High silicon cold-rolled non-oriented electrical steel and its preparation method

A technology of grain-oriented electrical steel and high silicon, applied in the direction of improving process efficiency, etc., can solve the problems of frequent edge cracks and broken belts, fluctuations in electromagnetic properties of finished products, and strong thermal sensitivity of high silicon steels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

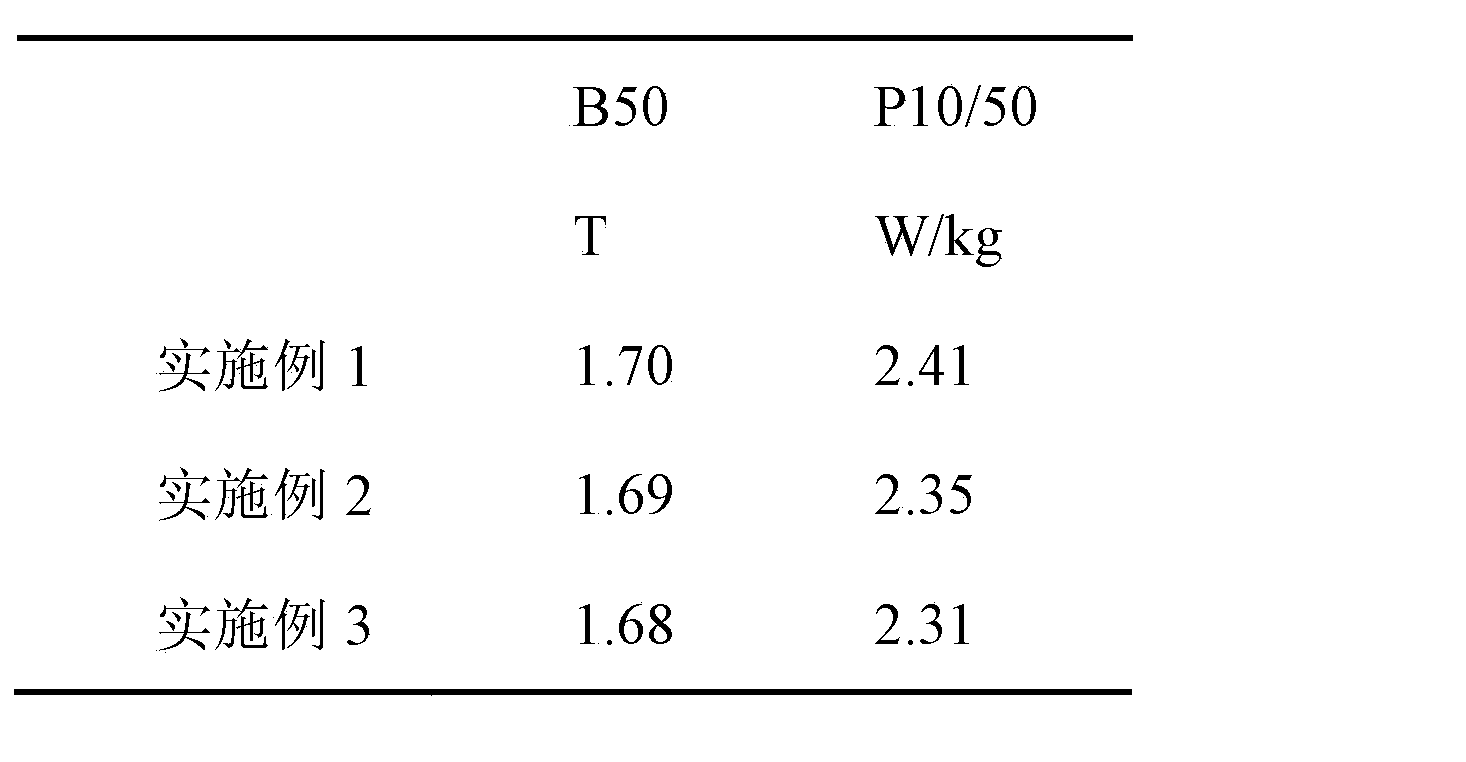

Embodiment 1

[0021] Example 1: C: 0.0011%, Si: 2.15%, Mn: 0.20%, P: 0.008%, S: 0.0013%, Als: 1.68%, N: 0.0019%, Ti: 0.0010%, Nb: 0.0015%, V : 0.0018%; the balance is iron and other unavoidable impurity elements.

[0022] The process steps are as follows:

[0023] a) Smelting: Converter smelting, RH vacuum refining treatment, control the content of elements such as sulfur, carbon, and niobium, vanadium, titanium that are easy to form fine dispersed two-phase particles;

[0024] b) Continuous casting: the molten steel is cast into a slab by continuous casting, the overheating temperature is 40°C, the pulling speed is 0.7m / min, and the ratio of equiaxed crystal ratio is 68%;

[0025] c) Hot rolling: billet heating temperature is 1100°C, high-temperature plan is adopted for key finish rolling and final rolling coiling, starting rolling temperature is 1020°C, finishing rolling temperature is 870°C, coiling temperature is 700°C, plate thickness is 1.5mm;

[0026] d) Normalization: use a normal...

Embodiment 2

[0030] Example 2: C: 0.0014%, Si: 2.3%, Mn: 0.25%, P: 0.007%, S: 0.0014%, Als: 1.70%, N: 0.0020%, Ti: 0.0012%, Nb: 0.0017%, V : 0.0013%; the balance is iron and other unavoidable impurity elements.

[0031] The process steps are as follows:

[0032] a) Smelting: Converter smelting, RH vacuum refining treatment, controlling the content of elements such as sulfur, carbon, and niobium, vanadium, and titanium that are easy to form fine dispersed two-phase particles;

[0033] b) Continuous casting: the molten steel is cast into a slab by continuous casting, the overheating temperature is 45°C, the pulling speed is 0.75m / min, and the ratio of equiaxed crystal ratio is 65%;

[0034] c) Hot rolling: billet heating temperature is 1120°C, key finish rolling and finishing coiling adopt high temperature plan, starting rolling temperature is 1030°C, finishing rolling temperature is 875°C, coiling temperature is 710°C, plate thickness is 1.5mm;

[0035] d) Normalization: use a normalized ...

Embodiment 3

[0039] Example 3: C: 0.0013%, Si: 2.48%, Mn: 0.25%, P: 0.007%, S: 0.0012%, Als: 1.90%, N: 0.0020%, Ti: 0.0011%, Nb: 0.0012%, V : 0.0017%; the balance is iron and other unavoidable impurity elements.

[0040] The process steps are as follows:

[0041] a) Smelting: Converter smelting, RH vacuum refining treatment, control the content of elements such as sulfur, carbon, and niobium, vanadium, titanium that are easy to form fine dispersed two-phase particles;

[0042] b) Continuous casting: the molten steel is cast into a slab by continuous casting, the overheating temperature is 48°C, the pulling speed is 0.8m / min, and the ratio of equiaxed crystal ratio is 63%;

[0043] c) Hot rolling: the billet heating temperature is 1130°C, the high temperature plan is adopted for the key finish rolling and final rolling coiling, the starting rolling temperature is 1040°C, the finishing rolling temperature is 880°C, the coiling temperature is 720°C, and the plate thickness is 1.5mm;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com