Function regulation and control structure production method based on continuous fiber composite material 3D printing

A 3D printing and continuous fiber technology, applied in the field of functional control structure preparation based on continuous fiber composite 3D printing, to meet the preparation requirements, improve mechanical properties, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

[0029] In this embodiment, a continuous fiber composite material 3D printer is used as the preparation device, Solidworks is the modeling software, ABAQUS is the simulation software, and ReplicatorG is the path generation software. The melt extrusion molding process is selected and the variable stiffness composite material with a central circular hole is used. Take a detailed description as an example.

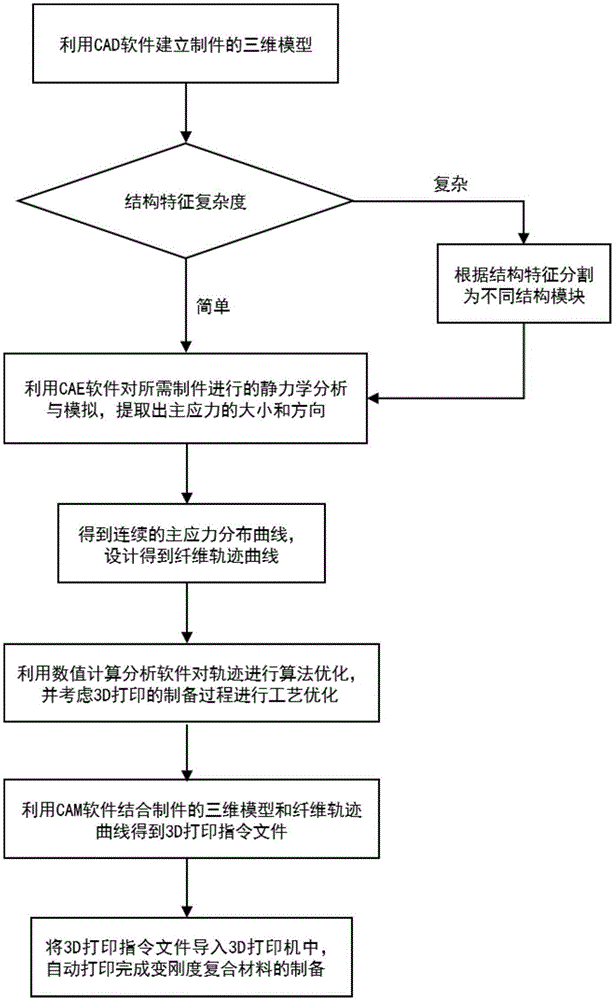

[0030] Reference figure 1 , A method for preparing a functional control structure based on continuous fiber composite 3D printing, including the following steps:

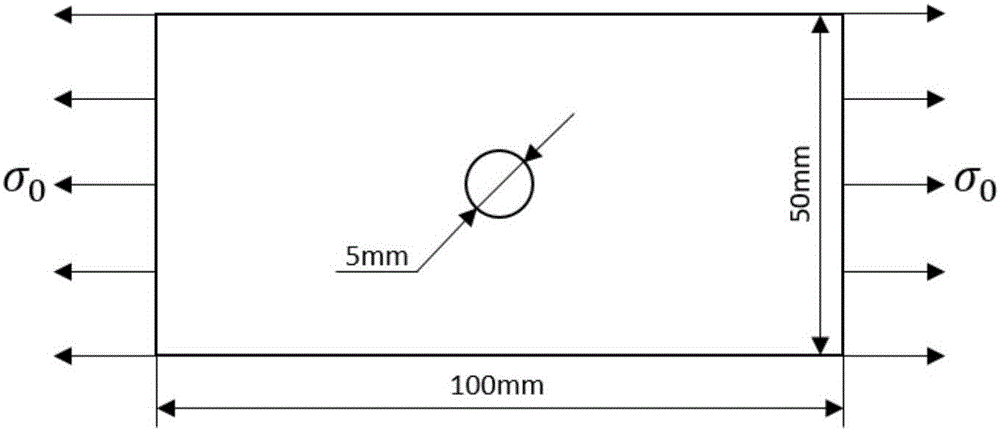

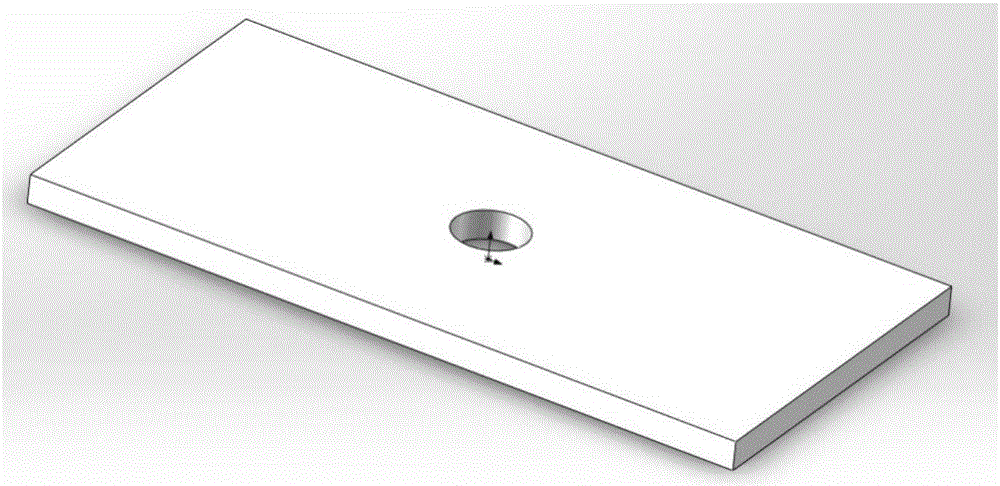

[0031] 1) Build a three-dimensional model: follow figure 2 The size and data of the fiber composite material, using the computer-aided design CAD software Solidworks, according to the shape characteristics of the fiber composite material, establish such as image 3 The three-dimensional model of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com