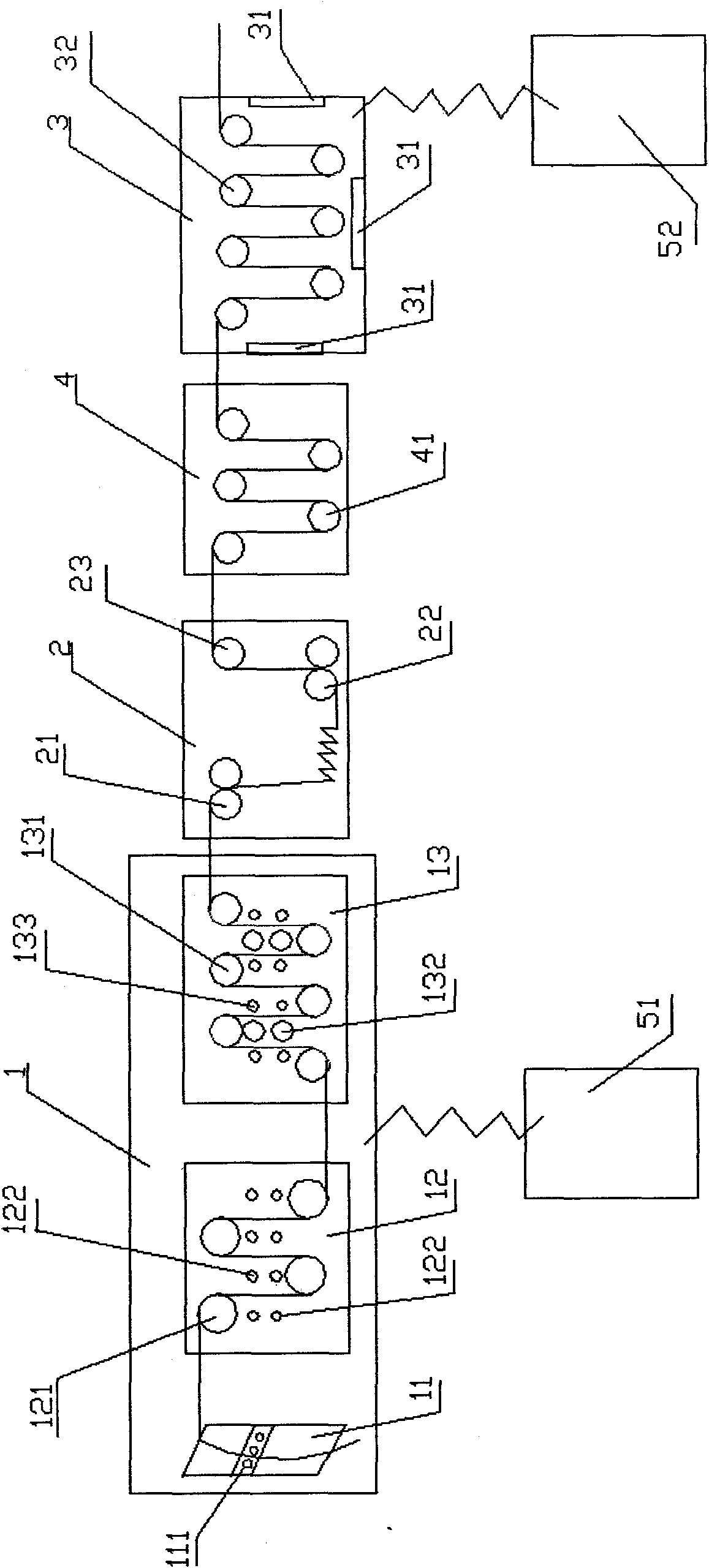

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

A plasma and fabric dyeing technology, applied in ultrasonic/sonic fiber treatment, dyeing method, fiber treatment, etc., can solve the problems of low dyeing dyeing rate, reduce dyeing temperature, reduce production energy consumption, and improve dyeing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

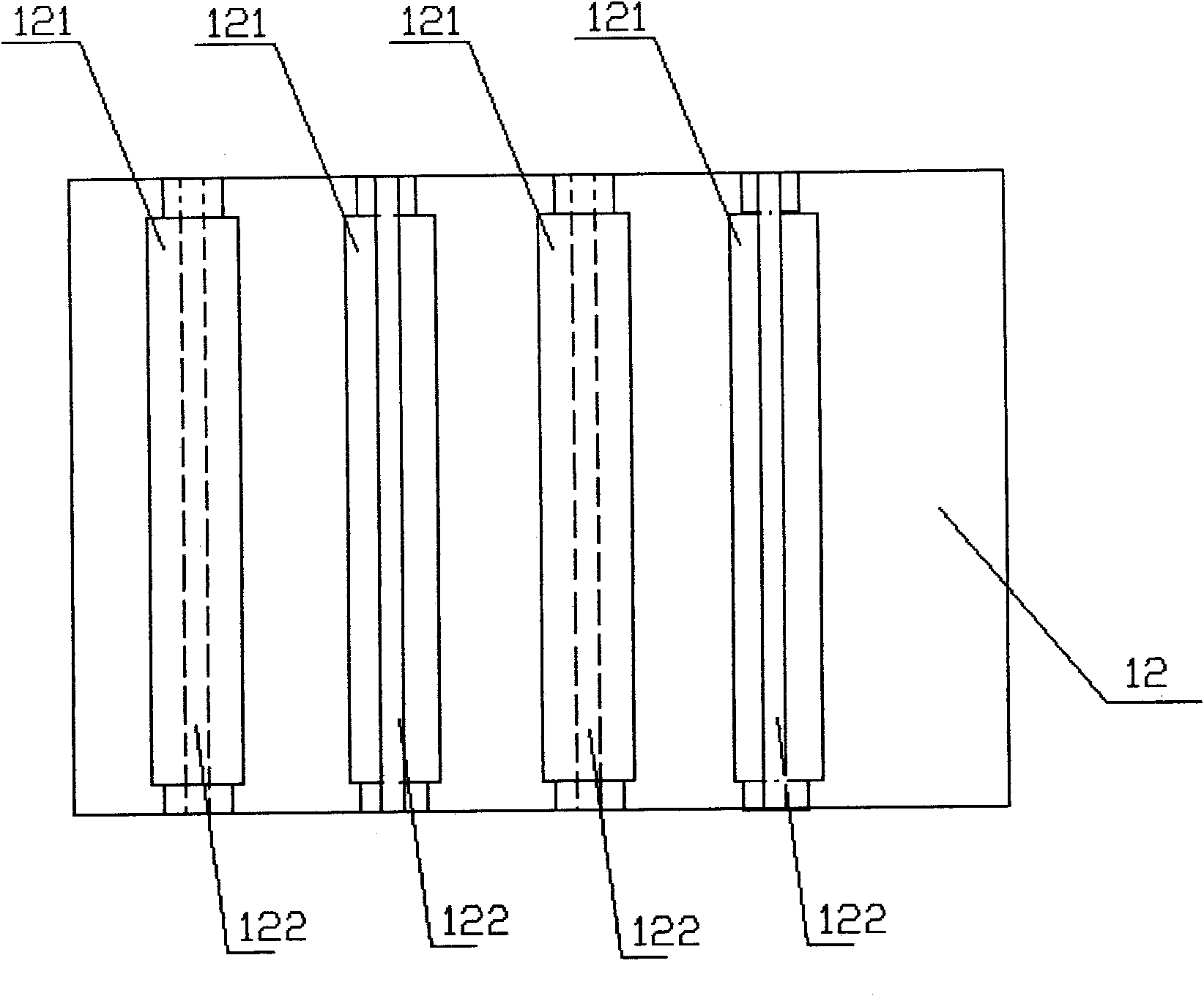

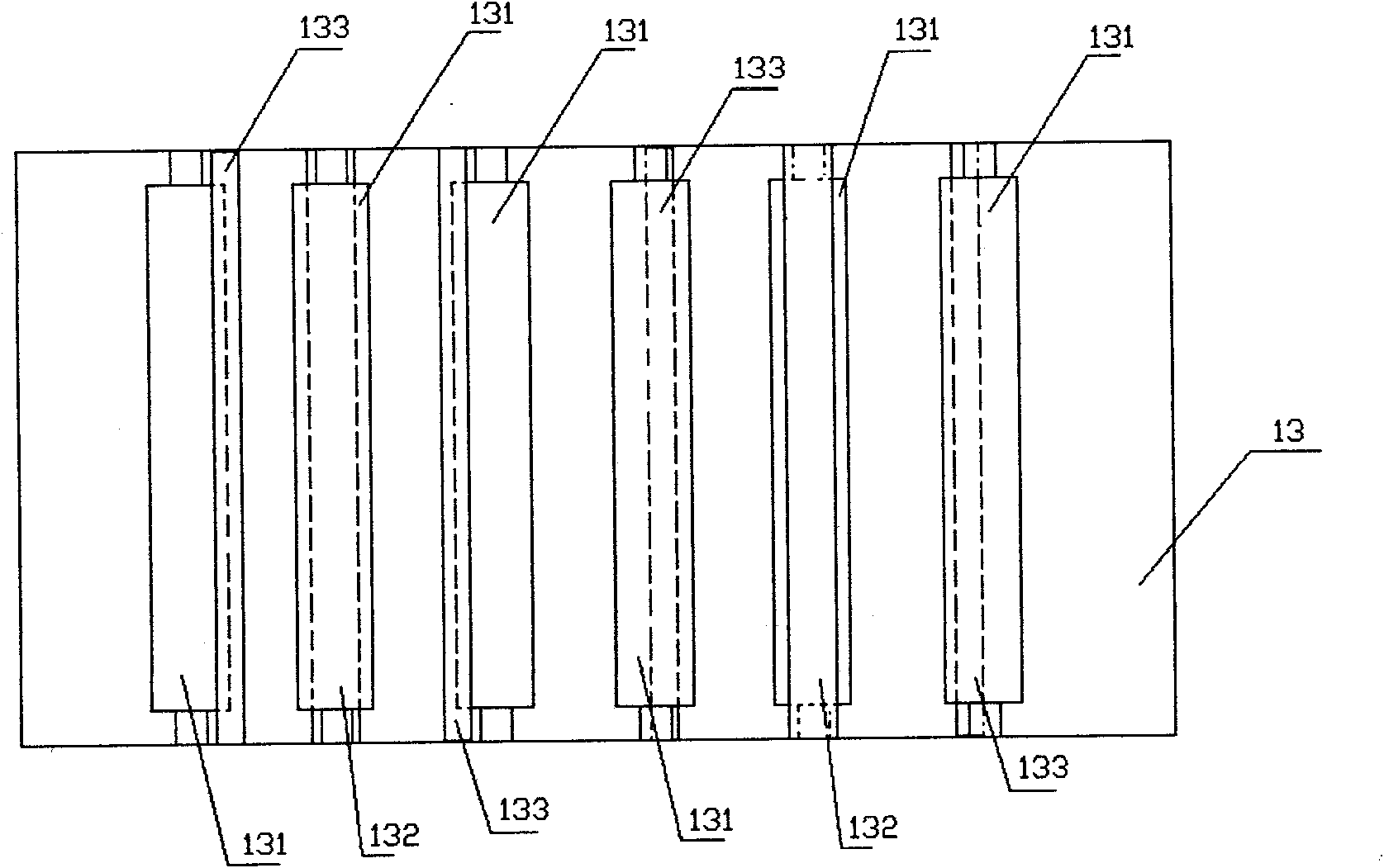

Method used

Image

Examples

Embodiment 1

[0055] The ramie gray cloth passes through the low-temperature and atmospheric-pressure plasma equipment at a speed of 70m / min, the infrared drying temperature is 100°C, the plasma discharge power is 10KW, the discharge treatment time is 15S, the grafting monomer is ethyl acrylate, and the grafting reaction The time is 1h, the grafting reaction temperature is 60°C, the grafting monomer concentration is 30%, the washing temperature is 60°C, the washing times are 3 times, the ultrasonic power is 550w, the frequency is 40KHz, the dye dosage is 1% (o.w.f.), and the dyeing temperature is 50°C , the dyeing time is 30min, the soaping temperature is 70°C, and the soaping time is 15min. Compared with the general dyeing method, the dyeing rate of the ramie fabric after dyeing is increased by 10%, and the COD index in the dyeing wastewater is reduced by 30%.

Embodiment 2

[0056] Embodiment 2: The ramie gray cloth is passed through the low-temperature and atmospheric-pressure plasma equipment at a speed of 30m / min, the infrared drying temperature is 115°C, the discharge power of the plasma is 50KW, the discharge treatment time is 50S, and the grafting monomer is ethyl acrylate , the grafting reaction time is 1h, the grafting reaction temperature is 60°C, the grafting monomer concentration is 25%, the washing temperature is 60°C, the washing times are 3 times, the ultrasonic power is 500w, the frequency is 35KHz, and the dye consumption is 0.7% (o.w.f.), The dyeing temperature is 50°C, the dyeing time is 30 minutes, the soaping temperature is 70°C, and the soaping time is 15 minutes. Compared with the general dyeing method, the dyeing rate of the ramie fabric after dyeing is increased by 17%, and the COD index in the dyeing wastewater is decreased by 43%.

Embodiment 3

[0057] Embodiment 3: the flax gray cloth is passed through the low-temperature and atmospheric-pressure plasma equipment at a speed of 70m / min, the infrared drying temperature is 110°C, the discharge power of the plasma is 15KW, the discharge treatment time is 15S, the grafting monomer is acrylic acid, and the grafting monomer is acrylic acid. The branching reaction time is 40min, the grafting reaction temperature is 80°C, the grafting monomer concentration is 25%, the washing temperature is 60°C, the washing times are 3 times, the ultrasonic power is 400w, the frequency is 35KHz, the dye dosage is 3% (o.w.f.), and the dyeing temperature is 55°C, dyeing time is 40min, soaping temperature is 65°C, soaping time is 15min. Compared with the general dyeing method, the dyeing rate of the linen fabric after dyeing is increased by 12%, and the COD index in the dyeing wastewater is reduced by 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com