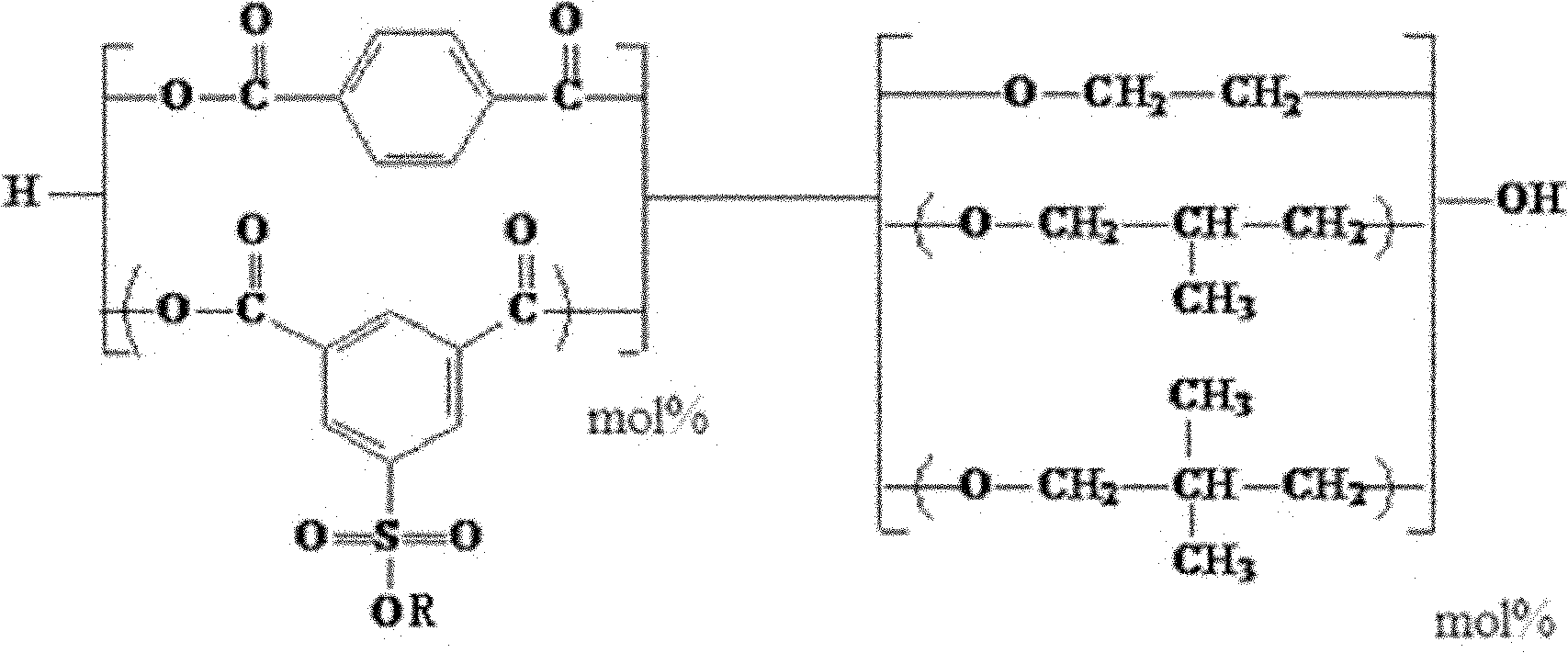

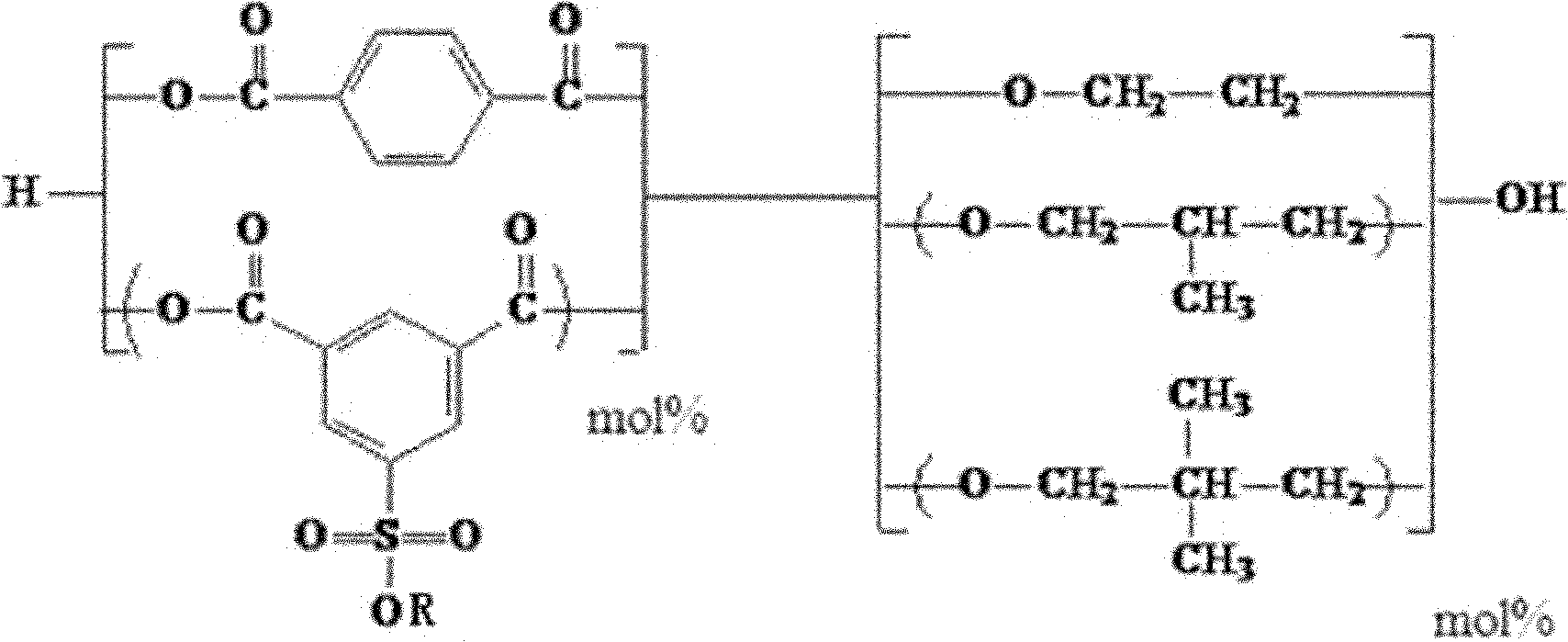

Polyester chip modified by blend with side chain aliphatic diol and preparation method thereof

An aliphatic diol and blend technology, applied in the direction of single-component polyester rayon, etc., can solve the problems of unstable spinning, difficult to control polymerization reaction, and high production cost, and achieve low cost and polymerization. The effect of easy control of physical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using continuous polymerization equipment, the first esterification kettle is filled with 1 ton of PTA, 600 kg of EG, and at the same time 0.2 kg of the catalyst antimony trioxide and 0.2 kg of triphenyl phosphate are added to carry out the esterification reaction. The reaction temperature is 260°C. After 3h, the materials were transferred to the second esterification kettle, and at the same time, a blend of aliphatic diols with side chains equivalent to 10mol% of PTA was injected (the molar ratio of MPO to NPG in the blend was 90: 10) With SIPE equivalent to 1.5mol% of PTA, further esterification, reaction temperature 250℃, after 2h reaction, the materials are transferred to polycondensation kettle, reaction temperature 270℃, gradually reduce to vacuum degree less than 130Pa, polycondensation 3h After discharging, pelletizing, and drying, the modified copolyester chip SULET is obtained. The intrinsic viscosity of SULET chips is 0.650, and the melting point is 238°C.

Embodiment 2

[0036] Using continuous polymerization equipment, the first esterification kettle is filled with 1 ton of PTA and 410 kg of EG, while adding 0.32 kg of the catalyst antimony trioxide and 0.6 kg of triphenyl phosphate to carry out the esterification reaction. The reaction temperature is 260°C. After 3h, the materials were transferred to the second esterification kettle, and at the same time, a blend of aliphatic diols with side chains equivalent to 20mol% of PTA was injected (the molar ratio of MPO to NPG in the blend was 50: 50) With SIPM equivalent to 2mol% of PTA, further esterification, reaction temperature 252℃, after 2h reaction, the materials are transferred to polycondensation kettle, reaction temperature 286℃, gradually reduce to vacuum degree less than 130Pa, after polycondensation 3h , Discharging, pelletizing and drying to obtain modified copolyester chips SULET. The intrinsic viscosity of SULET chips is 0.570 and the melting point is 225°C.

Embodiment 3

[0038] Using continuous polymerization equipment, the first esterification kettle is filled with 1 ton of PTA, 450 kg of EG, and at the same time 0.1 kg of the catalyst antimony trioxide and 0.2 kg of triphenyl phosphate are added to carry out the esterification reaction. The reaction temperature is 260°C. After 3h, the materials were transferred to the second esterification kettle, and the aliphatic glycol blend with side chains equivalent to 15mol% of PTA was injected at the same time (the molar ratio of MPO to NPG in the blend was 10: 90) With SIPE equivalent to 3mol% of PTA, further esterification, reaction temperature 250℃, after 2h reaction, the material is transferred to polycondensation kettle, reaction temperature 270℃, gradually reduce to vacuum degree less than 130Pa, after polycondensation 3h , Discharging, pelletizing and drying to obtain modified copolyester chips SULET. The intrinsic viscosity of SULET chips is 0.62, and the melting point is 231°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com