Patents

Literature

628results about How to "Improve electromagnetic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

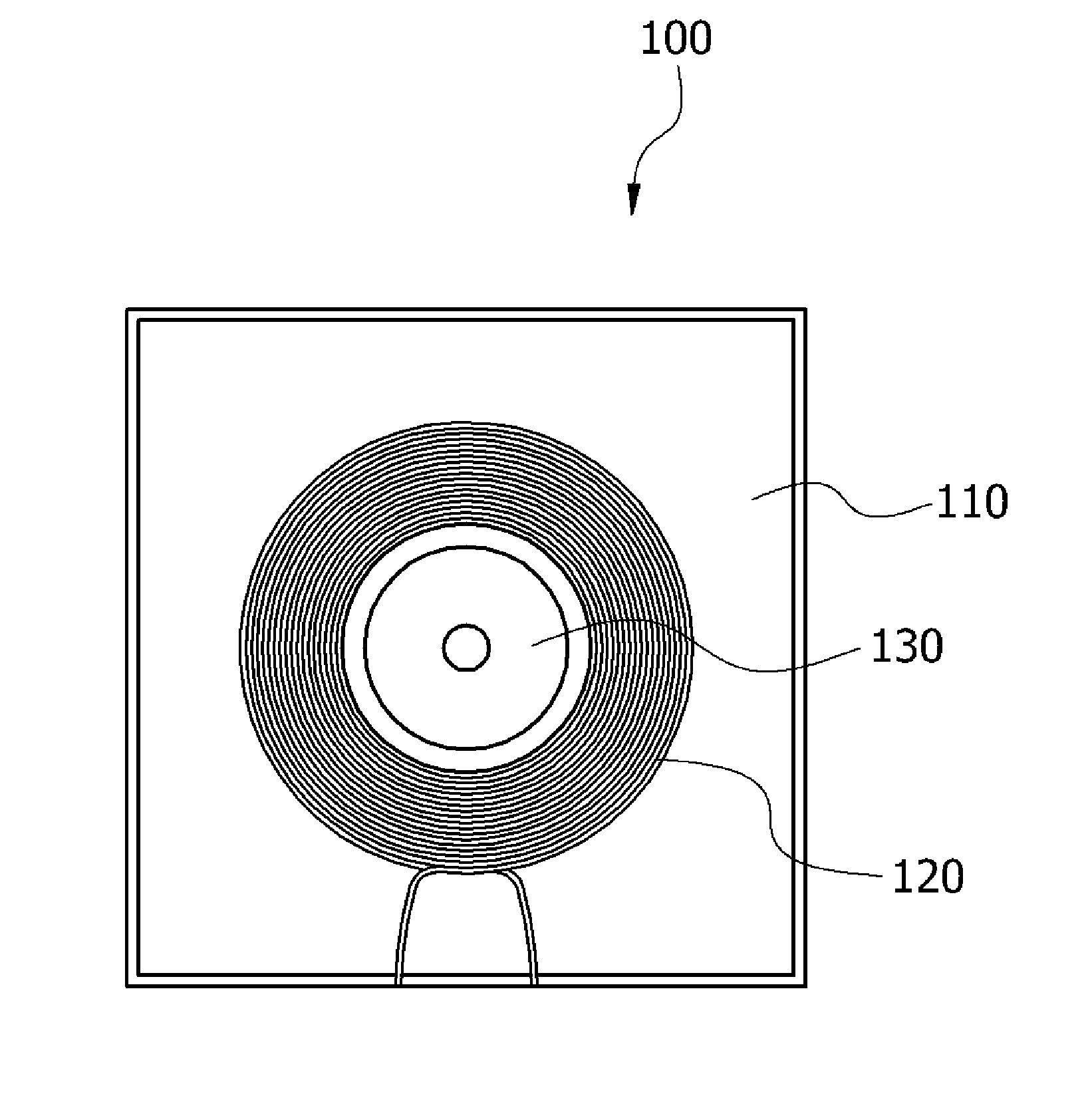

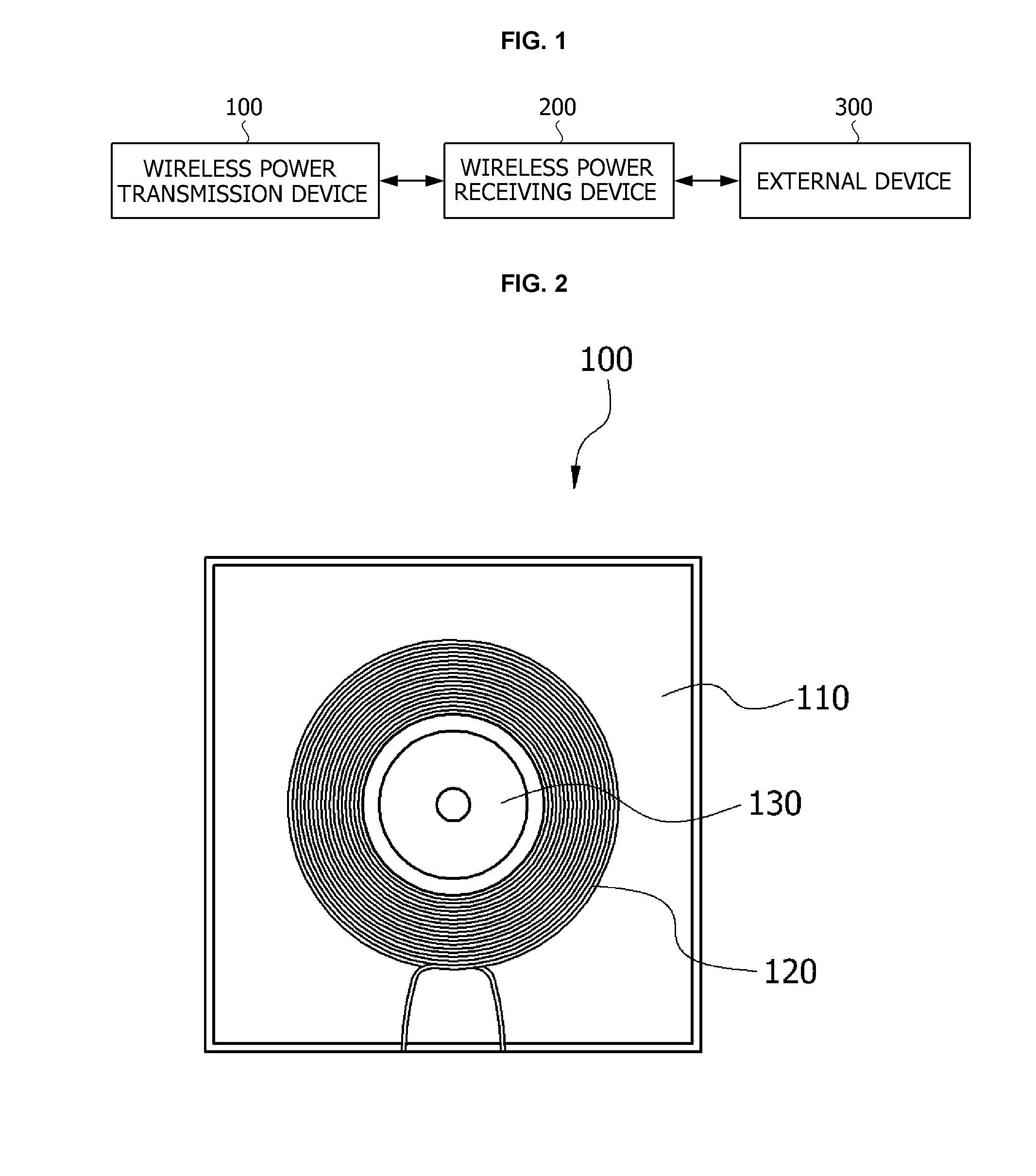

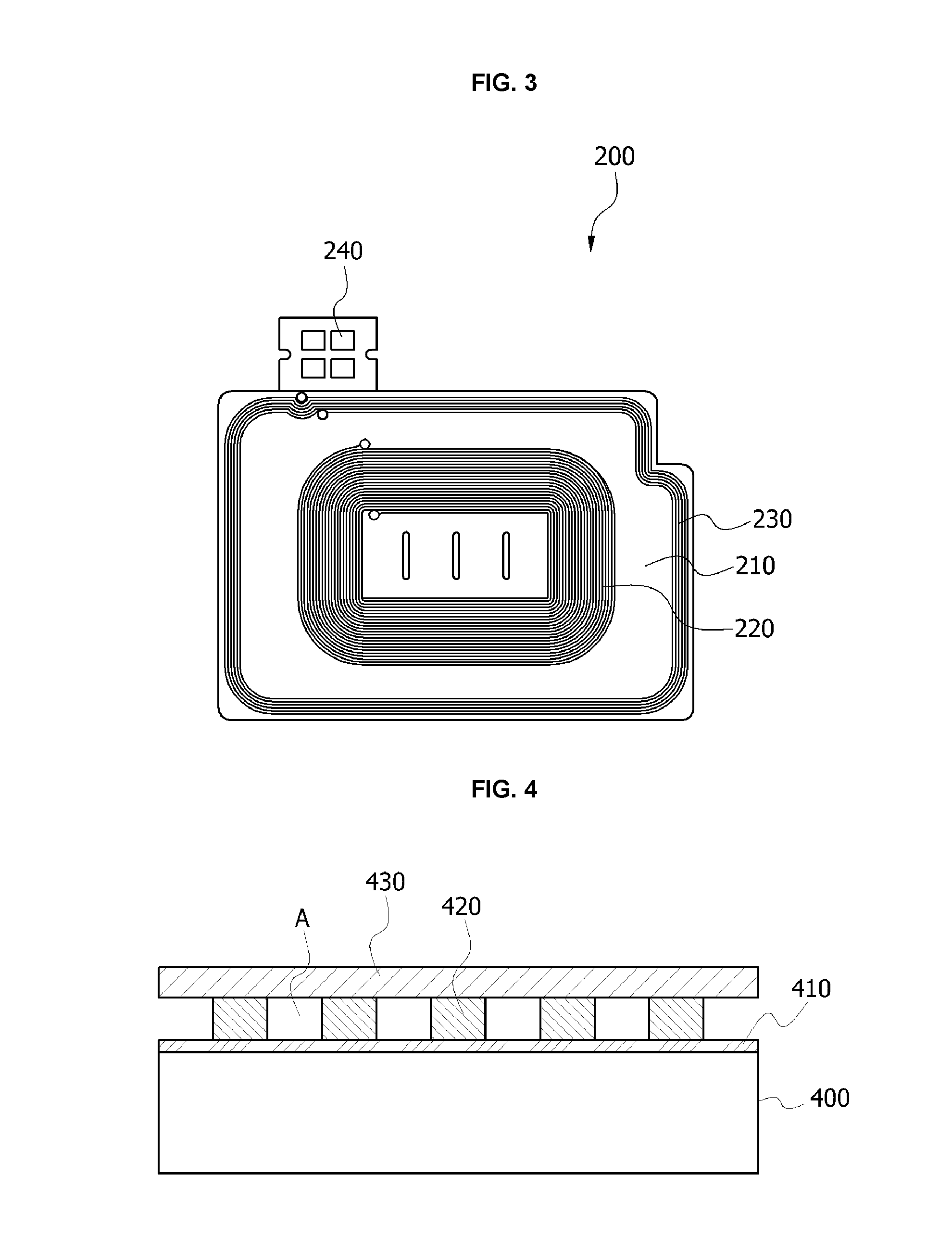

Receiving antenna and wireless power receiving device including the same

ActiveUS20160156103A1High power transmission efficiencyImprove electromagnetic performanceLoop antennas with ferromagnetic coreNear-field transmissionElectric power transmissionElectric power

A receiving antenna of a wireless power receiving device wirelessly charging electric power according to an embodiment of the present invention includes a substrate, a soft magnetic layer stacked on the substrate, and a receiving coil configured to receive electromagnetic energy emitted from a wireless power transmission device, wound in parallel with a plane of the soft magnetic layer, and formed inside of the soft magnetic layer, and an insulating layer is formed between the soft magnetic layer and the receiving coil.

Owner:SCRAMOGE TECH LTD

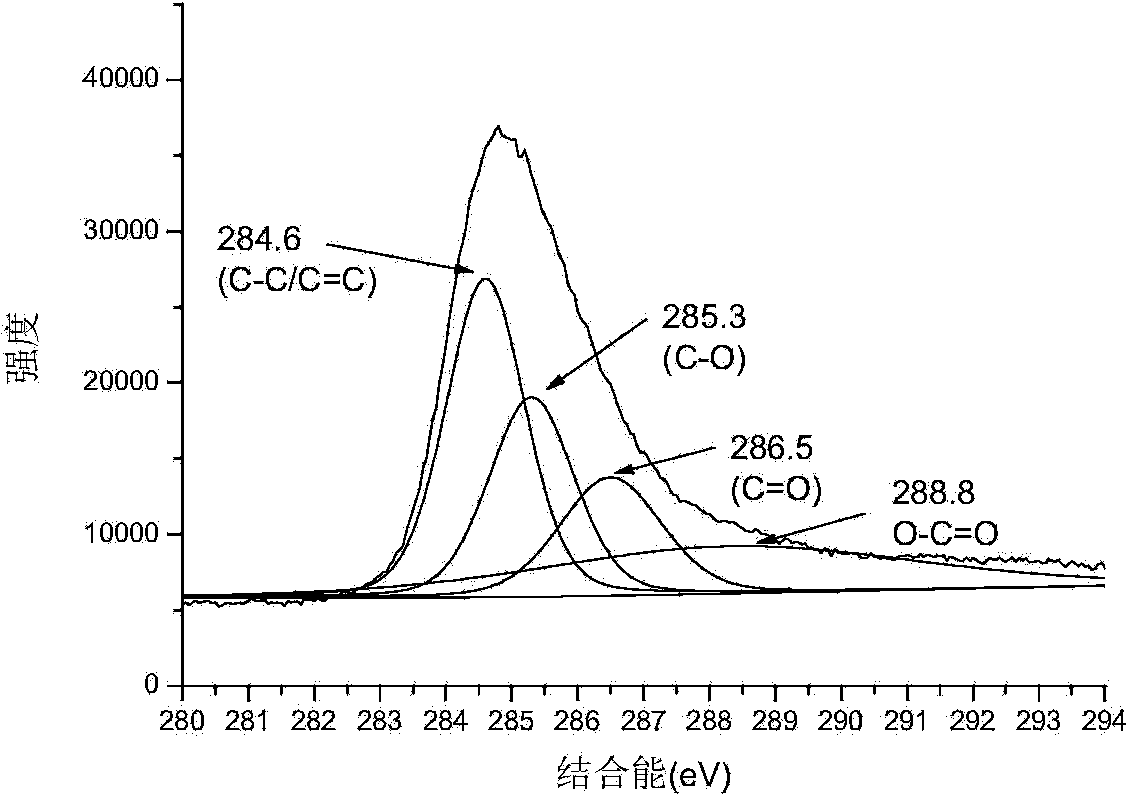

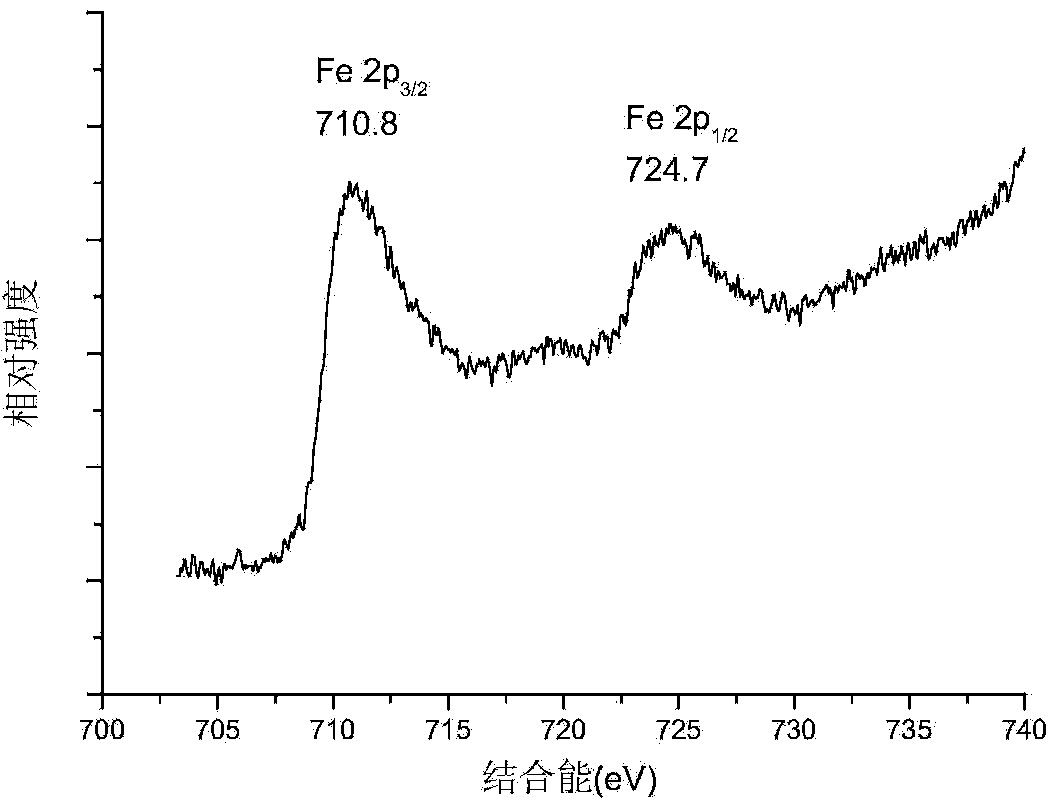

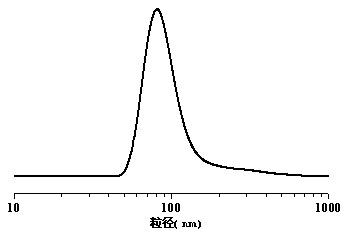

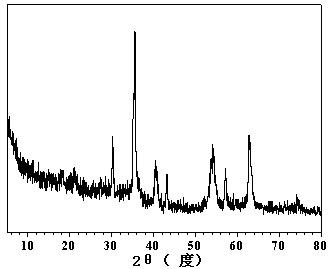

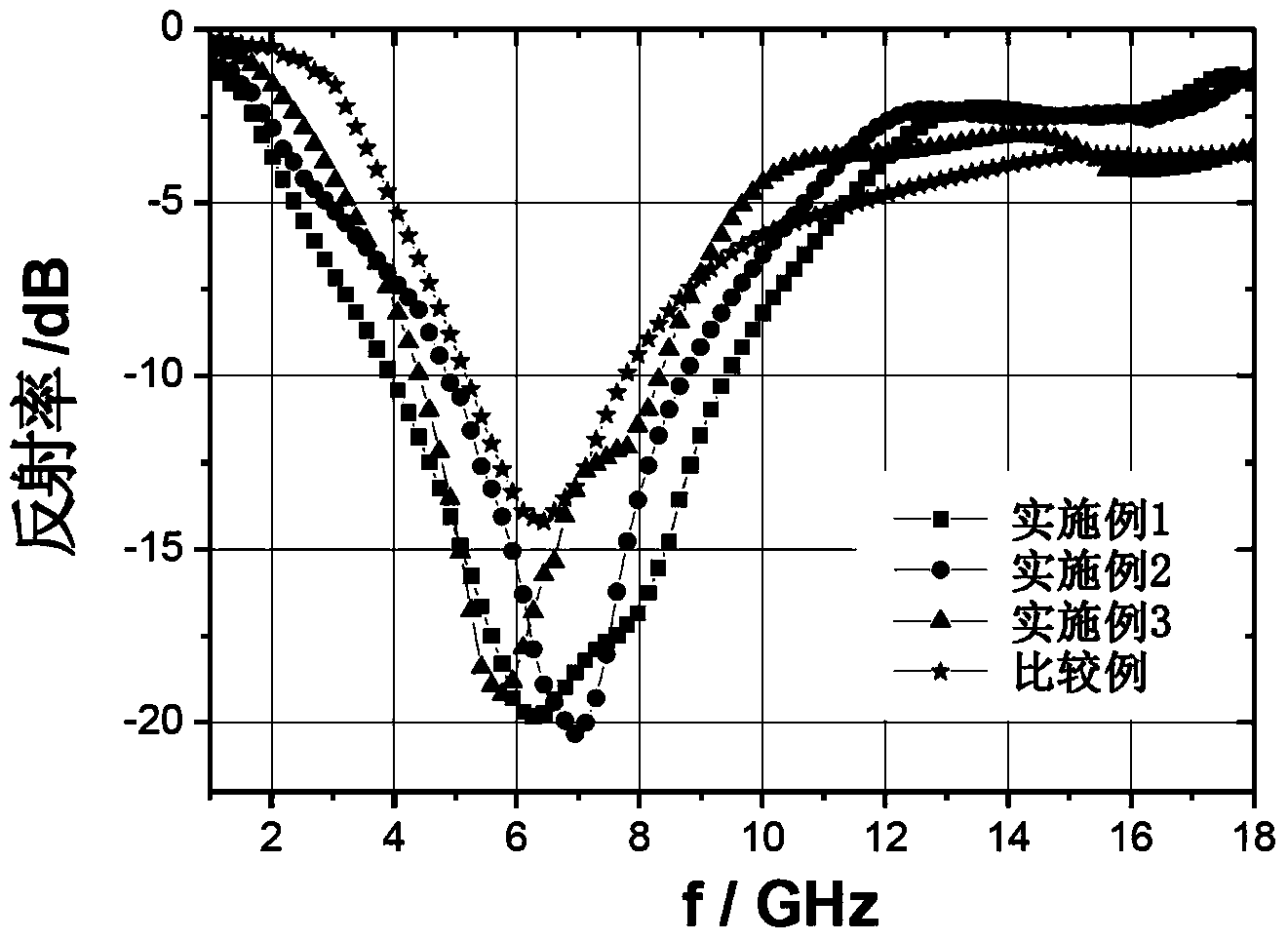

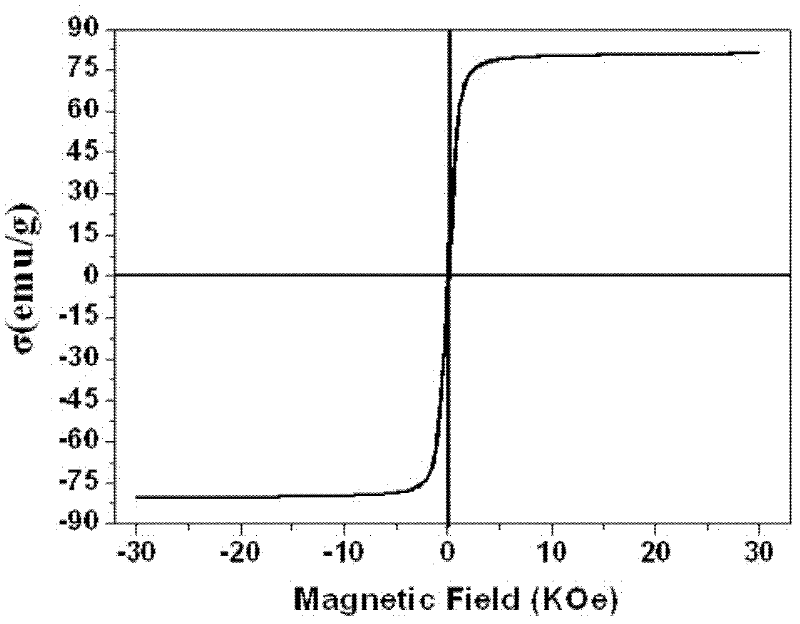

Polyaniline/oxidized graphene/ferriferrous oxide absorbing material and preparation method

InactiveCN104163919AStrong dielectric loss performanceHigh surface energyMaterials preparationTernary complex

The invention belongs to the field of electromagnetic wave absorbing material preparation and relates to a polyaniline / oxidized graphene / ferriferrous oxide composite material and its preparation method. The preparation method comprises the following steps: (1) preparing graphite oxide; (2) preparing ferriferrous oxide nanoparticles; (3) preparing a polyaniline / oxidized graphene / ferriferrous oxide ternary complex; and (4) weighing the polyaniline / oxidized graphene / ferriferrous oxide ternary complex and paraffin, and uniformly mixing to obtain the polyaniline / oxidized graphene / ferriferrous oxide absorbing material. The material provided by the invention has characteristics of low cost, simple preparation technology, strong electromagnetic wave absorbing capability, wide absorption band, low density and the like, has good electromagnetic property, and has important application value in the field of microwave absorption and electromagnetic shielding.

Owner:UNIV OF SCI & TECH BEIJING

High magnetic induction and high grad non-orientation electrical steel and its making process

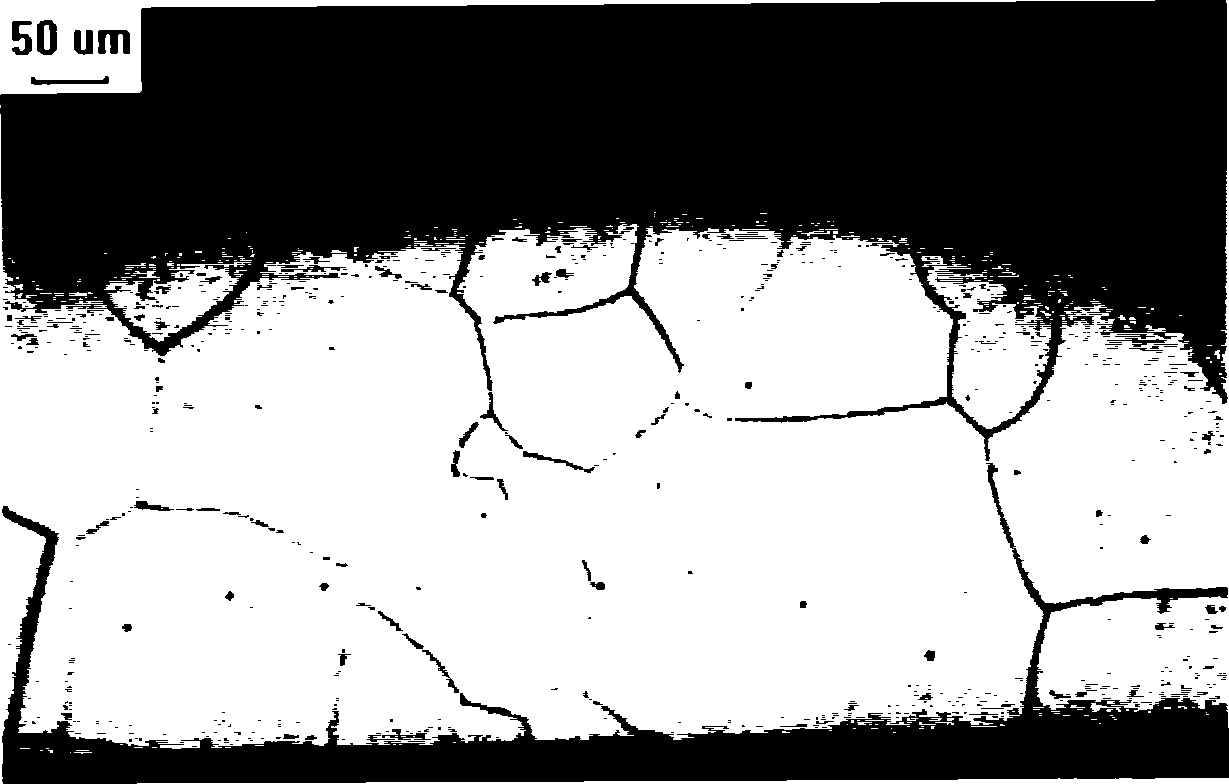

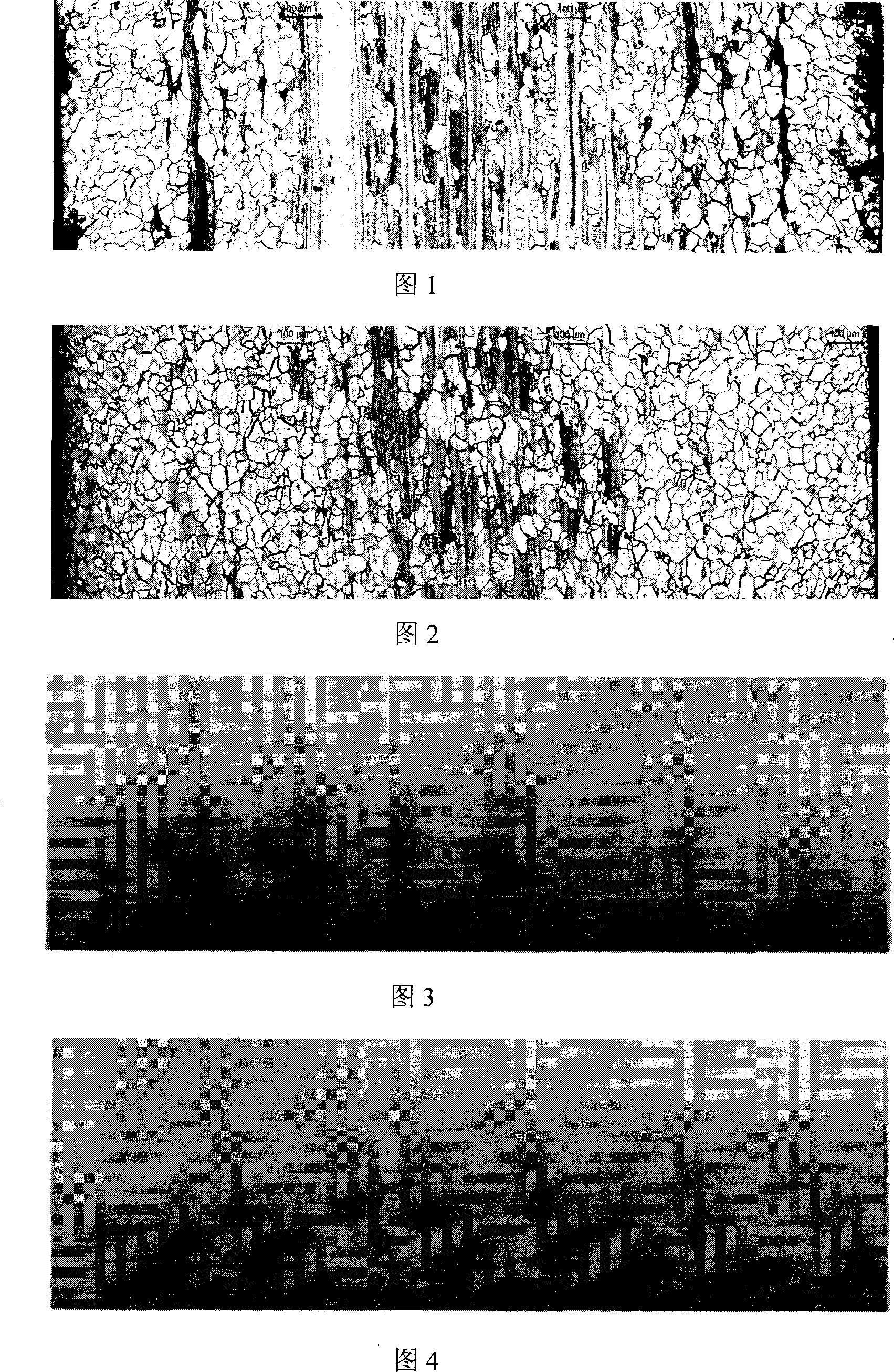

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

High grade cold rolling non-oriented silicon steel and method for manufacturing same

ActiveCN101139681ANo corrugated defectsGood electromagnetic performanceRoll mill control devicesMetal rolling arrangementsForeign matterMetallurgy

The invention provides a middle and high grade cold rolled no-orientation silicon steel and a manufacturing method for the no-orientation silicon steel, the components of which are C: 0.0015%-0.005% Si: 1.60%-3.30% Mn: 0.50-2.50% P<=0.050% S: 0.0010%-0.0050% Al: 0.15%-0.50% and N: 0.0010%-0.0050%, small amount of Sn, Sb, Cu can be added, total mount is <0.20%, the remainder are Fe and unavoidable foreign matters and Mn%=k is multiplied by |Si+2Al-2.05|%+0.28%, wherein, k=1.0-3.0. The manufacturing method is like follows: hot rolling, pickling, cold rolling and annealing the cast blanks of above components. The heating temperature for the cast blanks at hot rolling is 1050-1200 DEG C, the rolling passes are 3-5 no.s, the pressure-down rate is 20-40% for each pass; the temperature for fine and final rolling temperature is 800-900 DEG C, coiling temperature is 600-680 DEG C, and the annealing is done in a dry protective atmosphere. The method is of low process difficult, low cost and high product surface quality.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

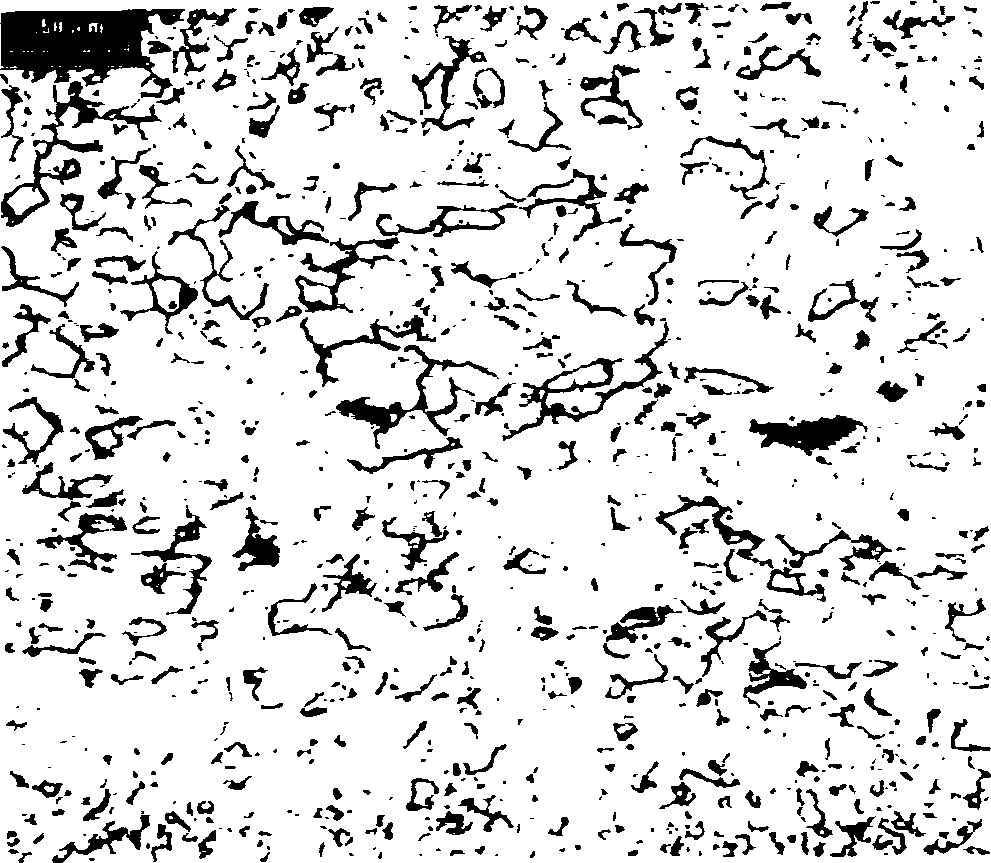

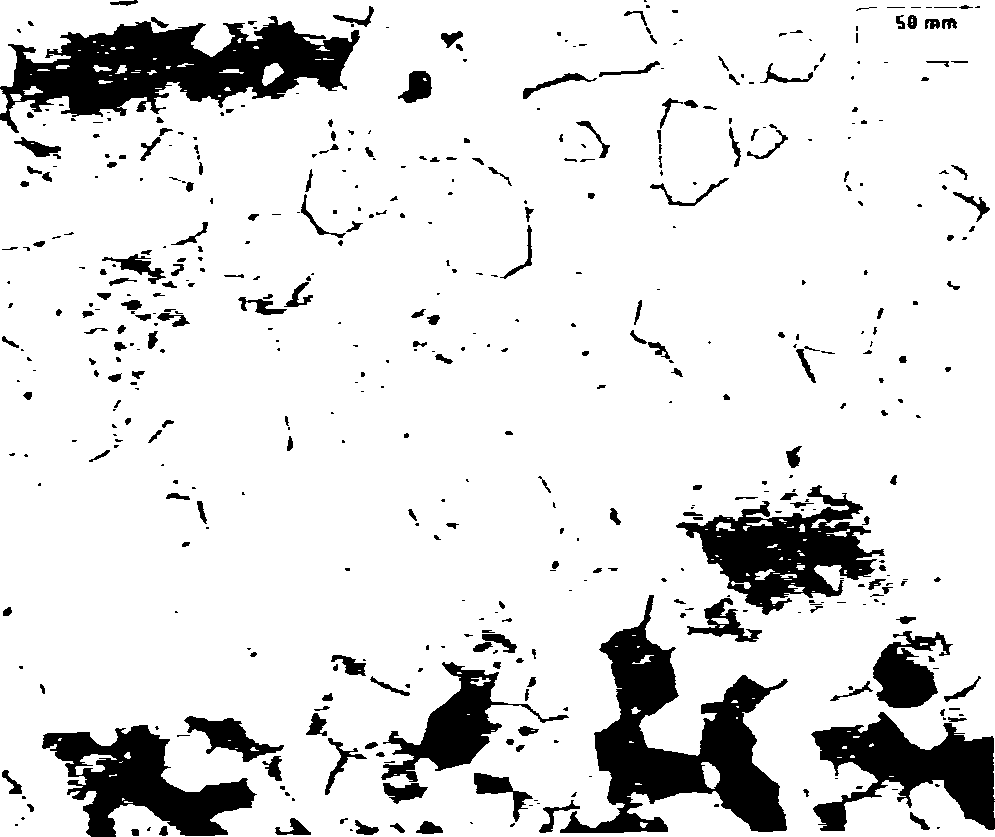

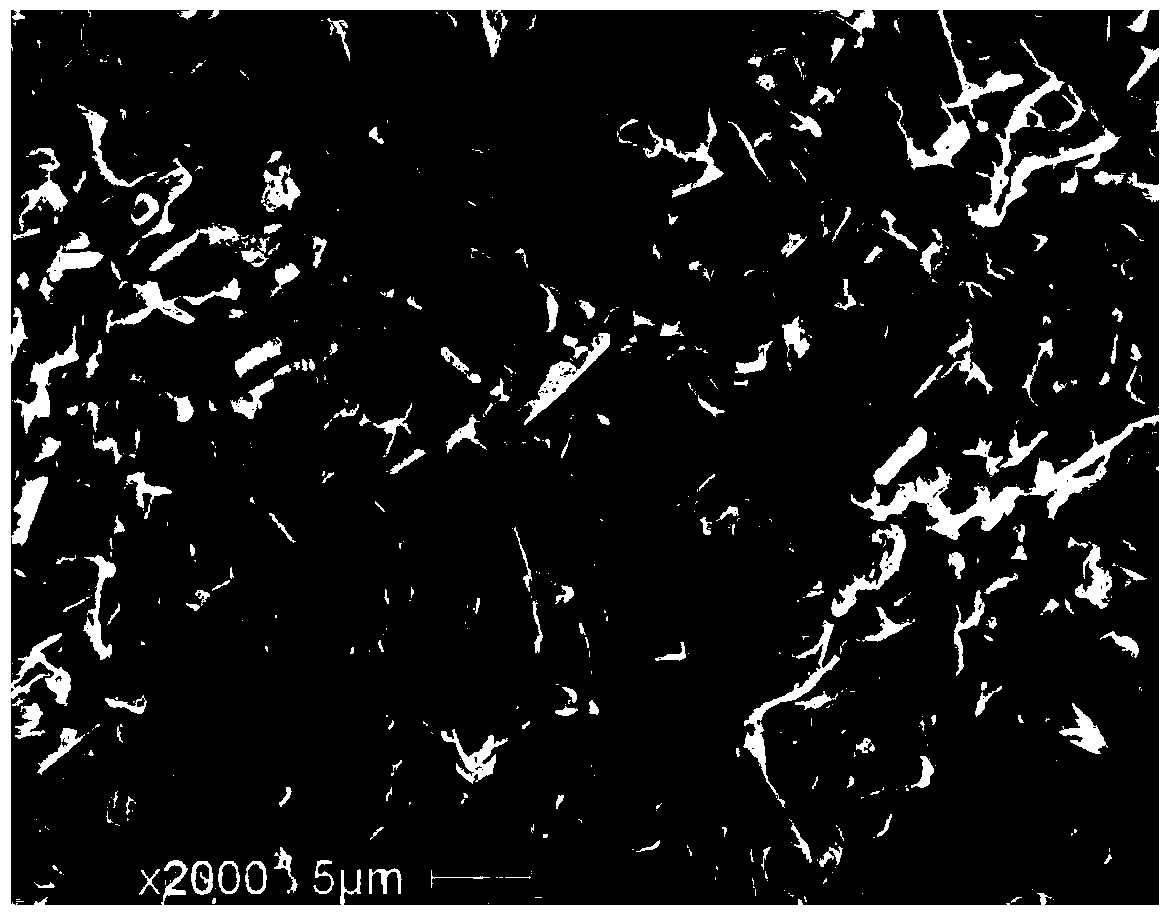

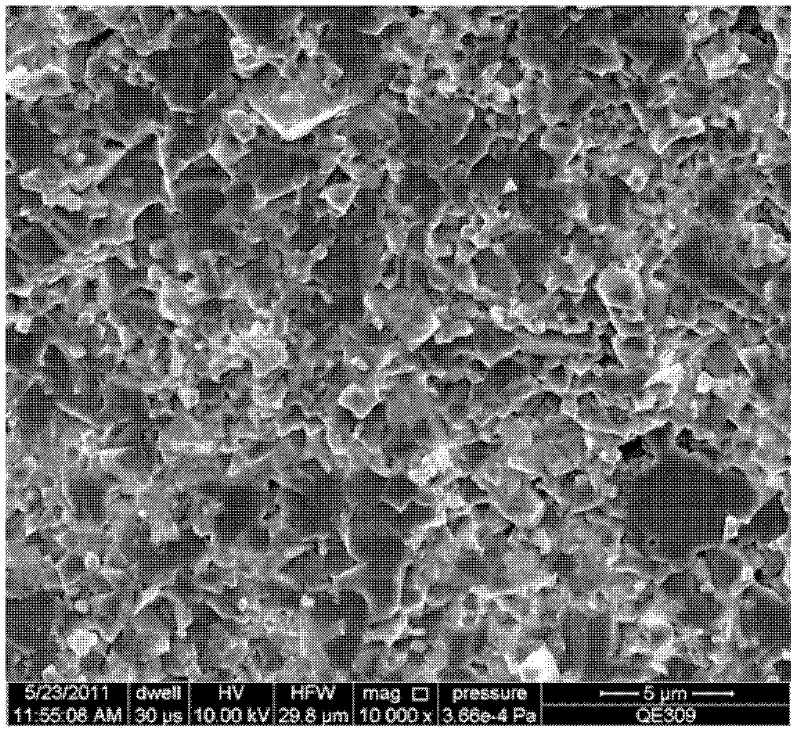

Preparation method of graphene with nano ferroferric oxide precipitated on surface

InactiveCN102674334AGive full play to the nano effectImprove mechanical propertiesMaterial nanotechnologyCarbon compoundsResin matrixCvd graphene

The invention belongs to the technical field of materials, and particularly relates to a preparation method of graphene with nano ferroferric oxide precipitated on surface, which concretely comprises the steps of: firstly, oxidizing natural flake graphite and obtaining graphite oxide; further carrying out ultrasonic stripping on the graphite oxide and forming graphene oxide suspension; then, carrying out reduction reaction on the graphene oxide suspension under the action of strong reducing agent, and obtaining black flocculent flake graphene; and finally, taking hydrogen peroxide as an oxidant, and depositing Fe3O4 on the surface of the graphene in an alkaline solution. The invention realizes the modification of nanoscale Fe3O4 for the surface of the graphene. The obtained modified graphene is not doped with other elements except the Fe element, and can be well dispersed in a high-performance resin matrix, so that the mechanical property, the thermal performance, the electromagnetic performance and the friction property of the resin matrix can be improved, and phenolic resin, bismaleimide, cyanate ester and other products can be updated, or a new application field can be developed..

Owner:TONGJI UNIV

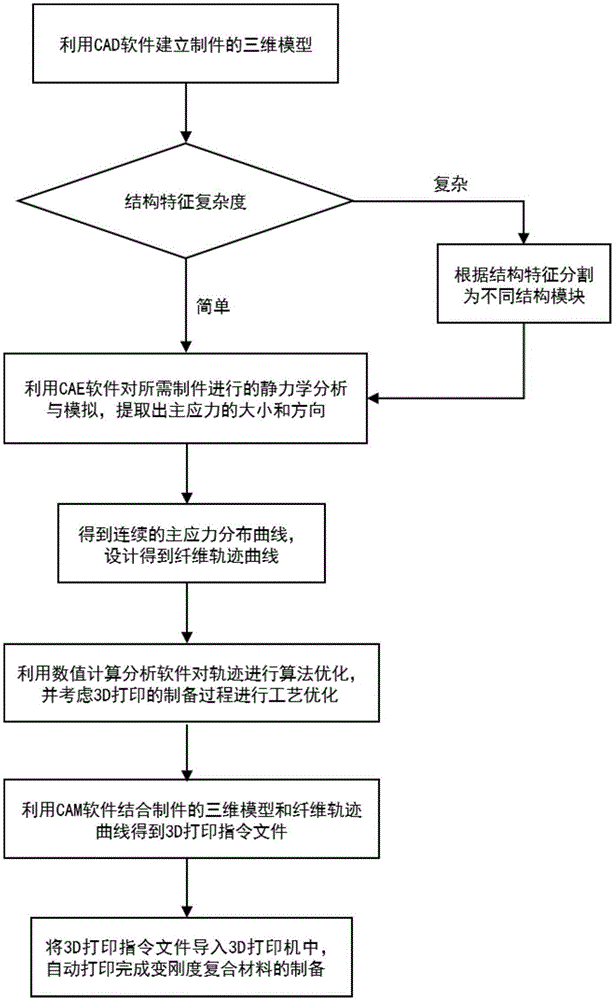

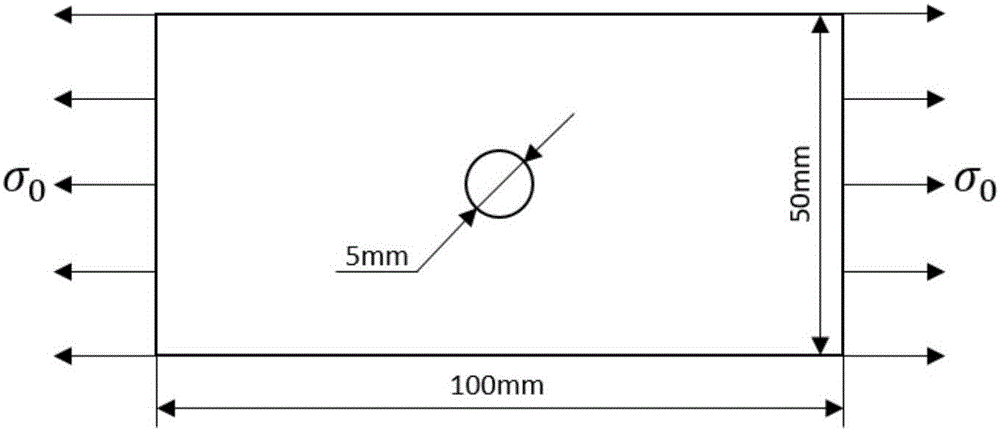

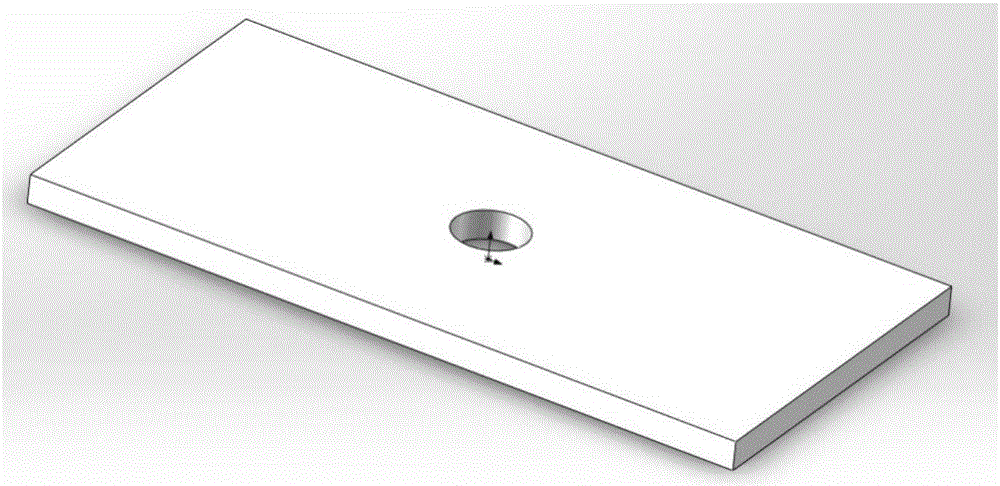

Function regulation and control structure production method based on continuous fiber composite material 3D printing

ActiveCN107433713AImprove mechanical propertiesStrong applicabilityAdditive manufacturing apparatus3D object support structuresThree dimensional modelComputer Aided Design

Owner:深圳协同创新高科技发展有限公司

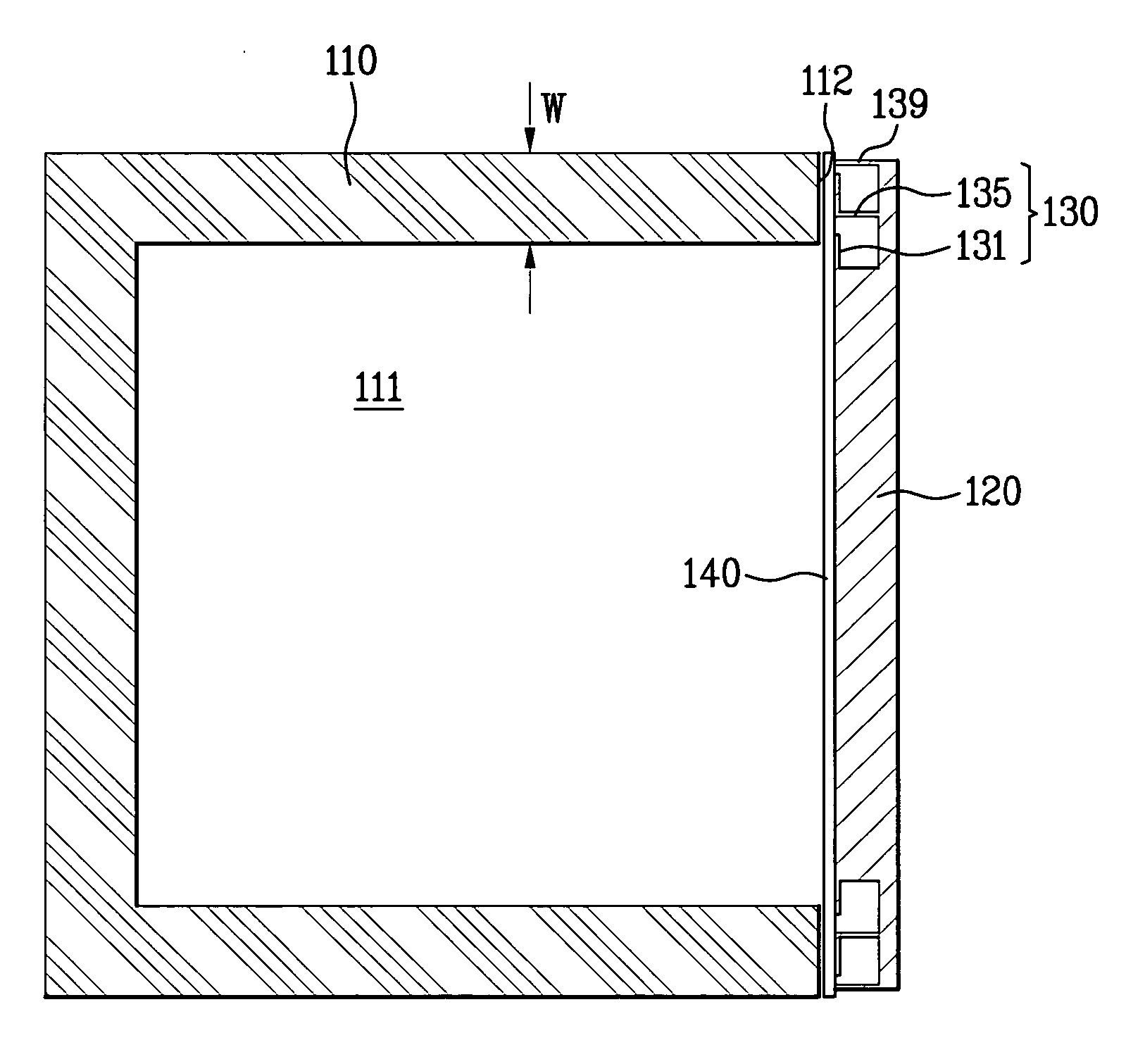

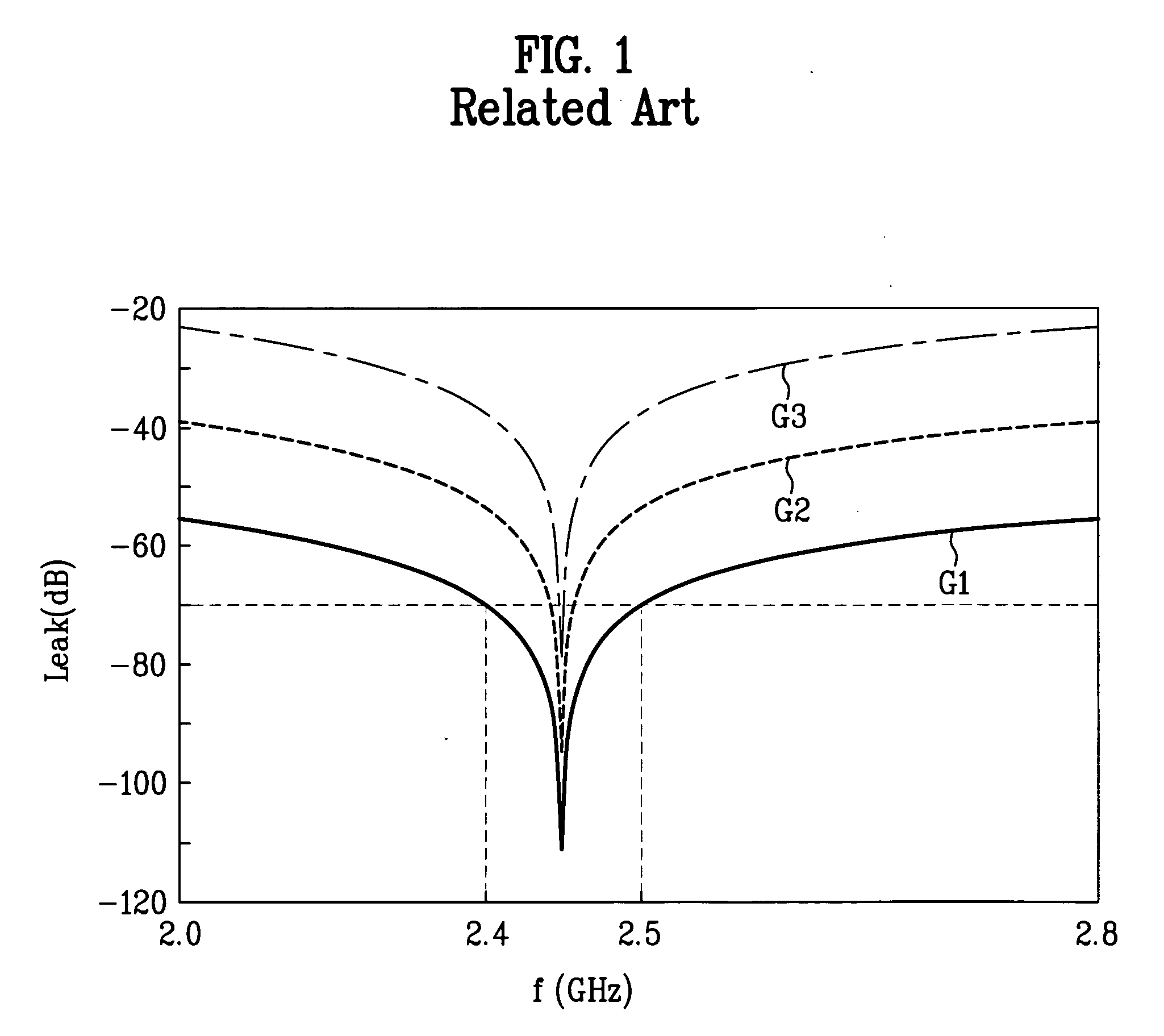

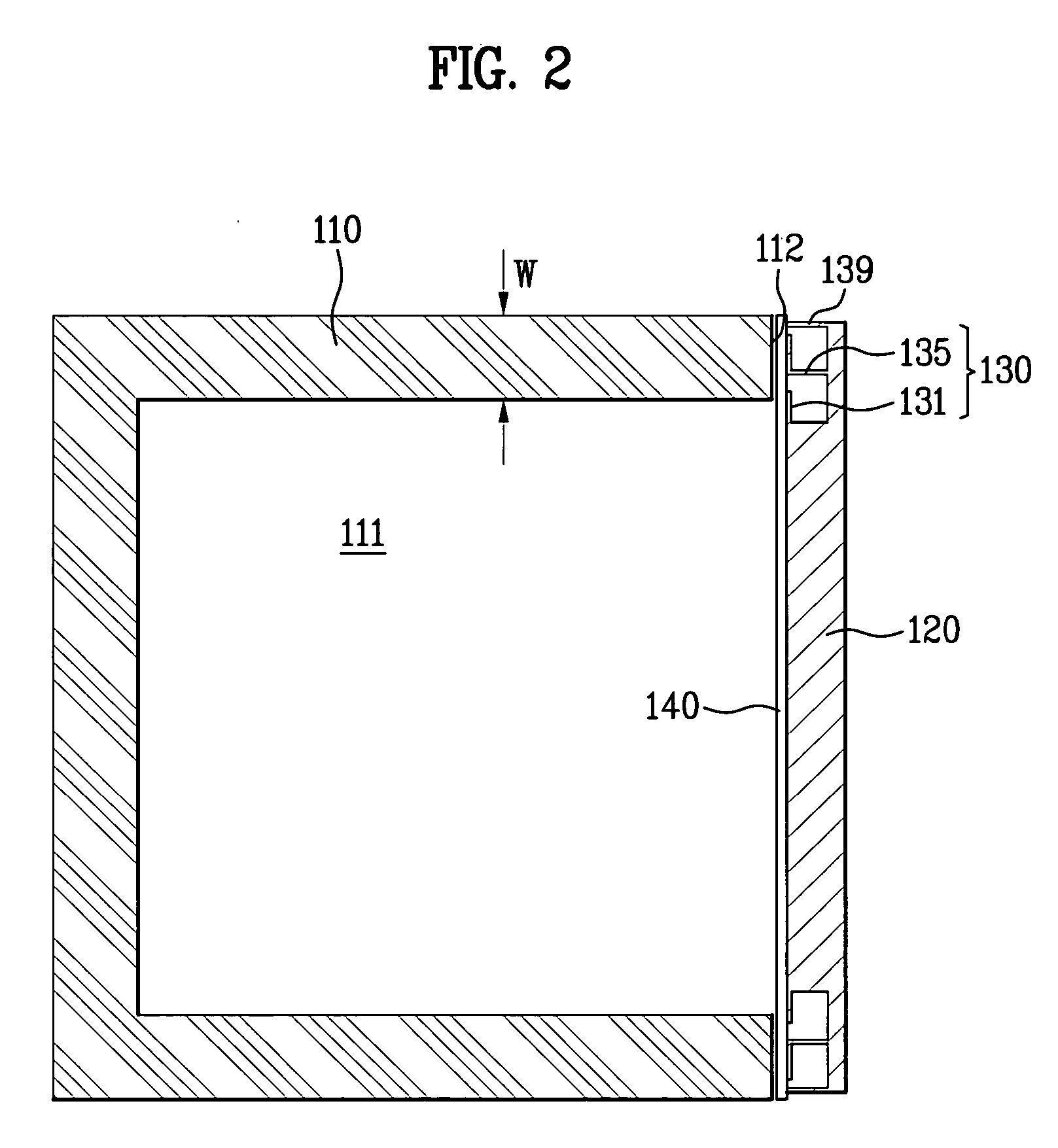

Heating apparatus using electromagnetic wave

ActiveUS20070039940A1Improve electromagnetic performanceIncreased absorption bandwidthElectrically conductive connectionsMagnetic/electric field screeningEngineeringThe chokes

A heating apparatus using an electromagnetic wave is disclosed, by which cut-of performance of an electromagnetic wave is enhanced by increasing an electromagnetic wave absorption bandwidth having cut-off performance below −70 dB. The present invention includes a door provided to an open front side of a body to be opened / closed and a choke filter having a panel type choke part arranged by at least one row each along an edge of the door and a filter part arranged by at least one row each along an edge of the choke part and having a plurality of slots, wherein a prescribed choke part is provided to a most inner side among rows of the choke and filter part.

Owner:LG ELECTRONICS INC

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

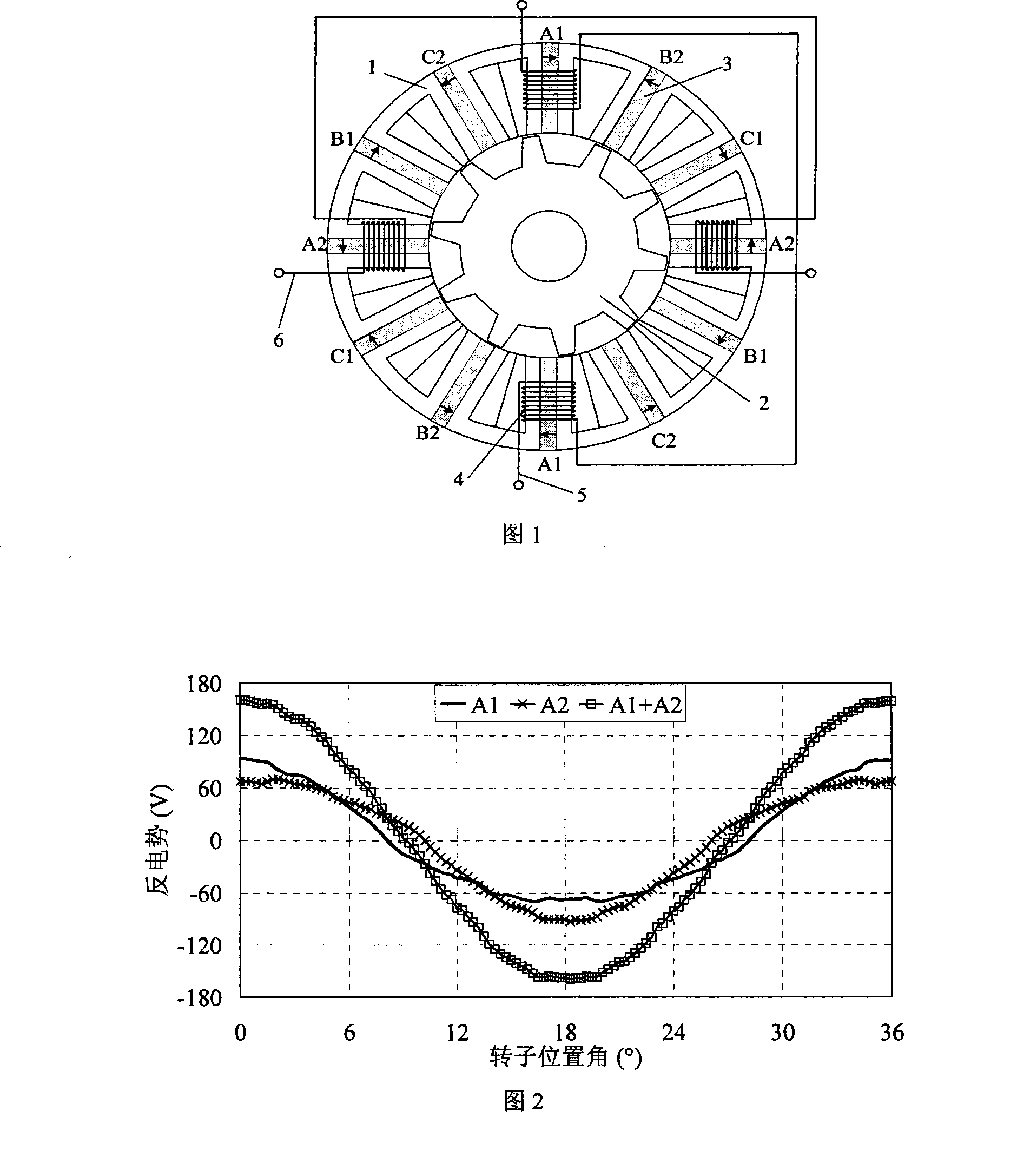

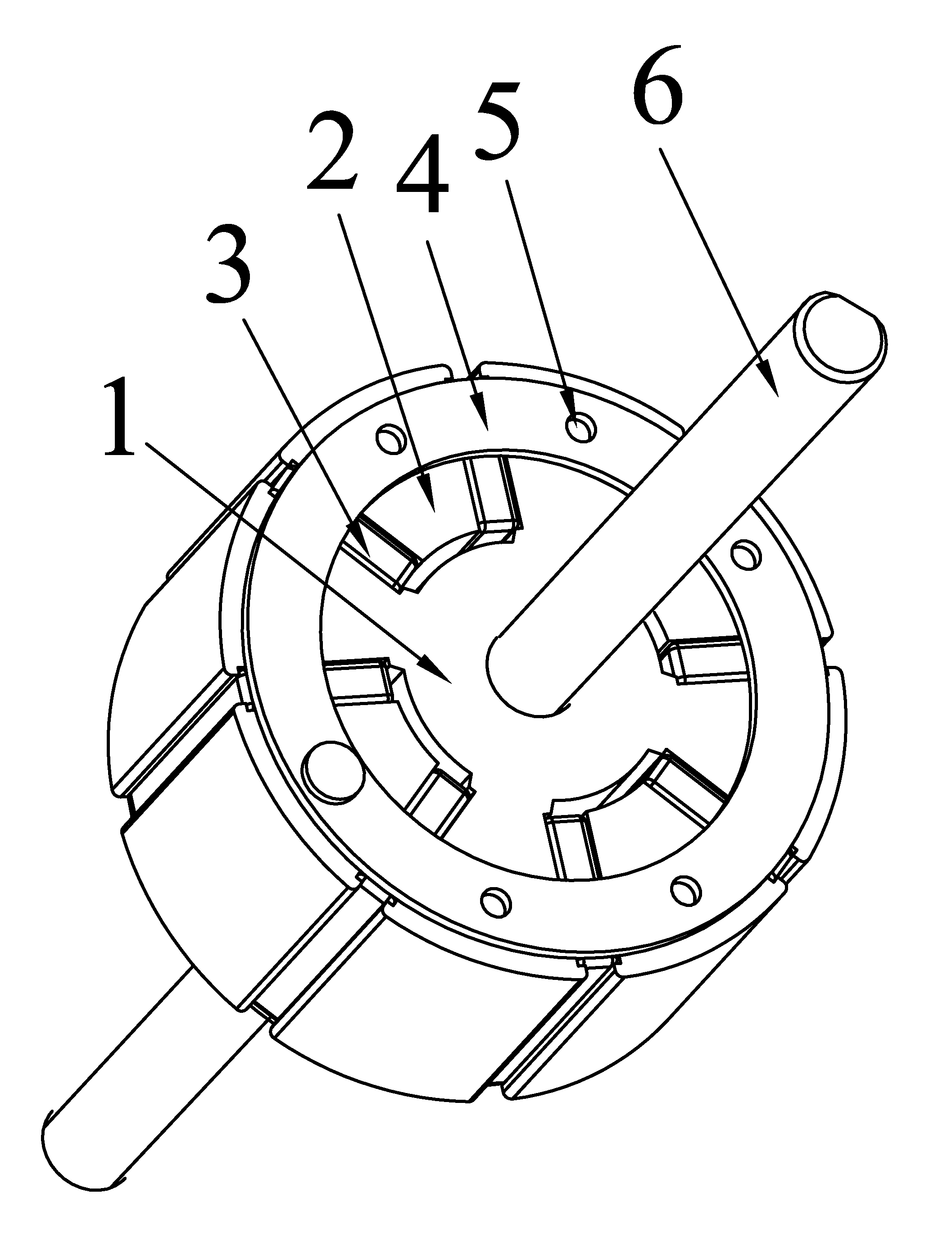

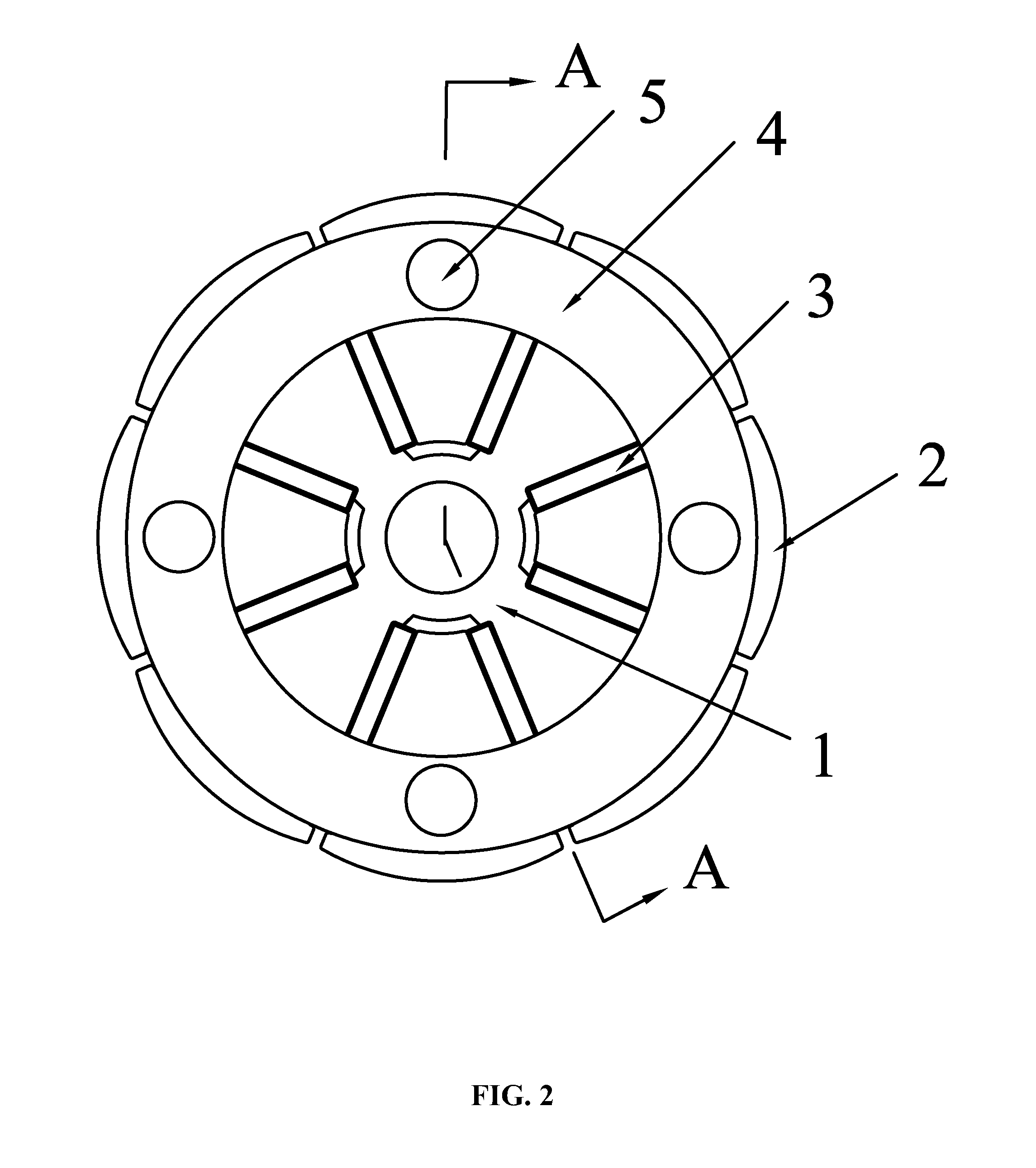

Double-channel fault tolerant type flux switch permanent magnet motor and control method thereof

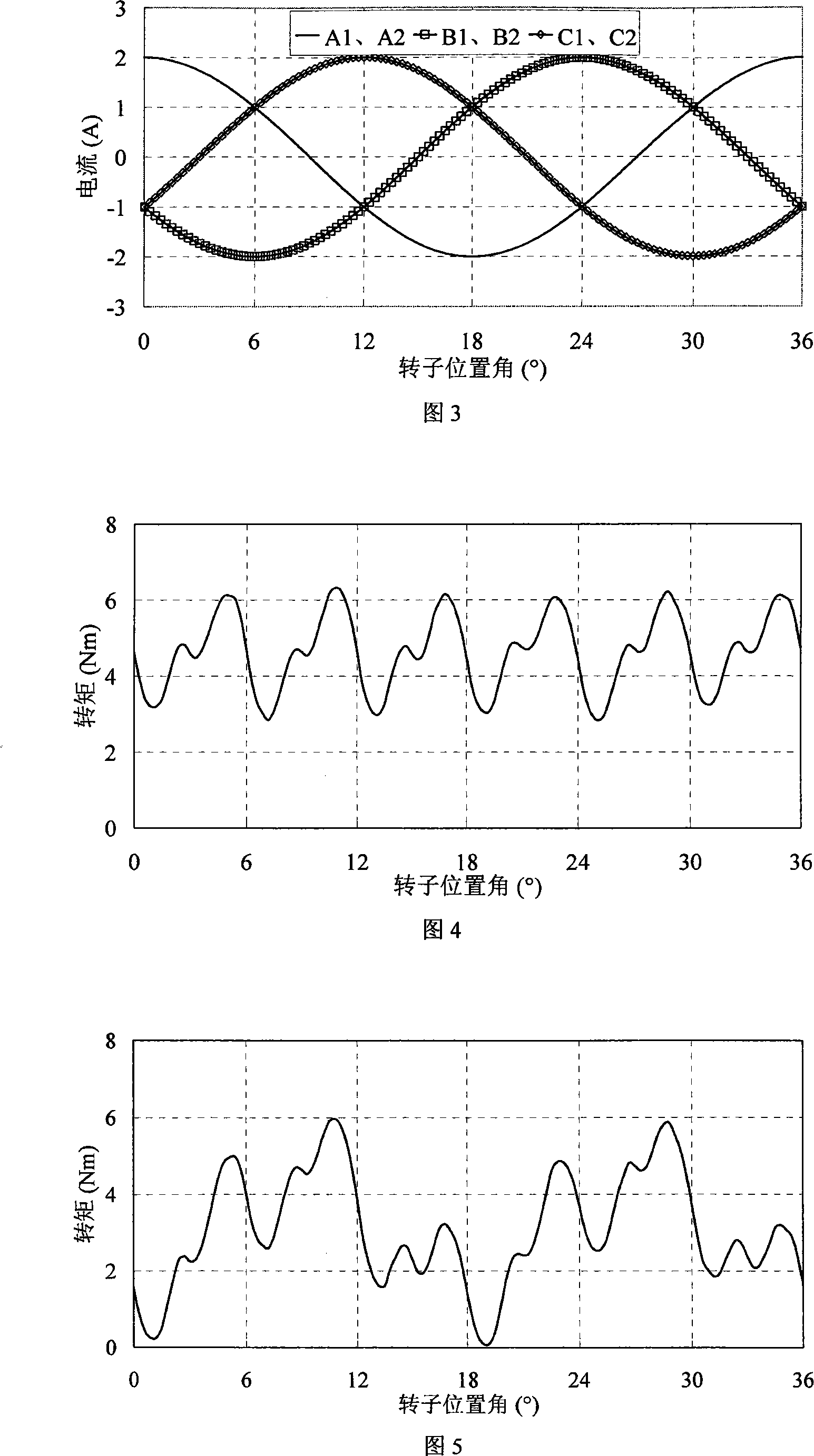

InactiveCN101159391AImprove reliabilityImprove power densityTorque ripple controlMagnetic circuit rotating partsFault tolerancePhase currents

A dual-channel fault tolerant flux switch permanent magnet motor is a novel stator permanent magnet motor. The fault tolerant motor adopts a doubly salient structure, and the inner loop of the stator (1) is provided with salient poles evenly. Permanent magnets (3) are arranged onto the circle of the stator in pairs, which can be cooled easily; the rotor (2) adopts a simple salient structure, without windings nor permanent magnets. The fault tolerance motor integrates the advantages of a switch magnet resistance motor and a rotator permanent magnet fault tolerance motor, and has the advantages of high credibility, high power density, and preferable operating capacity when a failure occurs. The invention provides a fault tolerance strategy, and can improve the electromagnetic performance of the motor when a failure occurs by adjusting the phase and amplitude of non-fault phase current; the invention can accomplish the torque output in the approximately normal running status and have high theory and practical value.

Owner:SOUTHEAST UNIV

Conductive material co-doping conductive concrete and preparation method thereof

The invention provides conductive material co-doping conductive concrete and a preparation method thereof. The concrete is formed by cement, silica fume, carbon fiber, carbon nanomaterials (carbon nano tube, carbon black and graphite), nano-zinc oxide, water reducer, filler, dispersant, defoaming agents and water. The multifunctional conductive material co-doping conductive concrete is simple in preparation method, and excellent in performance. Part of carbon fiber is replaced with the carbon nanomaterials, and compared with the traditional conductive concrete, the conductive material co-doping conductive concrete has the advantages that the cost is low, the conductive property is stable, and nano-zinc oxide is mixed, so that the conductivity of the concrete can be greatly improved. Under the power on condition, the concrete has the excellent electrothermal performance, and is applied to an airfield pavement, a bridge floor and a cement concrete pavement, so that the effect of melting ice and snow can be realized, the bearing load of the road, the concrete structure crack and extension situations can be detected; under the power off condition, the concrete has the excellent electromagnetic performance, and can efficiently shield electromagnetic waves, reduce electromagnetic radiation, and reduce electromagnetic interference.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

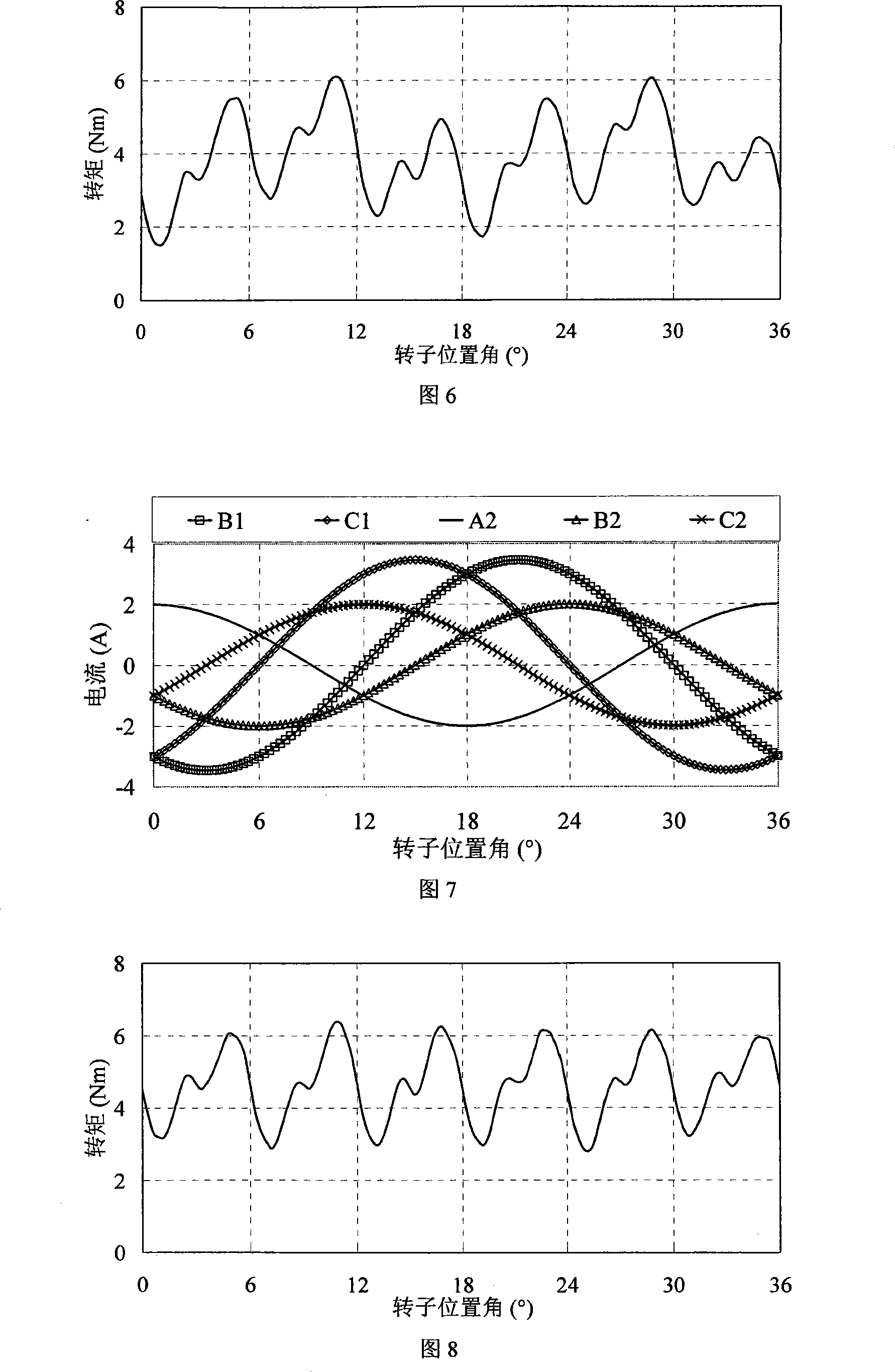

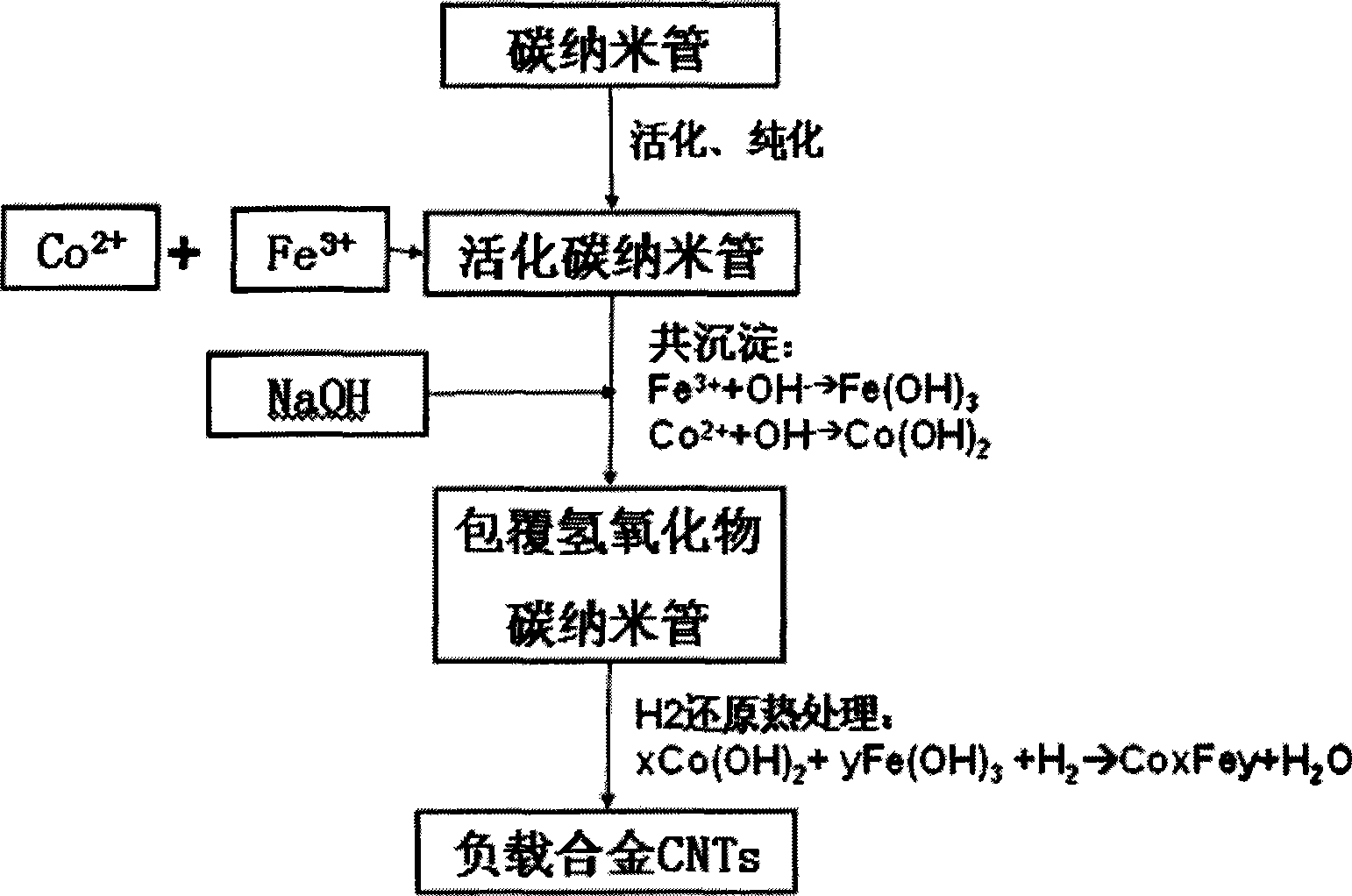

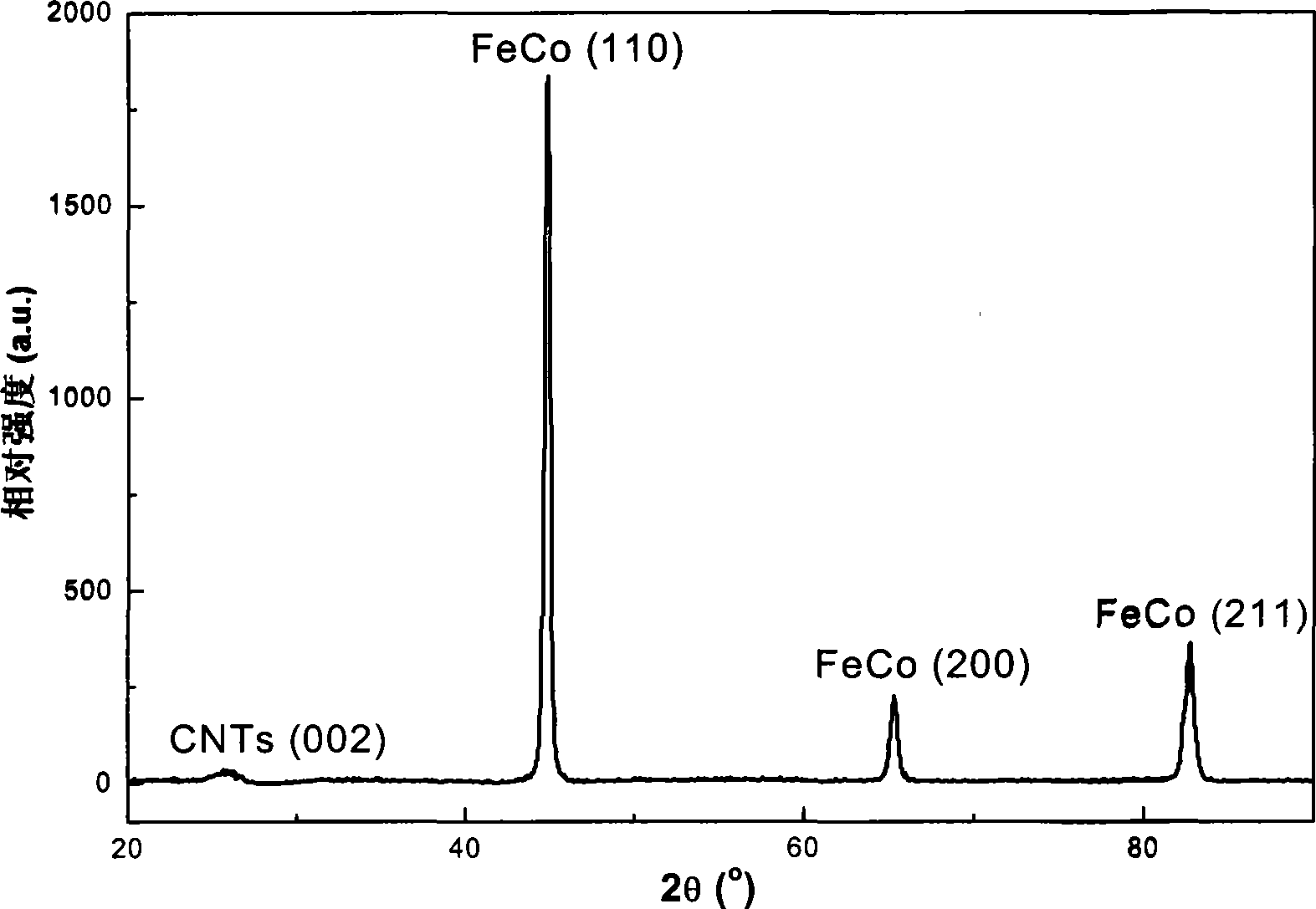

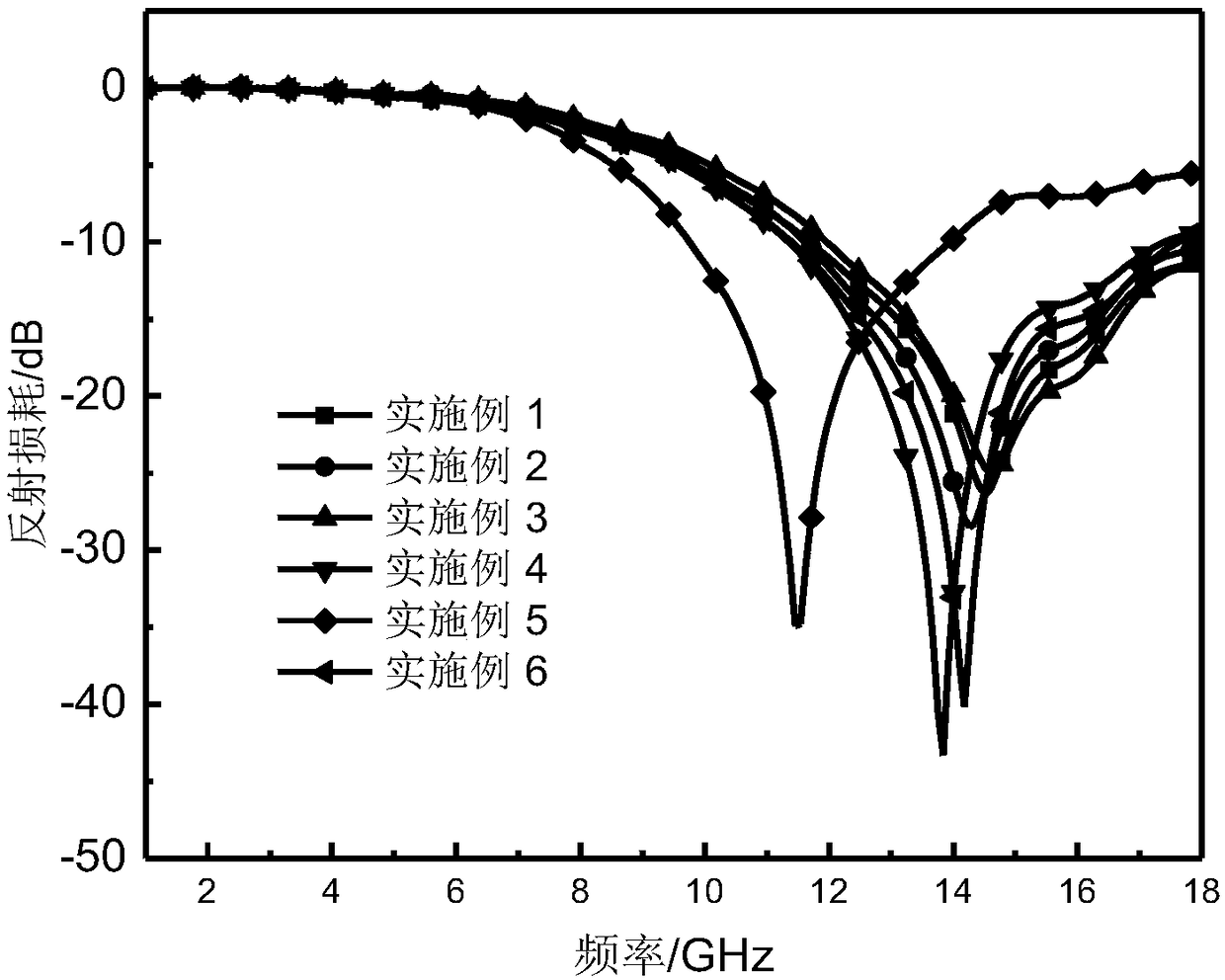

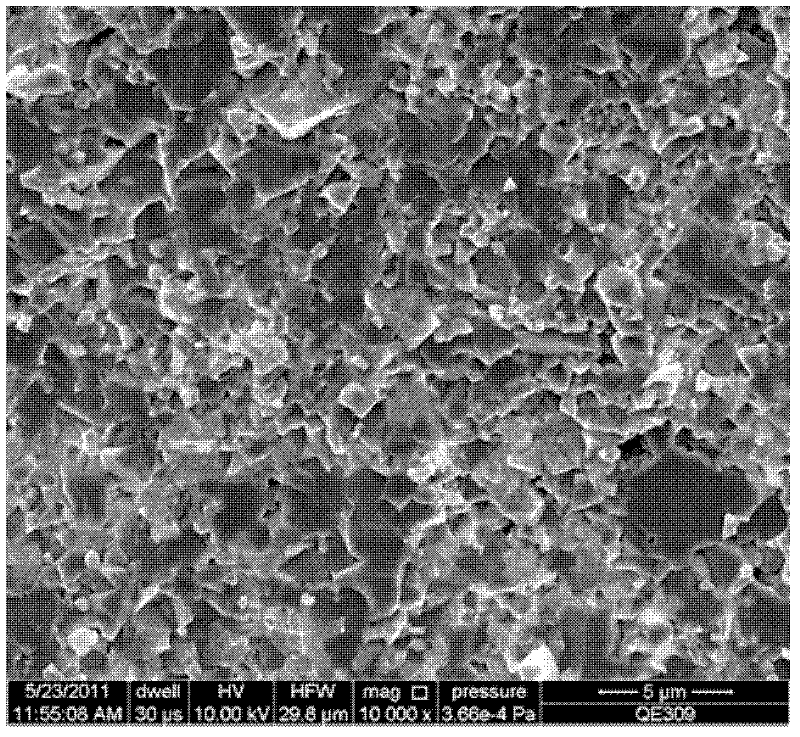

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

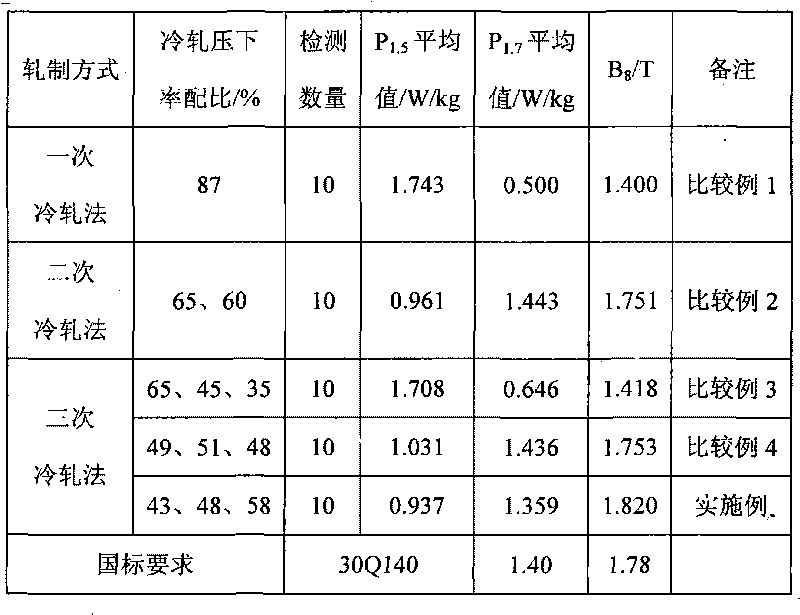

Method for manufacturing directional silicon steel

ActiveCN101748257AUniform internal organizationReduced high temperature annealing timeSiliconCoating

The invention discloses a method for manufacturing directional silicon steel. The method is characterized in that a rolling and treating process adopts a manufacture process of triple cold rolling, twice intermediate annealing, and once MgO coating, and finally carrying out high temperature annealing. One-pass roll separating force in the triple rolling is reduced, the internal tissue of the steel is uniform, so the time for high temperature annealing is reduced by 20 to 30 percent, and a product with strong (110)[001] structure is finally obtained. The method not only can obviously improve the electromagnetic performance (iron loss reduces but magnetic induction increases), ensures that the iron loss P1.7 is reduced by about 0.08W / kg, ensures the magnetic induction B8 is improved by about 0.07T, not only ensures that the product is improved from half to one grade, but also ensures that the total production time is obviously reduced, the total production time is remarkably shortened, thereby improving the manufacture efficiency of the directional silicon steel.

Owner:ANGANG STEEL CO LTD

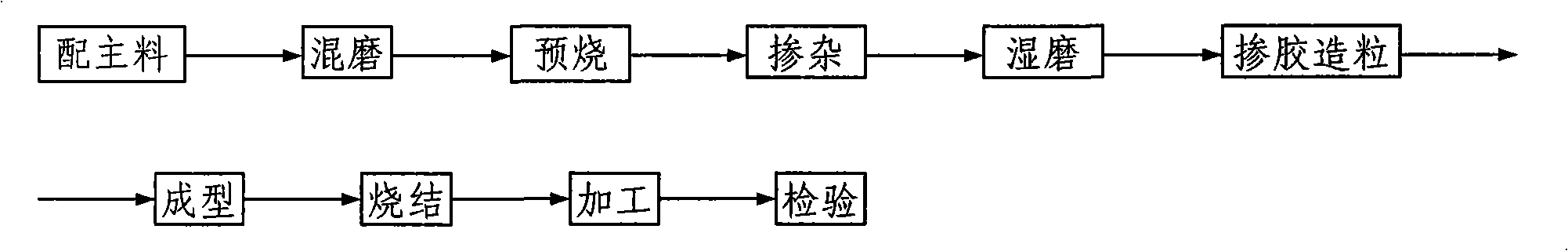

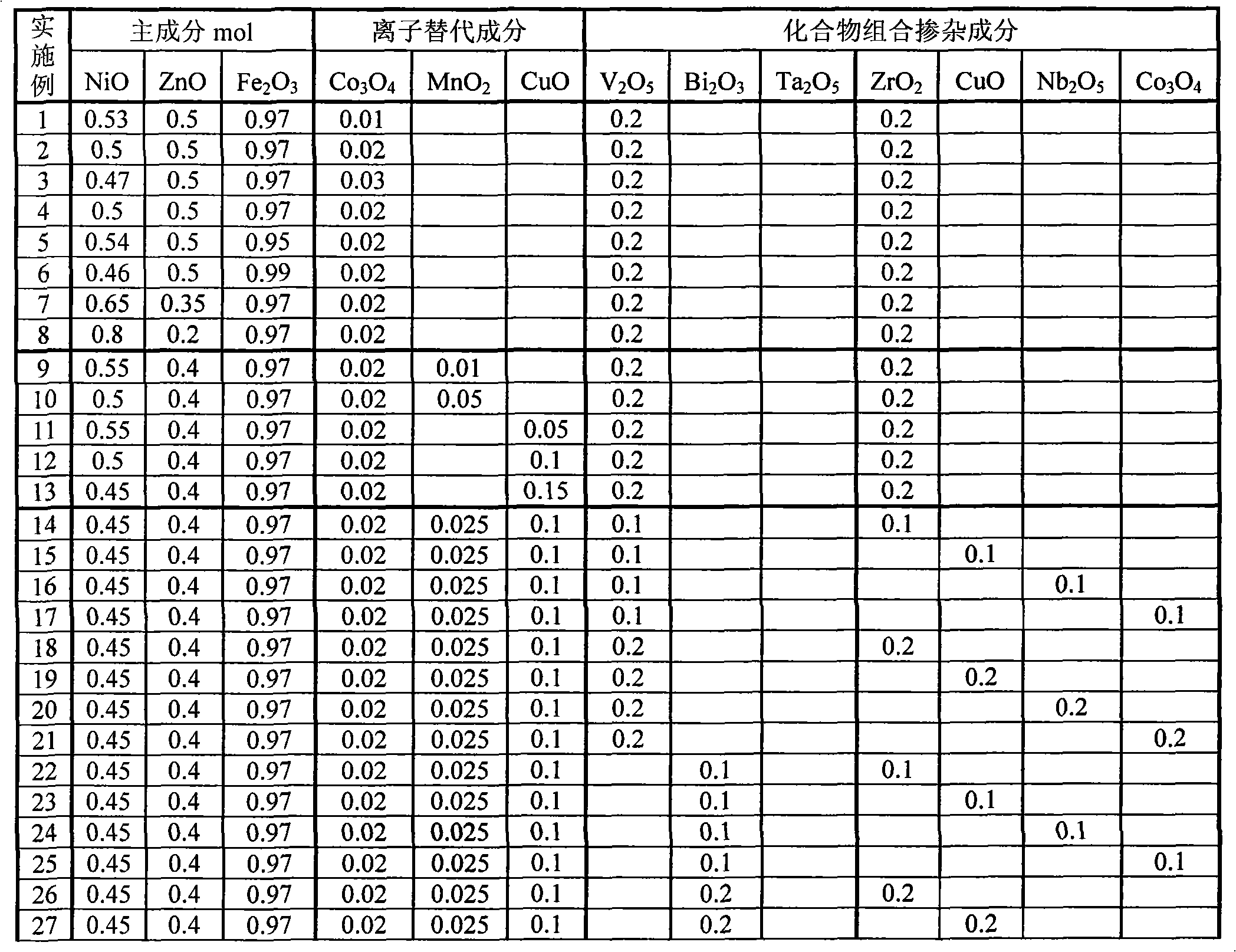

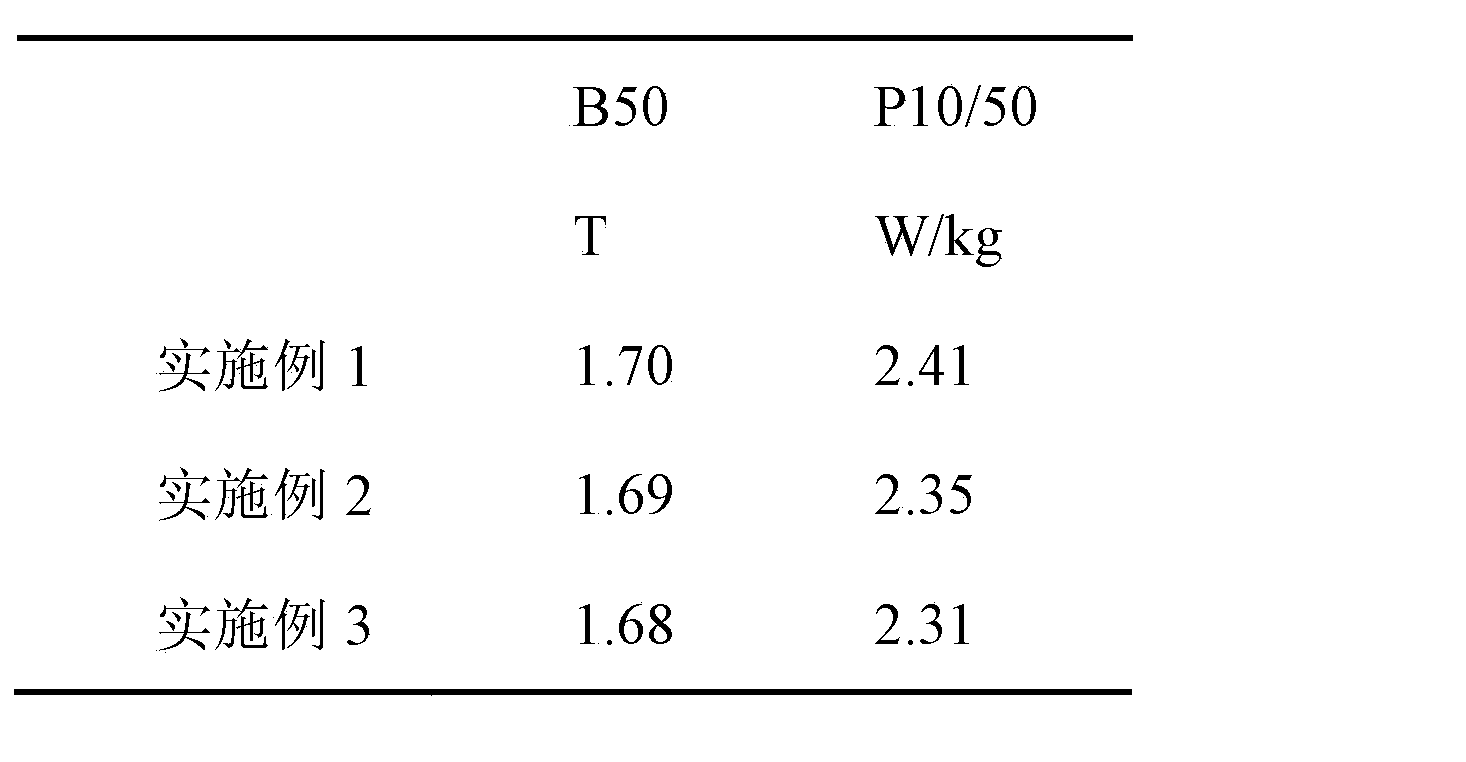

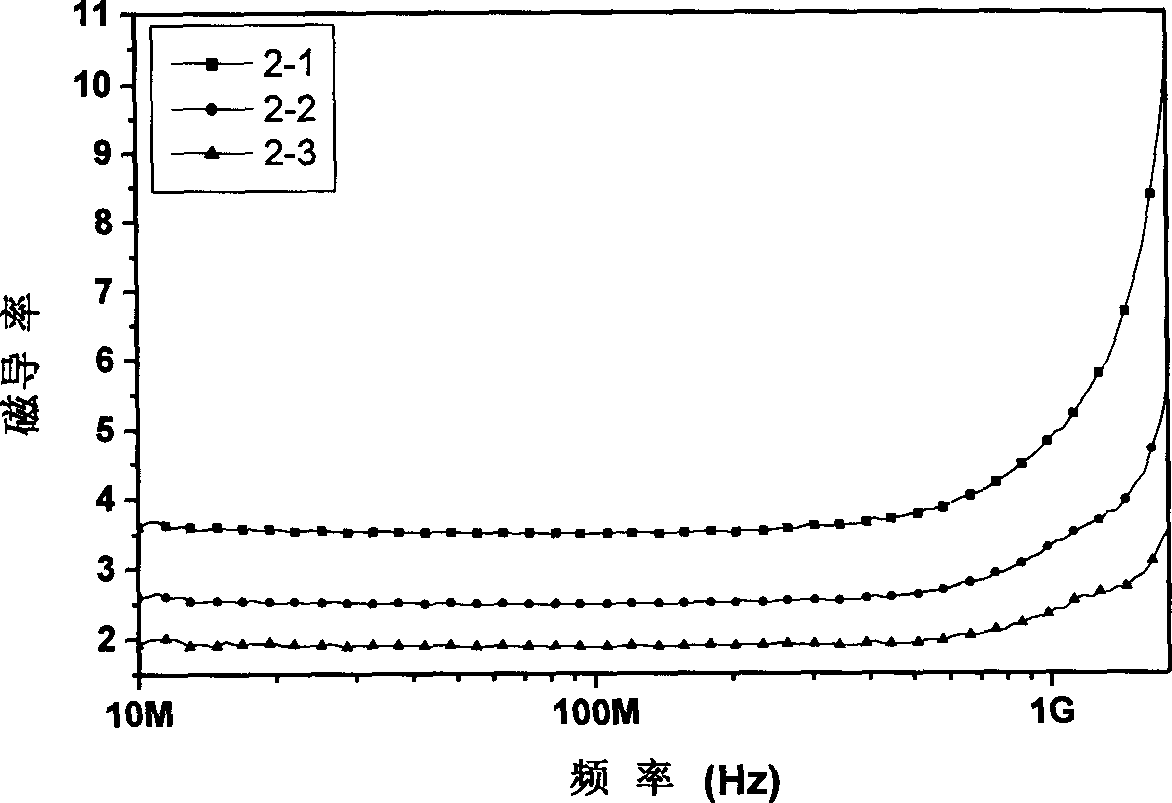

High-frequency high-power Ni-Zn base magnetic ferrite material and manufacturing method thereof

The invention discloses a high-frequency high-power Ni-Zn base magnetic ferrite material and a manufacturing method thereof. The Ni-Zn base magnetic ferrite material comprises a main ingredient, an ionic substitute ingredient and a compound composite and doped ingredient, wherein the main ingredient comprises Fe2O3, ZnO and the balance of NiO; the ionic substitute ingredient comprises one or more kinds of Co3O4, MnCO3 and CuO containing Co3O4; and the compound composite and doped ingredient comprises 2-3 kinds of V2O5, Bi2O3, Ta2O5, ZrO2, CuO, Nb2O5 and Co3O4. The manufacturing method comprises the following steps: (a) preparing a Ni-Zn base ferrite main ingredient mixture; (b) preparing a main ingredient pre-sintered material; (c) preparing micro-fine ferrite powder; (d) preparing a raw blank of a magnetic core; and (e) sintering the magnetic core. The invention obtains the Ni-Zn base magnetic ferrite material with high electromagnetic performance, high strength, high frequency and low loss by optimizing the composite design of a formulation and adopting the manufacturing method of the high-frequency high-power Ni-Zn base magnetic ferrite material. The Ni-Zn base magnetic ferrite material is used for high-power equipment of 1-30MHz and used as the magnetic core for a transformer, an inductor, a filter, a tuner, and the like.

Owner:CHONGQING MATERIALS RES INST

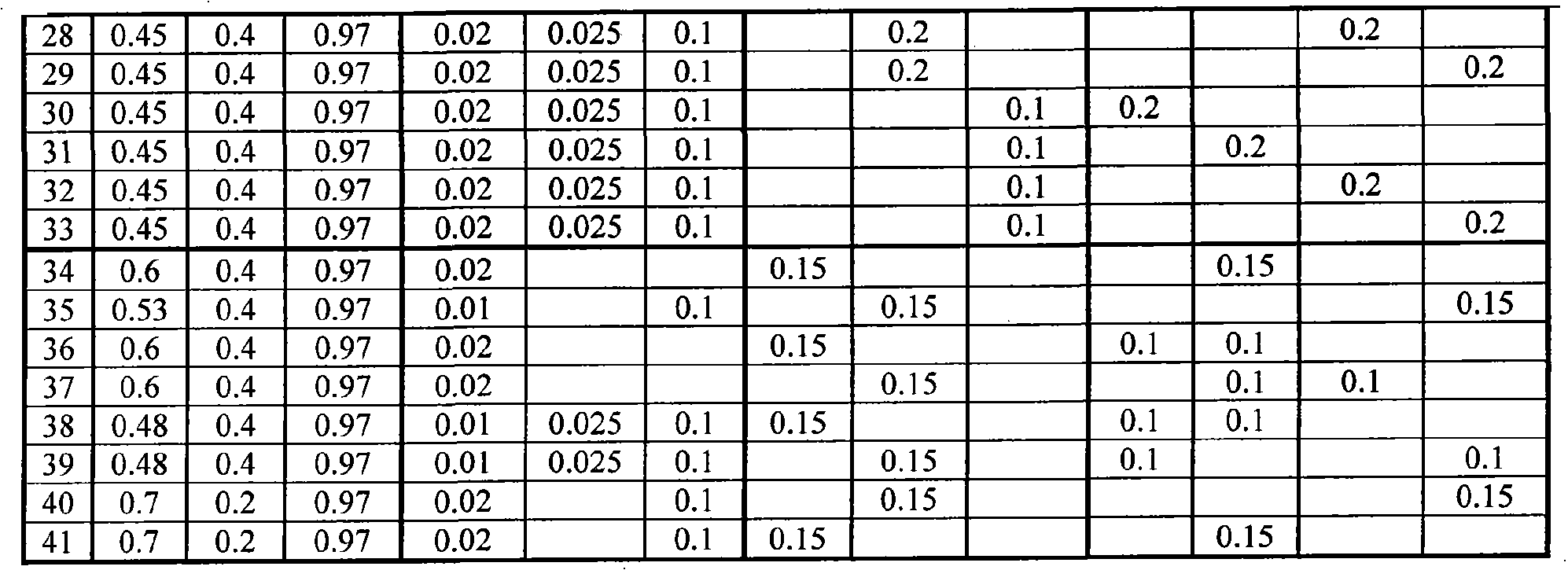

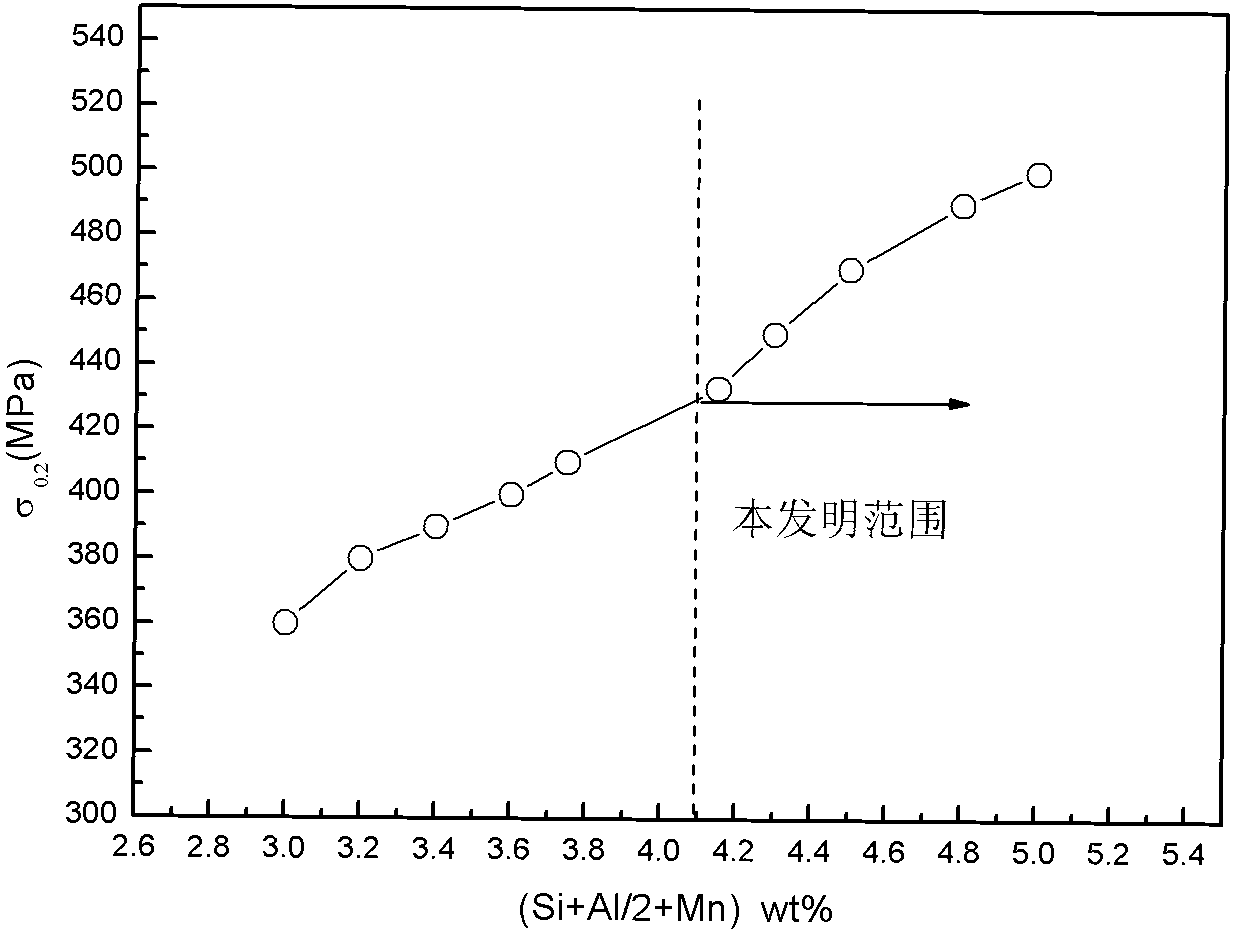

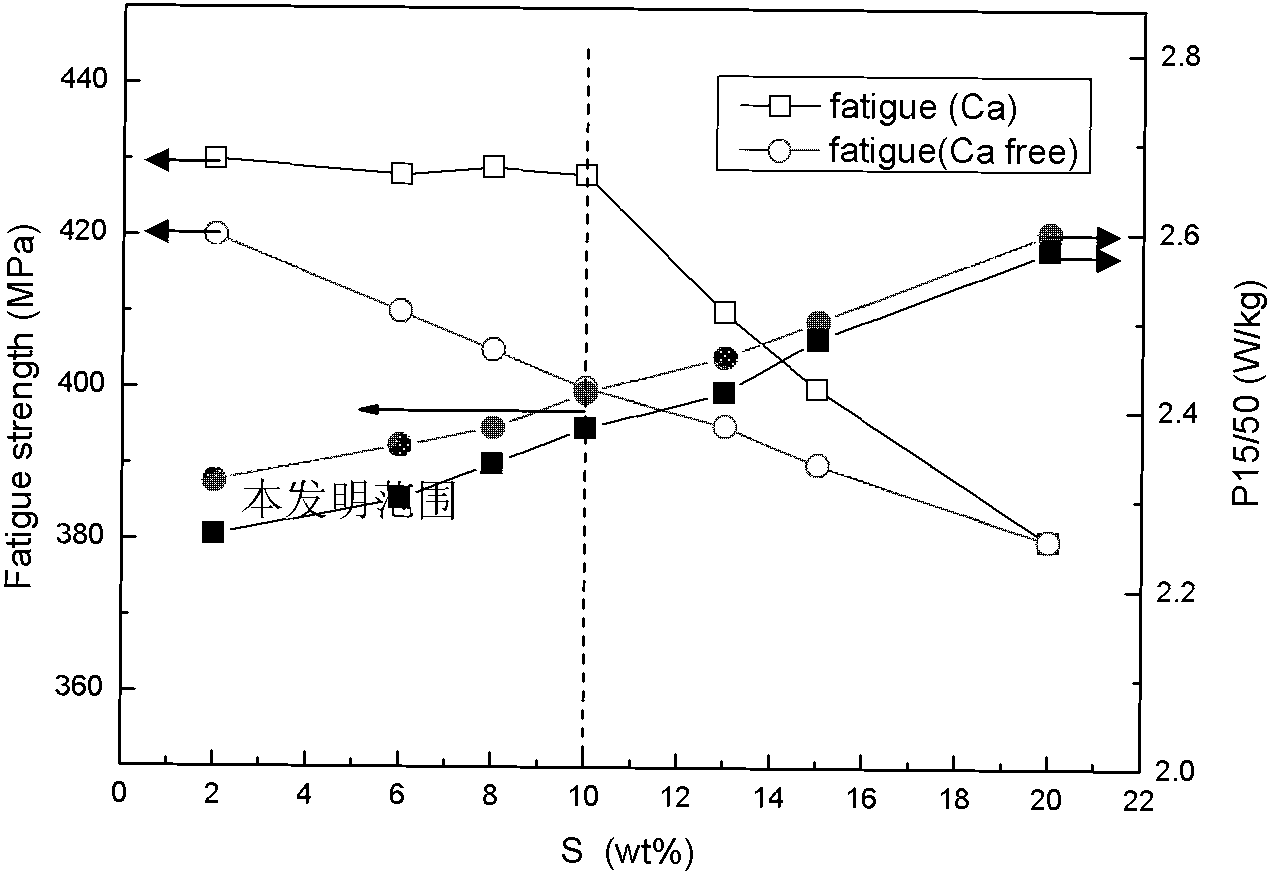

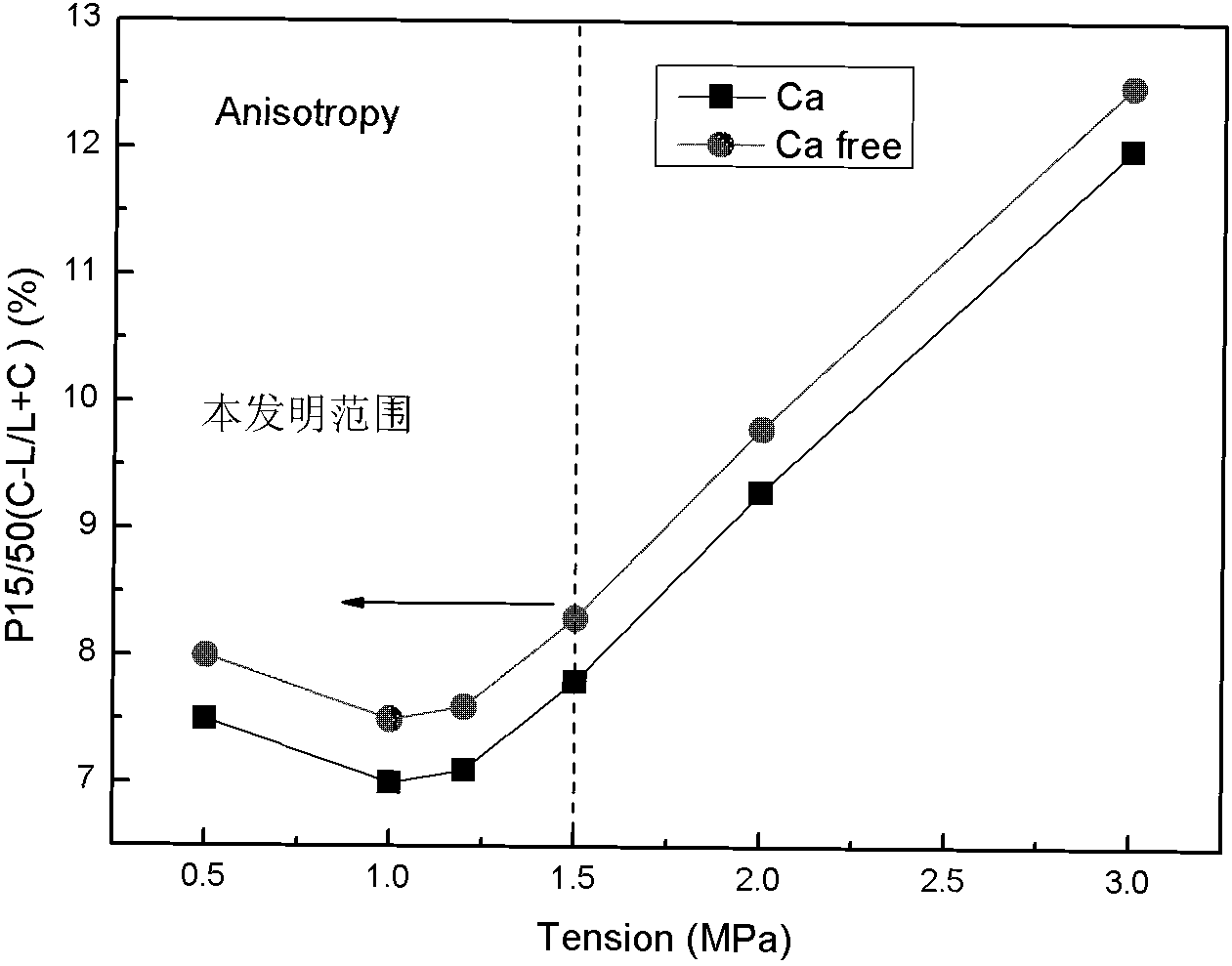

Non-oriented silicon steel for rotor and production method thereof

The invention discloses a non-oriented silicon steel for a rotor and a production method thereof. The steel consists of the following components in percentage by weight: 0.001-0.004% of C, 2.5-4.0% of Si, 0.5-1.5% of Al, 0.10-1.50% of Mn, not more than 0.02% of P, not more than 0.001% of S, not less than 4.1% and not more than 6.0% of Si+Al / 2+Mn, not more than 0.002% of N, not more than 0.005% of B and the balance of Fe and inevitable impurities. The production method mainly comprises the following steps of: refining process, namely sequentially deoxidizing Si and Al, and finally, adding CaSi alloy for Ca treatment; heating a casting blank in a heating furnace to be 1100 DEG C, insulating and then rolling; normalizing, carrying out acid cleaning and cold rolling, wherein the reduction rate is 70-78%; and tensioning and annealing a belt, wherein the temperature is 920-980 DEG C, and the tension is controlled between 0.5MPa and 1.5MPa. By utilizing the method, electrical sheets with excellent electromagnetic property, yield strength and fatigue performance can be obtained, the annealing temperature is reduced, the production energy consumption can be decreased, and furthermore, the production cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of magnetic nanoparticle loaded graphene aerogel composite material

InactiveCN108439376AGood electromagnetic performanceLarge specific surface areaOther chemical processesMagnetic/electric field screeningPolyvinyl alcoholMagnetite Nanoparticles

The invention provides a preparation method of a magnetic nanoparticle loaded graphene aerogel composite material and belongs to the technical field of functional magnetic materials. The method takesgraphene oxide, polyvinyl alcohol and metal salt as raw materials and comprises the following steps: preparing metal salt loaded three-dimensional porous crosslinking network graphene oxide aerogel through a hydrothermal method; freezing and drying, and roasting and reducing under a protection atmosphere to obtain the magnetic nanoparticle loaded graphene aerogel composite material in situ. The preparation method provided by the invention has the advantages of simplicity in operation, low cost and simple preparation technology and is a novel technology for macro preparation of the nanoparticlegraphene aerogel composite material; the magnetic performance and electric performance of the composite material can be adjusted through adjusting the ratio of graphene to the metal salt, and the prepared graphene aerogel composite material has the advantages of high specific surface area, small density, excellent electromagnetic performance and the like and can be used for an electromagnetic wave absorption material.

Owner:DALIAN UNIV OF TECH

High silicon cold-rolled non-oriented electrical steel and its preparation method

ActiveCN103882291AEasy to solveImprove electromagnetic performanceProcess efficiency improvementChemical compositionElectrical steel

The invention provides high silicon cold-rolled non-oriented electrical steel and its preparation method, the high silicon cold-rolled non-oriented electrical steel comprises the following chemical components by weight: less than 0.0015% of C, 2.0%-2.5% of Si, 0.10%-0.3% of Mn, less than or equal to 0.008% of P, less than 0.0015% of S, less than or equal to 0.0020% of N, 1.5%-2% of Als, less than 0.0020% of Ti, less than 0.0020% of Nb, less than 0.0020% of V, and balance of Fe and other inevitable residual elements. The preparation method comprises smelting, continuous casting, hot rolling, normalizing, cold rolling, two-stage annealing and final product annealing, through the composition design using Si and high Al, each technical process is controlled, a high silicon effect is achieved, adding of REM, Ca, Mg, Sb, Sn trace alloy elements is avoided, the cost is reduced, and the product production process stability and finished product electromagnetic property improvement are facilitated.

Owner:ANGANG STEEL CO LTD

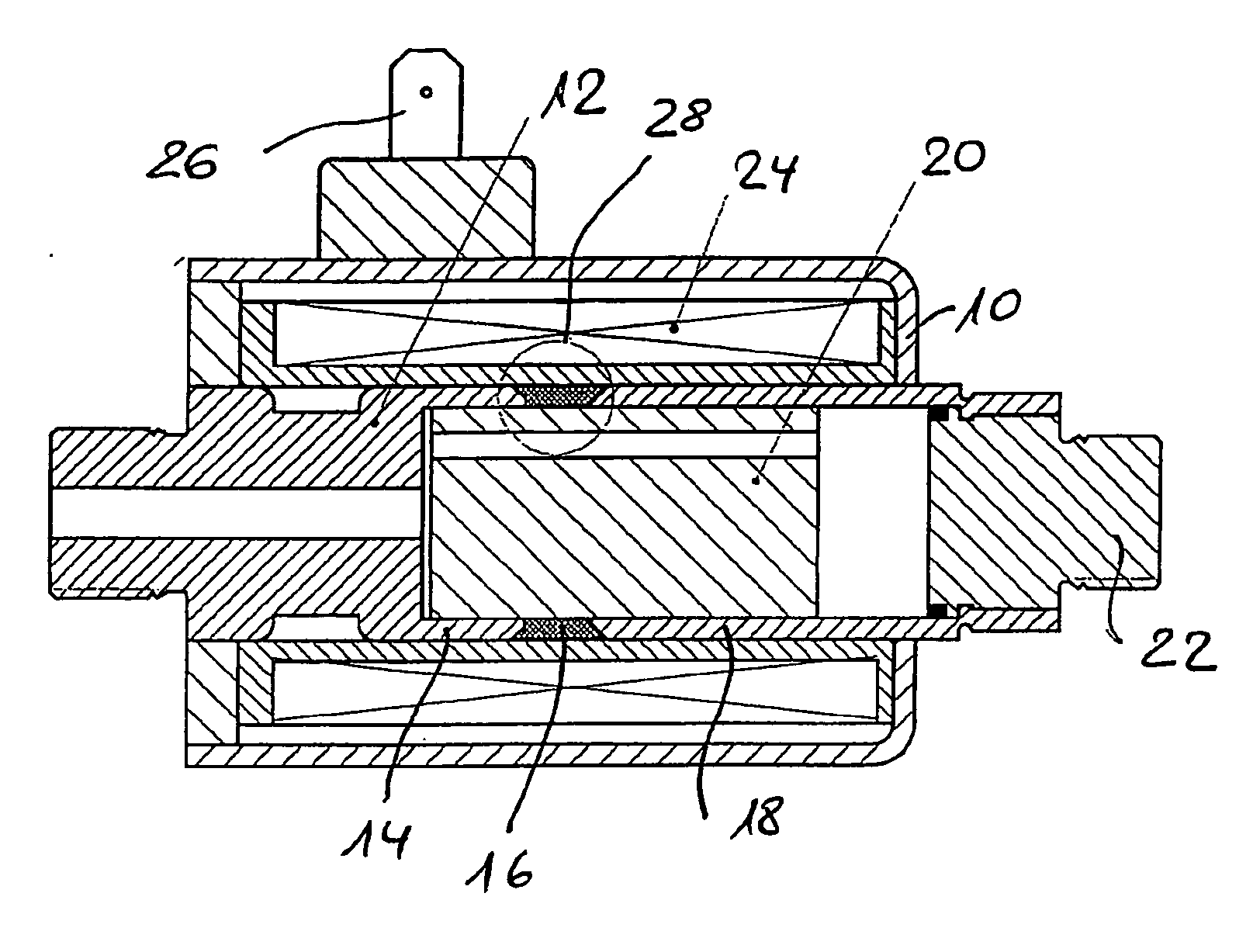

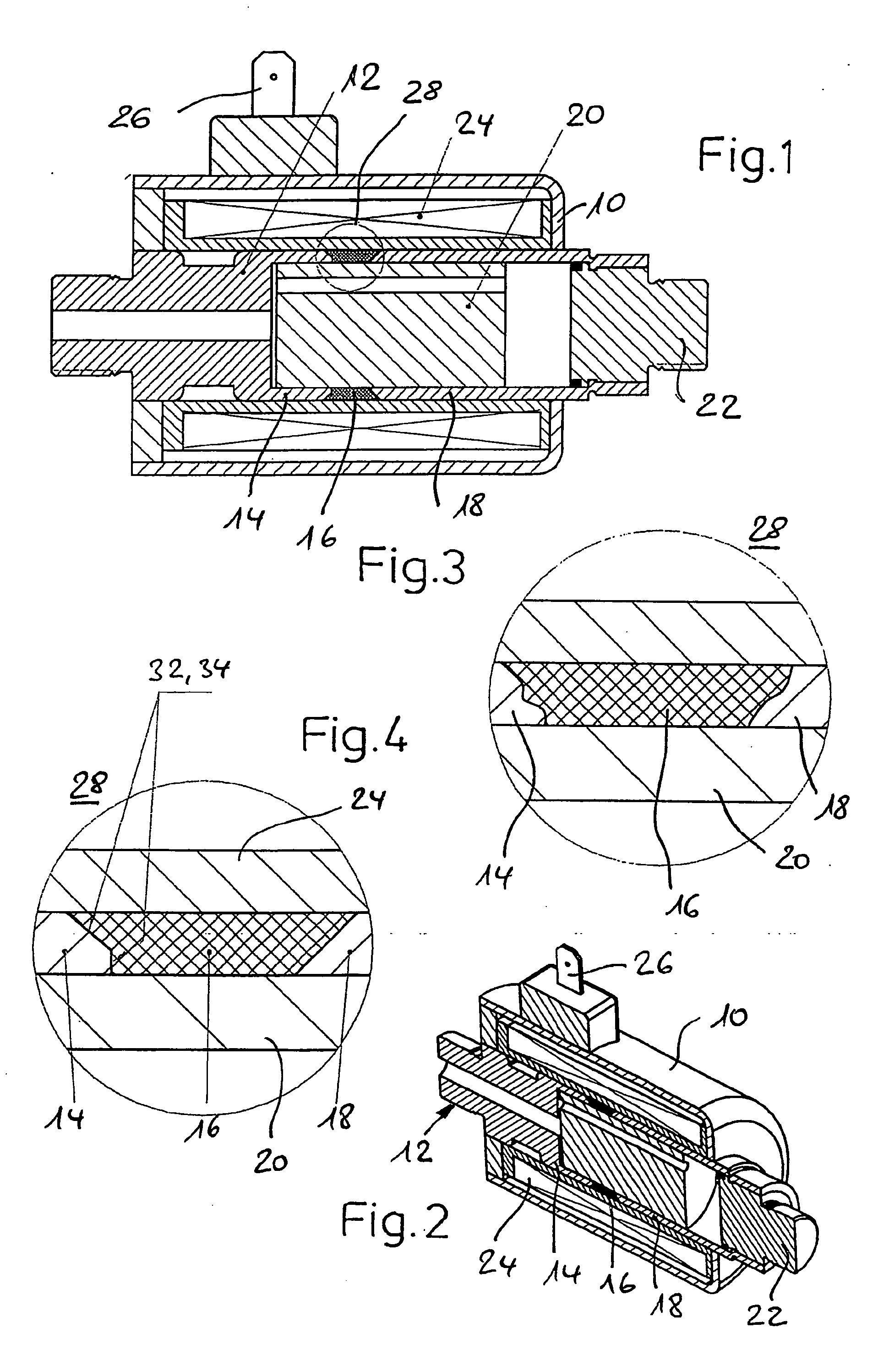

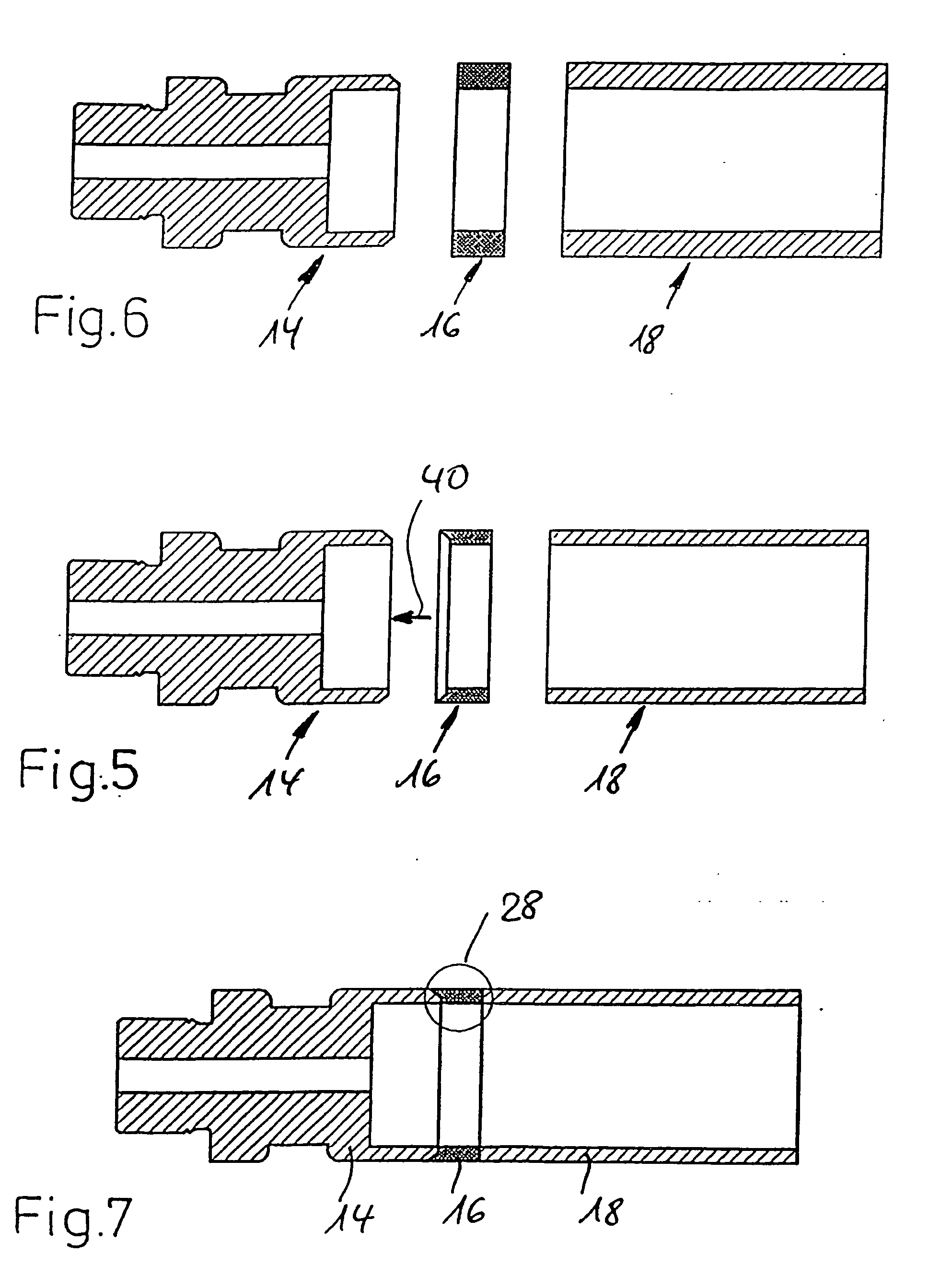

Electromagnetic actuating device

InactiveUS20060028311A1Low costImprove electromagnetic performanceElectromagnets with armaturesNon-electric welding apparatusFriction weldingEngineering

The invention relates to an electromagnetic actuating device, comprising an armature (20) which is provided in a housing (10) in such a way that it can be moved in an axial direction relative to a magnet frame (12) consisting of a core section (14) and a yoke section (18), and a coil device (24) which can be subjected to an electrical current in order to generate the movement, wherein the magnet frame is designed in a hollow-cylindrical manner in such a way that it at least partially surrounds the armature and comprises an intermediate section (16) consisting of non-magnetic material between the core section and the yoke section, wherein a permanent material connection is established in at least one of the cross-over areas (28) between the yoke section and the intermediate section and between the intermediate section and the core section by means of a friction welding method.

Owner:ETO MAGNETIC GMBH

Semi-process cold-rolling non-oriented electrical steel and production process thereof

The invention discloses a semi-process cold-rolling non-oriented electrical steel and a production process thereof, which mainly solves the technical problems that the prior art is high in energy consumption, large in pollution and high in cost. According to the technical scheme, the semi-process cold-rolling non-oriented electrical steel is a special steel which comprises the following ingredients by mass: not more than 0.01% of C, not more than 0.015% of P, not more than 0.012% of S, not less than 0.4% and not more than 0.60% of Si, not less than 0.6% and not more than 0.8% of Mn, not less than 0.15% and not more than 0.25% of Al, and the balance of Fe. The production process comprises the following steps: smelting molten steel, continuous casting, hot-rolling, punching and annealing, and specifically comprises the following steps: pretreating molten iron, smelting in a rotary furnace, blowing argon over the whole process, conducting RH (Rockwell Hardness) fine smelting, conducting CSP (Cast Steel Plate) continuous casting, putting in a CSP heating furnace, conducting CSP hot-continuous-casting, pickling and cold-rolling and annealing, wherein in the smelting process in the rotary furnace, silicon iron, ferromanganese iron and an aluminum alloy are added to conduct alloying so as to manufacture an alloy steel. The semi-process cold-rolling non-oriented electrical steel is mainly used in a production process of a motor iron core.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

Low-temperature sintering high performance soft magnetic ferrite material and manufacturing method

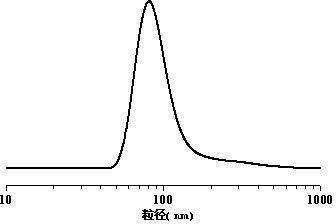

InactiveCN101593595AReduce contentDeterioration of electromagnetic performanceInorganic material magnetismBoric acidSilicon dioxide

The invention relates to a low-temperature sintering high performance MnZn power ferrite material, which comprises the following main components: 49.5 to 56.5mol percent of Fe2O3, 6.5 to 16 mol percent of ZnO and 29.5 to 41 mol percent of auxiliary element; the auxiliary element comprises calcium oxide, silicon dioxide and zinc metaborate, and the total addition amount is 0.01 to 0.25 weight percent of that of the main components. A manufacturing method comprises the following steps: putting the components into a sand mill pre-added with deionized water for grinding; controlling the average grain diameter to 0.5+ / -0.1 mu m; after the first spraying and prilling, presintering the obtained mixture in an electrothermal rotary kiln at a temperature of 850+ / -30 DEG C; putting the presintered materials into the sand mill for the second sand grind, and adding additives, namely the calcium oxide, the silicon dioxide and the zinc metaborate; performing the secondary spraying to obtain MnZn ferrite particle material powder; and molding and pressing the particle material into a blank and sintering the blank for 2 to 5 hours at a temperature of 1,150+ / -50 DEG C.

Owner:SHANDONG ZHONGRUI ELECTRONICS

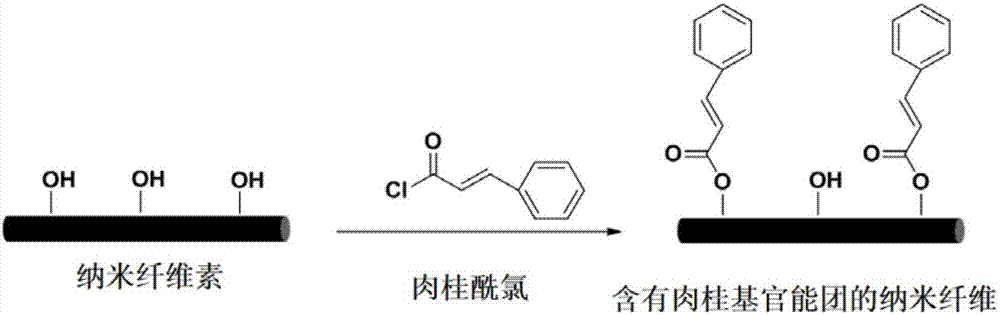

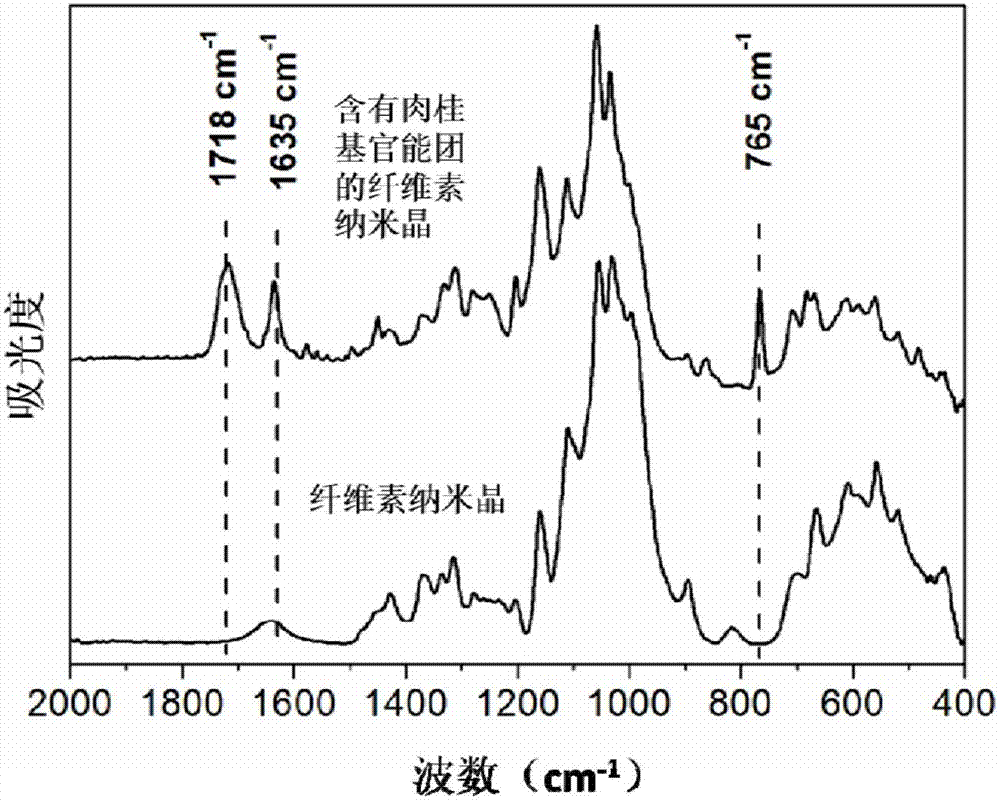

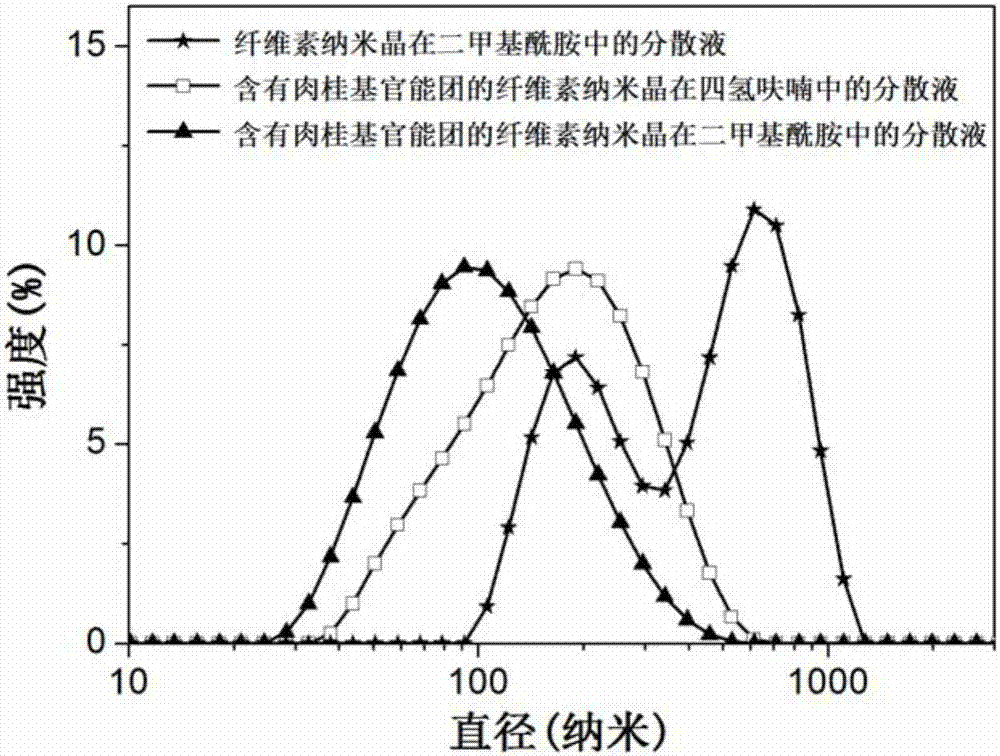

Nano cellulose containing cinnamyl functional group and preparation method and application of nano cellulose

InactiveCN107254002AAdjust Surface PropertiesImprove performanceCosmetic preparationsToilet preparationsCross-linkDispersity

The invention discloses nano cellulose containing a cinnamyl functional group and a preparation method and application of the nano cellulose and relates to the technical field of modified preparation and application of the nano cellulose. According to the preparation method, the nano cellulose is prepared through introducing the cinnamyl functional group to the nano cellulose; the cinnamyl functional group introduced to the nano cellulose is a micromolecule or a polymer of the cinnamyl functional group. According to the nano cellulose containing the cinnamyl functional group, excellent properties of the nano cellulose, such as excellent mechanical property, large specific surface area and good biocompatibility, are still kept; and meanwhile, the dispersity of the nano cellulose in an organic solvent and a hydrophobic material is improved. In addition, the nano cellulose containing the cinnamyl functional group has excellent ultraviolet absorption performance, and the nano cellulose containing the cinnamyl functional group is subjected to cross-linking reaction under ultraviolet radiation. The nano cellulose containing the cinnamyl functional group has a wide application prospect.

Owner:张振

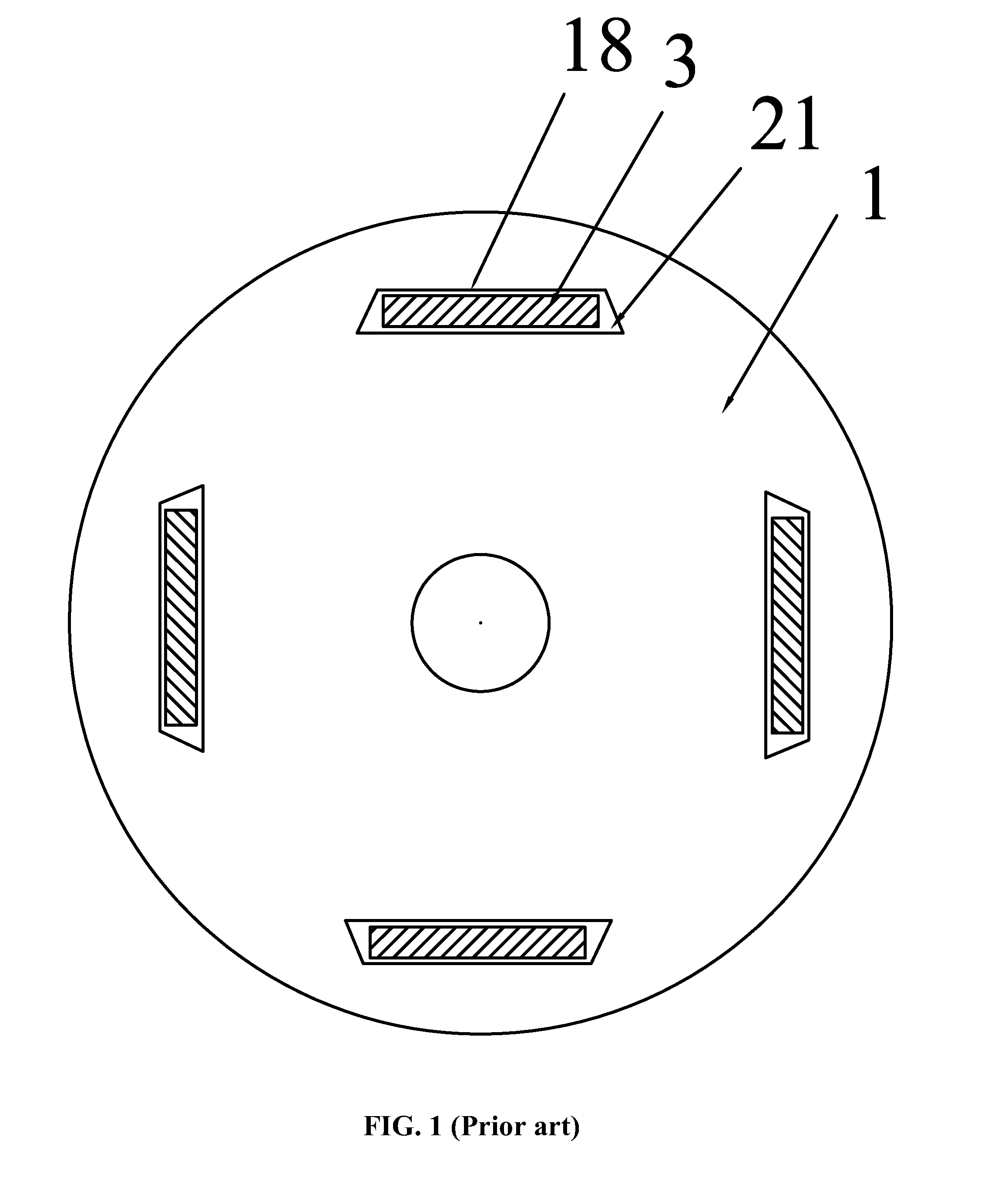

Permanent magnet rotor of motor

ActiveUS20120181895A1Simple structureLow manufacturing costMagnetic circuit rotating partsMagnetEngineering

A permanent magnet rotor of a motor including a rotor core and permanent magnets. The rotor core includes a central core, a plurality of sectional cores, and a connecting mechanism. The sectional cores are integrated with the central core via the connecting mechanism to form a whole iron core. Grooves are formed between each sectional core and the central core and the permanent magnets are embedded in the grooves. The permanent magnet rotor has a simple structure, excellent manufacturability in terms of production and assembly, low manufacturing costs, excellent electromagnetic performance, and meanwhile is robust enough to avoid potential deformation.

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

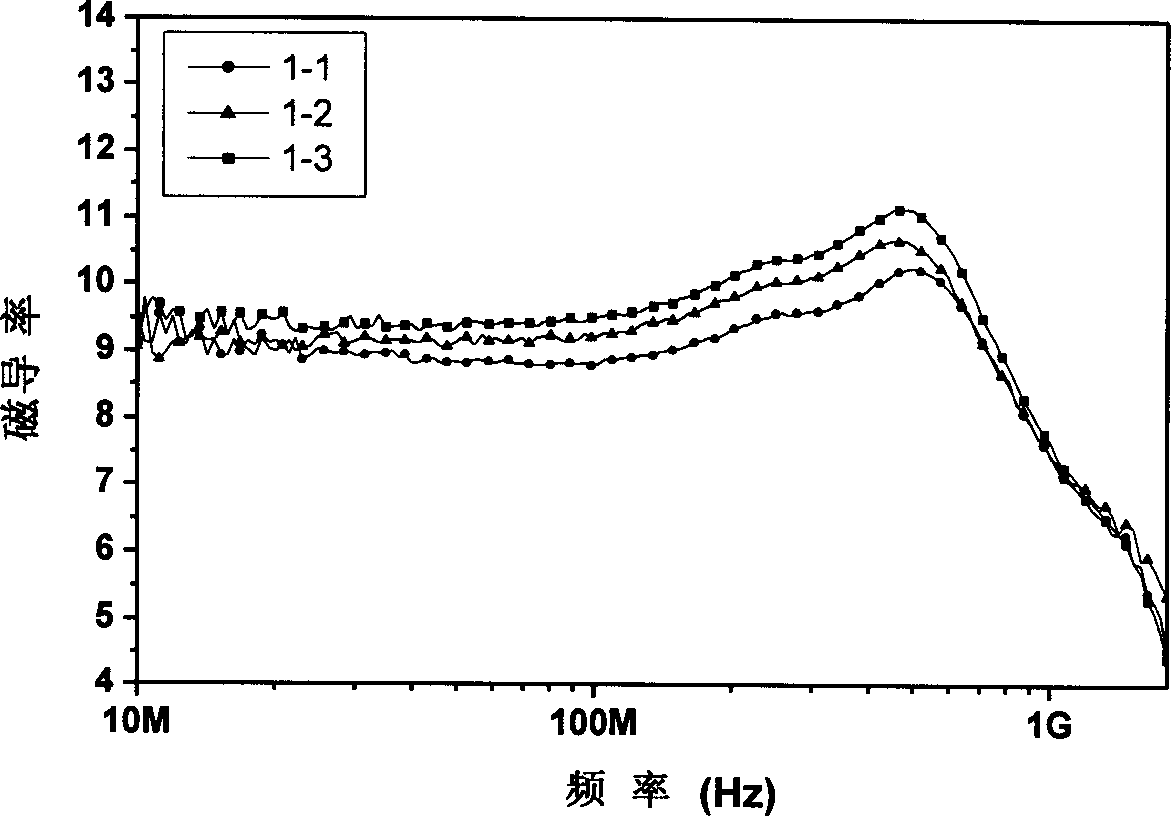

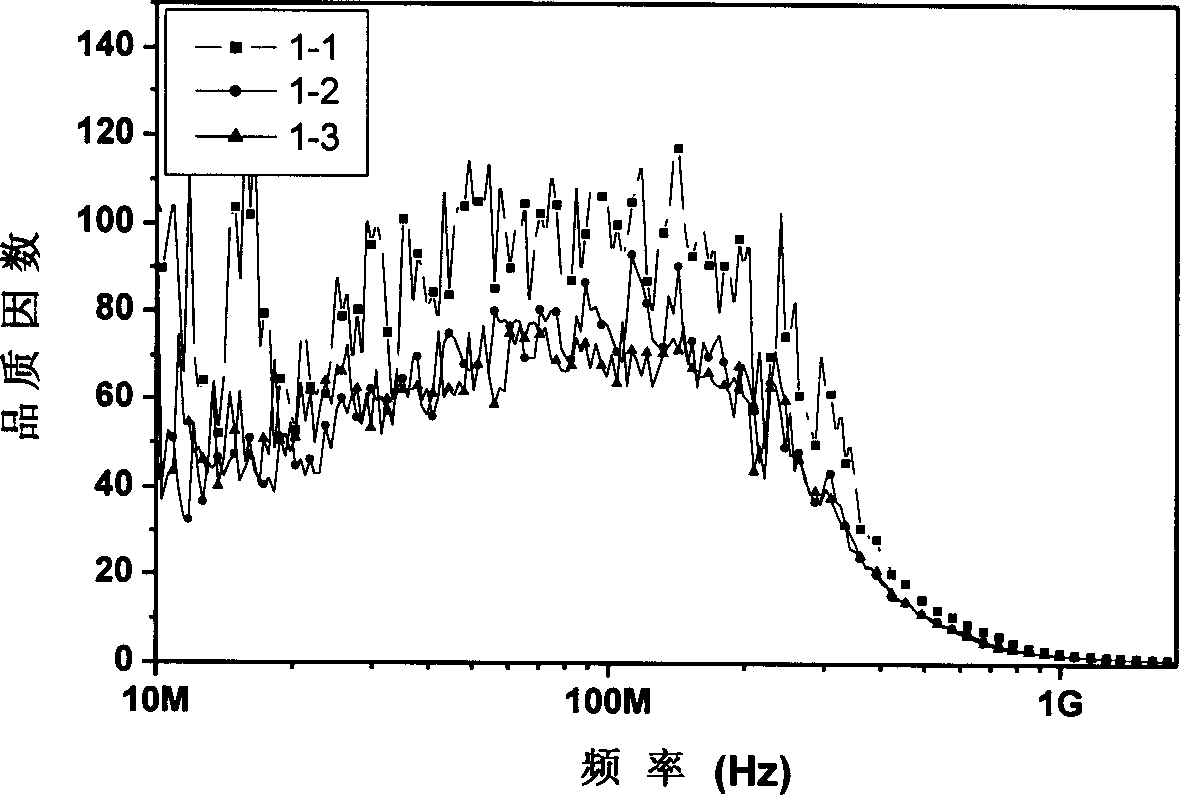

Components and preparing process of VHF plate sensor material

InactiveCN1397961AReduce performanceLower firing temperatureInorganic material magnetismCombustionSolid reaction

This invention relates to a formula of a VHF inductive chip material and its preparation method. There is not high performance low temp sintered ferrite materials at present so we have to use low dielectric ceramics as the medium instead to produce low inductance multi-chip inductors. The basis of the said material is a plane hexagon soft magnet ferrite matched with low temp combustion adjuvant processed by the solid phase reactance synthesis and the combustion adjuvant is applied with two times of doping VHF inductive material of excellent performance is got after ballmill, baking, preroast, ballmill, baking, granulation, formation sintering, realizing low temp sintering with temp below 900 deg.c.

Owner:TSINGHUA TONGFANG CO LTD +1

Soft magnetic structural-steel-plate with excellent toughness under low temperature and method for making same

ActiveCN1690242AImprove mechanical propertiesImprove electromagnetic performanceHigh intensityToughness

A soft magnetic structured steel sheet of fine low-temperature flexibility, the constituent (mass ratio) of which is: C 0.010 to 0.040 percent, Si 0.50 to 1.00 percent, Mn 1.00 to 1.50 percent, P equal to or less than 0.005 percent, Al 0.50 to 1.00 percent, Cr 0.20 to 0.50 percent, Cu 0.20 to 0.60 percent, Ti 0.005 to 0.02 percent, N 0.001 to 0.008 percent, Ni 0.30 to 0.80 percent, Ca 10 to 60 ppm, and the rest Fe and inescapable inclusion, Pcm equal to or less than 0.20 percent. The invention realizes the unification of high intensity, high flexibility, fine welding performance and fine electromechanical property of the soft magnetic structured steel sheet, which is in particular to the side guide absorbing bearing force, guiding force and driving force of the magnetic levitation vehicle.

Owner:BAOSHAN IRON & STEEL CO LTD

Soft magnetic structural steel and manufacturing method thereof

The present invention relates to a structure steel plate for track, in particular, it relates to a soft-magnetic structure steel for magnetic suspension track and its manufacture method. Its composition comprises: C 0.010%-0.040%, Si 1.0%-2.0%, Mn 0.60%-1.00%, P is less than or equal to 0.015%, S is less than or equal to 0.005%, Als 0.005%-0.020%, Cr is less than 0.60%, Cu 0.20-0.60%, Ti 0.005%-0.02%, N is less than or equal to 0.010%, Ni is less than or equal to 1.00%, Ca or REM is less than or equal to 0.010% and the rest is Fe and unavoidable impurity, in which the REM can be substituted for element Ca. Its manufacture process includes continuous casting process, hot-rolling process and normalizing process.

Owner:BAOSHAN IRON & STEEL CO LTD

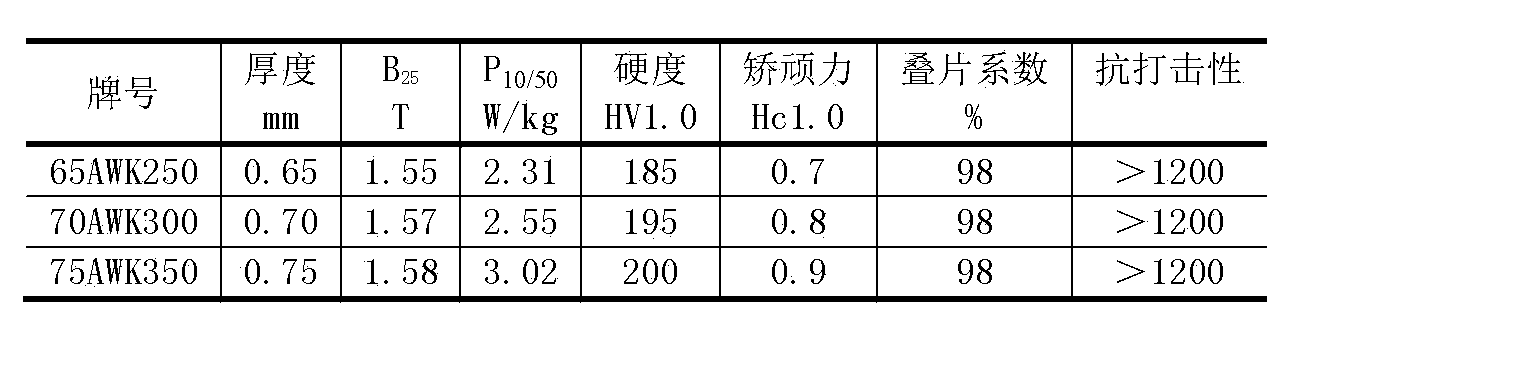

High-strength special-purpose cold-rolled non-oriented electrical steel and producing method thereof

The invention provides high-strength special-purpose cold-rolled non-oriented electrical steel and a producing method thereof. The steel comprises following chemical components by weight: not more than 0.0030% of C, 2.5-3.0% of Si, 0.10-0.5% of Mn, 0.005-0.20% of P, not more than 0.0015% of S, not more than 0.0040% of N and 0.140-1.10% of Als, with the balance being Fe and other unavoidable residual elements. The producing method includes smelting, continuous casting, hot rolling, normalizing, cold rolling and annealing. The electrical steel is low in coercive force, high in hardness, free of magnetic aging, high in strength and high in impact resistance. The product is flexible in production and can be produced in the same line with a high-grade product. The electrical steel has excellent electromagnetic performances, and can be widely used for manufacturing iron core materials of electromagnetic switches. The application field of the electrical steel is broadened.

Owner:ANGANG STEEL CO LTD

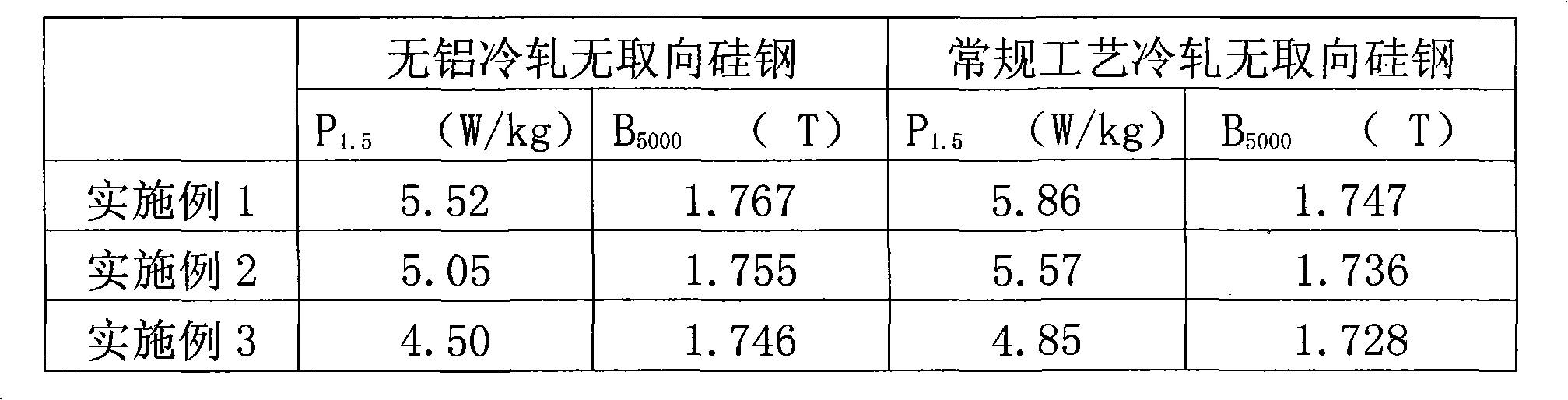

Method for producing aluminum-free steel grade of cold milling non-oriented silicon steel

ActiveCN101992210AReduce manufacturing costGood electromagnetic performanceProgramme control in sequence/logic controllersMetal rolling arrangementsSocial benefitsHydrogen

The invention relates to a method for producing aluminum-free steel grade of cold milling non-oriented silicon steel, which comprises the following steps of: controlling the quantity of Als to be not more than 0.0010 percent and the content of residual elements easily forming nitrides; adopting low-temperature heating and controlled-temperature milling for hot milling; adopting primary cold method milling or secondary cold method milling with the middle annealing for cold milling; and carrying out the integrated control measures such as wet hydrogen decarburization, recrystallization temperature annealing and the like. Thereby, the mass production of efficient aluminum-free cold milling non-oriented silicon steel can be realized with low production cost under the condition of the traditional equipment, the electromagnetic performance of the efficient aluminum-free cold milling non-oriented silicon steel is superior to the cold milling non-oriented silicon steel produced by the same-trademark conventional process, the iron loss is averagely reduced by about 0.4W / kg, the magnetic strength is averagely improved by 0.2T, and the method not only meets the market requirements, but also has obvious economic benefits and social benefits.

Owner:ANGANG STEEL CO LTD

Ferrite wave-absorbing material and preparation method thereof

InactiveCN103482969AHigh strengthHigh curie temperatureOther chemical processesCeramic sinteringRare-earth element

The invention relates to a ferrite wave-absorbing material and a preparation method of the ferrite wave-absorbing material. A ferrite is mingled with a rare earth element of samarium and is of a Co2 Z-type planar hexagonal structure. The chemical formula of the ferrite is 3(Ba0.5Sr0.5)O 2CoO yFe2O3 xSm2O3, wherein x and y are mole numbers, 0.15<=x<=0.5, and 10<=y<=12. According to the preparation method of the ferrite wave-absorbing material, on the basis of the traditional ferrite ceramic sintering technology, the Sm element is mingled in to adjust and control the microstructure of the material. Thus, the purpose of improving the electromagnetic property of the material is achieved, the raw materials are easy to obtain, complex equipment is not needed, the technology is easy to operate and master, the cost is low, and the preparation method of the ferrite wave-absorbing material is suitable for large-scale production. The Co2 Z-type ferrite wave-absorbing powder mingled with the rare earth element of samarium can be used for preparing a wave-absorbing coating and has high practical value and extensive application prospects in the electromagnetic shielding and cloaking field.

Owner:CENT IRON & STEEL RES INST

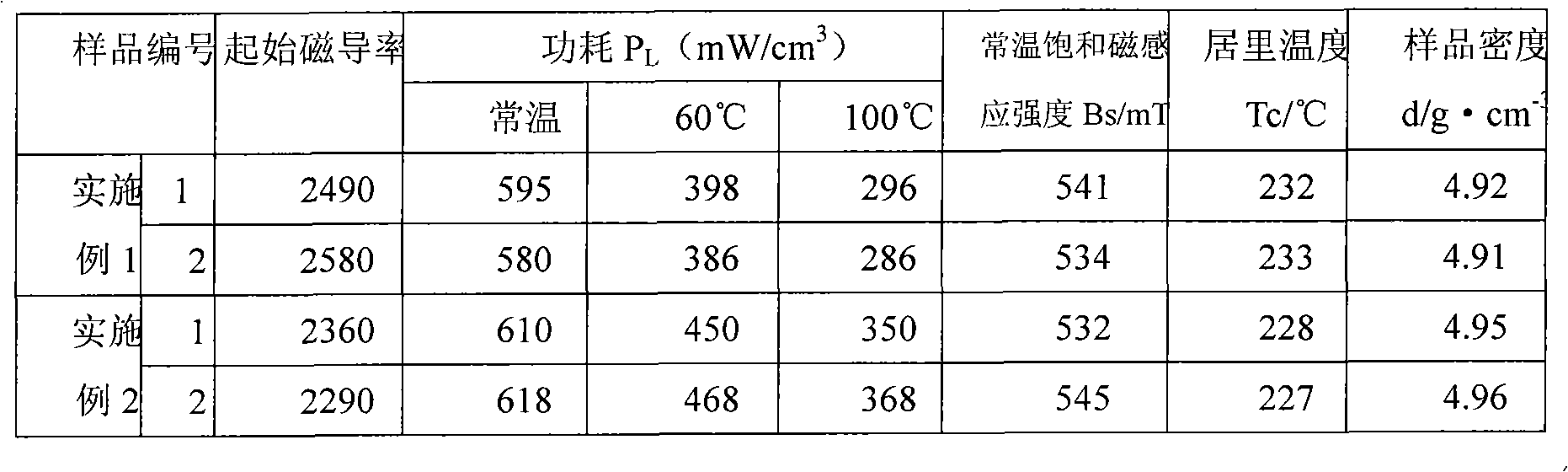

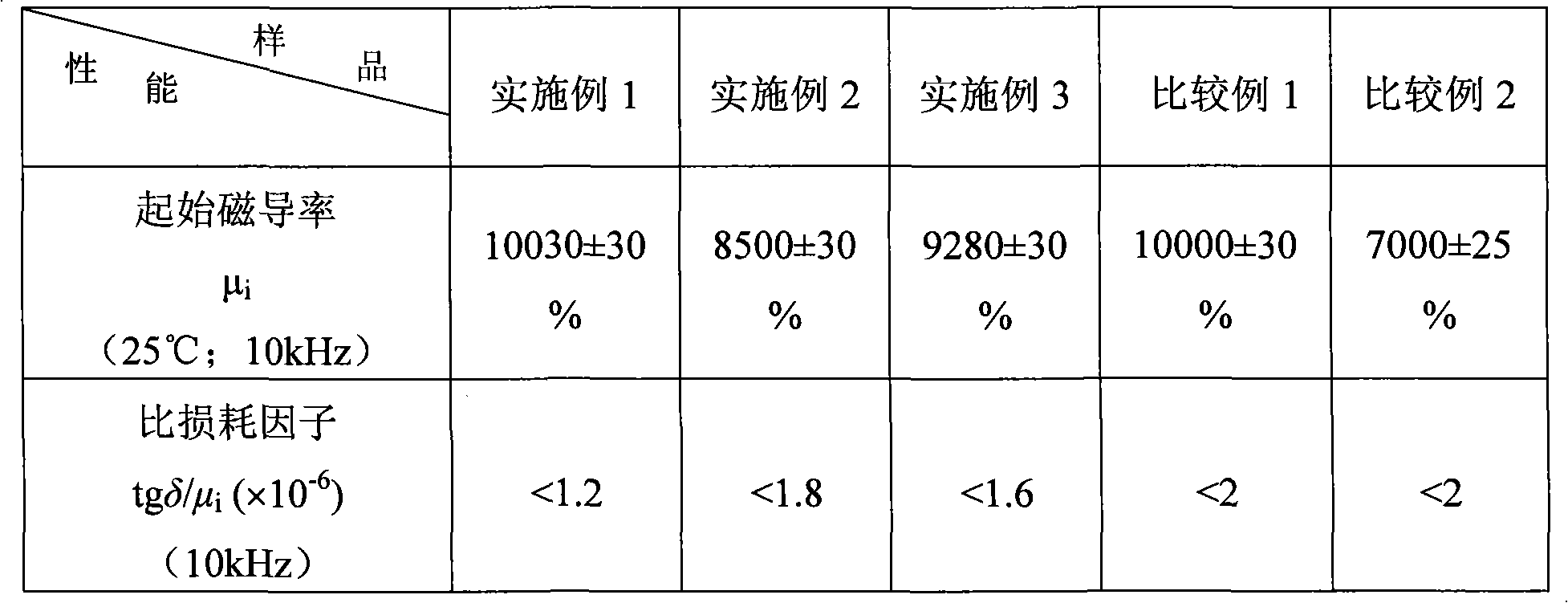

MnZn ferrite material of high initial permeability and low loss and preparation method thereof

ActiveCN101807463AHigh initial permeabilityLow loss characteristicInorganic material magnetismInitial permeabilityMaterials science

The invention discloses an MnZn ferrite magnetic material with high initial permeability and low loss and a preparation method thereof, the MnZn ferrite is prepared by principal components and auxiliary components, and the principal components and the mass percentage by oxide are as follows: 60-73wt% of Fe2O3, 13-33wt% of ZnO and balance Mn3O4; the auxiliary components are five oxides: 0.01-0.04wt% of SnO2, 0.01-0.04wt% of TiO2, 0.03-0.05wt% of Er2O3, 0.05-0.08wt% of Bi2O3 and 0.03-0.08wt% of PbO; and the soft magnetic ferrite material has not only high initial permeability but also low loss, and has excellent comprehensive soft magnetic properties.

Owner:苏州天铭磁业有限公司

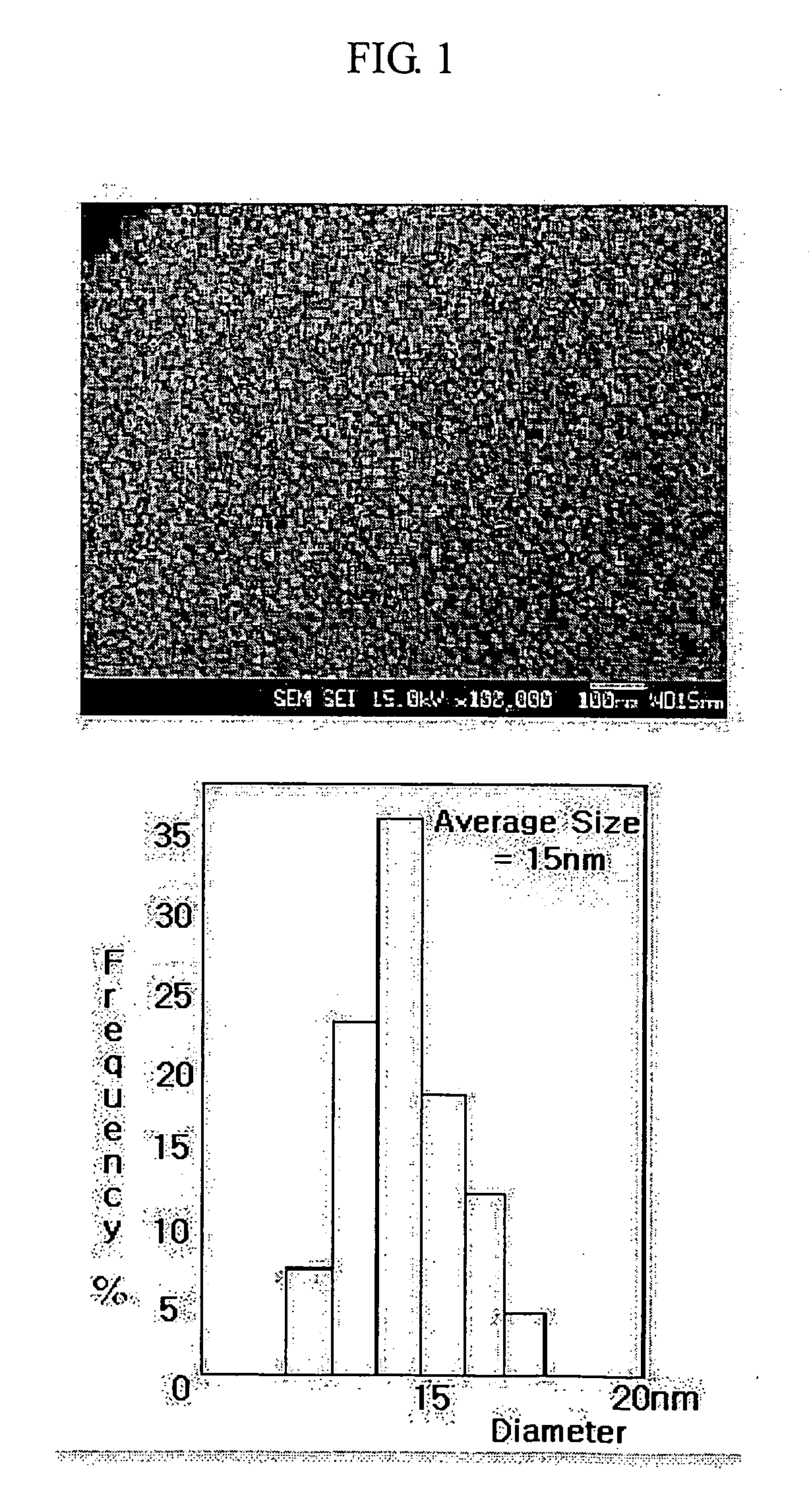

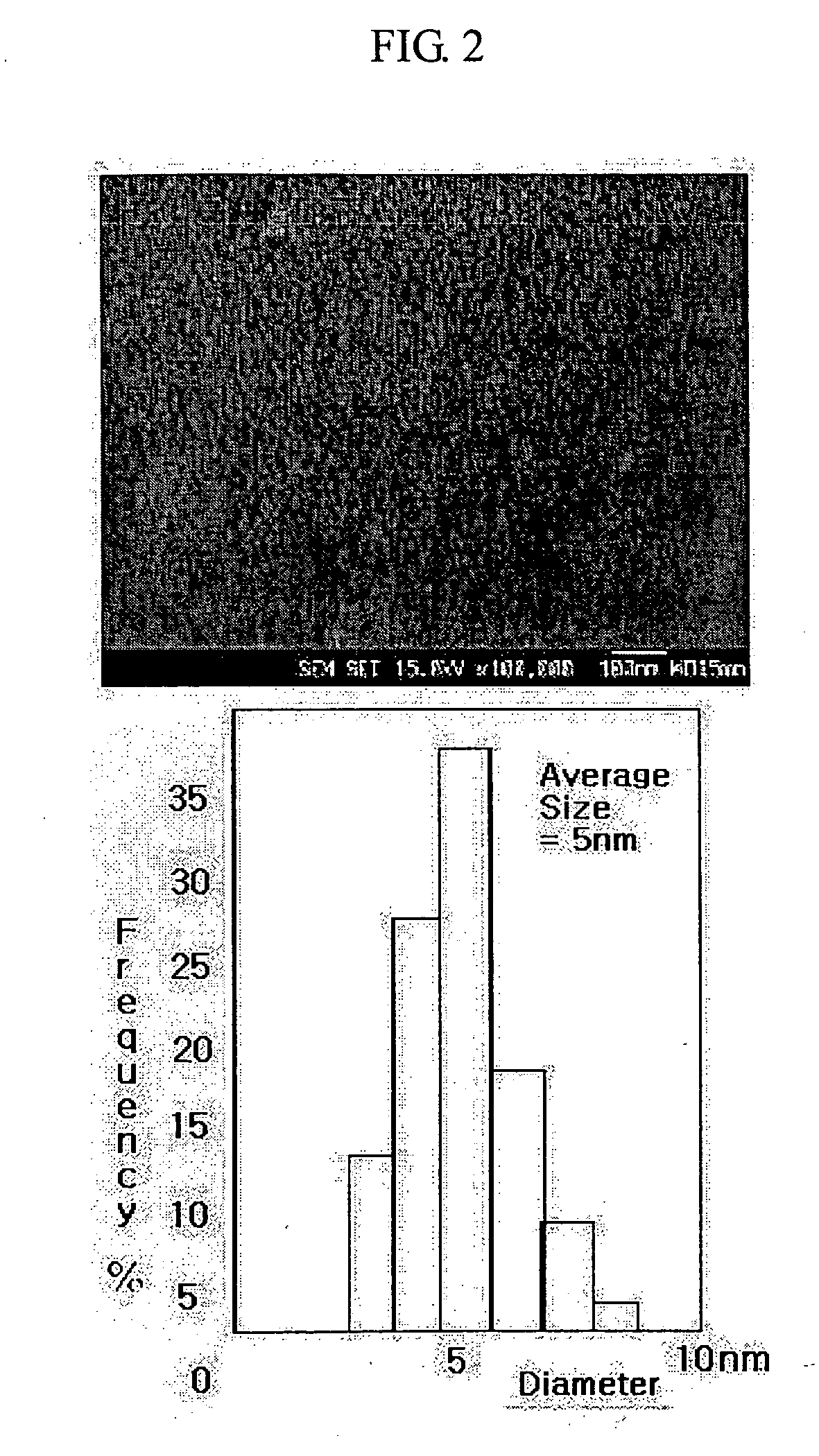

Metal nano-particles coated with silicon oxide and manufacturing method thereof

InactiveUS20060204754A1Retains inherent electromagnetic propertyInhibition of particle growthMaterial nanotechnologyNanostructure manufactureCompound (substance)Silicon oxide

Disclosed herein is a metal nanoparticle whose surface is coated with a silicon oxide. The silicon oxide is obtained from a silicon compound or a derivative thereof as a precursor and has a particle diameter of a few angstroms (A). Further disclosed is a method for manufacturing metal nanoparticles. The method comprises the steps of a) mixing metal ions, a solvent and an additive required for forming metal complex ions, b) adding a silicon compound or a derivative thereof as a precursor for forming silicon oxides, to the mixture of step a) to coat the surface of the metal ions, and c) adding a reducing agent to the mixture of step b) to reduce the metal ions. If necessary, the method further comprises the step of d) lyophilizing the resulting product of step c), i.e. metal nanoparticles. Since the surface of the metal nanoparticle of the present invention is coated with a silicon oxide, the metal nanoparticle is stabilized. In addition, the metal nanoparticle retains electromagnetic properties inherent to the metal and can be easily manufactured in an economical manner.

Owner:MIJINANOTECH

A preparation method of high-density ferrite-carbon nanotube composite bulk material

The invention discloses a method for preparing a high-density ferrite-carbon nanotube composite block material, specifically: weighing raw materials according to the stoichiometric ratio of each element in the chemical formula of the ferrite-carbon nanotube composite material, Synthesize the ferrite-carbon nanotube composite material powder, and then obtain the ferrite-carbon nanotube composite material embryo body through granulation molding, put the embryo body into a sagger made of wave-transparent material, and then put the Put the sagger into a professional microwave oven. Under an inert atmosphere, adjust the microwave power, control the heating rate, heat up to the sintering temperature, and finally cool down to room temperature to obtain a ferrite-carbon nanotube composite bulk material. The relative density of the ferrite-carbon nanotube composite bulk material prepared by the invention is as high as 99.99%, the electromagnetic performance is excellent, and the consistency is excellent, the phenomenon of deformation and cracking is greatly reduced, the yield of finished products is improved, and the sintering temperature is also reduced , shorten the holding time, and greatly improve the production efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com