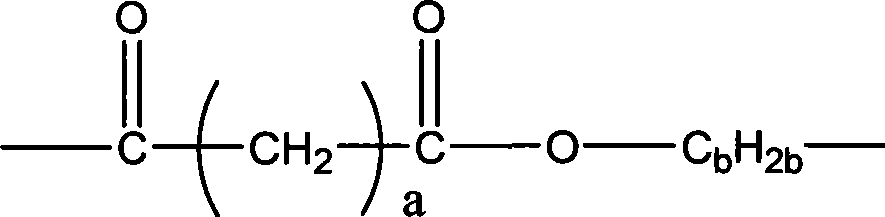

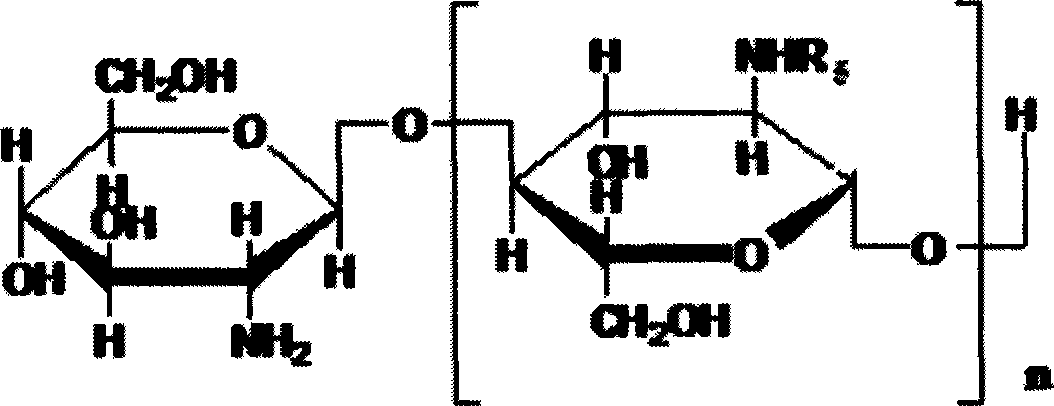

Preparation of chitosan-polyurethane ion complex elastomer material

A technology of elastomer material and chitosan, which is applied in the field of preparation of chitosan-polyurethane ion composite elastomer material, can solve the problem of single function of chitosan and polyurethane composite material, not much room for modification and improvement, The preparation process is not flexible enough to achieve the effect of simple preparation method, few steps, and flexible molecular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 10g of polytetrahydrofuran diol (Mn=1000) and 6.66g of isophorone diisocyanate successively in the three-necked flask, pass argon, stir mechanically, react at 75°C-85°C for 3 hours, then add 1.34g of diisocyanate Methylolpropionic acid, continue to react for 2 hours. Cool down, add 25ml of acetone to infiltrate, stir for 20 minutes, then add 1.01g of triethylamine and react for 20 minutes to obtain a colorless and transparent solution, that is, an acetone solution of polyurethane prepolymer. Stir mechanically, at room temperature, slowly drop 50ml of distilled water into the acetone solution of the polyurethane prepolymer, and react for 1 hour to obtain a stable colorless polyurethane microemulsion. The microemulsion was placed at room temperature for twelve months without precipitation.

Embodiment 2

[0046] Add 30g of amino silicone oil (Mn=3000), 5.22g of toluene diisocyanate, 30ml of tetrahydrofuran in sequence in the three-necked flask, pass argon, stir mechanically, react at 80°C-90°C for 2 hours, then add 1.50g of tartaric acid, continue React for 1 hour, lower the temperature and add 30ml of tetrahydrofuran for infiltration, stir for 30 minutes, then add 2.06g of diethyltriamine and react for 1 hour to obtain a colorless and transparent solution, that is, a solution of polyurethane prepolymer in tetrahydrofuran. With mechanical stirring and an oil bath at 20°C, slowly drop 100ml of distilled water into the tetrahydrofuran solution of the polyurethane prepolymer, and react for 36 hours to obtain a stable colorless polyurethane emulsion. The emulsion was stored at room temperature for twelve months without precipitation.

Embodiment 3

[0048] Add 200g of polyethylene oxide glycol (Mn=20000), 5.36g of terephthalylene diisocyanate successively in the three-necked flask, blow nitrogen, stir mechanically, react at 50°C-60°C for 6 hours, then add 1.63 g N, N-bishydroxyethylglycine, continue to react for 4 hours. Cool down, add 100ml DMSO for infiltration, stir for 30 minutes, then add 0.59g trimethylamine and react for 30 minutes to obtain a colorless and transparent solution, that is, a DMSO solution of polyurethane prepolymer. Mechanical stirring, oil bath 89 ° C, the DMSO solution of the polyurethane prepolymer was slowly dropped into 100ml of distilled water, and reacted for 10 minutes to obtain a stable colorless polyurethane microemulsion. The microemulsion was placed at room temperature for twelve months without precipitation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com