Patents

Literature

2771 results about "Disperse dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

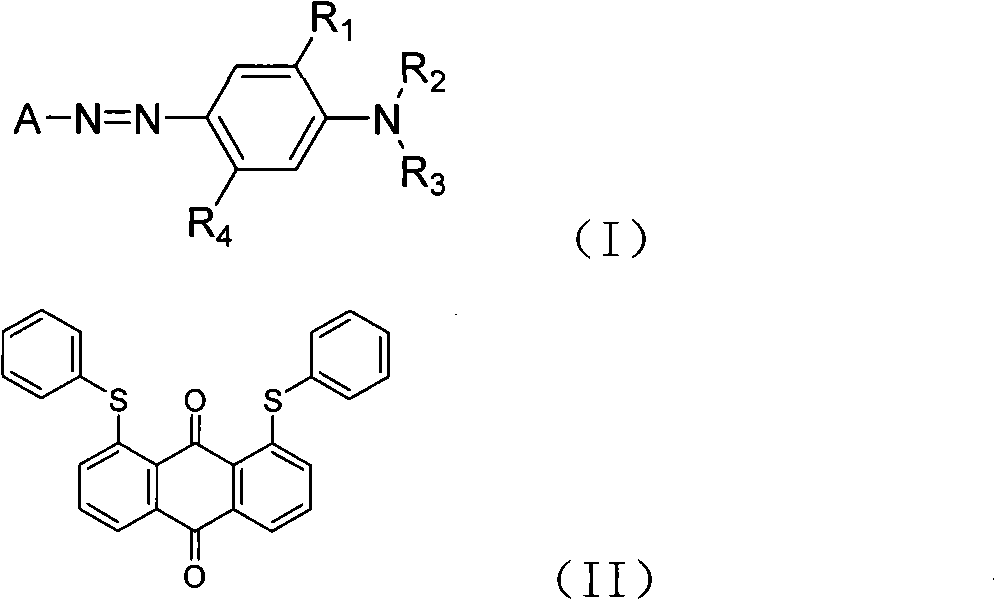

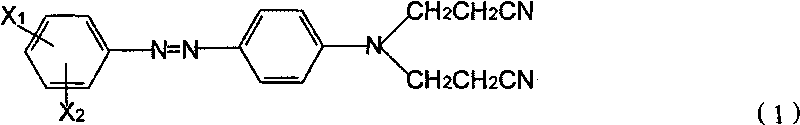

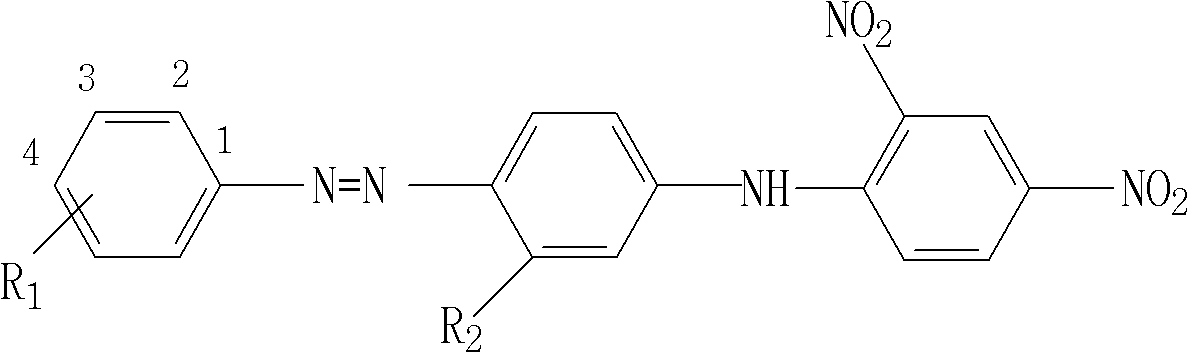

Disperse dyes are the only water-insoluble dyes that dye polyester and acetate fibers. Disperse dye molecules are the smallest dye molecules among all dyes. A disperse dye molecule is based on an azobenzene (as Disperse Red 1 or Disperse Orange 37) or anthraquinone molecule with nitro, amine, hydroxyl, etc. groups attached to it.

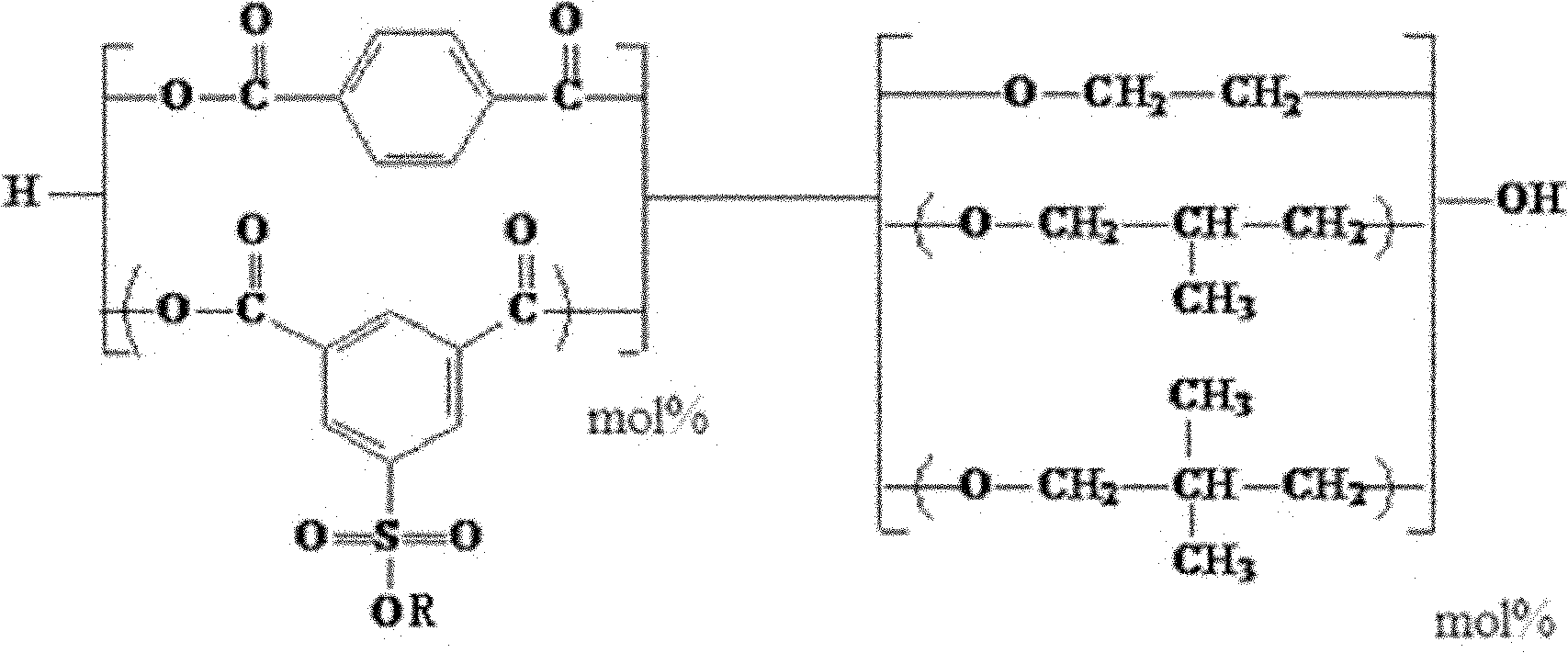

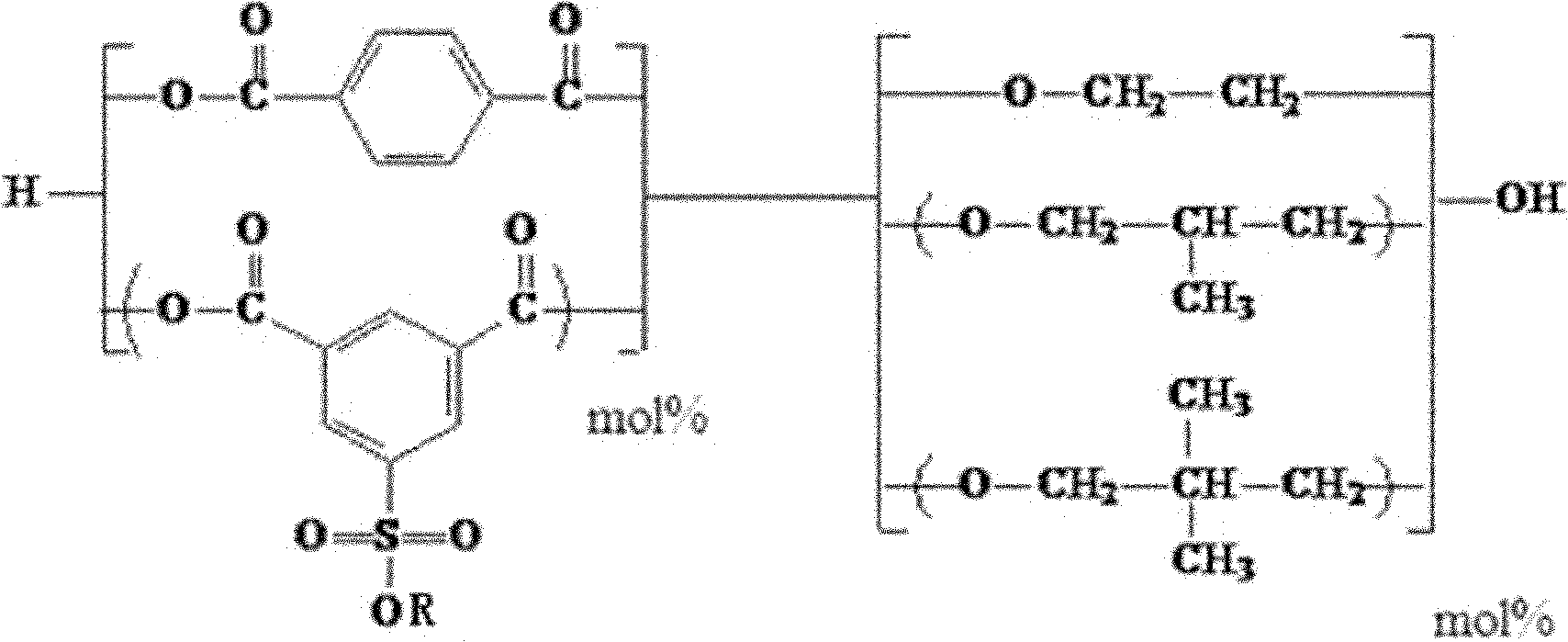

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

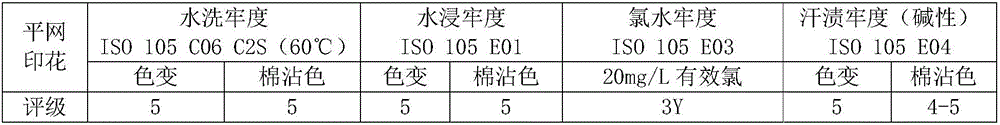

Environment-friendly disperse dye composition

ActiveCN101768376AIncrease profitProtect the environmentOrganic dyesDyeing processDisperse dyeSewage

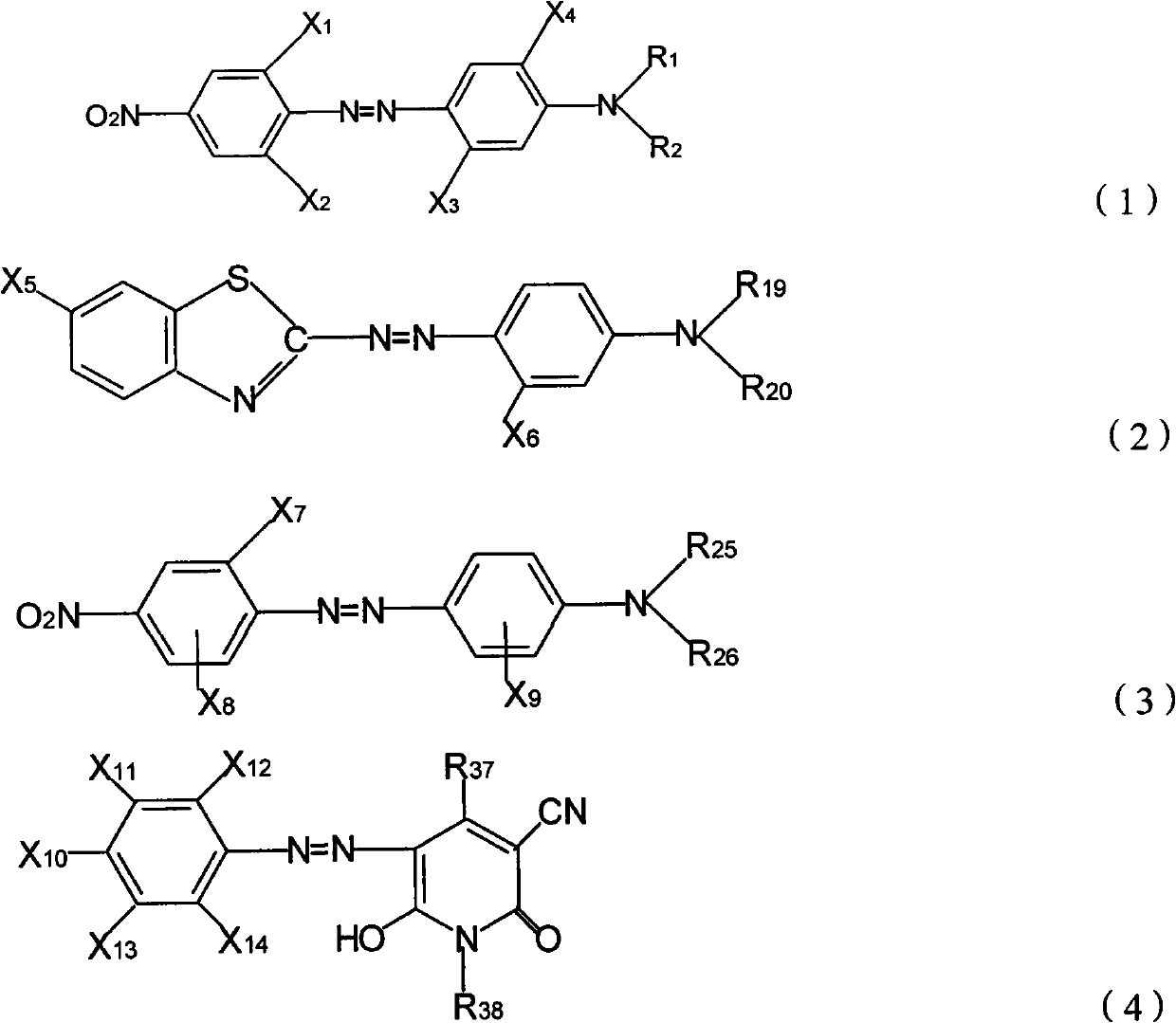

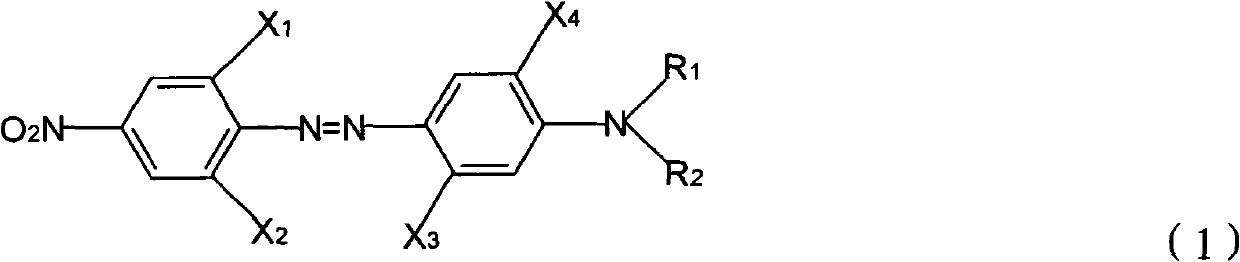

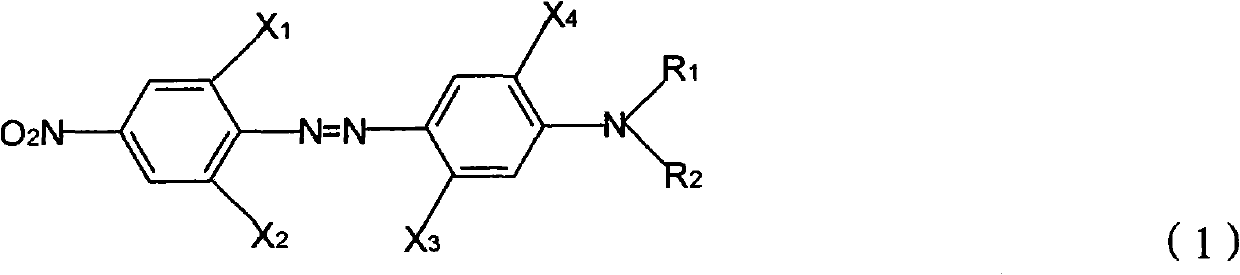

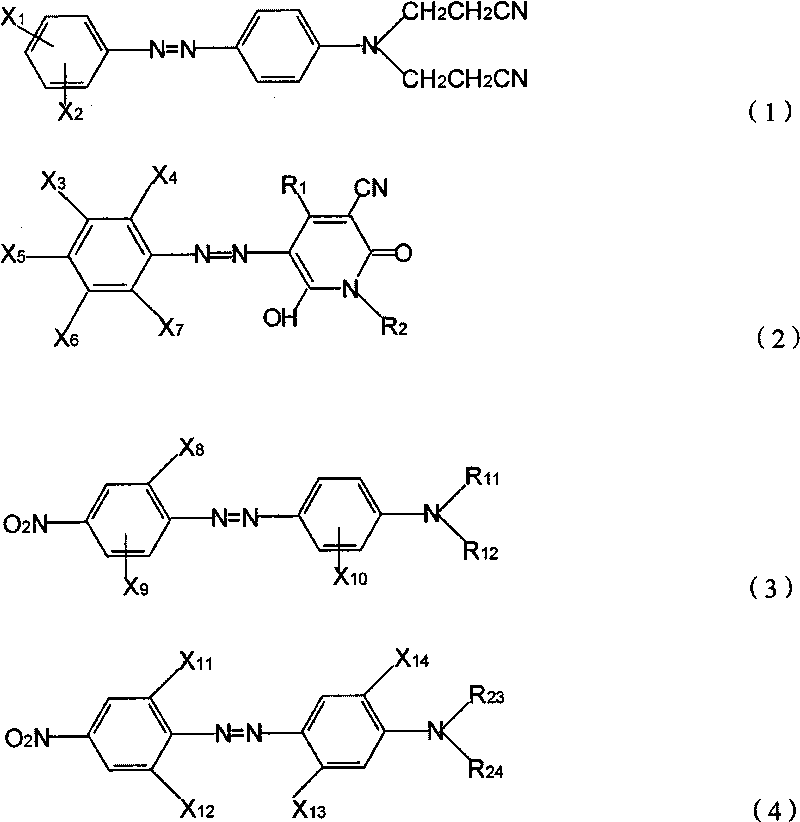

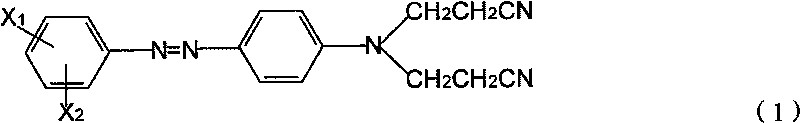

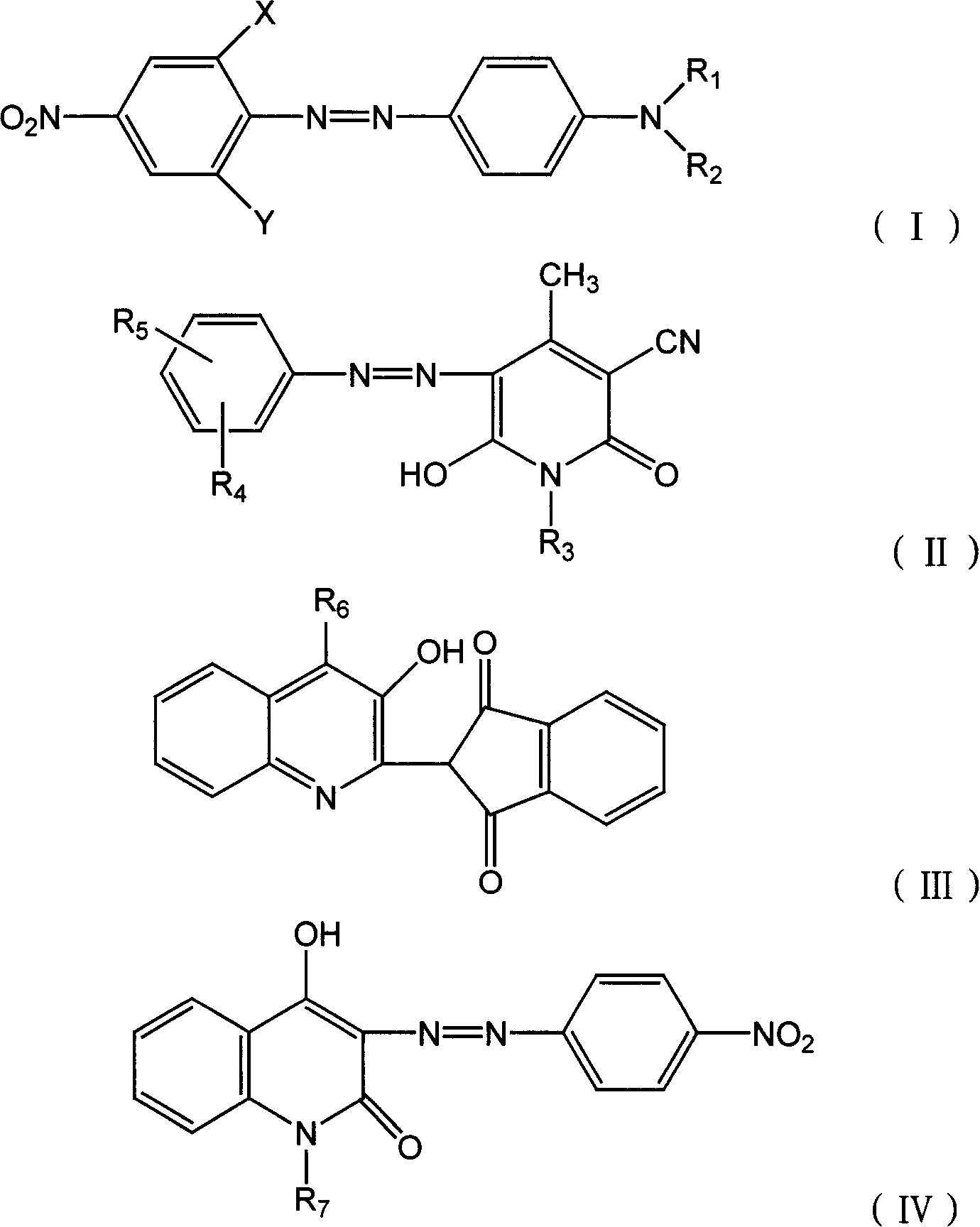

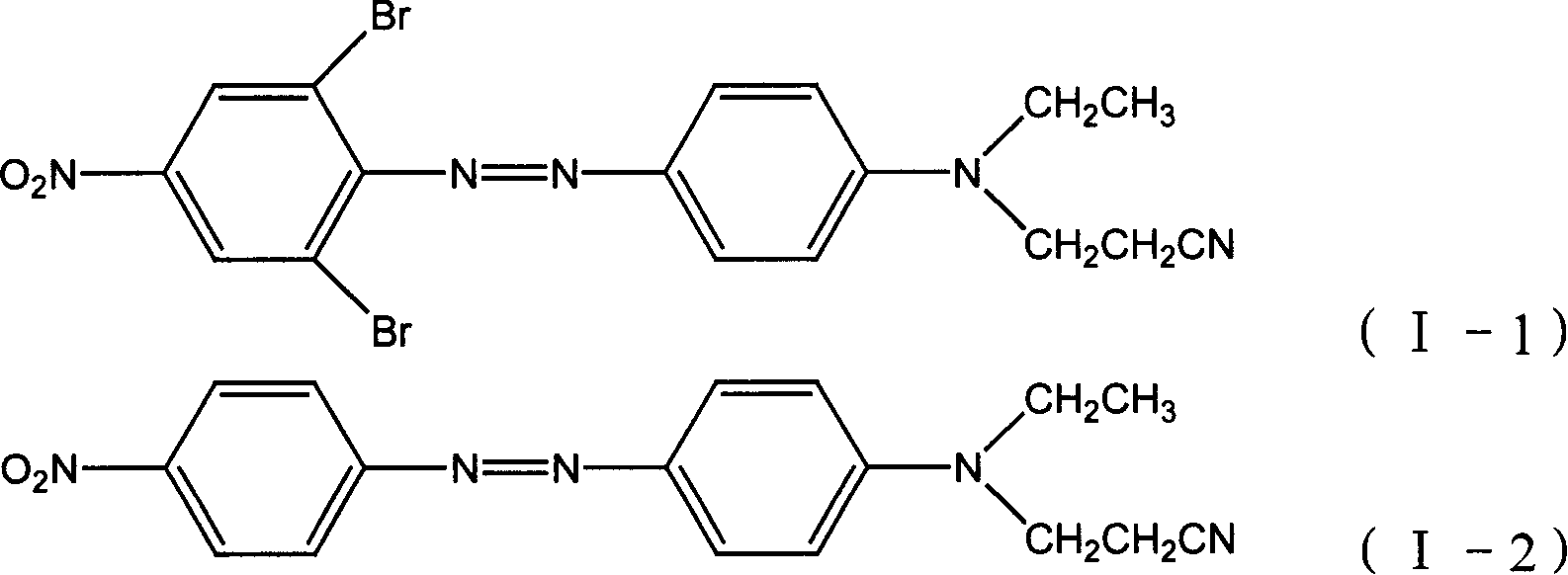

The invention discloses an environment-friendly disperse dye composition, which comprises the following components by weight percent: 10-75% of dye monomer A as shown in formula (1), 2-35% of dye monomer B as shown in formula (2), 8-50% of dye monomer C as shown in formula (3), and 1-10% of dye monomer D as shown in formula (4). The disperse dye composition can be regulated to obtain colored lights such as black, blue, grey, brown and the like; the obtained dye composition is an environment-friendly dye, and has wide suitable range of the pH value, good pile-on property, strong covering performance, good lifting power, colour yield, levelling property and various fastness, and can greatly improve the utilization rate of the dye and reduce the dye sewage.

Owner:ZHEJIANG RUNTU

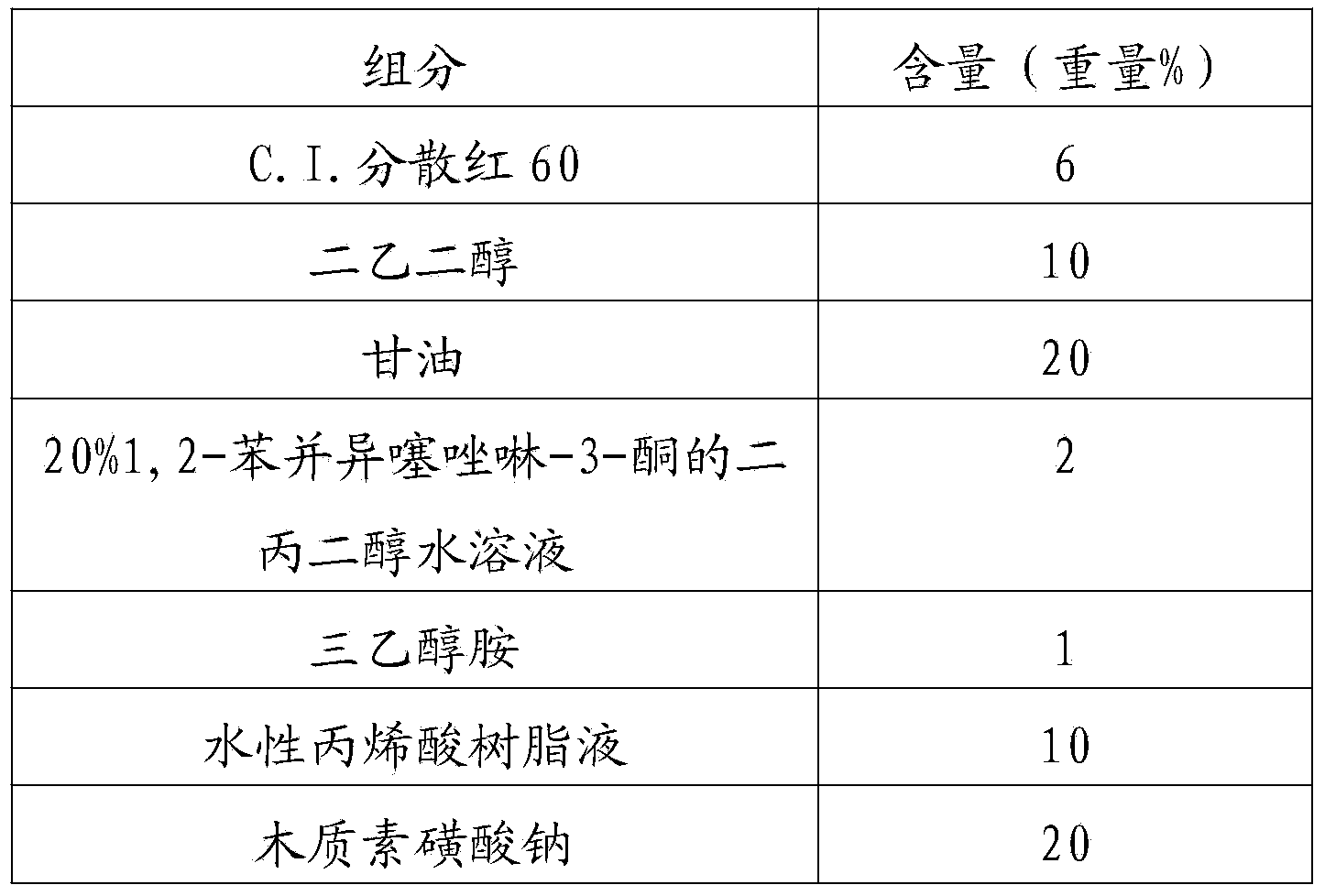

Waterborne digital ink-jet printing sublimation ink and preparation method thereof

ActiveCN101709177AAdjust surface tensionAdjust viscosityInksDyeing processDisperse dyeOrganic solvent

The invention provides waterborne digital ink-jet printing sublimation ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 2 to 15 percent of dispersing agent, 10 to 60 percent of deionized water, 10 to 50 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent, 0.05 to 0.5 percent of germicide, and 0.05 to 0.5 percent of defoaming agent. The preparation method comprises the following steps of: mixing 1 to 20 percent of dispersing agent, 10 to 40 percent of water soluble organic solvent, 0.1 to 2 percent of germicide, 0.1 to 2 percent of defoaming agent, and 30 to 50 percent of deionized water, adding 1 to 20 percent of disperse dye while stirring, and grinding the mixed solution to obtain color paste; uniformly mixing 15 to 50 percent of color paste, 10 to 30 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent and 20 to 50 percent of deionized water and filtering the mixed solution to obtain the waterborne digital ink-jet printing sublimation ink. When the waterborne digital ink-jet printing sublimation ink is used in a large-sized ink-jet printer using waterborne ink, the good printing smoothness and the water retention of a printing head are achieved, and the preparation process is simple.

Owner:上海英威喷墨科技有限公司

Pretreatment for low and non-porous media for inkjet printing

This invention pertains to inkjet printing on non-porous or low porous media and to a pretreatment solution for the non-porous or low porous media that allows high quality printing thereon. The preferred digitally printed inks are disperse dye or pigmented inks.

Owner:EI DU PONT DE NEMOURS & CO

Alkali-resistant disperse dye complex

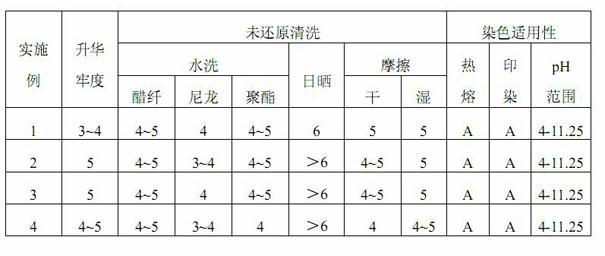

The invention discloses an alkali-resistant disperse dye complex, and relates to disperse blue BR-based alkali-resistant disperse dye complexes suitable for dyeing in a wide pH range. The complex comprises (1) alkali-resistant disperse dye blue complex, or (2) alkali-resistant disperse dye blue complex, or (3) alkali-resistant disperse dye black complex. The disperse dye complex of the invention has good dispersibility, dyeing stability and good reproducibility, and can effectively avoid the problems of stains, flaws, chromatic aberration and the like caused by dirt such as slurry, oil stain,wax and the like on fibers; and the pH value has wide range during use, dyeing can be performed in the pH range of 4.0 to 11.25, the dyed fabrics have full hue, and the dyed fabrics with predominant color fastness performance such as washing fatness, daylight fastness and the like can be obtained without reduction clearing.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

Dyeing and coating integrated dye dyeing and printing paste-shaped compound and application thereof

ActiveCN105970671AGuaranteed high sublimationGuaranteed wet rubbing fastnessDyeing processDisperse dyeHigh concentration

The invention relates to a textile dyeing and printing technique and specifically relates to a dyeing and coating integrated dye dyeing and printing paste-shaped compound for a hydrophobic textile material and an application thereof. The dye dyeing and printing paste-shaped compound is composed of 1-25% of dyeing and printing concentrated paste, 0.5-10% of thickening agents, 0.05-3% of pH modifiers and 62-98.45% of water. The paste-shaped compound provided by the invention is used for dyeing and printing the hydrophobic textile material and has the advantages of dye dyeing and printing and pigment dyeing and printing; the high sublimation, washing and dry and humid rubbing fastness are ensured while the color is bright and the hand feeling is soft; the generation of high concentration waste water in the traditional disperse dyeing and printing processes is avoided; and therefore, the dyeing and coating integrated dye dyeing and printing paste-shaped compound is a clean and environment-friendly dye dyeing and printing product.

Owner:SHENYANG RES INST OF CHEM IND

Fabric pre-treating method for digital ink-jet printing of dispersed dye

The invention relates to a fabric pre-treating method for digital ink-jet printing of a dispersed dye, which comprises the following steps of: (1) uniformly mixing 1 to 5 percent of water-soluble organic polymer, 2 to 3 percent of porous inorganic nano particle, 0.1 to 2 percent of surfactant and water to form a pre-treating agent; and (2) dipping, padding and coating a fabric dyed by a dispersed dye or sparing the pre-treating agent on the fabric dyed by the dispersed dye, wherein the fabric carrying liquid rate is 50 to 90 percent, drying the fabric, and heating the fabric at 180 to 220 DEG C for 0.5 to 20 minutes. The method of the invention is simple, low in cost and suitable for industrial production; the direct ink-jet printing of the fabric with the pre-treating agent has the advantages of uniform color, inhibited penetration phenomenon, high printing precision, sharp boundaries of patterns, clear detail and bright color; and the fabric offers a soft hand feel and has very good washing, friction and color fastness to light.

Owner:DONGHUA UNIV +1

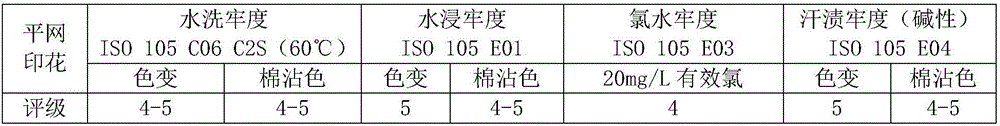

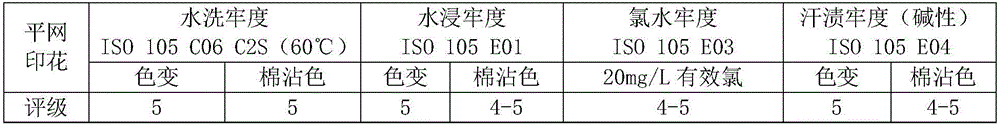

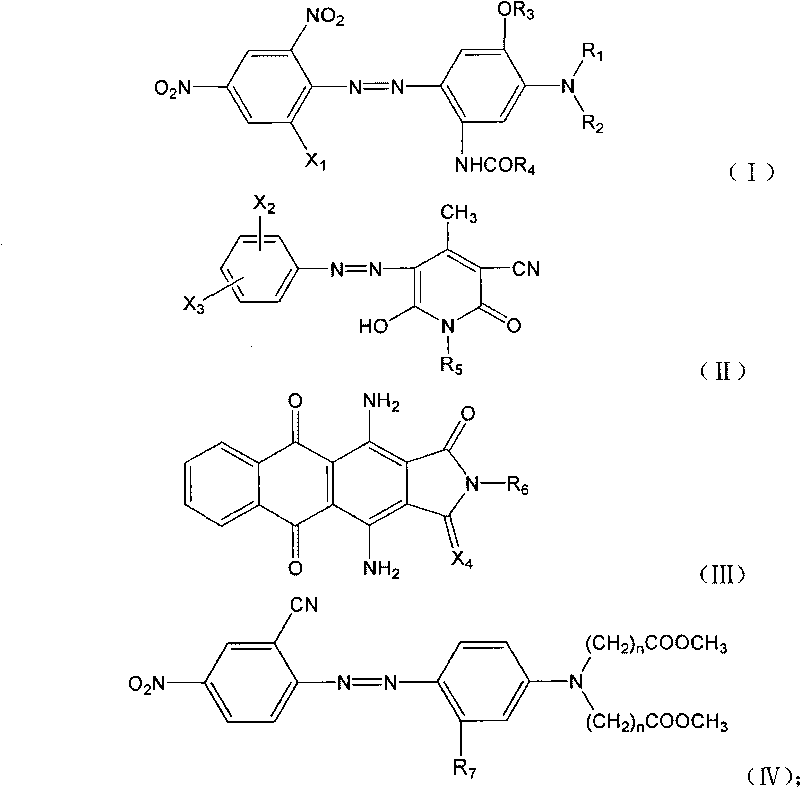

Composite black disperse dye

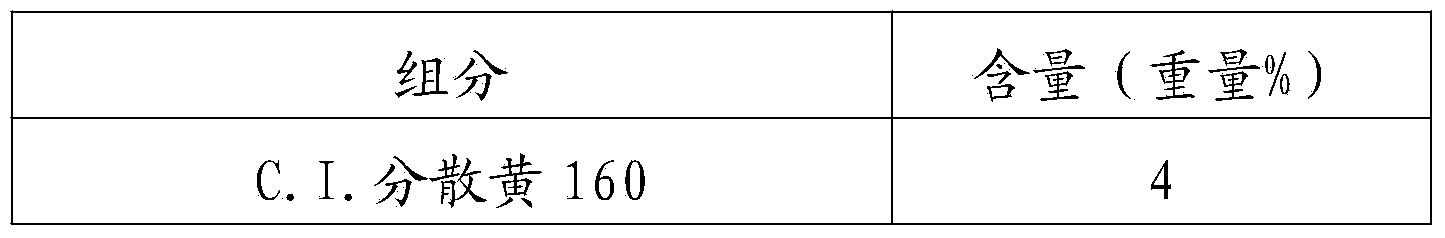

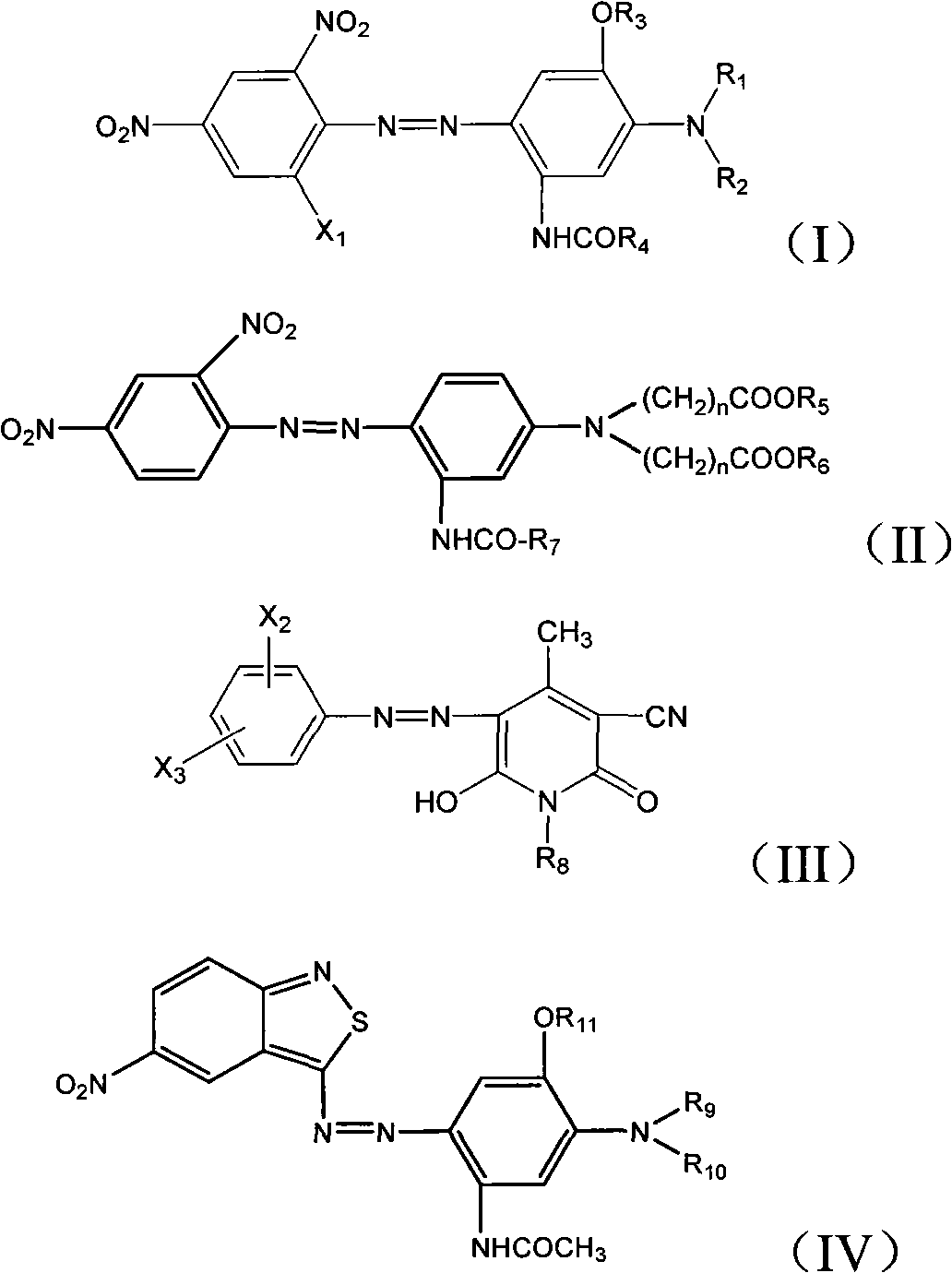

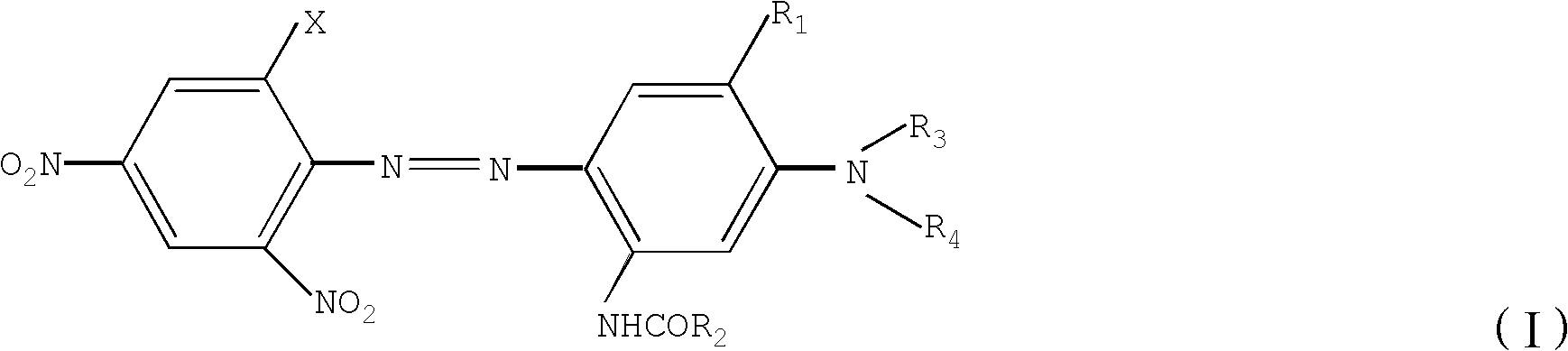

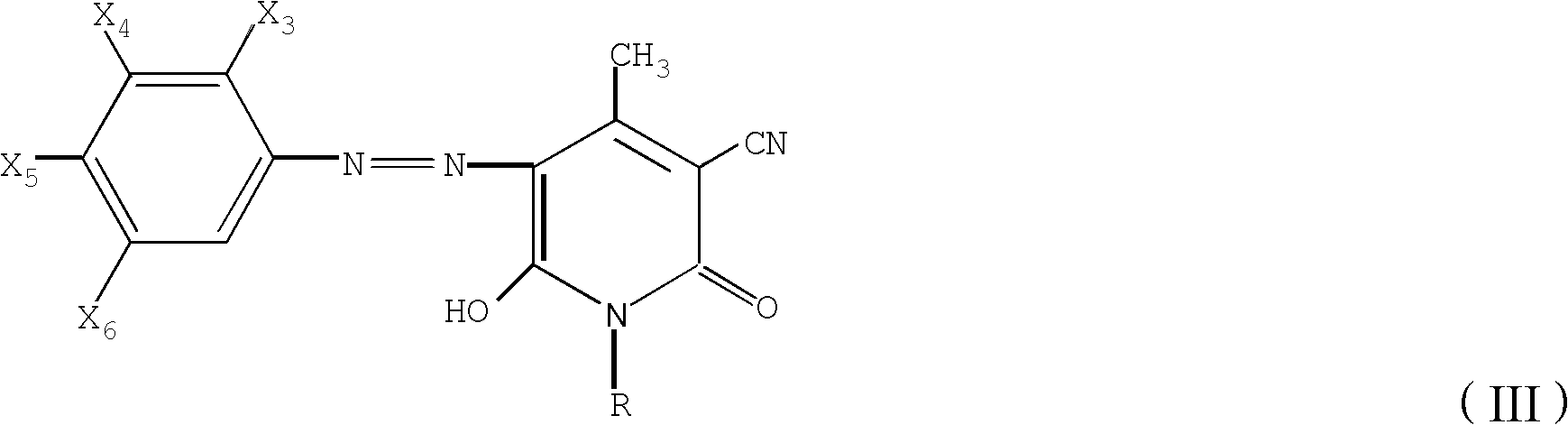

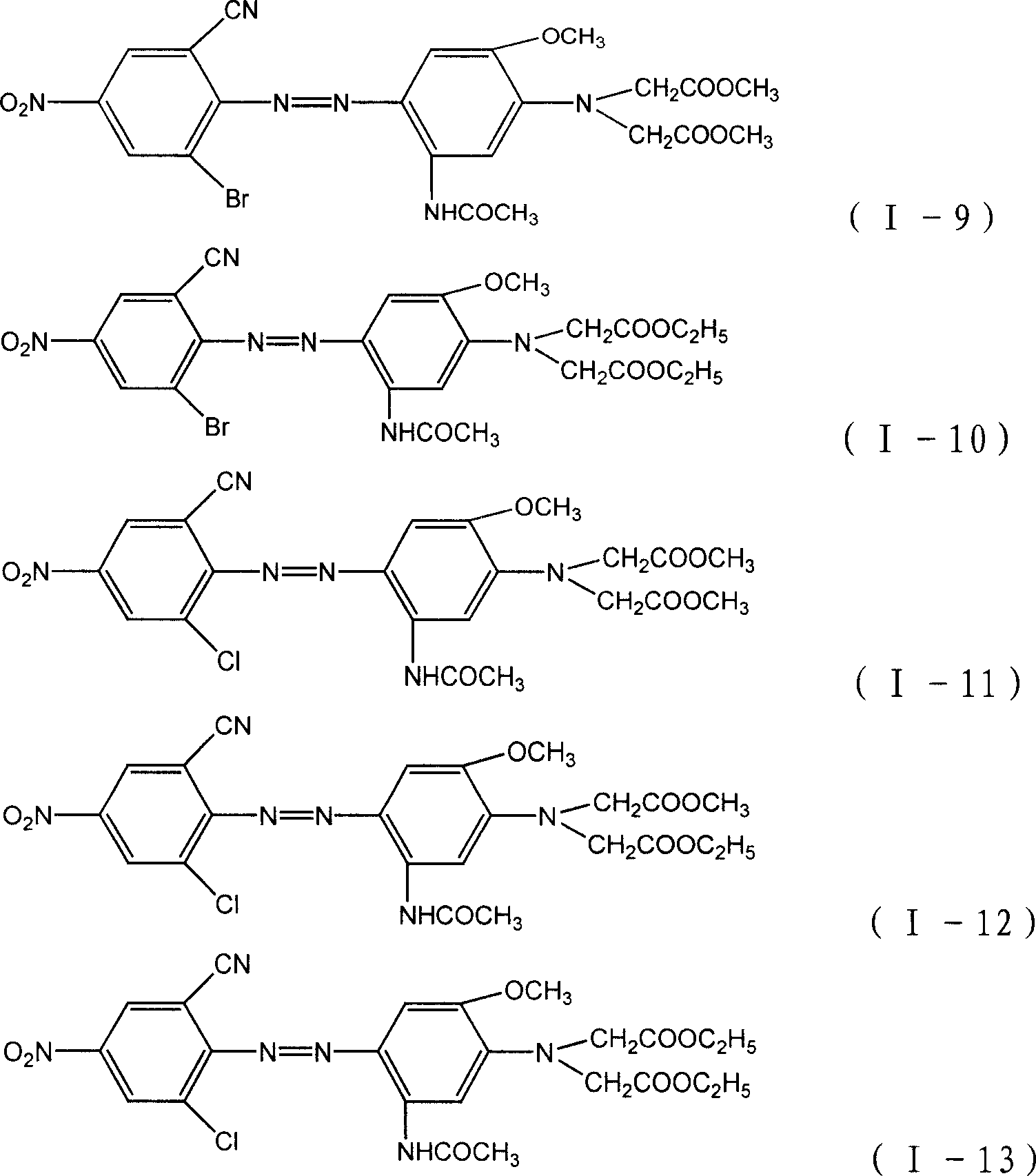

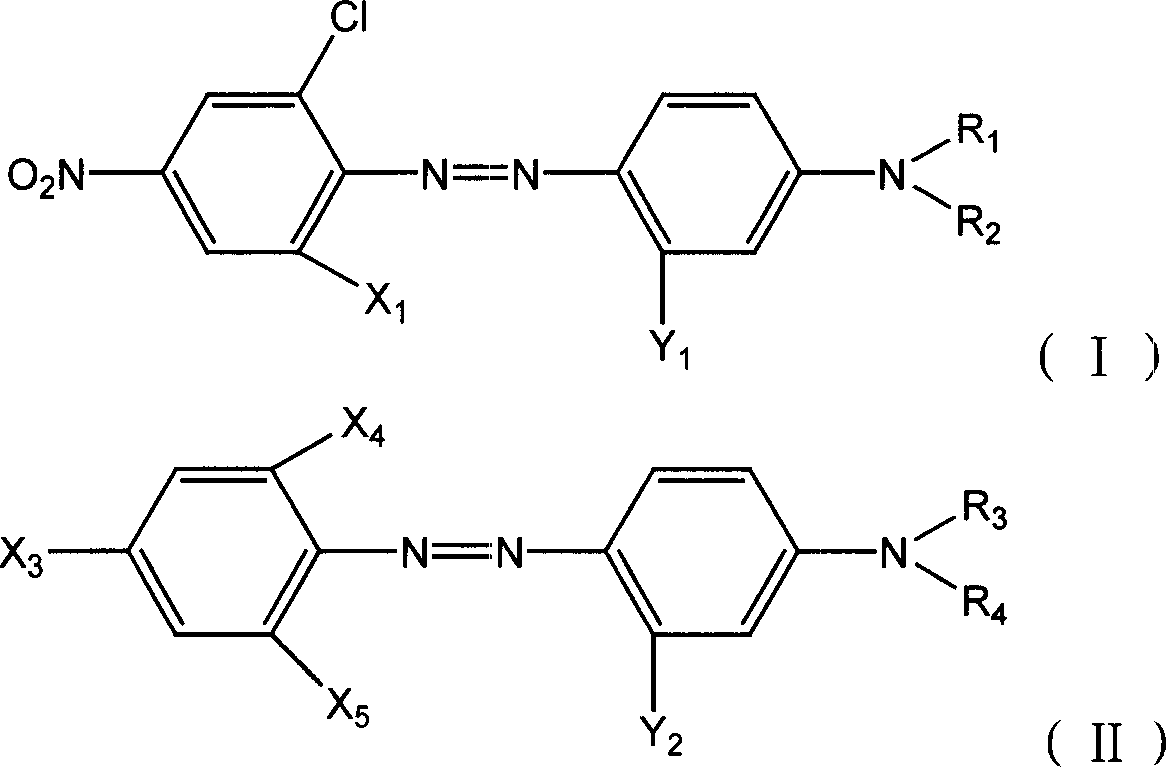

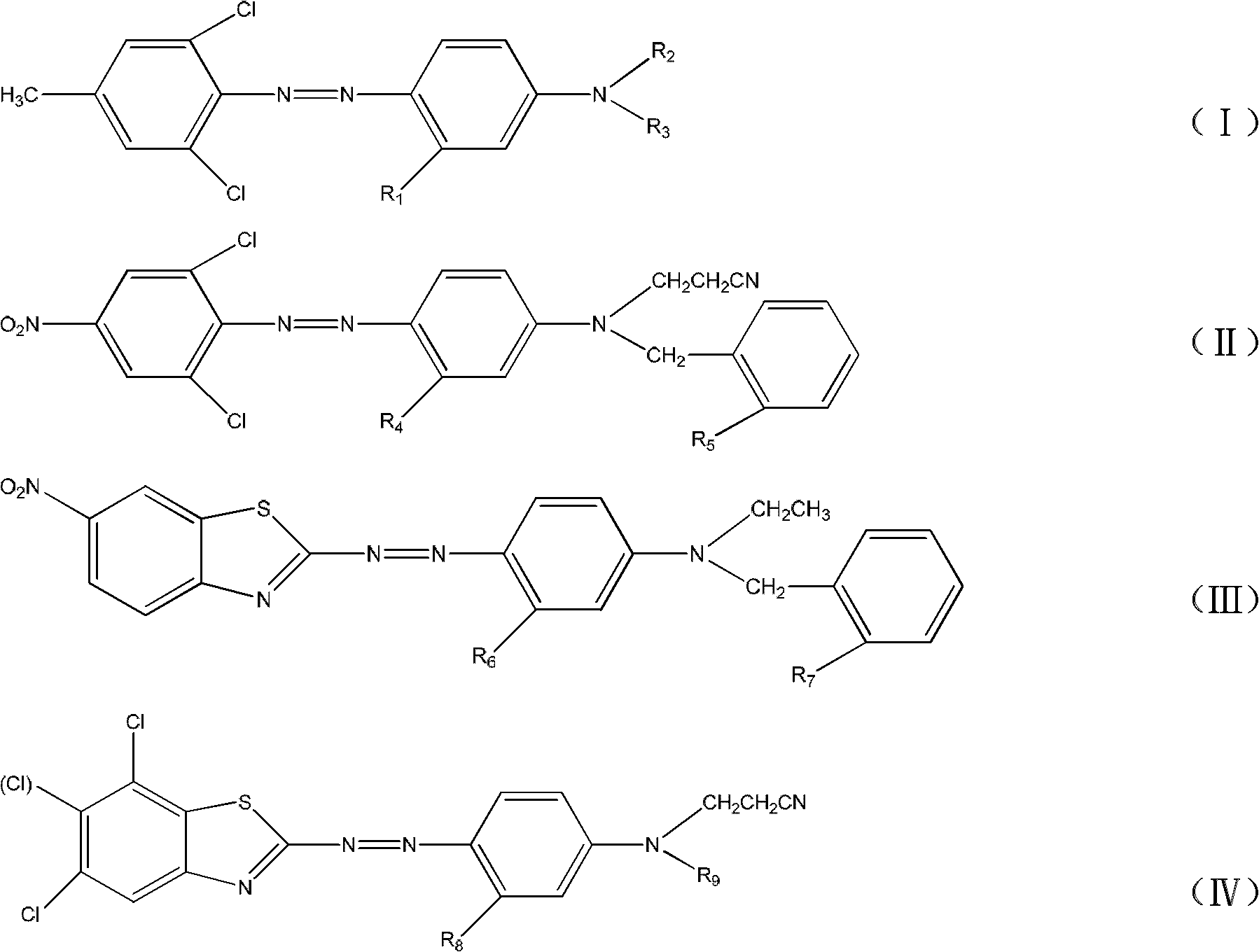

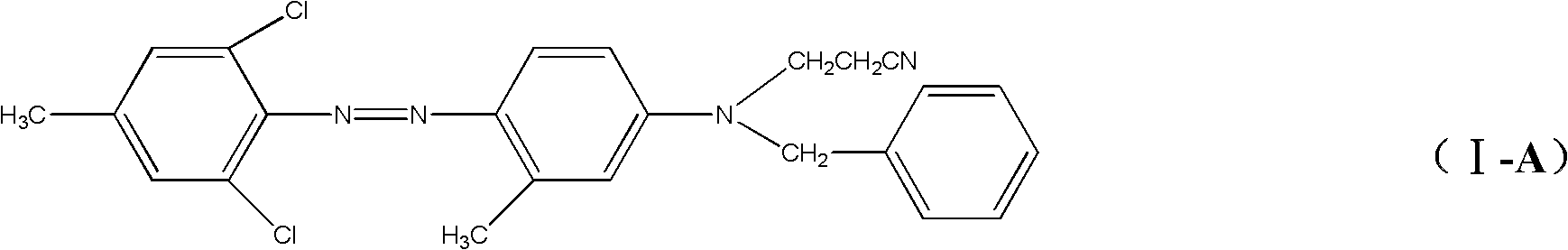

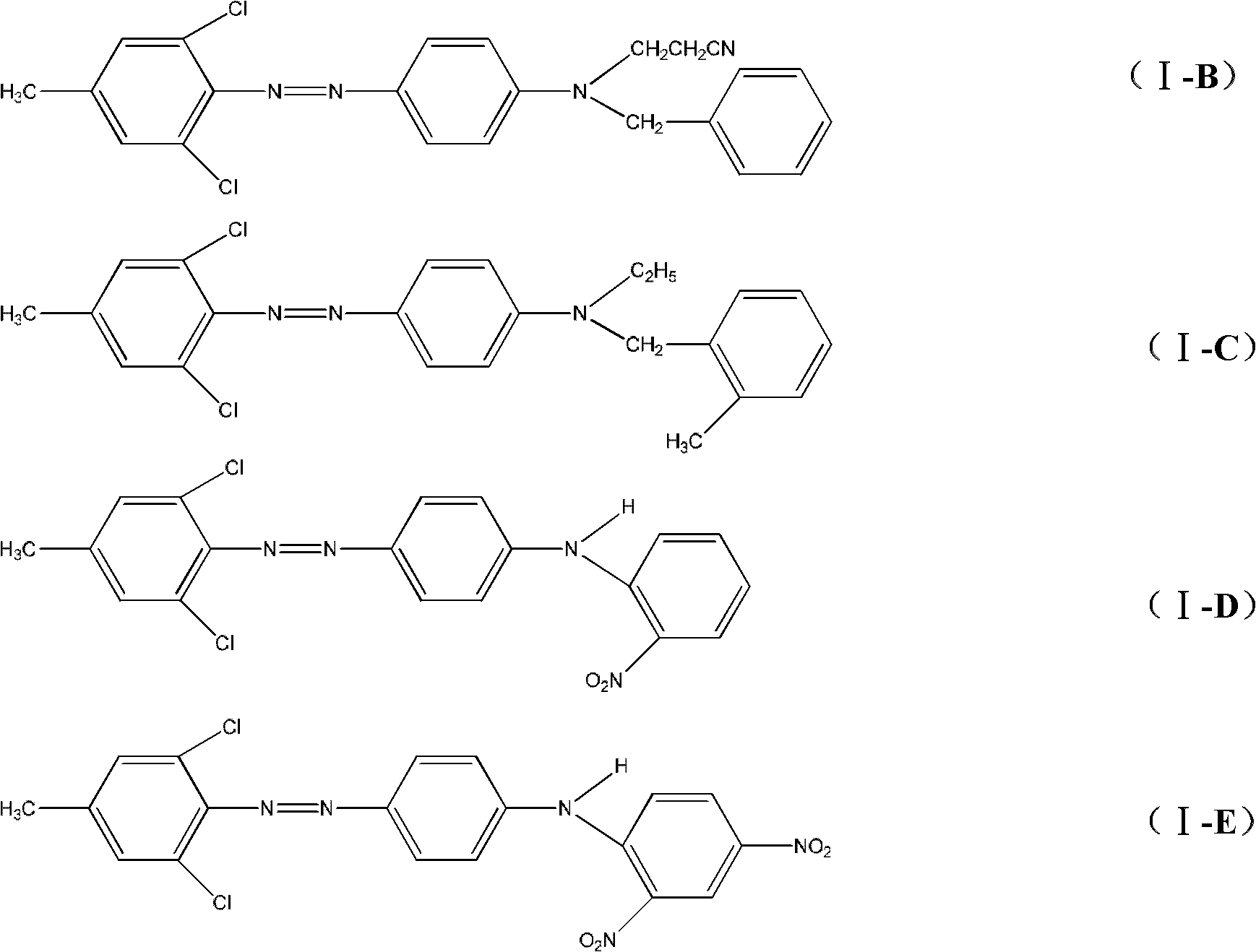

The invention provides a composite black disperse dye, which mainly comprises one or more blue components shown by a structural formula (I), one or more of yellow component B shown by a structural formula (II), one or more blue component C shown by a structural formula (III) and one or more red component D shown by a structural formula (IV), wherein based on the total weight of the components A, B, C and D, the components A account for 30 to 85 percent, the components B account for 1 to 45 percent, the components C account for 1 to 30 percent and the components D account for 1 to 30 percent. When the composite black disperse dye of the invention is used to dye a hydrophobic fiber material, a black dyed fabric which is bright in luster, high in rubbing fastness and desirable in color can be obtained by adjusting the proportion of the components. The composite black disperse dye is economic and environmentally-friendly and has excellent dying performance.

Owner:SHANGYU JINGUAN CHEM IND +2

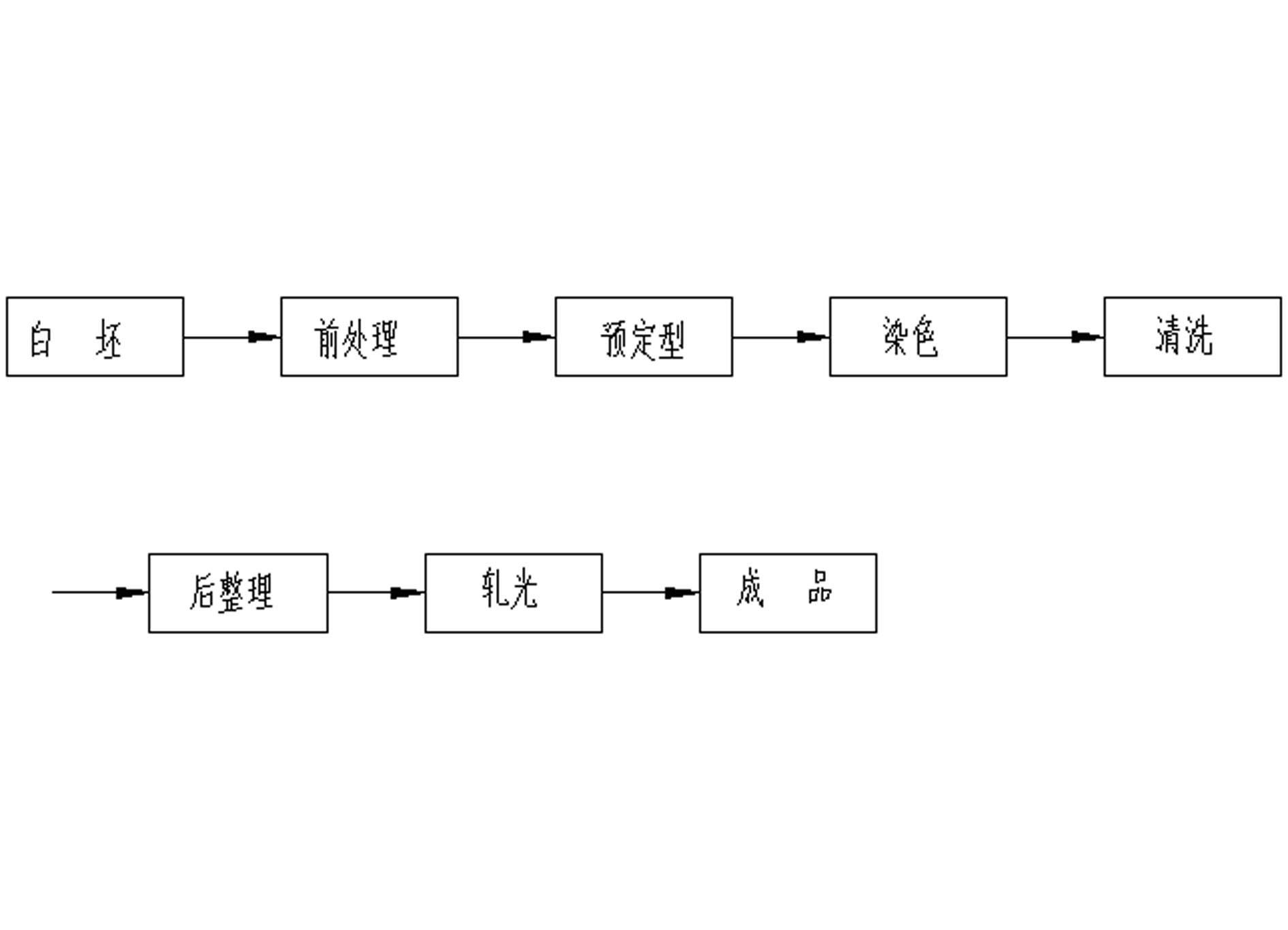

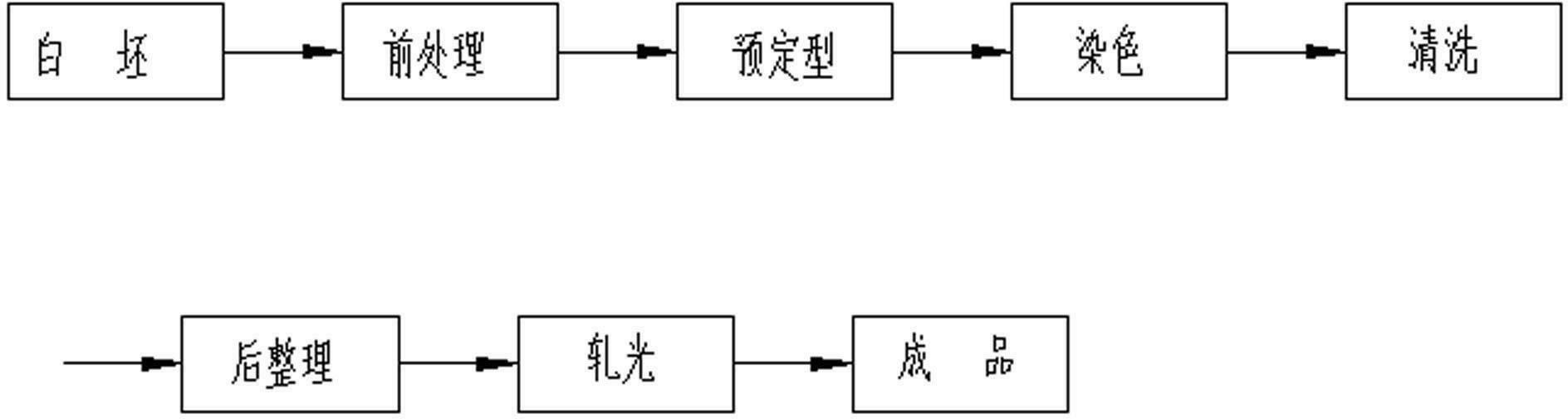

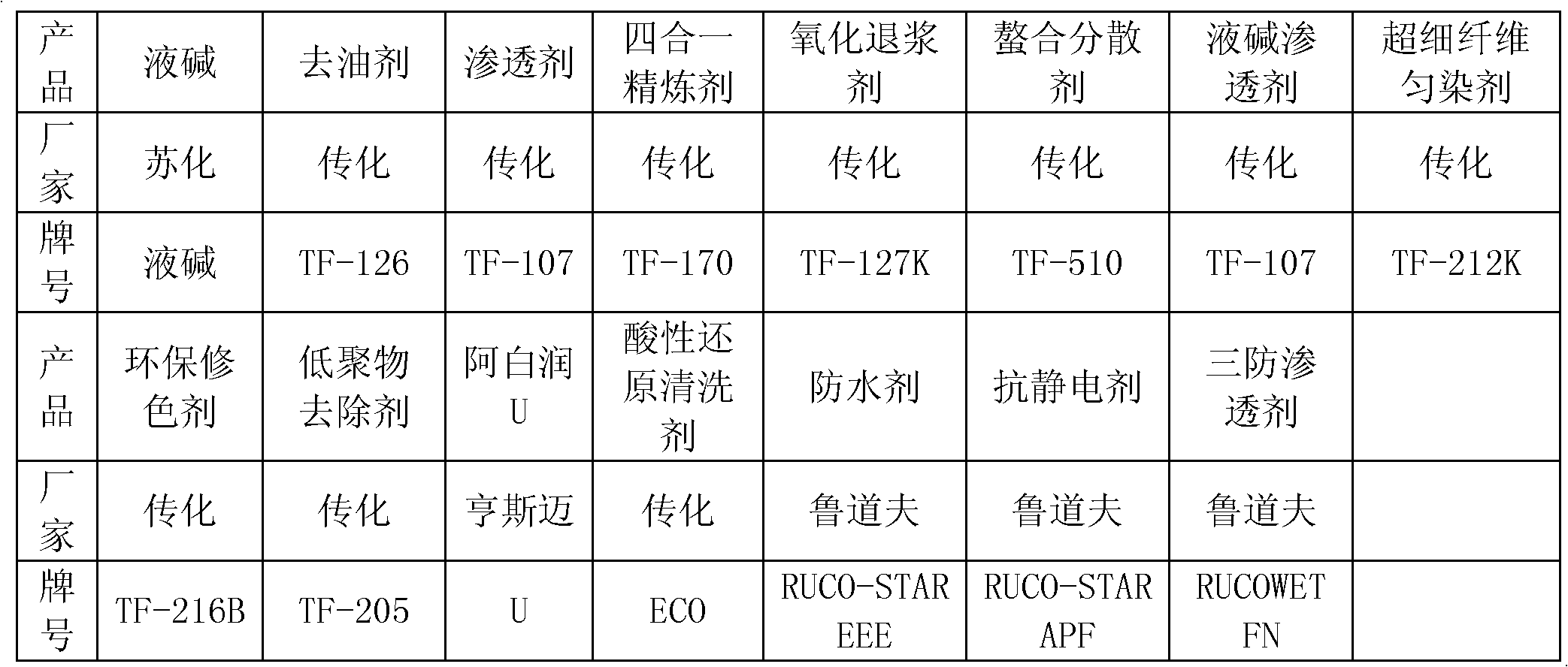

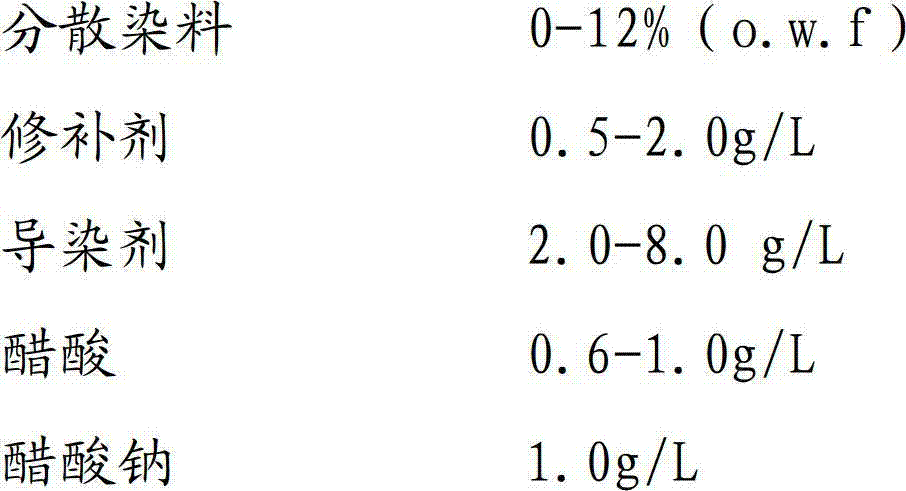

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211AReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnvironmental resistanceDisperse dye

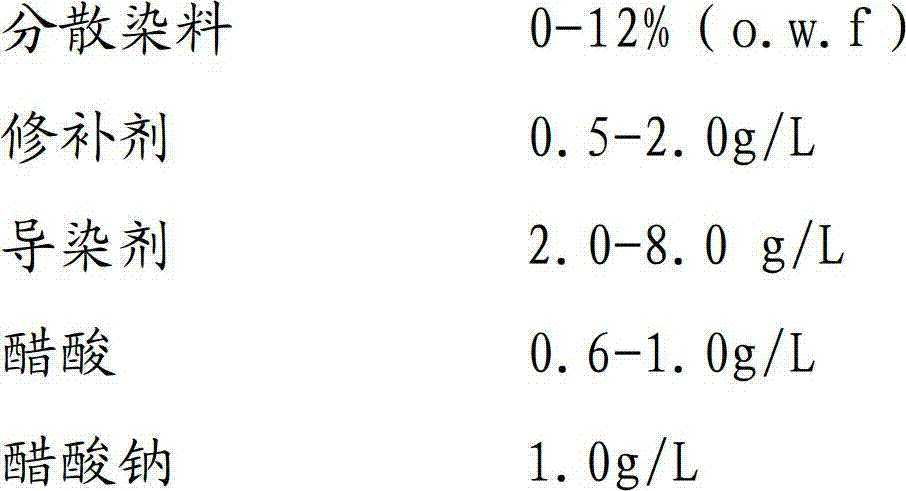

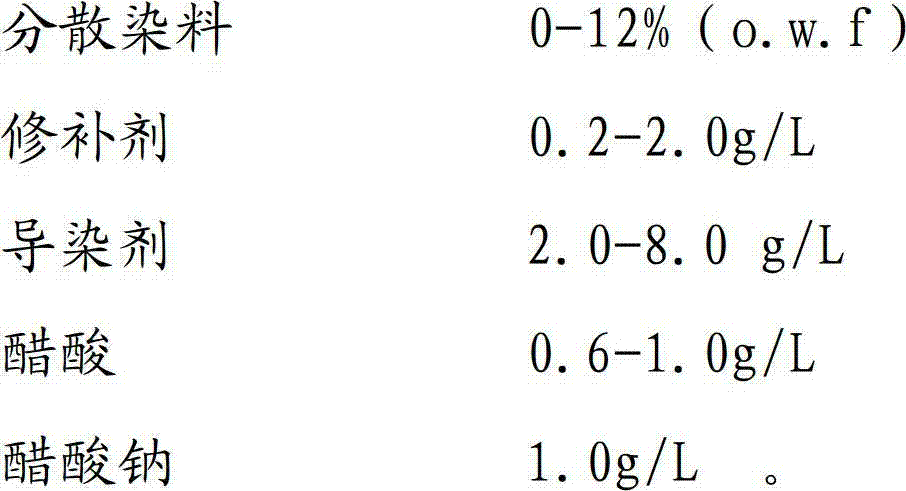

The invention relates to a novel dyeing and finishing processing technology of a micro polyester fabric. The novel dyeing and finishing process disclosed by the invention is characterized by comprising the following steps of: (1) pretreatment, namely carrying out cold rolling and stacking processing comprising three stages, namely cold stacking, hot alkali treatment and high efficiency washing, on polyester gray fabric; (2) presetting, namely carrying out high temperature tentering and presetting on a pretreated fabric white body by utilizing a setting machine; (3) dyeing, namely dyeing the preset fabric white body by adopting superfine fiber leveling agent; and (4) cleaning, namely carrying out cleaning post-processing on the dyed fabric to remove disperse dyes which are not set after fibres are dyed. According to the novel dyeing and finishing processing technology disclosed by the invention, an environment-friendly and low-energy-consumption cold rolling and stacking pretreatment technology is used for carrying out pretreatment on the micro polyester fabric, on one hand, desizing effect is good and good dyeing and finishing processing conditions are provided for dyeing, and on the other hand, crease mark of the fabric can be effectively reduced; meanwhile, a formula of a dyeing process additive can be adjusted, albafluid U is added to reduce fabric dyeing scratch, and dyeing defects can be prevented from being caused.

Owner:SHENGHONG GRP CO LTD

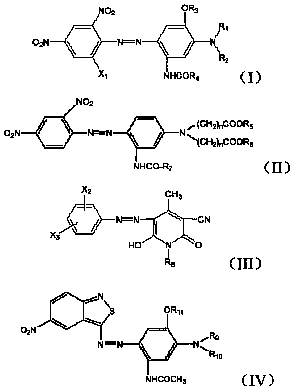

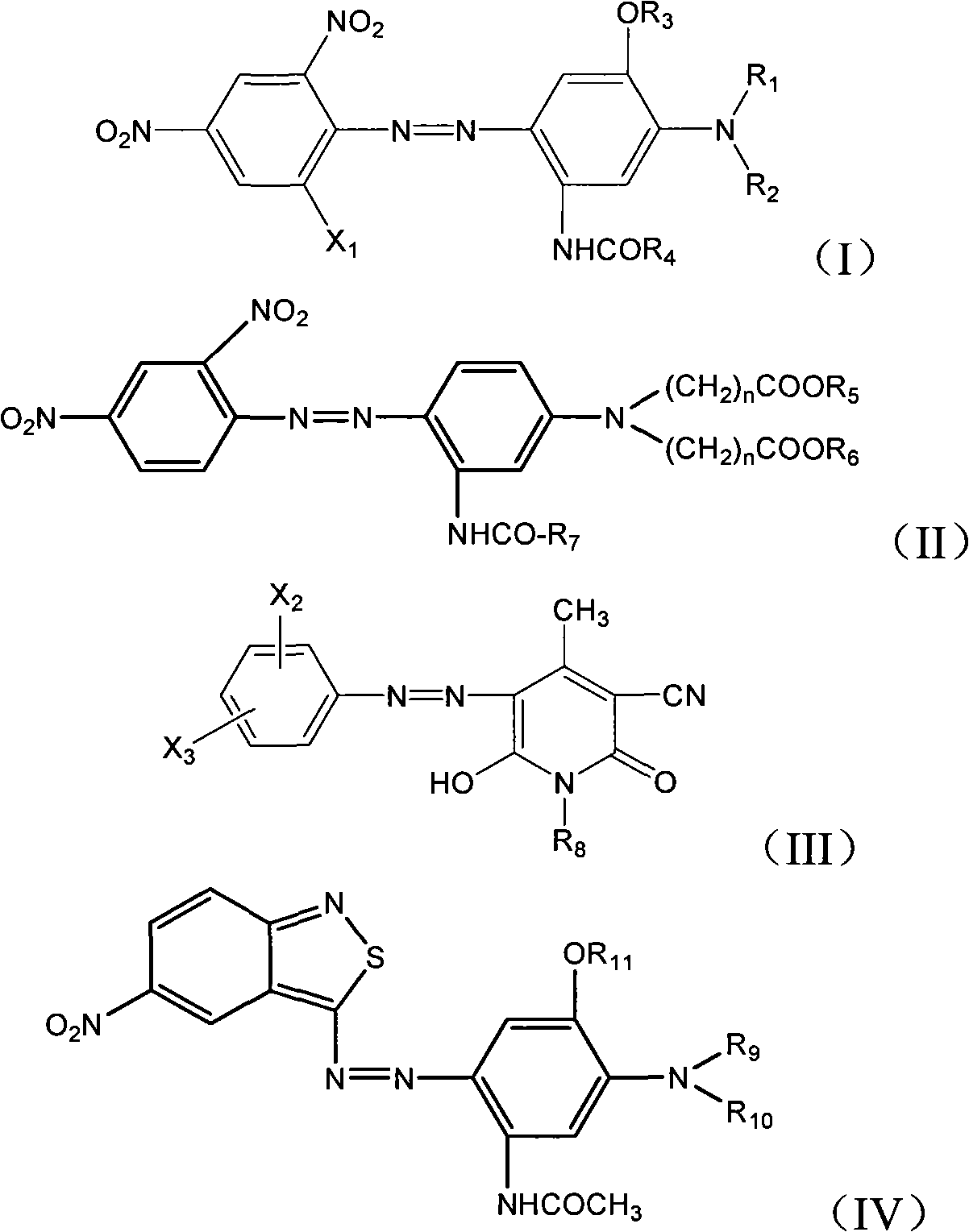

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

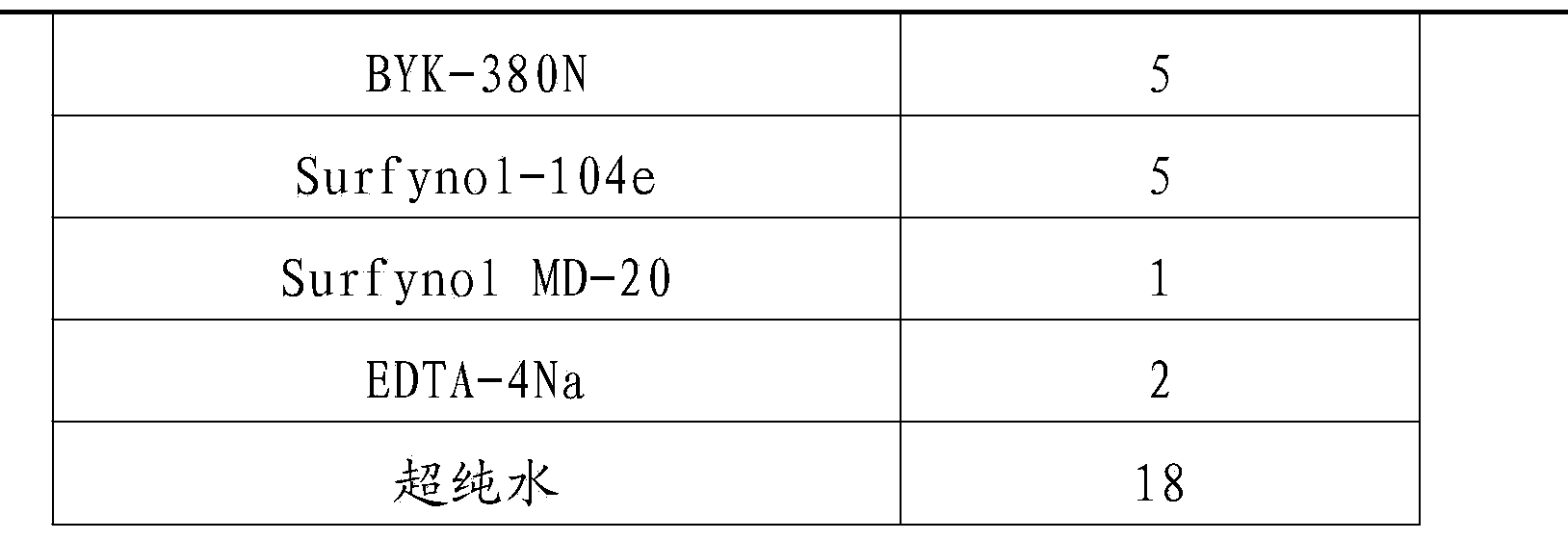

Sublimation ink-jetting ink used for industrial nozzle and manufacturing method thereof

The invention relates to an ink-jetting ink, in particular to a sublimation ink-jetting ink used for an industrial nozzle and a manufacturing method thereof. The sublimation ink-jetting ink comprises, by weight, 1-6% of disperse dyes, 10-14% of wetting agents, 5-20% of viscosity adjusting agents, 0.1-2% of bactericides, 0.01-1% of pH buffering agent, 1-10% of liquid resin, 0.1-40% of disperse agents, 0.01-5% of antifoaming agents, 0.1-5% of surface active agents, 0.01-2% of metal ion chelating agents and 10-80% of purified water. The manufacturing method of the sublimation ink-jetting ink used for the industrial nozzle includes color paste manufacturing and finished product manufacturing. The sublimation ink-jetting ink used for the industrial nozzle is simple in manufacturing method, smooth in ink jetting, free of blocking the nozzle, good in dispersion stability, free of going bad or denaturing even if being stored for a long time and low in cost, and diameters of dispersed ink points are even.

Owner:山东力美喷墨科技有限公司

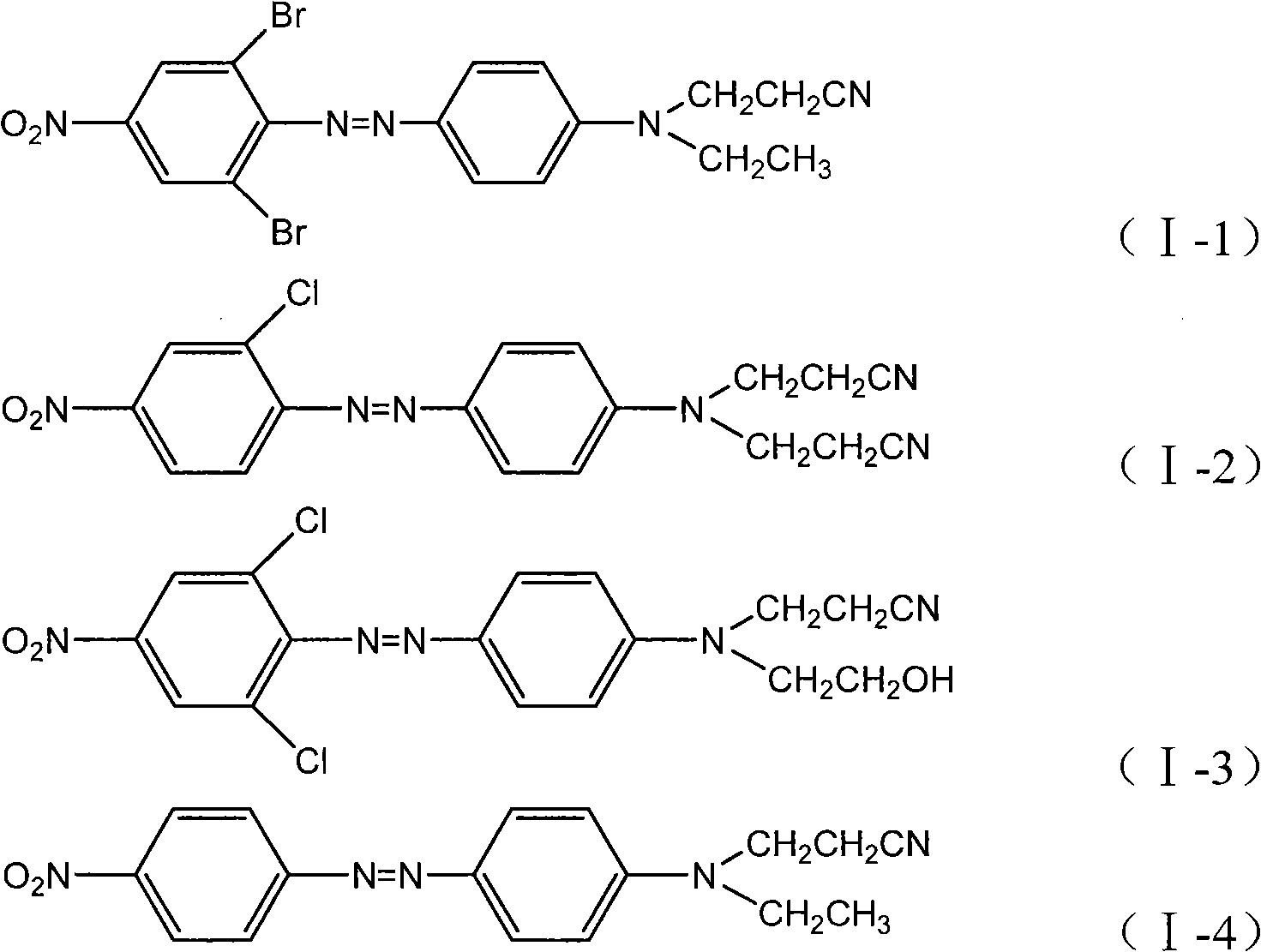

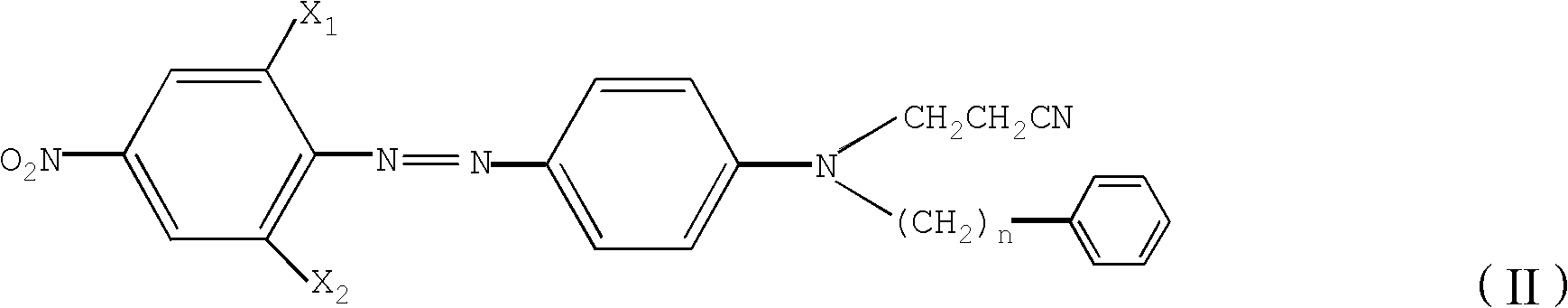

Black disperse dye composition

The invention provides a black disperse dye composition, which mainly comprises: one or more blue components A of which the structure is shown as a formula (I), one or more red components B of which the structure is shown as a formula (II), one or more yellow components C of which the structure is shown as a formula (III) and one or more green components D of which the structure is shown as a formula (IV). Based on the components A, components B, components C and components D, the mass fraction of the components A is 35-85%, the mass fraction of the components B is 1-25%, the mass fraction of the components C is 5-45% and the mass fraction of the components D is 1-35%. When the hydrophobic fiber material is dyed by using the dye prepared from the black disperse dye composition, black fabric with excellent color fastness especially excellent washing fastness after heat treatment can be obtained by adjusting the proportion of different components.

Owner:SHANGYU JINGUAN CHEM IND +2

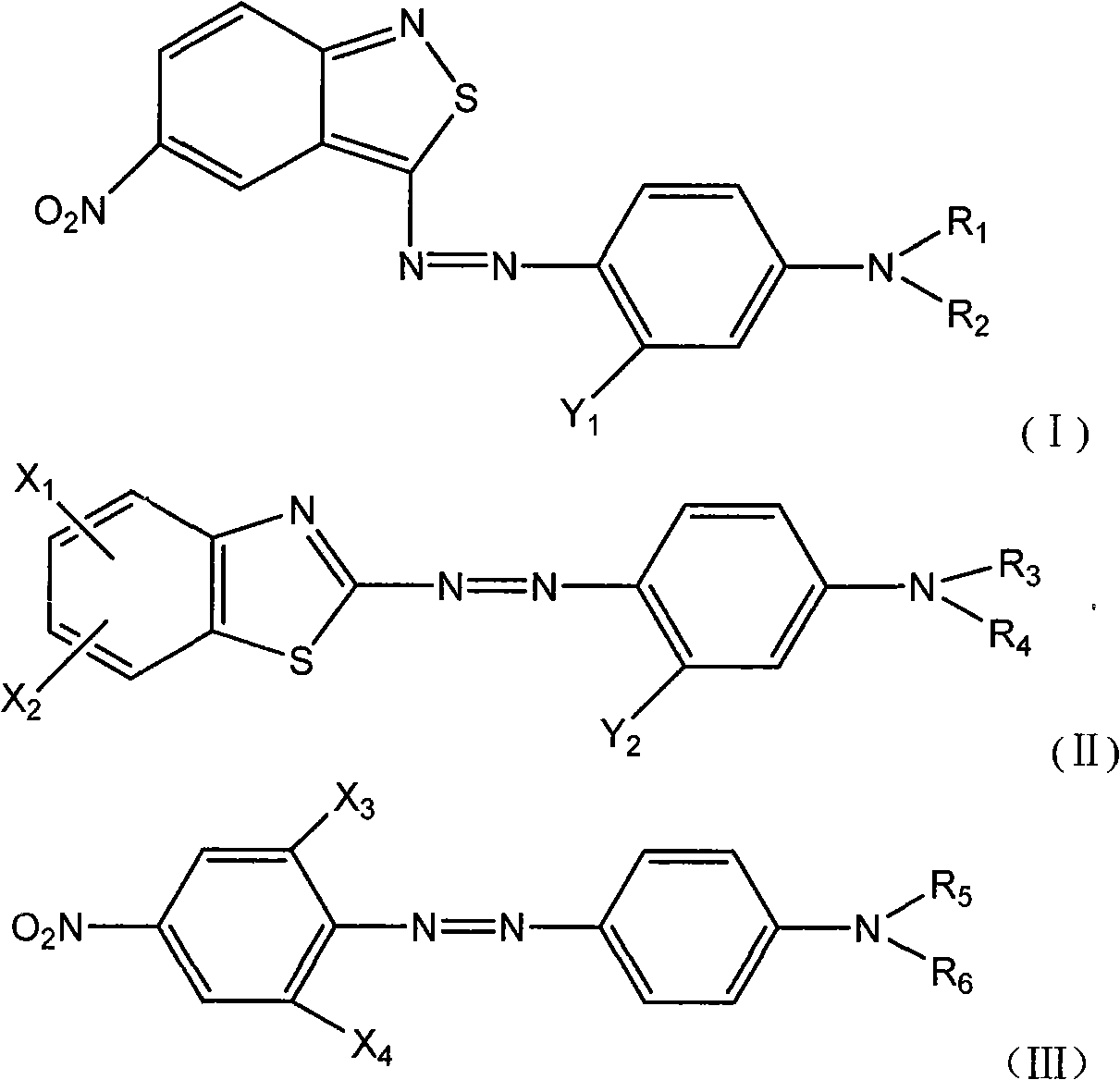

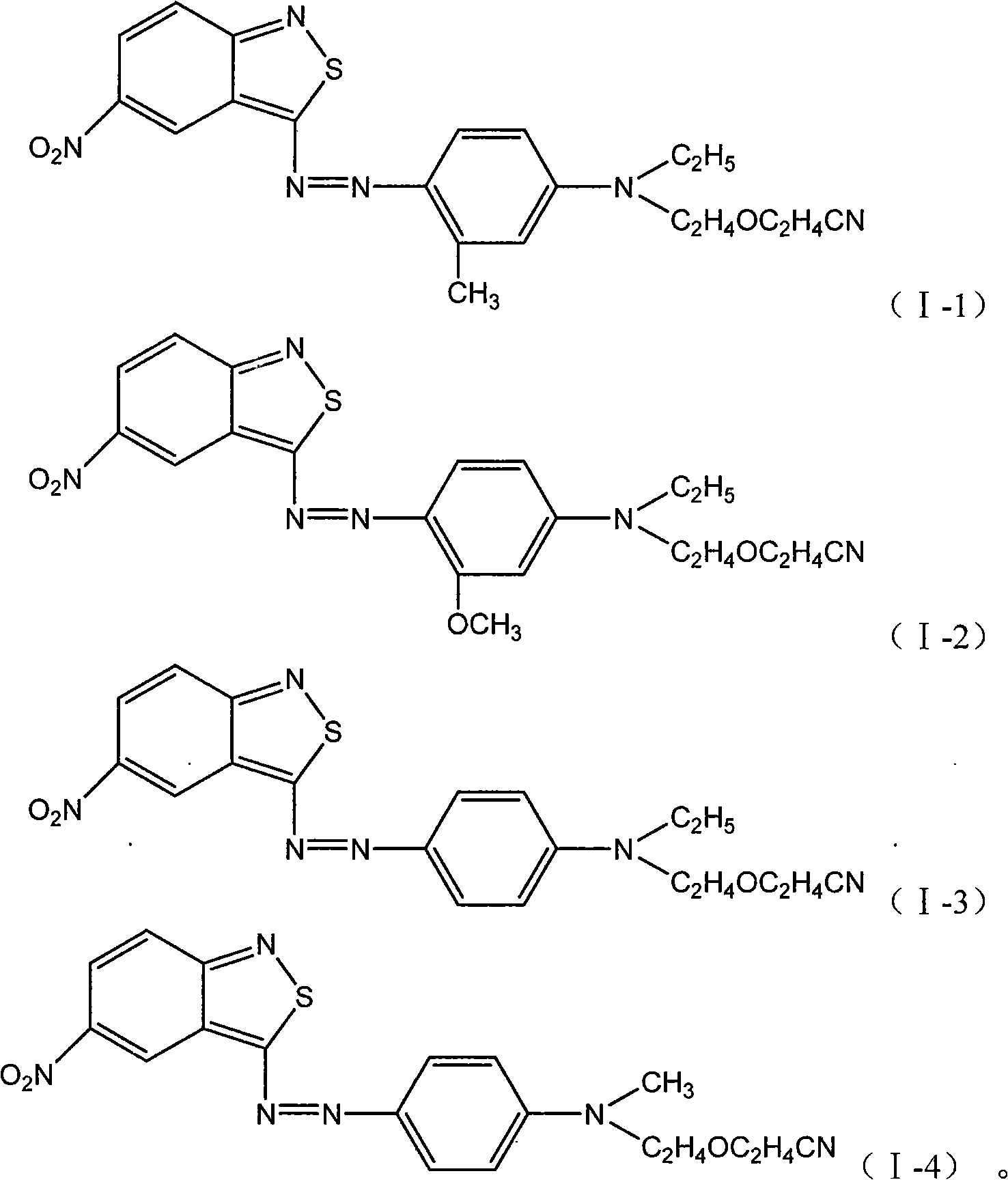

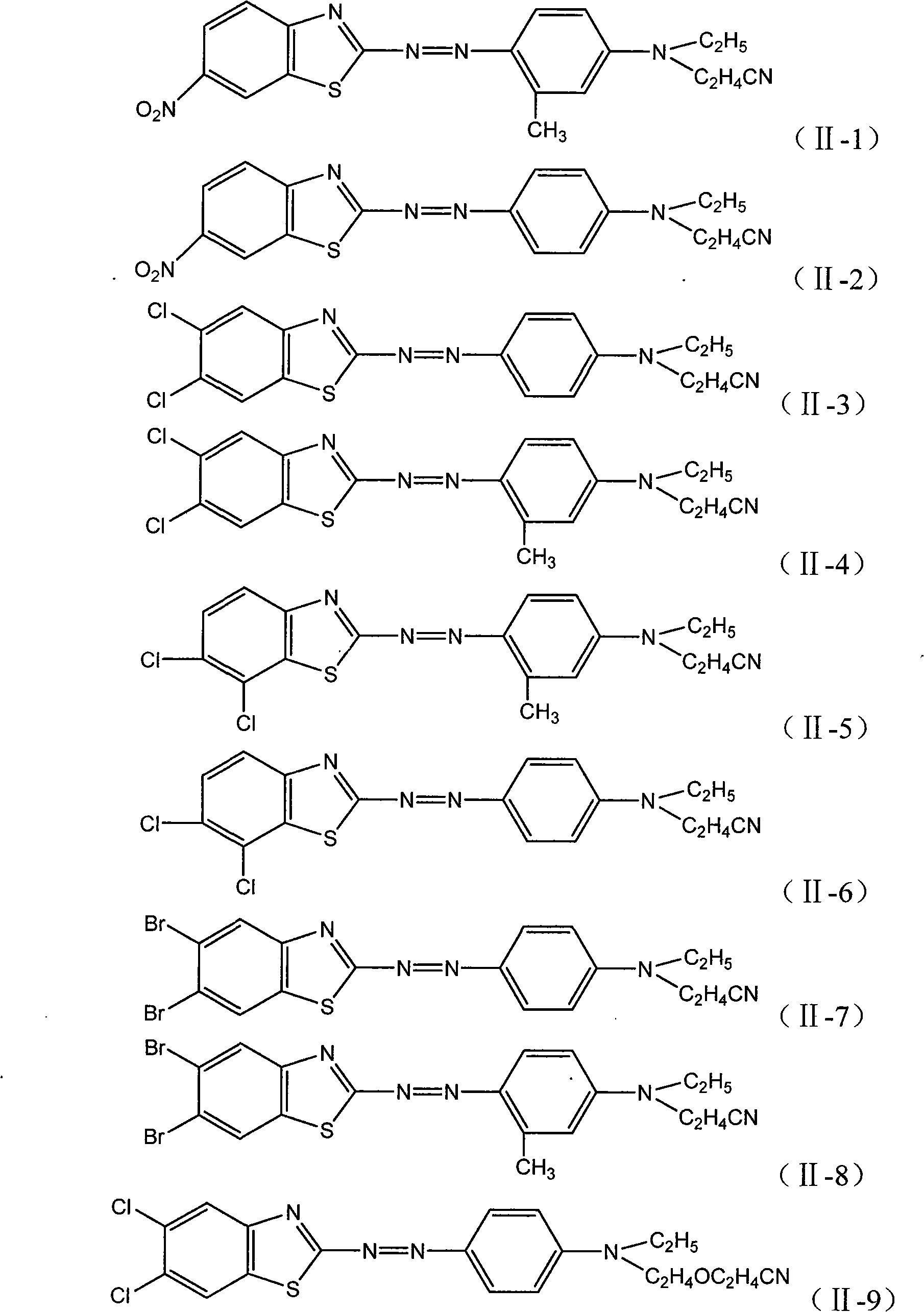

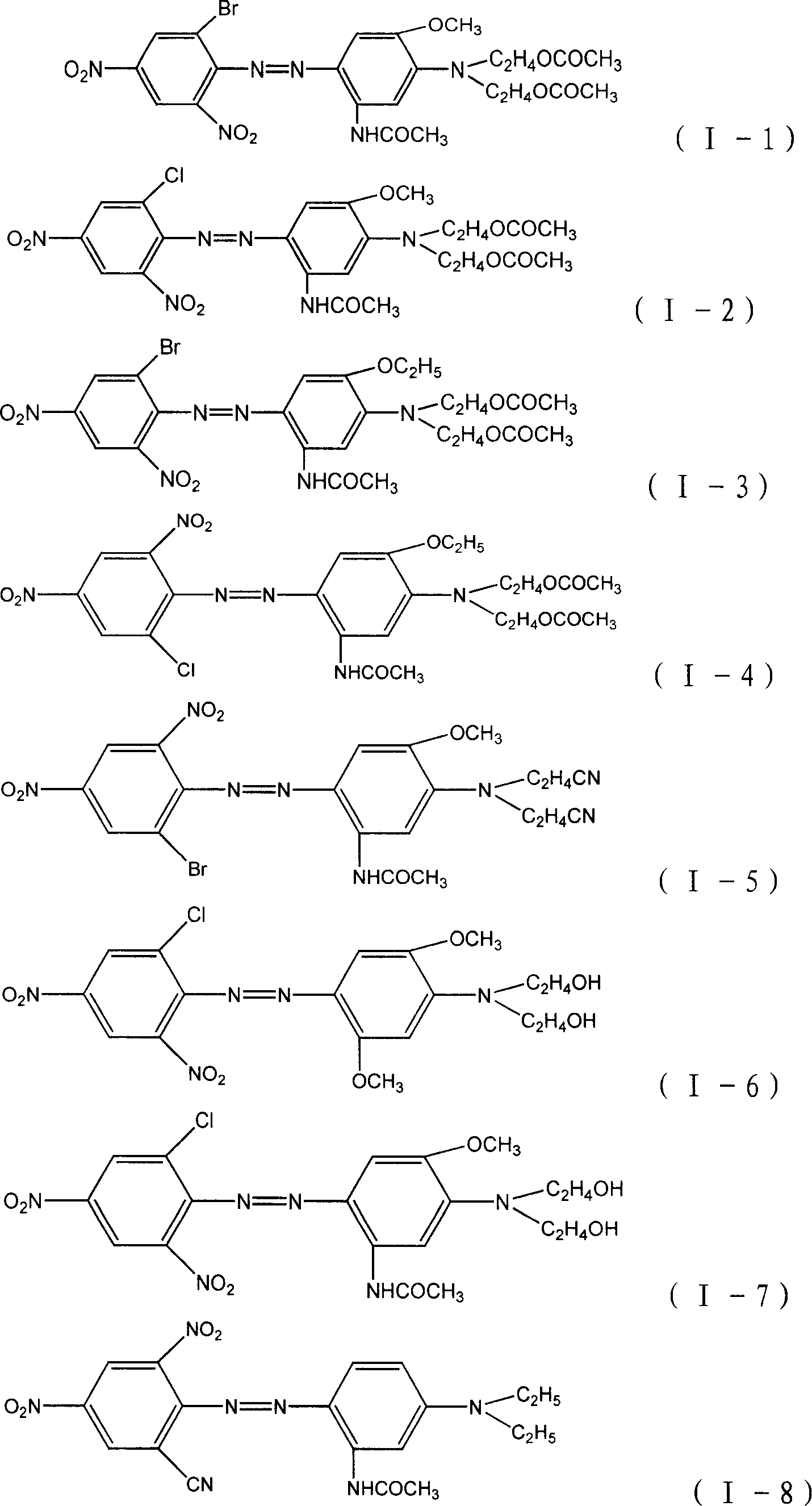

Disperse dye composition and disperse dyes

The invention provides a disperse dye composition and a disperse dye. The compositions comprises at least one component A shown as a formula (I), at least one component B shown as a formula (II) and at least one component C shown as a formula (III), wherein based on the component A, the component B and the component C, the mass percentage of the component A is 1 to 49 percent, the mass percentage of the component B is 50 to 98 percent, the mass percentage of the component C is 1 to 49 percent. The disperse dye composition of the invention can used for dyeing in liquid and paste states after micronization or in powdery and granular states after being dried by spray drying. Disperse dyes made by the formula of the disperse dye composition of the invention allow for adjustment of proportion of different dyes in the dyeing of polyester fiber materials to obtain dyed cloth with colors from deep blue to dark and the obtained dyed cloth has the advantages of bright color, good dispersivity, sun fastness, wash resistance, sweat resistance, etc.

Owner:ZHEJIANG LONGSHENG GROUP +1

Terylene/cotton/chinlon/spandex polycomponent seamless underwear dyeing process

The invention discloses a terylene / cotton / chinlon / spandex polycomponent seamless underwear dyeing process, which belongs to the technical field of pretreatment, dyeing and afterfinish processes of knitgoods. The process comprises the following steps: performing oxygen bleaching refining on cotton and refining oil removal on terylene / cotton / chinlon / spandex according to the prior oxygen bleaching refining and oil removing technological requirements; respectively adding various dyes and auxiliary agents to perform one-bath dyeing on the terylene / the cotton / the chinlon / the spandex; and finally performing softening treatment according to the prior softening treatment technological requirements, wherein the dyes and the auxiliary agents consist of a dispersing dye, a high-temperature neutral fixing reactive dye, a weak acidic or neutral dye, a chelating dispersant, sodium sulfate, a disperse leveling agent, a pH regulator P-7 and the like. The process reasonably selects the low-temperature dispersing dye and the high-temperature neutral fixing reactive dye, adopts one-bath process for dyeing, shortens the process flow and the dyeing time, reduces the using amount of steam and water, reduces pollution discharge, improves the production efficiency, and reduces the dyeing cost.

Owner:ZHEJIANG QIAOERTINGTING FASHION

Polyester chip modified by blend with side chain aliphatic diol and preparation method thereof

InactiveCN102120816ALow costEase of industrial productionMonocomponent polyesters artificial filamentDisperse dyeSide chain

The invention relates to a polyester chip modified by the blend with side chain aliphatic diol and a preparation method thereof. The polyester chip is copolymerized by the following monomers: (1) terephthalic acid; (2) ethylene glycol; (3) sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (4) the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol. The preparation method comprises the following steps: adding terephthalic acid and ethylene glycol in a first esterification kettle, adding catalyst and stabilizer simultaneously to perform esterification reaction, transferring the material to a second esterification kettle, injecting the blend of 2-methyl-1,3-propanediol and 2,2-dimethyl-1,3-propanediol to perform esterification with sodium or potassium 5-sulfoisophthalic acid dibasic ester; and (2) transferring the material to a polycondensation kettle, discharging, pelletizing and drying. The modified polyester chip of the invention is used to prepare the cationic or disperse dye atmospheric deep dyeing copolyester fiber; and the method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

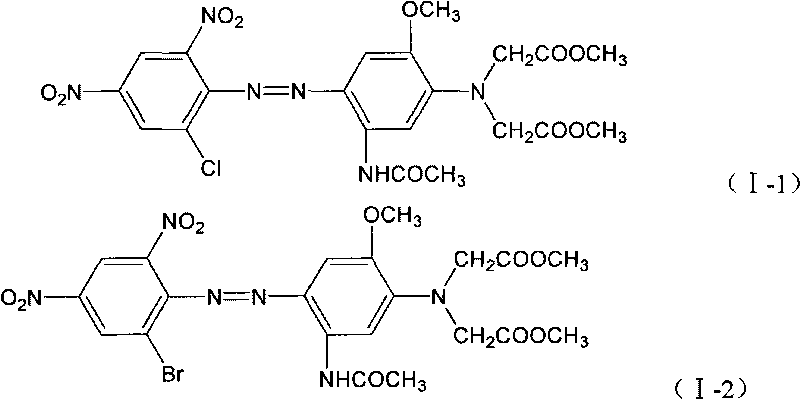

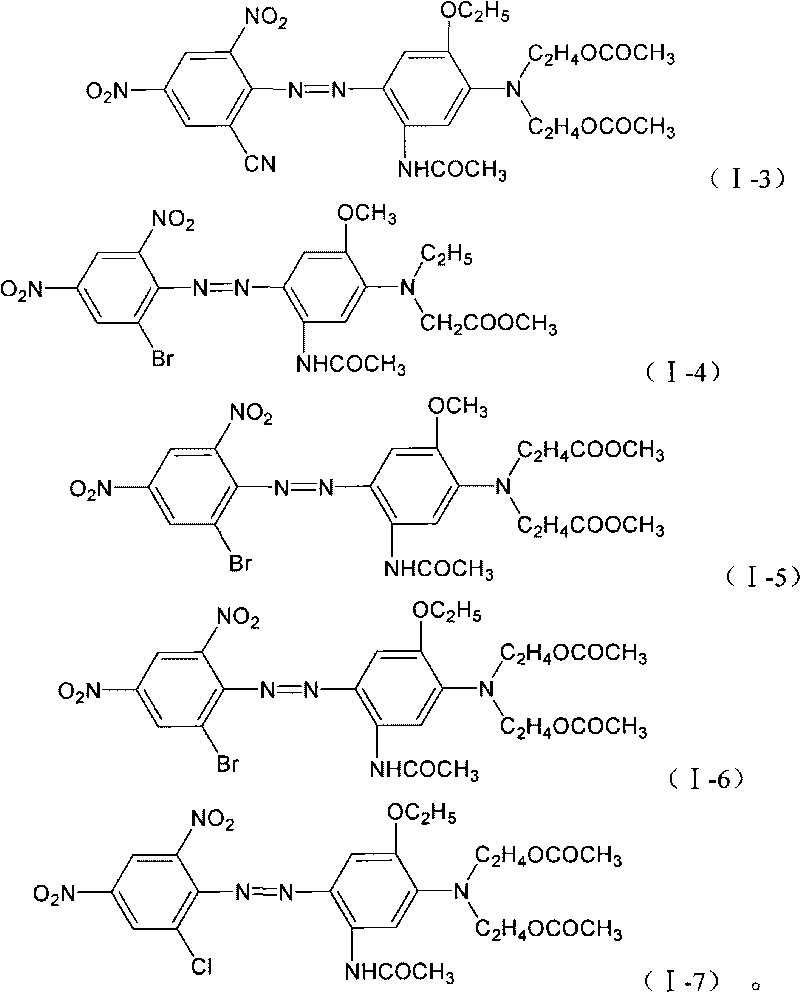

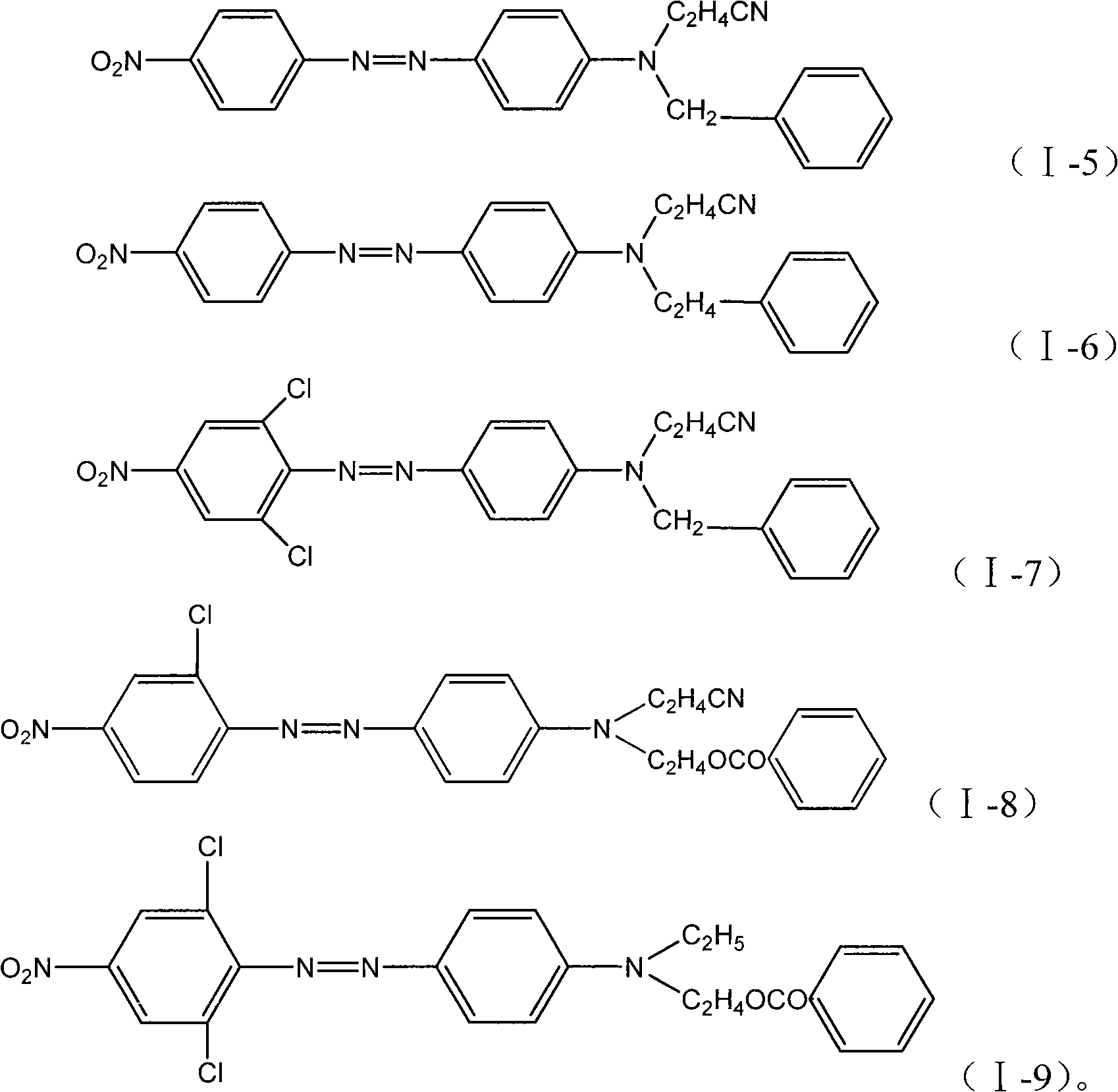

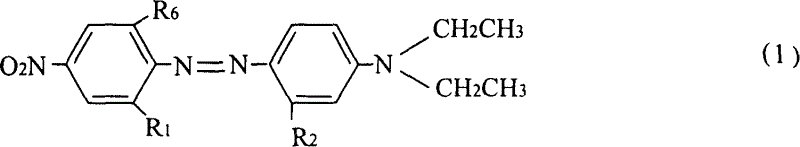

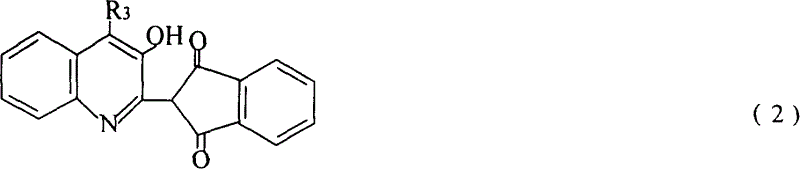

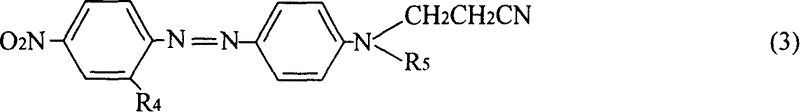

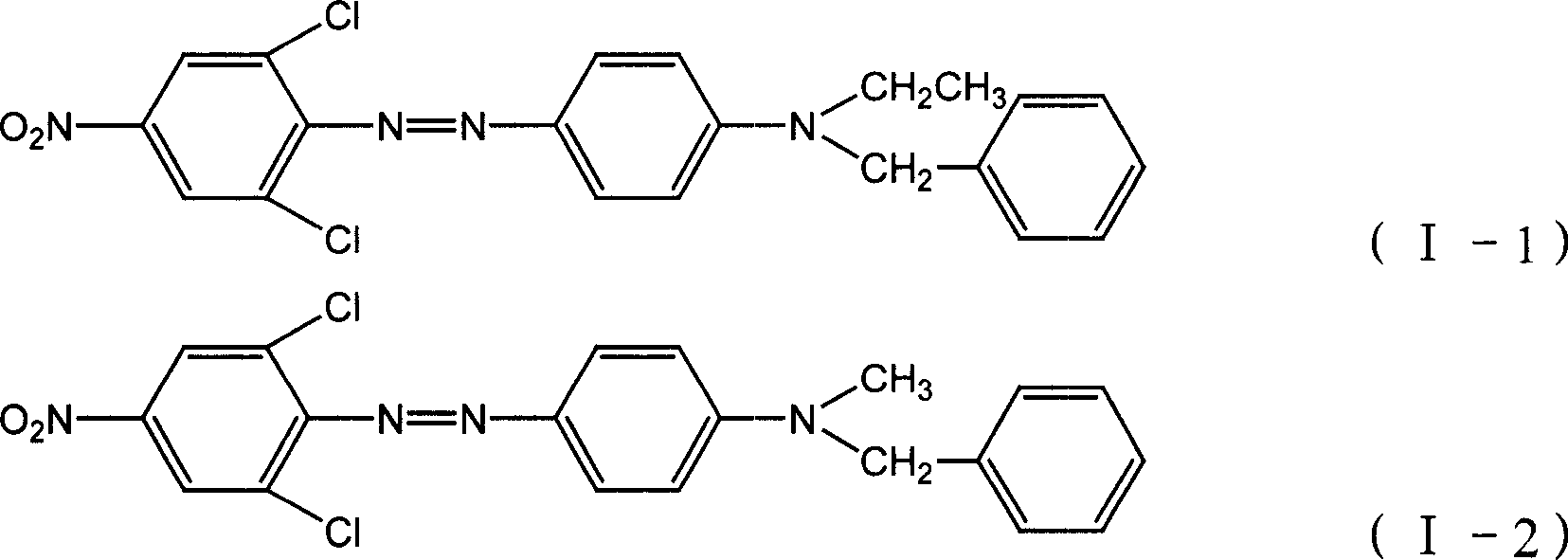

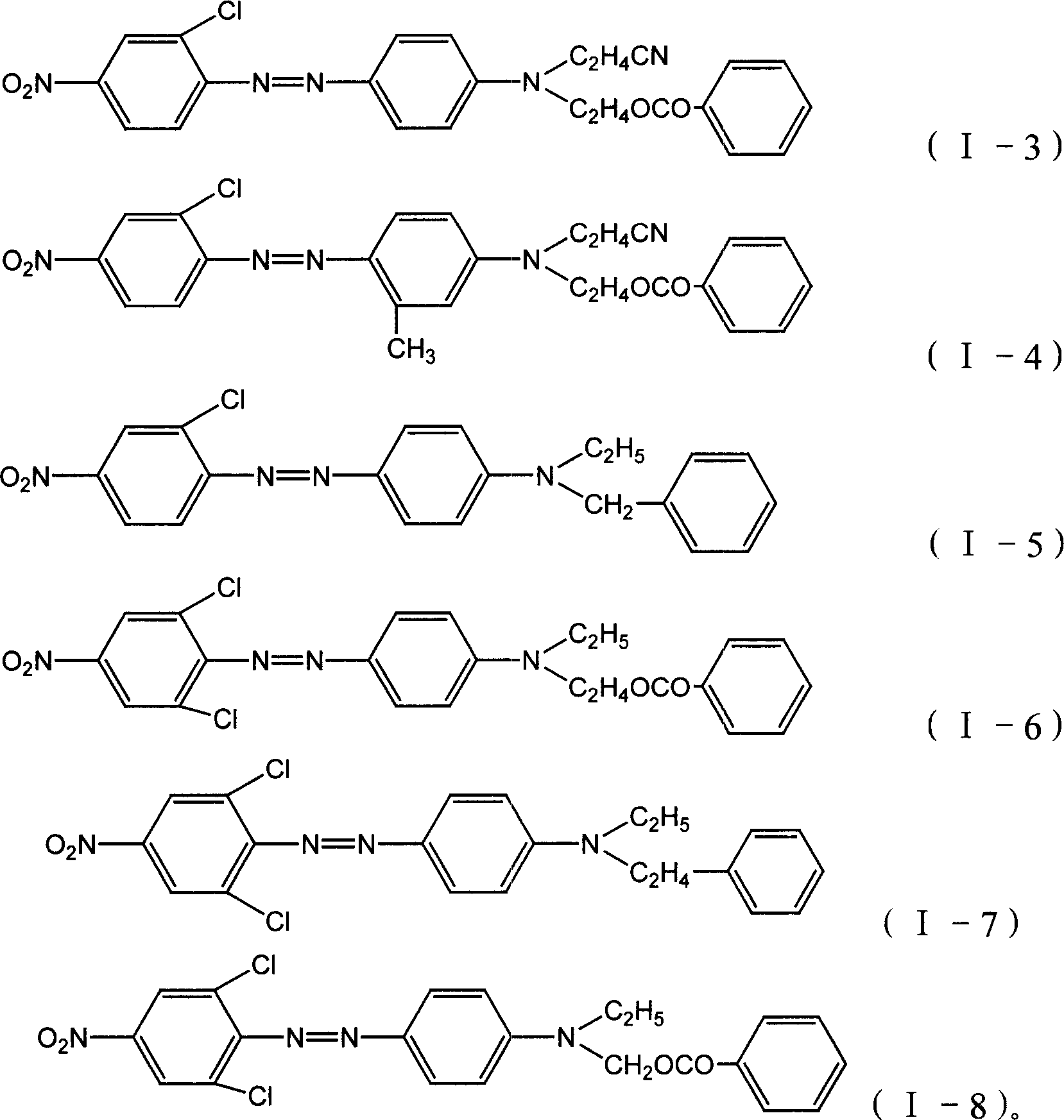

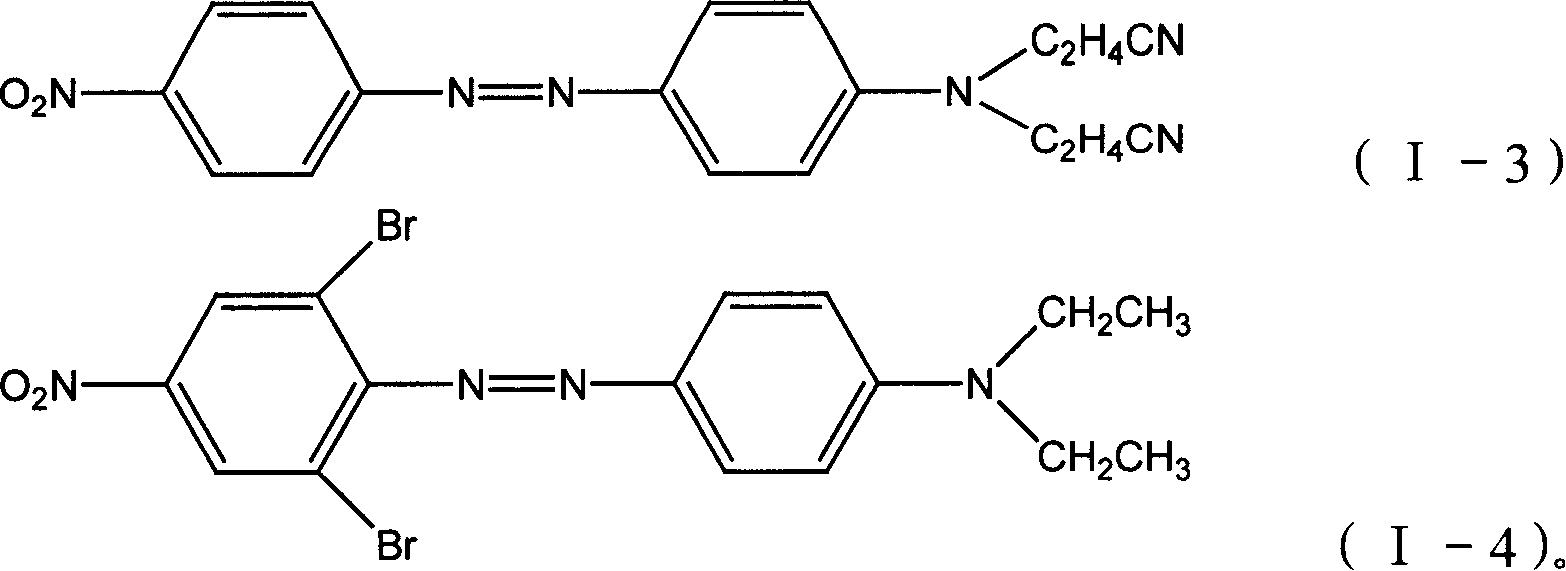

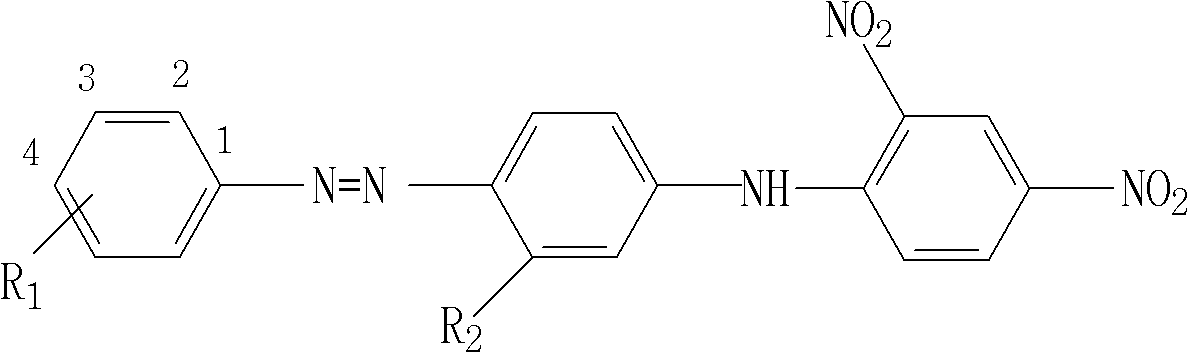

Azo dye composition and application thereof

ActiveCN101265369AChromatography is completeBright shadeOrganic dyesDyeing processAlkalinityDisperse dye

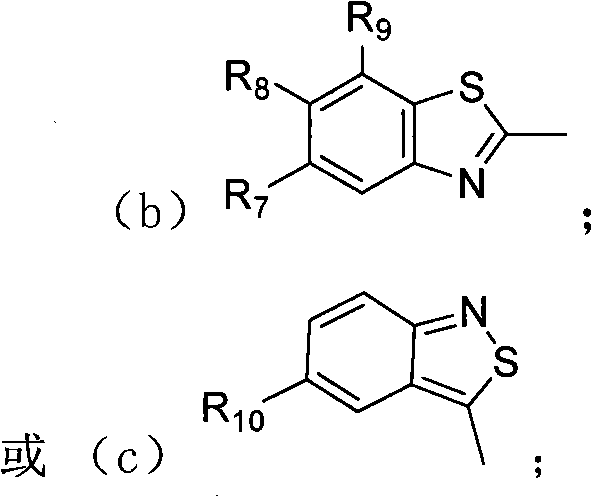

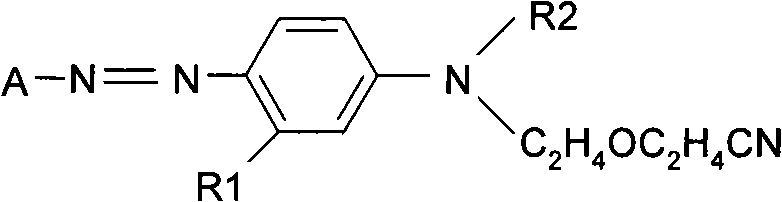

The invention relates to an azo dye compound and the application thereof. The compound is the combination of at least two dyes with A in the general formula (I) selected from any structure of (a), (b) or (c); any combination with A to be at least one from (a), at least one from (b) or at least one from (c); or the combination of at least one dye shown by the general formula (1) and at least one general disperse dye, or / and a dye as shown by the formula (2). Each substituent is shown as the claim of right. The compound can dye polyester and blended fabric thereof under the condition of strong alkalinity with pH more than or equal to 11 and less than or equal to 14; the alkalinity condition can effectively remove slurry and oil on the fabric, and overcomes the defect that decomposition products can be separated out in an acid bath, and cause dyeing defect. The cloth and the fabric adopting the azo dye compound are neat and have excellent styles. In addition, the polyester fiber and the blended fabric thereof can be pretreated with alkalinity and be dyed in a bath and at one step, thus improving the efficiency, and reducing the manufacturing cost and the waste water from dyeing.

Owner:浙江昱泰染化科技有限公司

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

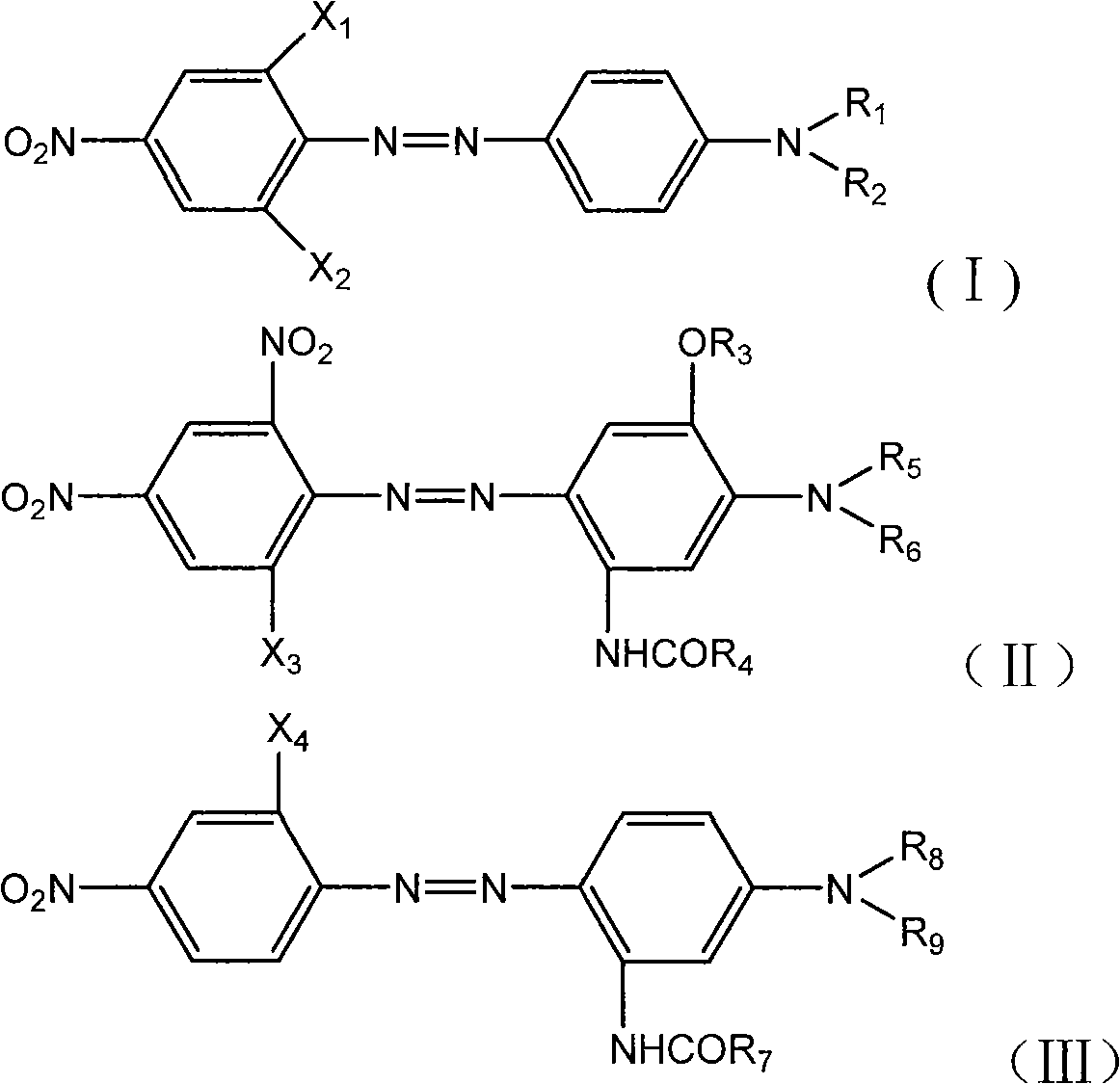

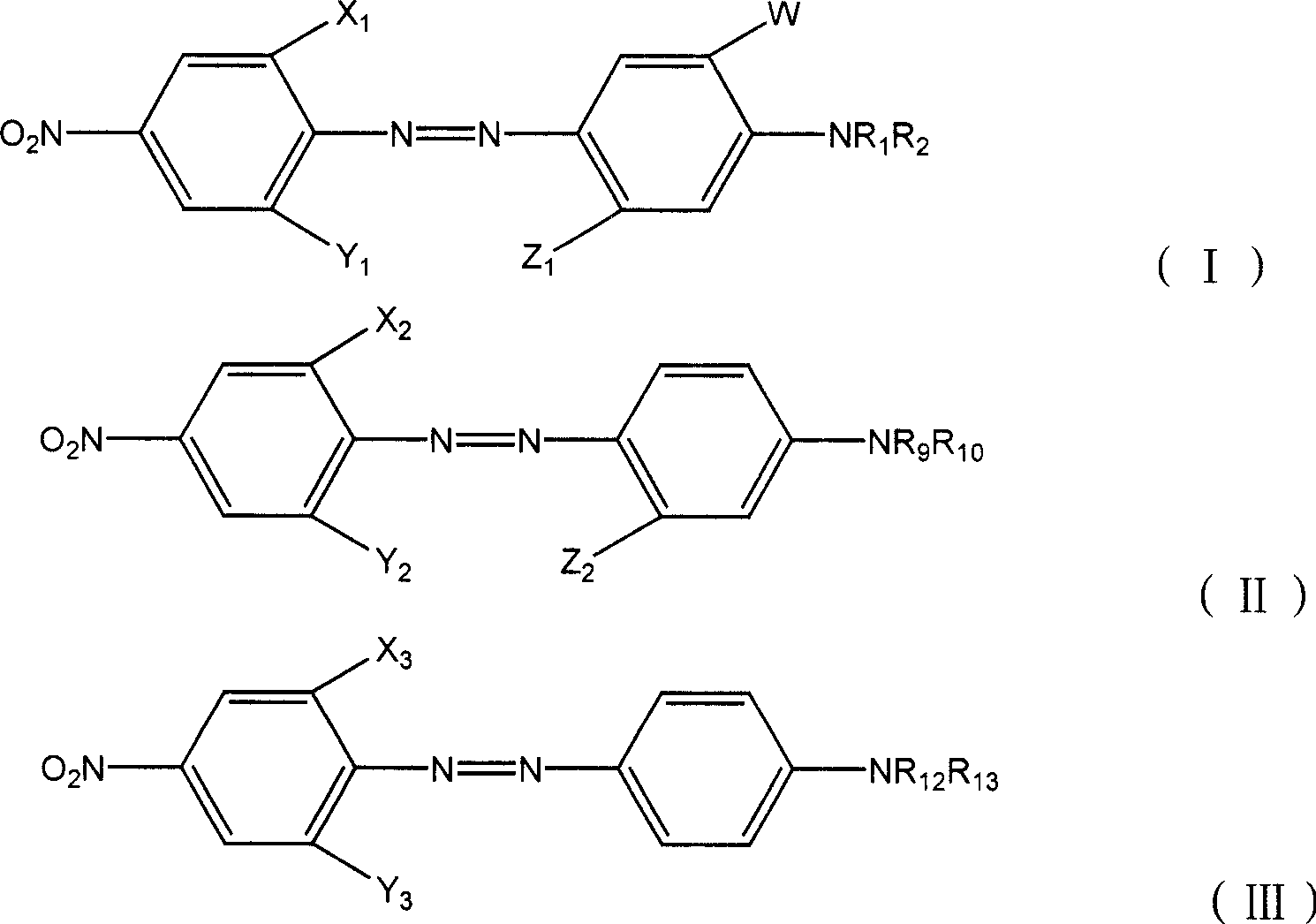

Black-blue disperse dye composition

The invention discloses a black-blue disperse dye composition, which comprises the following components in percentage by weight: 53 to 91 percent of component A, 5 to 46 percent of component B and 0 to 5 percent of component C, wherein the component A is one or more of components expressed in a formula (I), the component B is one or more of components expressed in a formula (II), and the component C is one or more of components expressed in a formula (III). The black-blue disperse dye composition has the advantages of good compatibility, good coverage, high dyeing rate, good dyeing depth and excellent fastnesses such as sunlight resistant fastness, friction resistant fastness, sublimation resistant fastness and the like, and particularly the washing fastness is obviously improved; and the composition is convenient to use and has good market prospect.

Owner:ZHEJIANG RUNTU

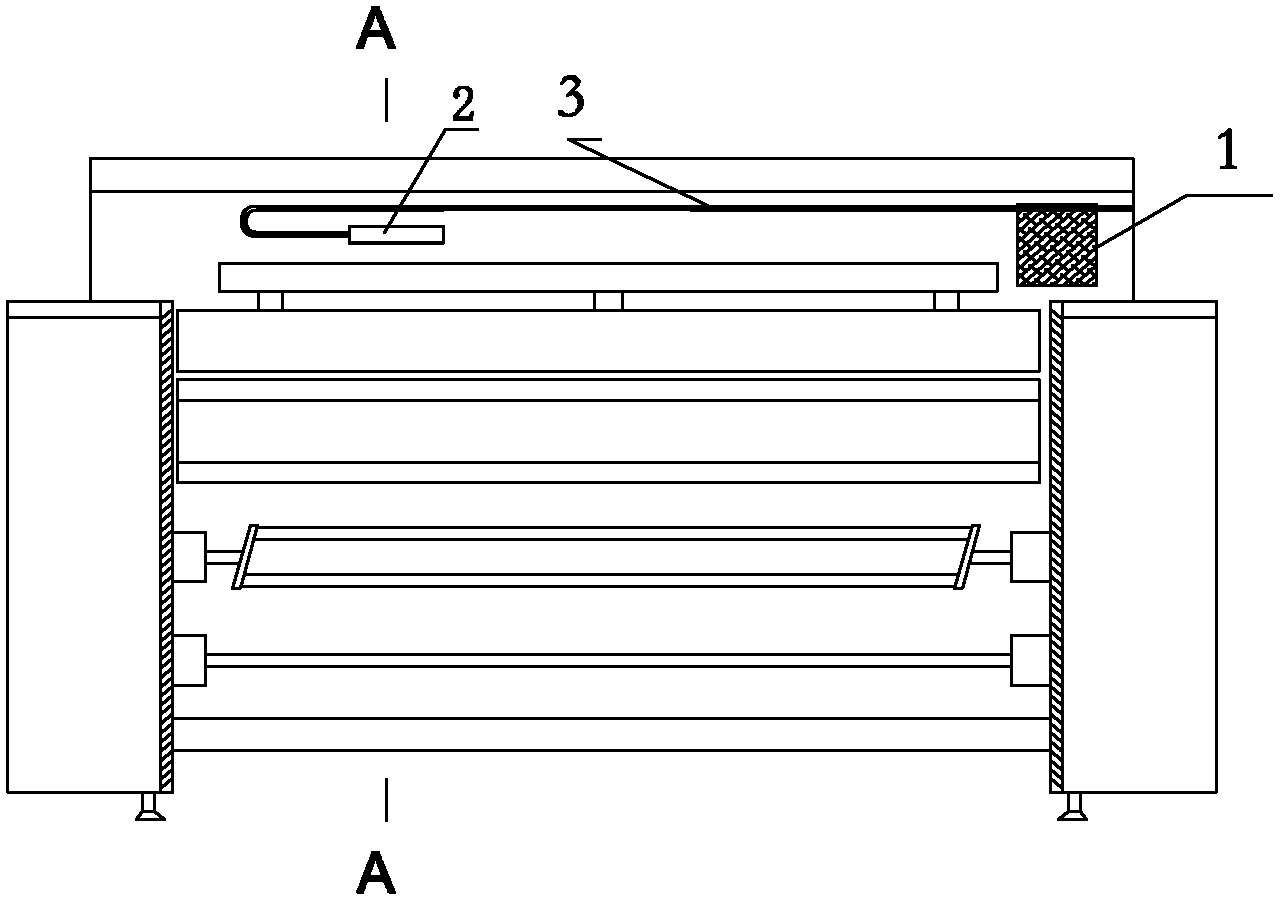

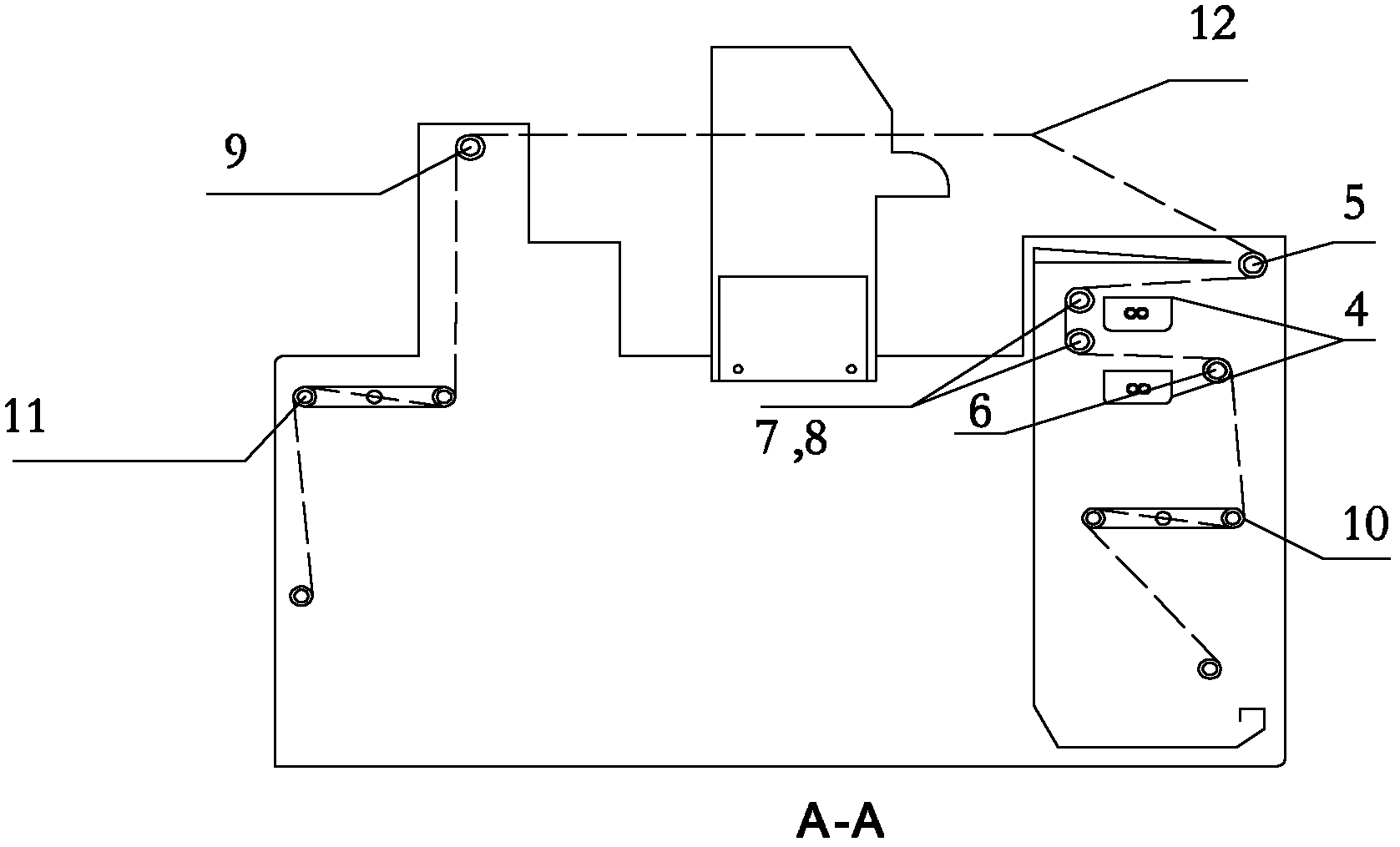

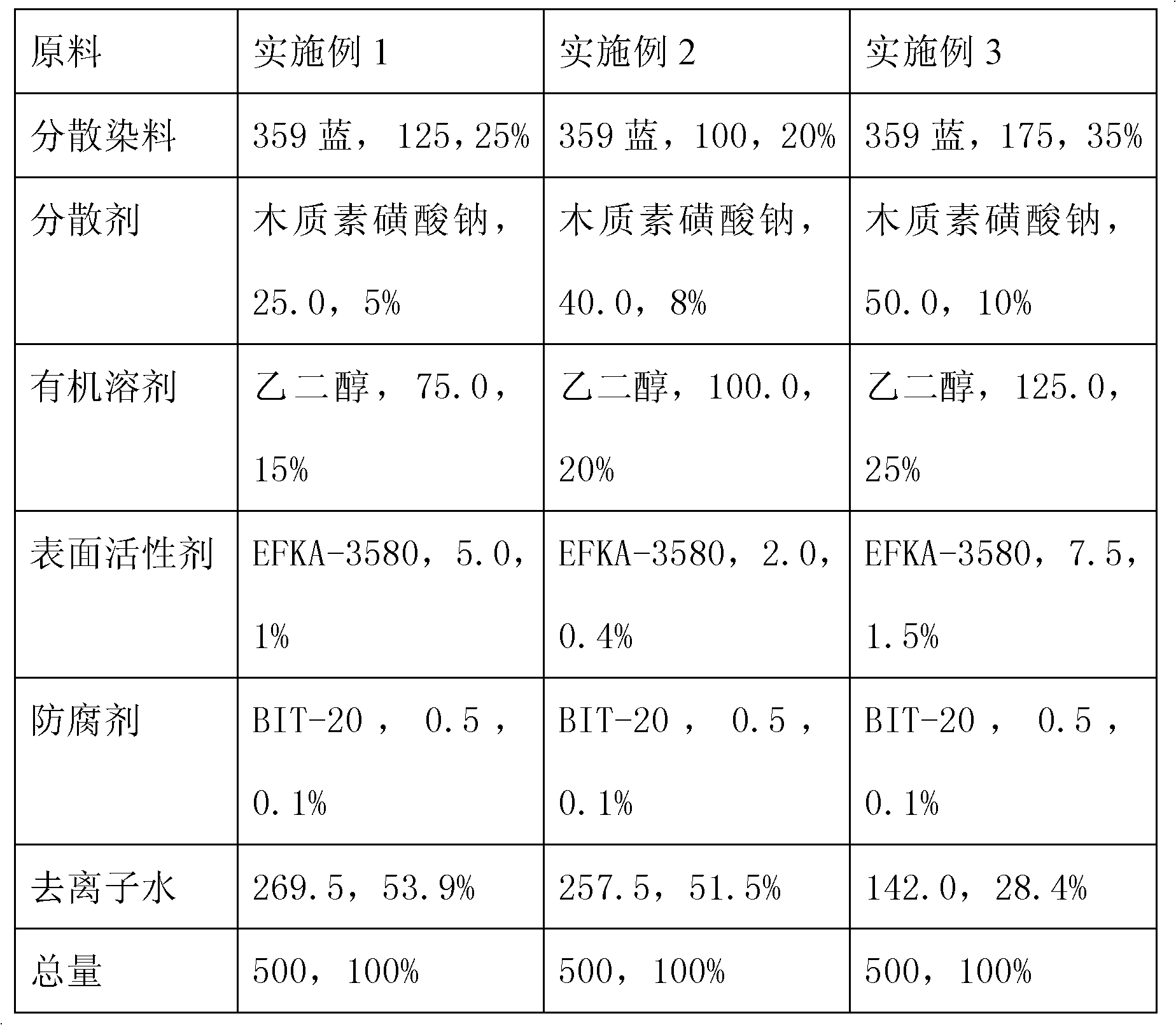

Thermal sublimation ink as well as direct printing technology and equipment

The invention discloses a thermal sublimation ink as well as a direct printing technology and equipment. The invention aims to solve the technical problem that the printing cost of polyester fiber cloth is lowered. The thermal sublimation ink comprises the following components in percentage by weight: 20-35% of dispersed dye, 5-10% of dispersing agent, 15-25% of organic solvent, 0.4-1.5% of surfactant, 0.1% of preservative and 40-59.5% of deionized water. The printing technology disclosed by the invention comprises the following steps: coating slurry on the polyester fiber cloth; and printing the thermal sublimation ink on the polyester fiber cloth by a printing machine. The equipment disclosed by the invention is characterized in that a printing system is composed of a printing head and an ink supply system connected to the printing head. Compared with the prior art, the thermal sublimation ink is characterized in that the thermal sublimation ink is directly printed on the sized polyester fiber cloth, the ink develops color on the cloth to form an image. The technical process is short, thus the production efficiency is greatly improved, and the production cost is reduced.

Owner:深圳市墨库图文技术有限公司

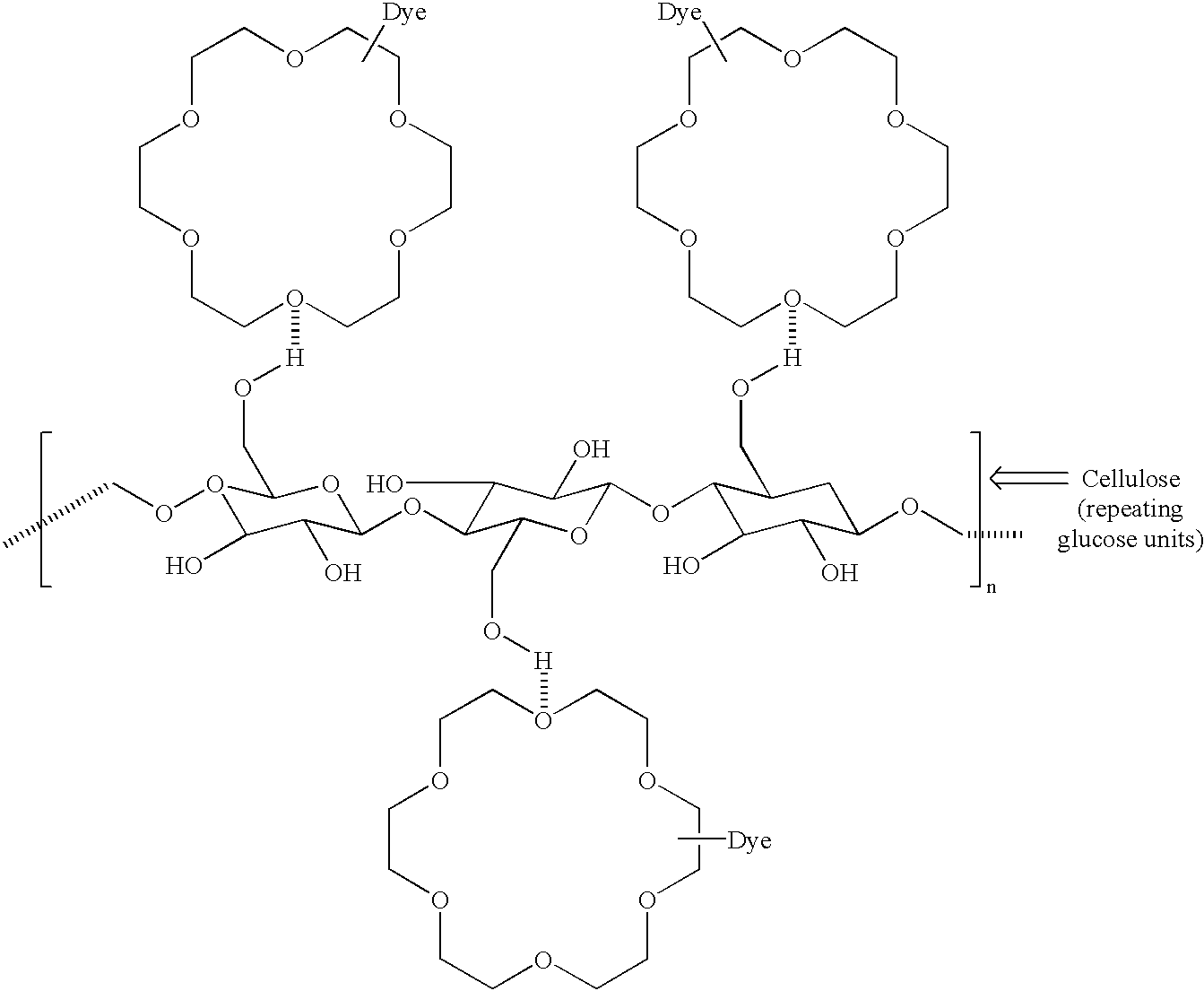

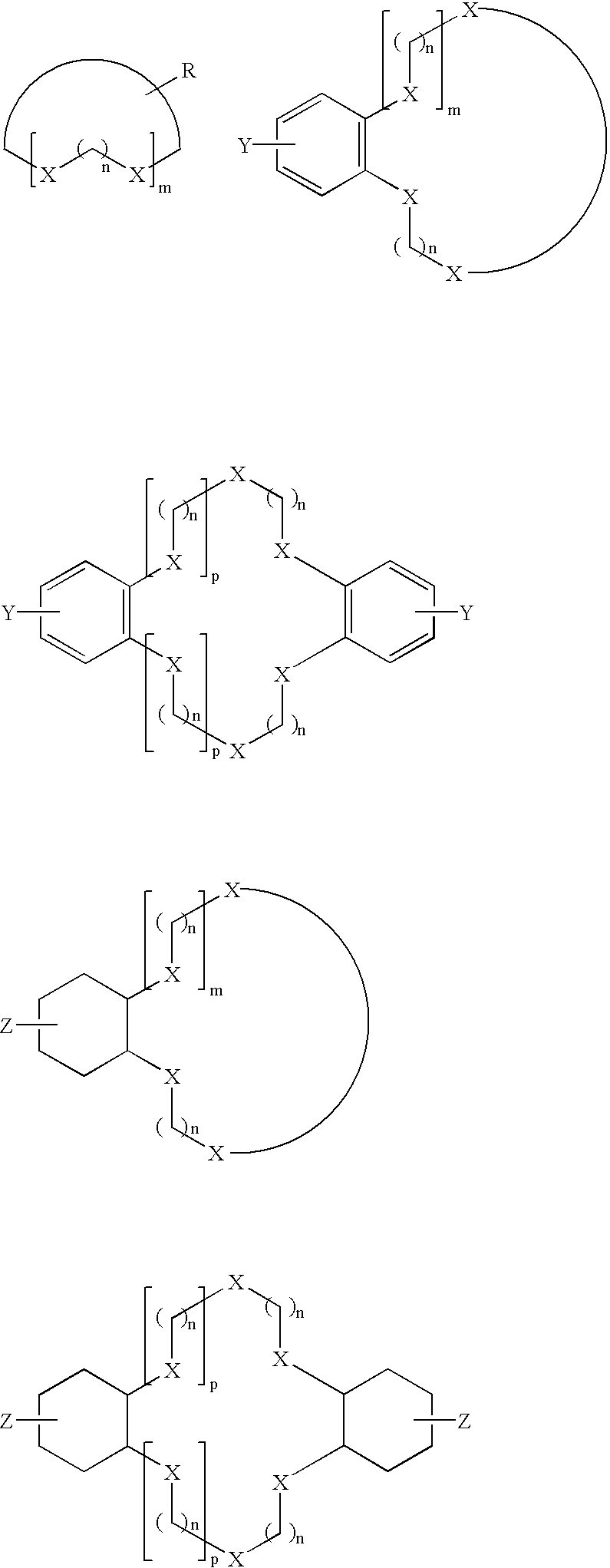

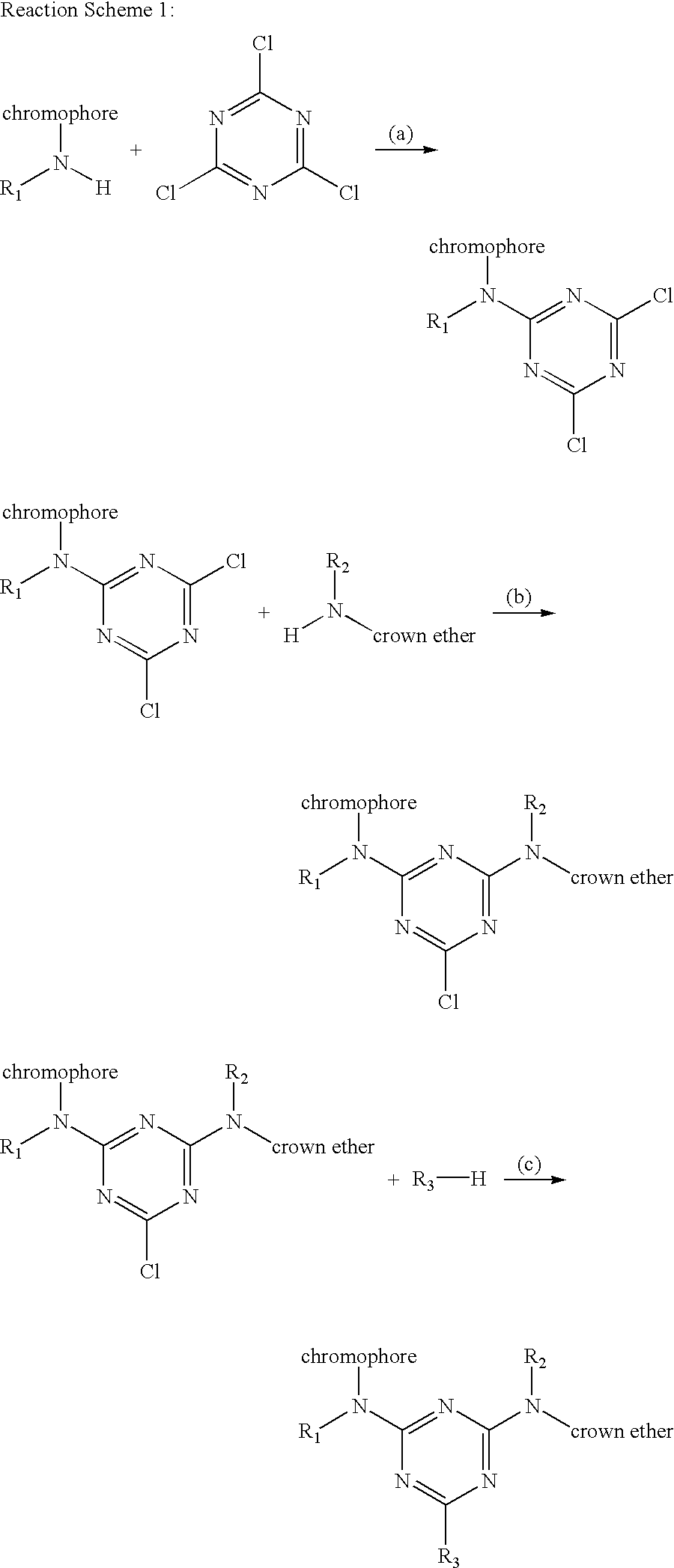

Derivatization of dyes/pigments with crown ethers and inkjet printing fluids containing the same

InactiveUS20020144626A1Improved lightfastnessImproved smearfastnessInksOrganic dyesDisperse dyeOrganic solvent

An inkjet ink is provided that employs one or more water-soluble colorants or water-insoluble colorants, such as solvent dyes, disperse dyes, or pigments. The colorant, whether water-soluble or water-insoluble, is derivatized with one or more crown ethers to render the water-insoluble colorants soluble in water and in water-miscible organic solvents commonly employed in inkjet printing, particularly thermal inkjet printing, and to impart improved properties to the colorants, such as lightfastness, smearfastness, and waterfastness. The inkjet ink comprises a vehicle and at least one crown ether derivatized colorant. The resulting inkjet ink evidences improved print quality properties, compared to inkjet inks containing colorants that are not so derivatized.

Owner:HEWLETT PACKARD DEV CO LP

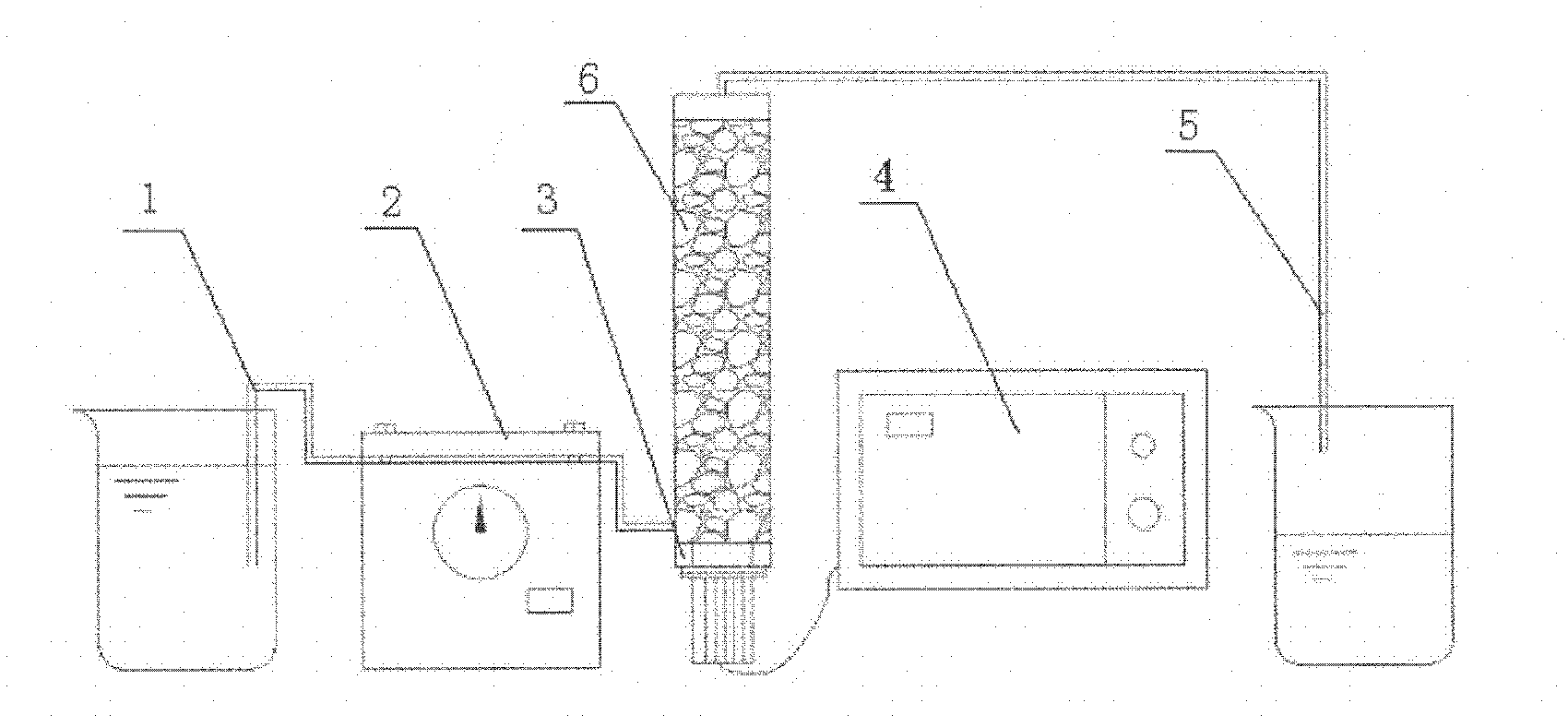

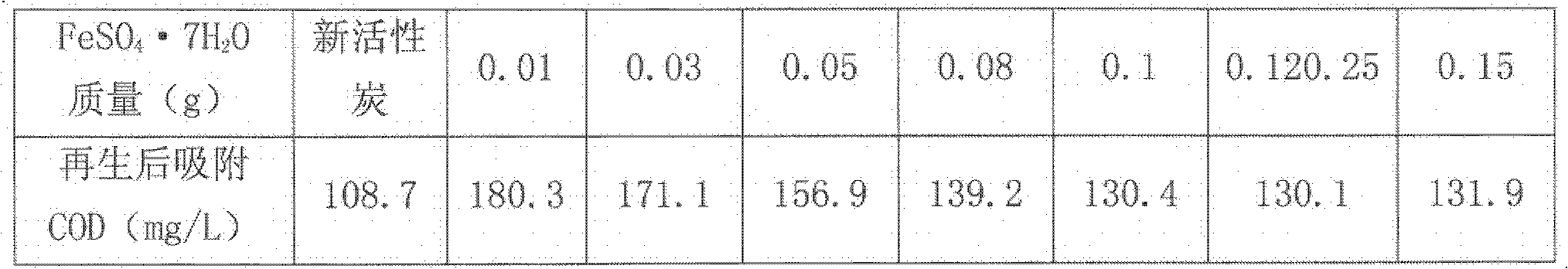

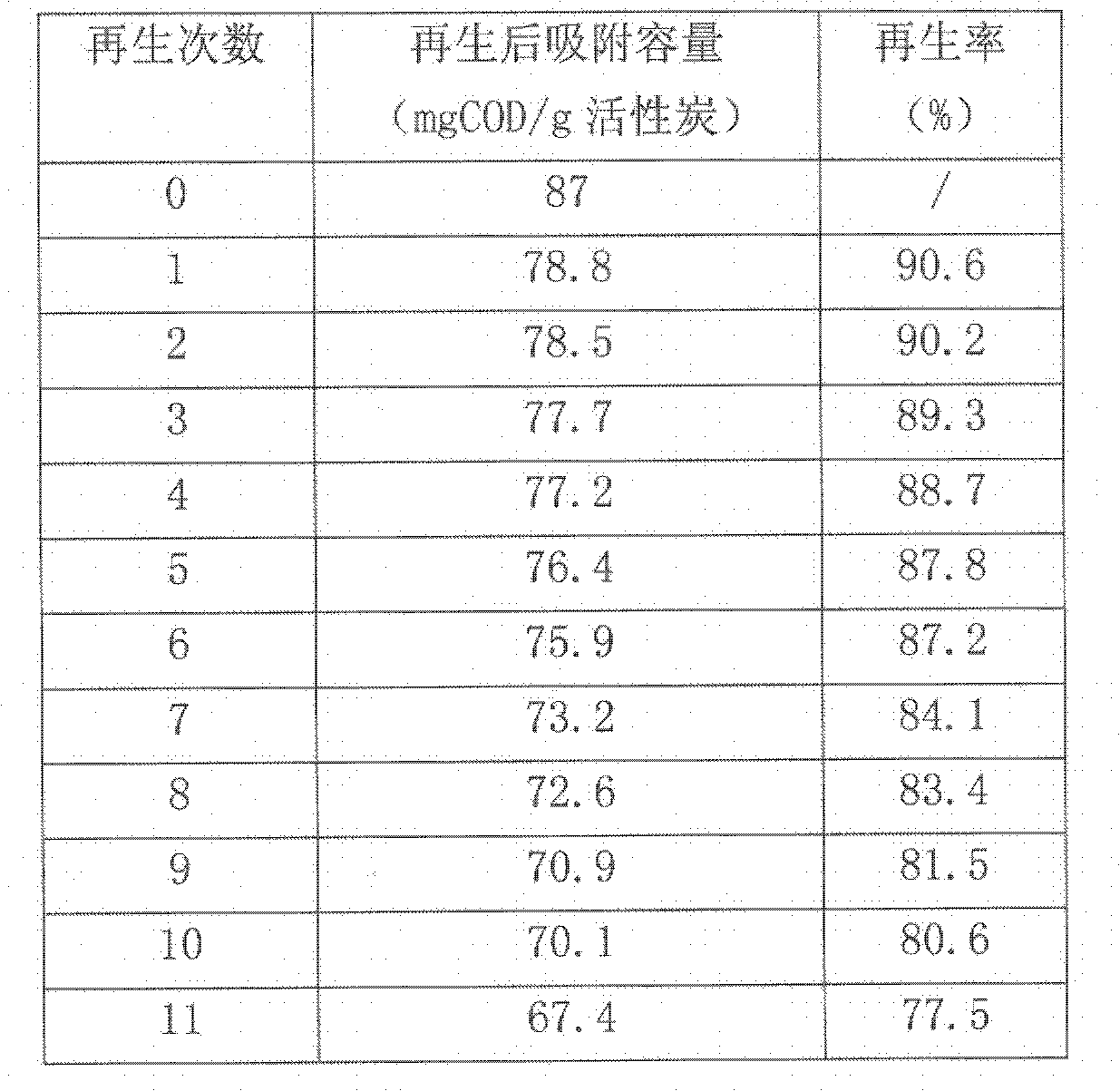

Regeneration method for activated carbon adsorbed and saturated by refractory organics

InactiveCN102658101ARestore adsorption activityEasy to operateCarbon compoundsCombustible gas purificationDisperse dyeActivated carbon

Owner:DONGHUA UNIV

Thermal sublimation digit printing ink-jet writing ink and preparation method

The invention relates to a thermal sublimation digital printing ink-jet ink and a preparation method thereof; the weight percentages of ink components are: (1) disperse dye: 1 to 10 percent; (2) dispersant: 1 to 10 percent; (3) organic solvent: 60 to 90 percent; (4) surfactant: 1 to 5 percent; (5) wetting agent: 1 to 5 percent; (6) defoamer: 1 to 5 percent. The preparation method comprises: (1) the disperse dye, the dispersant, the organic solvent, the wetting agent and the deformer are mixed at normal temperature, and a mixed solution can be obtained by stirring the mixture for 0.5 to 1 hour; (2) the mixed solution is homogenized for 0.5 to 5 hours under a high pressure homogenizer, and the stable-dispersed ink, the average particle size of the dispersed dye of which is 100 to 300 nanometers can be obtained; (3) the ink of magenta (M), cyan (C), yellow (Y), black (K), light cyan (Lc) or light magenta (Lm) can be obtained after the ink is filtered by a 2 microns filtering film and a 0.45 micron filtering film. The particle size of the thermal sublimation digital printing ink-jet ink of the invention is even in distribution and good in disperse stability and can be applied on the large scale piezoelectric type digital printing machines of the nozzles of XAAR and SPECTRA, etc and printed on polyester fabrics; ink jetting is smooth without blocking the nozzles; the thermal sublimation digital printing ink-jet ink can be stored for a long time; the patterns printed by the ink of the invention is colorful in color and the thermal sublimation digital printing ink-jet ink is good in color fixation rate, washing fastness and solarization fastness, is simple in the operation of the production method and is environment-friendly.

Owner:上海英威喷墨科技有限公司

Dispersed black dye composition

The present invention provides one kind of disperse black dye composition comprising one or several red dye component A's in the structure as shown in 30-90 wt%, one or several purple dye component B's in the structure in 1-15 wt% and one or several purple dye component C's in the structure in 5-60 wt%. The disperse black dye composition may be prepared into liquid with particle, emulsion, powder or granule. When it is used in dyeing polyester fiber material and the components are regulated properly, excellent black dyed fabric with bright color, excellent dispersivity, sunfastness, wash fastness, etc may be obtained.

Owner:浙江龙盛染料化工有限公司 +2

Composite environmental protection type grey disperse dyes

An environmental protection type composite disperse gray dye with high dye uptake, fastness, reproducibility and sublimation fastness contains proportionally dye monomers A, B and C and assistant.

Owner:ZHEJIANG RUNTU

Dispersing orange dye composition and dispersing dye

The invention discloses a dispersed orange dye composition, which is composed of 1-99% one or several dye A with formula (I) and 1-99% one or several dye B with formula (II), wherein the composition can be microparticled into liquid pattern, cream pattern or powder and particle pattern, which makes polyester fiber material display yellow to orange to red.

Owner:ZHEJIANG LONGSHENG GROUP

Method for dyeing cheese prepared from polyester-cotton blending stretch yarn

InactiveCN102733207ASolve the problem of shortage of dyed polyester-cotton blended elastic yarnAvoid VulnerabilityBiochemical fibre treatmentDyeing processTextile technologyDisperse dye

The invention belongs to the technical field of spinning and specifically relates to a method for dyeing cheese prepared from polyester-cotton blending stretch yarn. The method comprises the steps of loosen-type spooling, pretreatment, dyeing and washing, reduction clearing, after-treatment, dewatering and drying, and is characterized in that each loosen-type spooling bobbin is 0.6-1.2kg in weight and 0.28-0.42g / cm<3> in density; after a spooling step is completed; a dyeing working procedure is processed; in polyester dyeing process, low-temperature disperse dye is used and subjected to dyeing at 100-128 degrees centigrade for 15-60 minutes; then, the steps of reduction clearing, cotton dyeing, after-treatment, dewatering and drying are carried out. The method has the benefit that in the polyester dyeing process, the low-temperature disperse dye is used and subjected to dyeing at 100-128 degrees centigrade for 15-60 minutes; therefore, the dyed bobbin has the advantages of identical colors and elasticity in interior and exterior and high color one-time success rate, and avoids problems caused by a traditional dyeing method.

Owner:TIANJIN TIANGE TEXTILE

Medium-low temperature environmental-friendly disperse dye composition

The invention discloses a medium-low temperature environmental-friendly disperse dye composition, which comprises the following components in percentage by weight: 3-94 percent of dye compound A as shown in the formula (1), 3-55 percent of dye compound B as shown in the formula (2), 3-60 percent of dye compound C as shown in the formula (3) and 0-2 percent of dye compound D as shown in the formula (4). The dye composition has the advantages of bright color shade, good synchronism during dyeing, good reproducibility, and good leveling-dyeing property, coverage property and each fastness, and particularly has more remarkable advantages on compatibility among dyes and sublimation fastness; and moreover, the invention is environmental-friendly and overcomes the defect that environmental protection and good fastness property cannot be achieved at the same time in the prior art.

Owner:ZHEJIANG RUNTU

Disperse dye composition for disperse/reactive dye combination printing, and preparation and application thereof

ActiveCN102660145AAchieve one-step printing technologyImprove cleanlinessOrganic dyesDyeing processDisperse dyeYELLOW DYE

The invention relates to a disperse dye composition for disperse / reactive dye combination printing, and preparation and application thereof. The disperse dye composition comprises 2-4 of yellow dyes disclosed as a general formula (I), orange dyes disclosed as a general formula (II), blue dyes disclosed as a general formula (III) and red dyes disclosed as a general formula (IV), wherein the number of dyes disclosed as each general formula does not exceed two. The disperse dye composition is used for a disperse / reactive dye combination printing method. The disperse dye composition is suitable for disperse / reactive dye combination printing technique of terylene / cotton and terylene / viscose blend fabrics, and has the advantages of simple technological process, higher production efficiency, lower production cost and less printing wastewater; the printed fabric has the advantages of smooth cloth cover and favorable fabric style; and Compared with the traditional printing, the invention implements disperse / reactive dye one-step printing technology of terylene / cotton and terylene / viscose blend fabrics.

Owner:ZHEJIANG WANFENG CHEM

Disperse yellow-brown dye composition and disperse dye

The disperse yellow-brown dye composition and corresponding disperse dye are provided. The disperse yellow-brown dye composition consists of component A in 1-99 wt% and component B in 1-99 wt% basically, with the structures of component A and component B being shown. The disperse yellow-brown dye composition may be treated into liquid state with particle, emulsion, powder or granule. The disperse yellow-brown dye based on the disperse blue dye composition is used in dyeing polyester fiber material, and through regulating the ratio of different components, excellent yellow to orange dyed fabric with bright color, excellent dispersivity, sunfast property, water resistance, sweat resistance and other advantages may be obtained.

Owner:ZHEJIANG LONGSHENG GROUP

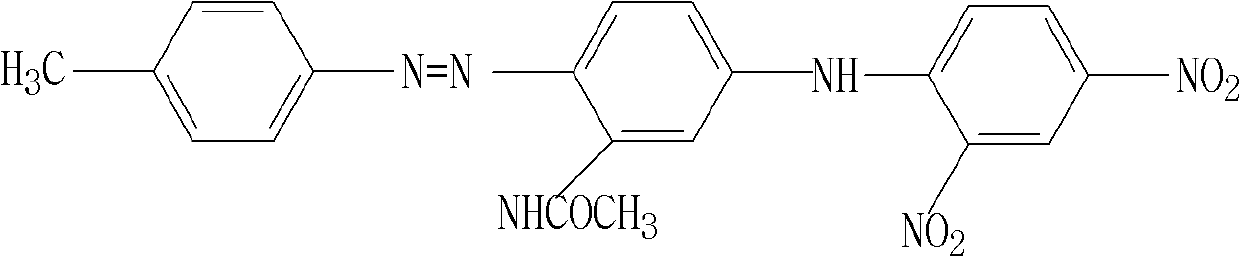

Yellow disperse dye capable of dyeing in acid and alkaline baths

ActiveCN102250485AGuaranteed to run throughQuality improvementMonoazo dyesDisperse dyeStructural formula

The invention relates to a yellow disperse dye capable of dyeing in acid and alkaline baths. The structural formula of the yellow disperse dye is shown in the specification, wherein, R1 is CH3, OCH3, OC2H5 or NHCOCH3; R2 is CH3 or NHCOR3; and R3 is H, CH3 or C2H5. The dye provided by the invention can be used for dyeing and printing of terylene and blended fabrics thereof, and especially is suitable for high-temperature high-pressure dyeing. In weak acid and strong alkaline baths (pH = 4.0-14), the yellow disperse dye can acquire the same dyeing shade and depth, and has good reproducibility and excellent sublimation and washing fastness.

Owner:PENGLAI JIAXIN DYES & CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com