A novel water-saving technique for yarn dyeing

A yarn dyeing and technical technology, which is applied in the field of water conservation, can solve the problems of large consumption and influence on level dyeing, and achieve the effects of reducing consumption, reducing sewage discharge, and saving water consumption for dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

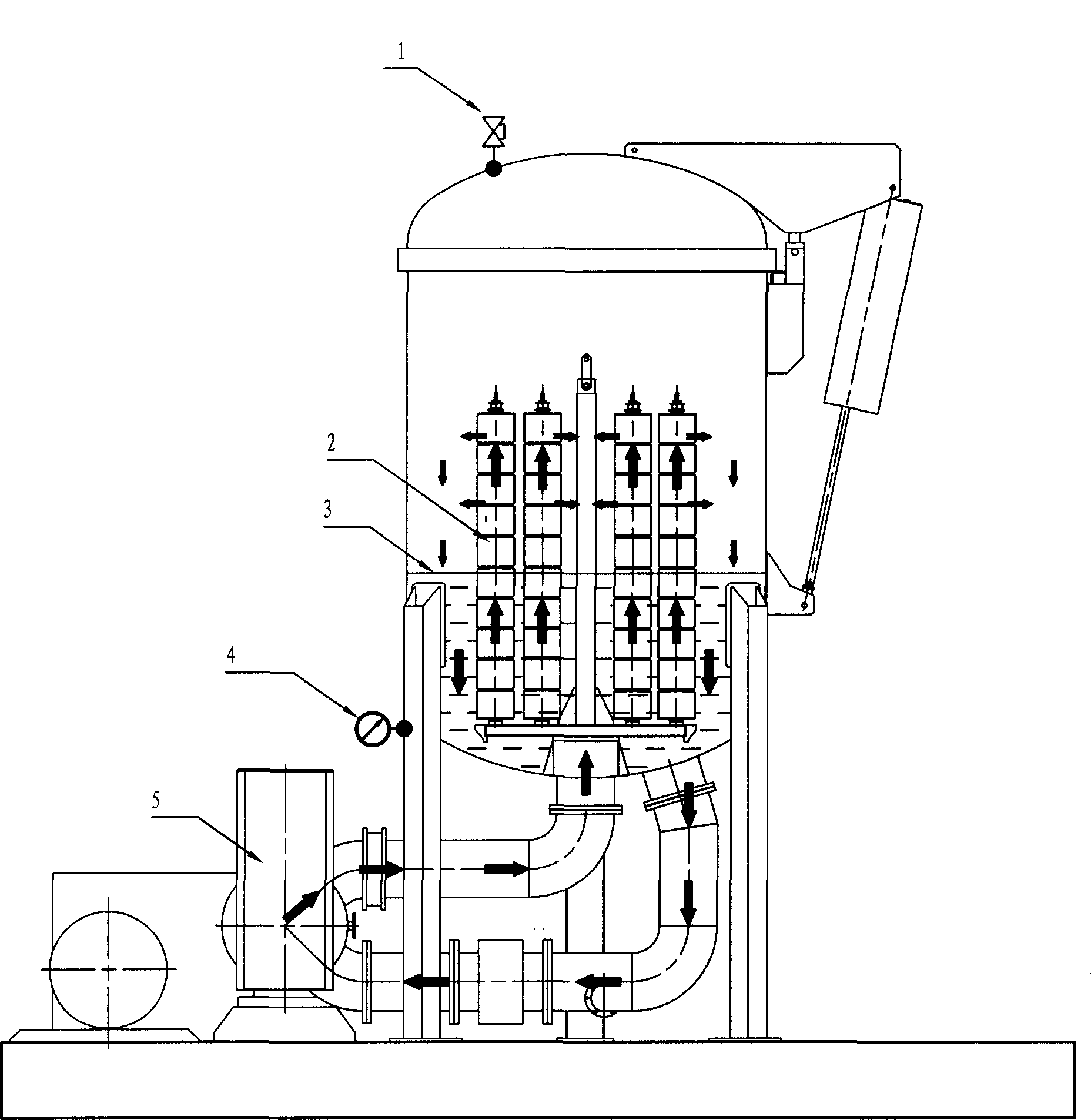

Image

Examples

Embodiment 1

[0028] Embodiment one: 80S / 2 pure cotton cheese dyeing (850 kilograms)

[0029] The water-saving dyeing method of 80S / 2 pure cotton cheese in the present embodiment is as follows:

[0030] 1. Determination of water level:

[0031] According to the adjustment, it is determined that the optimum water level for 850 kilograms of pure cotton cheese is 3200 liters.

[0032] 2. Dyeing process

[0033] Scouring→acid washing→washing at 85 degrees→compressed air squeezing→cold water washing→dyeing→high temperature washing→compressed air squeezing→pickling→soaping→compressed air squeezing→hot water washing→compressed air squeezing→cold washing →Compressed air to squeeze water→Fix color→Drying;

[0034] 1) The running direction of the main pump of the dye vat is a one-way cycle from inside to outside;

[0035] 2) The main pump speed range is 1200 rpm;

[0036] 3) The washing time is 5-10 minutes;

[0037] 4) Squeeze water by compressed air 1-3kg / cm2;

Embodiment 2

[0038] Embodiment two: 100S / 2 pure cotton beam dyeing (300 kilograms)

[0039] 1. Determination of water level:

[0040] According to adjustment, the optimal water level of determining 300 kilograms of pure cotton beam yarns is 2900 liters.

[0041] 2. Dyeing process

[0042] Scouring→acid washing→water washing at 85℃→compressed air squeezing→cold water washing→dyeing→high temperature washing→compressed air squeezing→pickling→soaping→compressed air squeezing→hot water washing→compressed air squeezing→cold washing →Compressed air to squeeze water→Fix color→Drying;

[0043] 1) The running direction of the main pump of the dye vat is a one-way cycle from inside to outside;

[0044] 2) The main pump speed range is 1150 rpm;

[0045] 3) The washing time is 5-10 minutes;

[0046] 4) Squeeze water by compressed air at 1-3kg / cm2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com