Patents

Literature

315results about How to "Performance is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

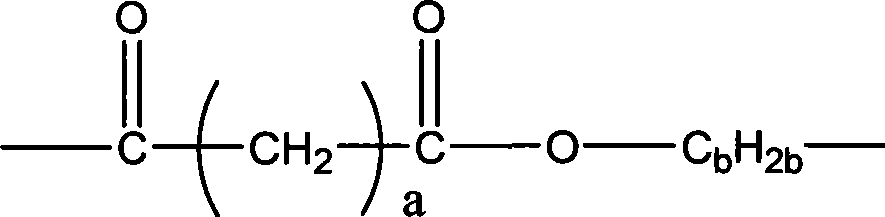

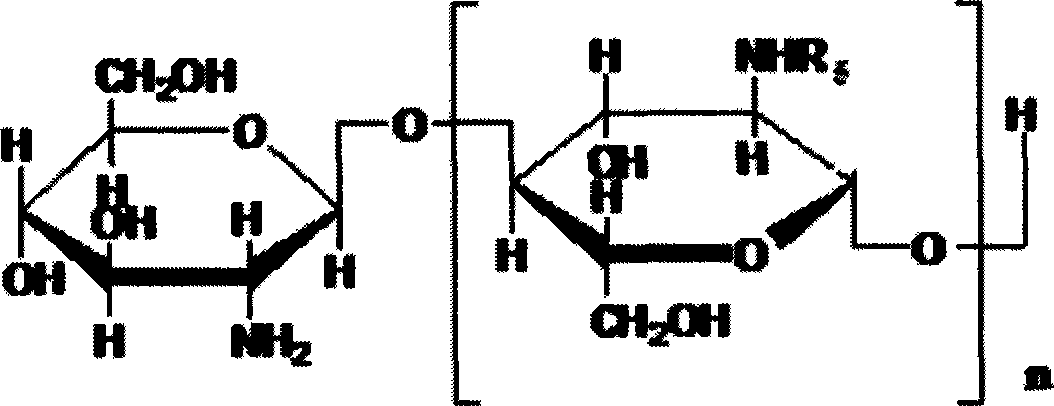

Preparation of chitosan-polyurethane ion complex elastomer material

The invention discloses a preparation method of chitosan-polyurethane ionic compound elastomeric material, which comprises the following steps: polyisocyanates reacts with polymer polylol and then reacts with diol or diamine, organic solvent and ionization reagent are added in the reactants to react with water for generating anionic waterborne polyurethane and further performs the ionic recombination reaction with cationic chitosan water solution to obtain the microemulsion or latex of chitosan-polyurethane ion composite, and finally the microemulsion or latex of chitosan-polyurethane ion composite is dried and solidified to obtain the chitosan-polyurethane ionic compoundelastomeric material. The chitosan-polyurethane ionic compoundelastomeric material has the advantages of good mechanical property, easy processing, good oil-water resistance property, good cohesive property with parent metal, controllable performance, good biocompatibility, biodegradable property, high biological activity, good blood contact property, good bacteriostatic property, good antibacterial property, and the like, can be applied in fields of mechanical industry, building industry, sport, medical treatment, and the like, and especially has wider purpose in aspects of life science research, medical materials and medical appliances.

Owner:NANJING UNIV

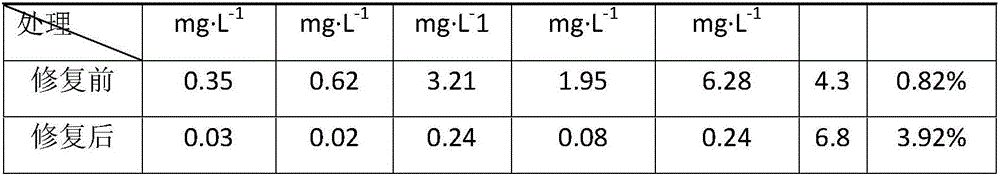

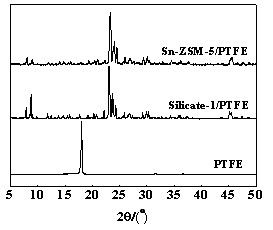

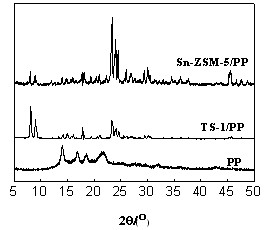

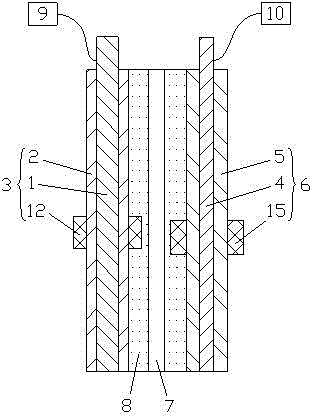

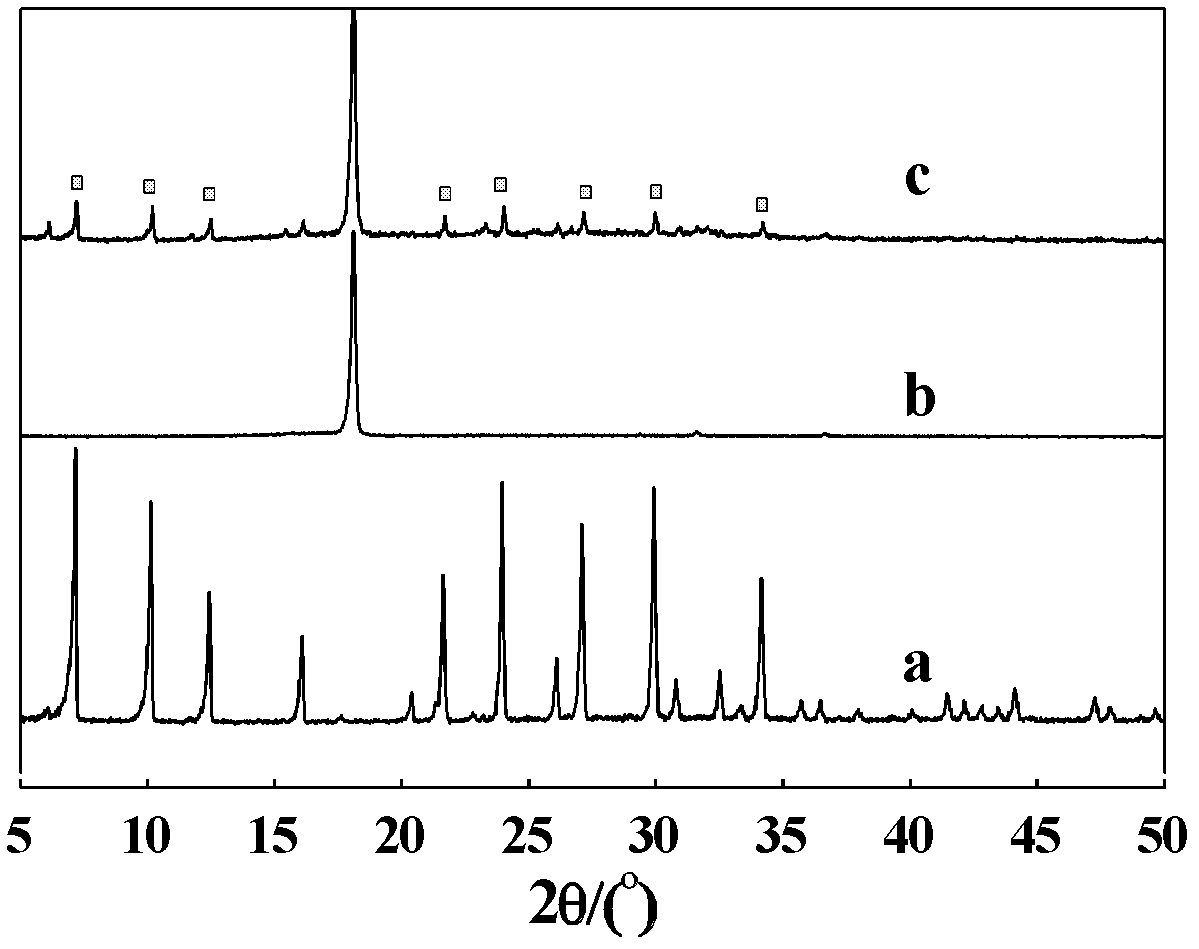

Preparation method and application of molecular sieve/organic composite infiltration, vaporization and separation membrane

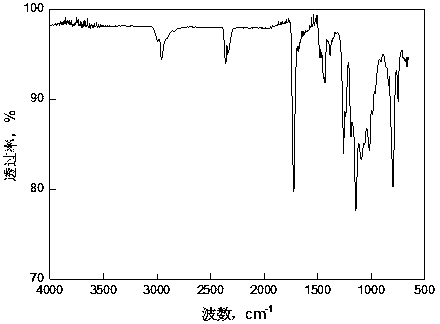

InactiveCN102139188APerformance is easy to controlGood surface continuitySemi-permeable membranesMolecular sieveOrganic chemistry

The invention belongs to the technical field of separation membranes, and relates to a preparation method and application of a molecular sieve / organic composite infiltration, vaporization and separation membrane. The preparation method comprises the following steps of: firstly adopting a hydrothermal method to prepare nano-level molecular sieve; putting the synthesized nano-level molecular sieve in a solvent, and dispersing the molecular sieve into uniform molecular sieve suspending liquid through ultrasound, wherein the mass fraction of the molecular sieve in the suspending liquid is 5-15%; uniformly coating the molecular sieve suspending liquid on an organic supporting body; drying the organic supporting body at the temperature of 20-60 DEG C to form a molecular sieve membrane; and repeating the coating for 2-4 times. Surface modification is performed on the organic supporting body by adopting methods such as plasma induction, silane coating and the like to modify the surface hydrophily. The method can be used for preparing a large-area molecular sieve / organic composite membrane; a prepared membrane can be assembled into a spirally coiled component; and the preparation method is beneficial for industrial magnification, and has a higher industrial application value. A better separation effect can be achieved when the prepared molecular sieve / organic composite membrane is used for the infiltration and vaporization of an organic water solution system.

Owner:CHANGZHOU UNIV +1

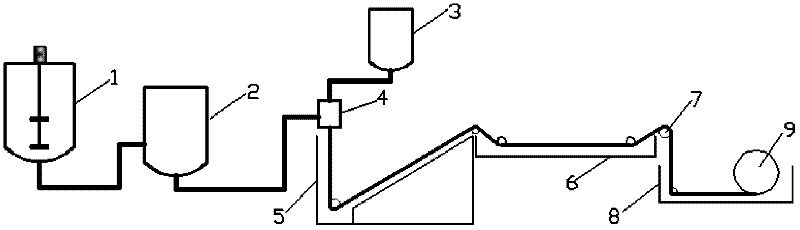

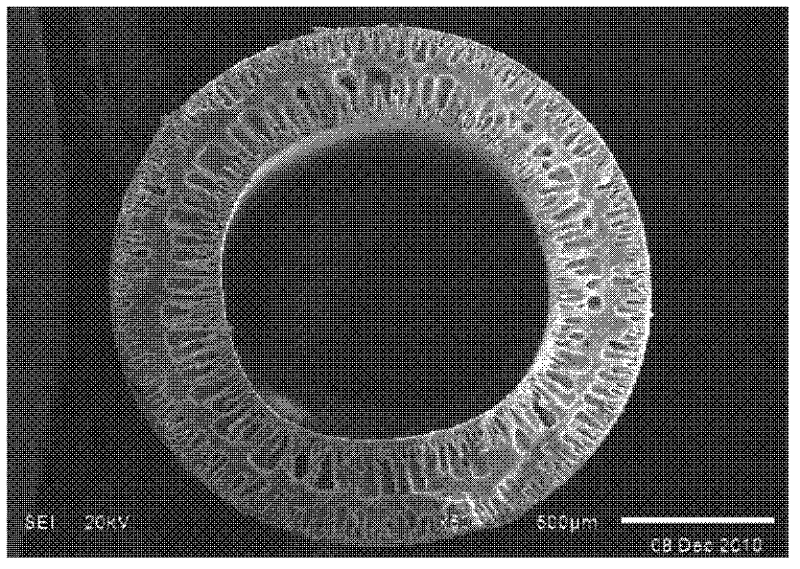

Method for preparing chemically perforated polyvinylidene fluoride hollow fiber ultrafiltration membrane

The invention discloses a method for preparing a chemically perforated polyvinylidene fluoride hollow fiber ultrafiltration membrane. The method comprises the following steps of: stirring and mixing polyvinylidene fluoride, a solvent, an additive and a chemical perforation agent, and preparing homogeneous membrane casting liquid; squeezing the membrane casting liquid and core liquid out from a spinning nozzle, and forming the membrane in an outer gel bath with certain components; and performing gel phase inversion and chemical post-treatment on the membrane, and thus obtaining the high-flux polyvinylidene fluoride hollow fiber ultrafiltration membrane. The method has the characteristics that: chemical enhanced perforation is performed by changing the composition of the core liquid, performing gel phase inversion and performing post-treatment according to reaction among between the core liquid, the gel bath and the post-treatment liquid and the chemical perforation agent, so that high flux, high intensity, high retention rate and high hydrophilism polyvinylidene fluoride ultrafiltration membrane can be prepared. The prepared polyvinylidene fluoride hollow fiber ultrafiltration membrane is high in performance; the flux is greater than 580 L / (m<2>h) in pure water; and the retention rate of bovine serum albumin (BSA) is over 95 percent.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

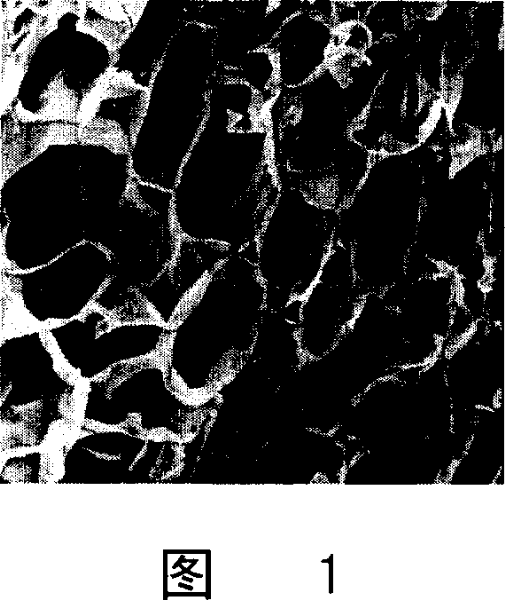

High-efficiency soft magnetic material and method for producing the same

InactiveCN101246773AGuaranteed mechanical propertiesExcellent soft magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMetalMagnet

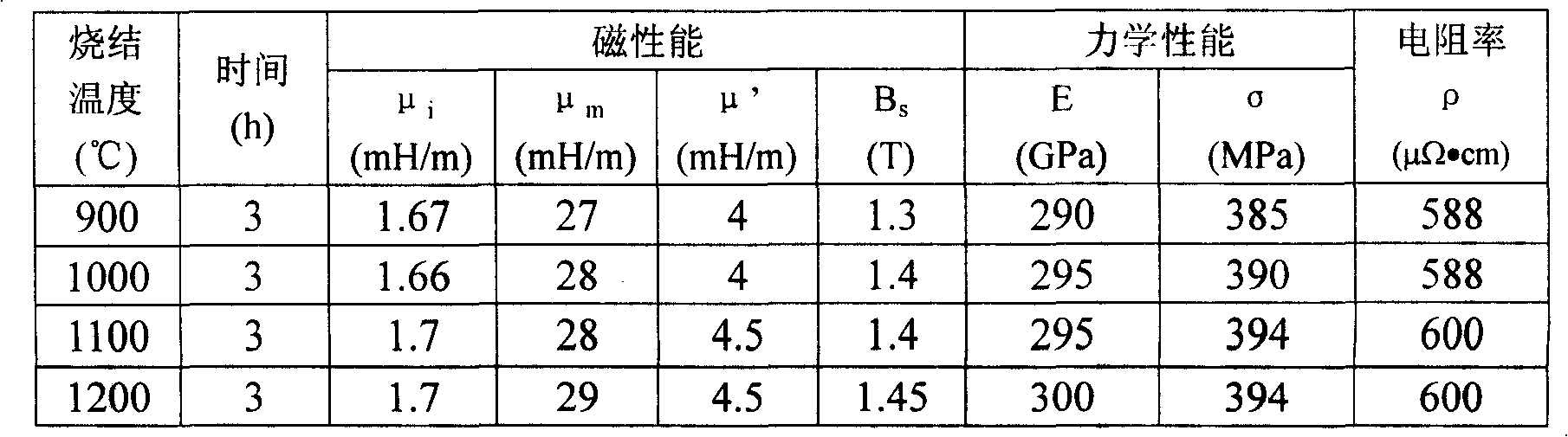

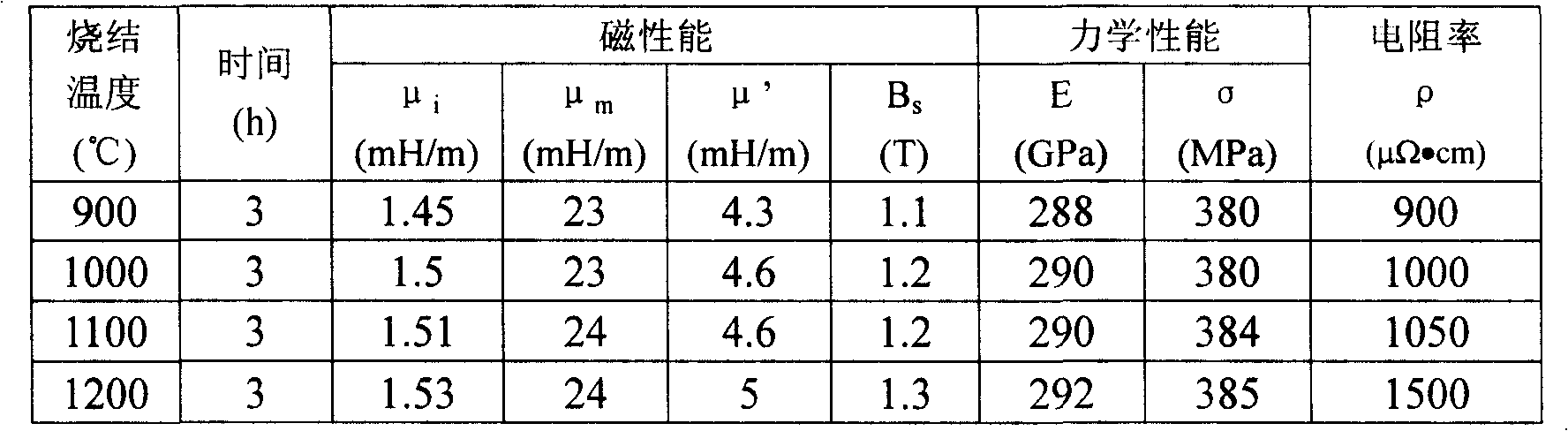

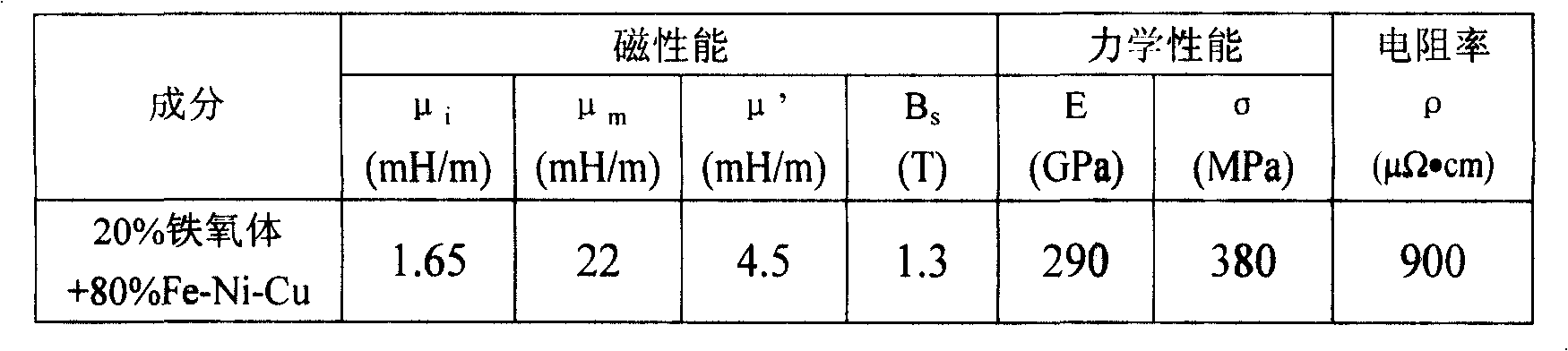

The invention relates to a highly efficient soft magnetic material and the preparing method thereof. The soft magnetic material is composed of metal soft magnetic material and soft magnetic ferrite, the metal soft magnetic material is composed of at least one selected from Fe-Ni-Me system (Me is one or more than two selected form Cu, Cr, Nb, V, W, Si, Pd, Zn, Al, Ti and Mn), Fe-Co system, Fe-Co-V system, Fe-Al system and Fe-Al-Me system (Me is one or more than two selected form Co, Cr and Mo), the soft magnetic ferrite is composed of at least one selected form Mn-Zn system, Ni-Zn system, Li-Zn system, Cu-Zn system and Mg-Zn system soft magnetic ferrites. The preparing method of the soft magnetic material comprises the steps of: cold pressing, and sintering, hot pressing or spark plasma sintering. The soft magnetic material does not have the drawbacks of low resistivity of the metal soft magnetic and low magnetic strength of the ferrite, as well as keeps the superior properties of the metal soft magnetic and low magnetic strength of the ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

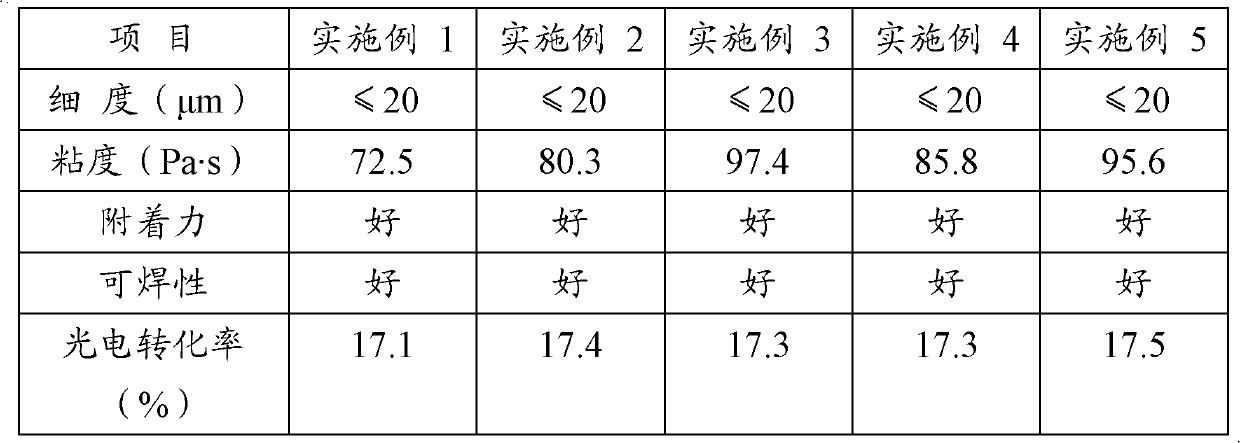

Lead-free environment-friendly electronic Ag/Al (silver/aluminum) paste and preparation method thereof

InactiveCN101950594AEliminate pollutionImprove compatibilityNon-conductive material with dispersed conductive materialCable/conductor manufactureAcrylic resinAluminium powder

The invention discloses a lead-free environment-friendly electronic Ag / Al (silver / aluminum) paste, which comprises the following raw materials in percentage by mass: 3 to 10 percent of inorganic binder, 10 to 20 percent of self-crosslinking acrylic resin, 50 to 60 percent of silver powder, 10 to 20 percent of aluminium powder, 0.5 to 5 percent of surface modifier, 0.5 to 5 percent of auxiliaries and 0.1 to 0.5 percent of defoaming agent. The invention also discloses a method for preparing the lead-free environment-friendly electronic Ag / Al paste, which comprises the following steps: evenly mixing the silver powder, the aluminium powder and the inorganic binder; adding the surface modifier, then evenly stirring the obtained mixture; adding the self-crosslinking acrylic resin, the auxiliaries and the defoaming agent into the obtained mixture, then grinding the obtained product for 5 to 8 hours; and filtrating the obtained product so as to obtain the lead-free environment-friendly electronic Ag / Al paste. The method for preparing the lead-free environment-friendly electronic Ag / Al paste has the advantages of lead-free environmental protection, simple process, convenient and easy operation, no required special equipment, small investment, and easy controlling on product performance.

Owner:ZHEJIANG UNIV

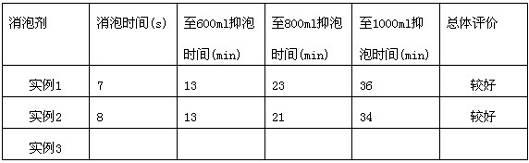

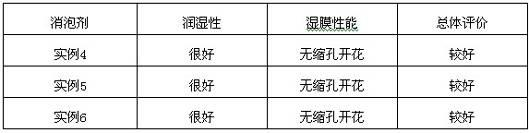

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939AStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

Lead-free environmental-friendly circuit board conductive silver paste and preparation method thereof

InactiveCN104036842AReduce dosageImprove printing effectMetal/alloy conductorsCable/conductor manufactureEnvironmental resistanceMicrosphere

The invention provides a kind of lead-free environmental-friendly circuit board conductive silver paste, which is prepared by the following raw material by weights: 60 to 70 of silver powder of 20 to 30mum, 5 to 8 of copper powder of 1 to 10nm, 8 to 10 of glass powder, 5 to 7 of SnO2 powder, 5 to 8 of silver powder of 40 to 60nm, 2 to 4 of pentaerythritol tristearate, 4 to 6 of isophorone, 3 to 5 of saturated polyester resin EK410, 4 to 7 of bisphenol F epoxy resin, 1 to 2 of salicylic acid, 3 to 5 of polyurethane resin, 1 to 2 of triallyl isocyanurate, 1 to 2 of microsphere starch, 1 to 2 of fumed silica, 4 to 6 of isobutyl ketone, 6 to 8 of ethanol , 2 to 4 of butanol, and 6 to 8 of butyl acetate. The lead-free environmental-friendly circuit board conductive silver paste and the preparation method thereof are characterized in that the use amount of the silver powder is small, the printing performance is good, the yield of the circuit board is high, the conductive performance is good, lead-free environmental-friendly performance is provided, the technology is simple, the operation is convenient and easy, and the product performance is convenient to control.

Owner:铜陵市超远精密电子科技有限公司

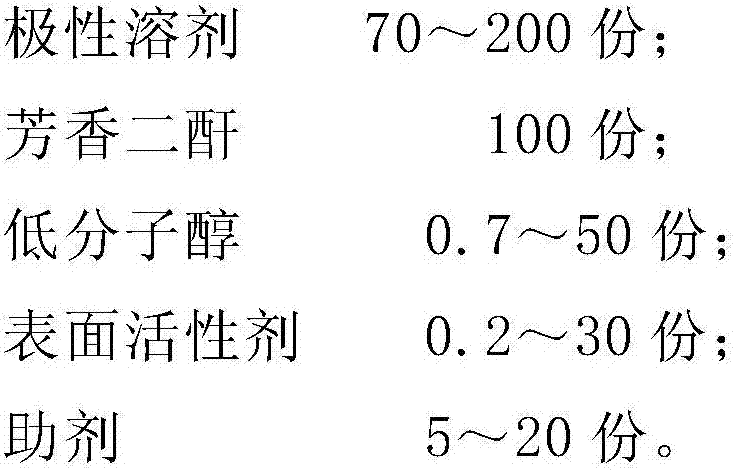

Lightweight sound-absorption heat-insulation polyimide foamed material, and preparation method thereof

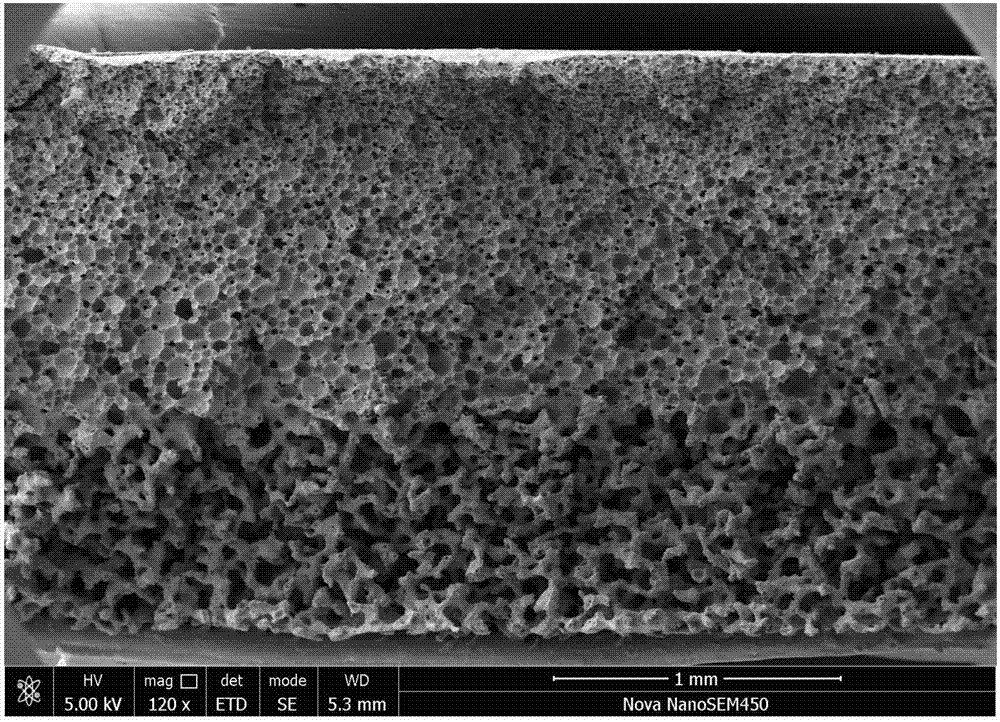

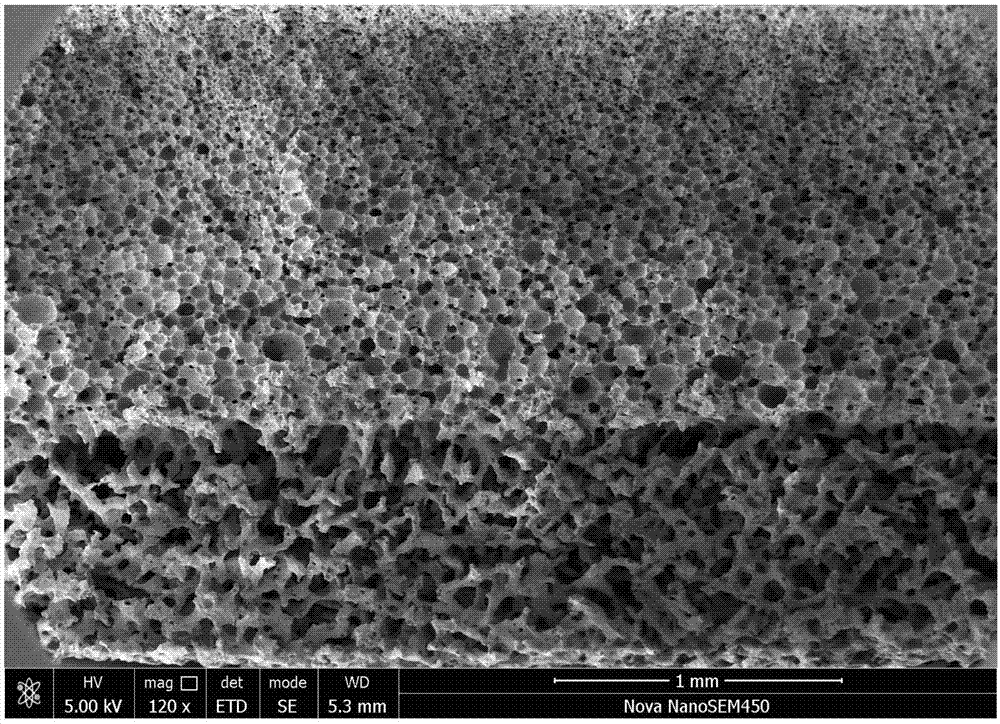

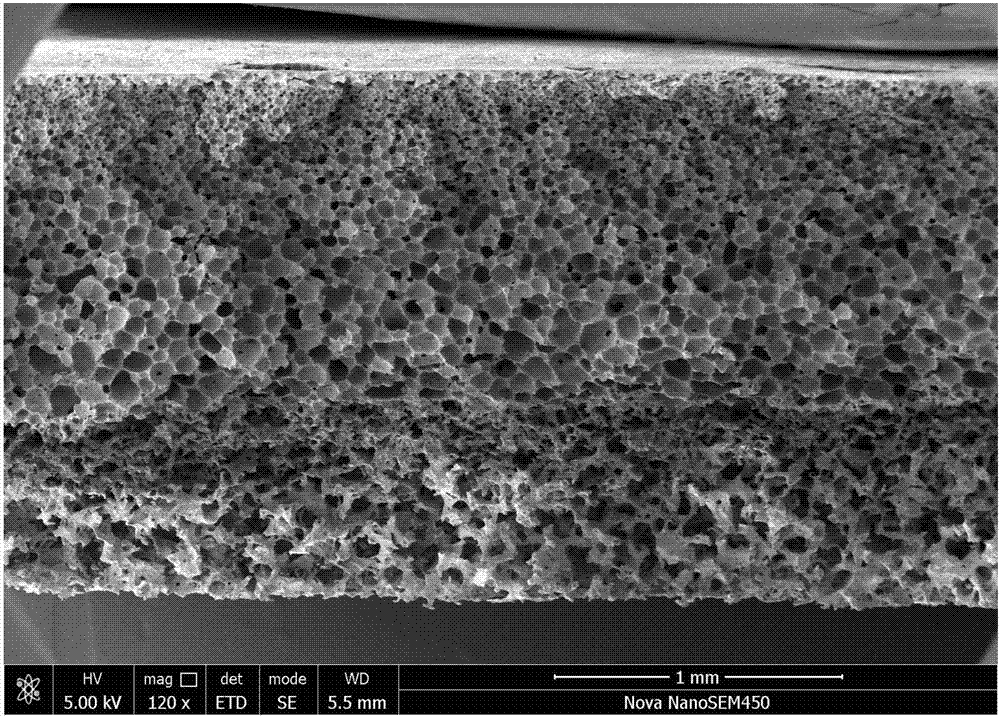

The invention discloses a lightweight sound-absorption heat-insulation polyimide foamed material, and a preparation method thereof. The preparation method comprises following steps: an aromatic dianhydride, a low molecular alcohol, a surfactant, and an auxiliary agent are mixed at a certain ratio, and are reacted in a polar solvent so as to obtain a foam precursor solution; the foam precursor solution is reacted with isocyanate in a mould, and semi-free foaming is carried out so as to obtain a foam intermediate; microwave radiation treatment, and heating curing in an aging oven are carried outso as to obtain the lightweight sound-absorption heat-insulation polyimide foamed material. The preparation route is short; the preparation method is simple; the foam precursor solution is low in viscosity and high in stability, is suitable for casting and extrusion process; the foaming process is simple, and is convenient to control; defects such as cracking, collapsing, nonuniformity, and incomplete material imidization are avoided; the obtained lightweight sound-absorption heat-insulation polyimide foamed material is high in stability and strength, is low in density, possesses excellent sound absorption and heat insulation performance, and can be widely used in fields such as aerospace, ship, automobile, refrigeration house, and other special application fields.

Owner:康达新材料(集团)股份有限公司

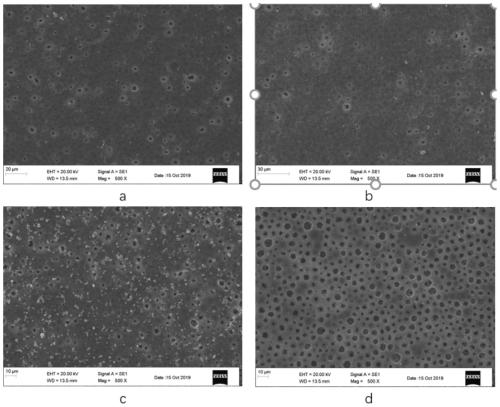

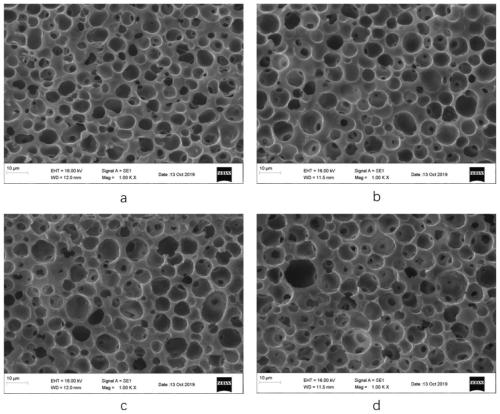

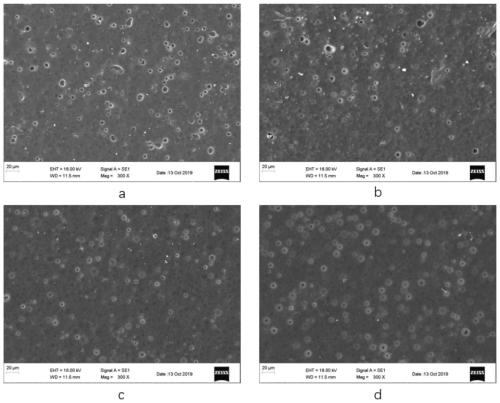

Polyurethane porous thin film containing grapheme as well as preparation method and application thereof

The invention discloses a polyurethane porous thin film containing grapheme as well as a preparation method and application thereof. The preparation method comprises the following steps: adding polyurethane into a solvent for dissolution, adding a grapheme solution, adding a pore-foaming agent and obtaining a suspension after mechanical stirring for a certain time; performing vacuum de-foaming on the suspension, casting into a film on a mold, curing into a film in an anhydrous ethanol coagulation bath and then putting in deionized water for soaking, so that the pore-foaming agent is dissolved and completely removed; taking out a thin film and putting in an air blast baking oven for drying to obtain the polyurethane porous thin film containing the grapheme. The film can be used for artificial skin and has the advantages of being good in water and gas permeability, high in water absorption rate, excellent in mechanical property, good in biological affinity and the like.

Owner:重庆石墨烯研究院有限公司 +1

Small fiber balls for solid buoyancy material and preparation method of small fiber balls

The invention discloses small fiber balls for a solid buoyancy material and a preparation method of the small fiber balls. The small fiber balls have nuclear shell structures, nucleating carriers are foam balls, and shell layers are powdery fiber reinforced resin matrix composite layers; the small fiber balls with the nuclear shell structures are prepared by adopting the expandable polystyrene foam balls as the nucleating carriers, uniformly coating the surfaces of the expandable polystyrene foam balls with powdery fiber reinforced resin systems, solidifying and washing. The physical performance of the small fiber balls can be conveniently and effectively controlled and improved by changing the foam diameter, the fiber and resin type and the coating thickness according to different environmental usage requirements.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

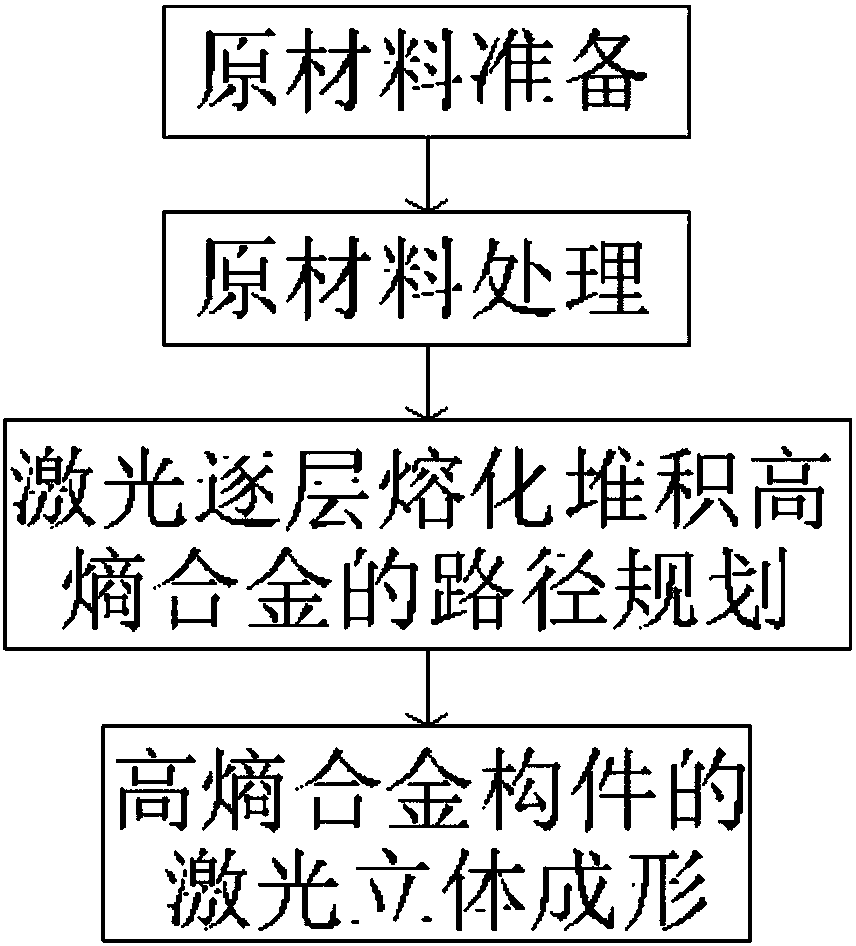

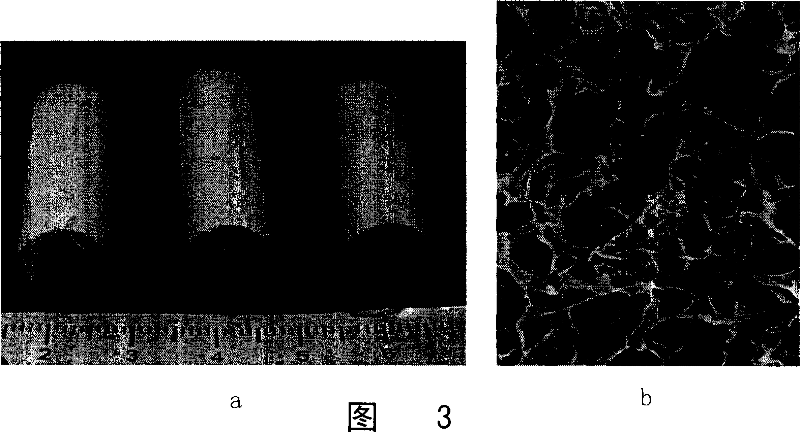

Laser solid forming method for high-entropy alloy member

ActiveCN108555295AHigh material utilizationImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyProcess optimizationHigh entropy alloys

The invention discloses a laser solid forming method for a high-entropy alloy member. The method comprises the steps of (1) raw material preparation; (2) raw material treatment; (3)route planning forlaser layer-by-layer fusion stackinghigh-entropy alloy; (4)laser solid forming ofthe high-entropy alloy member. The method is that through anorthogonal experiment, a process optimization parameter range of high-entropy alloy preparation is determined based on a large number of experiments, the influence rule of process parameters of laser power, air supply volume, scanning speed, power feed rate,scanning distance, layer thickness and the like on laser solid formingsingle track shapes and sizes of the high-entropy alloy member, the process parameter range is further determined, and the laser solid forming of the high-entropy alloy member is completed. The prepared high-entropy alloy member has the advantages of high forming efficiency, low cost, controllable internal organizations, high automation, easy operation and the like.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Chromium-free high boron iron-based casting alloy and preparation method

InactiveCN101979695AWide range of hardness adjustmentMeet the requirements of different working conditionsChromium freeChemical composition

The invention discloses a chromium-free high boron iron-based casting alloy and a preparation method. The high boron iron-based alloy comprises the following chemical components in percentage by weight: 0.2 to 1.0 percent of C, 1.0 to 4.5 percent of B, 0.20 to 0.70 percent of Si, 0.20 to 0.8 percent of Mn, less than 0.1 percent of S, less than 0.1 percent of P and the balance of Fe and inevitable trace impurities. The alloy is produced by an electric induction furnace, and smelted and cast and then is subjected to heat treatment and used. The alloy does not contain chromium and has a low price and high comprehensive performance, and the alloy performance can be controlled in a large range by controlling the proportions of boron and carbon so as to meet the requirement of different working conditions. The method has the advantages of low production cost, simple process, and high operability.

Owner:KUNMING UNIV OF SCI & TECH

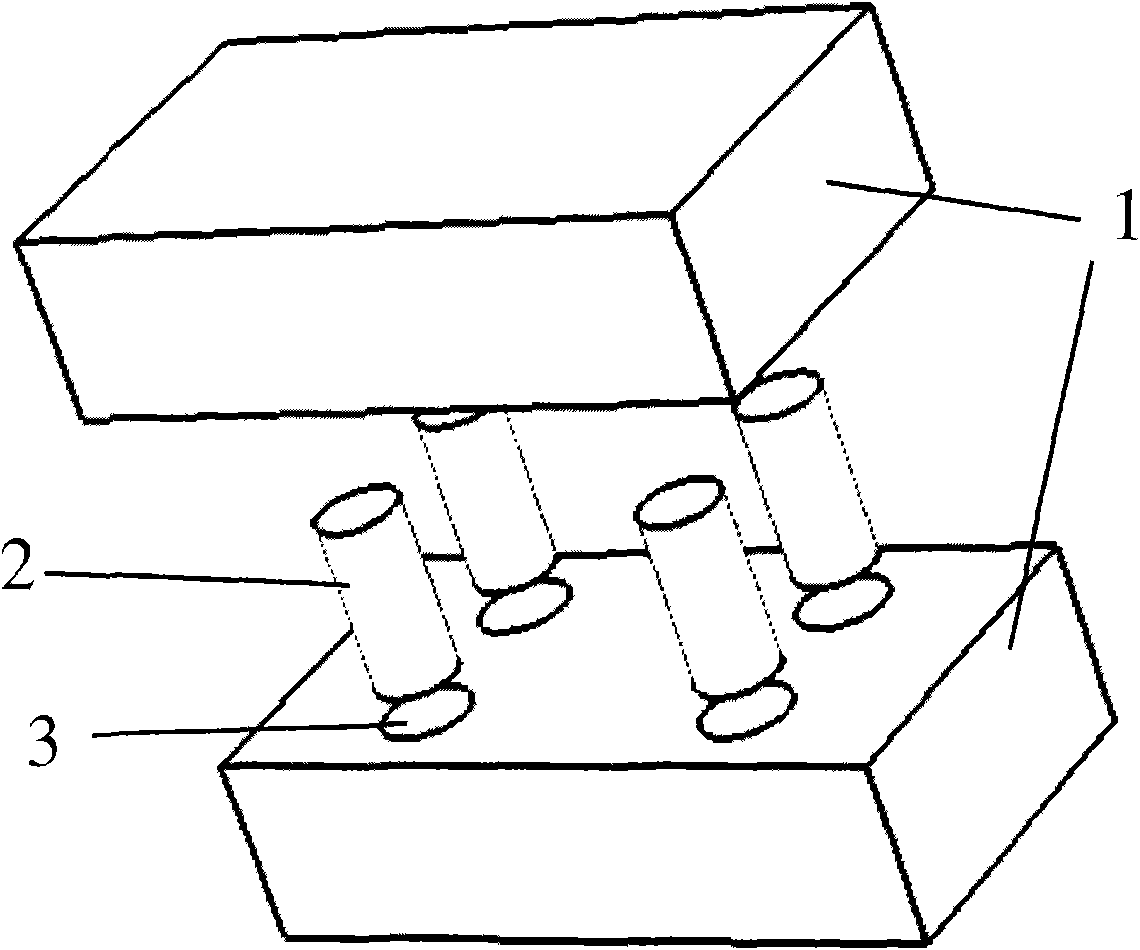

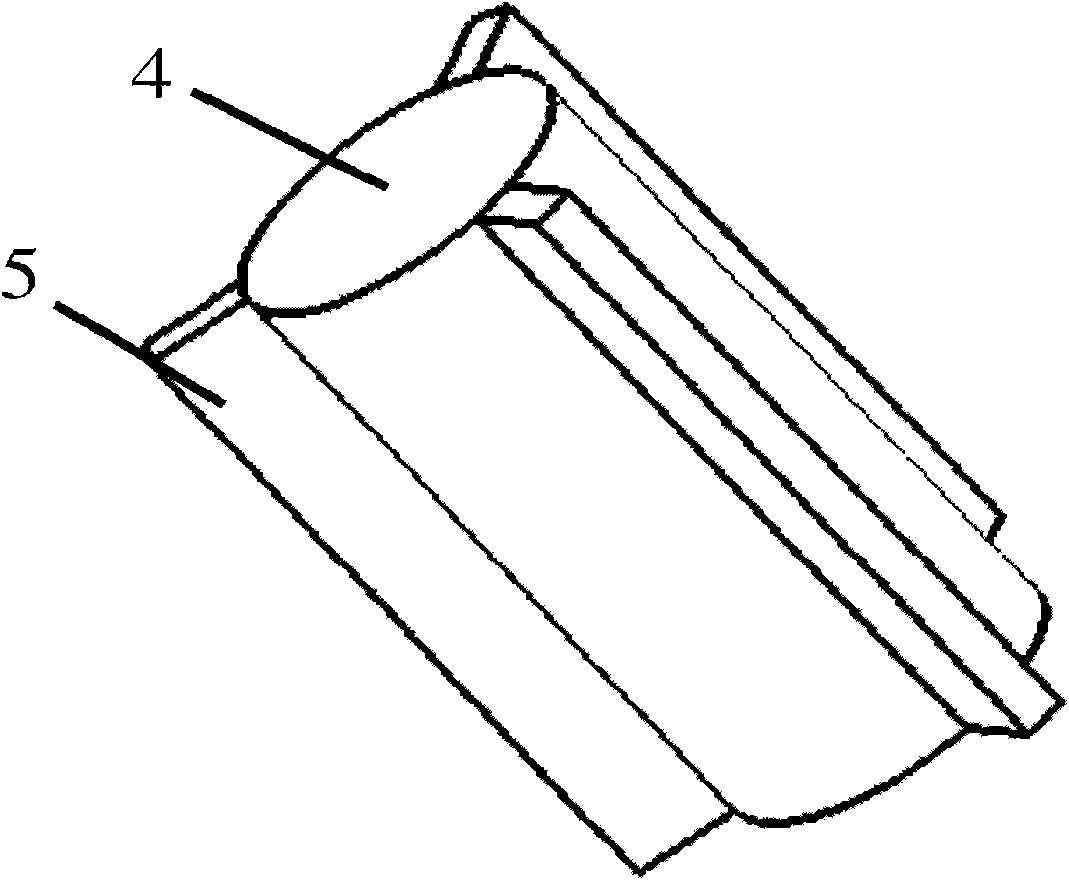

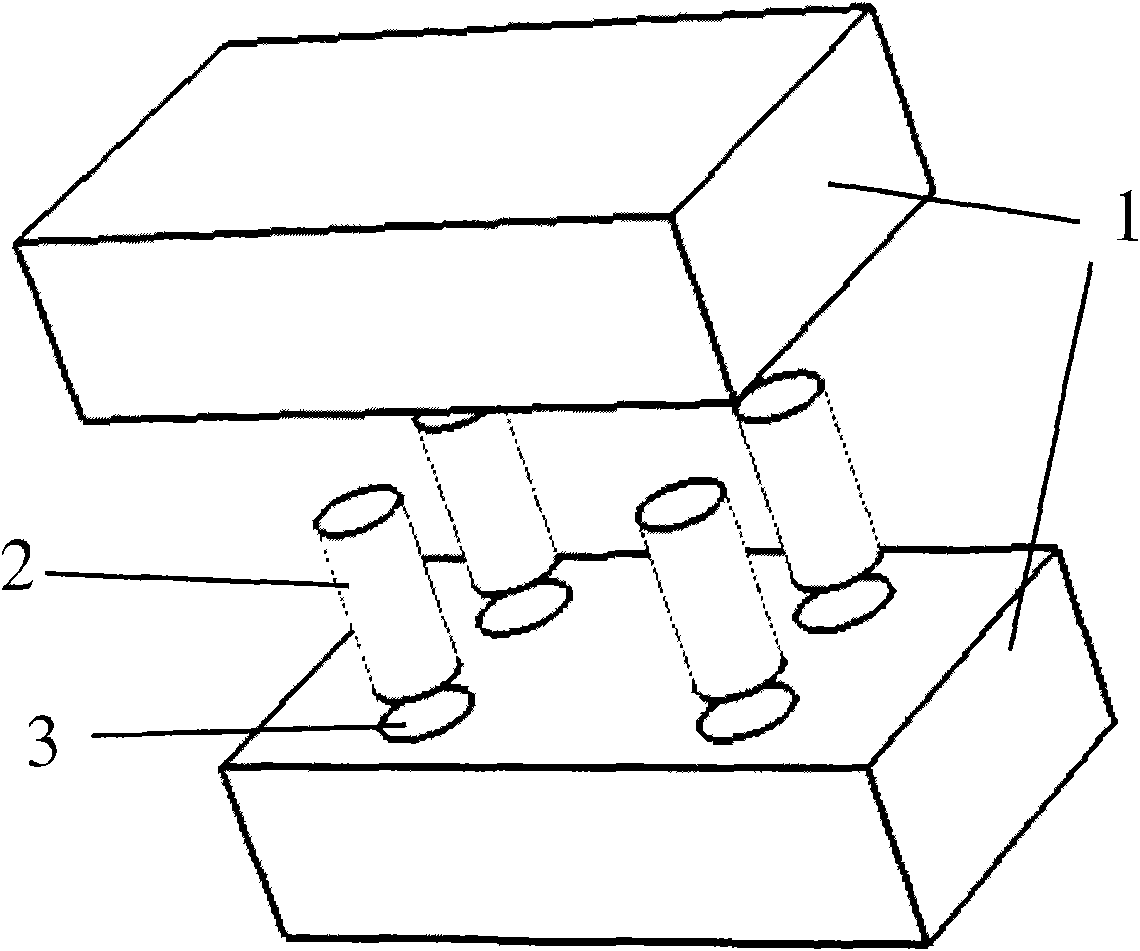

Method for manufacturing prefabricated concrete heat storage module for solar heat power generation

InactiveCN101876487AEasy constructionLow priceSolid waste managementSolar heat devicesSlagEngineering

The invention relates to a prefabricated concrete heat storage module for solar heat power generation. The prefabricated concrete heat storage module consists of two heat storage concrete blocks which have the same structure, wherein a heat exchange tube is arranged in each heat storage concrete block; the outer wall of each heat exchange tube is provided with a plurality of uniformly distributed heat exchange stainless steel fins; each heat storage concrete block is provided with a plurality of communicated concave connection grooves; and in assembling, the concave connection grooves of the two heat storage concrete blocks are connected into one body by the insertion of connecting rods. The manufacturing method comprises the following steps of: uniformly mixing raw materials by a dry process; adding water in an amount which is 4 to 6 percent based on the weight of the raw materials; uniformly mixing the raw materials and the water; placing a mixture in a steel mould which is provided with the heat exchange tube; demoulding after 24 hours; curing a product in water at the temperature of between 20 to 25 DEG C for 72 hours; and drying to form the prefabricated concrete heat storage module, wherein the raw materials comprise the following components: basalt aggregate, slag, aluminate cement, activated aluminum oxide powder, silicon powder, cyanite powder and natural graphite powder. The method for manufacturing the prefabricated concrete heat storage module for the solar heat power generation has the advantages of simple construction, low cost, convenient transportation, stable performance and the like.

Owner:WUHAN UNIV OF TECH

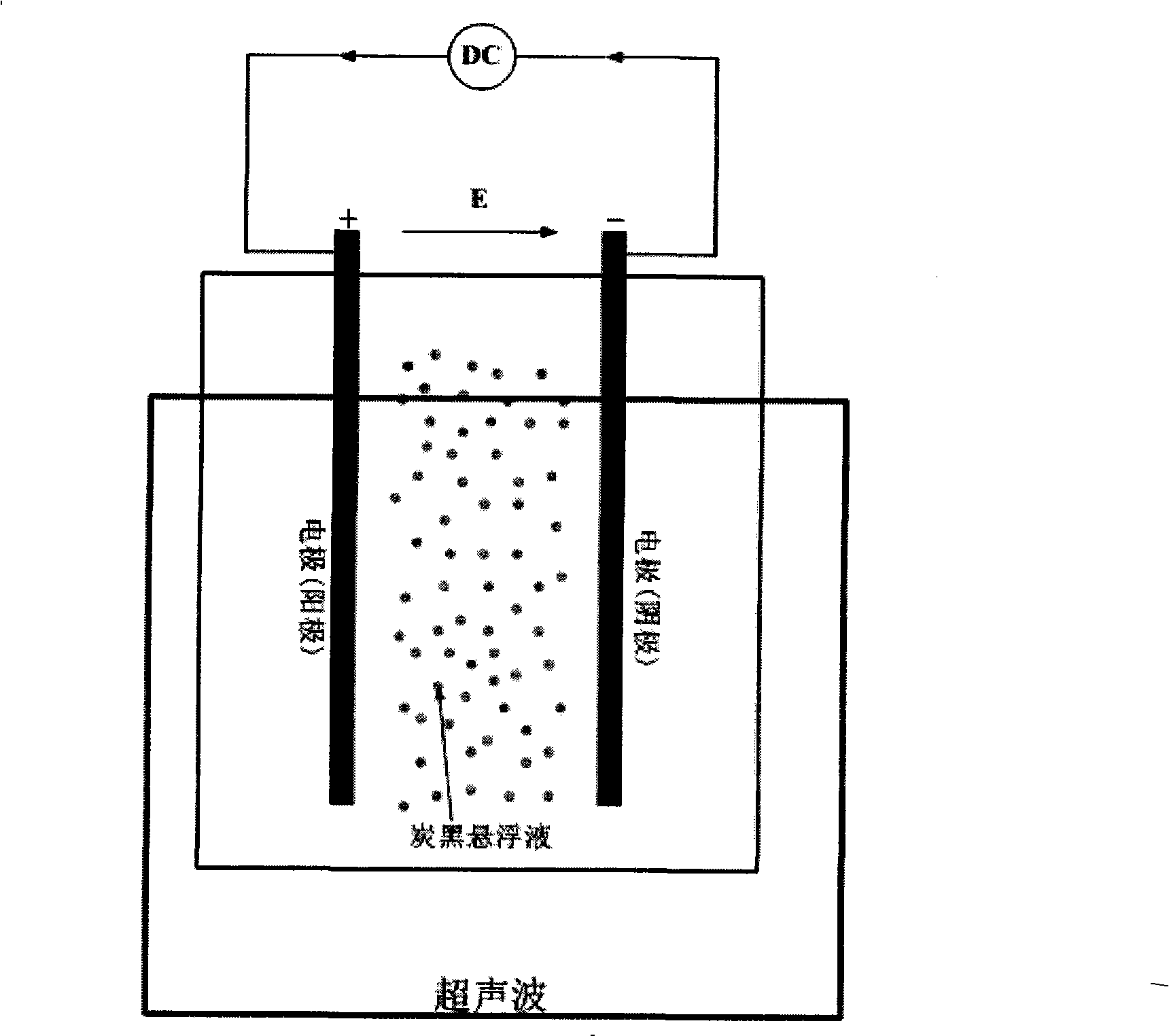

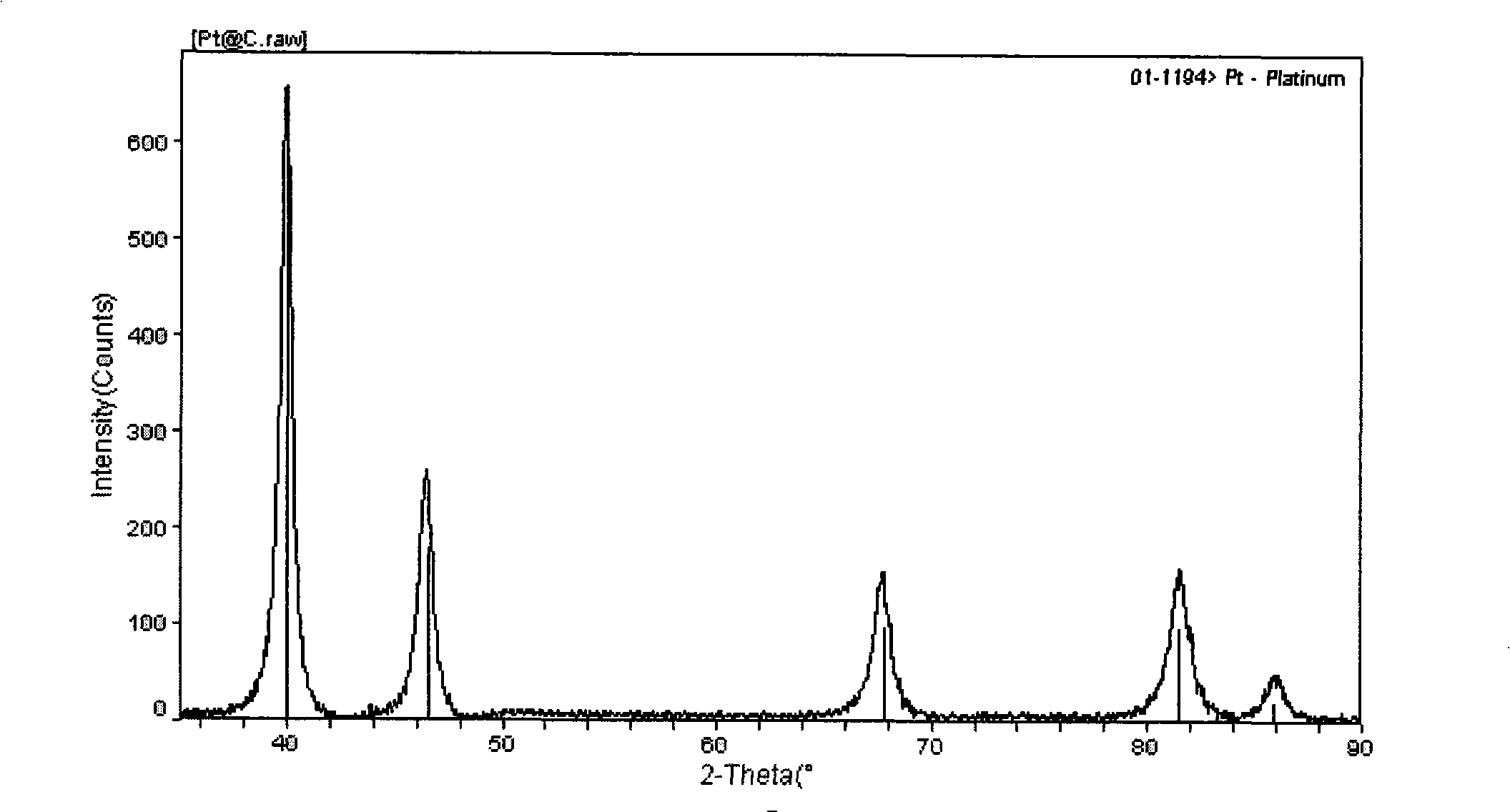

Method for preparing supported type nano Pt(Pt-M)/carrier catalyst

InactiveCN101352683AReduce manufacturing costLong electrode lifeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryVolt-ampere

The invention relates to a preparation method of a load-typed nanometer Pt (Pt-M) / carrier catalyst, which comprises that a carrier is uniformly dispersed in a chloroplatinic acid solution to obtain an electrolyte which is then infused to a ultrasound-imposed double-platinum-electrode electrolysis bath for electrodeposition, so as to obtain a catalyst suspension of a nanometer Pt (Pt-M) catalyst which is uniformly loaded on the carrier and then separated to obtain the load-typed nanometer Pt (Pt-M) / carrier catalyst. The preparation method loads the nanometer Pt (Pt-M) on the carrier directly, thus avoiding the defects of high-temperature reduction or use of reducers for preparation of other methods; the preparation method does not require to conduct separate activation or modification treatment to the carrier and has the advantages of simple process and catalyst with adjustable size, low cost and no environmental pollution, thus being a universal method easy for industrialized massive production. By determining with cyclic volt-ampere curves, in terms of performance, 40 percent load-typed nanometer Pt / C catalyst prepared by the invention is superior to similar products produced by the worldwide advanced Johnson Matthey Company.

Owner:NANJING UNIV

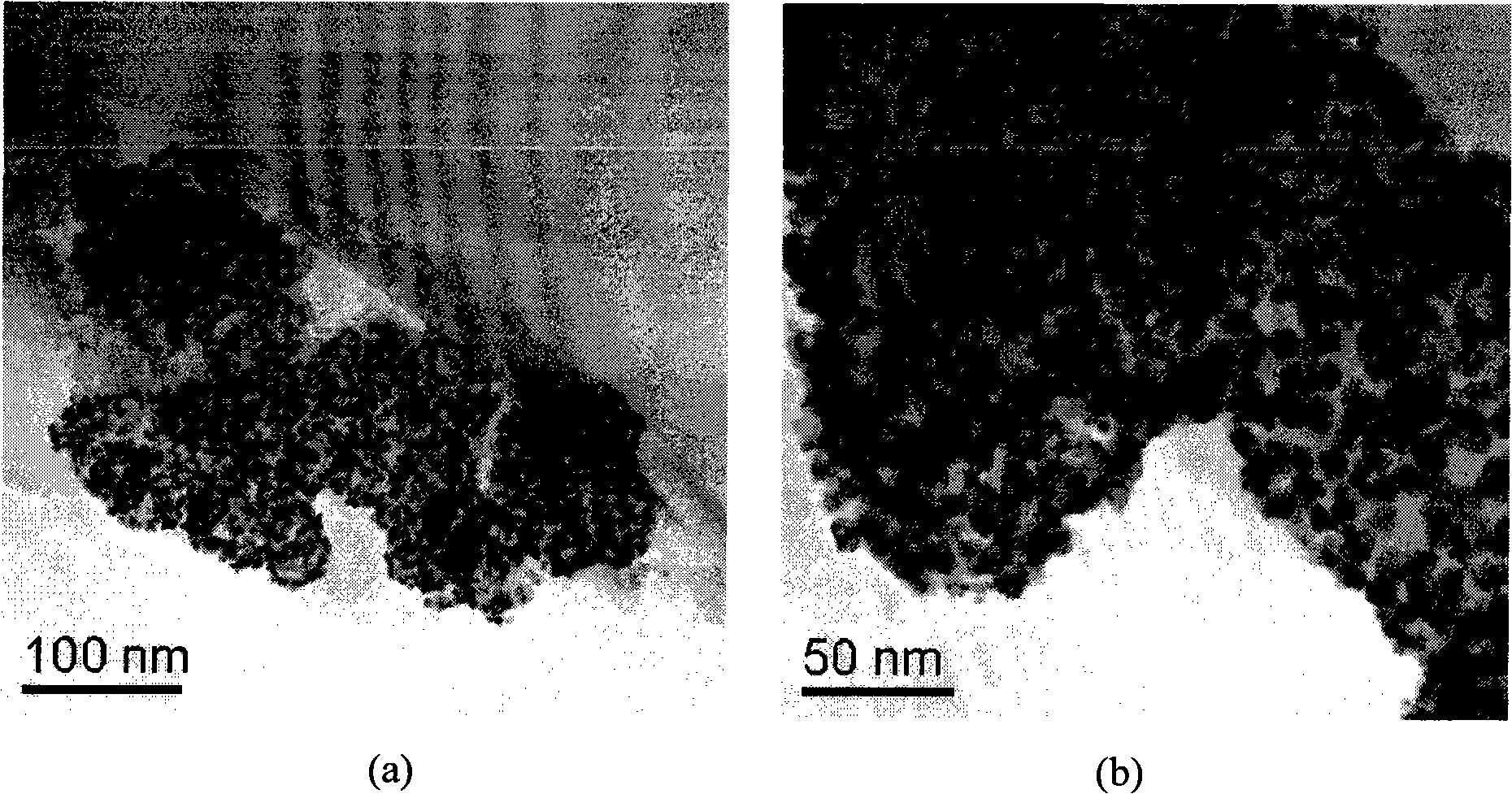

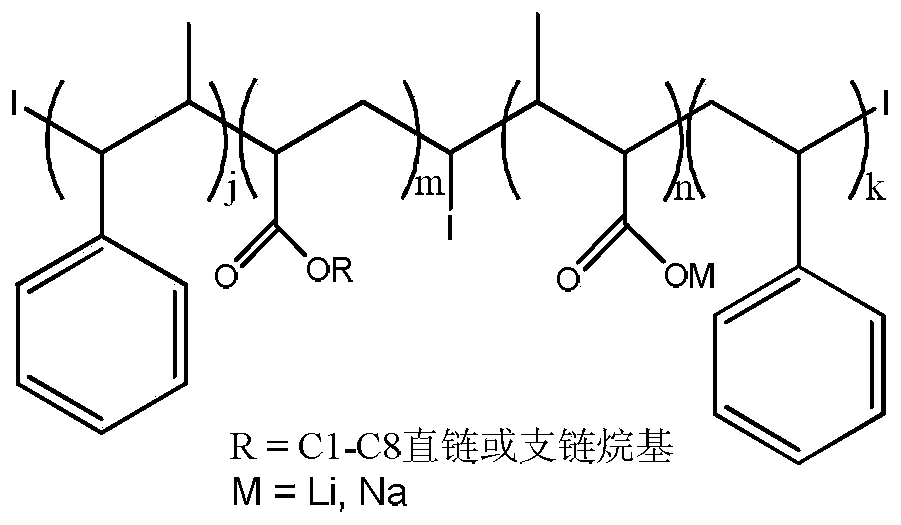

Preparation method of silicon-based negative electrode binder of lithium battery and binder

ActiveCN109722190ASimple preparation processPolymerization conditions are mildNon-macromolecular adhesive additivesCell electrodesEmulsionCurrent collector

The invention discloses a preparation method of a silicon-based negative electrode binder of a lithium battery and the binder. The preparation method comprises the following steps: firstly, polymerizing an iodine-transfer active radical fine emulsion to prepare a polyacrylate seed emulsion, then adding styrene monomers for further polymerization, and finally, carrying out partial hydrolysis on theblock copolymer under an alkaline condition to obtain the polyethylene-polyacrylate-polyacrylic acid-polystyrene block copolymer binder. According to the invention, the preparation process is simple,the polymerization conditions are mild, the molecular weight and composition regulation of the block copolymer are convenient, the performance is controllable, the prepared binder can be used for greatly enhancing the binding force between powder granules and a current collector and the binding force among the powder granules, and the problems of volume expansion and the like in charging and discharging processes of the battery when a silicon material is used as an active substance can be relieved. In addition, the binder has good electrical conductivity and low internal resistance and can beused for preparing the silicon-based negative electrode of the lithium battery, so that the lithium ion battery has excellent electrochemical performance.

Owner:ZHEJIANG CASNOVO MATERIALS

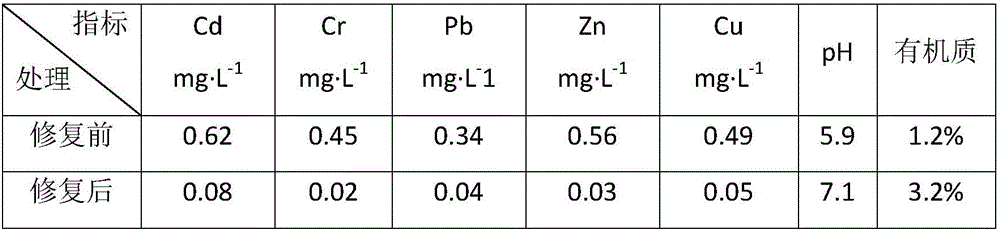

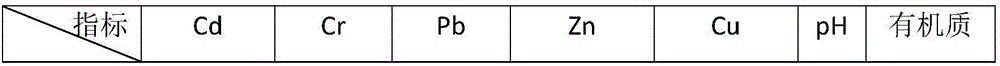

Heavy metal repairing material based on organic sludge and use method of material

InactiveCN106001098ALow water solubilityReduce exchangeable contentAgriculture tools and machinesContaminated soil reclamationSludgeResource utilization

The invention discloses a heavy metal restoration material based on organic sludge and a method for using the same. The restoration material is prepared from a certain proportion of organic treatment sludge, mineral materials and a compound stabilizing regulator as raw materials. The method of use is: add the heavy metal restoration material based on organic sludge to the contaminated soil polluted by heavy metals, wherein the mass ratio of the heavy metal restoration material based on organic sludge to the contaminated soil is 1:3-10, add water and stir to mix evenly , standing and aging for 15-60 days at a temperature of 5°C-45°C, an air humidity of 25%-90%, and a soil moisture content of 10%-60%. The restoration material can not only realize the resource utilization of urban sludge, but also solidify heavy metals in polluted soil, reduce the absorption of heavy metals by crops, improve soil structure, increase soil fertility, and revitalize barren land, and the cost of raw materials is extremely low. The usage method is simple and convenient to operate.

Owner:GEZHOUBA ZHONGGU TECH CO LTD

Preparation method for molecular sieve/organic composite permeable vaporization membrane

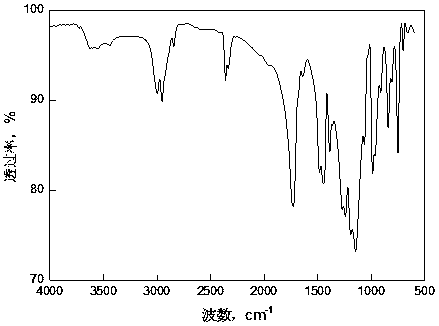

InactiveCN102500243APerformance is easy to controlGood surface continuitySemi-permeable membranesMolecular sieveAlcohol

The invention belongs to the field of membrane separation and particularly relates to a preparation method for inorganic / organic high polymer composite permeable vaporization membrane taking molecular sieve materials as a separation layer and an organic high polymer microfiltration membrane as a support body. The composite membrane can use permeable vaporization to enable organic matters in organic systems such as alcohols, ketones, amines and the like to pass through preferentially, so as to achieve the separation of organic matters and water.

Owner:CHANGZHOU UNIV

Preparation method of thermoplastic polyurethane porous membrane

PendingCN111100318APrevent intrusionGood mechanical propertiesAbsorbent padsBandagesPolymer scienceFoaming agent

The invention discloses a preparation method of a thermoplastic polyurethane porous membrane. The method can be used for preparing thermoplastic polyurethane porous membranes with different pore structures, and the porosity and water vapor permeability of a thermoplastic polyurethane porous membrane are controlled by controlling the content of a pore-foaming agent and coagulating bath. The methodcomprises the following steps: dissolving thermoplastic polyurethane or thermoplastic polyurethane and a pore-forming agent in a solvent, scraping a membrane on a flat plate by using a scraper, soaking the membrane in a coagulating bath at different temperatures to cause phase separation, and soaking the membrane in running water to wash out the residual solvent and pore-forming agent, thereby obtaining the thermoplastic polyurethane porous membrane. The preparation method is simple and convenient to operate, thermoplastic polyurethane porous membranes with different water vapor transmission rates and porosities can be prepared as required, and the thermoplastic polyurethane porous membranes have good mechanical properties, biocompatibility and chemical stability, can be applied to the fields of medical dressings, fabrics, leather and the like, and have good application prospects.

Owner:SUN YAT SEN UNIV

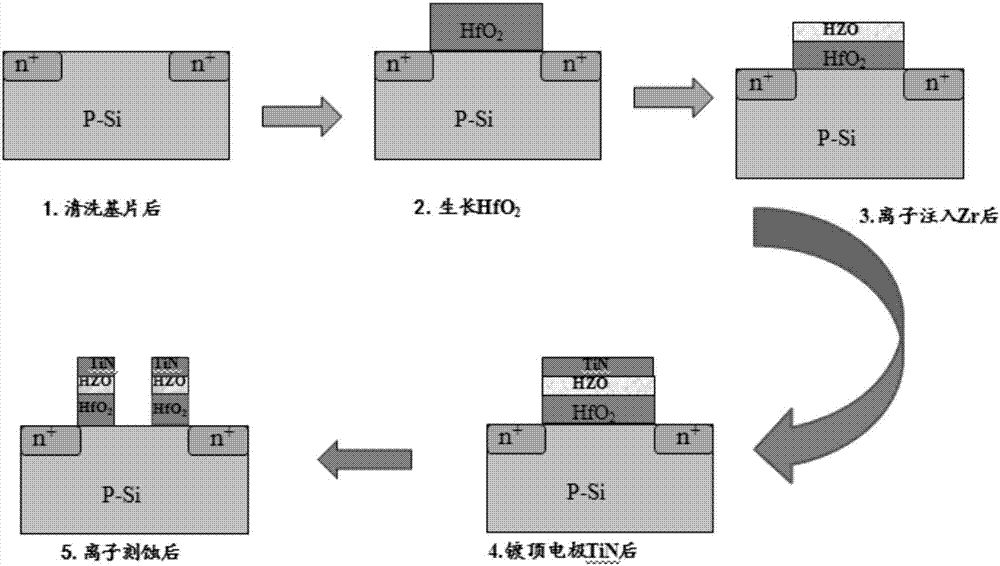

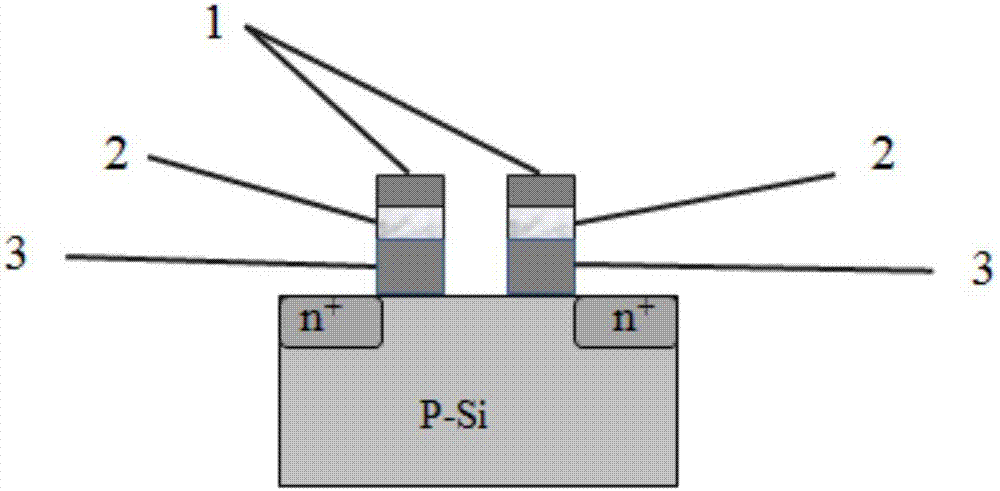

Ion implantation doping-based preparation method of hafnium oxide ferroelectric gate

ActiveCN107146759APrecise control of concentrationReduce interface effectsSemiconductor/solid-state device manufacturingSemiconductor devicesFerroelectric thin filmsThermal treatment

The invention provides an ion implantation doped HfO2 based preparation process of an HfO2 MIFS ferroelectric gate. The preparation process comprises the steps of firstly, cleaning a P-Si or n-Si substrate by a standard cleaning process to remove particles and other pollutants on a Si surface, afterwards depositing an appropriate thickness of HfO2 on a silicon wafer, and performing annealing; secondly, doping HfO2 by an ion implanter, and annealing the doped HfO2; thirdly, depositing a top electrode on the doped HfO2, namely halfnium oxide ferroelectric thin film, and performing rapid thermal treatment on the electrode; and finally, etching an MFIS multi-layer thin film structure to form an MFIS array unit which is matched with the sizes of a source, a drain and a channel by a reactive ion etching method. By the preparation process, the doping concentration of the HfO2 ferroelectric gate thin film can be accurately controlled, and the preparation process is a mature operation process for preparing the thin film relatively simple to prepare and with lower preparation temperature.

Owner:XIANGTAN UNIV

Prepn process of tantalum-containing carbon-base composite material precursor

The preparation process of tantalum-containing carbon-base composite material precursor includes mixing coal tar pitch or petroleum asphalt of softening point of 60-80 deg.c and tantalum chloride in the mass ratio of 100 to 1-20 in inert atmosphere and water-less environment; and reaction at 260-420 deg.c and self pressurizing or 0.3-1.0 MPa pressure while mechanical stirring for 4-10 hr. The preparation process is simple and low in cost, and the tantalum-containing carbon-base composite material precursor may be used as the soaking agent, adhesive or self-sintering material for preparing high performance tantalum-containing carbon-base composite material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A composite solid electrolyte with high ionic conductivity and a preparation method thereof

InactiveCN109148944AFast transferReduce contact interfaceSolid electrolytesSecondary cellsSolid state electrolyteMass ratio

The invention relates to a composite solid electrolyte with high ionic conductivity and a preparation method thereof, belonging to the technical field of solid electrolyte for lithium ion batteries. The composite solid electrolyte is composed of inorganic solid electrolyte, polymer electrolyte and lithium salt. The mass ratio of inorganic solid electrolyte, polymer electrolyte and lithium salt is0.2-0.8: 0.2-0.8: 0.05-0.5. The invention prepares inorganic solid electrolyte nanofibers by electrostatic spinning, prepares vertically oriented inorganic solid electrolyte skeleton by freeze castingmethod, and pours polymer and lithium salt to form composite solid electrolyte. Nanofibers instead of nanoparticles have obvious advantages in the preparation of intact and uniform inorganic solid electrolyte skeleton and the formation of fast Li + transport pathway, which can significantly improve the room temperature ionic conductivity of the electrolyte, up to 10<-4>S.cm<-1>. By adjusting thesize of nanofibers and freeze-casting conditions to control the skeleton structure, so as to regulate the comprehensive properties of the electrolyte.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

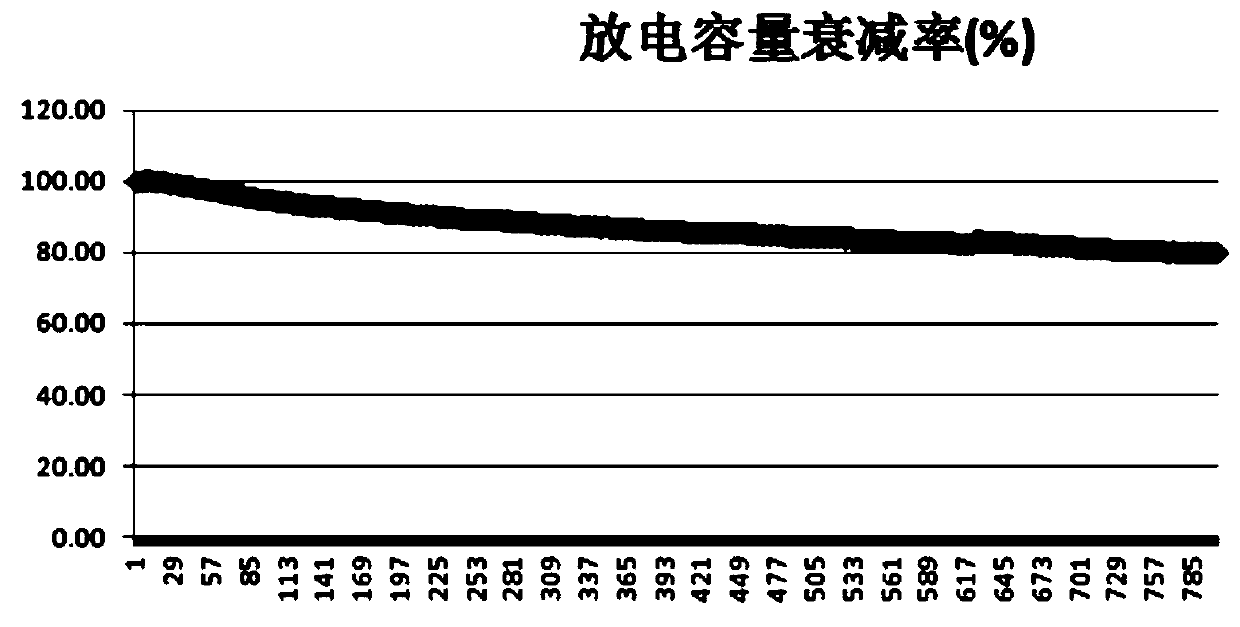

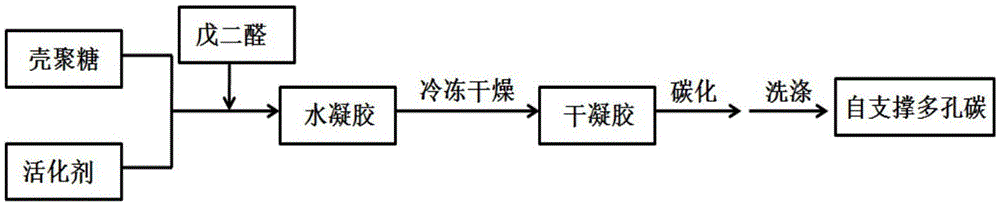

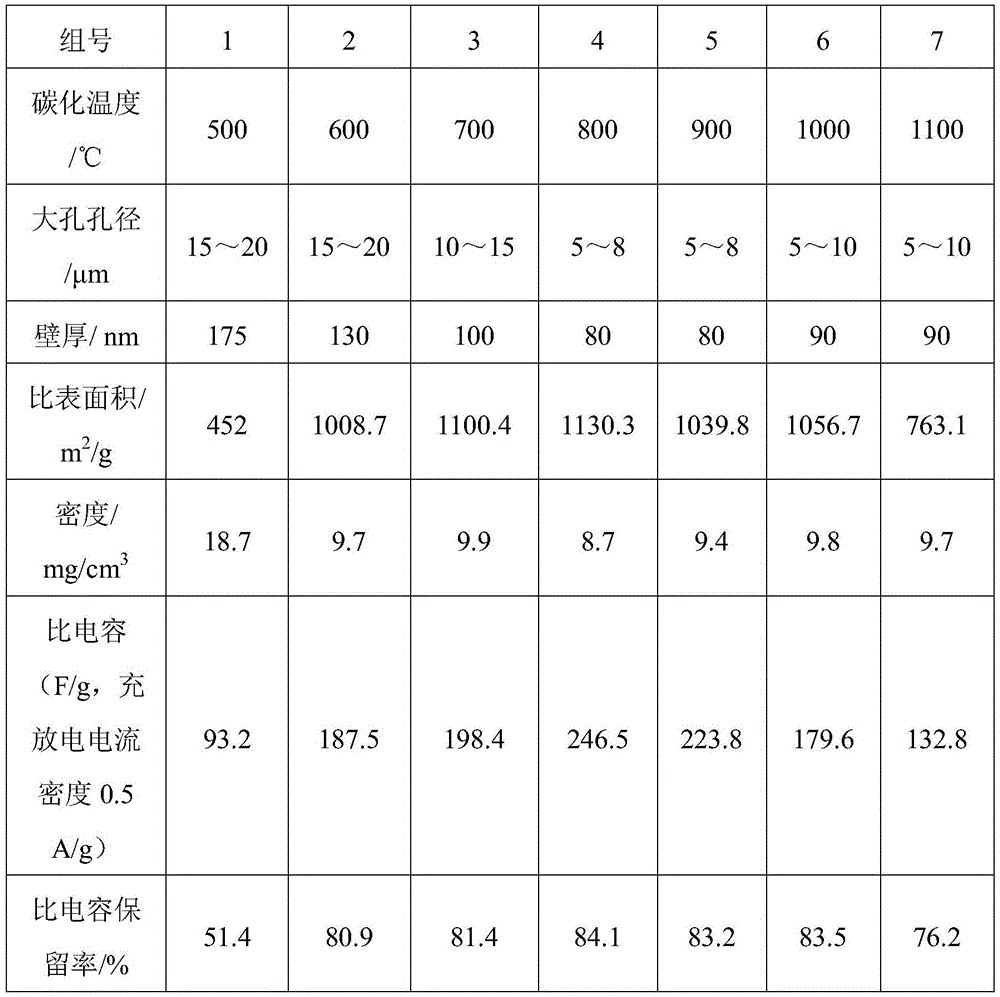

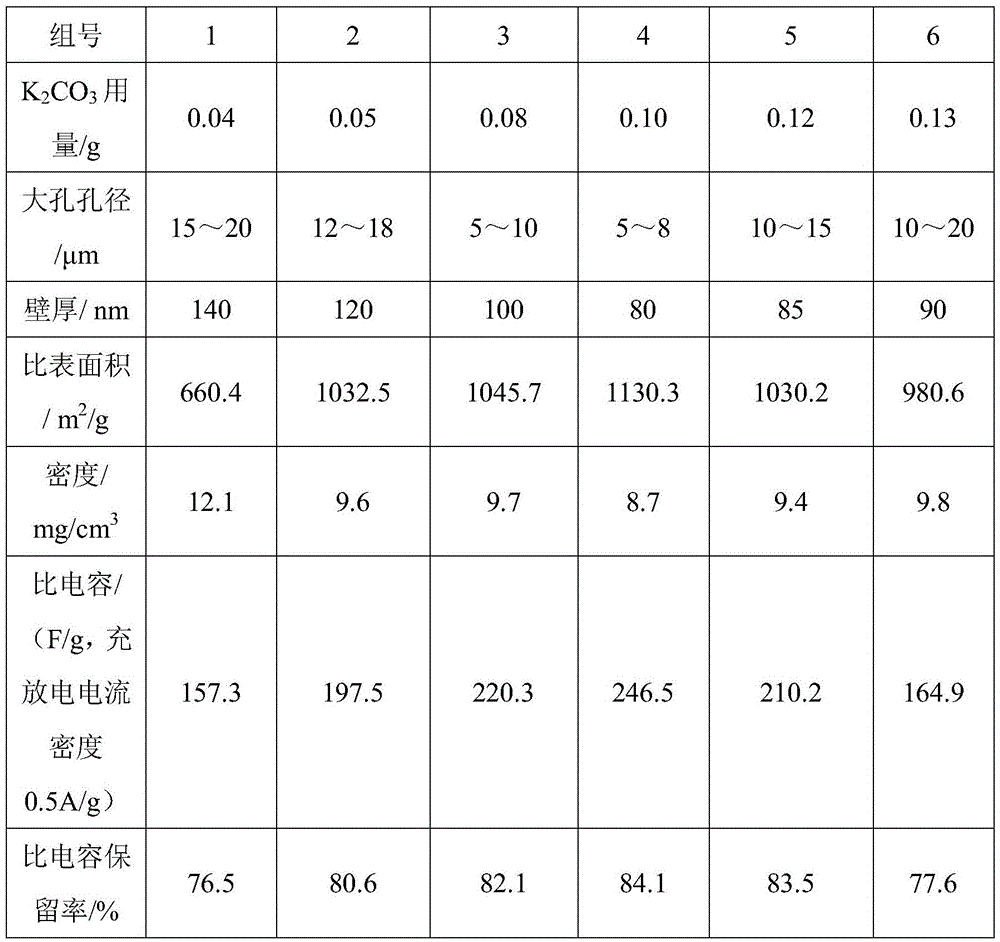

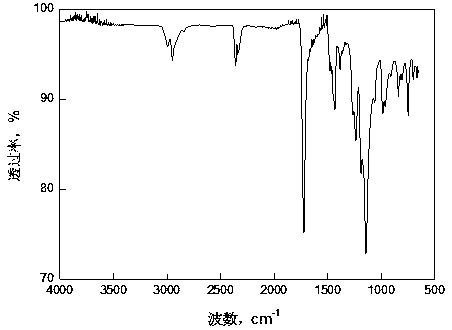

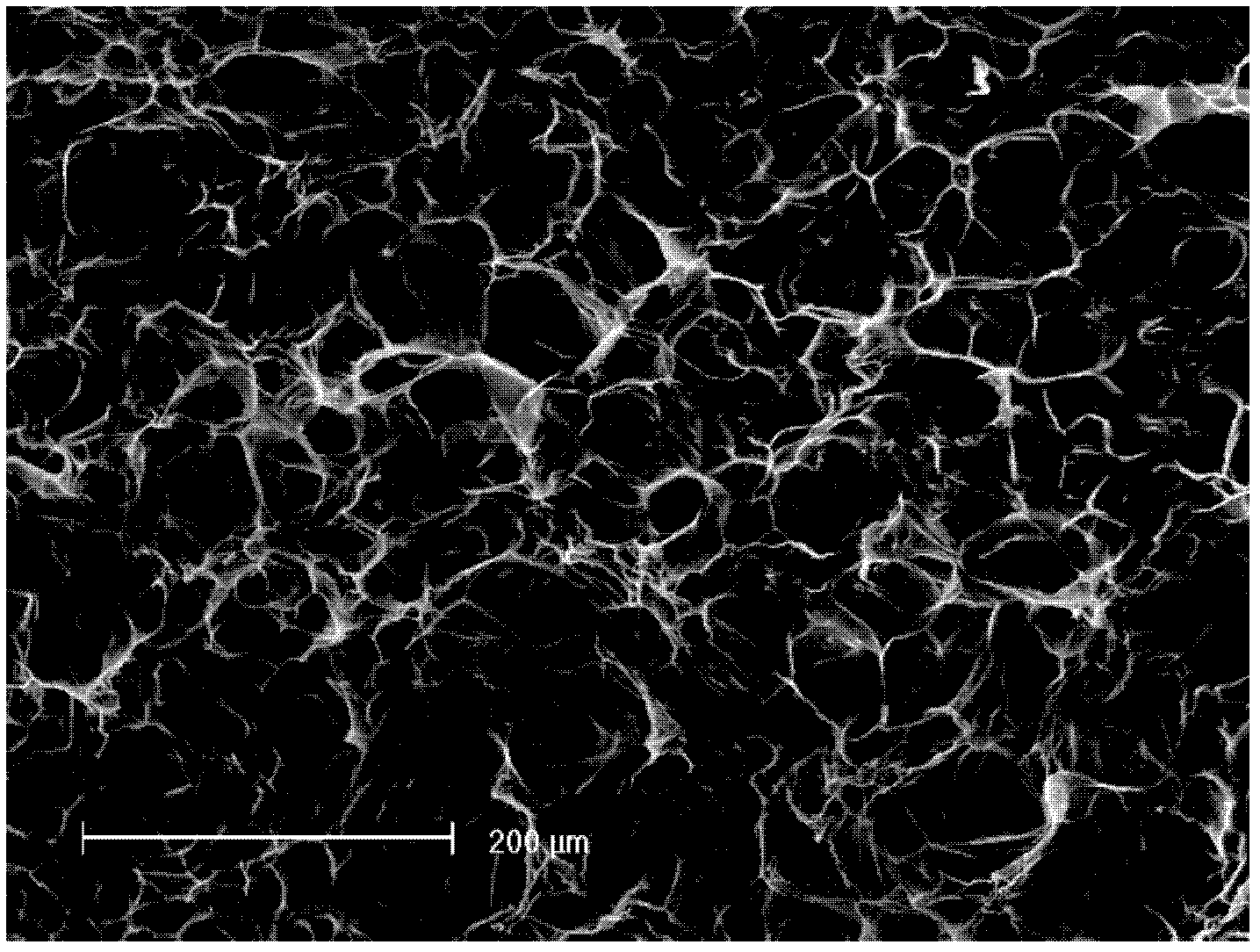

Self-supporting porous carbon used for supercapacitor electrode material and preparing method thereof

ActiveCN105600768APerformance is easy to controlEasy to manufactureHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses self-supporting porous carbon used for a supercapacitor electrode material and a preparing method thereof. The self-supporting porous carbon is of a three-dimensionally-communicated large-pore structure, the aperture of large pores is 5-20 microns, the wall thickness is 80-200 nm, mesoporous structures and micropore structures are formed on the hole walls, the specific area can be 1,000 m<2> / g or above, and the density is lower than 10 mg / cm<3>. Meanwhile, the invention discloses a preparing method of the self-supporting porous carbon. The self-supporting porous carbon has the advantages that the self-supporting porous carbon has multi-stage pore structures including the large-pore structure, the mesoporous structures and the micropore structures, the specific area can be 1,000 m<2> / g or above, the specific capacitance can be 246.5 F / g, the charging-discharging current density is increased to 10 A / g from 0.5 A / g, the specific capacitance retention rate is 80% or above and 95% or above after 10,000 times of circulation, and the power density of an assembled symmetric capacitor can be 25 Kw / kg.

Owner:YANCHENG INST OF TECH

Preparation method of self crosslinking type acrylateresin high-temperature sintering electronic silver paste

InactiveCN101834008AThixotropicAnti-sinkingNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolution polymerization

The invention discloses a preparation method of self crosslinking type acrylateresin high-temperature sintering electronic silver paste. The method comprises the following steps of: firstly, selecting acrylate monomers to prepare self crosslinking type acrylateresin through solution polymerization; then mixing and dispersing superfine silver powder, low-melting-point lead-free glass powder, a surface modifier, an auxiliary agent and a defoaming agent into the prepared self crosslinking type acrylateresin; and repeatedly grinding to prepare electronic silver paste. The method for preparing the high-temperature sintering electronic silver paste has the characteristics of simple process, convenience, easy application, no need of special equipment, low investment, convenient control of product properties, and the like.

Owner:ZHEJIANG UNIV

St/MAH-g-MMA (styrene/maleic anhydride-grafted-methyl methacrylate) graft copolymer, and preparation method and application thereof

The invention relates to an St / MAH-g-MMA (styrene / maleic anhydride-grafted-methyl methacrylate) graft copolymer, and a preparation method and application thereof, belonging to the technical field of high polymer synthesis. The synthesis technique of the St / MAH-g-MMA graft copolymer comprises a RAFT (reversible addition-fragmentation chain transfer) polymerization process using thioester as a chain-transfer agent, MMA macromolecule monomer synthesis, and preparation of the St / MAH-g-MMA graft copolymer. The method can be used for preparing series of graft copolymers with different chain lengths. The St / MAH-g-MMA graft copolymer can be used for modifying PC (polycarbonate), ABS (acrylonitrile-butadiene-styrene) and PS (polystyrene) to improve the glossiness, surface hardness, weather resistance and the like of the alloy.

Owner:ZHEJIANG UNIV OF TECH

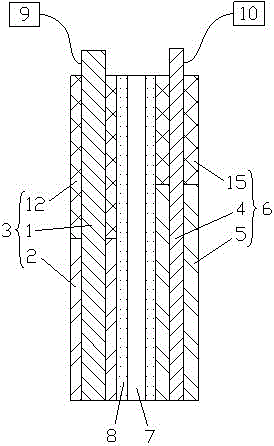

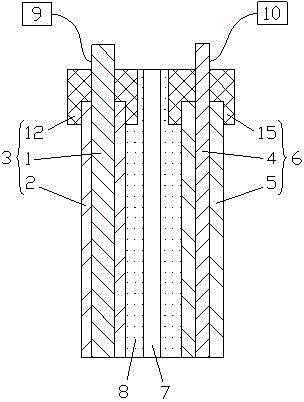

Super capacitor battery and manufacturing method thereof

InactiveCN104599852AIncrease energy densitySimple processHybrid capacitor electrodesHybrid/EDL manufactureElectric capacityHigh energy

The invention relates to a super capacitor battery and a manufacturing method thereof. The super capacitor battery is composed of a positive electrode, a negative electrode, a membrane, and an electrolyte. The positive electrode is connected with a positive electrode plate, and the negative electrode is connected with a negative electrode plate. At least one of the positive electrode plate and the negative electrode plate contains both a super capacitor electrode active material and a battery electrode active material. Each electrode plate is composed of a current collector and electrode active layers covering the surface of the current collector and containing electrode active material. The super capacitor electrode active material and the battery electrode active material are at least contained in different electrode active layers on the surface of the same current collector. No coverage exists or local coverage exists between the different electrode active layers. The super capacitor battery of the invention not only has high energy density and high power density, but also is simple in process and controllable in performance.

Owner:张彩欣

Three-dimensional isinglass multi-hole bracket and the preparing method

InactiveCN101036803AUniform pore structureControllable pore structureCoatingsProsthesisFreeze-dryingGelatin

The invention discloses 3D gelatin porous scaffold material, with features of homogeneous pore size and distribution, easily forming, resisting compression and resisting bending. The invention also discloses a method of 3D gelatin porous scaffold material using latex freeze drying method. The said 3D gelatin porous scaffold material is especiallu adapted for skin tissue scaffold material.

Owner:SHANGHAI TISSUE ENG LIFE SCI

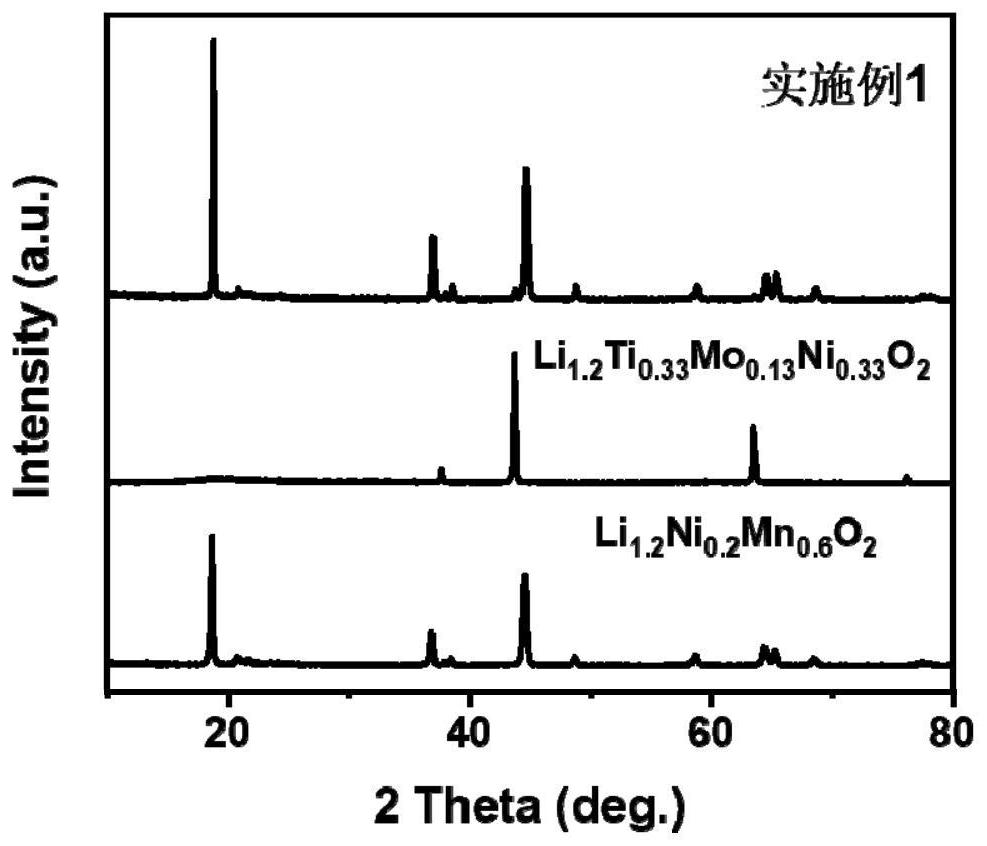

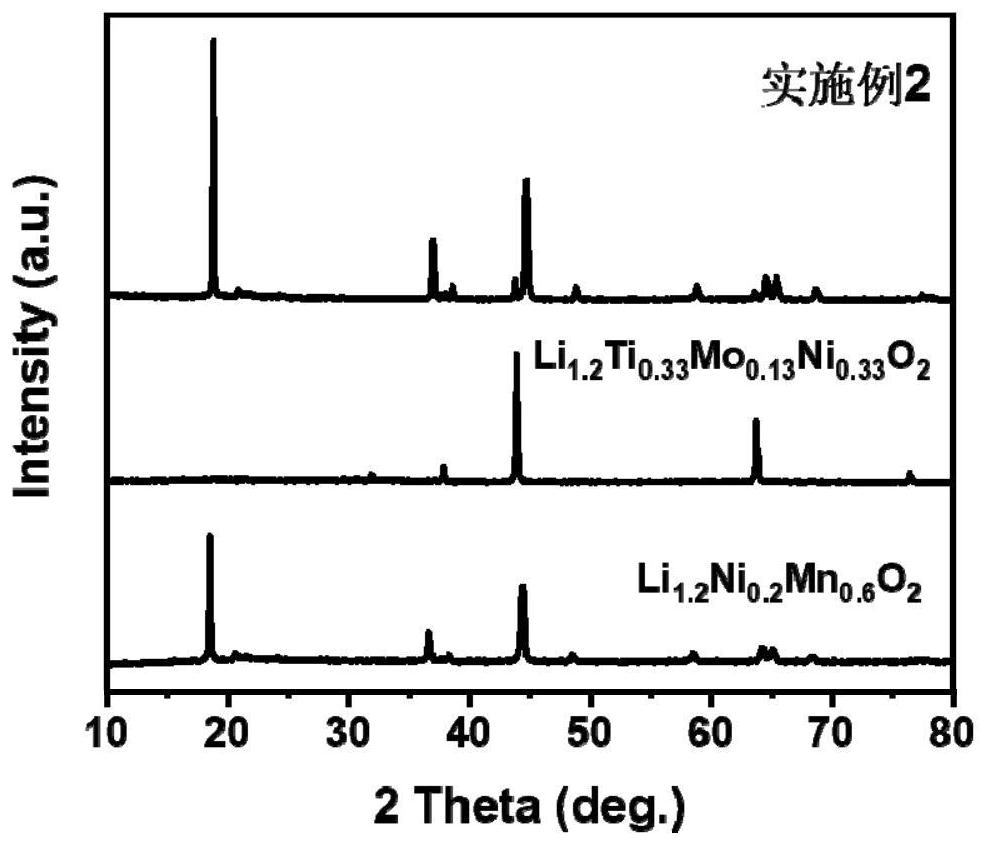

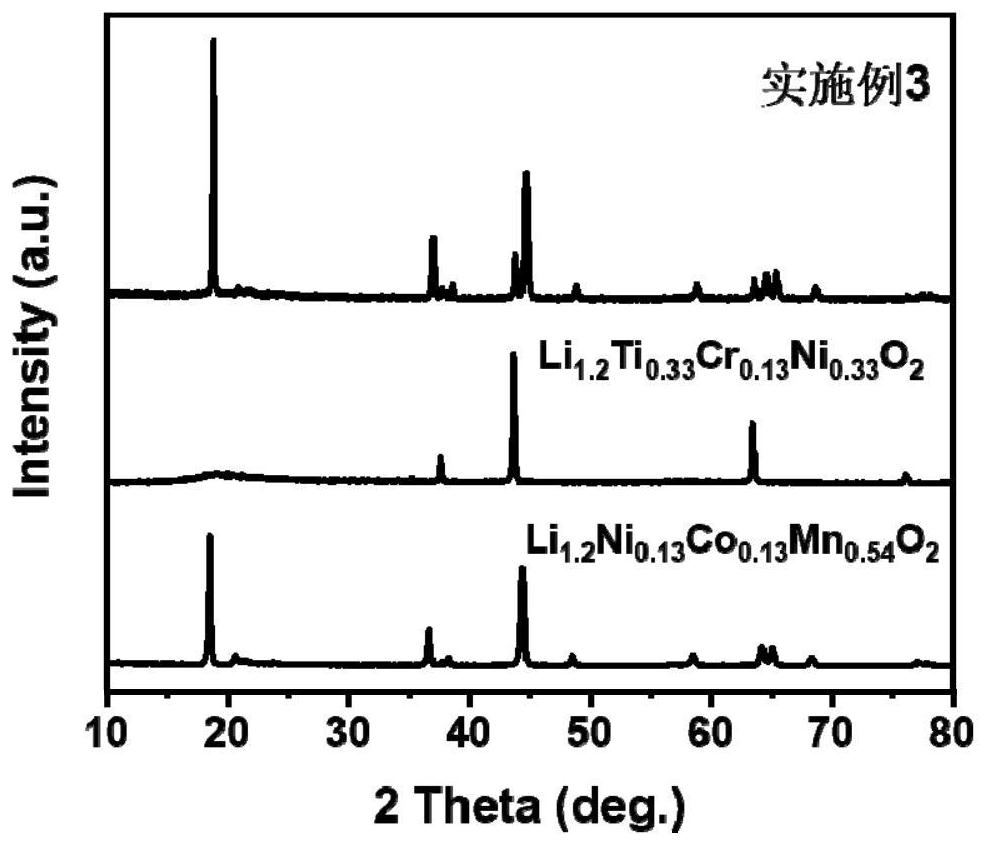

Mixed lithium-rich positive electrode material and preparation method and application thereof

ActiveCN113690414AImprove lithium ion mobilityGood material consistencySecondary cellsPositive electrodesCharge and dischargeLithium

The invention discloses a mixed lithium-rich positive electrode material and a preparation method and application thereof. The mixed lithium-rich positive electrode material is prepared by mixing a layered lithium-rich manganese-based positive electrode material and a lithium-rich disordered rock salt structure positive electrode material, wherein the chemical general formula of the layered lithium-rich manganese-based positive electrode material is xLi2MnO3.(1-x) LiMO2, and x is greater than 0 and less than 1; the chemical general formula of the lithium-rich disordered rock salt structure positive electrode material is Li1 + aTibMcNidO2, wherein 0.1<a<0.3, 0.1<b<0.4, 0.1<c<0.4, 0.2<d<0.4 and a+4b+6c+2d=3. The lithium-rich manganese-based positive electrode material component in the positive electrode material has a typical layered structure, transition metal redox and lattice oxygen redox exist in the charging / discharging process at the same time, and the lithium-rich disordered rock salt structure positive electrode material component has a three-dimensional disordered cation skeleton structure, which can stabilize the oxygen lattices and oxygen variable valence reaction in the lithium-rich oxide positive electrode material, and improve the lithium ion migration capability; the two positive electrode materials generate a specific synergistic effect, advantage complementation is realized, the material consistency is good, the performance is controllable, and the defects in the prior art are overcome.

Owner:北京理工大学重庆创新中心 +1

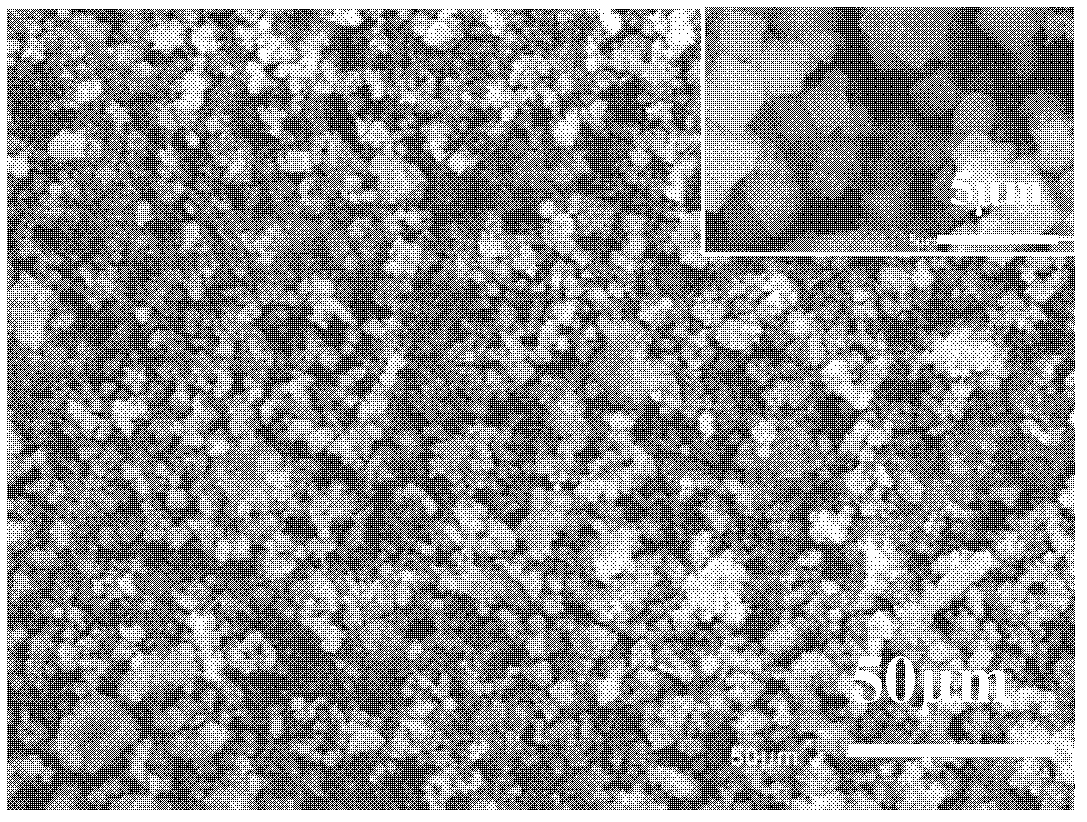

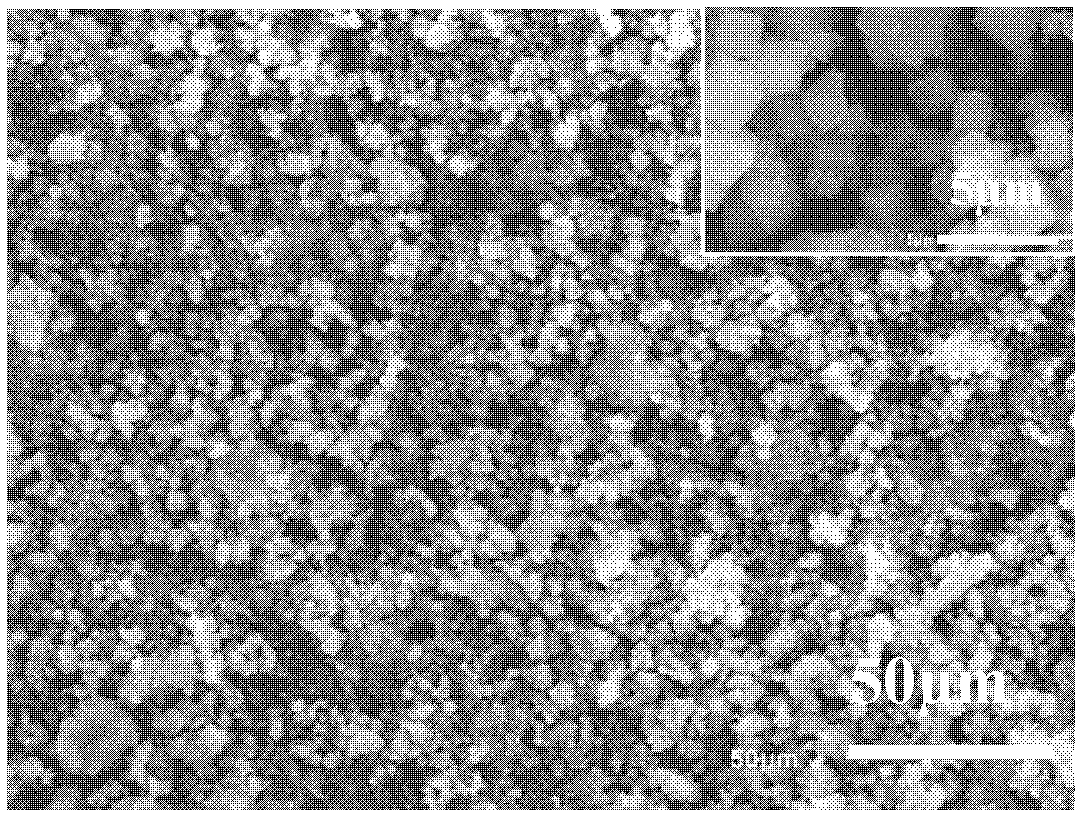

Preparation method of graphene coated electric-conductive fiber

InactiveCN108330679AImprove conductivityImprove mechanical propertiesSynthetic fibresCarbon fibresGraphene coatingConductive coating

The invention belongs to the technical field of carbon material and composite materials and particularly provides a preparation method of a graphene coated electric-conductive fiber. The method includes the steps of: 1) reducing graphene oxide into a graphene hydrosol as a precursor and performing impregnation dip-coating process to uniformly coating the fiber with graphene, which can be repeatedfor several times; 2) drying the fiber so that the surface of the fiber is coated with a complete and continuous graphene thin film, thus producing the graphene coated electric-conductive fiber. Meanwhile, when the sol is dried and dehydrated, the sol is shrunk, so that the compression generated during the shrinking process can tightly press the graphene coating layer onto the surface of the fiber, and the graphene is tightly combined with the fiber and is not liable to fall off. On the surface of the fiber, the lamellas of graphene are overlapped and communicated to form the electric-conductive coating layer, thus significantly improving electric-conductivity of fibers. The fiber composite material has excellent conductivity, can be used for eliminating static electricity and electromagnetic shielding and has great application prospect. The preparation method has simple processes and is controllable in product performance, and is suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Three-dimensional chitosan hydrogel and preparation method thereof

ActiveCN102604149AGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisToxicantSoft tissue engineering

The invention discloses a method for preparing three-dimensional chitosan hydrogel by using a high temperature crosslinking method and the obtained chitosan hydrogel. The method comprises the following steps of: (a) dispersing chitosan powder into a deionized water; (b) adjusting the pH of chitosan dispersion obtained in the step (a) to be subacid; (c) carrying out high temperature crosslinking on the solution obtained in the step (b) at the high temperature of 80-125 DEG C; and (d) after the crosslinking reaction is completed, soaking and cleaning an obtained product by using a posttreatment liquid so as to remove a residual acid liquid. The high temperature crosslinking method is simple in the preparation process; the reaction time is short; raw materials are unnecessary for special treatment; highly-toxic chemical substances such as crosslinking agents are not introduced to a preparation course; no any chemical toxicant remains in a final product; and the three-dimensional chitosan hydrogel is even in pore structure, good in connectivity and easy to form, and is very suitably used as a support material of soft tissue engineering such as skin and cartilage.

Owner:SHANGHAI HUAYI BIO LAB CO LTD

Pervaporation hybridigation composite film as well as preparation method and application thereof

InactiveCN102380320AImprove continuityImprove mechanical stabilityDistillationComposite filmPolyvinyl acetate

The invention provides a pervaporation hybridigation composite film, which consists of a separation layer and a support layer, wherein the separation layer is a mixture of hydrophilic NaA (naphthaleneacetic acid) and PVA (polyvinyl acetate). The pervaporation hybridigation composite film has the advantages that the separation performance is good, in addition, the mechanical intensity is high, the materialization stability is good, the preparation process is simple, the large-area preparation is easy, the further amplification is favorably realized, and the industrial production is finally realized. The invention also provides a preparation method of the composite film and application to the separation of mixtures of organic matter and water.

Owner:BEIJING CLP JIAMEI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com