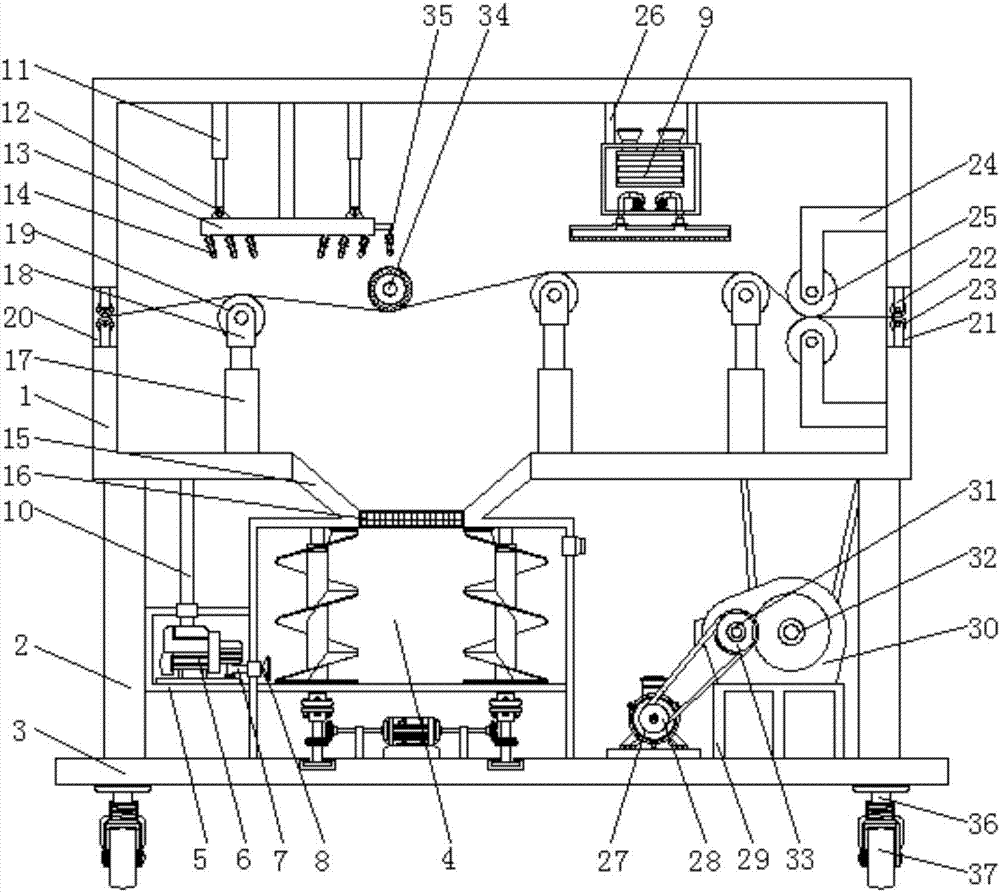

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

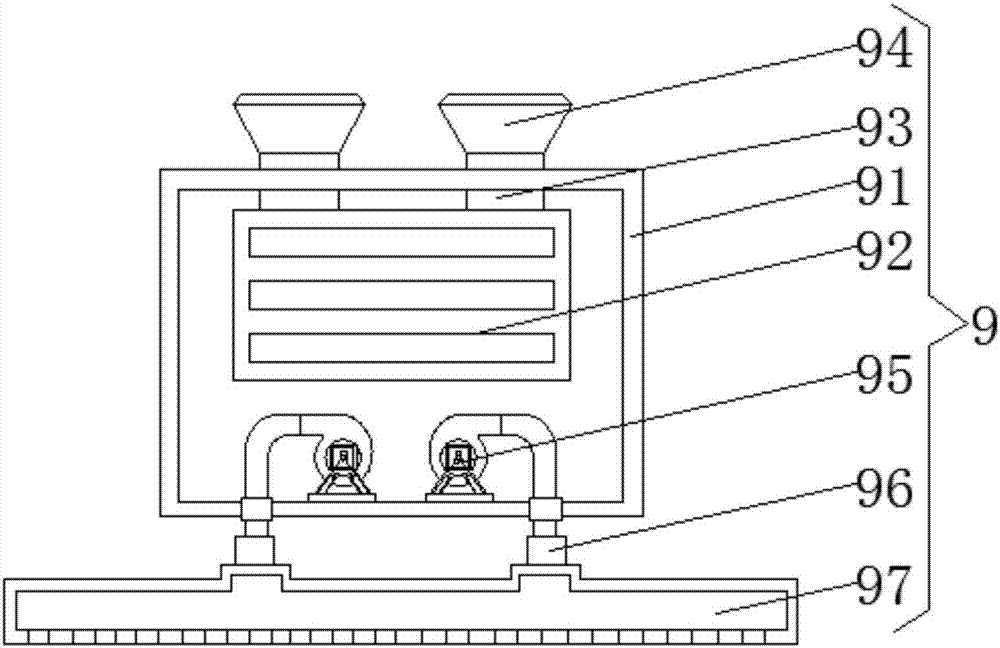

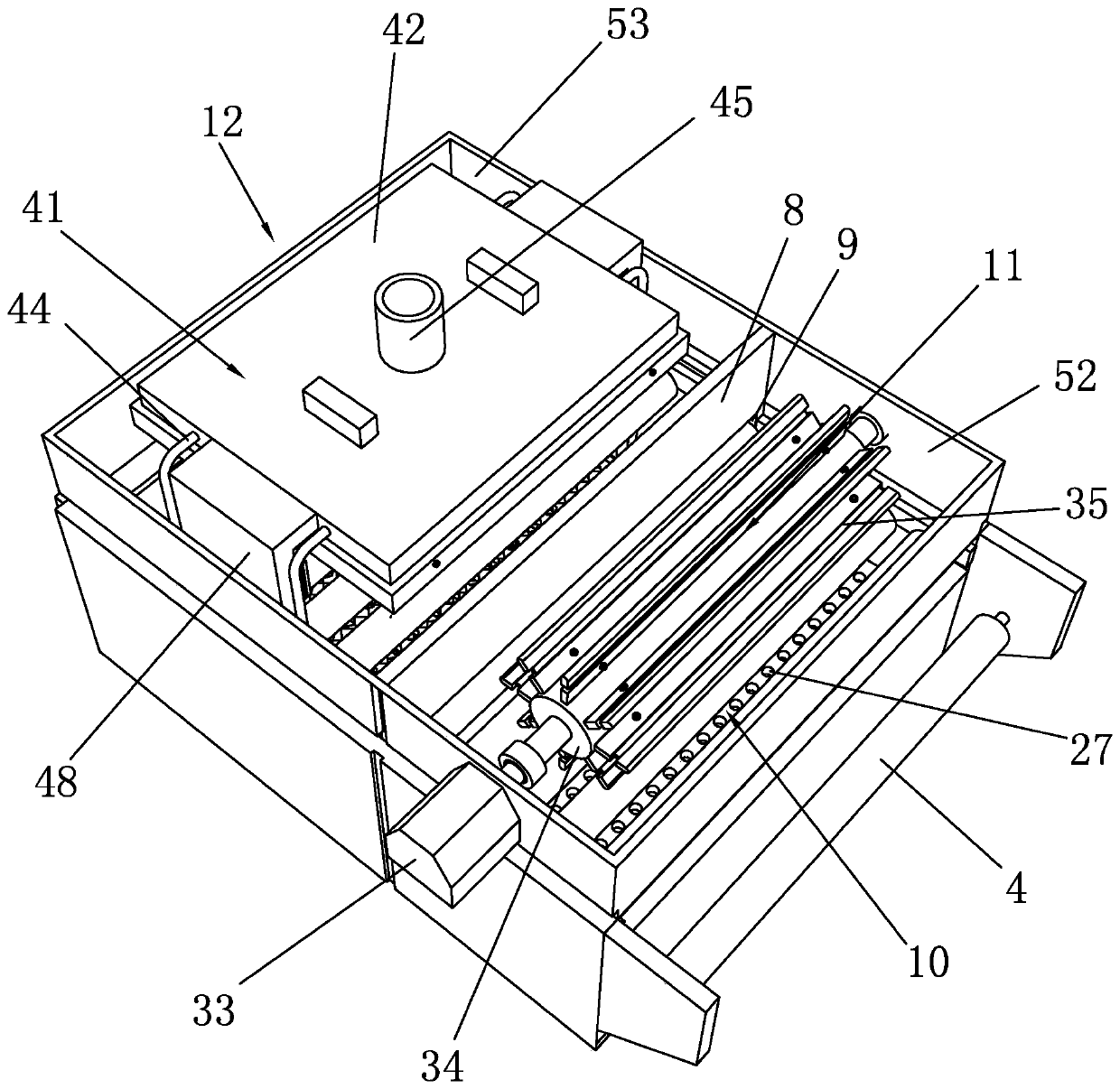

Preparation method and electret equipment of polypropylene melt-blown non-woven fabric

ActiveCN110820174AImprove permeabilityKeep for a long timeLiquid/gas/vapor removal by gas jetsNeedling machinesPolymer scienceWater flow

The invention discloses a preparation method and electret equipment of a polypropylene melt-blown non-woven fabric. The preparation method includes the steps of melt-blowing production, pure water preparation, electret technology and drying technology. The preparation method has the advantages that more electrets can be generated by the aid of spunlace electret, electrodes lost in the spunlace electret process are made up, so that the non-woven fabric is better in permeability, the electrets are stable, retention time is long, adsorptivity is strong, good filtering effects can be achieved under the condition of low resistance, atomized water can be prevented from running off into a working environment by the aid of a splash-proof device, the working environment can be improved, pure waterafter puncture can be maximally recovered by the aid of a pure water recovery device, and the pure water is prevented from flowing to the outside.

Owner:邯郸恒永防护洁净用品有限公司

Wetting, drying, and ironing device for textile production

InactiveCN108060543AReduce defective rateGuaranteed qualityLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingWater dischargeEngineering

Owner:石小英

Fabric drying molding device

InactiveCN107604579AAvoid wrinklesGood shaping effectMechanical cleaningPressure cleaningReciprocating motionPulp and paper industry

The invention discloses a fabric drying molding device. The fabric drying molding device comprises a casing and a working table, wherein two sides of the working table are fixedly connected with two sides of the inner wall of the casing; electric telescopic links are fixedly connected with two sides of the top of the inner wall of the casing; a movable plate is fixedly connected with bottom ends of the electric telescopic links; two sides of the movable plate are in sliding connection with two sides of the inner wall of the casing respectively. The invention relates to the technical field of textile product processing. According to the fabric drying molding device, the movable plate is driven by the electric telescopic links to stretch and retract and driven to move up and down, fabric isconveniently placed on the working table, a first motor works to drive a screw rod to rotate, a spreading device is driven to move towards two sides to spread and flatten the fabric, a transverse plate is driven by a moving device to reciprocate leftwards and rightwards, a draught fan blows air into a heating box, air is heated by a heating plate and blown out by an air outlet hopper for drying the fabric, the drying is uniform, and the device is simple to use, convenient to operate and good in processing effect.

Owner:ANHUI SHAWOSI CLOTHING CO LTD

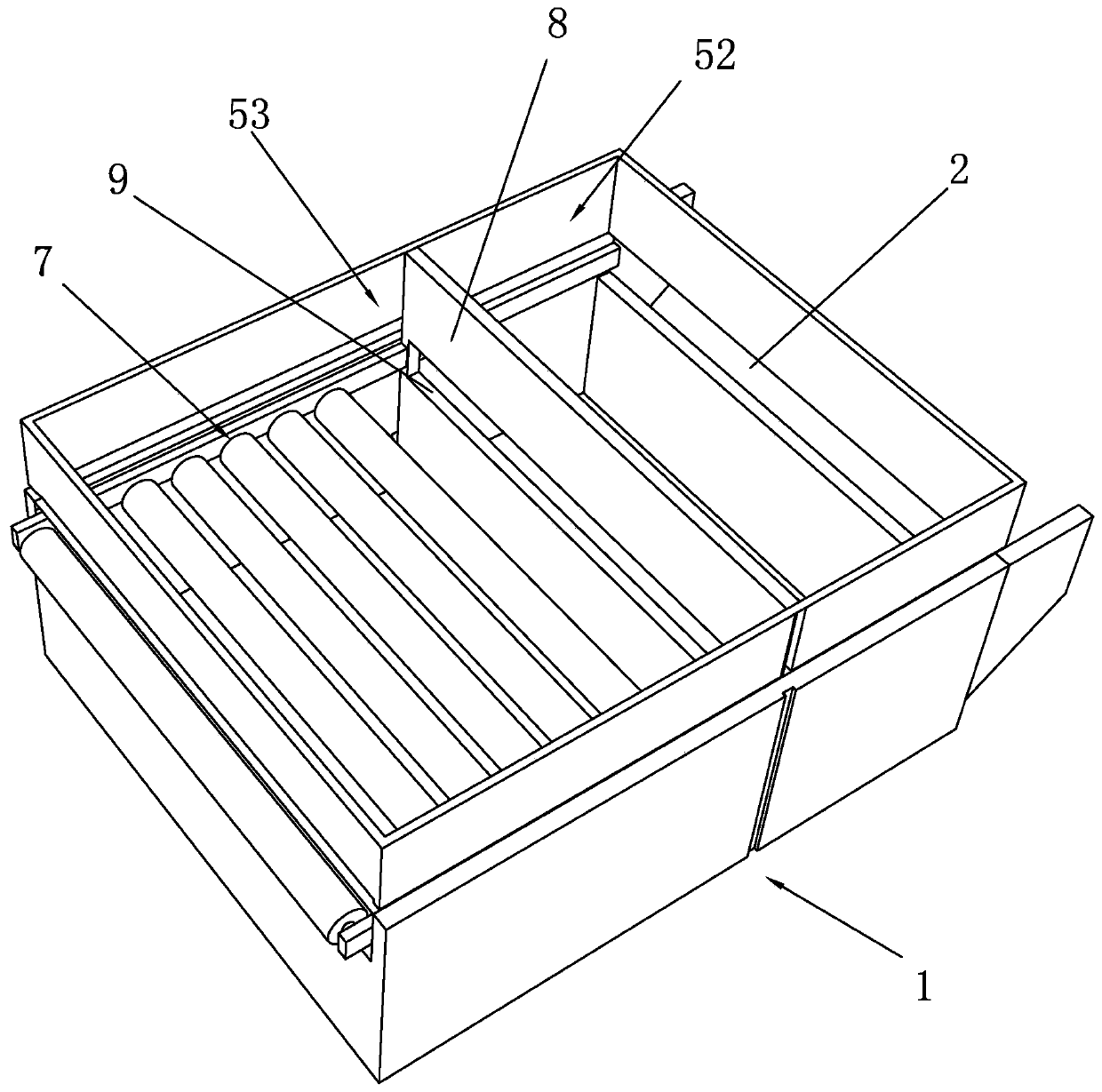

Oscillation type drying system used for non-woven fabric production

InactiveCN110736324AImprove drying effectReduce lossDrying gas arrangementsDrying machines with progressive movementsNonwoven fabricMaterial distribution

The invention relates to an oscillation type drying system used for non-woven fabric production. The oscillation type drying system comprises a box body. A vertical partition plate is arranged in an inner cavity of the box body. The inner cavity of the box body is divided into a preheating cavity and a drying cavity through the vertical partition plate. Inlets and outlets are symmetrically formedin the middle portions of the left side wall and the right side wall of the box body. A communicating opening is formed in the portion, corresponding to the inlets and outlets, of the middle portion of the vertical partition plate. A first guide roller set is arranged in the preheating cavity. A second guide roller set is arranged in the drying cavity. A U-shaped plate is arranged on the lower portion of the drying cavity. The second guide roller set is distributed along the U-shaped face of the U-shaped plate. A transverse partition plate is arranged on the lower portion of the preheating cavity. An air heater is arranged in a lower side cavity of the transverse partition plate. A hot air pipe is arranged on the lower side of the U-shaped plate. According to the oscillation type drying system, by means of the technological means such as an arranged hot air circulation pipeline, an arranged material distribution vibration mechanism and an arranged preheating structure, the technical problems that in the prior art, the non-woven fabric drying efficiency is low, the drying effect is poor and the drying energy consumption is large are solved.

Owner:长兴燕莎纺织有限公司

Garment fabric dyeing and drying integrated device and dyeing process thereof

InactiveCN106757899AGuaranteed dyeingIncrease productivityTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsSpray nozzleWater level

The invention discloses a garment fabric dyeing and drying integrated device and a dyeing process thereof. The garment fabric dyeing and drying integrated device comprises a controller and a dyeing device body, wherein the controller is arranged on the outer wall of the dyeing device body, a delivery device is arranged inside the dyeing device body, a waste liquid recovery tank is arranged below the delivery device, a dye stirrer is arranged above the dyeing device body, a hot water tank is arranged besides the dye stirrer, a heater is arranged on the side face of the hot water tank, a water level detector is arranged inside the hot water tank, and a drying device is arranged at the rear portion of the dyeing device body. The garment fabric dyeing and drying integrated device has the advantages that comprehensive dyeing is ensured through multiple rows of spray nozzles, meanwhile cloth dyeing and drying work can be directly completed, and the production efficiency is improved.

Owner:卢楚坚

Cloth soaking and coloring automatic equipment and operation method thereof

PendingCN111826853AUniform colorImprove production efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFuel tankElectric machinery

The invention discloses cloth soaking and coloring automation equipment and an operation method thereof, and belongs to cloth soaking and coloring automation equipment. The cloth soaking and coloringautomation equipment comprises a base, wherein the upper end of the base is fixedly connected with a dye box; and a feeding hole and a discharging hole are formed in the two sides of the upper end ofa fuel tank respectively. During cloth dyeing, driving motors in the motor box are started and drive a stirring paddle to rotate, and the stirring paddle stirs liquid in the dye box, so that the liquid in the dye box is always kept uniform; the uniform coloring of the cloth during dyeing can be ensured; and the situation of secondary processing of unqualified products is avoided. Moreover, an airbellow works to suck and blow external air flow into a heating box, the heating box heats and conveys the blown air into the drying box, and the hot air flow can dry the cloth in an accelerated manner, so that the cloth making efficiency can be improved, and the cloth can be dried more quickly.

Owner:常胜男

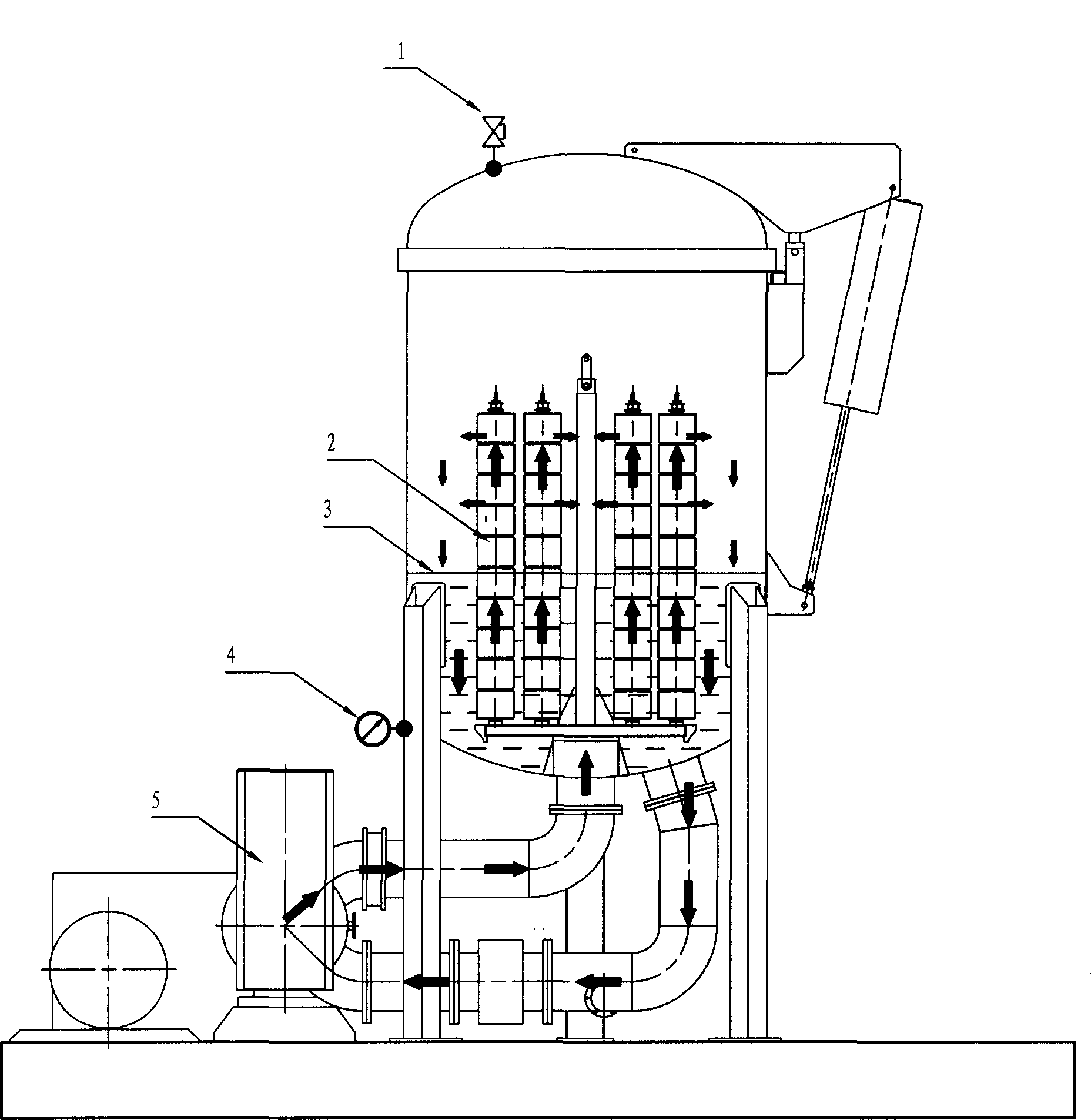

Down feather screening device

ActiveCN107587209ASpray evenlyAvoid enteringFibre cleaning/opening machinesTextile treatment machine arrangementsAir pumpAir compressor

The invention discloses a down feather screening device. The device comprises an air pump, a motor, a pneumatic retractable rod, a bracket, atomizing nozzles, a fixing rod, a vibration motor, a vibration box, a sieve net, a water tank, a drying box, an air compressor, a stirring motor, a water pump, a winch board, an air heater, a connecting frame, a miniature motor, a first screw rod, a fixture and a second screw rod; the motor and the second screw rod are utilized to control the movement of the fixture in the horizontal direction to make the fixture enter the drying box; down feathers are introduced into the drying box, a stirring motor, a stirring stick and the winch board are utilized to prevent the down feathers from accumulating at the bottom of the drying device, and drying is conducted more fully; a pressure gauge and a safety valve are utilized to control the safety of the drying box, and a filter net is utilized to prevent the down feather or impurities from entering the equipment. The down feather screening device is easy to operate, the down feathers can be screened to remove impurities and dust particles and then cleaned and dried, the production efficiency is improved, the resources are saved, and the cost is reduced.

Owner:安徽芙芮雅羽绒有限公司

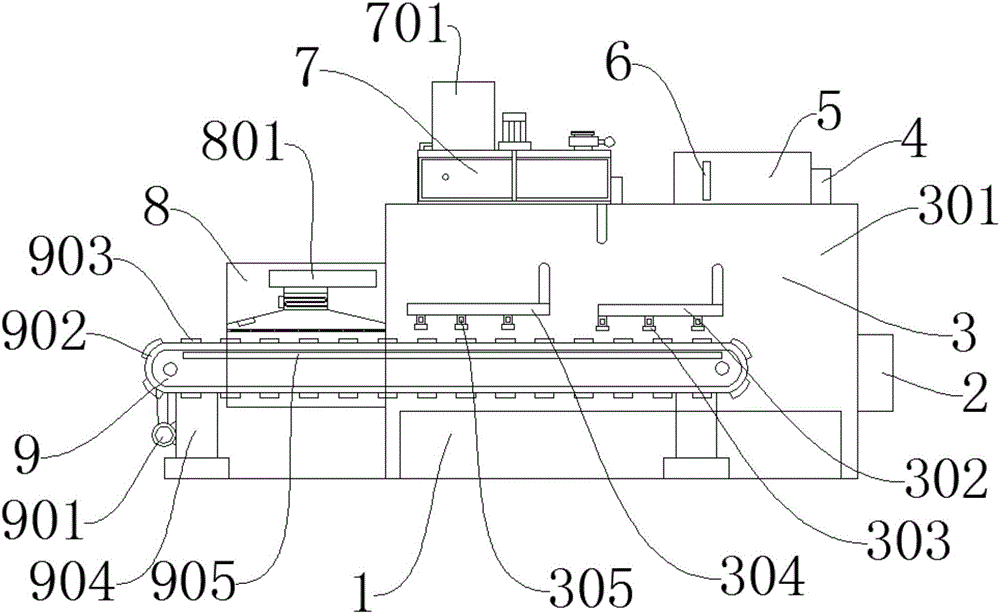

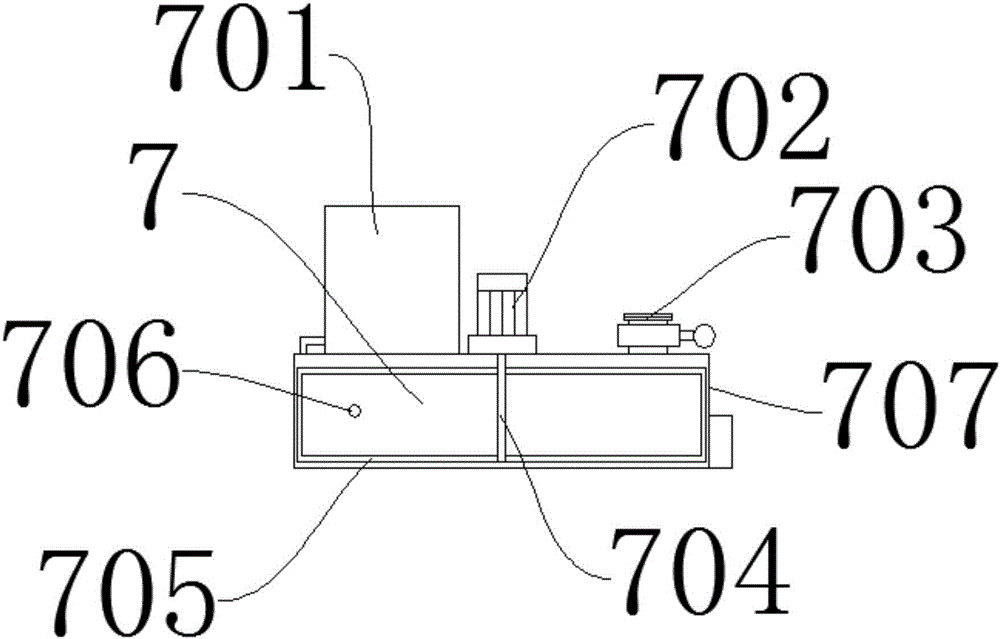

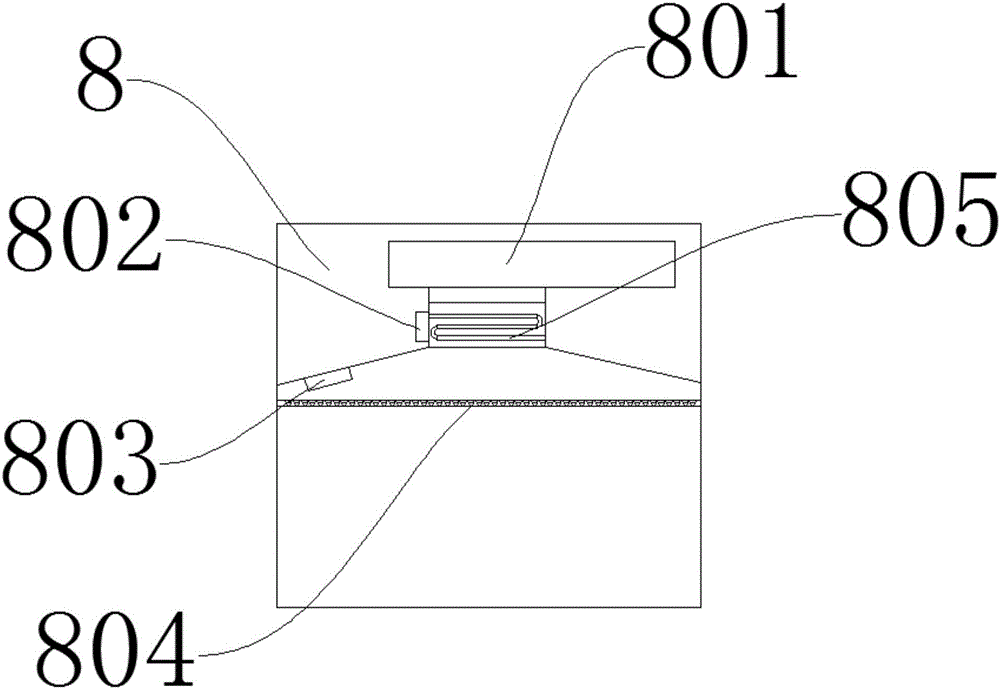

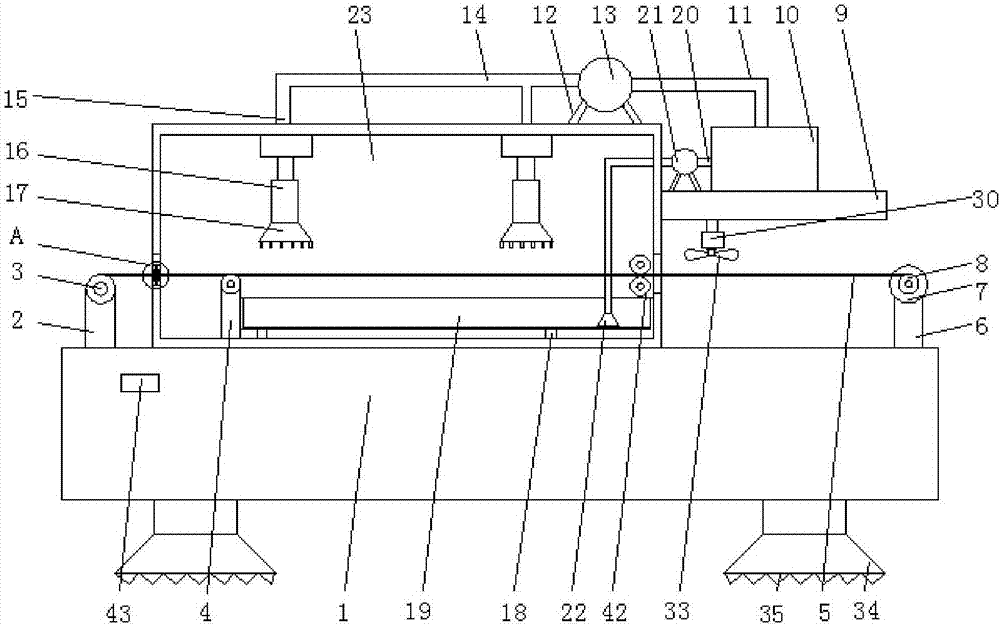

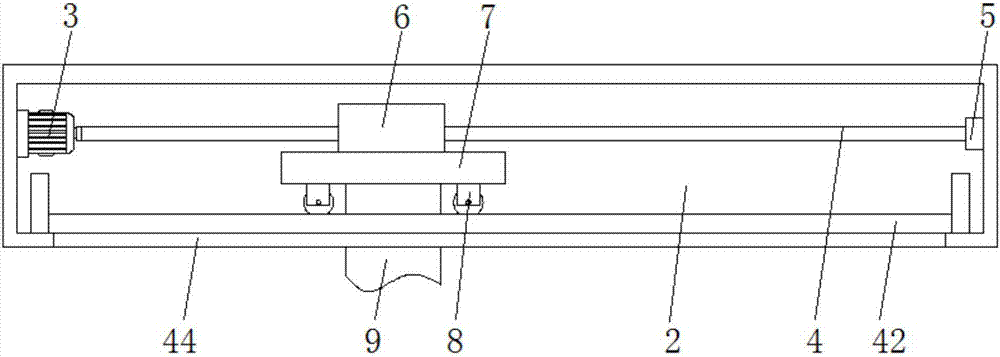

Cloth spreading machine for garment making and use method thereof

ActiveCN108914433AReduce labor intensitySimple structureLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingAgricultural engineeringPre compression

The invention relates to the field of garment making and specifically relates to a cloth spreading machine for garment making and a use method thereof. The machine comprises a working platform; the working platform is provided with a flattening device; a pre-compression device is arranged, at the right side of the flattening device, on the working platform; a humidifying device is arranged on theworking platform on the right side of the pre-compression device; an ironing device is arranged on the working platform on the right side of the humidifying device; a drying device is arranged on theworking platform on the right side of the ironing device; a winding device is arranged on the working platform on the right side of the drying device. The invention has the advantages of simple structure, convenient operation, high automation degree, can save manpower, reduce labor intensity of workers, can carry out drying treatment on the ironed cloth, and has high working efficiency and the mildew phenomenon after the cloth is placed for a long time is avoided.

Owner:濮阳黑蚂蚁服饰有限公司

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

Textile dyeing device with good dyeing effect

InactiveCN107326569AEasy to dyeImprove dyeing effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile printerStaining

The invention provides a textile dyeing device with good dyeing effect and relates to the field of textile printing and dyeing. The textile dyeing device with good dyeing effect includes a fixed seat, the top side of the fixed seat supports a column, the top of the support column is movably connected with a cloth roll, and the surface of the cloth roll is lapped with a textile cloth body , the top of the fixed seat is fixedly connected with a dyeing box, the bottom of the inner wall of the dyeing box is fixedly connected with a connecting roller, and the other side of the top of the fixed seat is fixedly connected with a support rod. The textile dyeing device with good dyeing effect is set by the cloth take-up roller on the top of the fixed seat and the cloth take-up wheel on the first motor on the top of the fixed seat, so that when the textile fabric is dyed, the cloth passes through the cloth take-up wheel and the cloth take-up roller The cooperation will become tense, so that there will be no creases in the placement of the fabric, so that the dye can be dyed better, and it solves the problem of poor dyeing effect of the current textiles and waste of dye.

Owner:梅明会

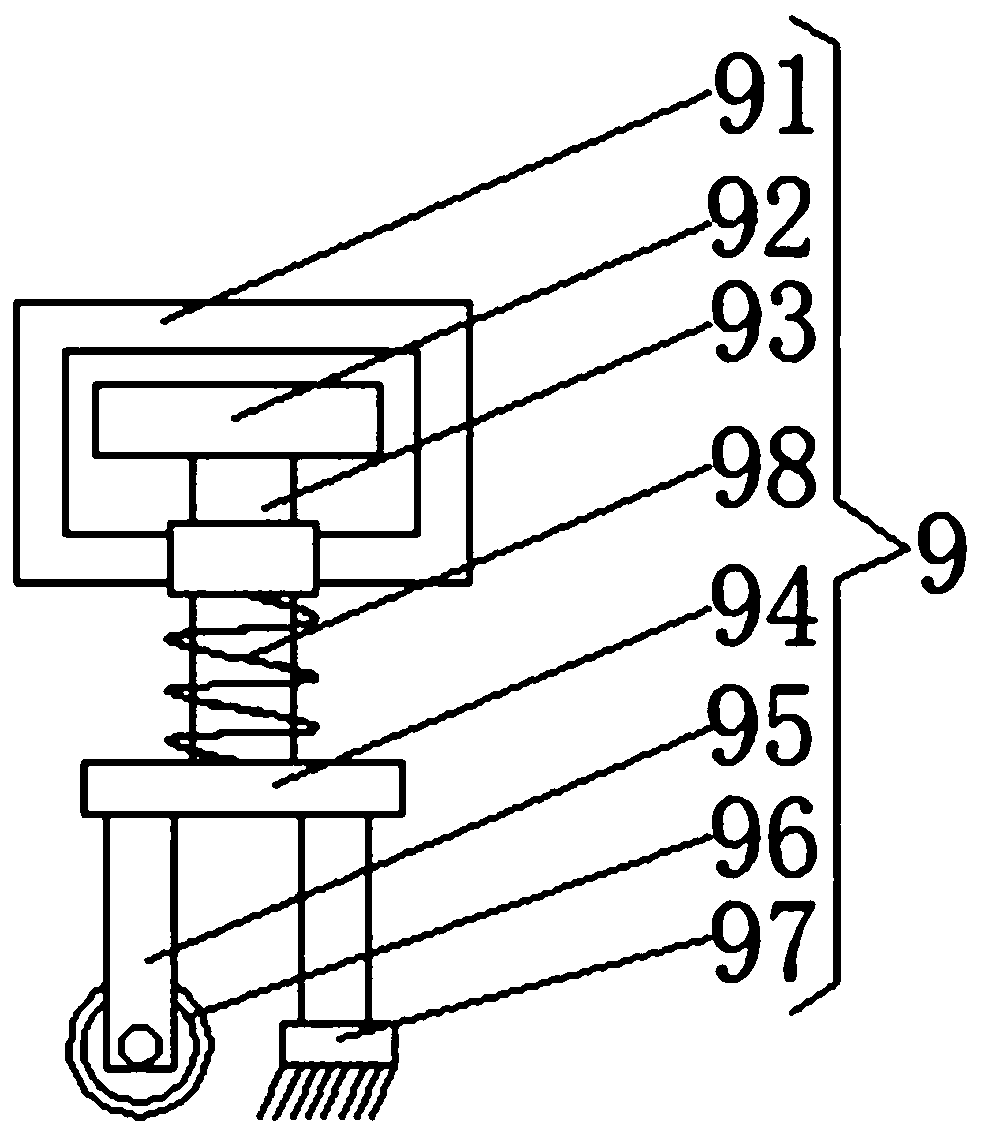

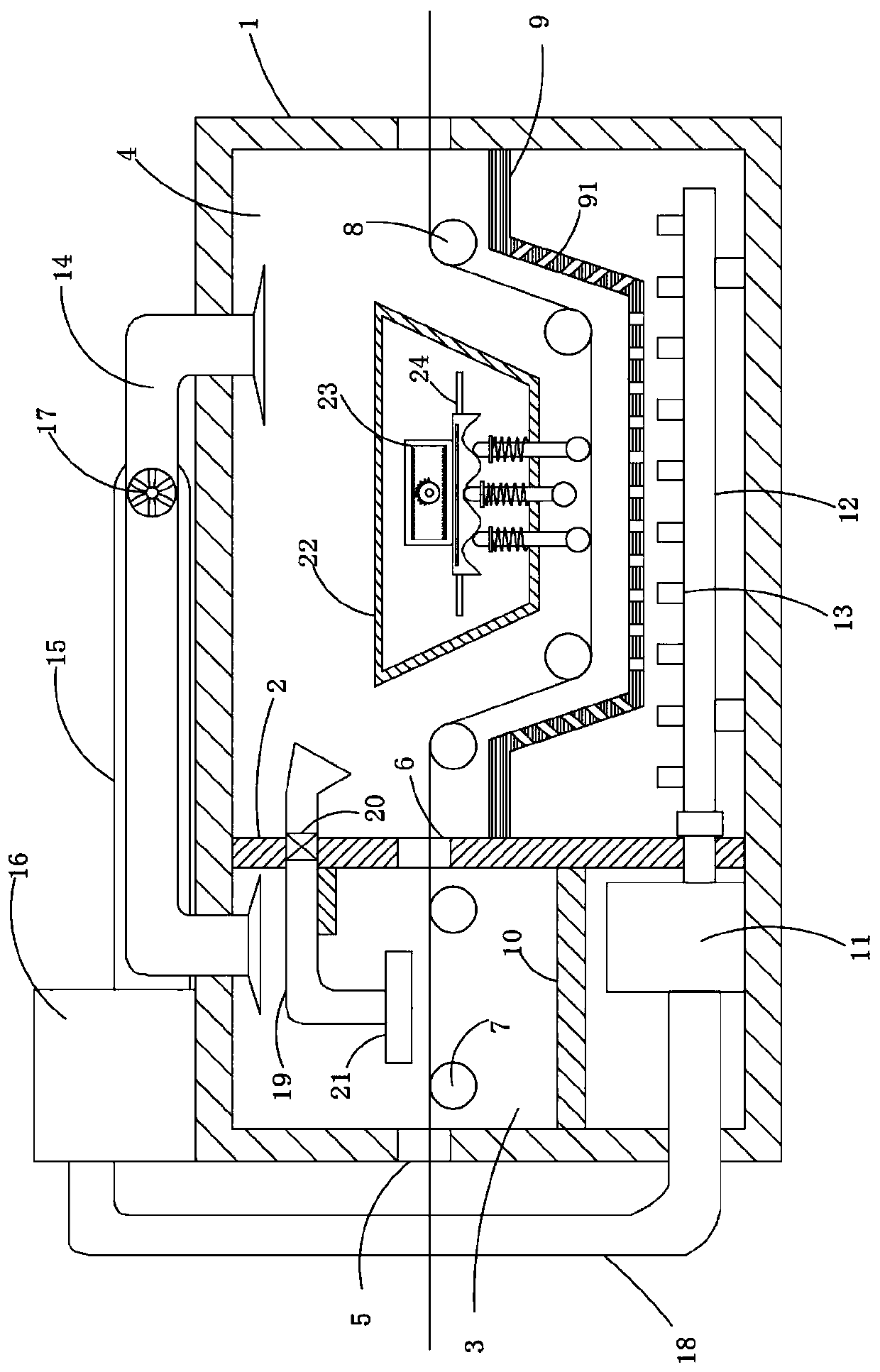

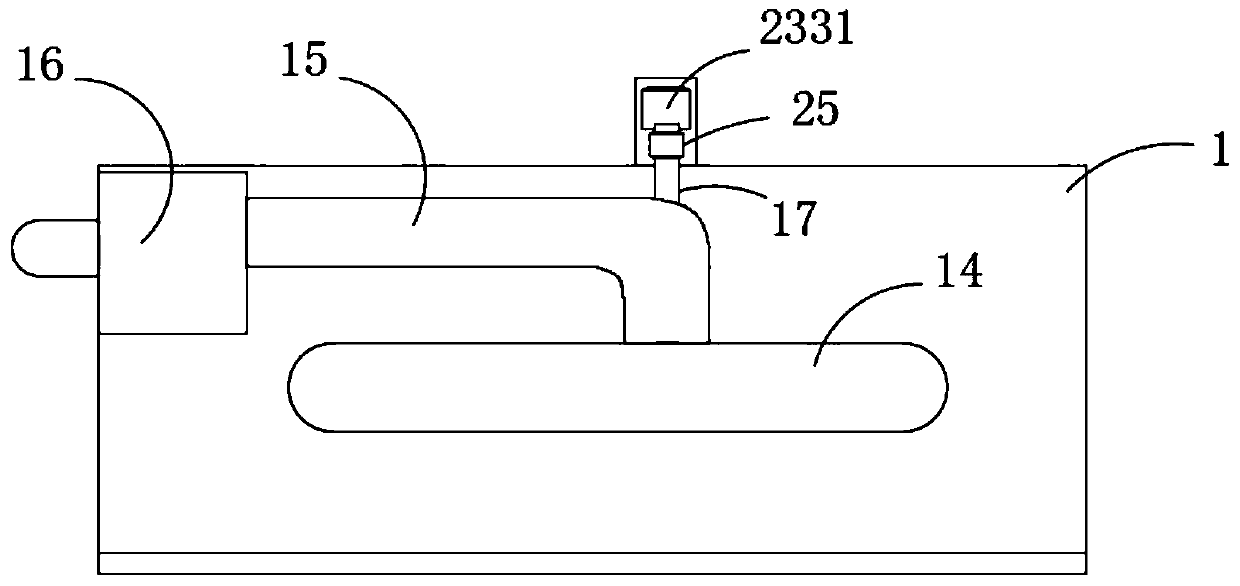

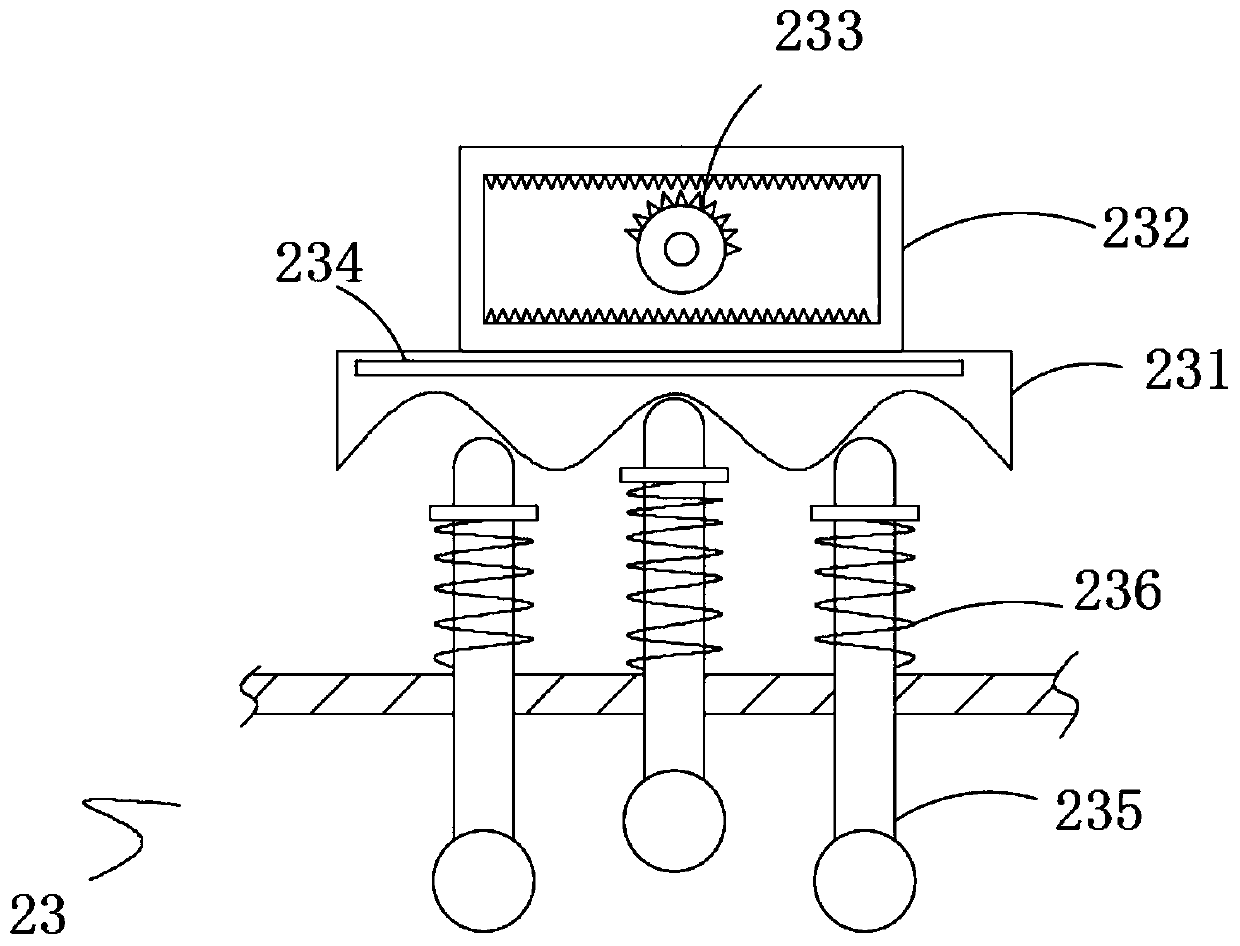

Cleaning-conveniently spinning device

InactiveCN108118420AAvoid pollutionReduce pollutionLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnEngineering

The invention belongs to the field of a spinning device, and particularly to a cleaning-conveniently spinning device. For a textile machine is polluted by massive spreading of fluff dust and unable toclean the interwoven cloth for the fluff on a yarn is easy to drop when the yarn of the existing textile machine passes through a roll wheel and other guide devices, the following plan is presented;the spinning device comprises a device main body; one side of the device main body is orderly equipped with a horizontal fixing plate, a teasing plate, an ultra-wear-resisting thread crossing device and a collecting box with an opened top end from top to bottom orderly; multiple rotary shafts are rotationally connected to the fixing plate, and multiple comb teeth are connected to the teasing plate; the side wall at one side of the collecting box is equipped with an exhaust fan. The cleaning-conveniently spinning device can collect and clean fluff and dust on the yarn, prevent fluff from polluting the spinning device, reduce the maintenance of the spinning device in later period while clean and dry the interwoven cloth; thus the cloth does not need to clean in later period, the spinning effect is good.

Owner:苏州朦井纺织科技有限公司

Textile fabric wrinkle removal equipment

InactiveCN110079950AAffect qualityAffect water delivery operationsMechanical cleaningPressure cleaningWrinkle skinWrinkle

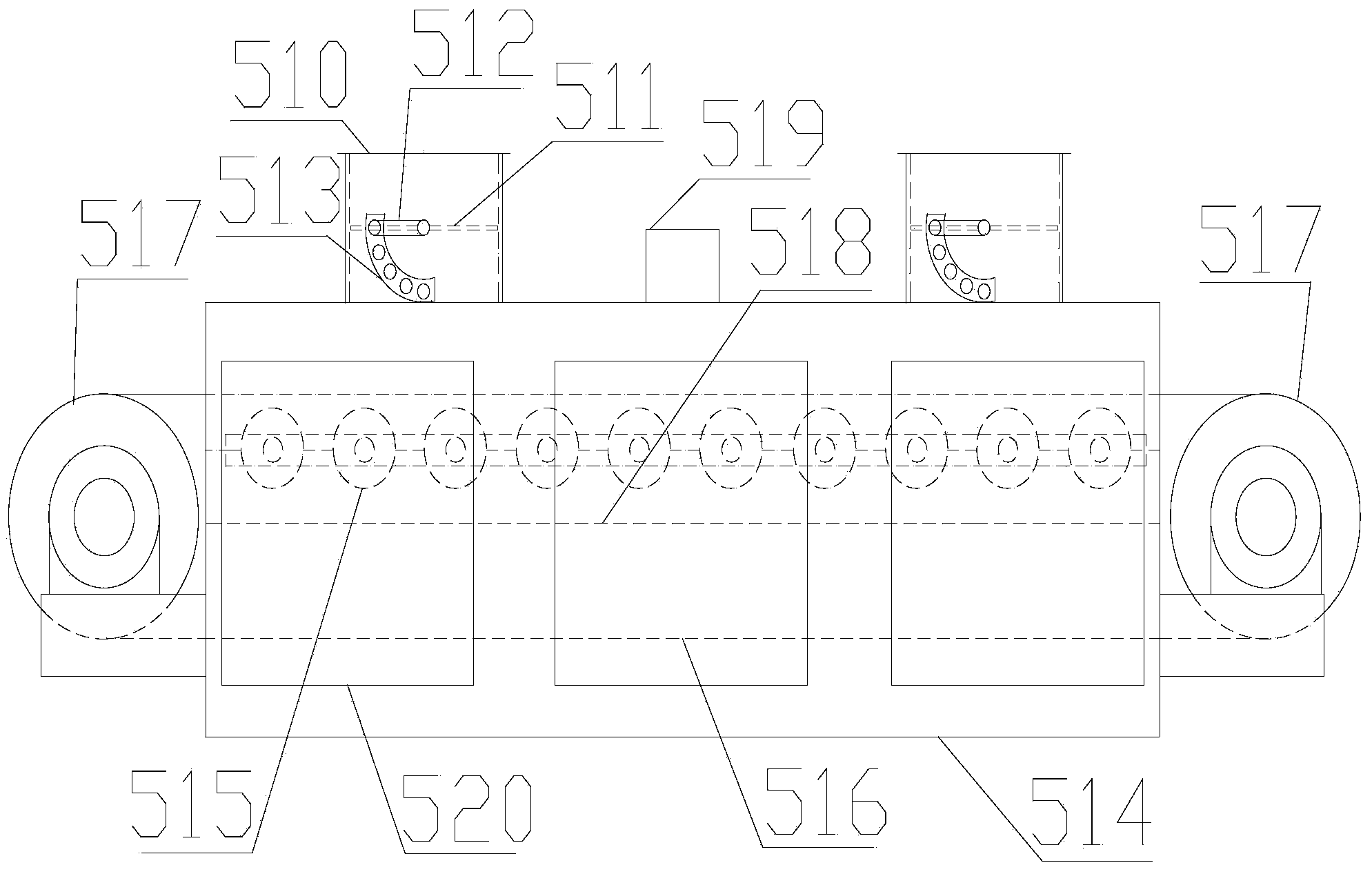

The invention relates to textile fabric wrinkle removal equipment, and belongs to the technical field of textile equipment. The equipment comprises a conveying component, a dust removal component, a spraying component, a wrinkle removal component, a compressing component, a drying component and a storage component, wherein the dust removal component, the spraying component, the wrinkle removal component, the compressing component, the conveying component and the drying component are all arranged at the top of the conveying component; the dust removal component and the drying component are symmetrically arranged at the feeding end and the discharging end of the conveying component; the spraying component is arranged on one side of the wrinkle removal component; the compressing component isarranged at the other end of the wrinkle removal component; the storage component is arranged on one side of the conveying component; a feeding rack is arranged on one side of the feeding end of the conveying component; a feeding roll rotationally connected with the feeding rack is arranged on the feeding rack. The equipment performs dust removal treatment on textile through the dust removal component, performs drying treatment on the textile through the drying component, and guarantees the wrinkle removal quality of the textile after dust removal and drying are performed.

Owner:王楠

Fabric printing and dyeing device

ActiveCN105803709ASolve uneven densityGuaranteed reliabilitySucessive textile treatmentsTextile treatment containersEngineeringMechanical engineering

The invention provides a fabric printing and dyeing device, belonging to the technical field of machinery. The fabric printing and dyeing device solves the problem that the existing clothing fabric spray printing and dyeing device is poor in efficiency. The fabric printing and dyeing device comprises a printing and dyeing chamber and a conveyer belt arranged in the printing and dyeing chamber along the transverse direction, wherein a liquid outlet pipe is arranged above the conveyer belt; a spray head is arranged on the liquid outlet pipe; an air outlet cylinder is also arranged above the conveyer belt; the printing and dyeing chamber is also internally provided with an air supply mechanism capable of conveying hot air into the air outlet cylinder, and a driving part capable of driving the liquid outlet pipe to make reciprocating translation along the length direction of the conveyer belt; a wind deflector is arranged under the conveyer belt; a plurality of vent holes are respectively formed in the upper side wall and the lower side wall of the conveyer belt in a penetrating way; a mixing tank is arranged at the outer side of the printing and dyeing chamber; a liquid inlet is formed in the top of the mixing tank, and a liquid outlet is formed in the right side of the mixing tank; a liquid pumping machine is fixed between the mixing tank and the printing and dyeing chamber; an inlet of the liquid pumping machine is communicated with the liquid outlet, and an outlet of the liquid pumping machine is communicated with an inner cavity of the liquid outlet pipe by a tubular connecting piece. The fabric printing and dyeing device has the advantage of being high in efficiency.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

Textile cleaning device

InactiveCN109750484AEfficient dryingEasy to scrape offMechanical cleaningPressure cleaningFiberWater vapor

The invention discloses a textile cleaning device, and particularly relates to the technical field of textiles. The textile cleaning device comprises a rack, a box body is arranged at the top of the rack, an unwinding roller is arranged on one side of the box body, and a winding roller is arranged on the side, away from the unwinding roller, of the box body; and two symmetrically-distributed firststeering rollers are arranged in the box body, and two symmetrically-distributed second steering rollers are arranged at the bottoms of the first steering rollers. According to the textile cleaning device, output shafts of motors are in transmission connection with sweeping wheels, thus dust and fiber impurities on the surface of a textile cloth are swept and pumped out by dust suction pumps fromdust suction openings, atomizing spraying heads spray water vapor to moisten the textile cloth, dust fall in the box body is achieved, meanwhile, scraper plates conveniently scrap hair balls on the surface of the textile cloth, the first dust suction pump and the second dust suction pump are arranged on the two sides of the textile cloth correspondingly, the first scraper plate and the second scraper plate are arranged on the two sides of the textile cloth correspondingly, thus double-sided clearing is achieved, the working efficiency is improved, a first air heater and a second air heater are arranged on the two sides of the textile cloth correspondingly, thus the textile cloth can be effectively dried, and the textile cloth is leveled by matching with the atomizing spraying heads.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Textile fabric dip-dye device

ActiveCN108517632AMeet the needs of the patternMeet needsLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsPulp and paper industryFan blade

The invention discloses a textile fabric dip-dye device. The device comprises a first cylinder body, a second cylinder body, a raw material roller, a plurality of fabric dyeing rollers, a fabric pressing roller group and a finished-product roller which are arranged side by side, the side wall of the first cylinder body is hollow, rotary shafts are rotatably connected within the fabric dyeing rollers, a rotary shaft is fixedly connected with the interior of the first cylinder body, the device further comprises a wind blowing pipe, fan blades and a heating wire, the wind blowing pipe is locatedon the rear side of the second cylinder body and is communicated with the second cylinder body, the fan blades and the heating wire are fixed at two ends of the wind blowing pipe respectively, a bevelgear group is arranged between the fan blades and one fabric pressing roller, a communication port through which the inner cavity of the second cylinder body is communicated with a cavity of the sidewall of the first cylinder body is formed in the second cylinder body, a gas discharging port is formed in the side wall of the first cylinder body, the rotary shaft is a hollow pipe, paint fills therotary shaft, a strip-shaped port is formed in the rotary shaft, and a plurality of through holes are formed in the fabric pressing rollers. By means of the device, the problems that only one color can be dyed during one dip-dye process of fabrics, decorative patterns cannot be dyed and the drying effect is poor are solved.

Owner:NINGBO WENZE TEXTILE CO LTD

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

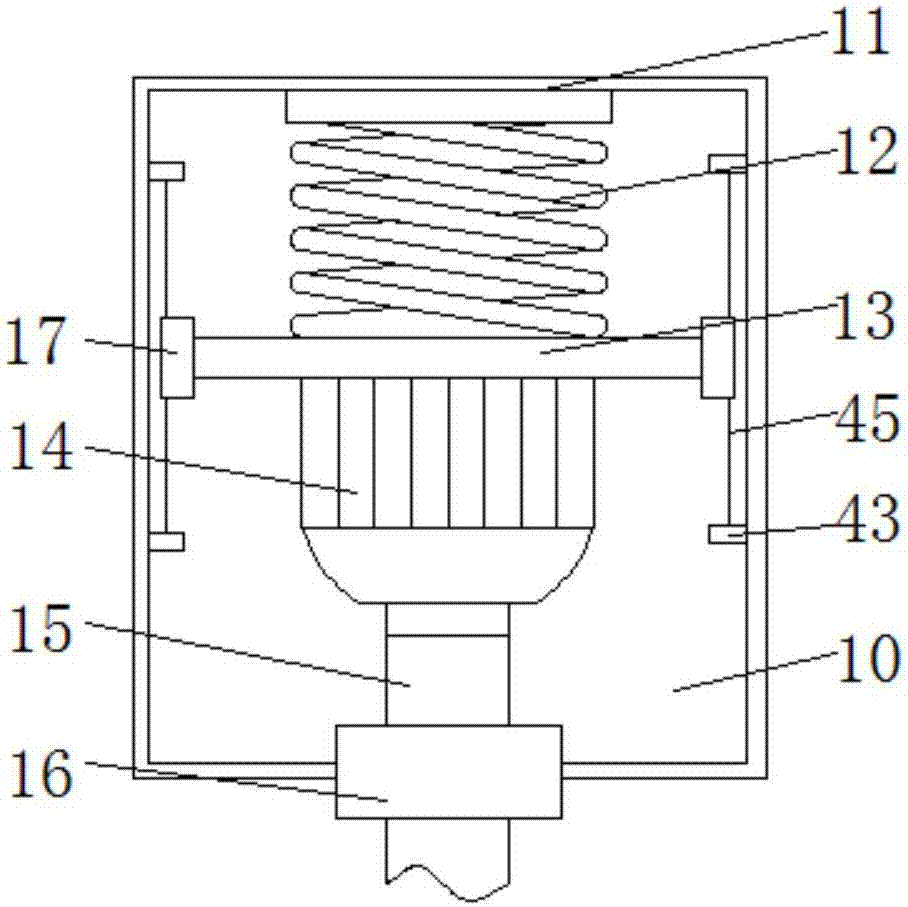

Drying box for spinning

InactiveCN107764014AEasy to dryImprove product qualityMechanical cleaningPressure cleaningTextile yarnEngineering

The invention relates to the technical field of spinning, particularly to a drying box for spinning. The drying box comprises a drying box unit, and an electric heating layer is arranged on the innerwall of the drying box unit; a hollow pipe is arranged in the drying box unit; one end of the hollow pipe is connected with the inner wall of the drying box unit through a connecting rod; the other end of the hollow pipe is connected with an air inlet pipe, and the other end of the hollow pipe communicates with the air inlet pipe; the other end of the air inlet pipe penetrates through a shell of the drying box unit and is connected with a hot air blower; and the hot air blower is fixed to the outer surface of the drying box unit. According to the drying box for spinning provided by the invention, the hollow pipe capable of blowing air to yarns is arranged, a spiral groove is formed in the surface of the hollow pipe, an air outlet is formed in the bottom surface of the groove, and the yarnspassing through the groove can be quickly dried; besides, cleaning devices are arranged in the groove, and impurities on the surfaces of the yarns are removed; and a dust collection pipe and a centrifugal fan are arranged, the yarns are dedusted, and quality of a processed product is higher.

Owner:JIANGSU CHENFEI SPORTS GOODS CO LTD

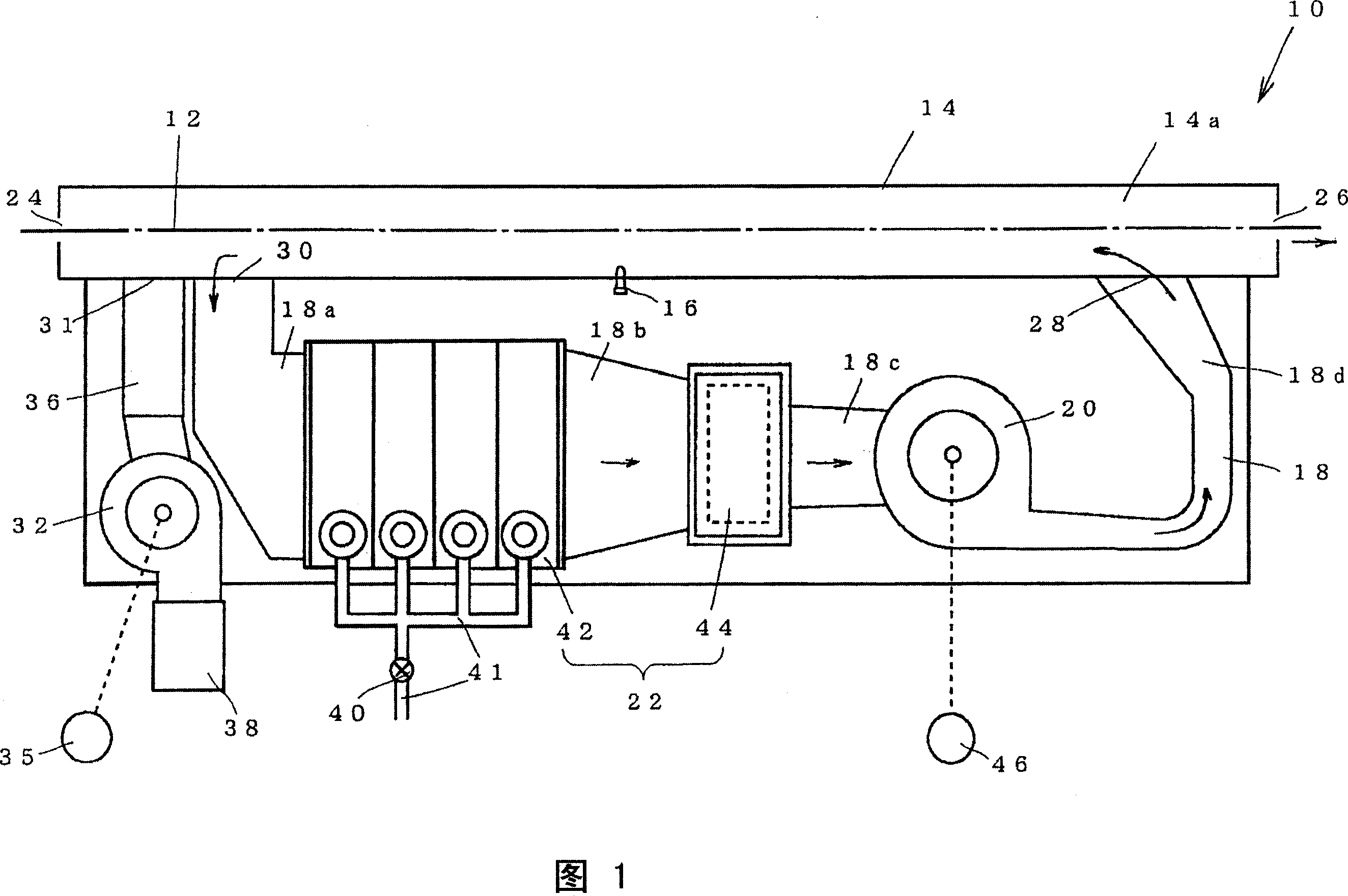

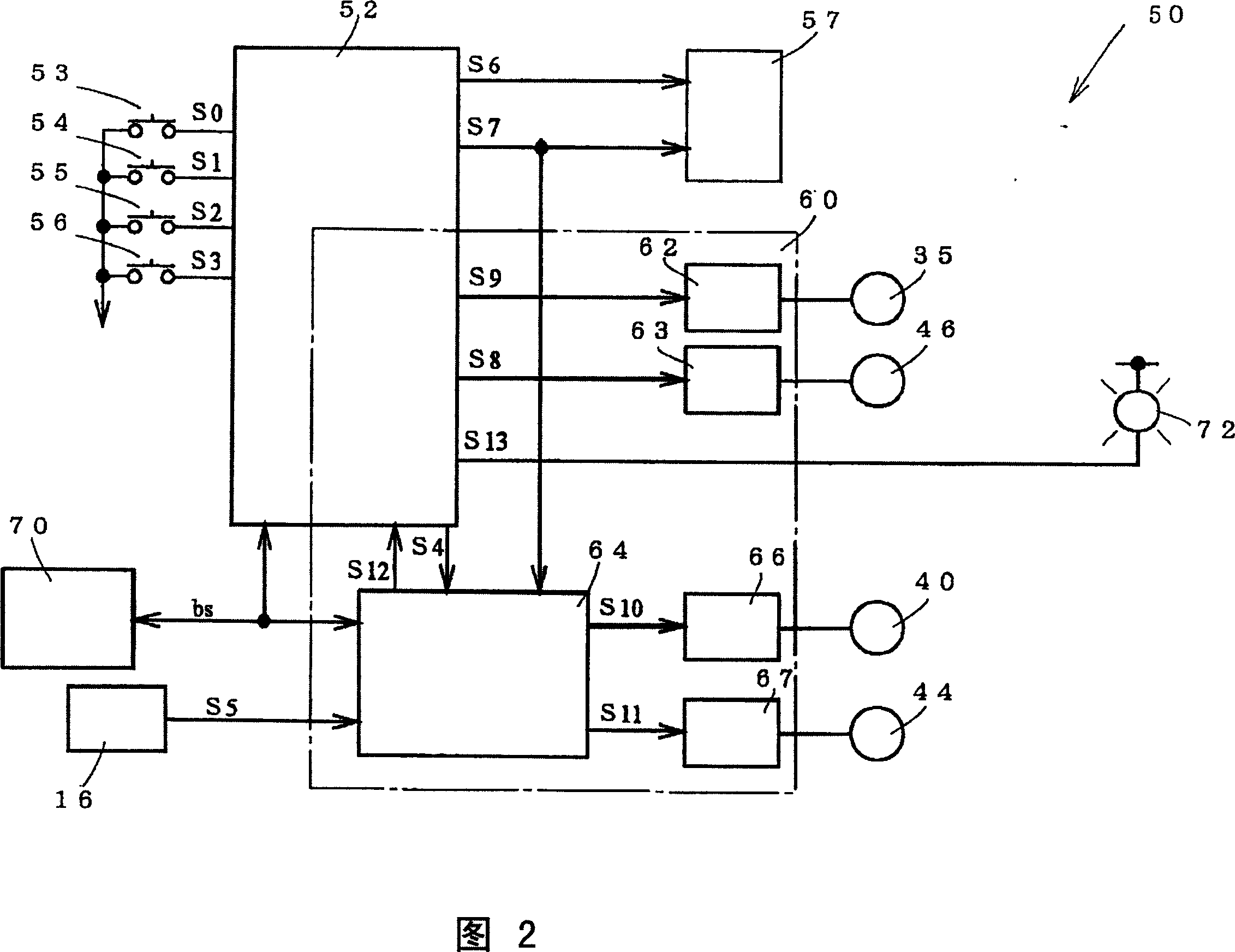

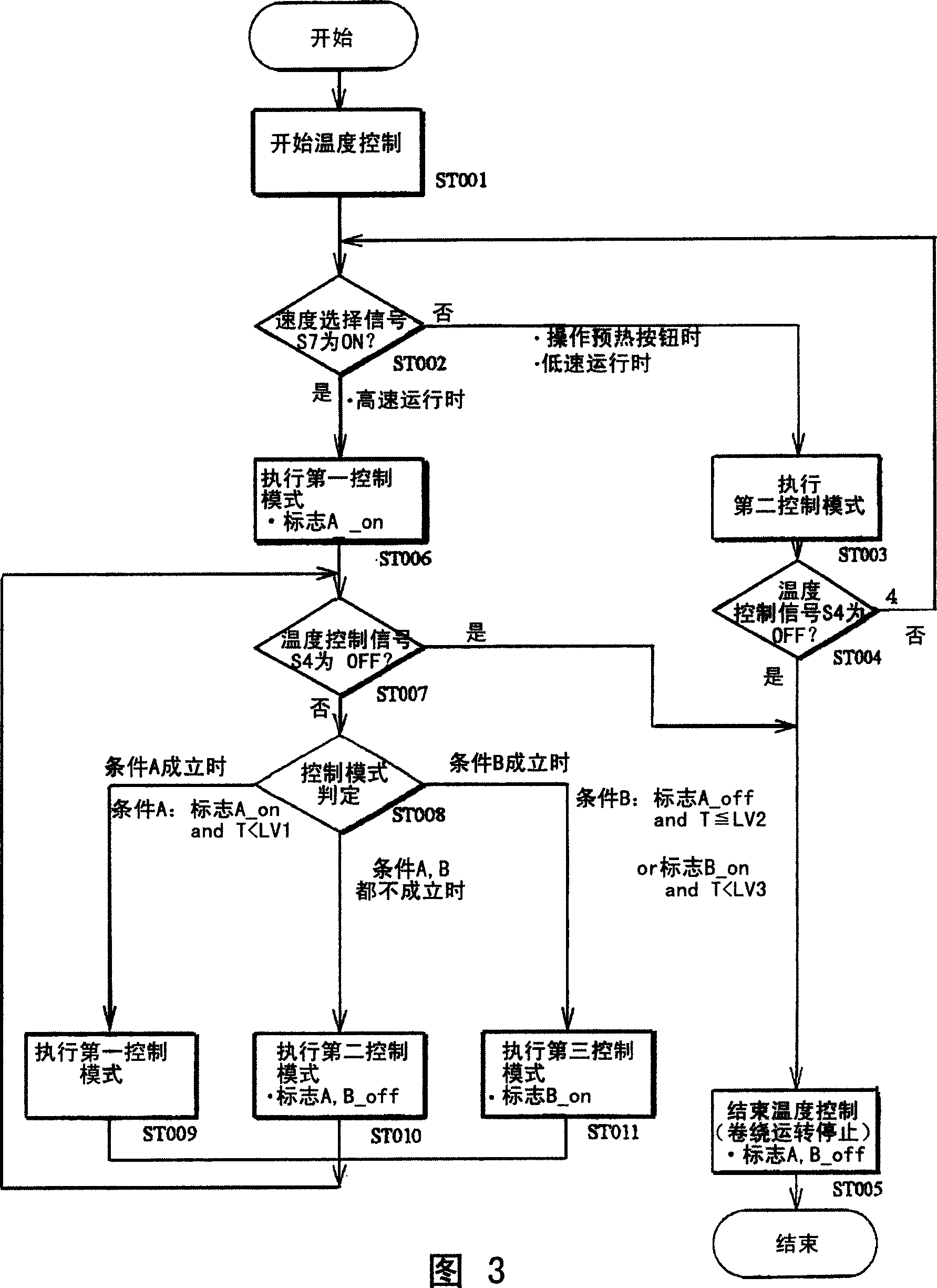

Temperature controlling method for hot blast drying device used in warp sizing device

The object of the present invention is to provide a temperature control technology which is used in a warp yarn sizing apparatus and for hot air drying apparatus having several air heaters with different kinds and can improve the productivity of good warp yarn bundle and is in favor of the energy cost. A temperature controller of the invention at least programs a first control mode which detects the inner temperature of a dry chamber, outputs a heat operating signal to each heat regulator to make the detected temperature adjacent to a prescribed value to execute temperature control; and a second control mode for outputting a heat operating signal for restraining the heating unit function extend in the heat compared with the first control mode, the temperature controller is running in the hot air drying apparatus to execute one of the two control modes, and execute another control mode when the internal temperature of the dry chamber becomes prescribed status.

Owner:TSUDAKOMA KOGYO KK

Device for weaving with washing and drying functions

InactiveCN106048927AEnsure cleanlinessMake sure to drainTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringManipulator

The invention discloses a device for weaving with washing and drying functions, which comprises a frame, and a longitudinal guide rail, a cylinder and a controller which are arranged on the frame, and a transverse guide rail is connected to the cylinder; the transverse guide rail is vertically connected with two longitudinal guide rails so that an H-shaped structure is formed. A manipulator is connected to the transverse guide rail; the manipulator and the cylinder are connected with a controller; a fabric washing mechanism, a fabric filtering mechanism, and a fabric drying mechanism are successively arranged below the manipulator. The washing and drying device are simple in structure and convenient and quick to use. Through the washing and filtering, cleaning, filtering and drying of fabrics are ensured; the fabrics are easy to dry; dust permeating the interior of a drying box can be filtered and adsorbed; service lifetime of the drying box is prolonged; and situations that fabrics are polluted are reduced.

Owner:SUZHOU KANGJIAN TEXTILE

Dyeing and drying equipment of colored yarns for spinning

ActiveCN107780081AWill not stickTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnSpray nozzle

The invention relates to spinning equipment and in particular relates to dyeing and drying equipment of colored yarns for spinning. Aiming at solving the technical problems, the invention provides thedyeing and drying equipment of the colored yarns for spinning, which has the advantages that dyestuff can be completely attached on the colored yarns and the colored yarns can be dried by blowing intime after dyeing and are not stuck together. In order to solve the technical problems, the invention provides the dyeing and drying equipment of the colored yarns for spinning; the dyeing and dryingequipment comprises a bottom plate, a dyeing box, a collection box, a supporting plate and the like; the dyeing box is arranged at the right side on the bottom plate; the collection box is arranged atthe left side on the bottom plate; the supporting plate is mounted at the left side on the bottom plate through a welding manner; a fixed plate is mounted below the right side of the supporting platethrough the welding manner. By adopting the dyeing and drying equipment of the colored yarns for spinning, provided by the invention, the effects that the dyestuff can be completely attached on the colored yarns and the colored yarns can be dried by blowing in time after dyeing and are not stuck together are realized; an electric wheel drives a spraying nozzle to spray out the dyestuff and the spraying nozzle is driven to rotate so that the dyestuff can be completely attached to the colored yarns.

Owner:浙江森创服装股份有限公司

A novel water-saving technique for yarn dyeing

ActiveCN1837447AAchieve the purpose of cleaningConserve waterLiquid/gas/vapor removal by gas jetsLiquid/gas/vapor yarns/filaments treatmentYarnWater saving

The invention relates to a water conservation technique for yarn dyeing, wherein low level dyeing is realized through modification of dye liquor recycling pattern and optimization of the dyeing process, the water consumption can be 20-50% lower then the conventional procedures.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Weftless cloth cleaning device having good cleaning effect

InactiveCN107385725AEasy to cleanClean upMechanical cleaningPressure cleaningWaste collectionEngineering

The invention provides a weft-free cloth cleaning device with good cleaning effect, which relates to the textile field. The non-weft cloth cleaning device with good cleaning effect includes a cleaning box, a fixed box is fixedly installed on the top of the cleaning box, a first motor is fixedly connected to one side of the inner wall of the fixed box, and the output end of the first motor is fixedly connected to There is a threaded rod, the end of the threaded rod away from the first motor is threadedly connected with a bearing seat, the end of the bearing seat away from the threaded rod is fixedly connected with the inner wall of the fixed box, and the inside of the fixed box is provided with a movable sleeve. The non-weft cloth cleaning device with good cleaning effect has a simple structure and is easy to operate. Through the action of the vacuum cleaner installed on one side of the cleaning box, some sundries on the produced non-weft cloth are absorbed by the waste collection container on the side of the vacuum cleaner. The interior will be more clean during cleaning, which is convenient for the cleaning of the non-weft cloth, which solves the troublesome problem of the current non-weft cloth cleaning.

Owner:范威

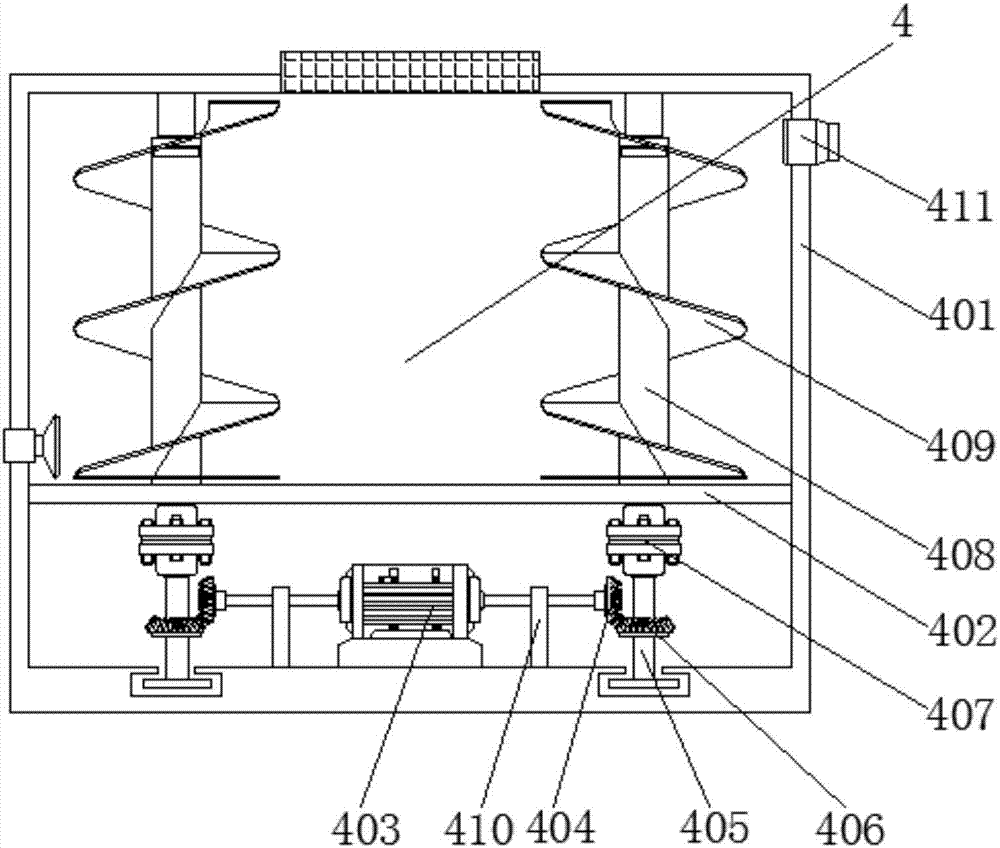

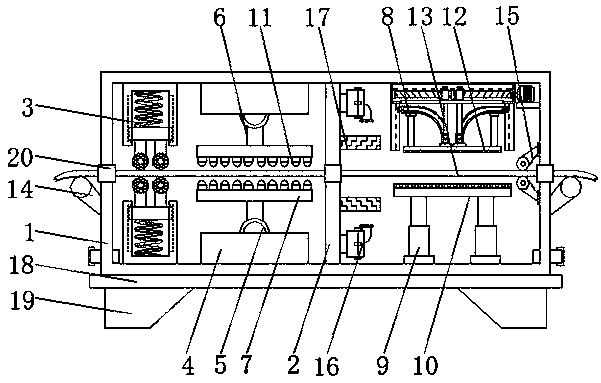

Cotton yarn processing slasher

InactiveCN110344192AConveying orderlyQuick and orderly sizingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnPulp and paper industry

The invention belongs to the technical field of cotton yarn processing, particularly relates to a cotton yarn processing slasher, and aims to solve the problem of low sizing efficiency of an existingyarn. The technical scheme includes that the slasher comprises a frame, a first guide roller, a second guide roller, a third guide roller, a squeezing roller component and a fourth guide roller, a yarn unwinding device and a yarn winding device are arranged on two sides of the frame, a squeezing device, a drying box and a heating box are arranged on a mounting plate on the frame, the drying box iscommunicated with the heating box through an air supply device, a sizing box storing slurry is arranged on the frame, yarns are outputted by the yarn unwinding device, sequentially pass the first guide roller, the second guide roller, third guide roller and the squeezing roller component and are soaked into the slurry, the yarns are squeezed by the squeezing device, and the squeezed yarns penetrate the drying box, pass the fourth guide roller and are wound on the yarn winding device. According to the slasher, the yarns can be rapidly conveyed, sized, dried and wound, so that the sizing efficiency of the yarns is improved.

Owner:徐州嘉搏纺织股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com