Patents

Literature

408results about How to "Shorten dyeing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

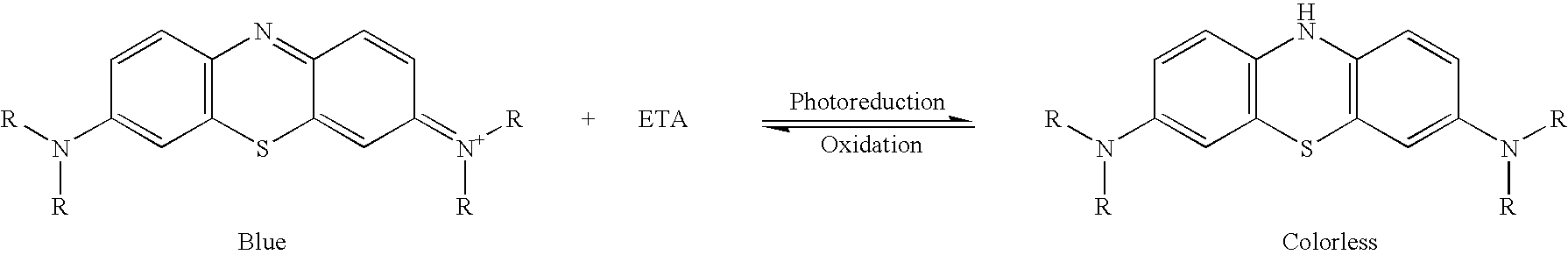

Laser reactive dyes for DVD copy protection system

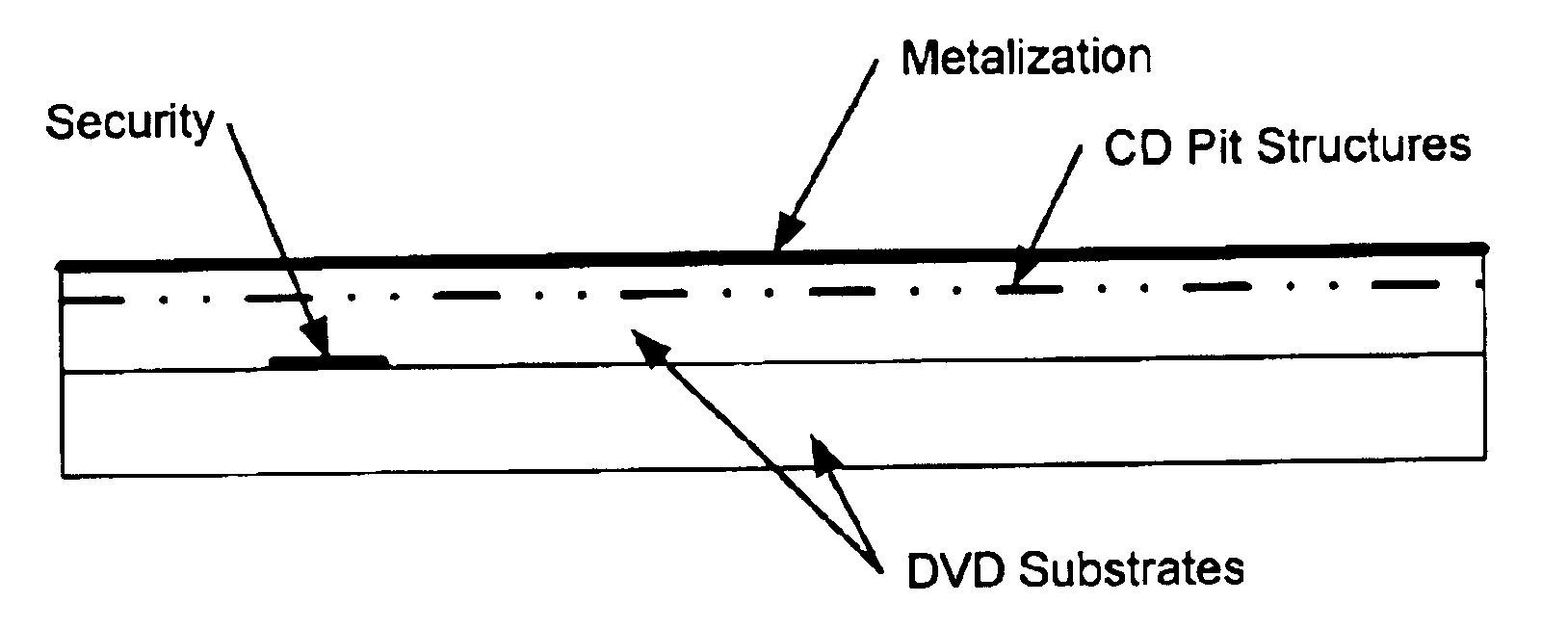

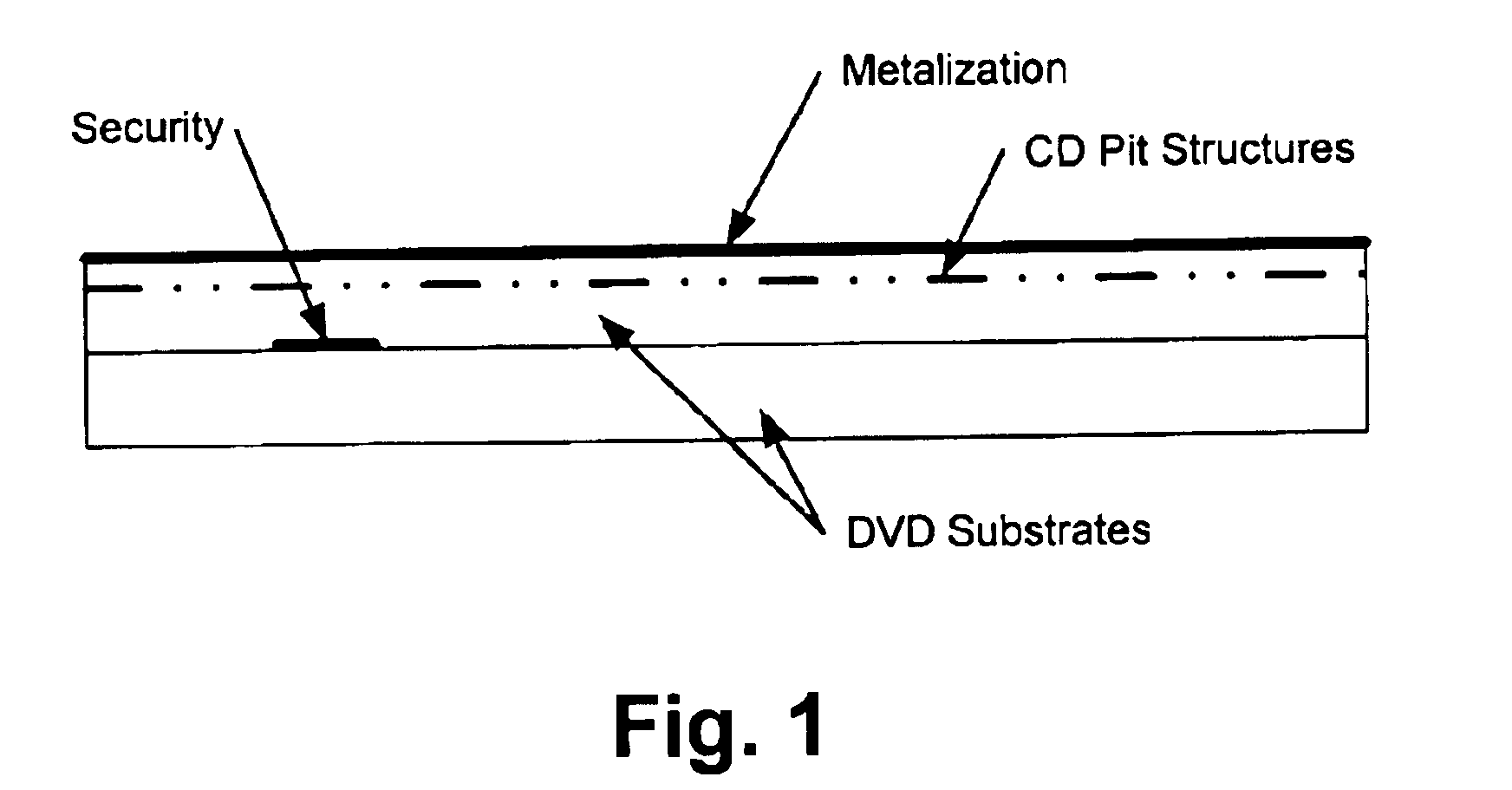

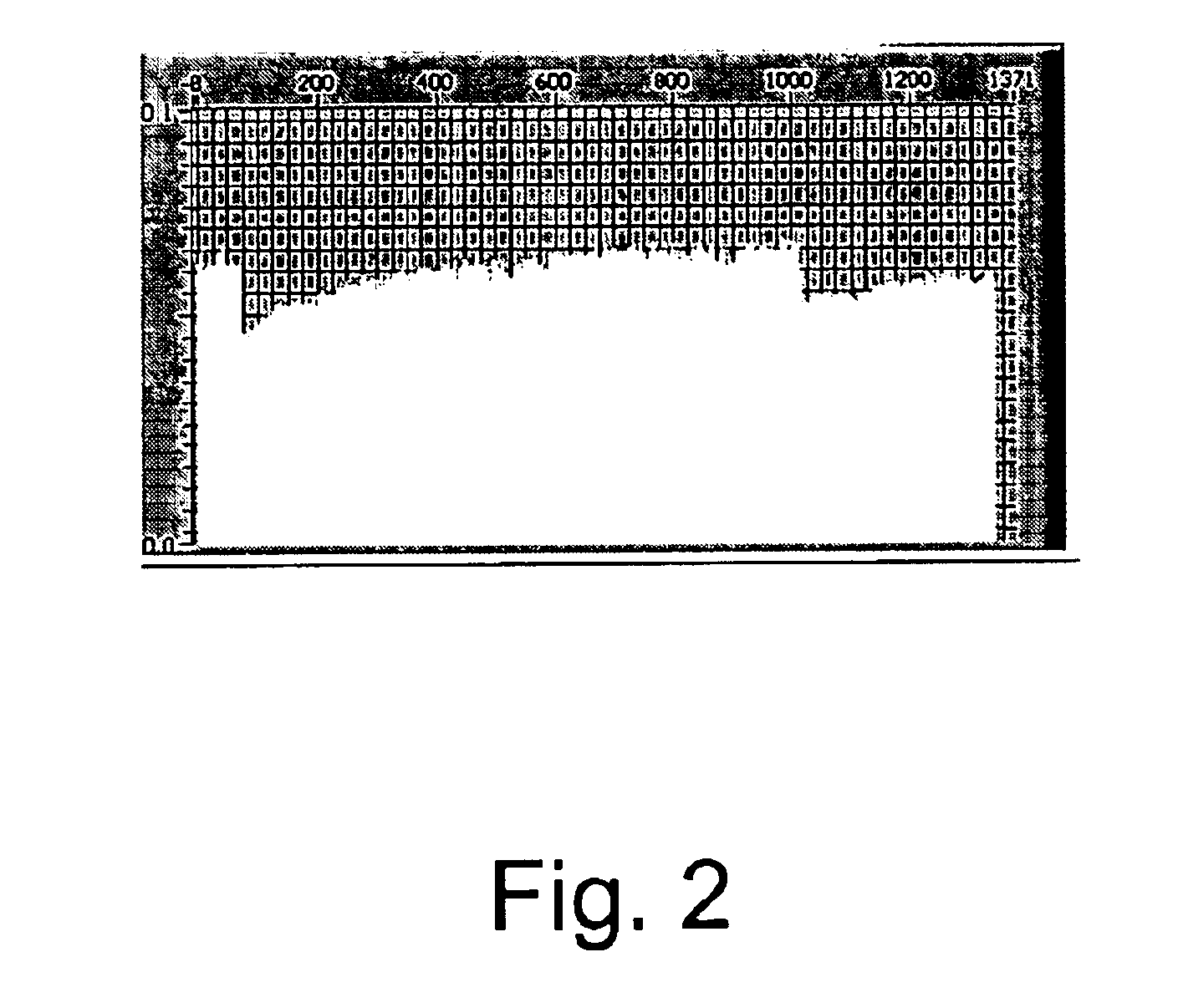

A method and system for providing copy-protected optical medium using transient optical state change security materials capable of changing optical state when exposed to a wavelength of about 630 nm to about 660 nm and software code to detect such change in optical state.

Owner:VERIFICATION TECH INC

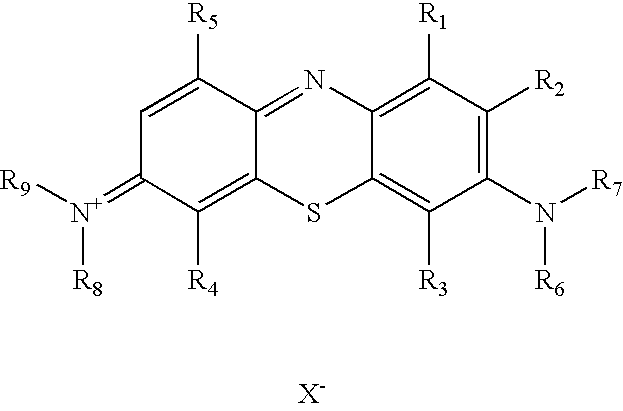

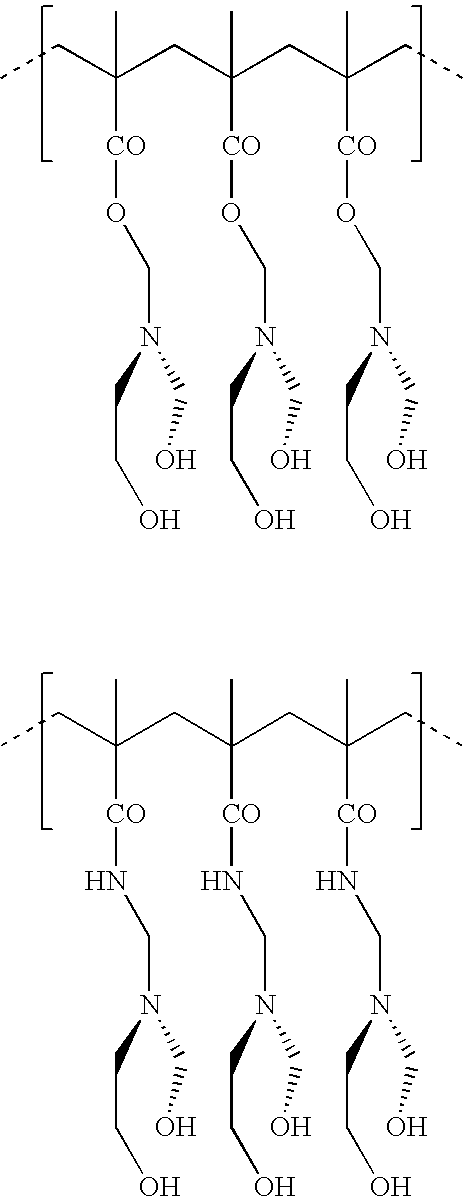

Bis-propyl amine analog and composition

InactiveUS20040152017A1Shorten dyeing timeOrganic chemistryLayered productsPropylamineElectron transfer

Copy-protected optical medium utilizing a composition comprising a transient optical state change security materials capable of changing optical state when exposed to a wavelength of about 630 nm to about 660 nm and an electron transfer agent.

Owner:VIG RAKESH +7

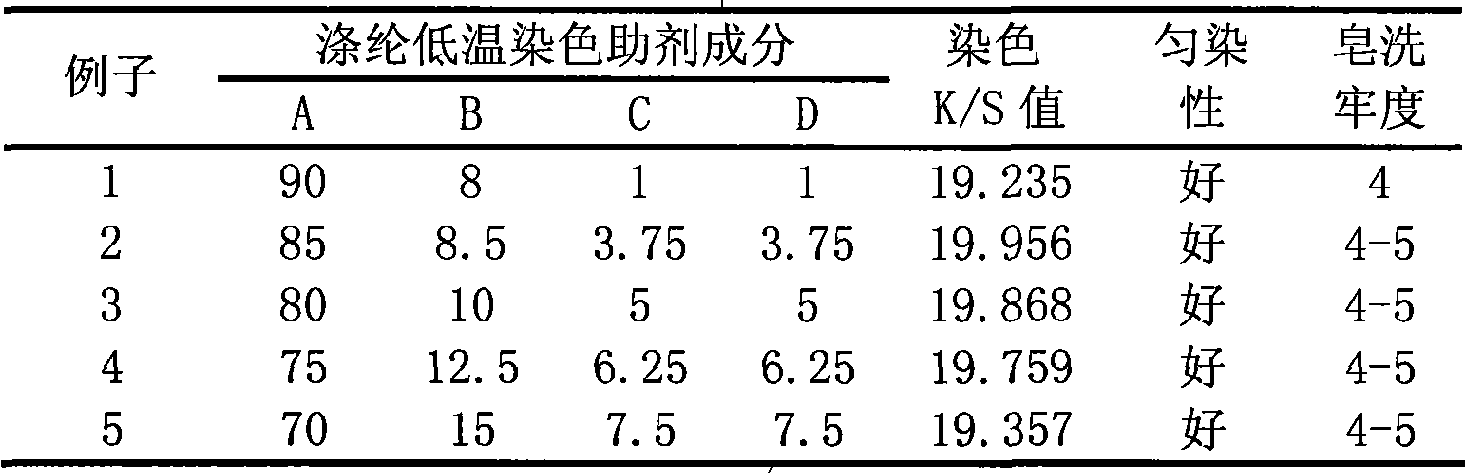

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

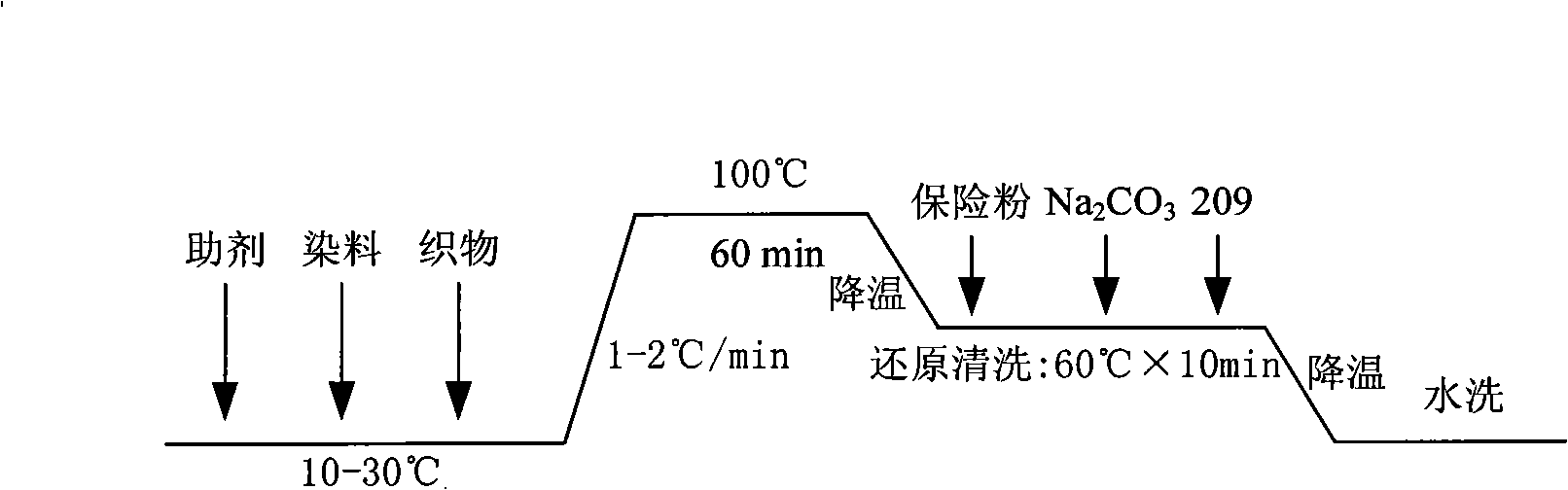

Method for dyeing fabric containing polyester fiber and cotton fiber

ActiveCN102392371AReduce reduction washing processReduce usageDyeing processVegetal fibresPolyesterFiber

The invention discloses a method for dyeing a fabric containing polyester fiber and cotton fiber. The method comprises the following steps of: (1) immerging the fabric containing polyester fiber and cotton fiber into a dyeing vat filled with a first dyeing solution so as to dye the polyester fiber in the fabric; (2) after discharging out the first dyeing solution, adding a refining solution to the dyeing vat and refining the fabric; (3) after discharging out the refining solution, adding a second dyeing solution to the dyeing vat so as to dye the cotton fiber in the fabric; (4) first soaping the dyed fabric and then pickling the fabric for fixation. Compared with the traditional process, the method for dyeing the fabric containing polyester fiber and cotton fiber, disclosed by the invention, is used for reducing the washing reducing process after the polyester fiber is dyed so that the use of sodium hydrosulfite is avoided, the dyeing time is reduced, the water usage is reduced, the energy consumption is largely saved and no pollution to the environment is avoided.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

Quick immune histochemical detection reagent for milk gland cancer lymph node metastasis and its detecting method

InactiveCN1945333AAvoid cross reactionReduce stepsPreparing sample for investigationBiological testingCancer cellLymphatic Spread

The present invention is one kind of reagent for quick immune histohcemical detection of lymphatic metastasis of mammary cancer and corresponding detecting method. Several kinds of directly marked antibody capable of distinguishing metastatic cancer cell and inherent lymph node cell are mixed into reagent and one-step reacted to stain the metastatic cancer cell in lymph node specifically. The present invention is used in the fast pathological diagnosis of early lymphatic metastasis of mammary cancer, and has raised sensitivity, high accuracy and high specificity.

Owner:孙爱静

Method for dyeing wool/copper ammonia fiber blended fabrics

The invention relates to a method for dyeing wool / copper ammonia fiber blended fabrics. A bath process for dyeing is realized by adopting Lanasol dyes produced by US Huntsman Textile Effects (China) Co. Ltd. In the dyeing process, Abairun C is added as an anti-wrinkle lubricant and Abaixiao FFC-01 is added as a penetration enhancer. The method comprises the steps of dyeing and post treatment: (1) dyeing: putting the wool / copper ammonia fiber blended fabrics into an overflow dyeing machine, adding glacial acetic acid, the Abaixiao FFC-01, the Abairun C, glauber salt and the Lanasol dyes, keeping the temperature of 90+ / -2 DEG C for 20-30 minutes, cooling to 70+ / -2 DEG C, adding calcined soda and keeping the temperature for 50-70 minutes; and (2) post treatment: putting the dyed wool / copper ammonia fiber blended fabrics in soaping agent 209, adding calcined soda, treating at 80-90 DEG C for 20-30 minutes, putting in glacial acetic acid after rinsing and treating at 40+ / -2 DEG C for 10 minutes. The bath ratio in the dyeing process is 1:15-20, and the bath ratio in the post treatment process is 1:15-1:20. The invention has the advantages of good dyeing effect, good color fastness and little damage to the fabrics in the dyeing process.

Owner:HEILAN HOME

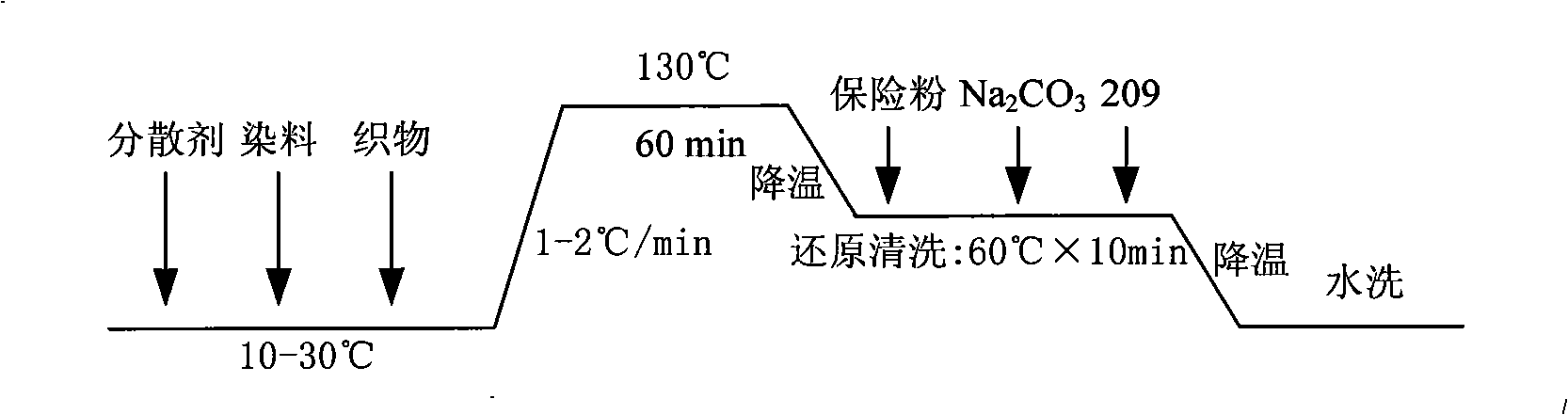

Modified terylene/chinlon/spandex multi-component seamless underwear one-bath-process dyeing technology

ActiveCN102660878AShort processShorten dyeing timeDry-cleaning apparatus for textilesDyeing processWater rinsingDyeing

The invention relates to a modified terylene / chinlon / spandex multi-component seamless underwear one-bath-process dyeing technology, and belongs to the technical field of knitting product dyeing process. The technology comprises the following steps of: putting a modified terylene / chinlon / spandex multi-component seamless underwear into a dyeing cylinder; feeding water and adding an additive and dye, and carrying out one-bath, refining and deoiling, and dyeing the modified terylene / chinlon / spandex; and then carrying out hot water rinsing, soaping and water rinsing, wherein the modified terylene / chinlon / spandex is soft. According to the invention, the dyeing process is shortened effectively, the dyeing time is shortened, the production efficiency is improved, and pollution discharge is reduced.

Owner:ZHEJIANG QIAOERTINGTING FASHION

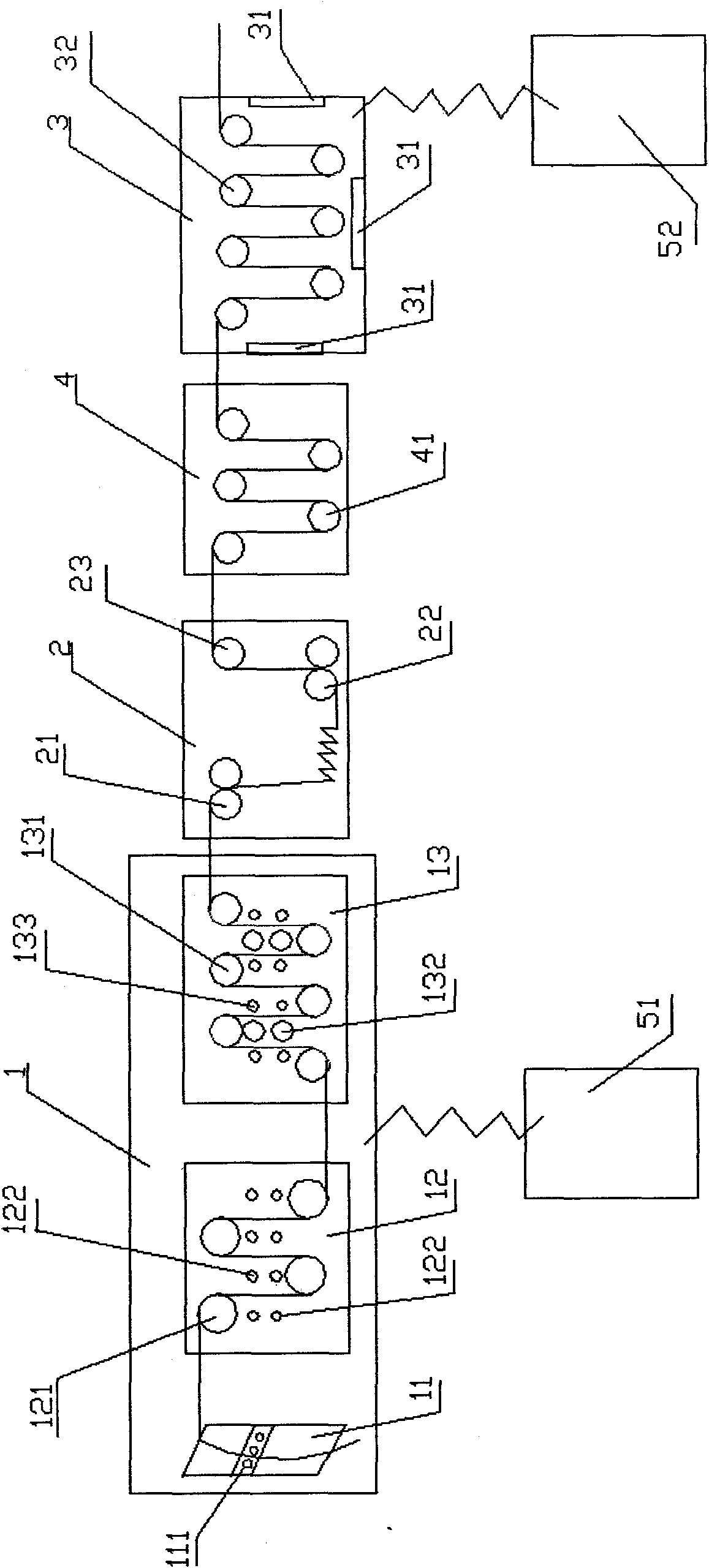

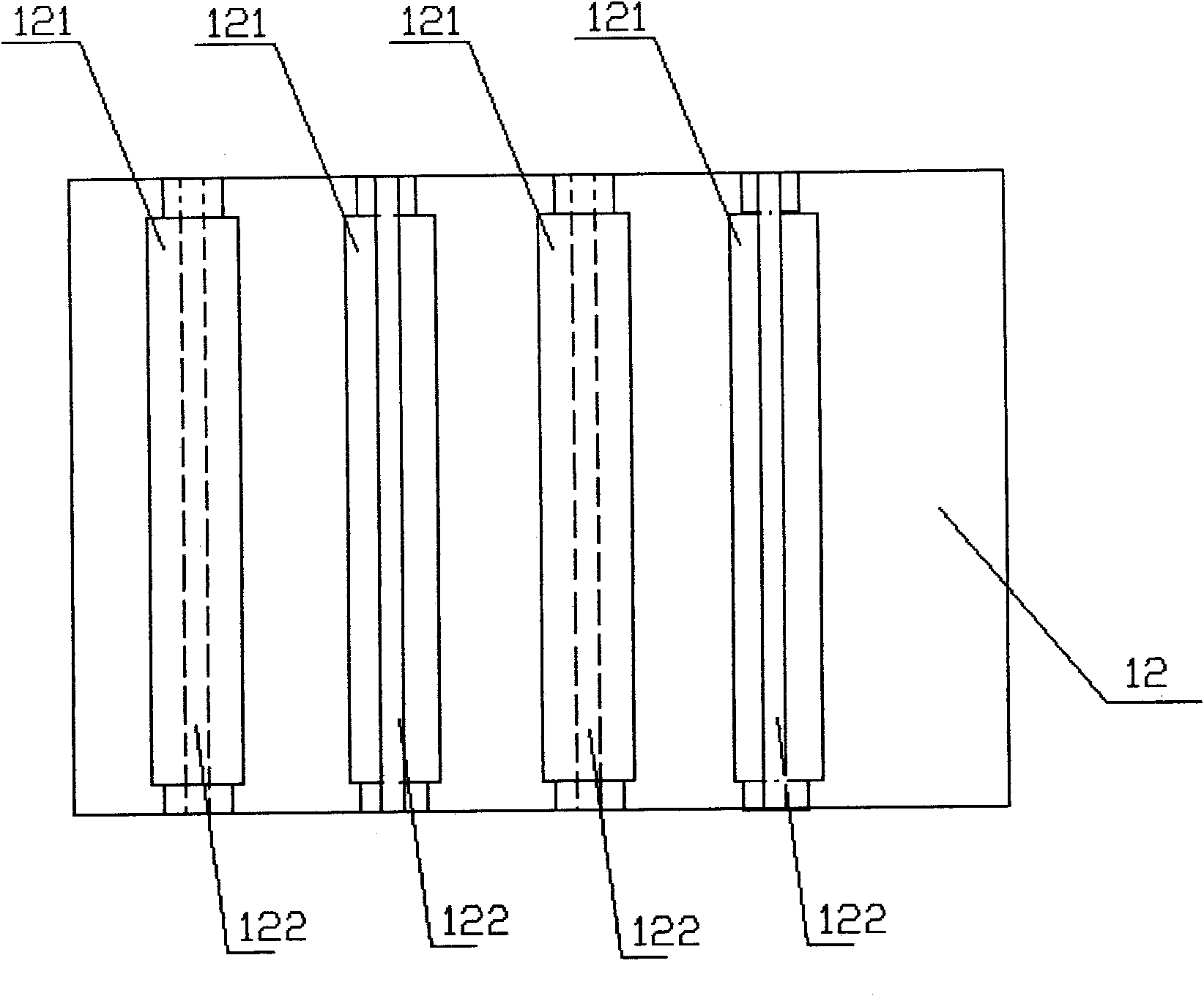

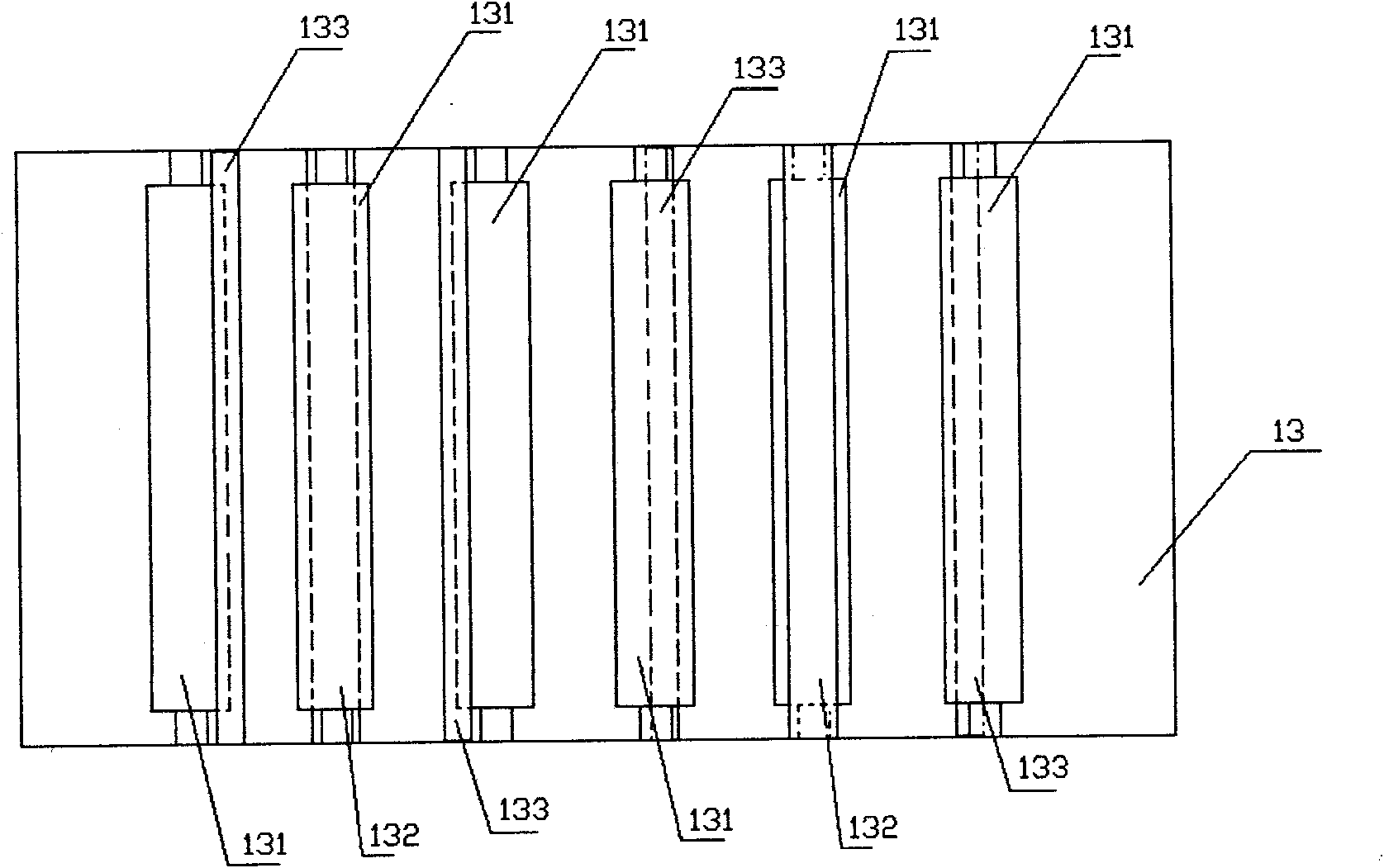

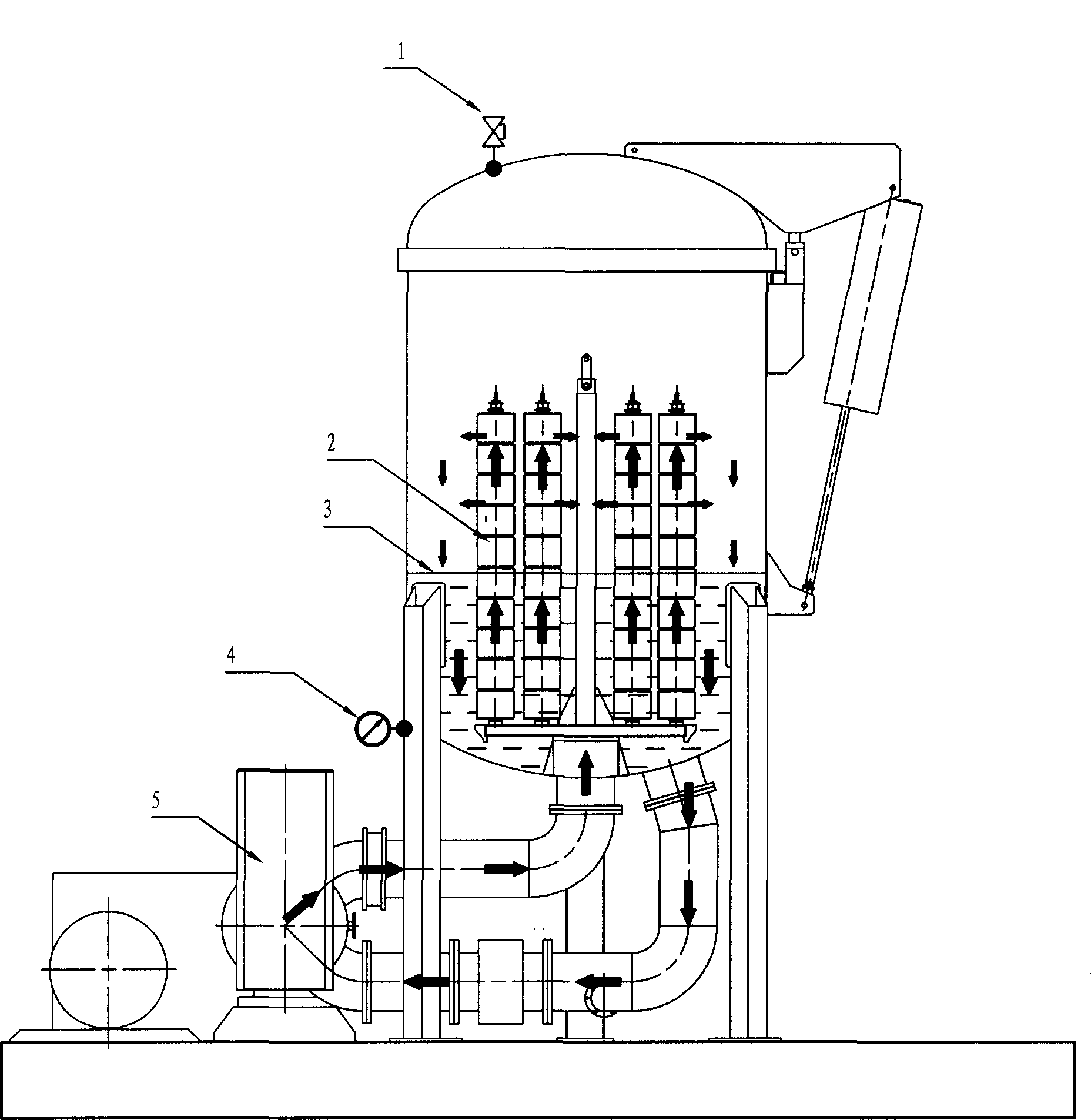

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

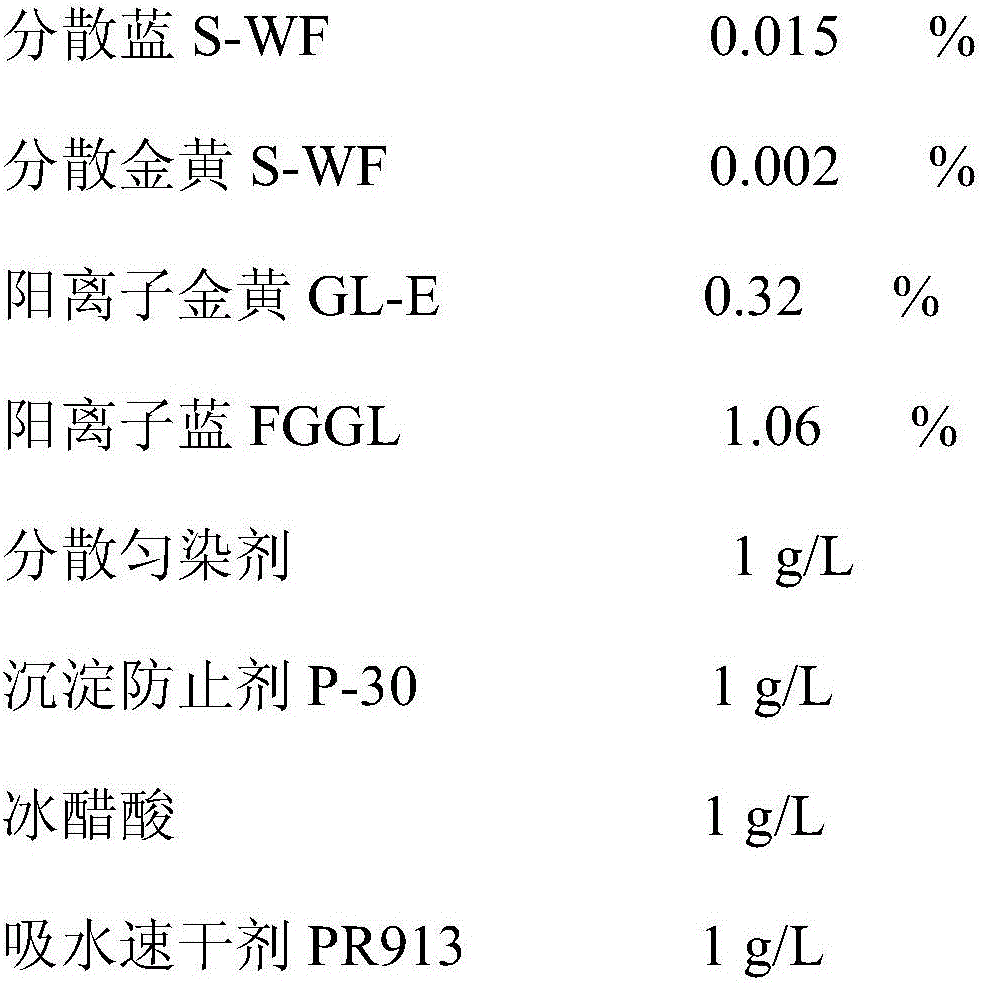

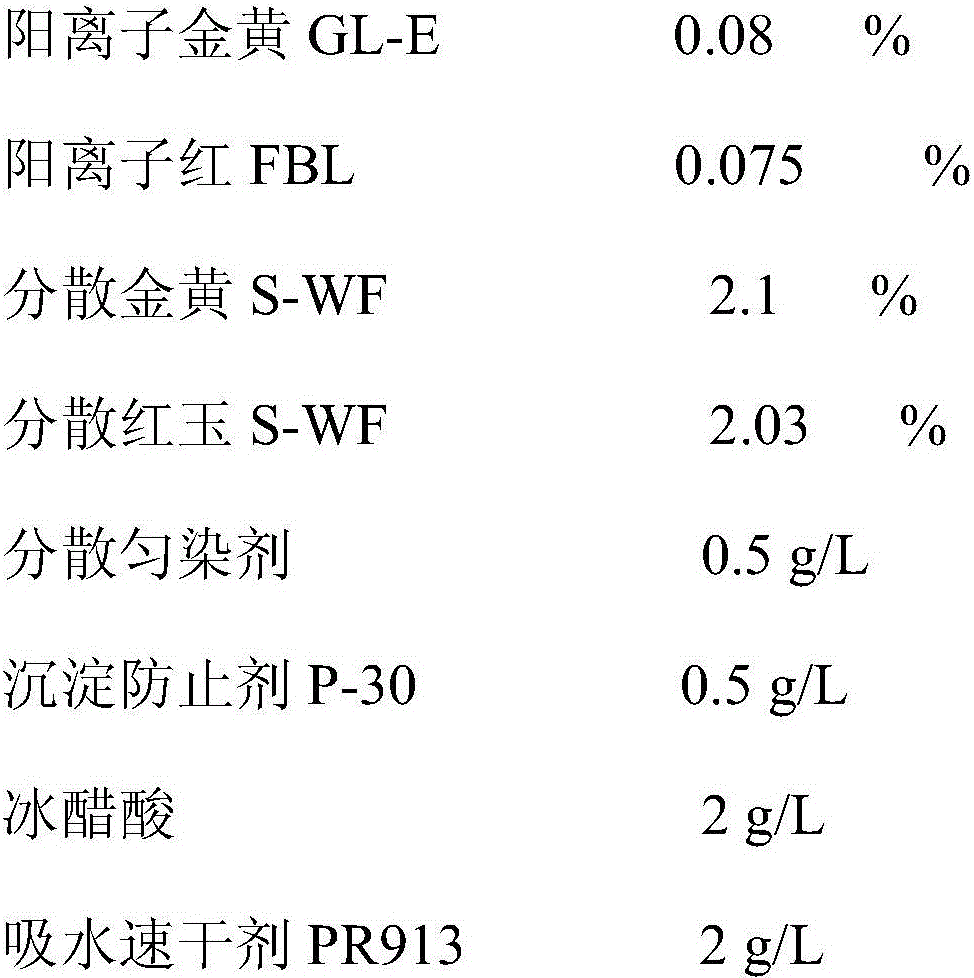

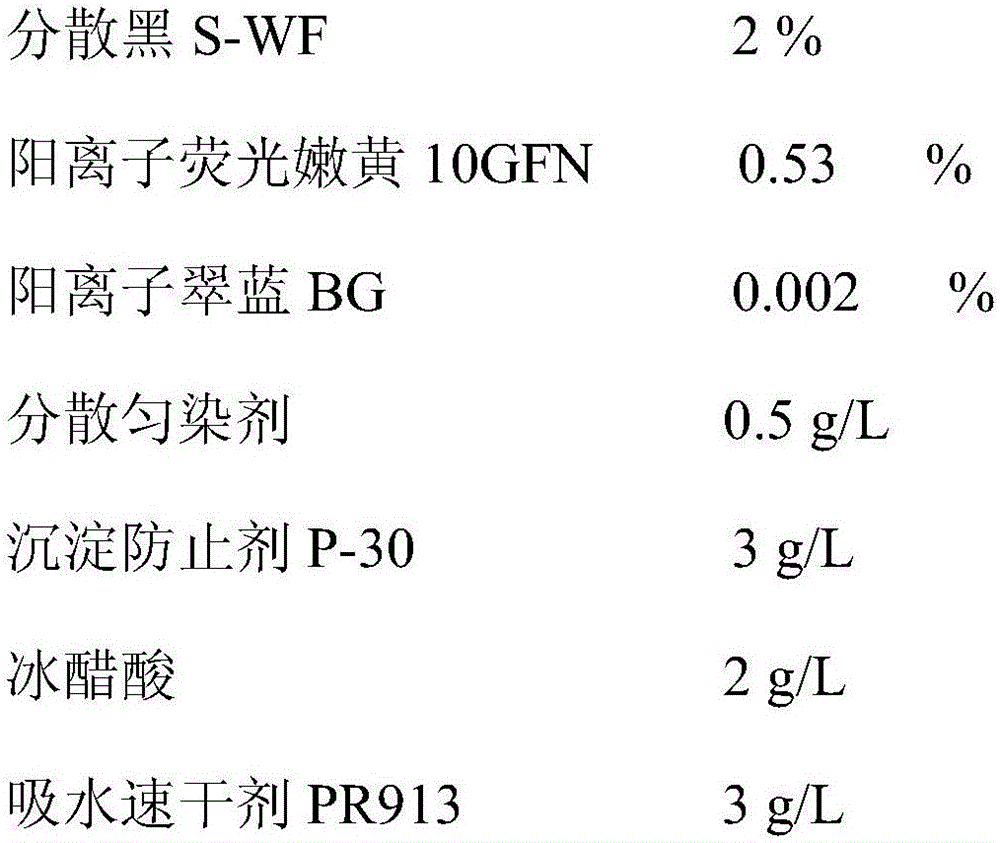

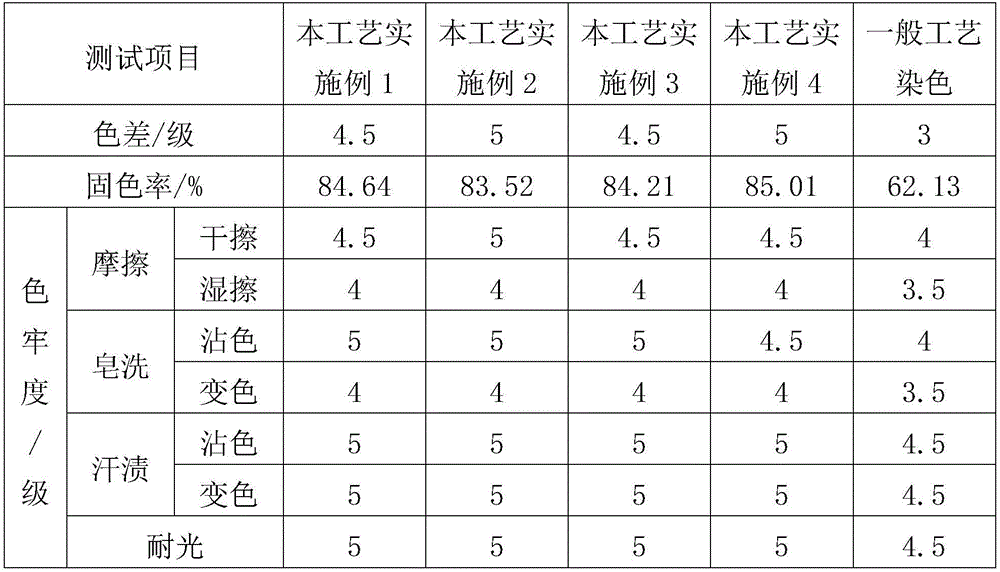

Cationic modified polyester/polyester one-bath process dyeing technology

The invention relates to a one-bath dyeing process for yarns and fabrics prepared by blending, doubling and interweaving cationic modified polyester and polyester, and belongs to the technical field of yarn and fabric dyeing processes. The process comprises the following steps: putting yarns or fabrics containing cationic modified polyester or polyester into a dye vat, heating in water, adding a water-absorbing quick-dry agent, a dispersing and leveling agent and glacial acetic acid for uniformly rotating; adding disperse dyes for uniformly rotating, adding an anti-settling agent for uniformly rotating, adding cationic dyes, heating to the temperature of 80+ / -2 DEG C at a speed of 1-1.5 DEG C per minute after uniform rotating, maintaining the temperature for 8-12 minutes, heating to the temperature of 100+ / -2 DEG C at a speed of 0.5-1 DEG C per minute, heating to the temperature of 130+ / -2 DEG C at a speed of 1.5-2 DEG C per minute, maintaining the temperature for 55+ / -5 minutes, cooling to 80 DEG C or below and draining, performing hot washing, soaping, washing and softening. According to the invention, the dyeing time can be reduced, the production efficiency is improved, pollution discharge is reduced, and the dyeing cost is reduced.

Owner:ZHEJIANG QIAOERTINGTING FASHION

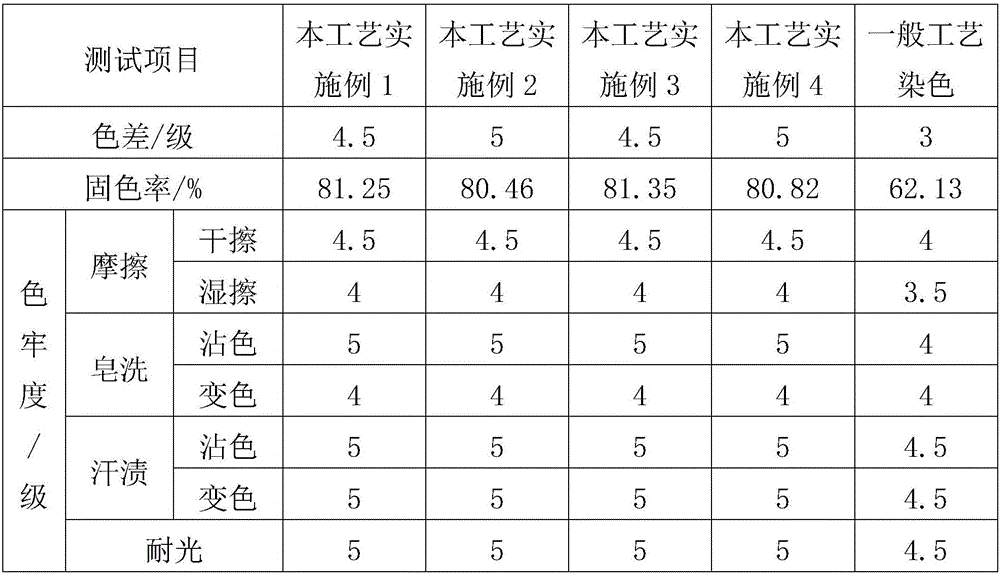

Polyester-cotton disperse dye, and reactive dye one-bath process dyeing method

ActiveCN106245368AHigh color fixing rateAvoid hydrolysisDry-cleaning apparatus for textilesDyeing processDisperse dyePh buffering

The invention discloses a polyester-cotton disperse dye, and a reactive dye one-bath process dyeing method. The reactive dye one-bath process dyeing method comprise following steps: a dyeing solution is prepared at normal temperature; pH value of the dyeing solution is adjusted to 4 to 6; polyester-cotton fabric is immersed; the temperature is increased to 95 to 105 DEG C at a rate of 2 to 3 DEG C / min, and then is increased to 130 to 150 DEG C at a rate of 1 to 2 DEG C / min; suction filtration of the dyeing solution and isolation of disperse dye microcapsules are carried out, and continuous dyeing is carried out for 15 to 25min; the temperature is reduced to 85 to 95 DEG C at a rate of 1.5 to 2.5 DEG C / min; and primary water washing, soaping, afterwashing, and drying are carried out. The dyeing solution comprise, 0.5 to 1.5%owf of a reactive dye, 30 to 40g / L of anhydrous sodium sulfate, 1.5 to 3.5g / L of a pH buffering agent, 0.5 to 5%owf of disperse dye microcapsule, and 0.1 to 3g / L of a dyeing auxiliary. The reactive dye one-bath process dyeing method is simple; period is short; fixation rate is high; and levelling properties are excellent.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

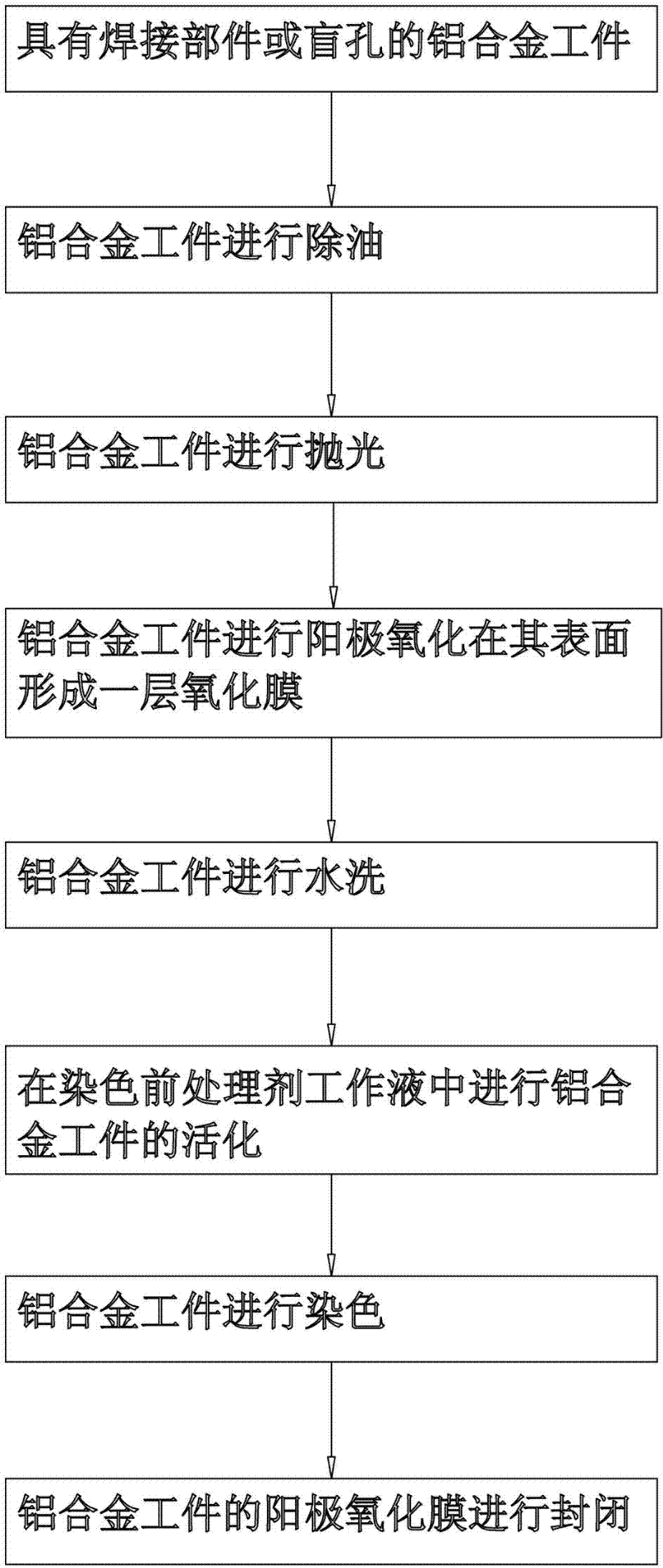

Pre-dyeing treatment agent for surface of blind hole workpiece in aluminum alloy welding area and application technology thereof

ActiveCN102534722APrevent poor dyeingImprove dyeing effectSurface reaction electrolytic coatingOrganic acidSURFACTANT BLEND

The invention discloses a pre-dyeing treatment agent for a surface of a blind hole workpiece in an aluminum alloy welding area and an application technology thereof. The pre-dyeing treatment agent comprises the following raw materials by mass percent: 70-85% of organic acids, 13-28% of organic acid salts and 0.5-2% of anionic surfactants. By utilizing a working solution of the pre-dyeing treatment agent to perform pre-dyeing treatment on an aluminum alloy workpiece with a welded blind hole structure, the dyeing quality of the workpiece is greatly increased, the dyeing speed is increased, the dyeing time is reduced and the dyeing reject ratio is greatly reduced. By utilizing the working solution of the pre-dyeing treatment agent to treat the aluminum alloy workpiece with the welded blind hole structure, the environmental pollution is avoided, the dyeing yield is greatly increased and is above 98%, the color quality of products is stable, the time is greatly saved and the production efficiency is increased, so that the defects and the inferior treating effect of the prior art are overcome.

Owner:ZHUHAI ALLMELUX CHEM +1

Dyeing finishing process of elastic jean fabric

InactiveCN104032595AShort dyeing timeImprove dyeing efficiencyDry-cleaning apparatus for textilesDyeing processAfter treatmentEngineering

The invention relates to the textile field and in particular relates to a dyeing finishing process of an elastic jean fabric. The dyeing finishing process comprises the steps of material selection, pretreatment, water washing, slacking treatment, dyeing, water washing, color fixation, heat setting and after-treatment. The dyeing finishing process is characterized in that the water washing and slacking treatment steps are added after the pretreatment step so that the jean fabric is more stable and subsequent dye homogeneity can be achieved more easily; in addition, as the color fixation step is added after the second time of water washing to further fix the dyeing of the fabric, the dyeing effect of the fabric can be improved; the dyeing finishing process has obvious beneficial effects and is suitable for popularization and utilization.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

Polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology

ActiveCN106245352AImprove adsorption capacityImprove dyeing uniformityDyeing processMicroballoon preparationDisperse dyeOrganic solvent

The invention discloses a polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology. The technology comprises the steps of: S1, polyester dyeing: dipping a to-be-dyed polyester-cotton fabric in a dye solution containing microcapsule disperse dye, conducting heat preservation at 65-75DEG C, then performing heat preservation at 110-130DEG C, and carrying out cooling to 30-40DEG C, using chitosan to serve as the carrier of the disperse dye, and then conducting crosslinking curing; S2. cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, carrying out stirring reaction, then adding a reactive dye, performing heat preservation at 55-65DEG C, adding an organic solvent, conducting heat preservation at 70-90DEG C, then adding organic amine and sodium carbonate, and performing heat preservation at 60-100DEG C; and S3, aftertreatment: performing cooling to room temperature, and then carrying out primary washing, soaping and after-washing. The polyester-cotton microcapsule disperse reactive dye one-bath dyeing technology provided by the invention has the advantages of simple process, little pollution, wide dye applicability, uniform coloring, high color fixation rate and good level-dyeing properties.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Method for dip-dyeing polyester rayon (cotton) fabrics or yarns with disperse and reactive dyes by one-bath process

The invention discloses a method for dip-dyeing polyester rayon (cotton) fabrics or yarns with disperse and reactive dyes by a one-bath process. The invention is characterized in that the reactive dyes at the low temperature of 60-65 DEG C or dual temperature of 60-65 DEG C and 85-90 DEG C are adopted, and alkali with a pH value of 11-11.5 is added to dye the cotton or rayon fibers; and then acid is added until the pH value is 5-6, the temperature is raised to about 130 DEG C, and the disperse dyes are used to dye the polyester fibers. By using the one-bath two-step dyeing technology instead of the traditional two-bath process, the dyeing time is greatly shortened, the yield is increased, and the consumption of energy and water quantity and the alkali usage are reduced, thus lowering the production cost, reducing the sewage and the content of alkali in the sewage and being beneficial to environmental protection; when the disperse dyes are used for dyeing, the dye liquid is a buffer system formed by sodium acetate generated by firstly adding alkali, then adding acetic acid and neutralizing the alkali and the acetic acid and acetic acid, thus improving the dye reproducibility (one-time dyeing success rate) and reducing the rehandling possibility; and the method has very obvious practical value.

Owner:ZHEJIANG SCI-TECH UNIV

Semi-material dyeing technology of silk-cotton interweaving garment material

ActiveCN103711008ASolve the problem of poor coverageAvoid bareDyeing processColour fastnessPolymer science

The invention provides a semi-material dyeing technology of a silk-cotton interweaving garment material, and belongs to the technical field of silk-cotton goods dyeing. The semi-material dyeing technology comprises the following steps: firstly respectively preparing a first coloring agent and a second coloring agent; then pre-processing a silk-cotton interweaving garment material by adopting one bath process in a dyeing process, keeping temperature at 55-65 DEG C, and dyeing the silk-cotton interweaving garment material at a constant temperature by adopting a jig dyeing method; when dyeing for one half of the total dyeing time, adding 14-36g / L of sodium carbonate to the first coloring agent, uniformly stirring, then adding the second coloring agent to the first coloring agent, keeping temperature at 55-65 DEG C, dyeing at a constant temperature by adopting a jig dyeing method till the total dyeing time is over, and discharging waste liquid, wherein the total dyeing time is 60-200 minutes. The silk-cotton interweaving garment material obtained by adopting the method has the advantages that the dye up-take of silk fibers and cotton fibers is consistent, the color fastness of cotton is improved, the fabric obtained by adopting the method has bright integral color without exposed white, and the color fastness of the fabric is high.

Owner:ZIBO DARANFANG SILK GRP

Method for separating X sperm and Y sperm of pig

The invention relates to a method for separating X sperm and Y sperm of a pig. The method comprises the main steps of: (1) collecting semen of a boar under the temperature of 30+ / -2 DEG C and storing temporally; (2) using the semen diluting liquid to dilute the original semen according to the proper proportion, then adding a fluorescent stain with proper concentration, and carrying out light-tight hatching dyeing in a water bath, then adding food pigment for dyeing and then filtering; (3) using a flow cytometer to separate X sperm and Y sperm under the temperature of 20 DEG C to 25 DEG C; and (4) using a receiving pipe filled with sperm receiving liquid to collect the separated X sperm and Y sperm, and being used for storing or inseminating after centrifugation and concentration. The method for separating X sperm and Y sperm of the pig can improve the resolution of the X sperm and Y sperm and separating accuracy rate with the separating accuracy rate of more than 90 percent, and can effectively maintain high quality of sperms and high efficiency of recovery of separated sperms. By being combined with the propagation technologies of artificial insemination, vitro insemination and the like, the method can effectively improve the efficiency of farming industry.

Owner:GUANGXI UNIV

One-bath two-step scouring and dyeing method of reactive dye of cotton knitting fabric and cotton yarn

The invention discloses a one-bath two-step scouring and dyeing method of reactive dye of cotton knitting fabric and cotton yarn. The formula thereof is as follows: 1.0 to 10 percent of reactive dye of B, M and KN type or K, KD and KE type (fabric or yarn weight), 30 to 100 g / L of sodium sulfate or salt, 2.5 to 3.5g / L of multifunctional color-fixing alkali with the bath ratio of 1:6 to 15; or 1.0 to 10 percent of reactive dye of B, M and KN type and K, KD and KE type, 30 to 100 g / L of sodium sulfate or salt, 0.5 to 1.0g / L of penetrating agent, 1.0 to 2.0g / L of refining agent, 10 to 15g / L of pure alkali with the bath ratio of 1:6 to 15. The scouring and dyeing process is as follows: cotton knitting fabric or cotton yarn, two-temperature scouring and dyeing (dyeing with the temperature of 60 to 65 DEG C or 80 to 90 DEG C and refining with the temperature of 95 to 98 DEG C), soaping, washing and finishing. The method improves yield, simultaneously reduces the using amount of water by about 30 percent when in scouring and dyeing, reduces production cost, reduces the discharge of sewage and is beneficial to environmental protection.

Owner:ZHEJIANG SCI-TECH UNIV

Hematoxylin-eosin mixed staining solution

ActiveCN105651580AEasy to operateShorten dyeing timePreparing sample for investigationAlcoholPreservative

The invention provides a hematoxylin-eosin mixed staining solution, which is characterized by comprising the following components: hematoxylin, an oxidant, a mordant, eosin, alcohol, weak acid, a preservative and water. The novel staining solution is prepared by mixing hematoxylin and eosin together; and cell and tissue samples only need one-time staining for staining both the hematoxylin and eosin. The present invention also provides a preparation method and a staining method of the hematoxylin-eosin mixed staining solution, and solves the problems of complicated operation, time consumption, false blue, unclear hierarchy and short retention time on the traditional hematoxylin-eosin staining.

Owner:安徽雷根生物技术有限公司

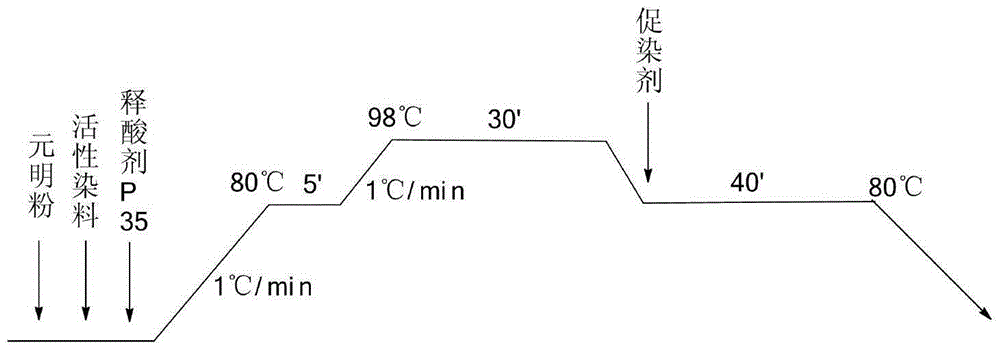

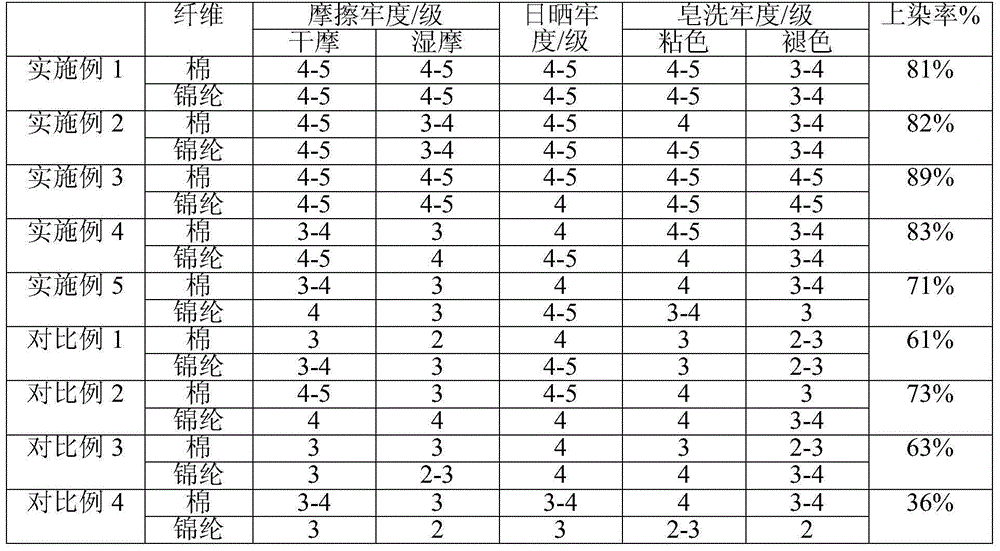

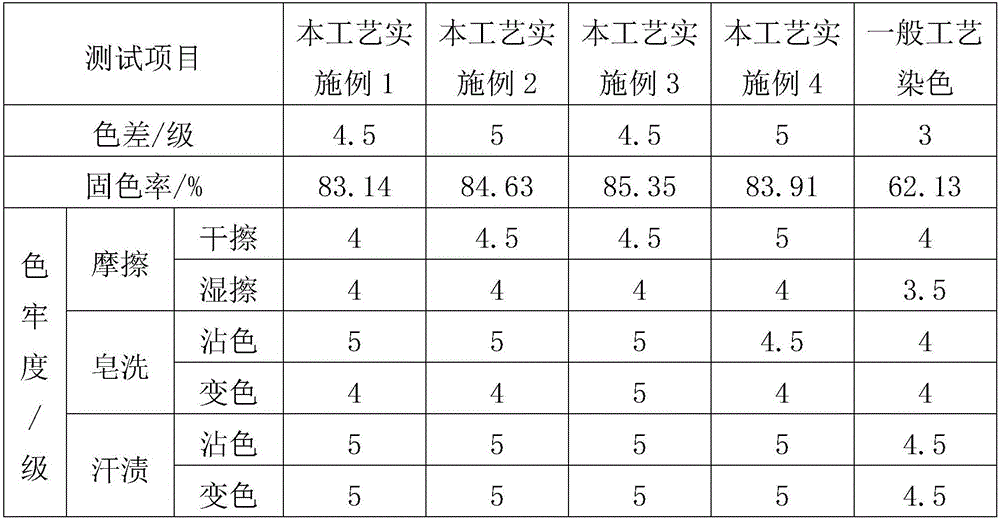

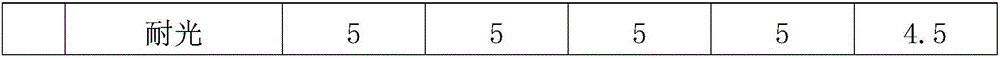

One-bath dyeing method for brocade cotton through reactive dyes

The invention discloses a one-bath dyeing method for brocade cotton through reactive dyes. The method comprises steps as follows: step (1), brocade cotton cloth is pretreated, dye liquor is added, and the bath ratio of the brocade cotton cloth to the dye liquor is 1: (4-6); step (2), the dye liquor is gradiently heated to 95-100 DEG C, the cloth is kept at the temperature to be dyed for 30-40 min, the dye liquor is cooled to 80-85 DEG C, a dyeing accelerant solution is added, and color fixation is performed for 40-50 min; step (3), the dyed brocade cotton is obtained through aftertreatment after dyeing in the step (2) is completed. One-bath dyeing of the brocade cotton is realized through coordination of the temperature, an acid-releasing agent, anhydrous sodium sulphate and the reactive dyes, a process is simple, energy is saved, and the prepared dyed brocade cotton has high washing fastness and small chromatic aberration.

Owner:浙江劲光纺织科技有限公司

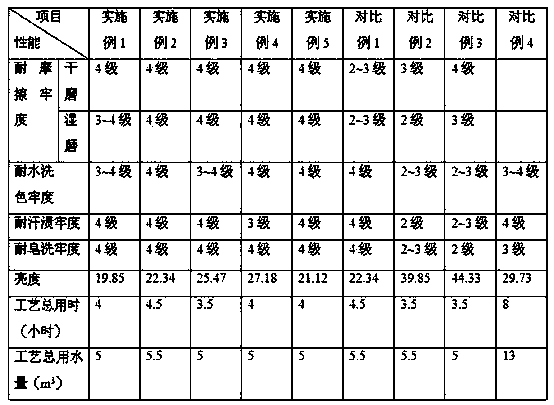

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

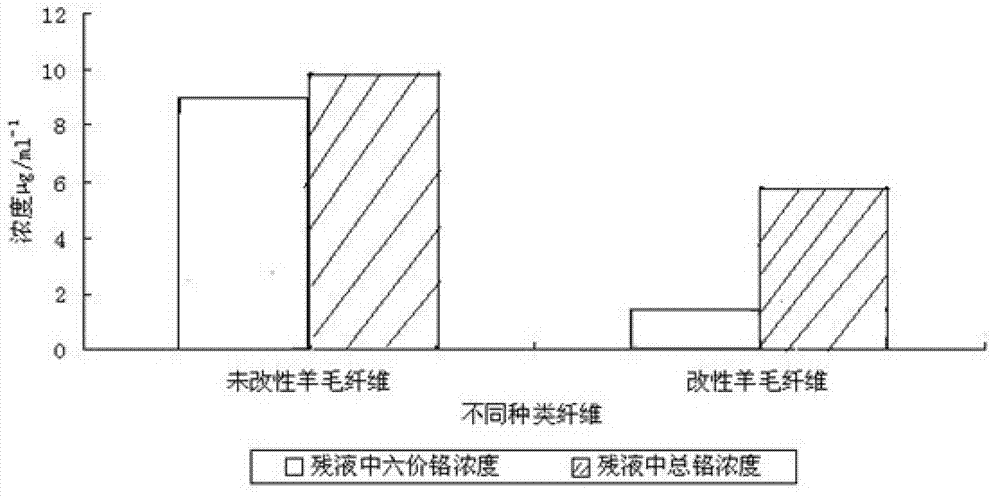

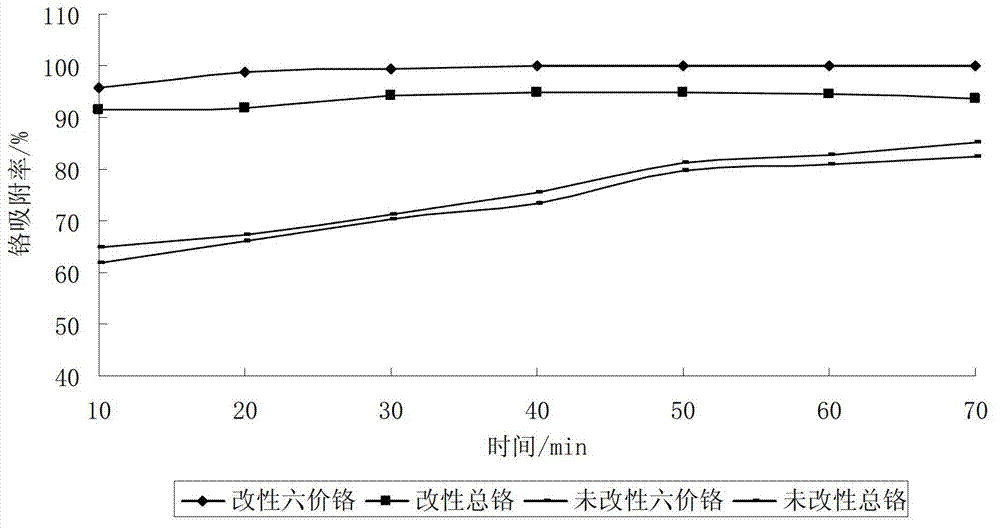

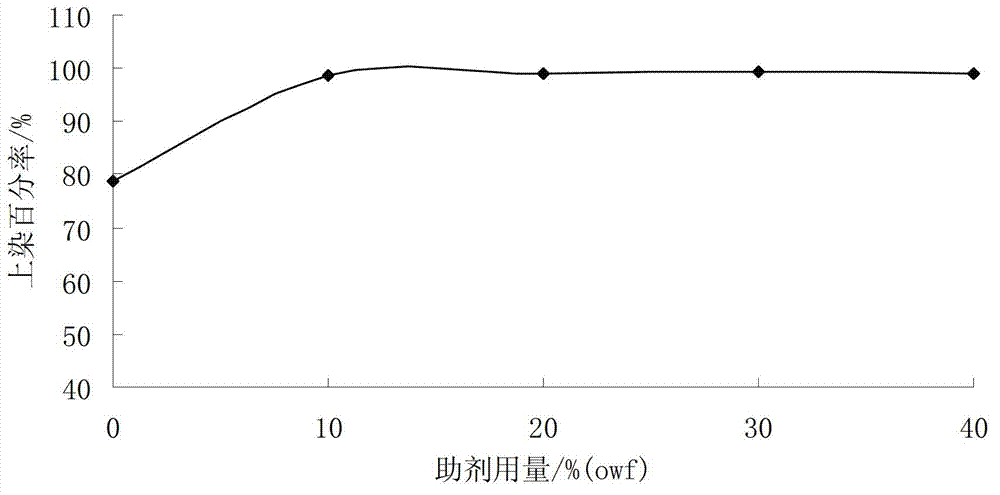

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251AEfficient reuseReduce pollutionDepsipeptidesPeptide preparation methodsCross-linkKeratin

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

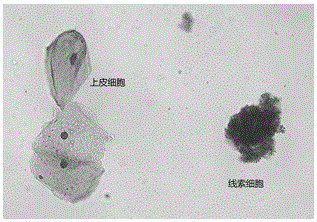

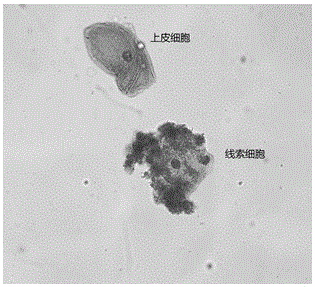

Vaginal secretion staining fluid, and preparation method and staining method thereof

ActiveCN105067412ASpeed up screeningShorten dyeing timePreparing sample for investigationStainingSurface layer

The invention discloses a vaginal secretion staining fluid, and a preparation method and a staining method thereof. According to the preparation method, a blue basic dyestuff and a red basic dyestuff are mixed so as to obtain the vaginal secretion staining fluid, so that the vaginal secretion staining fluid possesses staining effects of universal staining fluid, staining time can be shortened greatly, staining time is shortened from general 5-30min to 20s, staining efficiency is increased greatly, and screening speed of clinical samples is accelerated. And in addition, imagines obtained via staining with the vaginal secretion staining fluid are clear, and are convenient for identification; surface layer squamous epithelial cells, middle layer epithelial cells, bottom layer epithelial cells, clue cells, leukocytes, erythrocytes, monilia albicans, and trichomonad can be identified clearly; and the vaginal secretion staining fluid is suitable for large-scale sample clinical screening.

Owner:DIRUI MEDICAL TECH CO LTD

Cotton or viscose/chinlon/spandex seamless underwear one-bath-process dyeing technology

The invention relates to a cotton or viscose / chinlon / spandex seamless underwear one-bath-process dyeing technology, and belongs to the technical field of a knitwear dyeing technology. The technology comprises the following steps: keeping to-be-dyed cotton or viscose / chinlon / spandex seamless underwear in a dyeing jar, adding water to a specified water amount, heating up to 25-35 DEG C, sequentially adding salt or anhydrous sodium sulfate and a leveling agent, and keeping operating for 5-10min; then adding a reactive dye, a weak acid dye or a neutral dye and operating for 5-10min; heating up to 58-62 DEG C at 0.5-1 DEG C / min, then adding sodium carbonate and preserving heat for 30-50min; neutralizing sodium carbonate with dyeing acid, slowly regulating pH value to 6-7, heating up to 93-97 DEG C at 1-1.5 DEG C / min after rotating evenly and preserving heat for 40-60min; and cooling, draining, and finally carrying out post-treatment. The technology disclosed by the invention can effectively shorten dyeing process, shorten dyeing time, improve production efficiency, reduce discharged pollution and lower dyeing cost.

Owner:ZHEJIANG QIAOERTINGTING FASHION +1

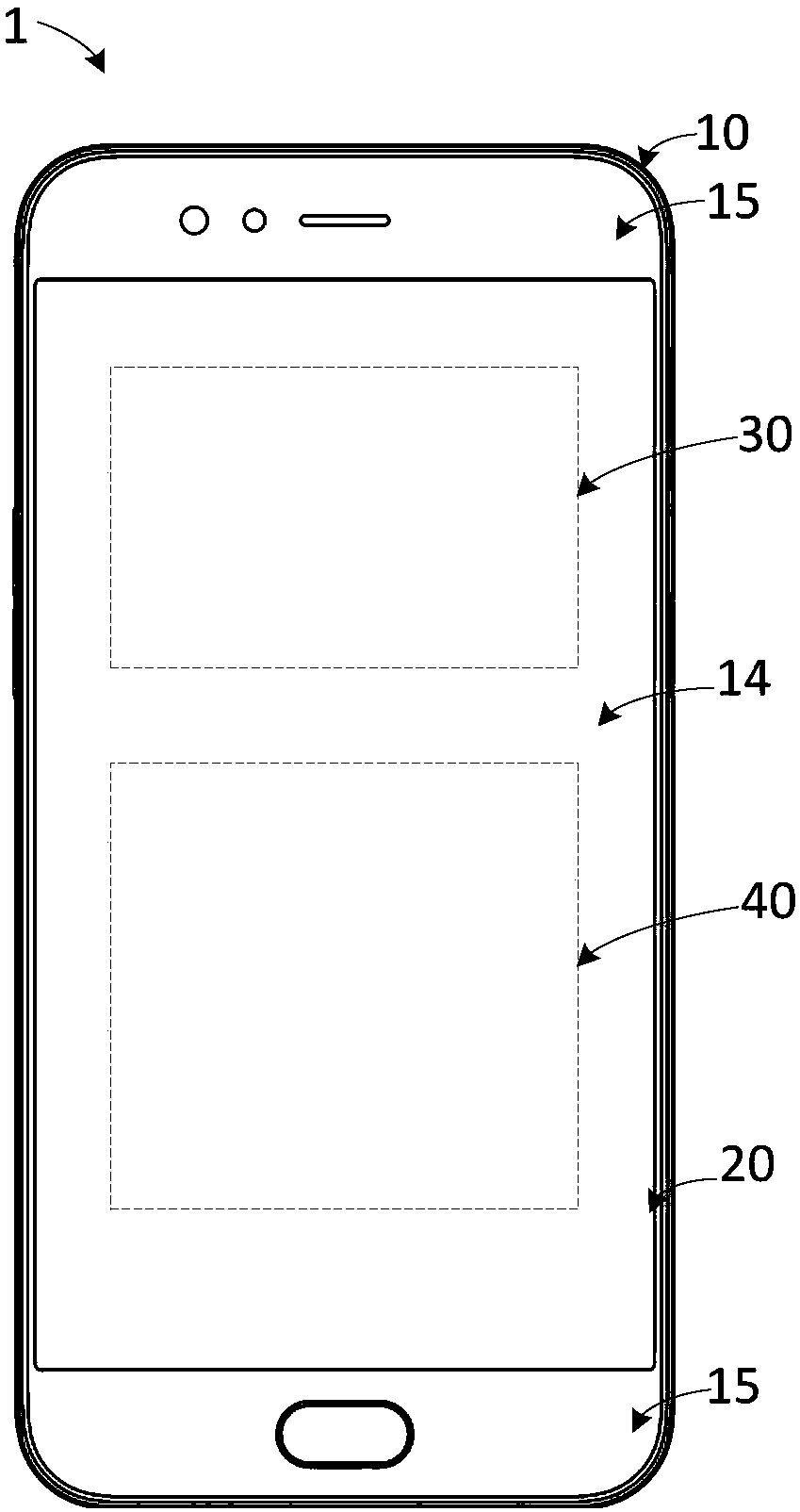

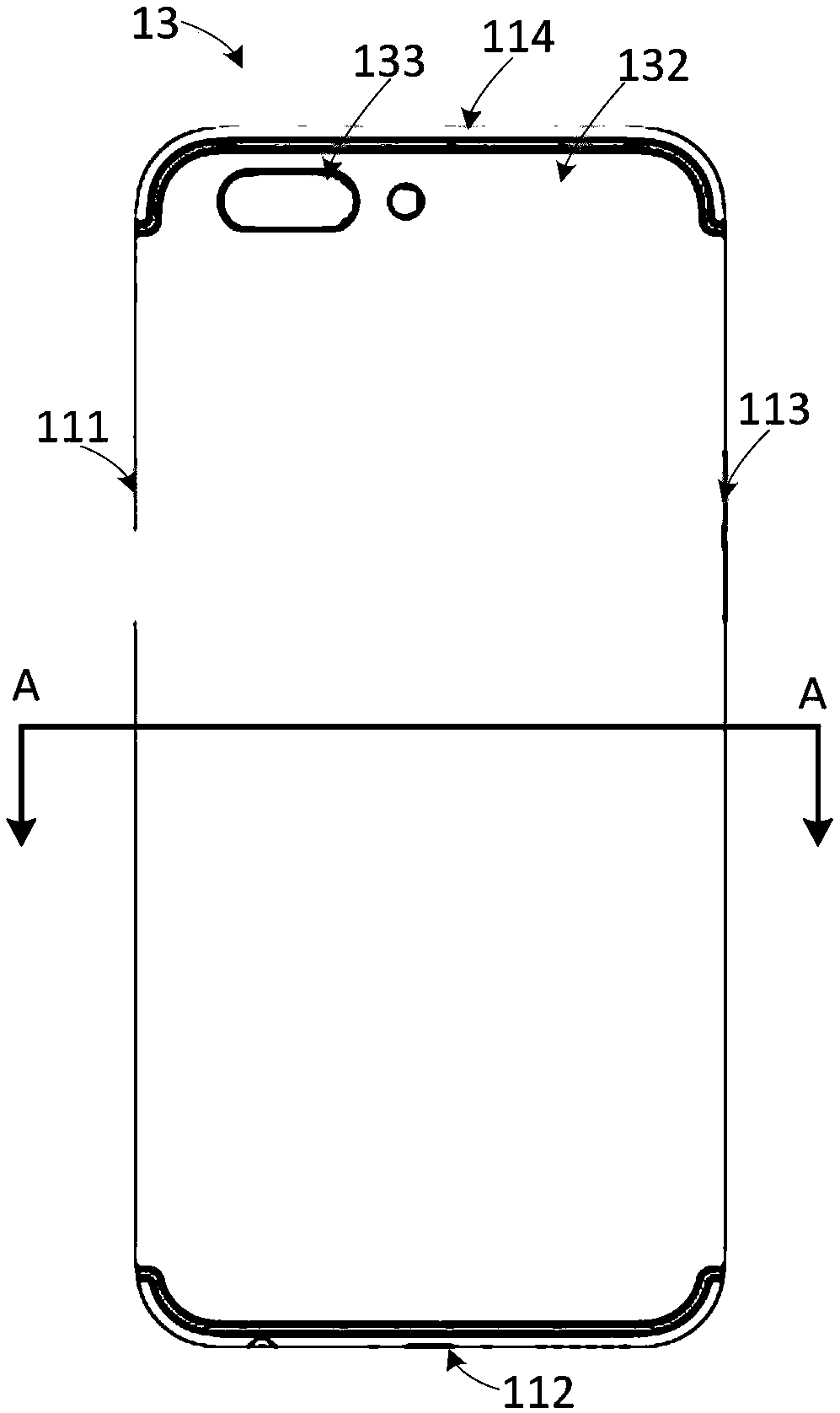

Shell and manufacturing method therefor, and electronic equipment

ActiveCN107864581ADo not meet demandShorten dyeing timeSurface reaction electrolytic coatingCasings/cabinets/drawers detailsEngineeringElectric equipment

Embodiments of the invention disclose a shell and a manufacturing method therefor, and electronic equipment. The manufacturing method for the shell comprises the steps of providing a shell substrate and performing oxidization treatment on the outer surface of the shell substrate to form an oxidation film on the outer surface of the shell substrate; performing dyeing treatment of a first color on the oxidization film in a direction from the fourth edge to the second edge in sequence, wherein the dyeing time is reduced in sequence, and forming the first color on the oxidization film, wherein thefirst color is shallowed in a direction from the fourth edge to the second edge gradually; and performing dyeing treatment of a second color on the oxidization film in a direction from the second edge to the fourth edge in sequence, wherein the dyeing time is reduced in sequence, and forming the second color on the oxidization film, wherein the second color is shallowed in a direction from the second edge to the fourth edge gradually, forming the first color close to the fourth edge and the second color close to the second edge on the oxidization film, and forming a mixed color between the fourth edge and the second edge. By virtue of the embodiments, the processes can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for rapidly dyeing wool with mordant dyes

ActiveCN101942769BMeet the quality requirements for color fastnessAvoid damageDry-cleaning apparatus for textilesDyeing processElectricityYarn

The invention relates to a method for rapidly dyeing wool with mordant dyes, comprising the following steps: preparing dyeing, adding low-temperature rapid dyeing assistants and dyes, raising temperature rapidly, carrying out dyeing at low temperature, adding mordants and formic acid without lowering temperature, carrying out mordanting at low temperature and carrying out aftertreatment and taking the wool out of the tank. In the invention, rapid temperature raising, lower dyeing temperature and the method of adding mordants without lowering temperature realize low-temperature rapid dyeing with mordant dyes by after-chrome dyeing. Compared with the traditional after-chrome dyeing method with mordant dyes, the method has the following advantages: fiber damage is lowered, the handfeel is good, the luster is bright, the yarn spinnability is improved, the color fastness conforms to the quality requirement of wool top dyeing color fastness and the dyeing time is shortened by 30-50%; and the method greatly reduces water, electricity, steam and labor consumption, improves the labor productivity and conforms to the requirement for low carbon economy.

Owner:JIANGSU DANMAO TEXTILE

A novel water-saving technique for yarn dyeing

ActiveCN1837447AAchieve the purpose of cleaningConserve waterLiquid/gas/vapor removal by gas jetsLiquid/gas/vapor yarns/filaments treatmentYarnWater saving

The invention relates to a water conservation technique for yarn dyeing, wherein low level dyeing is realized through modification of dye liquor recycling pattern and optimization of the dyeing process, the water consumption can be 20-50% lower then the conventional procedures.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Process of wet steaming salt-free dyeing for cellulose fiber fabric

InactiveCN102635000AOvercoming the disadvantages of contaminationShorten dyeing timeDyeing processProcess engineeringCellulose fiber

The invention belongs to the fiber fabric dyeing process, especially relating to a process of wet steaming salt-free dyeing for a cellulose fiber fabric, which has the effects of energy conservation and emission reduction. A method of dyeing fabric with an active dye by means of a proportional pump comprises the following three process steps: (1) a step of mixing a padding dye with a fixing agent; (2) a step of steaming fixation; and (3) a step of water washing. The technical proposal of the process, compared with the traditional pad drying and pad steaming processes, only employs a reducing soaper without a padding machine, so that the dyeing time is shortened and the dyeing efficiency is improved; the wet steaming salt-free process, compared with the batch-type cold pad dyeing process, has the advantages that the time of dyeing padding is shortened and the tinctorial yield is consistent; as the improvement of the fixing alkaline agent overcomes the shortcoming of water glass contamination, the continuity of pad dyeing is realized and the production efficiency is improved.

Owner:HUAFANG

Salt-free low-alkali dyeing method for shortening dyeing time of reactive dye

ActiveCN103498348AReduce dosageImprove color fixing efficiencyDyeing processTextile printerColour fastness

The invention relates to a salt-free low-alkali dyeing method for shortening dyeing time of a reactive dye, which belongs to the field of a textile printing and dyeing technology. By adoption of the method, a preparation and a process route of the dyeing liquid in the prior dyeing art are changed, by adopting the method of dyeing a to-be-dyed textile into a dyeing liquid mixed with a high-ratio ethanol organic solvent, a small amount of water and the dye, the problems that the dyeing time is longer and a dye-fixing agent is difficult to dissolve into an organic solvent in the traditional dyeing process are solved, the immersing dyeing time of the textile is greatly shortened, the salt-free dyeing of the textile is realized, and the dosage of the dye-fixing alkaline agent is reduced. The dyeing method related by the invention is simple in process, high in dye-fixing rate, and good in dyeing effect and color fastness, and furthermore, by adoption of the method, the dosage of water is greatly reduced, the dosages of chemical assistants are effectively reduced, the ethanol solvents can be recycled, the pollution is less, the cost is low, and therefore the dyeing method is clear, energy-saving, safe and environment-friendly.

Owner:WUHAN TEXTILE UNIV +1

Dyeing composition for hair

ActiveUS20070074355A1Fast swellingShorten dyeing timeCosmetic preparationsHair cosmeticsCeramideDyeing

Disclosed herein is a hair dyeing composition. The composition induces swelling of hair to expand the cortex by the use of arginine, which is a constituent ingredient of hair, and as a result, effectively allows a colorant to infiltrate into the cuticle, thereby increasing the dyeing rate. Therefore, the composition can markedly decrease the dyeing time to 1˜5 minutes from 20˜30 minutes required in conventional hair dyeing compositions. In addition, the combined effects of aloe vera gel, ceramide and hair keratin enables prevention of damage to the hair during dyeing.

Owner:KIRIN COSMETICS +1

Dyeing process for chinlon bamboo joint fabric cotton fibre

The invention relates to a dyeing process for chinlon bamboo joint fabric cotton fibre. The dyeing process comprises the steps of carrying out earlier stage processing, refining, dyeing, drying and aftertreatment on cotton fibre, wherein during dyeing step, reactive dyes are adopted, specifically, the process comprises the following steps: putting the dyes and anhydrous sodium sulphate into a dye vat for mixing for 20-30 minutes according to different color requirements and ratio of various dyes, running for 10-30 minutes under normal temperature, rising the temperature till reaching the temperature needed by dyeing at the speed of 0.5-3 DEG C / minute, selecting a proper alkali adding ratio curve according to different characteristic of dyes, adding alkali liquids by adopting automatic alkali adding equipment, keeping the temperature for 15-30 DEG C, discharging residual liquid and carrying out aftertreatment. A fabric manufactured by the cotton fibre has advantages of good abrasive resistance, washability, good colour fastness and the like.

Owner:TIANXI TEXTILE PROD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com