Patents

Literature

469 results about "Complex ions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A complex ion has a metal ion at its centre with a number of other molecules or ions surrounding it. These can be considered to be attached to the central ion by co-ordinate (dative covalent) bonds.

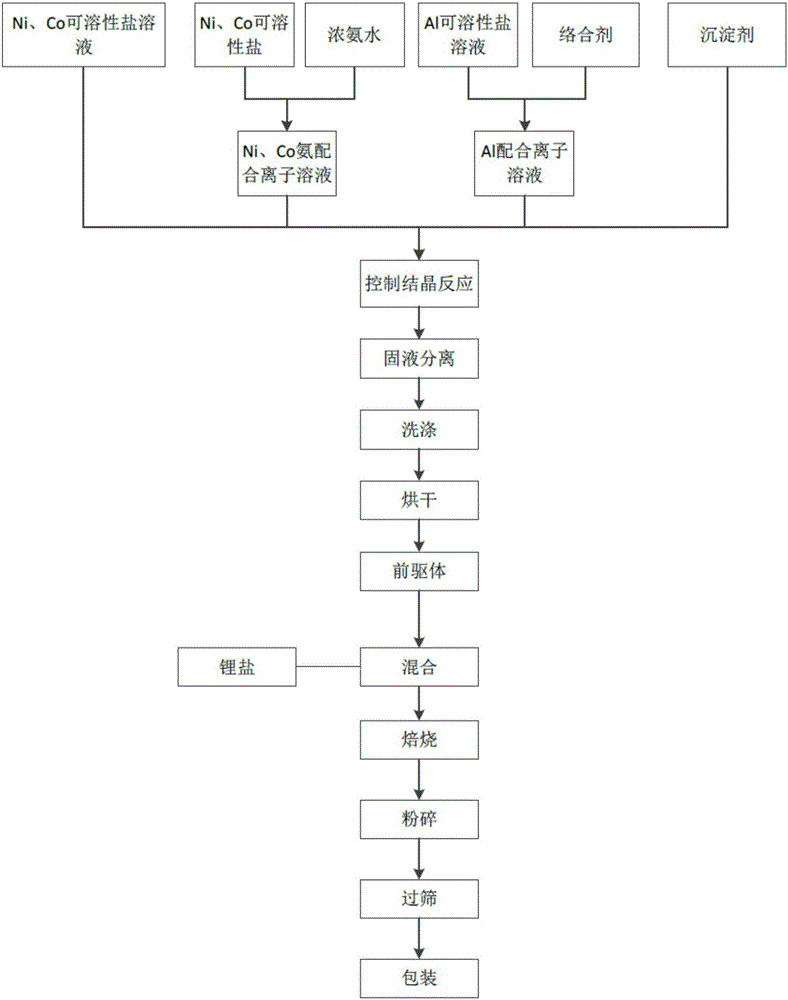

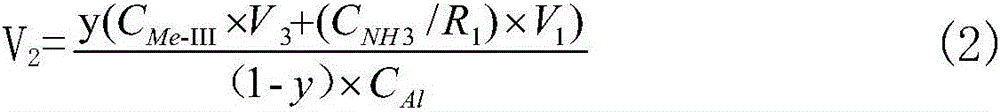

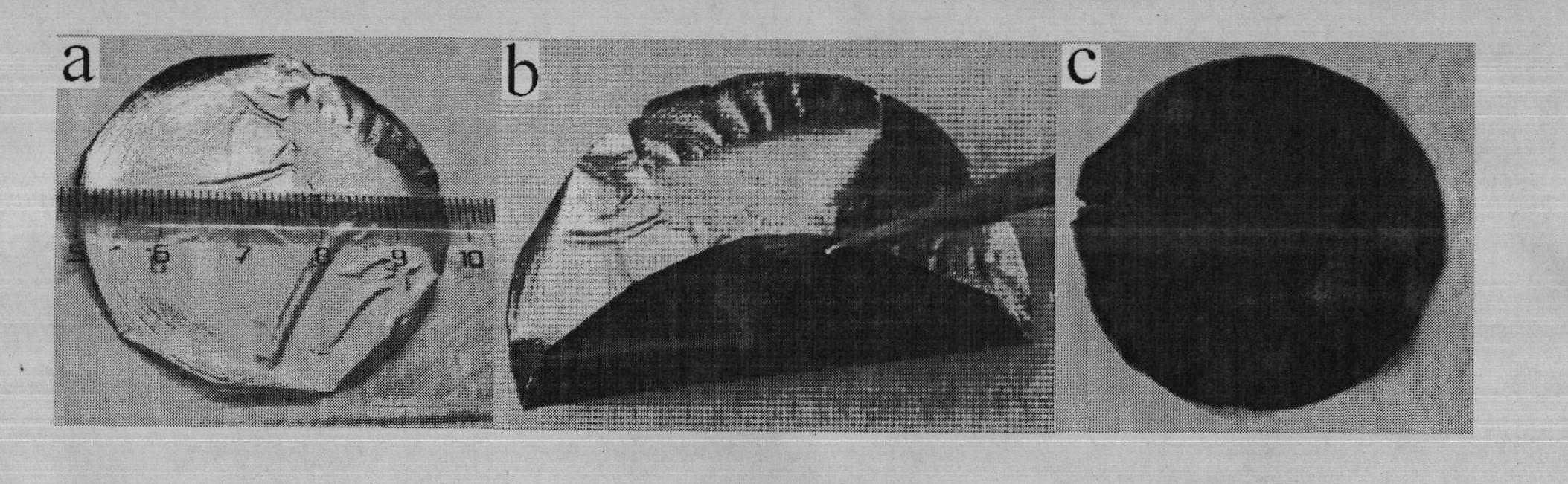

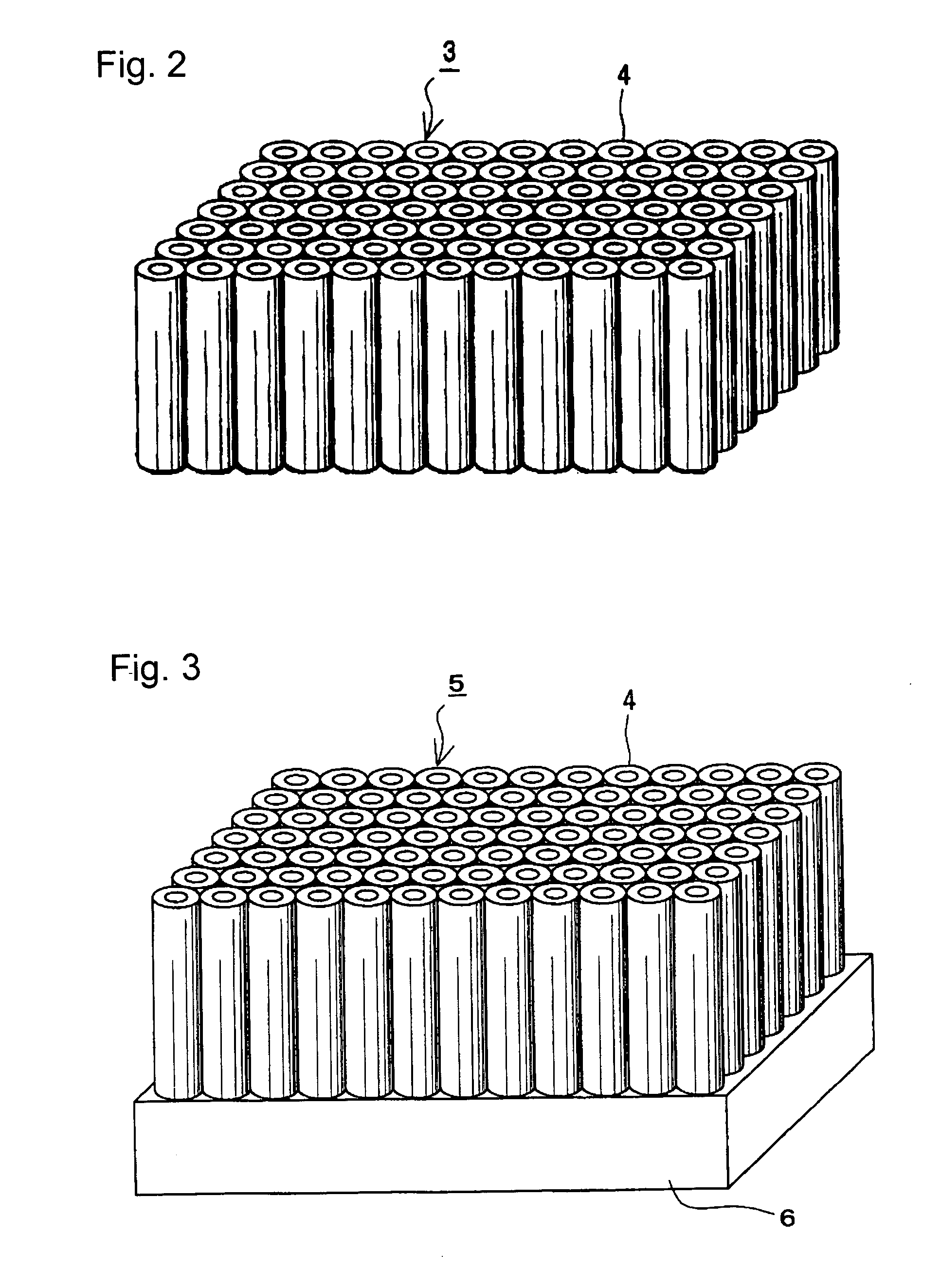

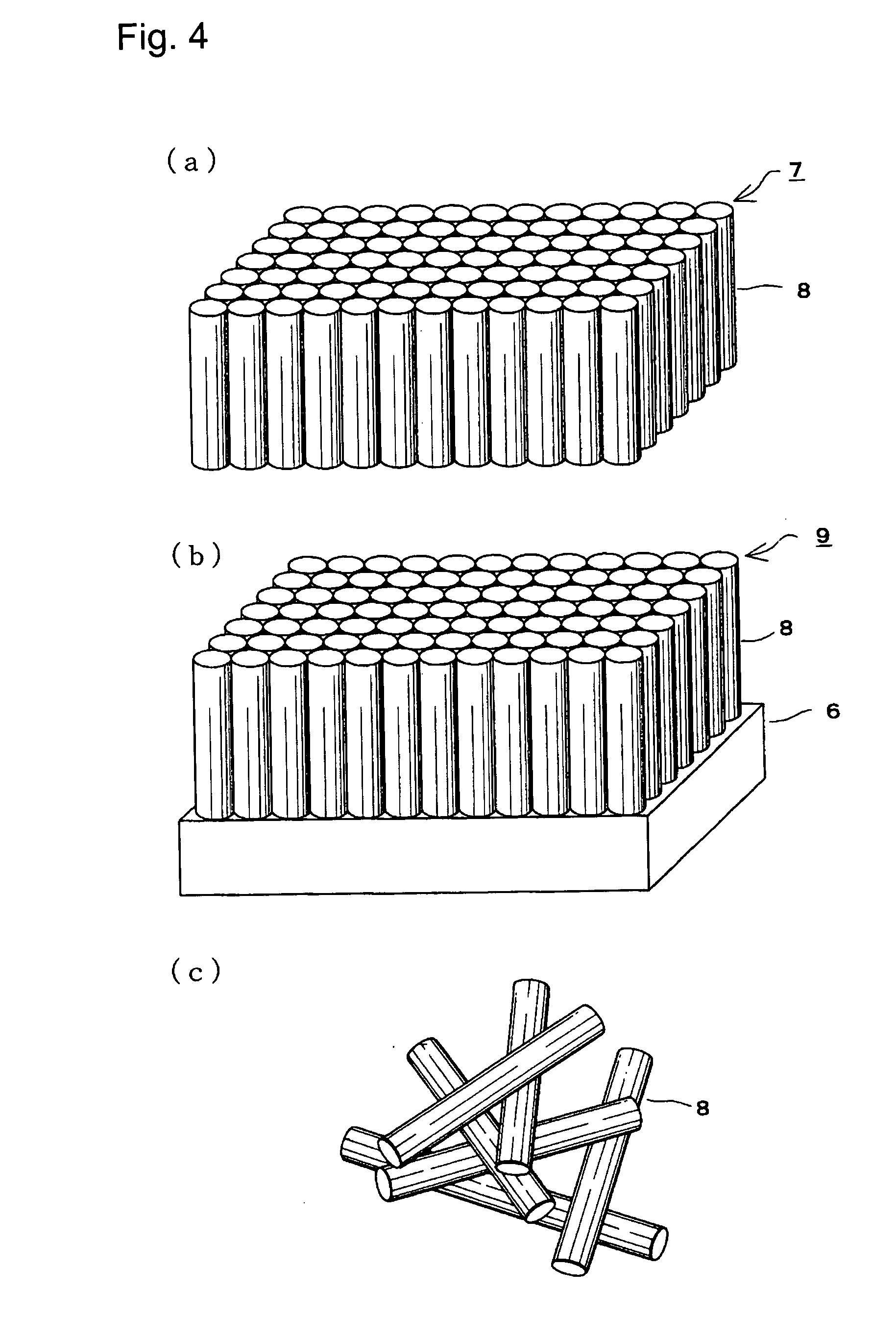

Nickel-cobalt-aluminum ternary precursor as well as preparation method thereof and preparing anode material and method

ActiveCN106299347AImprove mixing uniformityHigh tap densityCell electrodesReaction temperatureSlurry

The invention discloses a nickel-cobalt-aluminum ternary precursor as well as a preparation method thereof and a preparing anode material and a method. The preparation method comprises the following steps: dissolving soluble salts of Ni and Co into ammonia water so as to prepare a Ni and Co ammonia complex ion solution as a complexing agent solution, adding a complexing agent into an aluminum salt solution so as to prepare an Al complex ion solution as an aluminum source solution, combining and adding the Ni and Co soluble salt solution, a precipitant solution, the complexing agent solution and the aluminum source solution into a reaction kettle, controlling a reaction pH value and reaction temperature, controlling the reaction time to be at least greater than 10h, performing solid-liquid separation on slurry obtained through reaction, and washing and drying the obtained solid, thereby obtaining the nickel-cobalt-aluminum ternary precursor. A nickel-cobalt-aluminum ternary anode material can be prepared from a mixture of the precursor and a lithium salt through high-temperature thermal treatment in the presence of air or oxygen. The mixing uniformity of three elements of Ni, Co and Al can be effectively improved, and the tap density of the precursor material can be improved, and the spherical degree of granules can be increased.

Owner:TIANJIN B&M SCI & TECH

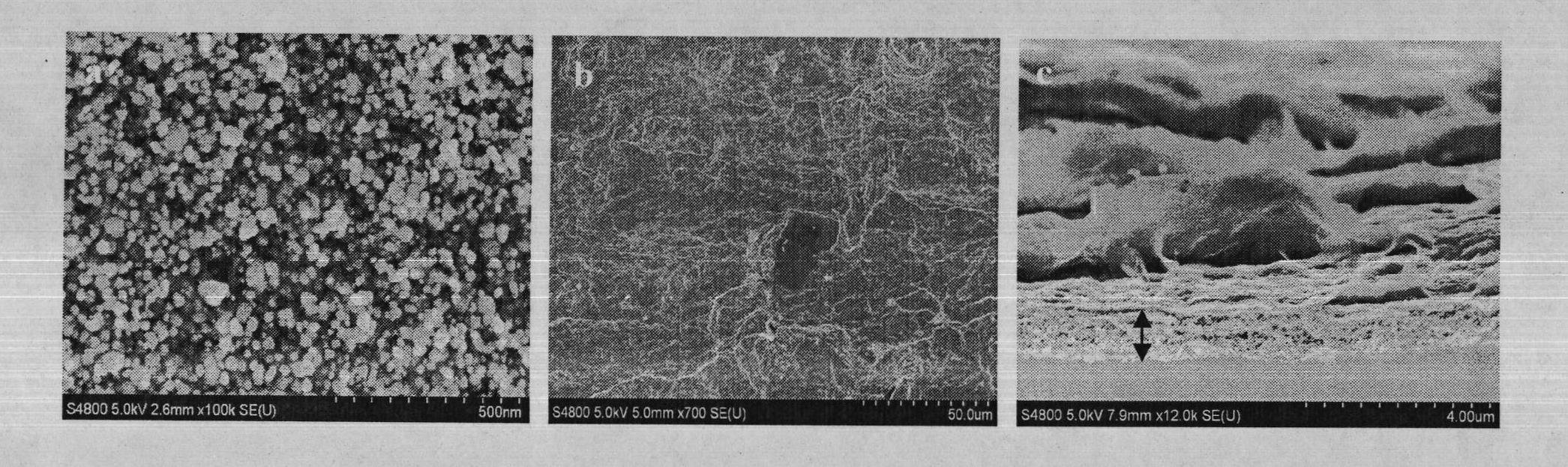

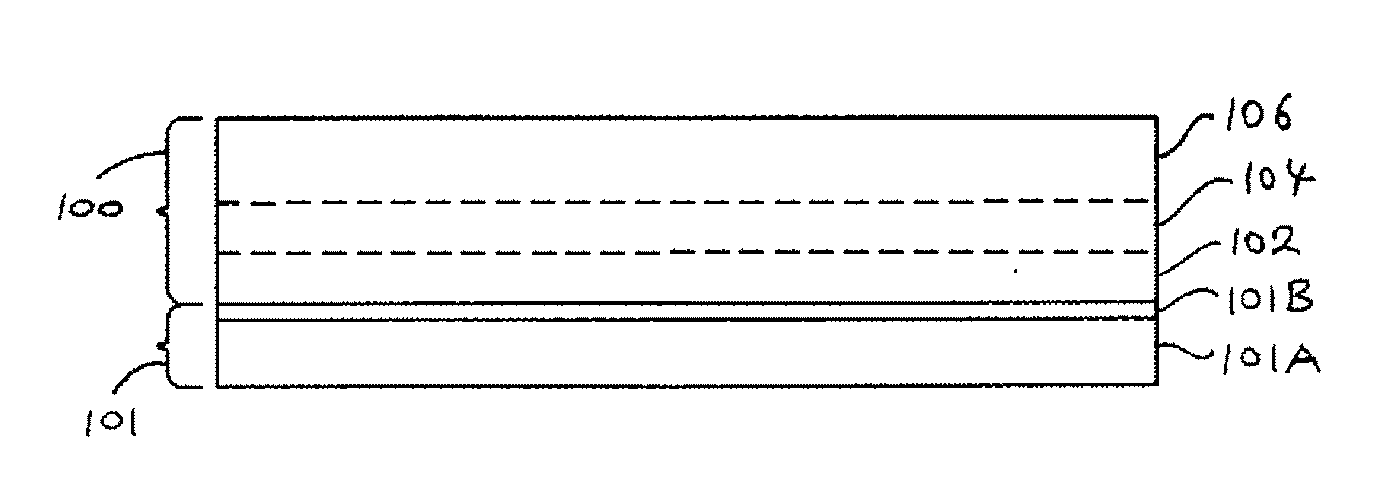

Self-assembly preparation method of noble metal-graphene double-layer composite conductive film

InactiveCN102021573AImprove conductivityHigh strengthMetallic material coating processesSolventCvd graphene

The invention provides a self-assembly preparation method of a noble metal-graphene double-layer composite conductive film. The noble metal-graphene double-layer composite conductive film is obtained by taking noble metal ions or complex ions and graphene oxide as raw materials and adopting a solvent-induced self-assembly method. In the method, the thickness of the noble metal layer, the graphenelayer and the overall film of the double-layer composite conductive film can be regulated and controlled through concentrations and volumes of noble metal ionic solution and graphene oxide solution, and the electrical conductivities of the silver layer and the graphene layer in the double-layer composite conductive film can be regulated and controlled. The invention provides a stable and reliablepreparation method of the noble metal-graphene double-layer composite conductive film which can be applied to an electronic device.

Owner:HUNAN UNIV

Emergency restoring process for pollution of water body, substrate sludge and mud flat by heavy metal

InactiveCN101786713ALow costSolve secondary pollutionWater contaminantsWater/sewage treatment by flocculation/precipitationSludgeLiving environment

The invention discloses an emergency restoring process for pollution of a water body, substrate sludge and a mud flat by heavy metal. A complex agent is first added to the water body, and most heavy metal ions in ionized and absorbed states are converted into dissolved complex ions; short fibers and a heavy metal capturing agent are added to the water body so as to convert the heavy metal complex ions into suspended matters, and then a flocculating agent is added to flocculate the suspended matters; a flocculation assisting agent is added to the water body to form a fiber enhanced flocculating body; an Mg / magnetic composite material prepared by magnetic substances and magnesium powder in advance is thrown into the water body so as to lead the fiber enhanced flocculating body to capture air bubbles and float to the water surface; finally, the fiber enhanced flocculating body is captured to carry out emergency restoration. The emergency restoring process is convenient for in-situ emergency restoration of the stormy wavy water body in a large scale, so as to avoid the disadvantages that the present biological restoring method leads to slow treatment and is limited by the biological living environment in the aspect of the application range, thereby not only solving the problem of secondary sedimentation pollution caused by the present chemical restoring method, but also solving the bottleneck problem that the present dissolved air floatation process cannot carry out entire water-area pipe laying operation.

Owner:QUANZHOU NORMAL UNIV

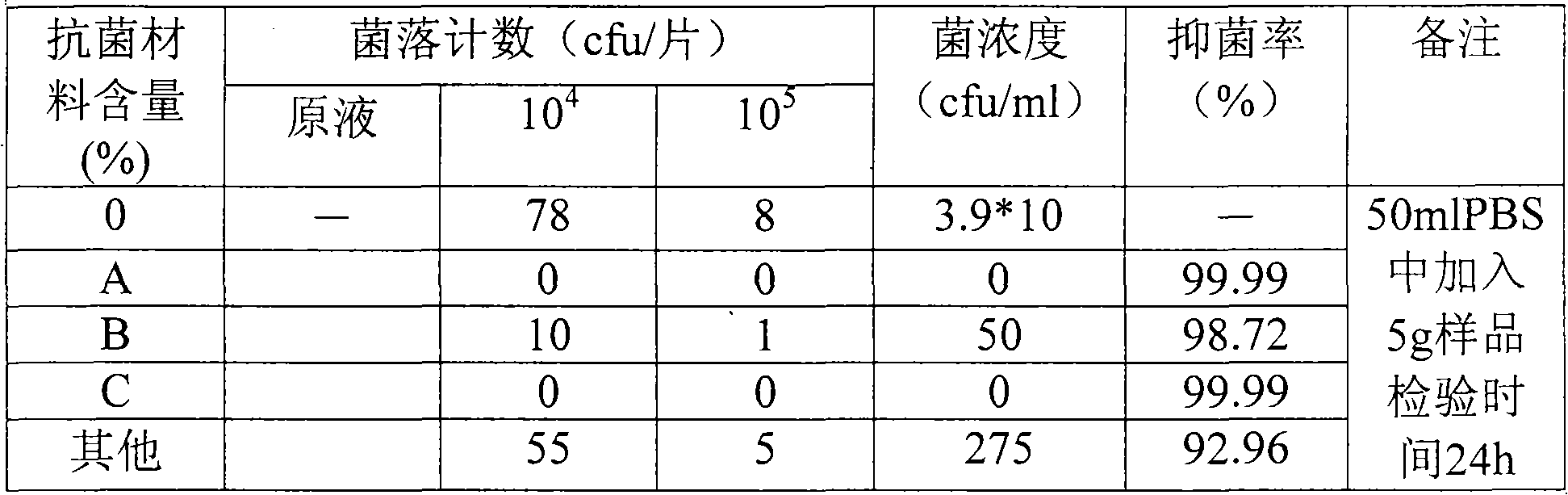

Ag-carrying nano antibiotic material and its preparation method and use

InactiveCN101305735AAging resistantHigh temperature resistantBiocideDisinfectantsAntibiotic YSilver ion

The invention discloses an silver-supported antibacterial nano-material and the preparation method and the application thereof. The preparation method comprises the following steps: (1) adding surfactant to a water solution of NH4H2PO4 and ZrOCl2*8H2O, co-precipitating, filtering, rinsing, dewatering, drying and pulverizing to obtain a nano-scale mesoporous zirconium phosphate carrier; and (2) adding dispersant and water to the carrier prepared in the step (1) to obtain a suspension A; mixing AgNO3, NH3*H2O and water to obtain a sliver-ammine complex ion water solution B; mixing the suspension A and the sliver-ammine complex ion water solution B, adding acid to inhibit the hydrolysis so that the generated nano-scale silver ions cluster is adhered to the carrier; and filtering, rinsing, dewatering, drying, sintering and pulverizing to obtain nano-scale silver ion antibacterial powder. The antibacterial nano-material has excellent antibacterial performances such as persistent effect, stability, high temperature resistance, etc. and can be applied in the fields such as building materials, public facilities, medical facilities and appliance, daily products, etc.

Owner:SHANGHAI SONGMING COMML CONSULTANT & SERVICE

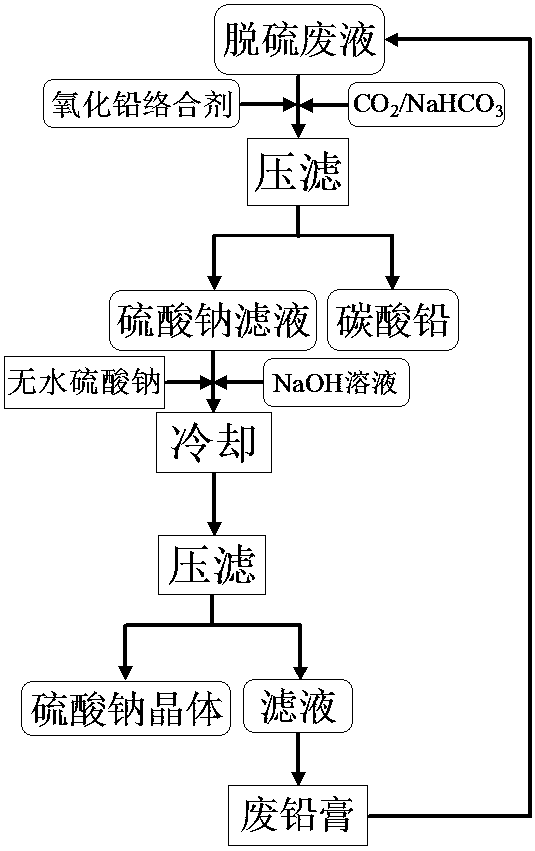

Method of recovering sodium sulfate from lead-bearing desulfurized waste liquid

ActiveCN103771459AStrong complexing abilityEliminate secondary pollutionAlkali metal sulfite/sulfate purificationLead carbonateLead oxide

The invention discloses a method of recovering sodium sulfate from a lead-bearing desulfurized waste liquid. The method is characterized by comprising the following steps: after adding a complexing agent into the lead plaster-bearing desulfurized waste liquid, forming a lead carbonate precipitate of lead complex ions in the liquor by adopting carbon dioxide or sodium hydrogen carbonate, and then carrying out solid-liquid separation to obtain a sodium sulfate filtrate and the lead carbonate precipitate; adding anhydrous sodium sulfate and sodium hydroxide into the sodium sulfate filtrate obtained by separating lead carbonate, and cooling at low temperature to separate out sodium sulfate crystals; and returning the filtrate without the sodium sulfate crystals again for desulfurization of lead oxide-bearing wastes.

Owner:BEIJING UNIV OF CHEM TECH

Cyanide-free gold plating solution

The invention discloses a cyanide-free gold plating solution. The cyanide-free gold plating solution comprises sulphurous acid gold salt, a main complexing agent, an auxiliary complexing agent, conducting salt, a stabilizing agent and a pH buffering agent. Under the synthetic action of the sulphurous acid gold salt, the stabilizing agent and the other components, stable composite complex ions are formed through the cyanide-free gold plating solution, the plating solution is more stable, the storage period of the plating solution is long, and the sealed storage period at the normal temperature can reach over 6 months.

Owner:SHENZHEN RUN SUN CHEM TECH

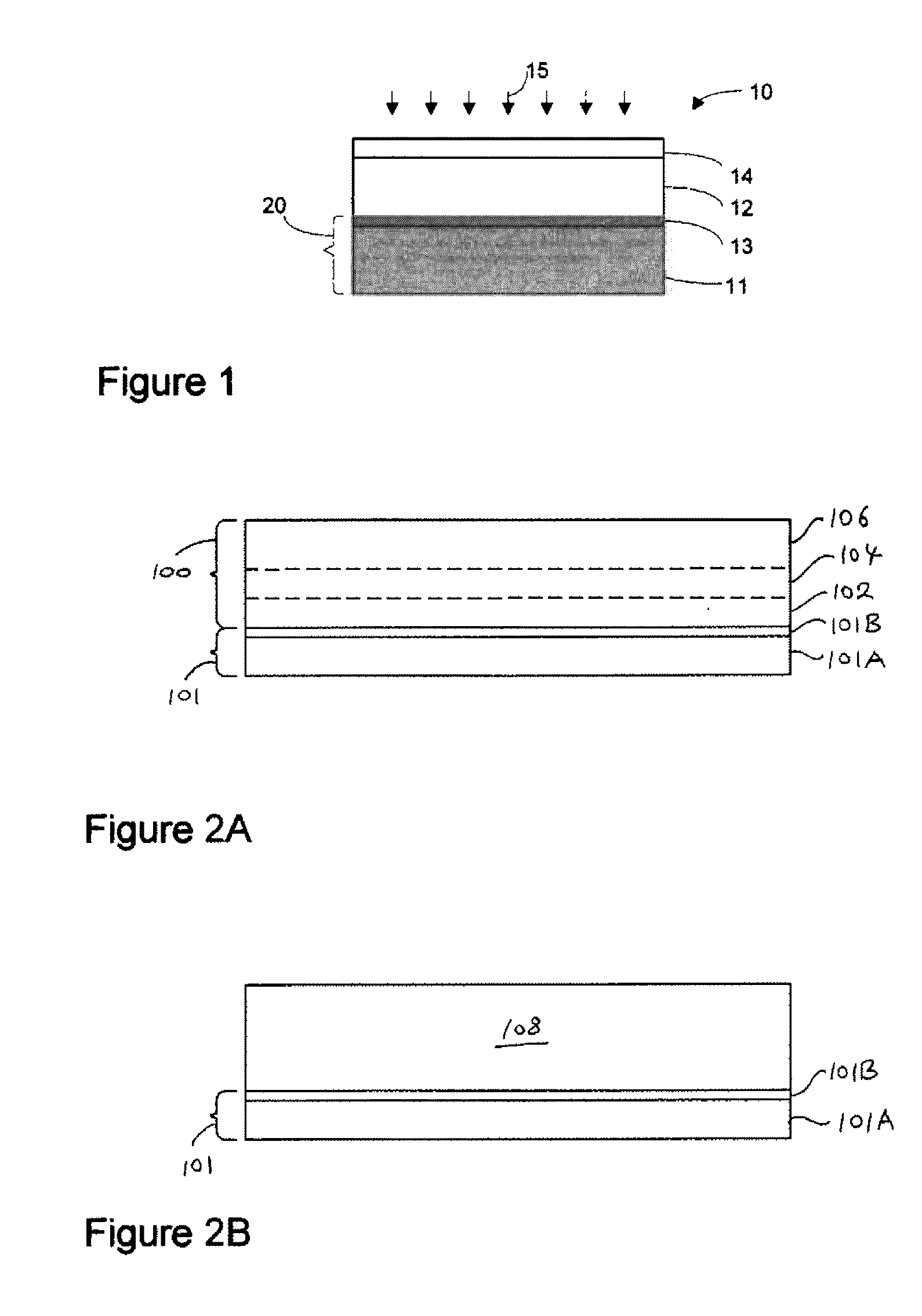

Selenium containing electrodeposition solution and methods

InactiveUS20100140098A1Electrolytic inorganic material coatingFinal product manufactureSolventSolar cell

The present inventions relate to selenium containing electrodeposition solutions used to manufacture solar cell absorber layers. In one aspect is described an electrodeposition solution to electrodeposit a Group IB-Group VIA thin film that includes a a solvent; a Group IB material source; a Group VIA material source; and at least one complexing that forms a complex ion of the Group IB material. Also described are methods of electroplating using electrodeposition solutions.

Owner:SOLOPOWER

Method for displacement chemical silver plating on copper powder

InactiveCN101709461AIncrease profitHigh activityLiquid/solution decomposition chemical coatingAcid etchingSilver plate

The invention discloses a method for displacement chemical silver plating on copper powder. The method comprises the following steps of: cleaning and oil removal, water washing, acid etching, water washing, catalytic liquid treating, chemical silver plating and the like. In the method, a catalytic liquid capable of preplanting catalytic mass points is developed; the surface of the copper powder is preplanted with discretely distributed palladium mass points after the copper powder is treated by the catalytic liquid at a room temperature by controlling components, pH value and treatment time of the catalytic liquid; and the preplanted palladium mass points can catalyze and promote the silver ion reduction to improve precipitation speed and to retard copper-ammonia complex ions to be absorbed on the copper surface so as to obtain a sliver plating layer with good cladding performance in the chemical silver-plating process for the copper powder. Compared with the conventional method of displacement chemical silver plating, the method realizes surface activation of the copper powder by pretreating the catalytic liquid, a silver content of the silver plating copper powder is greatly improved, the problems of poor cladding performance of replacement type chemical silver plating and the like are solved, and the method is simple in process and convenient to operate and has good application prospect.

Owner:GUANGDONG UNIV OF TECH

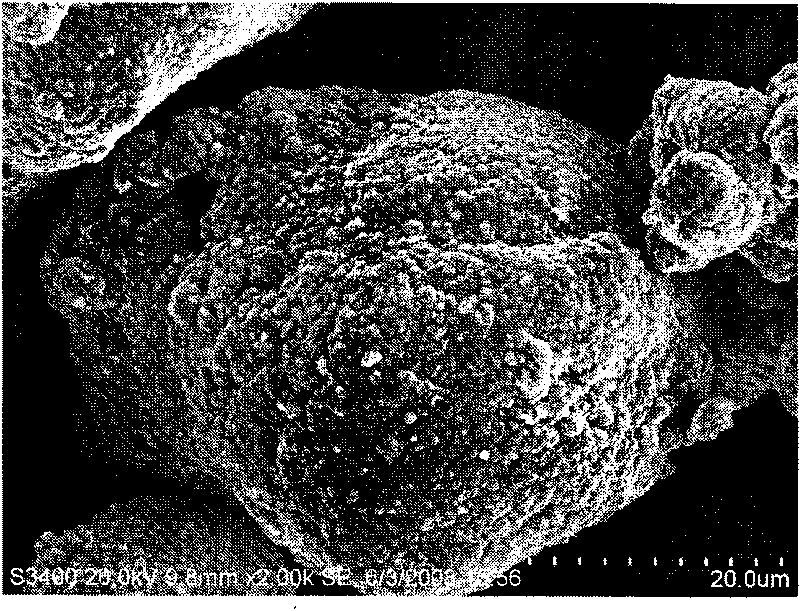

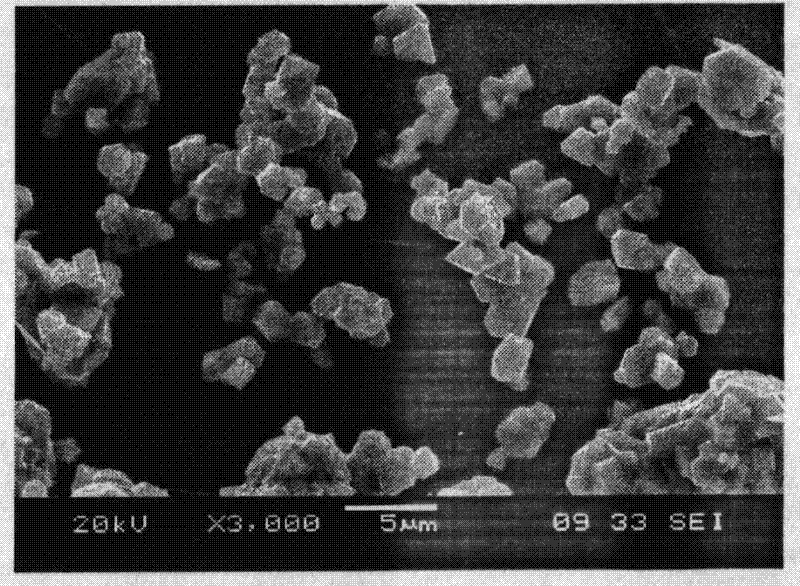

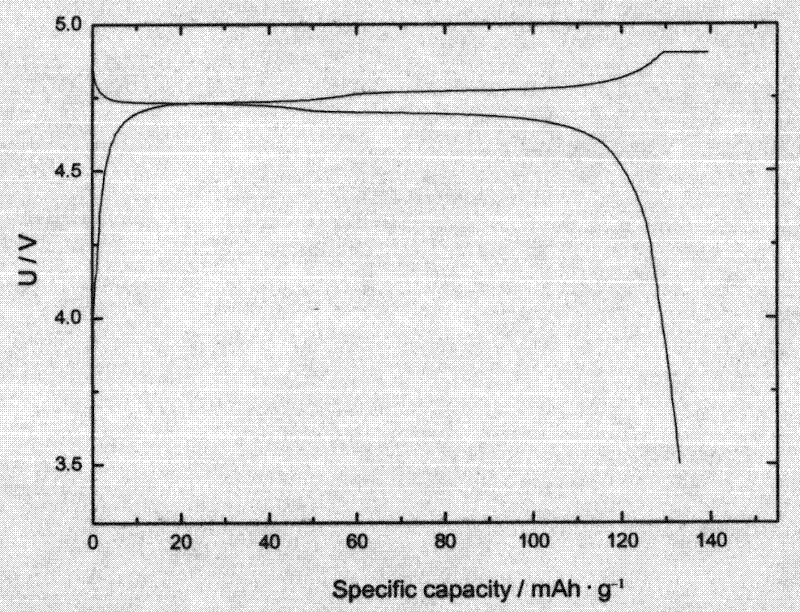

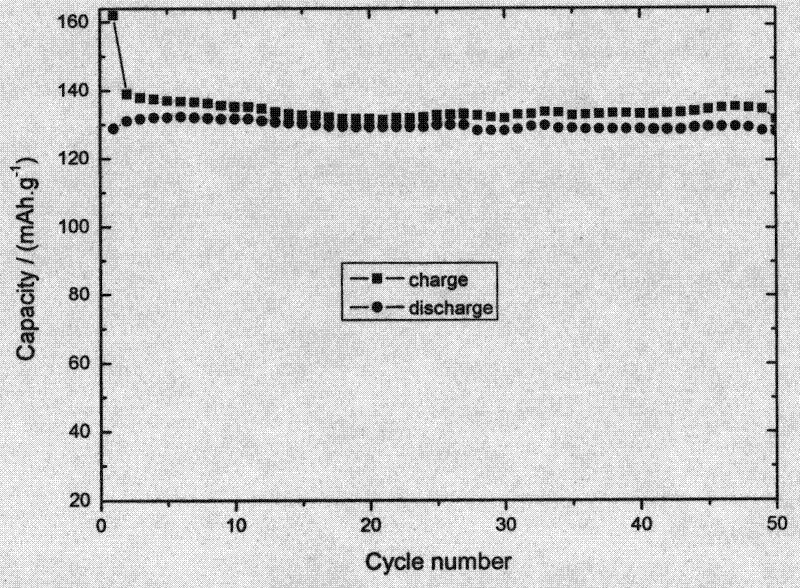

Method for synthesizing cathode material LiNi0.5Mn1.5O4 for 5V lithium ion batteries

The invention discloses a method for synthesizing cathode material LiNi0.5Mn1.5O4 for 5V lithium ion batteries. Manganese salt, nickel salt and lithium compound are used as main material, oxalic acid is used as precipitator, and aqueous ammonia is used as complexing agent; the manganese salt and the nickel salt are proportionally mixed and then dissolved in water, so that manganese salt-nickel salt mixture is produced, and a moderate amount of oxalic acid is dissolved in water, so that oxalic acid solution is produced; the manganese salt-nickel salt mixture is first blended and reacts with the aqueous ammonia to form manganese and nickel ammonia complex ions, and then is blended and reacts with the oxalic acid solution to form manganese oxalate containing nickel; the manganese oxalate containing nickel and the mother solution are directly dried, so that manganese oxalate powder containing nickel is obtained, and the manganese oxalate powder containing nickel is then roasted under the temperature of 400 DEG C to 650 DEG C for three to fifteen hours, so that manganese oxide containing nickel is obtained; and the manganese oxide containing nickel and the compound of lithium are uniformly mixed and ground, and are then roasted under the temperature of 700 DEG C to 950 DEG C for eight to thirty hours. The invention has the advantage of simple technique and easy control, and the synthesized cathode material LiNi0.5Mn1.5O4 has good electrochemical properties.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

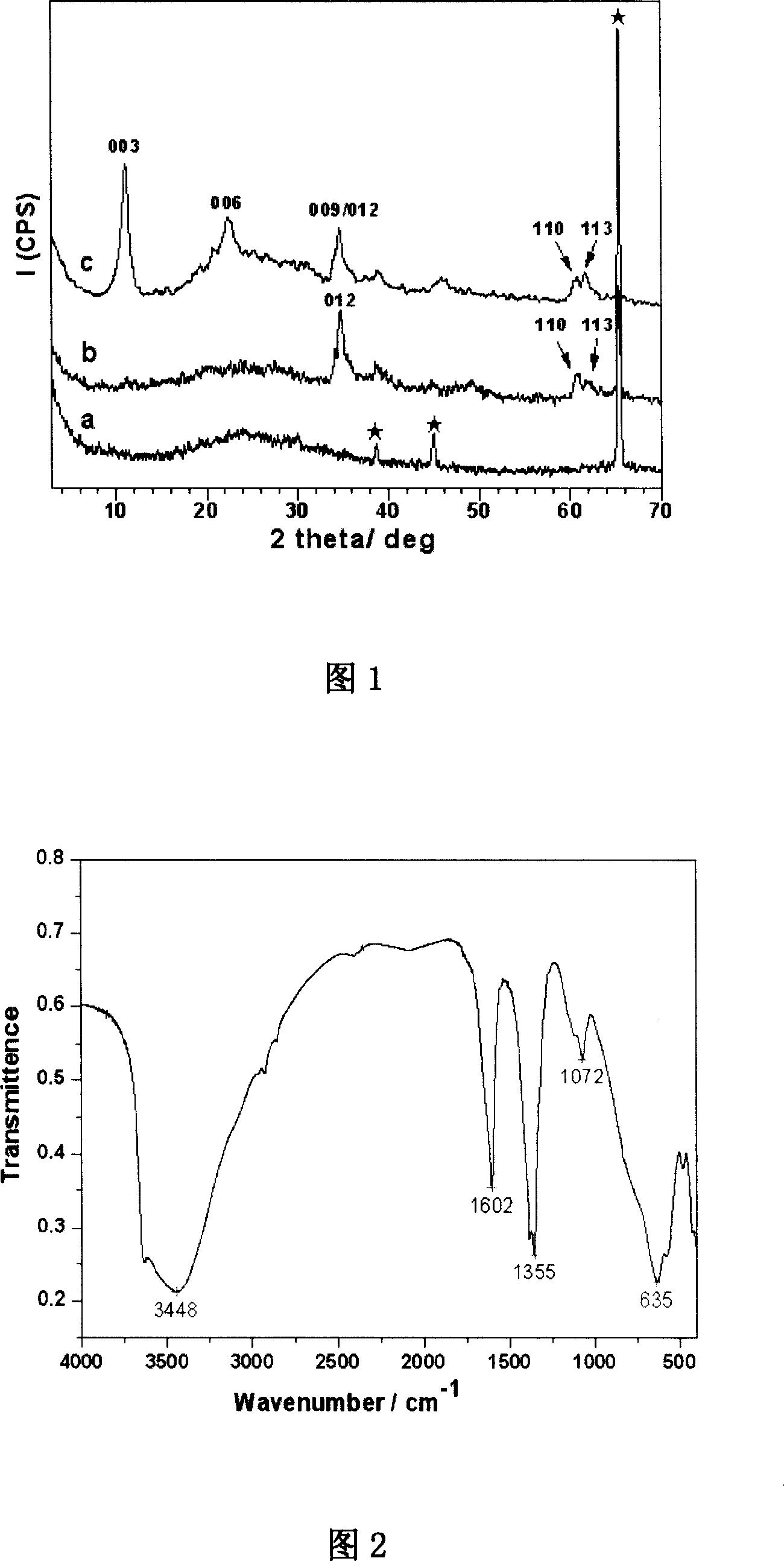

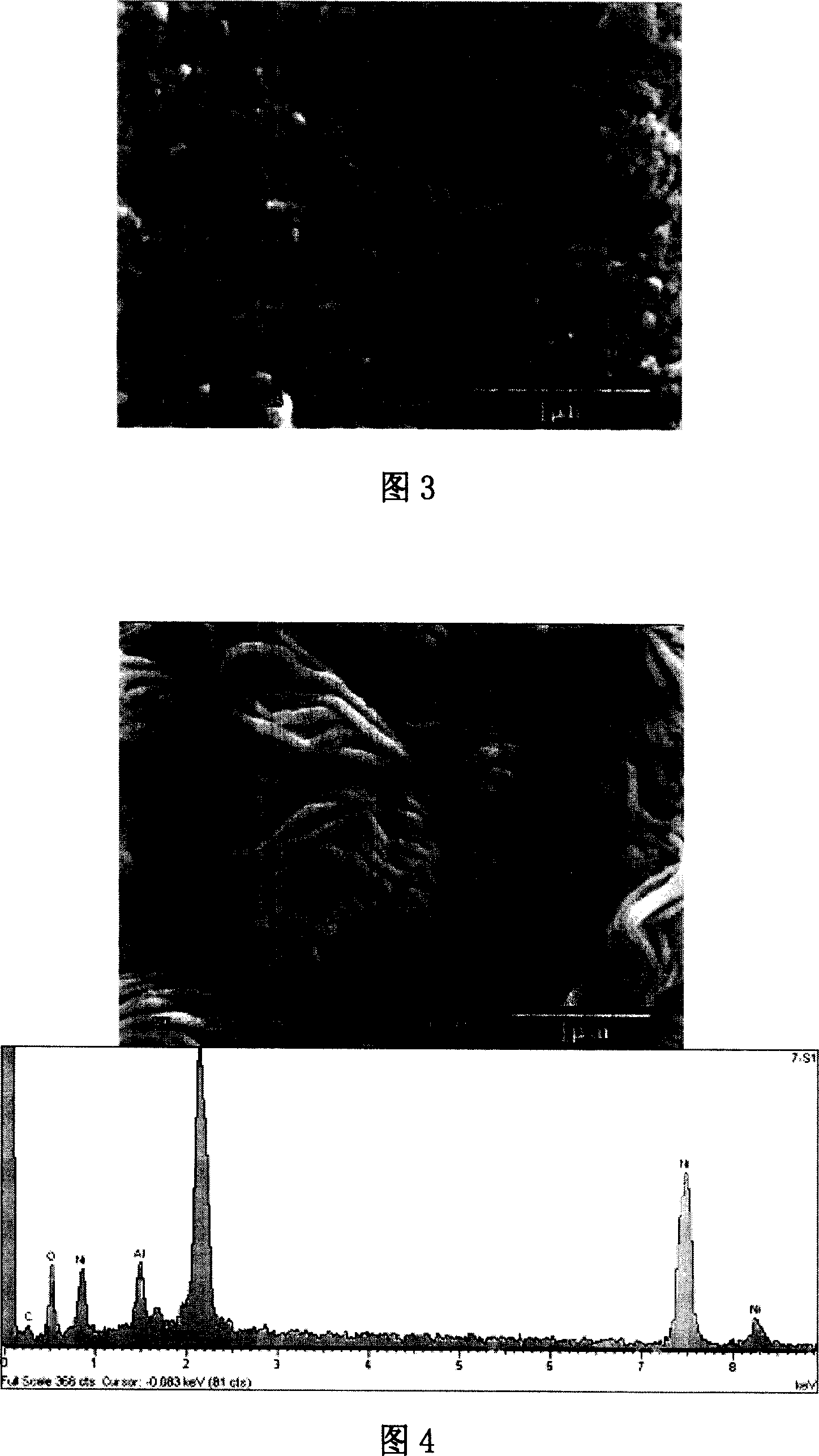

Vertically oriented hydrotalcite film in nano and micron composite structure and its preparing process

InactiveCN1986419AWith vertical orientationGood flexibilityAluminium compoundsSurface reaction electrolytic coatingCrystal orientationHydrotalcite

The present invention relates to vertically oriented LDHs film in nanometer and micron composite structure and its preparation process. By means of in-situ synthesis technology, and using aluminum sheet through surface anode oxidation as substrate and Al3+ source, and through dropping ammonia water to regulate the pH value of the reaction solution, reacting bivalent metal ion M2+ inside solution and ammonium nitrate in alkaline condition to produce metal complex ion to control the slow release of M2+ and the nucleation rate of LDHs on the substrate, the present invention grows oriented LDHs film with crystal face perpendicular to the substrate surface or (00l) direction and controllable density. The present invention is superior to available method, which has poor LDHs crystal orientation and other problems.

Owner:BEIJING UNIV OF CHEM TECH

Oxide nanostructure, method for producing same, and use thereof

InactiveUS20050255315A1Well formedEasy to prepareFixed microstructural devicesVolume/mass flow measurementElectrolysisNanostructure

The present invention provides a method of preparing directly a desired nano-structure of oxide without electrolyzing the target oxide, a nano-structure having structural resistance and various useful uses of the nano-structure. Into a solution containing a fluoride complex ion comprising metal element of the target oxide in which the metal is at least one selected from the group consisting of transition metal elements, group IA elements, group IIA elements, group IIIB elements, group IVB elements, group VB elements and group VIB elements, a template having nano-structure made from oxide is immersed, and the reaction condition is adjusted to substitute oxide of the template with the target oxide.

Owner:OSAKA INDAL PROMOTION ORG

Alkalescent chemical silver plating solution

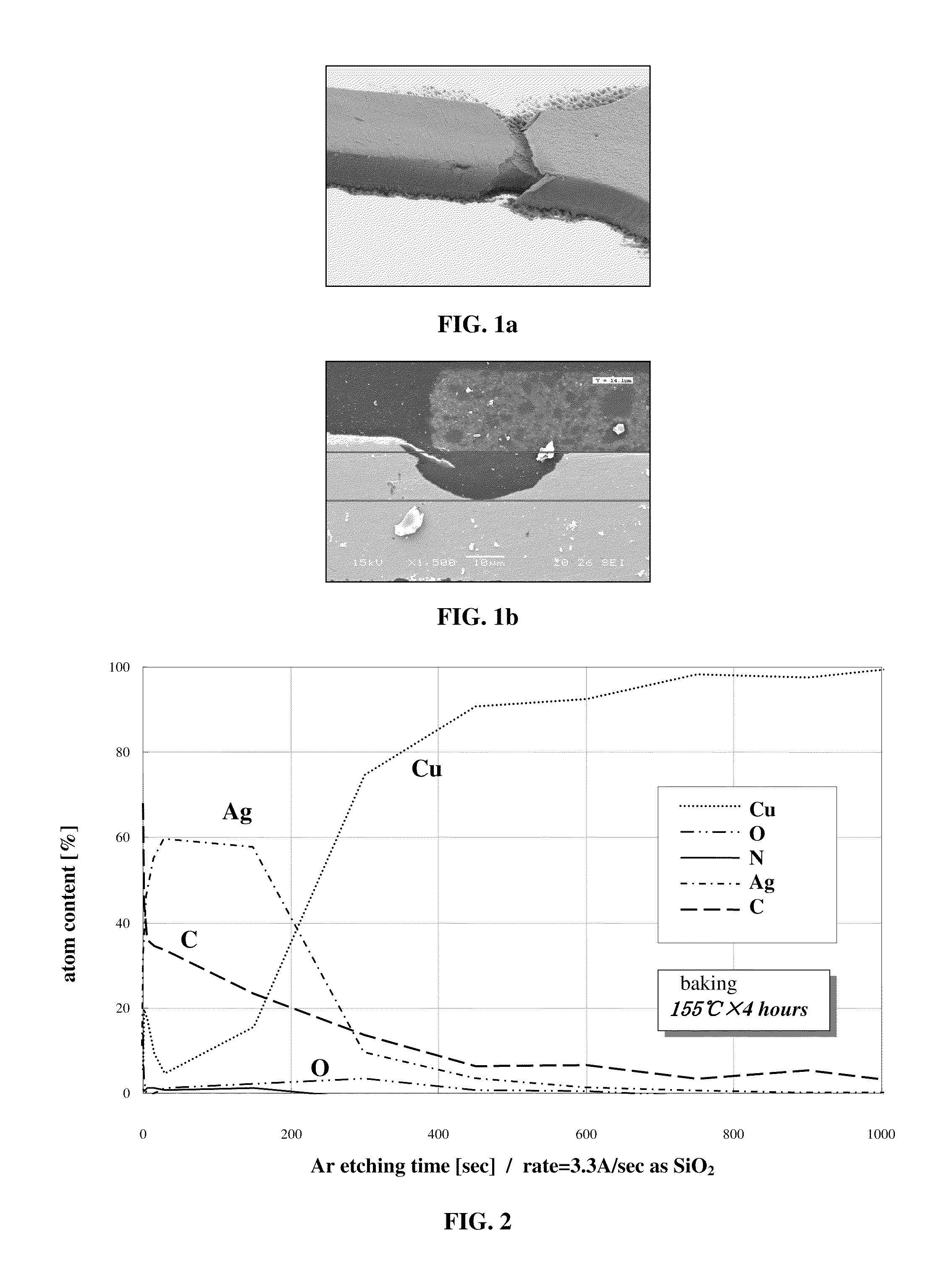

ActiveUS8163073B2Easy to cleanReduce contact resistanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingCopper wireSolder ball

An alkalescent chemical silver electroless plating solution, which comprises: 0.01˜20 g / L silver ion or silver complex ion, 0.1˜150 g / L amine complexing agent, 0.1˜150 g / L amino acids complexing agent, and 0.1˜150 g / L polyhydroxy acids complexing agent. The alkalescent chemical silver plating solution provided by the present invention is able to overcome problems existing in acidic chemical silver plating processes commonly used at present. These problems include gnawing and corrosion of copper wires, lateral corrosion and difficulty of plating silver in blind holes, presence of solder ball voids and low strength of soldering. The silver layer plated by said silver plating solution possesses characteristics of high corrosion resistance, low contact resistance, no electromigration, high welding strength, and avoidance of bubbles produced in the solder when the plating pieces are being welded.

Owner:CHARTERMATE INT

Molecular engram polymer and preparation and application thereof

InactiveCN101787123AAmplify selectivityHighly selective adsorptionOther chemical processesChemical microanalysisElutionPhysical chemistry

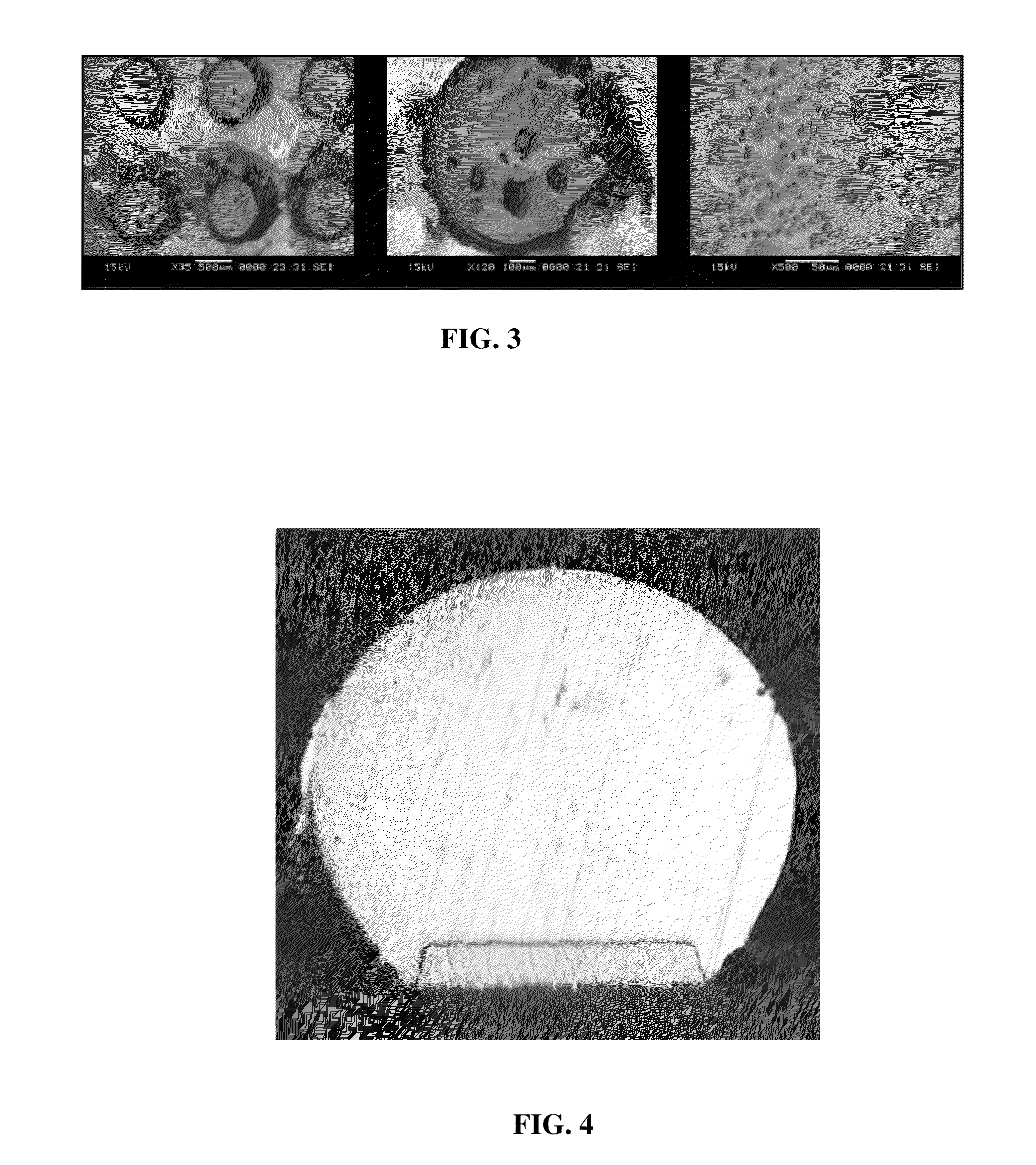

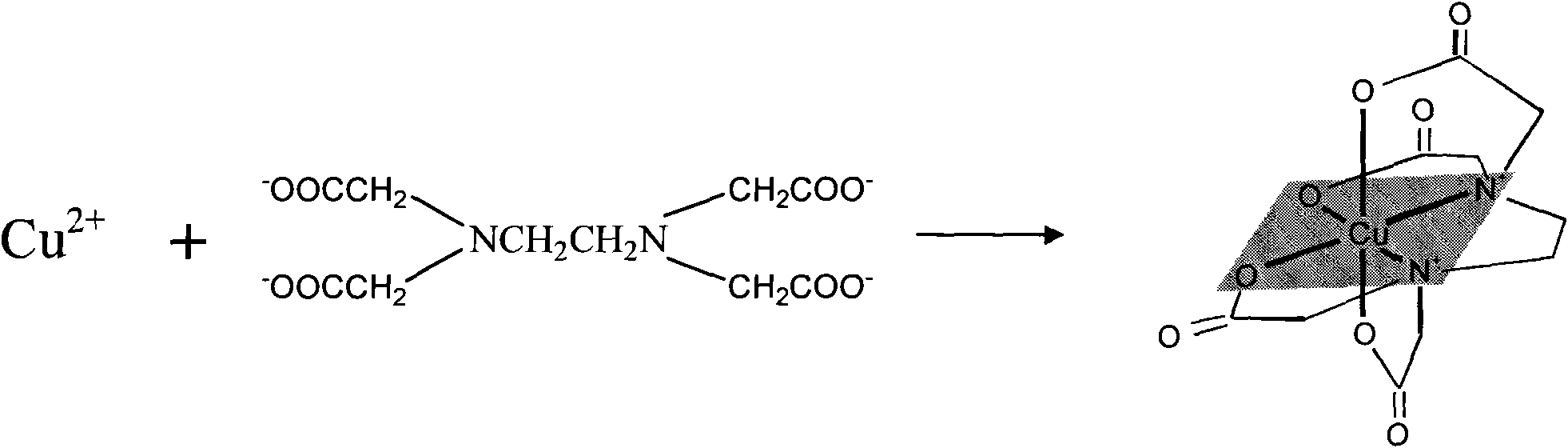

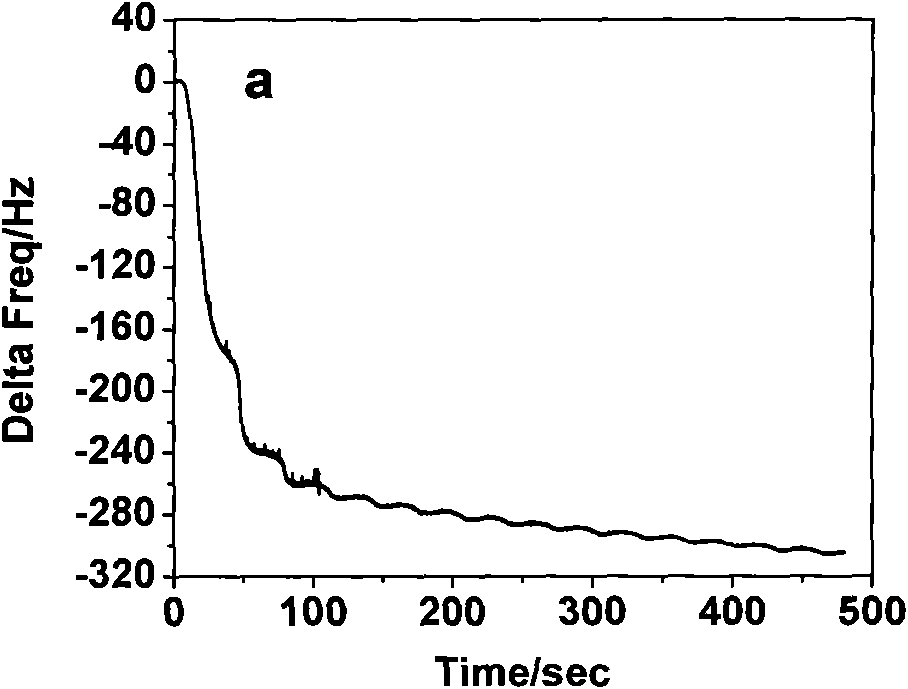

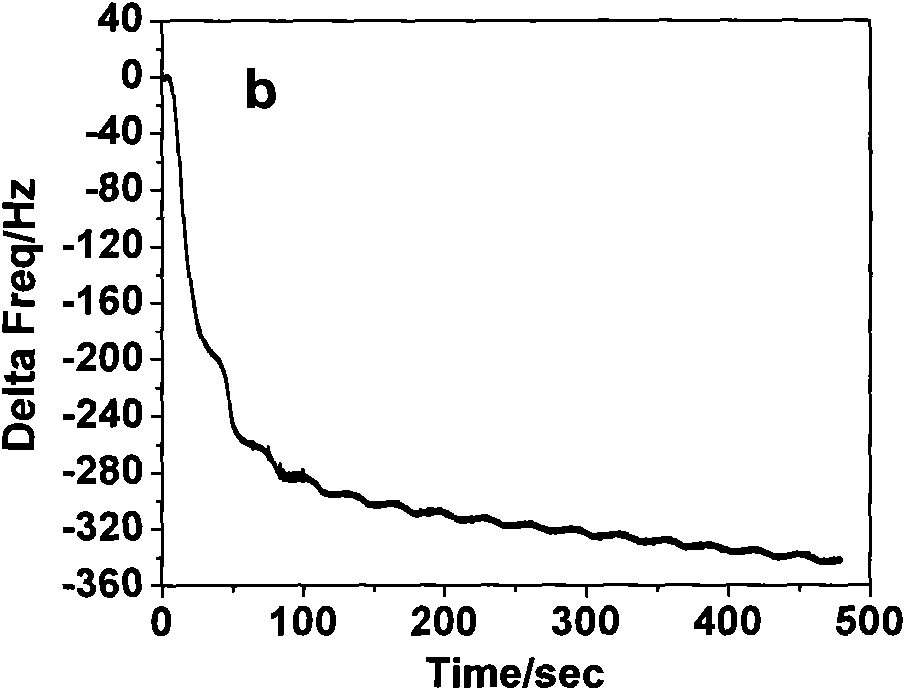

The invention relates to a molecular engram polymer, which is used for metal ion detection. The engram and elution objects are metal complex ions; engram geometric dimensioning and combination point location of the polymer are matched with the specificity of the metal complex ions; the polymer is synthesized in-situ on metal membrane surface of a quartz microbalance and a surface plasma resonance device, the metal complex ions are eluted, the metal ions to be detected are processed by complexation and then are selectively absorbed by the molecular engram polymer, and finally the type and content of the metal ions are detected. In the invention, metal ion complexation is adopted to enlarge small changes of metal ion volume by a large extent, template molecular geometric structure memory performance of the molecular engram polymer is utilized to realize high preferential adsorption to improve metal ion detection selectivity effectively, and mass increase and geometric dimensioning enlargement caused by metal ion complexation help further improve sensitivity and antijamming capability of metal ion detection.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method and application of 2-mercaptobenzothiazole modified activated carbon

ActiveCN107215872ASimple processLow modification costOther chemical processesCarbon compoundsActivated carbonOrganic solvent

The invention discloses a preparation method and application of 2-mercaptobenzothiazole modified activated carbon, belonging to the fields of wet metallurgy and precious metal recovery. The preparation method comprises the steps of dissolving 2-mercaptobenzothiazole as an activated carbon modifying agent with an organic solvent or a strong base solution, and preparing 2-mercaptobenzothiazole modified activated carbon by virtue of an impregnation method, wherein the 2-mercaptobenzothiazole modified activated carbon is used for adsorbing Au(S2O3)2<3->. According to the preparation method, the disadvantages that cyanogen is polluted during adsorption recovery of activated carbon supported copper cyanide complex ions (Cu(CN)4<2->), a modifying process of loaded prussian blue is complicated, and continuous adsorption is difficultly realized, and the like are solved; the modified activated carbon is capable of adsorbing gold in thiosulfate gold leaching and has the advantages of multistage adsorption capacity and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for prepn. of electrode catalyst with function of anti-CD and contg. platinum and ruthenium series carried on carbon nanometer tube

InactiveCN1418725AHas the ability to resist COGood dispersionCell electrodesCatalyst activation/preparationPorosityIn situ chemical reduction

The preparation method of Pt-Ru series CO resistant electrode catalyst is characterized by that it uses carbon nano tube as carrier, utilizes the in-situ chemical reduction homogeneous precipitation method and makes the ions of Pt, Ru and Sn into compounding ion respectively (called complex ion for short), then it uses two kinds of three kinds of complex ions and mixes them together to obtain metastable colloid, them adopts cheap reduction agent formaldehyde (or sodium borohydride or ethyl alcohol or hydrogen gas) to make the metastable colloid be reduced and deposited on the activated carbonnano tube so as to obtain the invented electrode catalyst for proton-exchange membrane fuel cell. It possesses good electric catalytic activity and resistance to Co, and features large specific area,high porosity, good dispersion property and low ptatinum use level.

Owner:BEIJING JIAOTONG UNIV +1

High-efficient method of extracting uranyl ions from water

ActiveCN104485148ASimple methodEasy to operateRadioactive decontaminationEnvironmental resistanceWastewater

The invention discloses a high-efficient method of extracting uranyl ions from water and belongs to the field of the water treatment technology; the method comprises the steps: absorbing the uranyl ions from the surface of an absorbing material in advance; throwing the absorbing material absorbed with the uranyl ions in advance to waste water containing the uranyl ions, stirring, filtering and finally collecting filter residues. The high-efficient method of extracting the uranyl ions from water has the advantages of simple method, easy operation at normal temperature and no other impurities introduced; the method is green, environmental-friendly, economic and effective; the secondary pollution caused by toxic pollutants is avoided; high-salt and complex ion environments in water can be overcome effectively and the selective extraction of the uranyl ions in water is realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

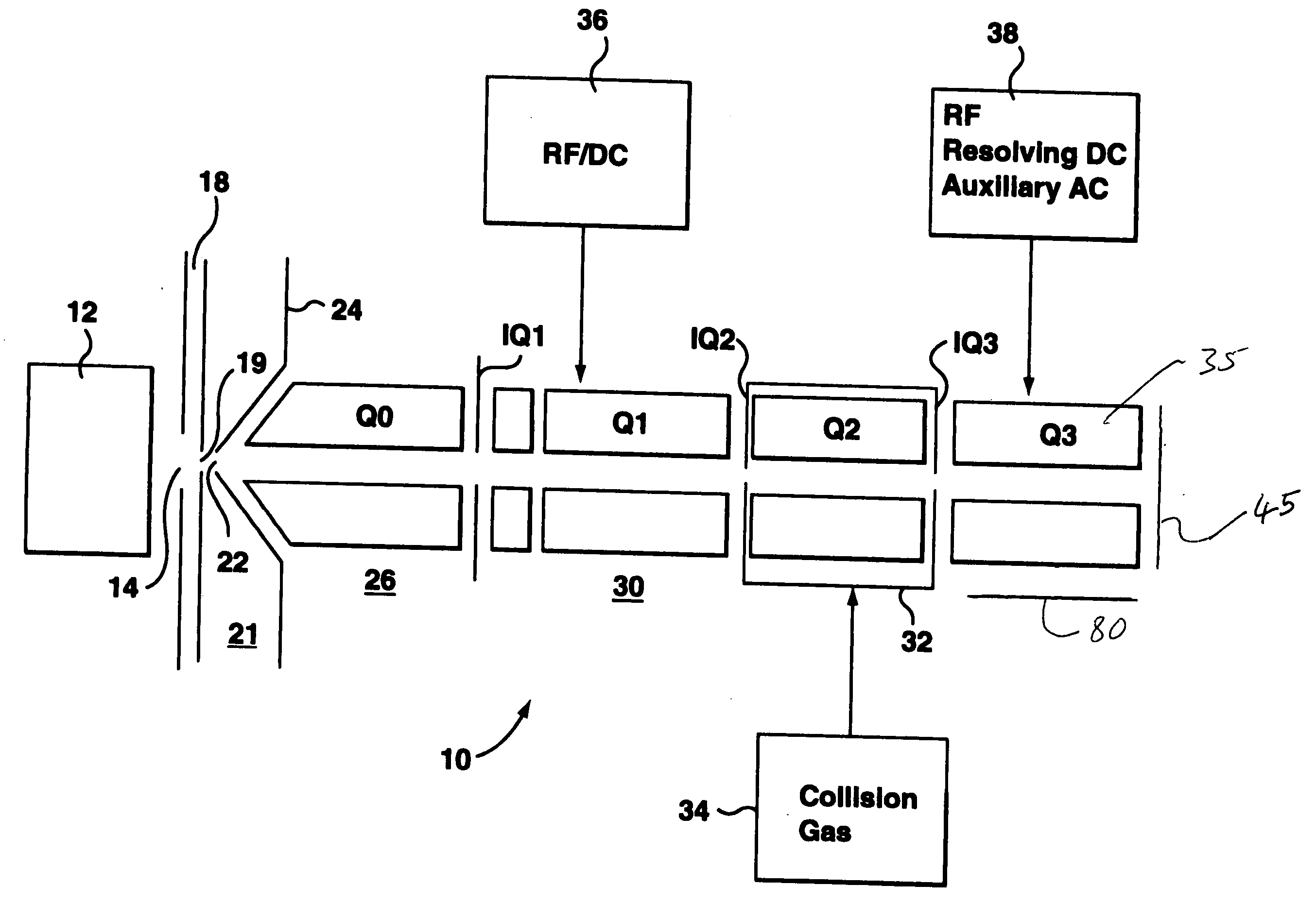

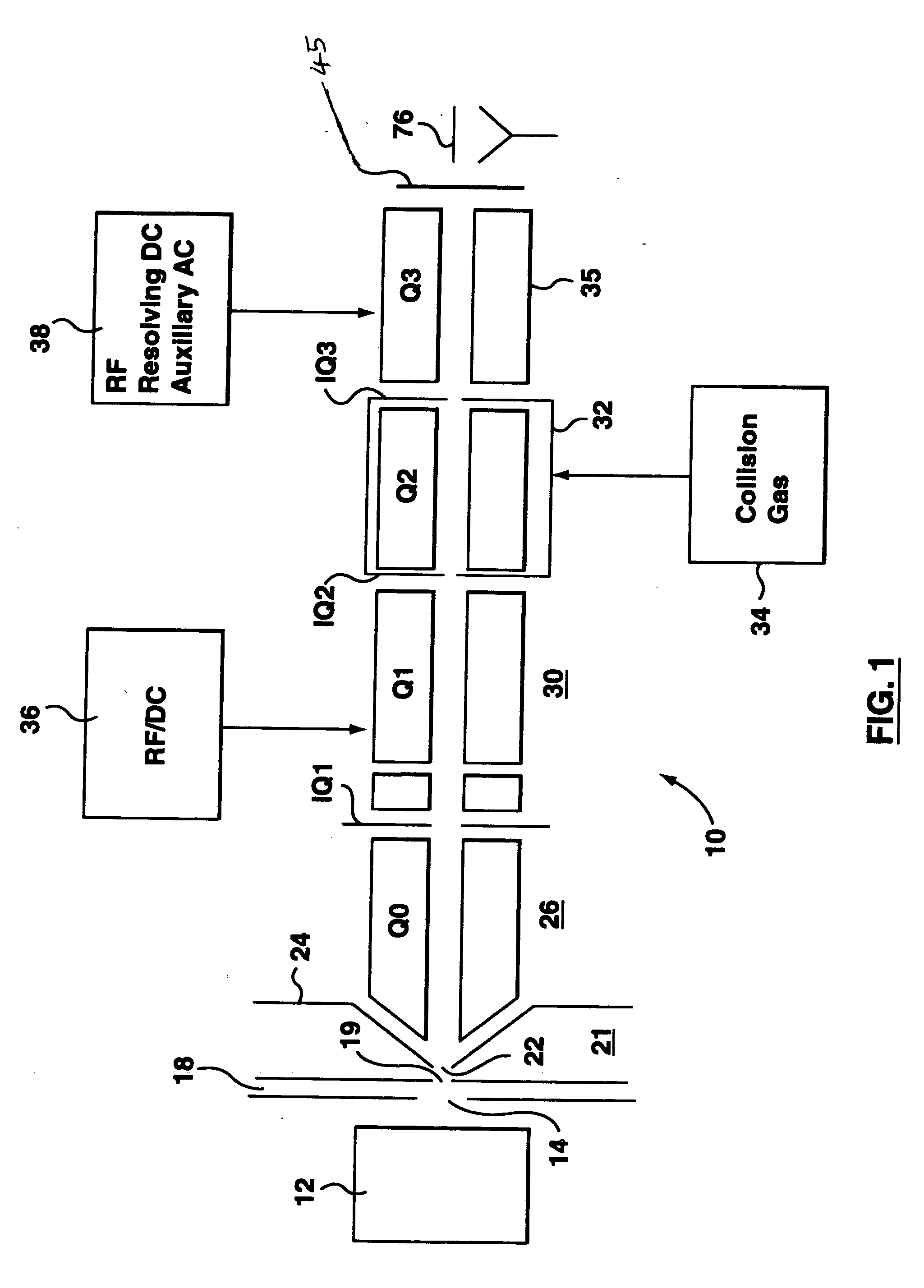

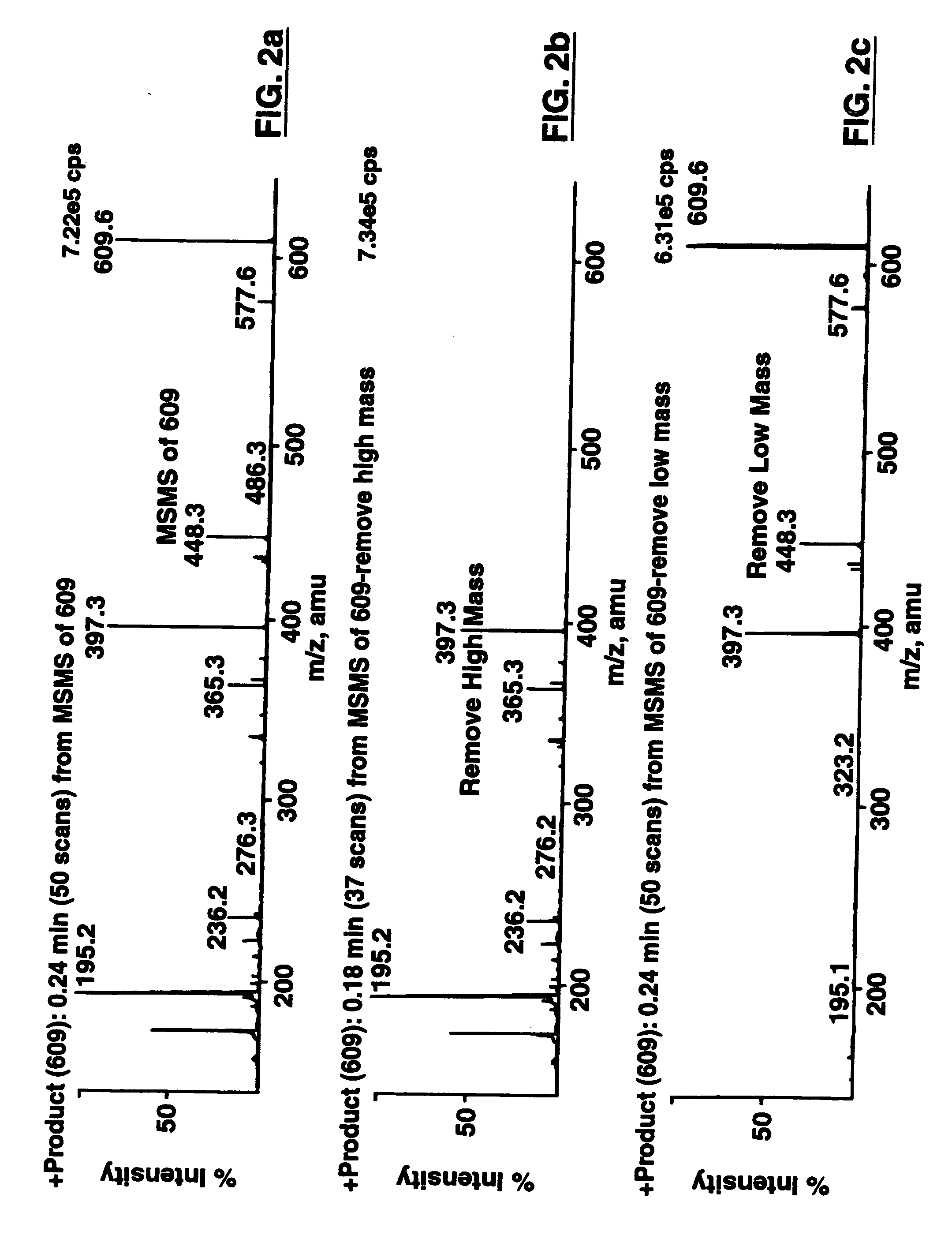

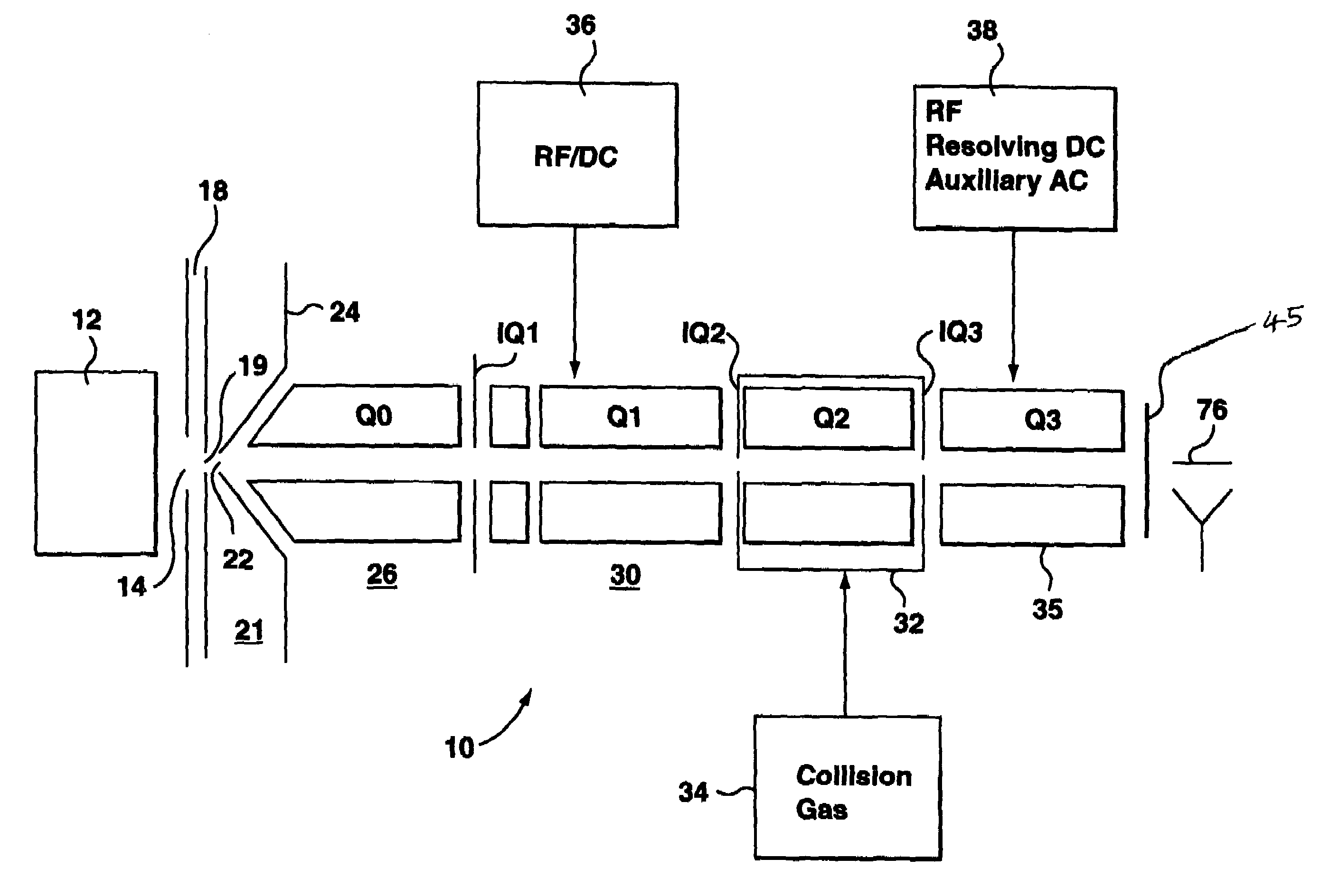

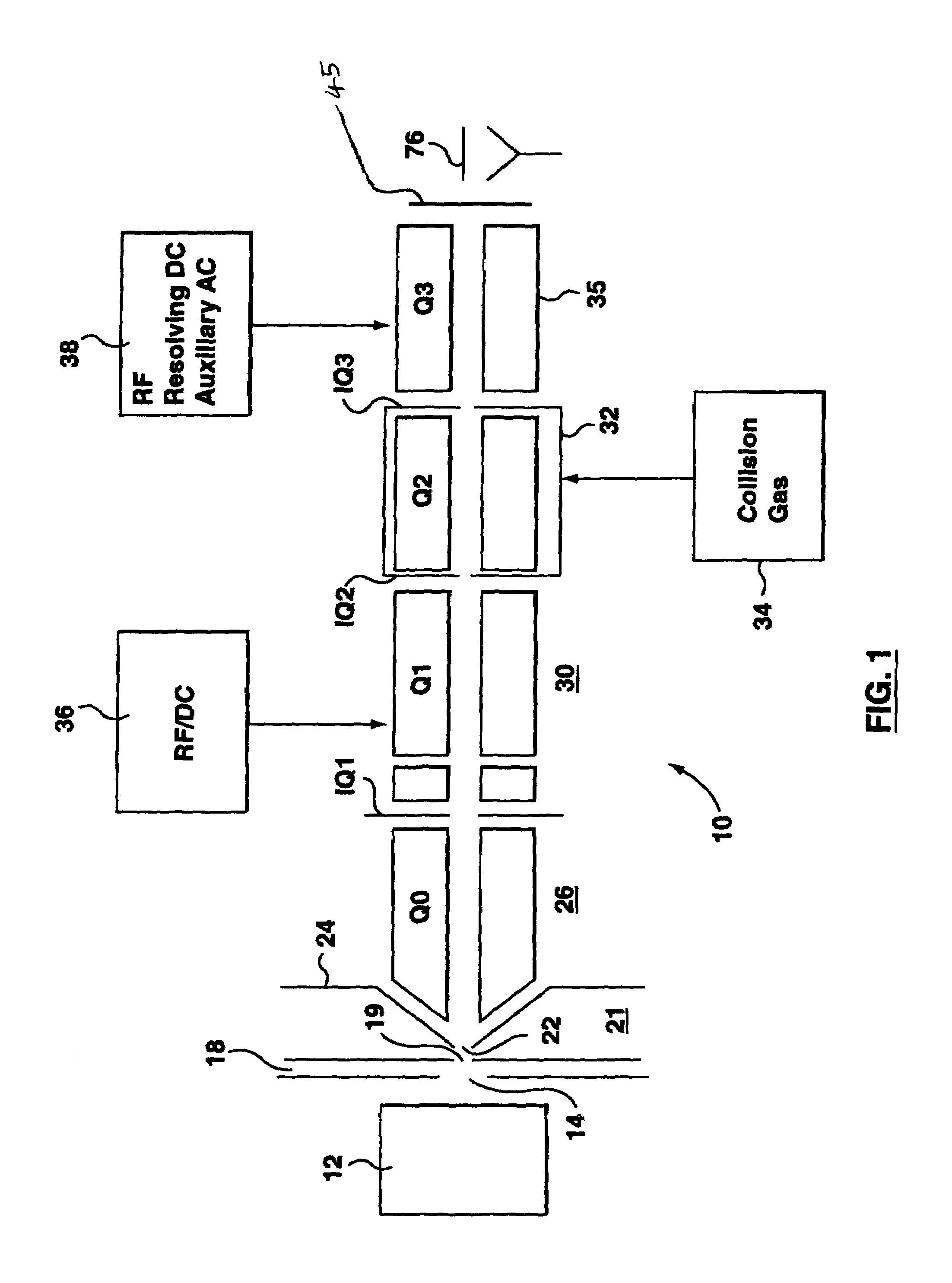

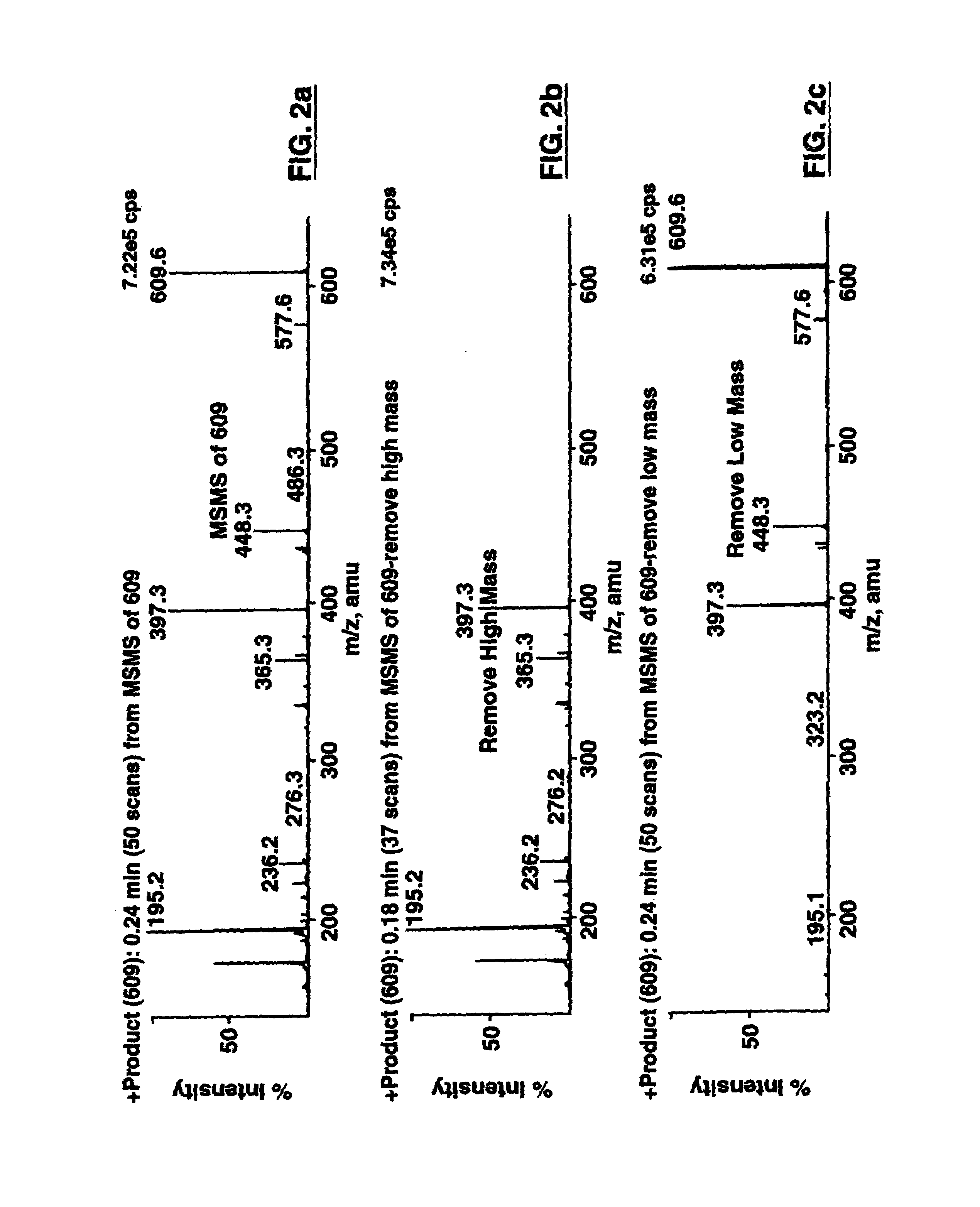

Triple quadrupole mass spectrometer with capability to perform multiple mass analysis steps

A method of analyzing a substance comprises ionizing the substance to form a string of ions. The ions are then subject to a first mass analysis step. In one embodiment, the ions are accelerated into a collision cell in known manner to form primary fragment ions. These primary fragment ions are then accelerated into a downstream mass analyzer, to promote secondary fragmentation. In another embodiment of the invention, ions are passed through the collision cell, without fragmentation, and then accelerated from the collision cell into a low pressure section, which may be a mass analyzer or a rod set for collecting and collimating ions. This is done under conditions that promote fragmentation. The operating conditions of the low pressure section can be such as to promote collection or retention of ions depending upon their mass, and more specifically to reject low mass ions. This enables primary fragment ions to be cooled, and secondary fragment ions to be formed subsequently from these ions after they have disipated some of their energy. This enables control of secondary fragmentation processes, and offers numerous opportunities for analyzing complex ions.

Owner:DH TECH DEVMENT PTE +2

Triple quadrupole mass spectrometer with capability to perform multiple mass analysis steps

InactiveUS7060972B2Stability-of-path spectrometersIsotope separationTriple quadrupole mass spectrometryMass analyzer

A method of analyzing a substance comprises ionizing the substance to form a string of ions. The ions are then subject to a first mass analysis step. In one embodiment, the ions are accelerated into a collision cell in known manner to form primary fragment ions. These primary fragment ions are then accelerated into a downstream mass analyzer, to promote secondary fragmentation. In another embodiment of the invention, ions are passed through the collision cell, without fragmentation, and then accelerated from the collision cell into a low pressure section, which may be a mass analyzer or a rod set for collecting and collimating ions. This is done under conditions that promote fragmentation. The operating conditions of the low pressure section can be such as to promote collection or retention of ions depending upon their mass, and more specifically to reject low mass ions. This enables primary fragment ions to be cooled, and secondary fragment ions to be formed subsequently from these ions after they have disipated some of their energy. This enables control of secondary fragmentation processes, and offers numerous opportunities for analyzing complex ions.

Owner:DH TECH DEVMENT PTE +2

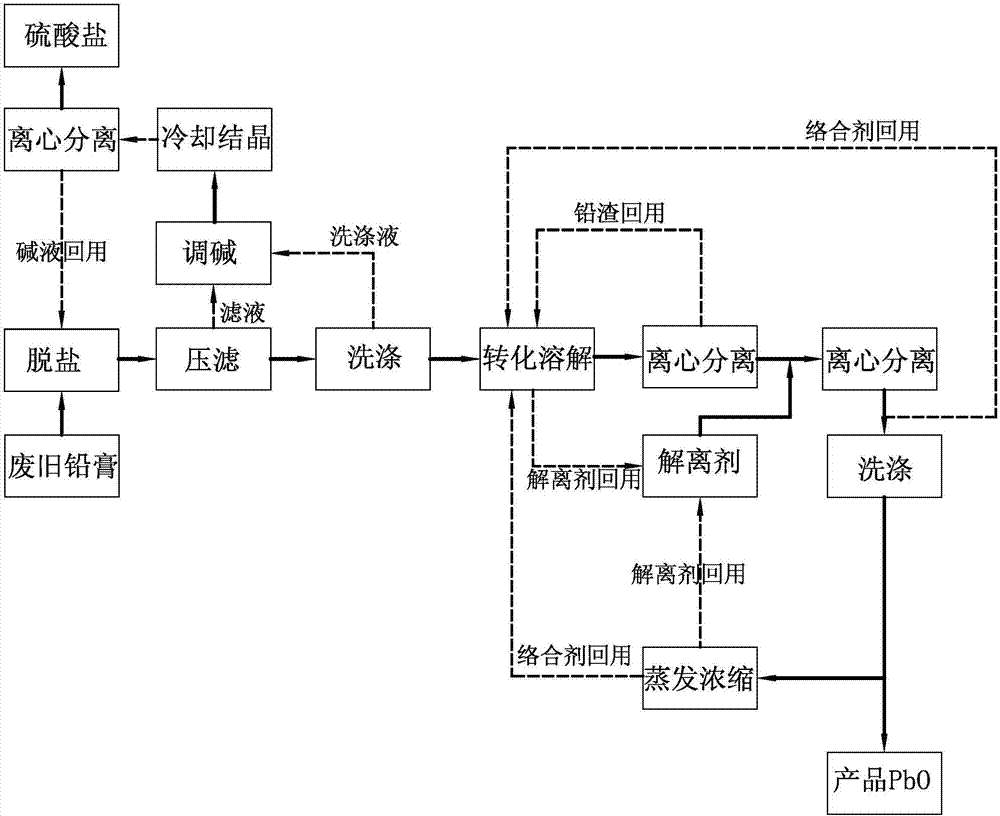

Method for recycling lead oxide from lead plaster of waste lead-acid storage battery

ActiveCN107460339AImprove economyAchieve a reversible cycleLead monoxideWaste accumulators reclaimingEnvironmental resistanceLead dioxide

The invention relates to the technical field of clean recycling of waste batteries and discloses a method for recycling lead oxide from lead plaster of a waste lead-acid storage battery. The method comprises the following steps that (1) pre-desalination is conducted, specifically, the lead plaster of the waste lead-acid storage battery is added with alkali liquor to be subjected to pre-desalination, so that lead acid, lead acetate, lead nitrate, lead perchlorate or lead carbonate in the lead plaster is removed; (2) dissolution is conducted, specifically, a complexing agent solution is added into the lead plaster subjected to pre-desalination, all PbO in the lead plaster reacts with a complexing agent to generate lead complex ions, and a lead-bearing solution and filter residues are obtained; (3) dissociation is conducted, specifically, the pH value of the lead-bearing solution is adjusted by adding a dissociation agent solution, so that the lead complex ions are dissociated, and the PbO and a mixed solution containing the complexing agent and a dissociation agent are obtained; and (4) separating is conducted, specifically, a lead oxide product is obtained after solid-liquid separation and washing. According to the method, the technological condition is mild, the technological process is environmentally friendly, the technological procedure is simple, energy consumption is small, the cost is low, the lead oxide recycling rate is high, the purity is high, and the method has very high industrial application value.

Owner:CHAOWEI POWER CO LTD

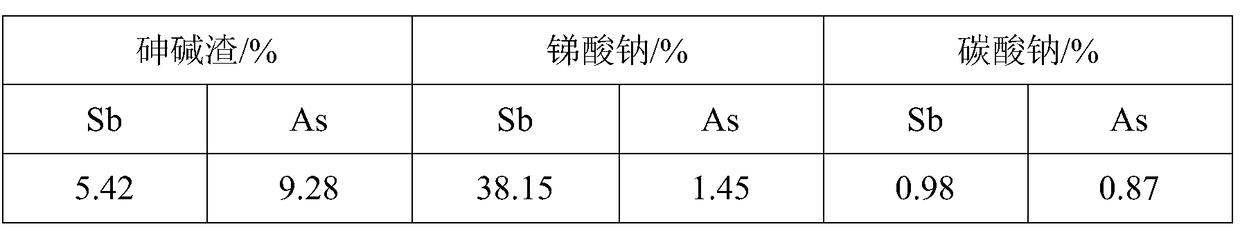

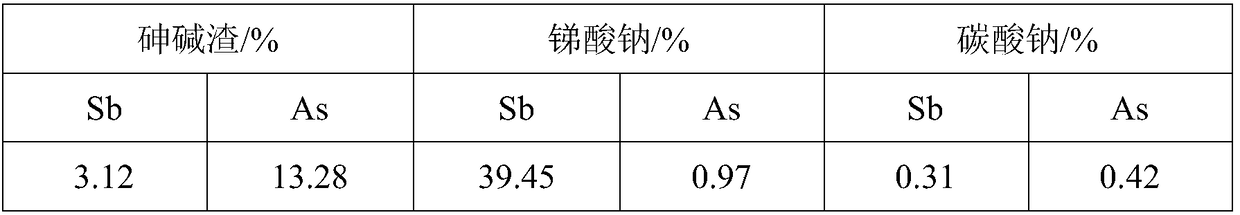

Method for achieving efficient and comprehensive resource utilization of arsenic-alkali residues

ActiveCN108611494AReduce the difficulty of recyclingHigh crystallinityProcess efficiency improvementSodium bicarbonateResource utilization

The invention discloses a method for achieving efficient and comprehensive resource utilization of arsenic-alkali residues. The method comprises the steps that after oxidation and water logging are conducted on the arsenic-alkali residues, solid-liquid separation is conducted, so that leachate and antimony-enriched residues are obtained; an ammonium-source solution is made to react with metallic oxide, so that a metallic ammonium complex ion solution is obtained; the metallic ammonium complex ion solution and a crystal growth accelerant are added to the leachate for a reaction, a mixed solution obtained after the reaction is sequentially subjected to aging, crystallization, precipitation and solid-liquid separation, and an obtained solid phase is an ammonium arsenate metallic salt product;and firstly, treatment of heating for ammonium removal is conducted on a liquid phase, then, carbon dioxide is introduced for a reaction, so that sodium bicarbonate crystals are separated out, and thermal decomposition is conducted on the sodium bicarbonate crystals, so that a sodium carbonate product is obtained. By means of the method, antimony, alkali and arsenic can be rapidly and efficientlyseparated out of the arsenic-alkali residues; the effect that the arsenic is efficiently separated from the alkali is achieved; and in addition, the method is low in cost, simple in process and convenient to operate, and the requirement of industrialized production is met.

Owner:CENT SOUTH UNIV

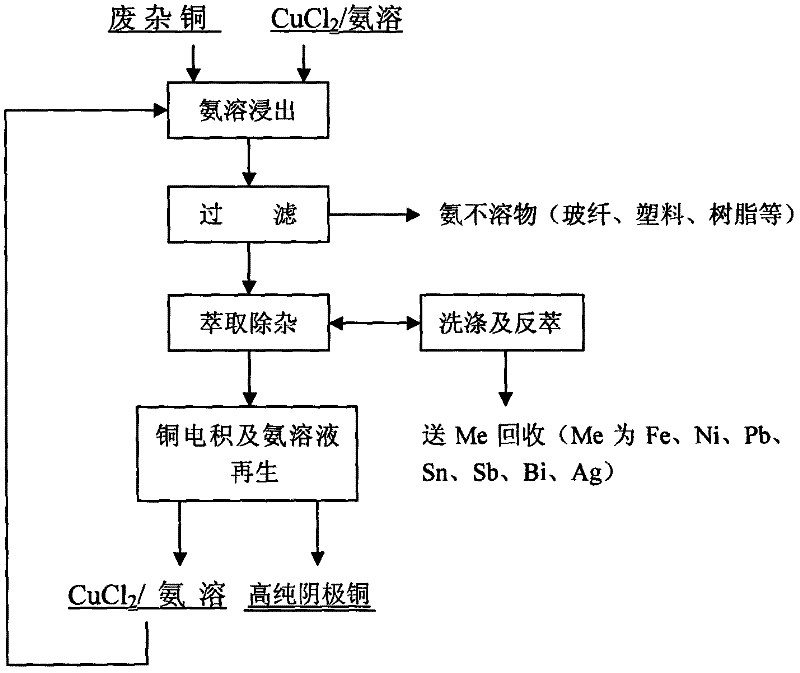

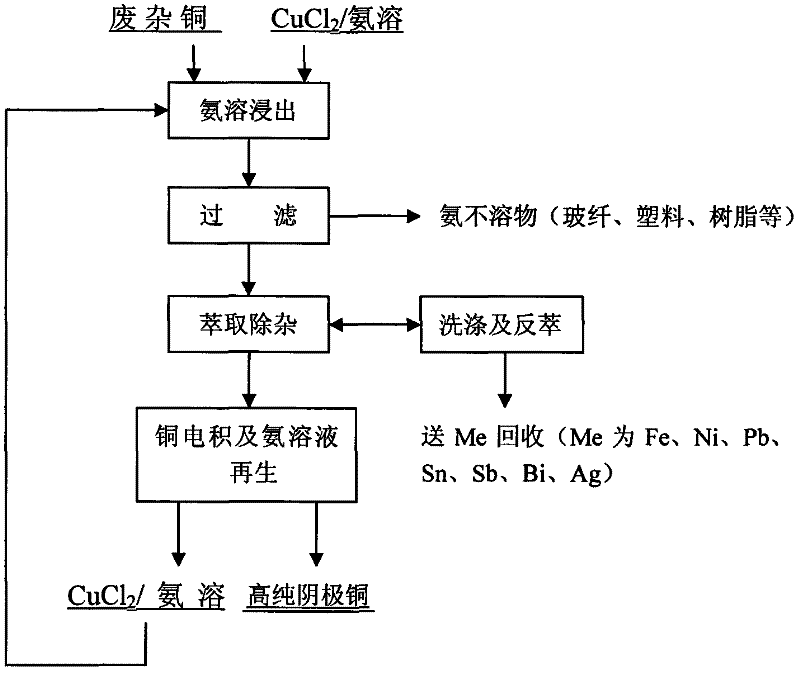

Method for extracting copper from scrap copper through wet process

InactiveCN102443703ALower specific resistanceReduce concentration overpotentialPhotography auxillary processesProcess efficiency improvementEnvironmental resistanceElectrolysis

The invention relates to a method for extracting copper from scrap copper through a wet process. The method comprises the steps of: A) ammonia dissolving leaching: putting scrap copper in a multicomponent solution of ammonia, an ammonia salt, a monovalent chloride, and a divalent copper chloride to form an appropriate electric potential, and reacting the scrap copper with ammonia complex ions so as to be dissolved in the multicomponent solution and generate stable monovalent copper complex ions, filtering out most of metal element impurities Fe, Ni, Al, Sn and Pb from the scrap copper, leaving a small amount of impurities to undergo an oxidation reaction and react with ammonia molecules to generate complex ions of different coordination numbers and exist in the solution; B) extraction for impurity removing: extracting impurities Ag, Fe, Ni, Zn, Bi, Cr, Mn, Sb, Pb, and Sn into an organic phase, and keeping the monovalent copper complex ions in the solution; C) diaphragm electrolytic deposition for preparing high-purity cathode copper: carrying out electrolytic deposition of copper in the cathode chamber of a negative ion membrane electrolyzer, thus obtaining a well crystallized negative copper plate. The method of the invention is characterized by environmental protection and low energy consumption, and can generate high-purity copper directly.

Owner:周毅舟

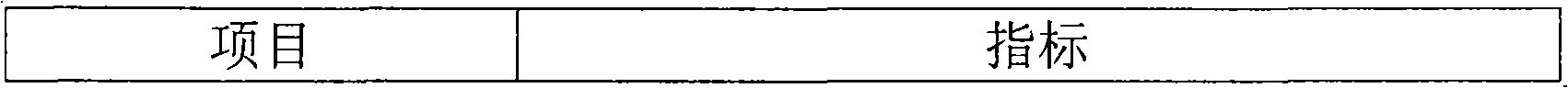

Technology for total-cladding composite ion plating of surface of aramid fiber or laid fabric with nanometals, and product thereof

ActiveCN104831527AStrong adhesionGood uniformityFibre typesVacuum evaporation coatingIonNitrogen gas

The invention relates to a technology for total-cladding composite ion plating of the surface of an aramid fiber or laid fabric with nanometals. A substrate is the aramid fiber or the laid fabric made of the aramid fiber. The technology comprises the following steps: 1, carrying out dewatering degassing treatment on the substrate in a vacuum chamber with the vacuum degree of 10-3.0*10<-4>Pa and the heating temperature of 60-180DEG C; 2, carrying out plasma surface cleaning treatment on the substrate by adopting a cathode ion film plating device with argon or nitrogen as a protection gas under a vacuum degree of 1.0*10<-1>-3.0*10<-4>Pa at a temperature of -10 - -30DEG C under a substrate running speed of 3.0-10.0m / min, generating metal ions and nanoparticles with the density of 1.0-10.0g / m<2> in adopting a composite ion film plating mode with metals as a target material, and carrying out total-cladding plating on the surface of the substrate with a nanometal plating layer with the granularity of below 100nm; and 3, cutting the above obtained material, metering, and carrying out vacuum packaging. The technology greatly reduces the influences of water and ultraviolet ray on the aramid fiber, and greatly protects excellent mechanical performances of the aramid fiber.

Owner:ALDO NEW TECH MATERIALSJIAXING CO LTD

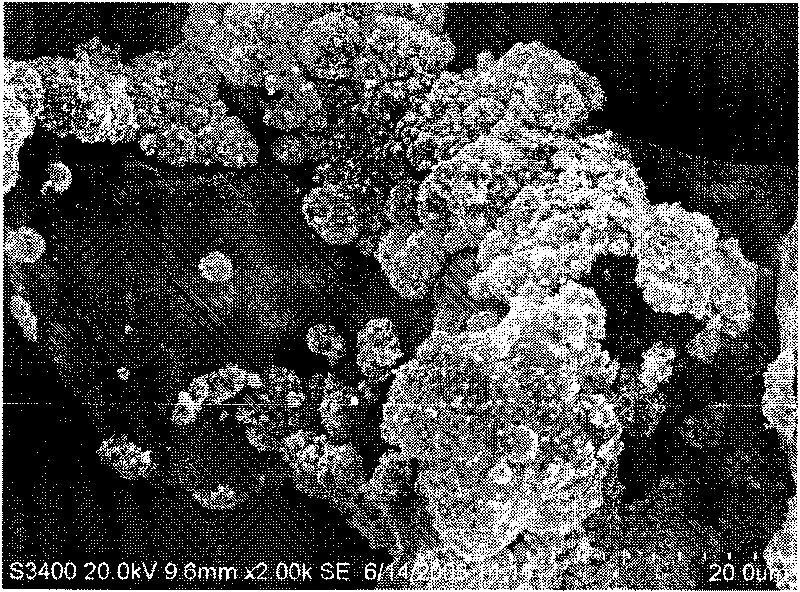

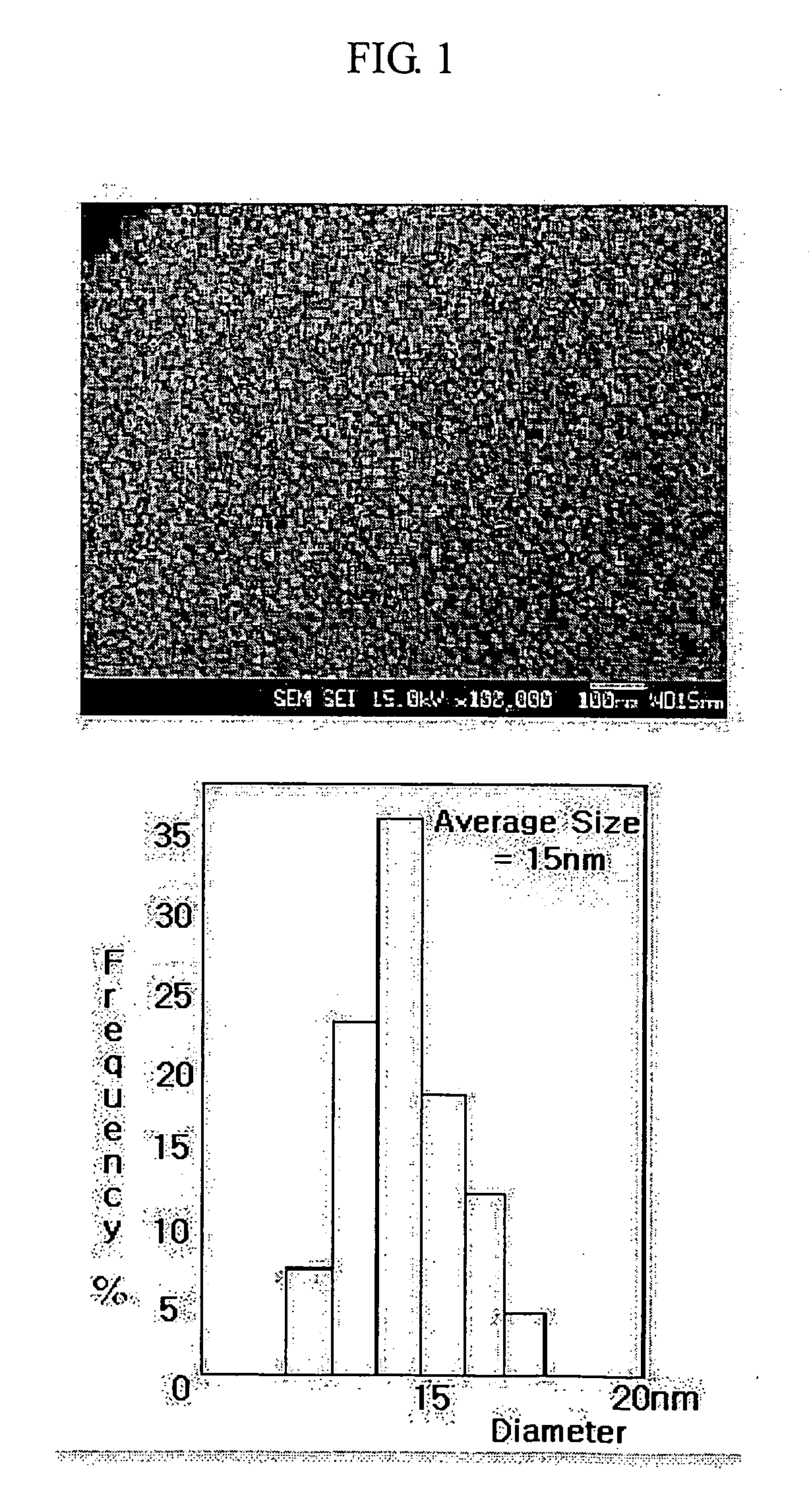

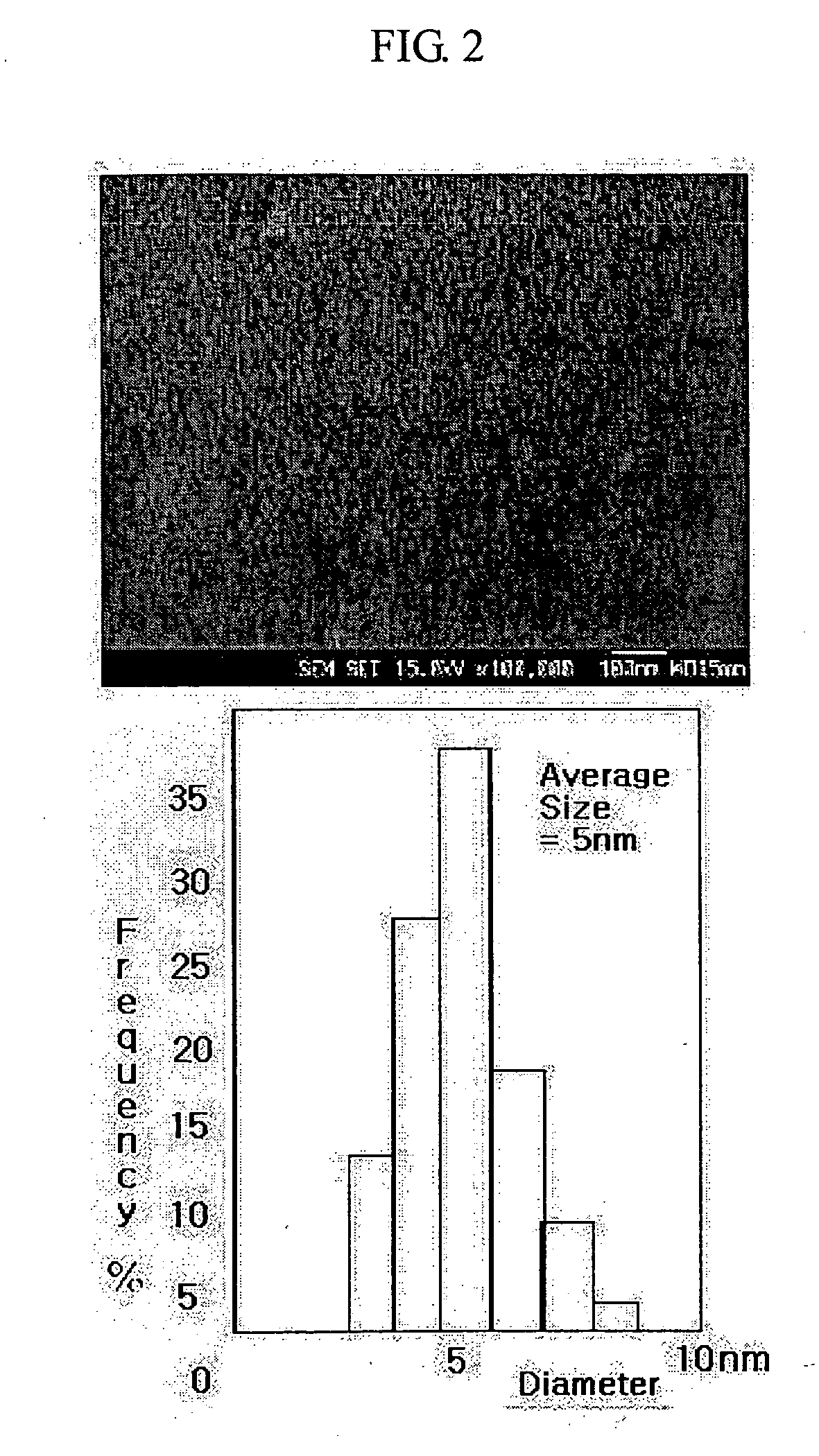

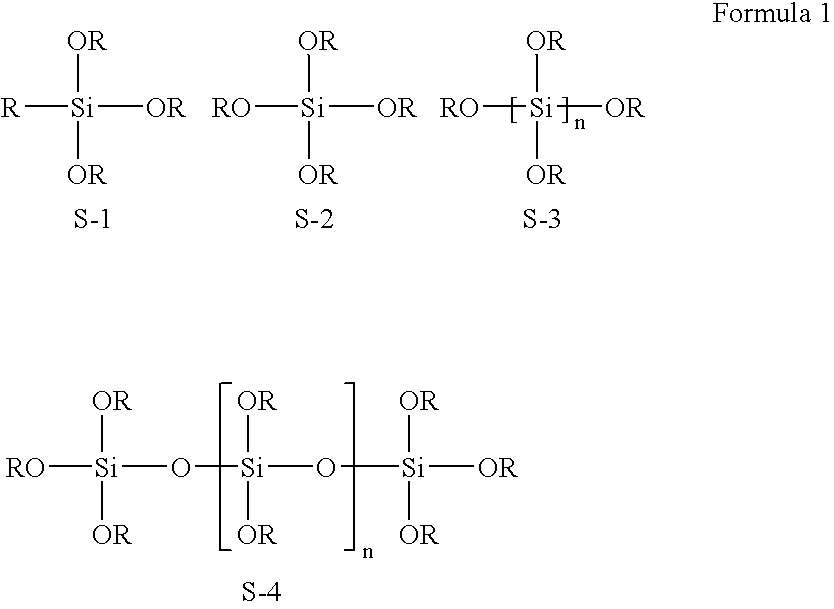

Metal nano-particles coated with silicon oxide and manufacturing method thereof

InactiveUS20060204754A1Retains inherent electromagnetic propertyInhibition of particle growthMaterial nanotechnologyNanostructure manufactureCompound (substance)Silicon oxide

Disclosed herein is a metal nanoparticle whose surface is coated with a silicon oxide. The silicon oxide is obtained from a silicon compound or a derivative thereof as a precursor and has a particle diameter of a few angstroms (A). Further disclosed is a method for manufacturing metal nanoparticles. The method comprises the steps of a) mixing metal ions, a solvent and an additive required for forming metal complex ions, b) adding a silicon compound or a derivative thereof as a precursor for forming silicon oxides, to the mixture of step a) to coat the surface of the metal ions, and c) adding a reducing agent to the mixture of step b) to reduce the metal ions. If necessary, the method further comprises the step of d) lyophilizing the resulting product of step c), i.e. metal nanoparticles. Since the surface of the metal nanoparticle of the present invention is coated with a silicon oxide, the metal nanoparticle is stabilized. In addition, the metal nanoparticle retains electromagnetic properties inherent to the metal and can be easily manufactured in an economical manner.

Owner:MIJINANOTECH

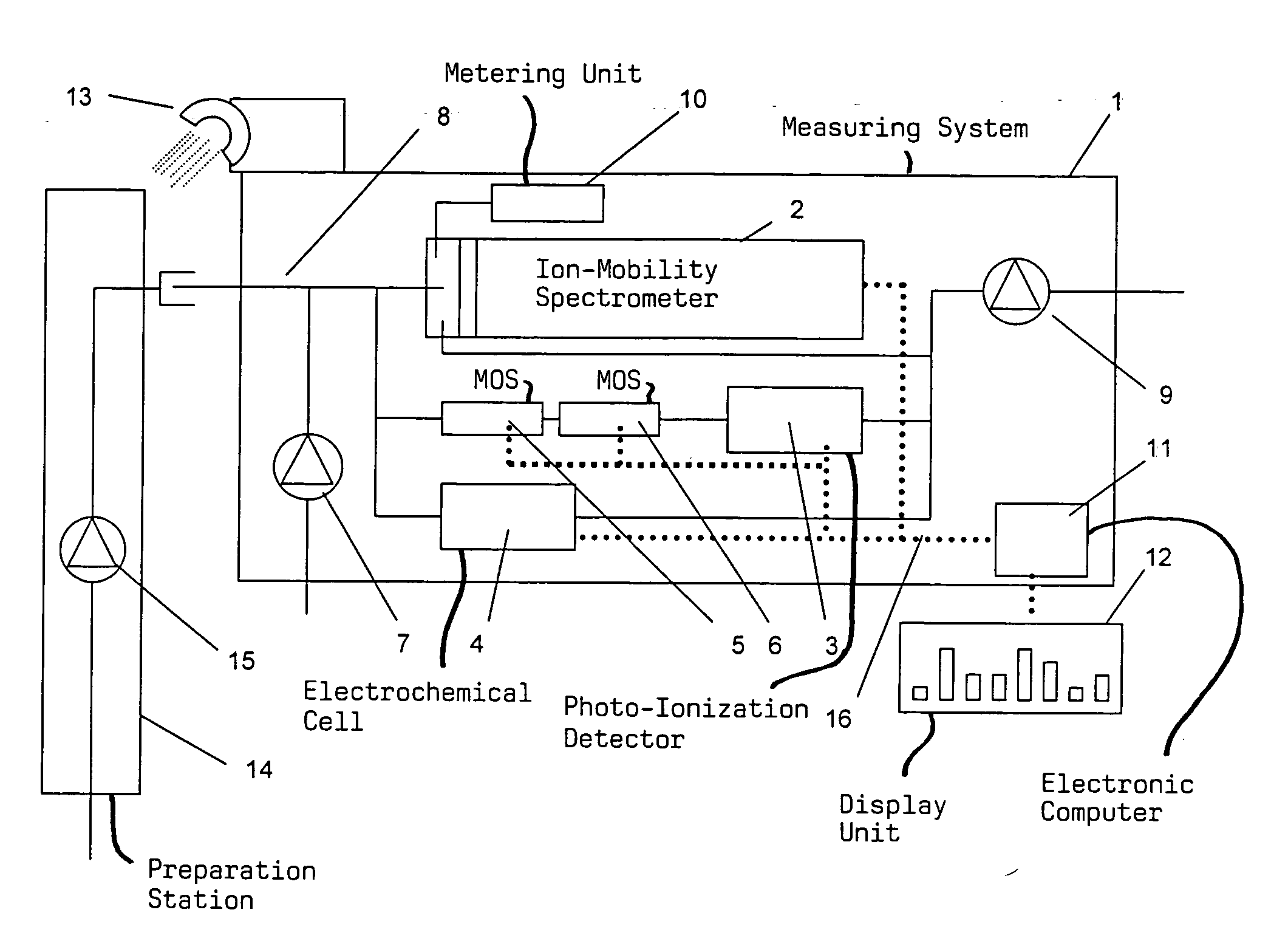

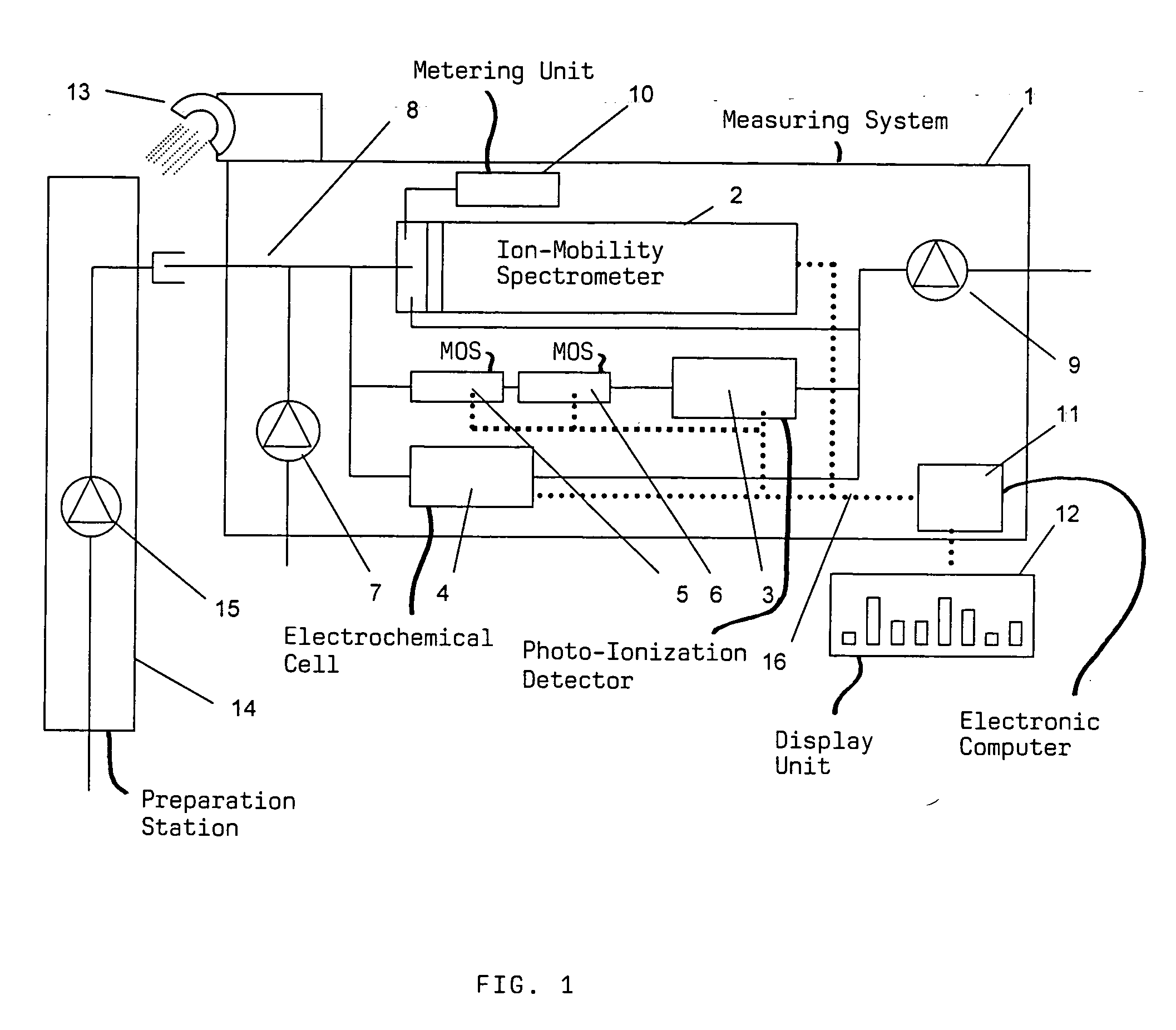

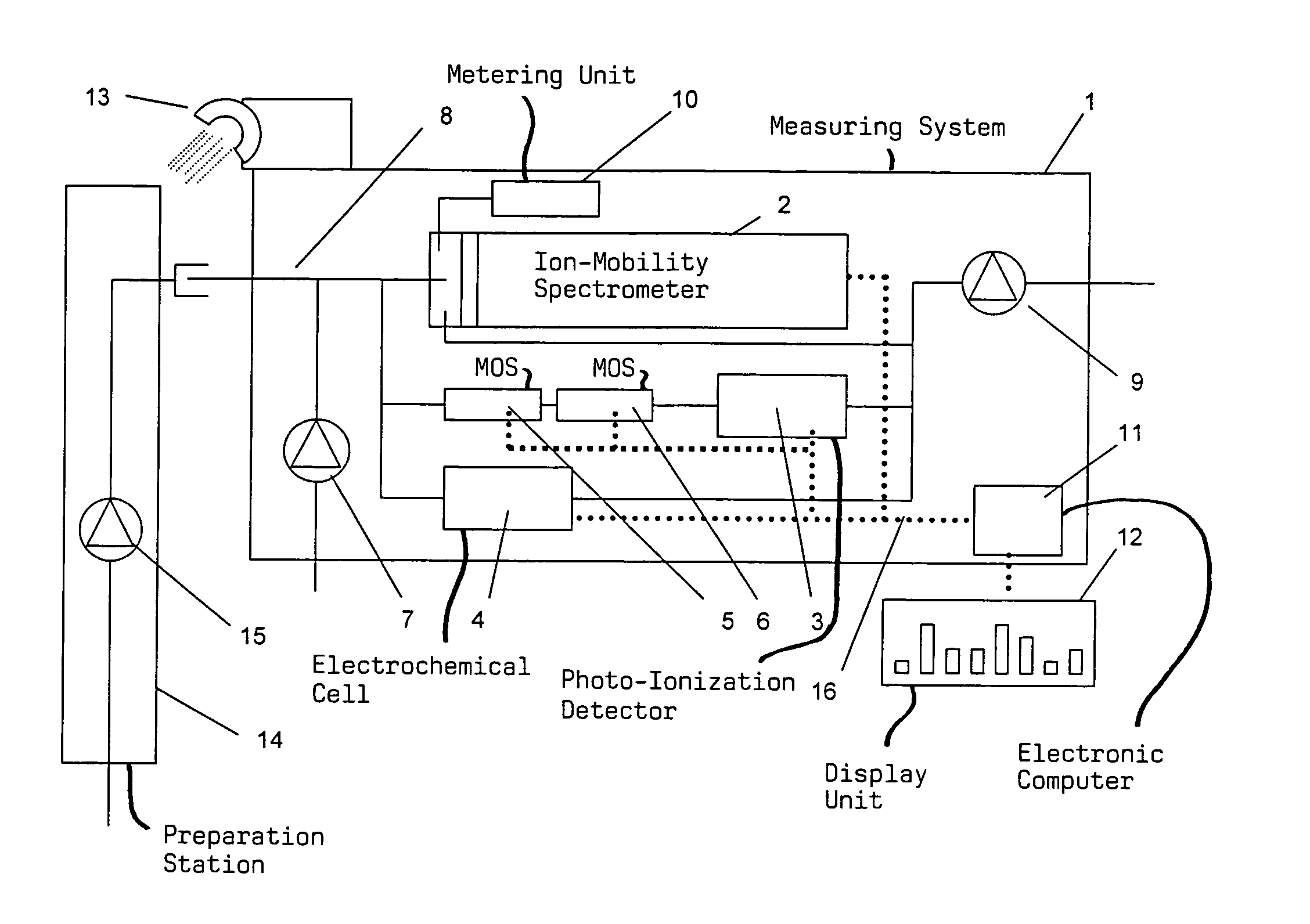

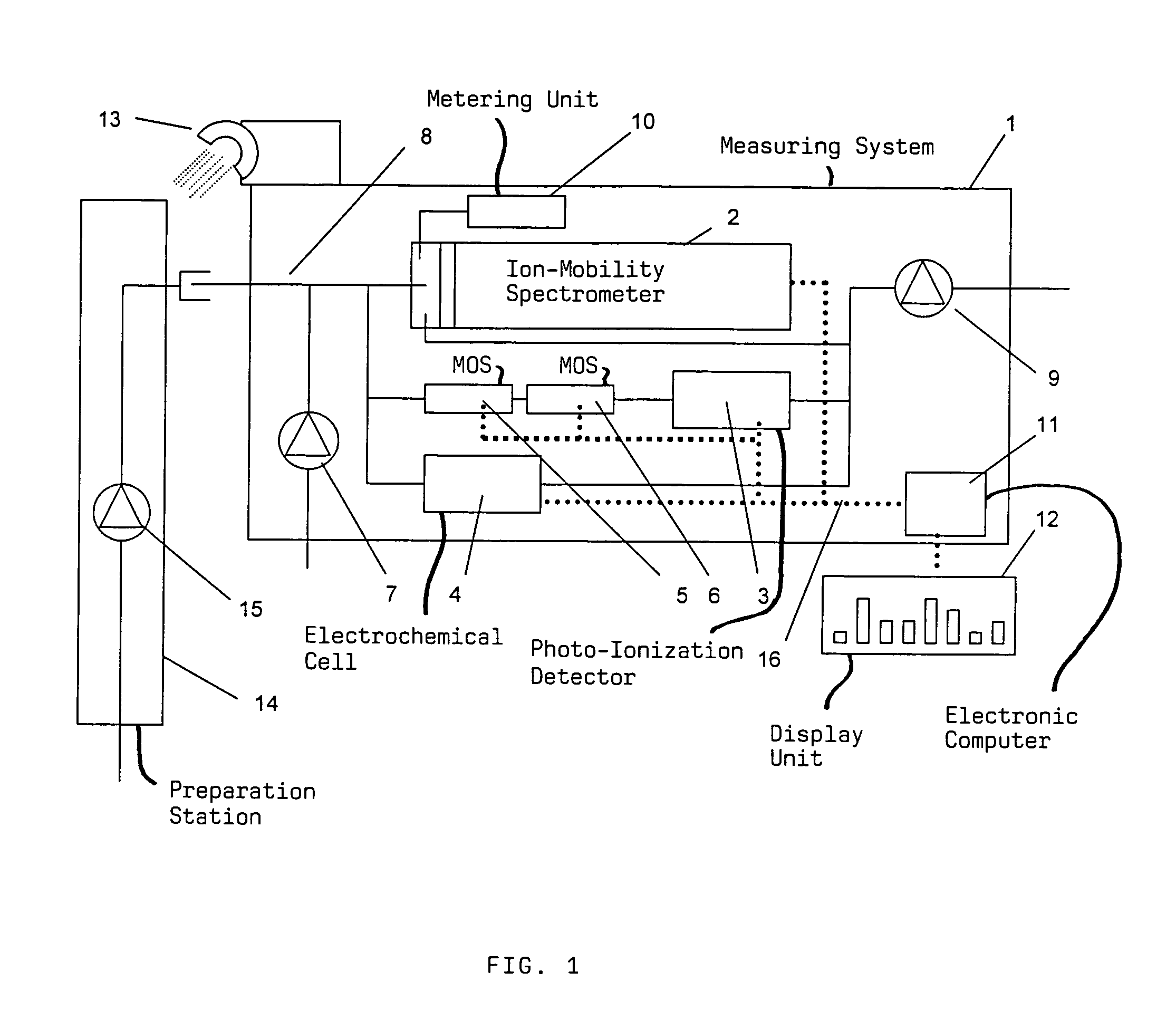

Method and arrangement for detecting harmful substances

ActiveUS20060219892A1Avoid overexposureMeasuring rangeTime-of-flight spectrometersScattering properties measurementsHazardous substanceGas passing

A method and an arrangement detect harmful substances while eliminating or minimizing the drawbacks of an ion mobility spectrometer (IMS). The sample gas flow is mixed with a reference gas utilizing a pump (7). A reaction gas is supplied via a metering unit (10) to the ion-mobility spectrometer (2) when complex ion-mobility spectrometer spectra are present. The measurement signals obtained as to the gas-quantity ratio between the sample gas and the reference gas are adapted to the original concentration and are then compared to previously defined and stored measured values via a signal height comparison or a pattern recognition. The measuring system is rinsed following the measurement phase by feeding the reference gas and is cleaned by metering an additional cleansing gas when harmful substances are detected which could be rinsed away. Such methods and measuring systems are used for identifying harmful substances in ambient air.

Owner:AIRSENSE ANALYTICS

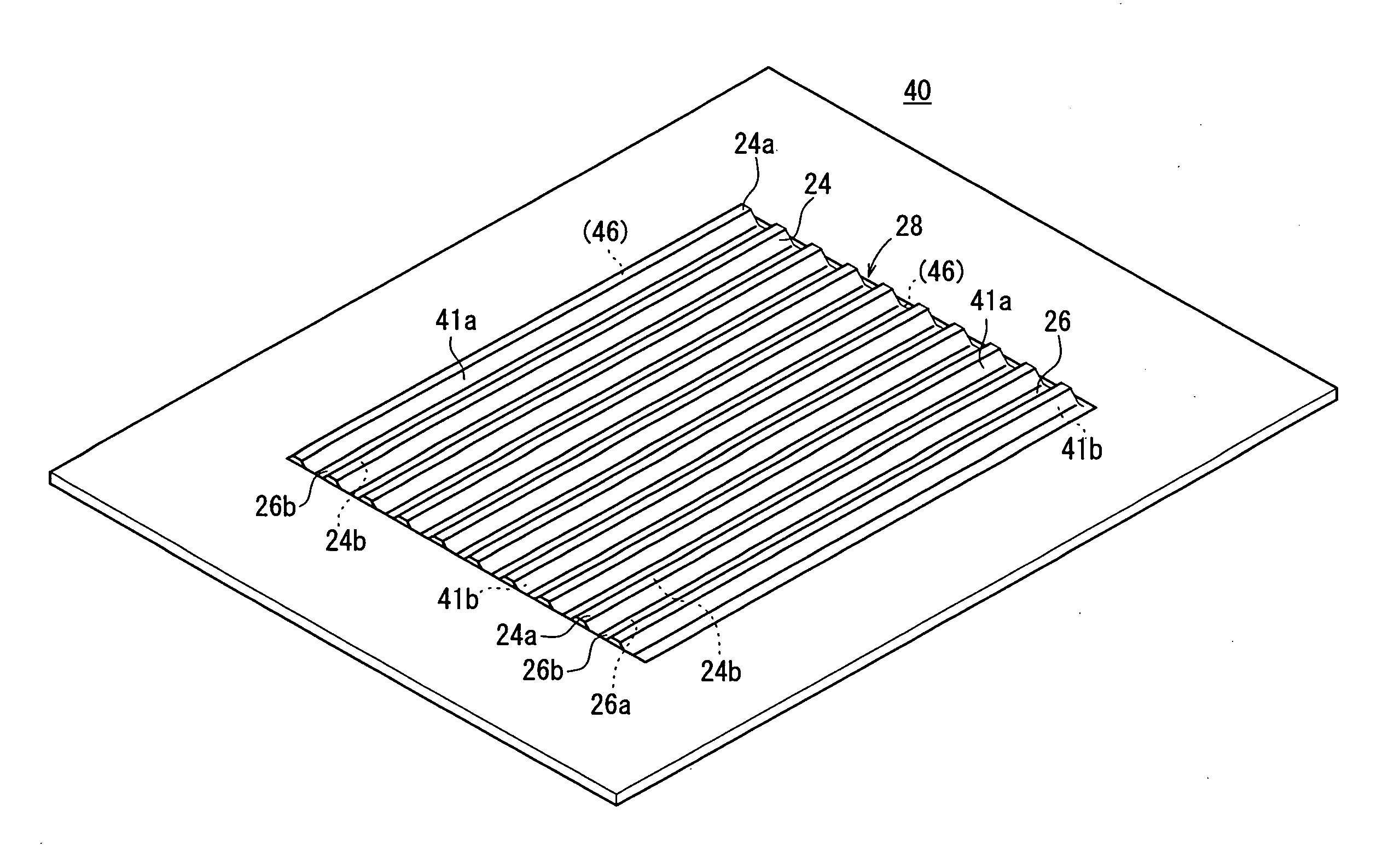

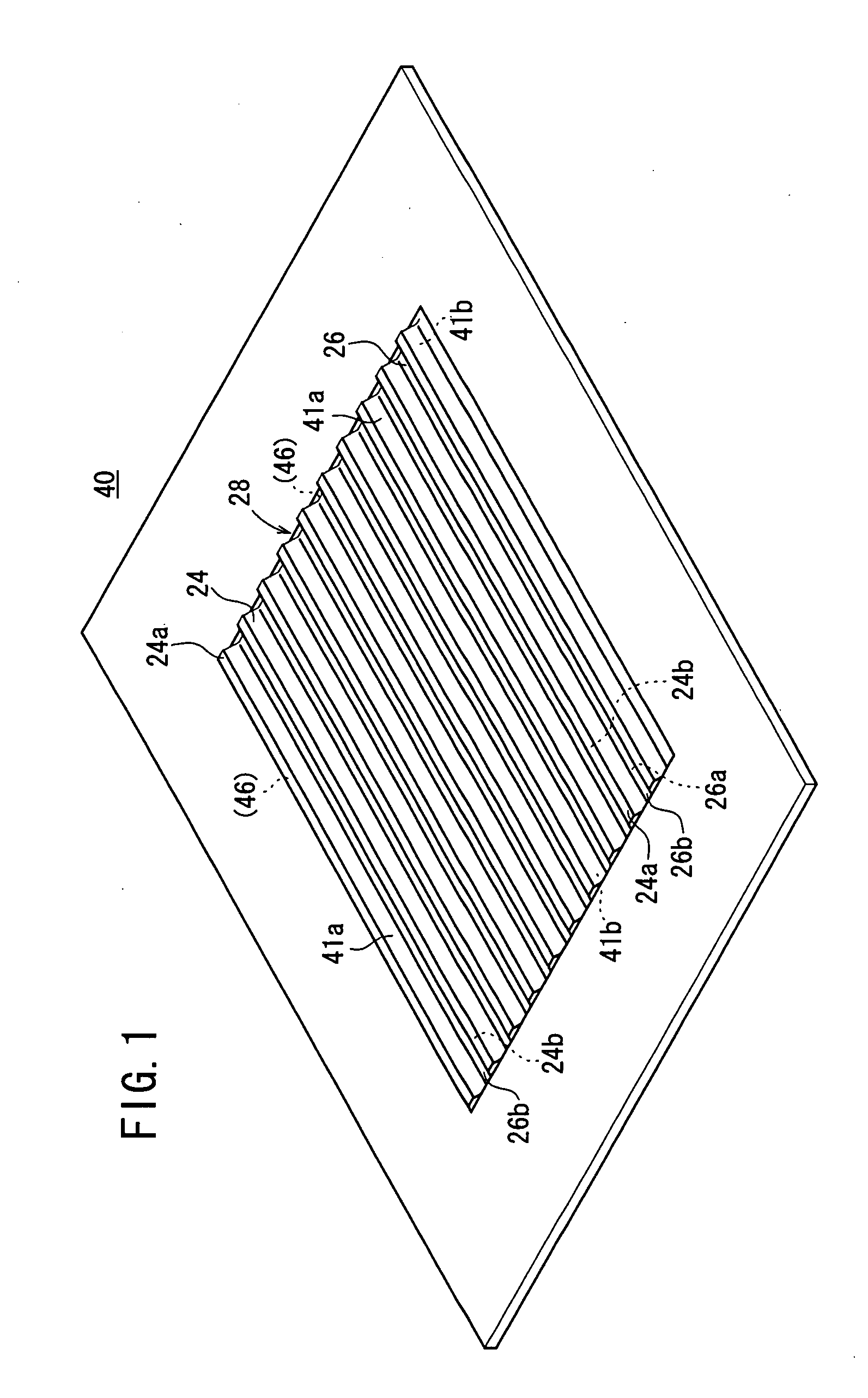

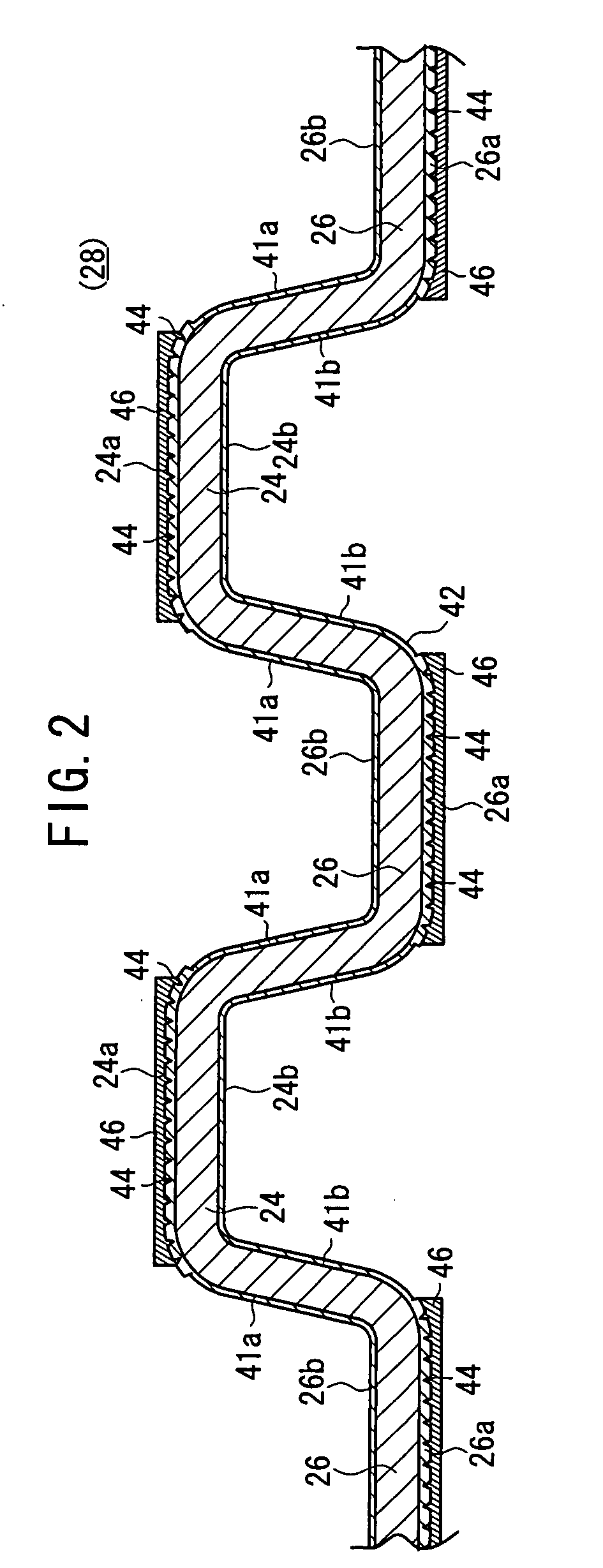

Separator for fuel cell and method for manufacturing the same

InactiveUS20090042084A1Improve insulation performanceEasy to getFinal product manufactureCell electrodesPlatinumFuel cells

At first step S1, a passivation film is removed by performing pickling on a separator for fuel cell and then a new passivation film is formed b performing heating at 200-280° preferably. At second step S2, mechanical polishing is performed on the horizontal top surfaces in the waiving portion of the separator for fuel cell, and a chipped portion is provided by chipping off a part of the passivation film. At third step S3, the separator for fuel cell is plated to form a first plating film composed of gold, rhodium, platinum or an alloy of two or more kinds of them starting at the periphery of the chipped portion. A complex ion stabilizer for suppressing dissociation of complex ions is added to plating bath.

Owner:HONDA MOTOR CO LTD

Method for preparing fertilizer-grade ammonium nitrate concentrated solution by use of mother liquid after immersion tin of tin-stripping waste liquid of circuit board

ActiveCN102775197ASimple processLarge amount of processingAmmonium nitrate fertilisersLiquid wasteEvaporation

The invention discloses a method for preparing a fertilizer-grade ammonium nitrate concentrated solution by use of the mother liquid after immersion tin of a tin-stripping waste liquid of a circuit board. The method is characterized by comprising the following successive steps of: neutralizing and precipitating the tin compound of the nitric acid type tin-stripping waste liquid by ammonia water, and removing the trace amount of copper-ammonia complex ions and organic acid stannum complex ions of the weak-acid filtering stock by a chelate ion exchange resin column in an ion exchange adsorption mode; adding powdery or granular active carbon into the processed filtering stock while stirring, wherein the added active carbon is 0.1-1% of the filtering stock by weight; and performing evaporation concentration of the ammonium nitrate solution after impurity removal according to the conventional technology, and controlling the sum of ammonium nitrogen and nitrate nitrogen to 100-200g nitrogen per liter to obtain the fertilizer-grade ammonium nitrate concentrated solution. Based on the existing ammonia water neutralizing method for processing the tin-stripping waste liquid, the invention provides a method for preparing the fertilizer-grade ammonium nitrate concentrated solution with a simple technology, large processing amount and low cost for the remaining ammonium nitrate waste liquid; and the prepared fertilizer-grade ammonium nitrate concentrated solution can be used for producing a compound fertilizer, an organic-inorganic compound fertilizer or a liquid humic acid-containing water-soluble fertilizer in a large scale.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Method and arrangement for detecting harmful substances

ActiveUS7227136B2Compensate for and minimize disadvantageLow detection limitTime-of-flight spectrometersScattering properties measurementsHazardous substanceGas passing

A method and an arrangement detect harmful substances while eliminating or minimizing the drawbacks of an ion-mobility spectrometer (IMS). The sample gas flow is mixed with a reference gas utilizing a pump (7). A reaction gas is supplied via a metering unit (10) to the ion-mobility spectrometer (2) when complex ion-mobility spectrometer spectra are present. The measurement signals obtained as to the gas-quantity ratio between the sample gas and the reference gas are adapted to the original concentration and are then compared to previously defined and stored measured values via a signal height comparison or a pattern recognition. The measuring system is rinsed following the measurement phase by feeding the reference gas and is cleaned by metering an additional cleansing gas when harmful substances are detected which could not be rinsed away. Such methods and measuring systems are used for identifying harmful substances in ambient air.

Owner:AIRSENSE ANALYTICS

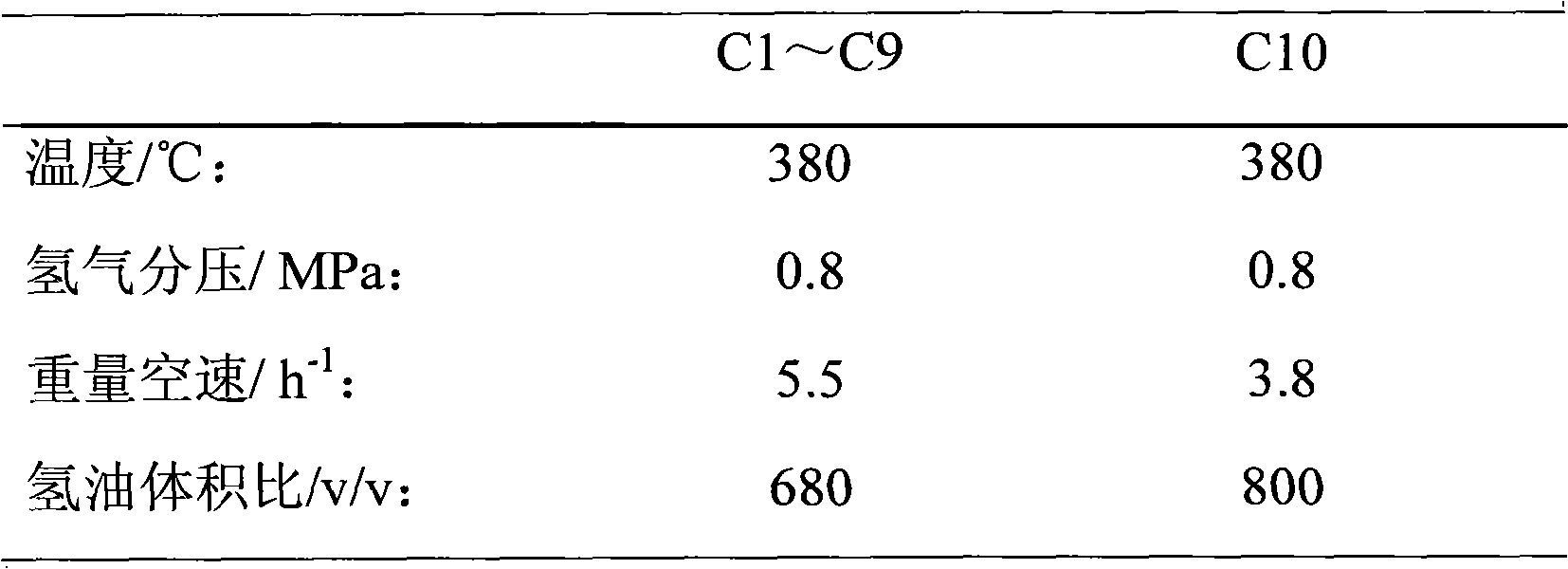

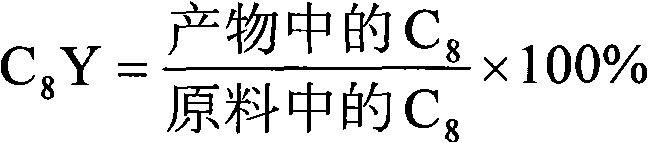

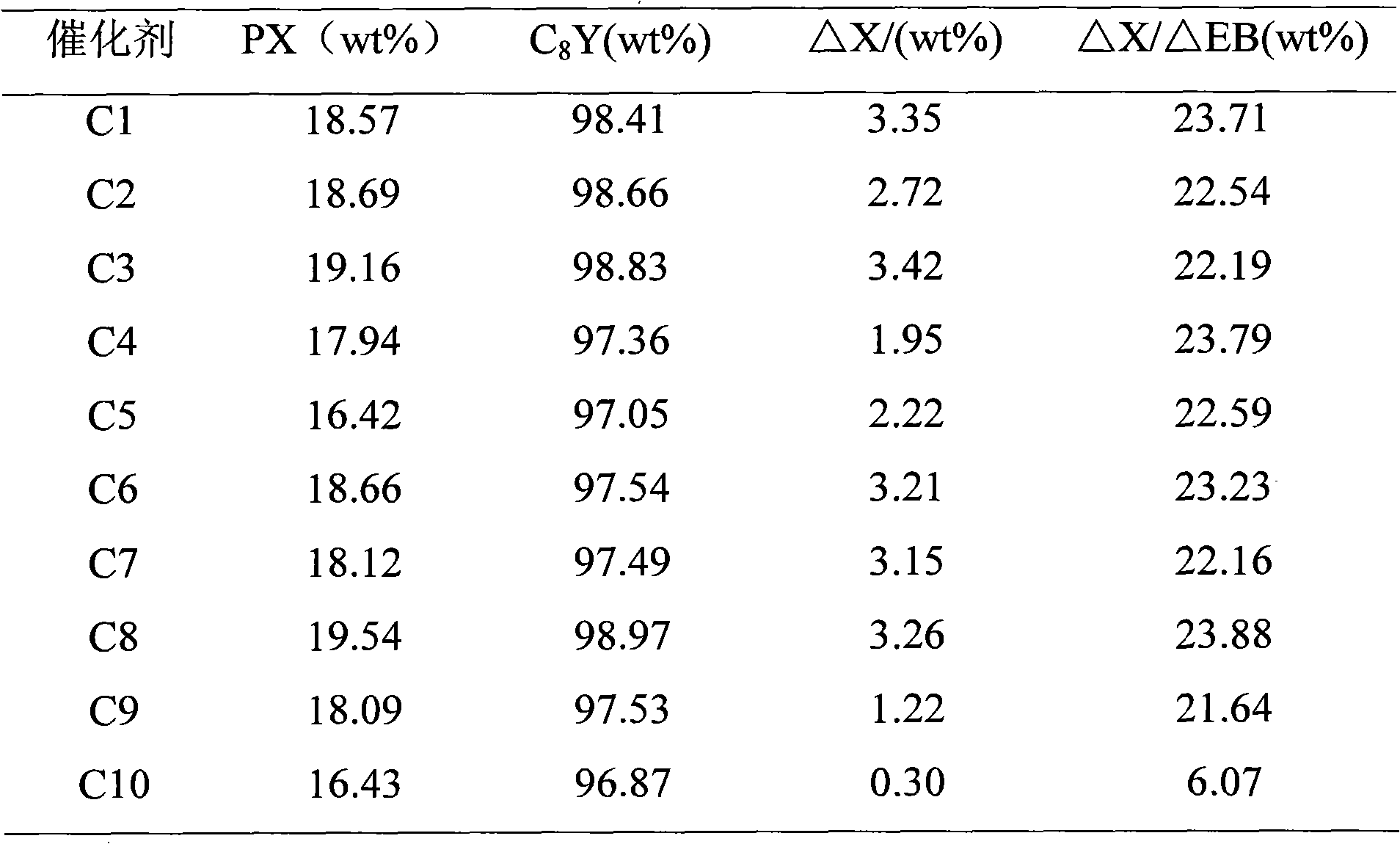

Metal-modified eutectic zeolite catalyst with EUO (Europium Oxide) structure as well as preparation method and application thereof

ActiveCN101987298AEasy to makeGood mechanical crushing strengthHydrocarbon by isomerisationMolecular sieve catalystsCerium nitrateIsomerization

The invention relates to a metal-modified eutectic zeolite catalyst with an EUO (Europium Oxide) structure as well as a preparation method and application thereof. The metal-modified eutectic zeolite catalyst comprises the components by weight based on 100 percent: 1-90 percent of hydrogenous zeolite with the EUO structure, 0.01-2.0 percent of Pt and / or Pd, 0.01-4.0 percent of Ce and / or La and the balance of bonding agent, wherein the zeolite comprises an element T containing silicon, aluminum and / or magnesium; the atom ratio of Si to T is 8-100; the preparation method comprises the following steps of: roasting the zeolite with the EUO structure in the low-oxygen concentration atmosphere; mixing the zeolite with the bonding agent and forming; roasting; making the mixture exchange ion with NH4Cl water solution and impregnating with platinic chloride solution or ammonium platonic complex ions and / or palladium chloride; meanwhile, adding cerium nitrate solution and / or lanthanum nitrate solution; and filtering, drying and activating. The invention can be used for isomerization reaction of C8 aronmatic, can greatly improve the reactivity and improve the quantity of the conversion of phenylethane into a target product of dimethylbenzene and effectively inhibit side effects in the isomerized process.

Owner:PETROCHINA CO LTD

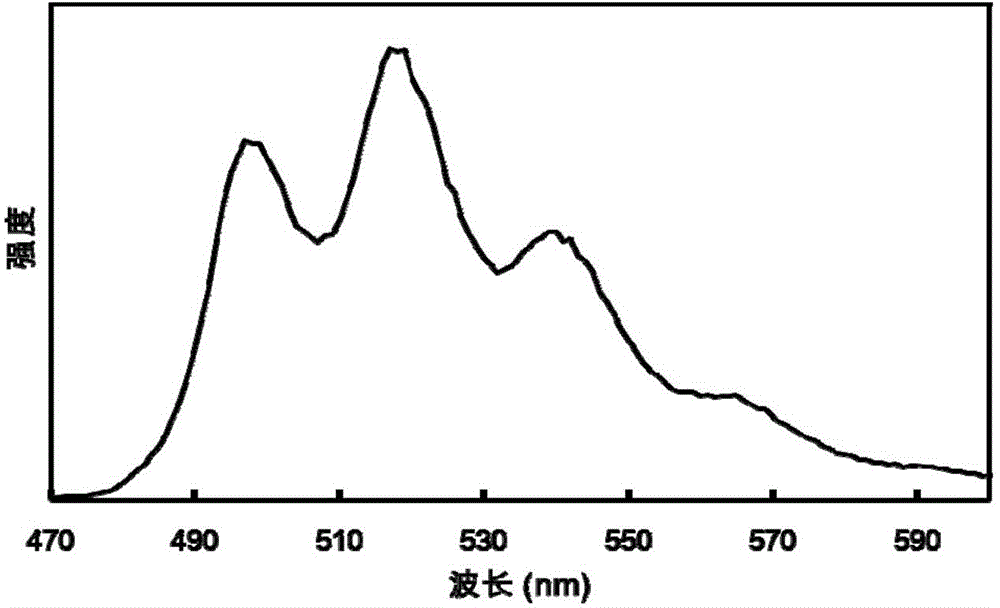

Method for preparing nano zinc gallate with blue fluorescence

InactiveCN102139912AHigh crystallinityImprove uniformityGallium/indium/thallium compoundsNanotechnologyFluorescenceZinc gallate

The invention discloses a method for preparing nano zinc gallate with blue fluorescence in the technical field of nano materials. The method comprises the following steps of: adding a surfactant into solution of zinc salt to prepare zinc complex ion solution; sequentially adding gallium salt and controlling the pH value; and reacting under heating to obtain the zinc gallate nano material. By the method, the defects that luminescent materials emitting pure blue light are relatively a few in the prior art and most of the luminescent materials have relatively poor dispersibility or light-emitting property because most of the luminescent materials are formed by high-temperature solid phase sintering, and other defects, are overcome. The method is simple and low in production cost. The obtained zinc gallate nano material can further meet industrial requirements.

Owner:SHANGHAI JIAO TONG UNIV

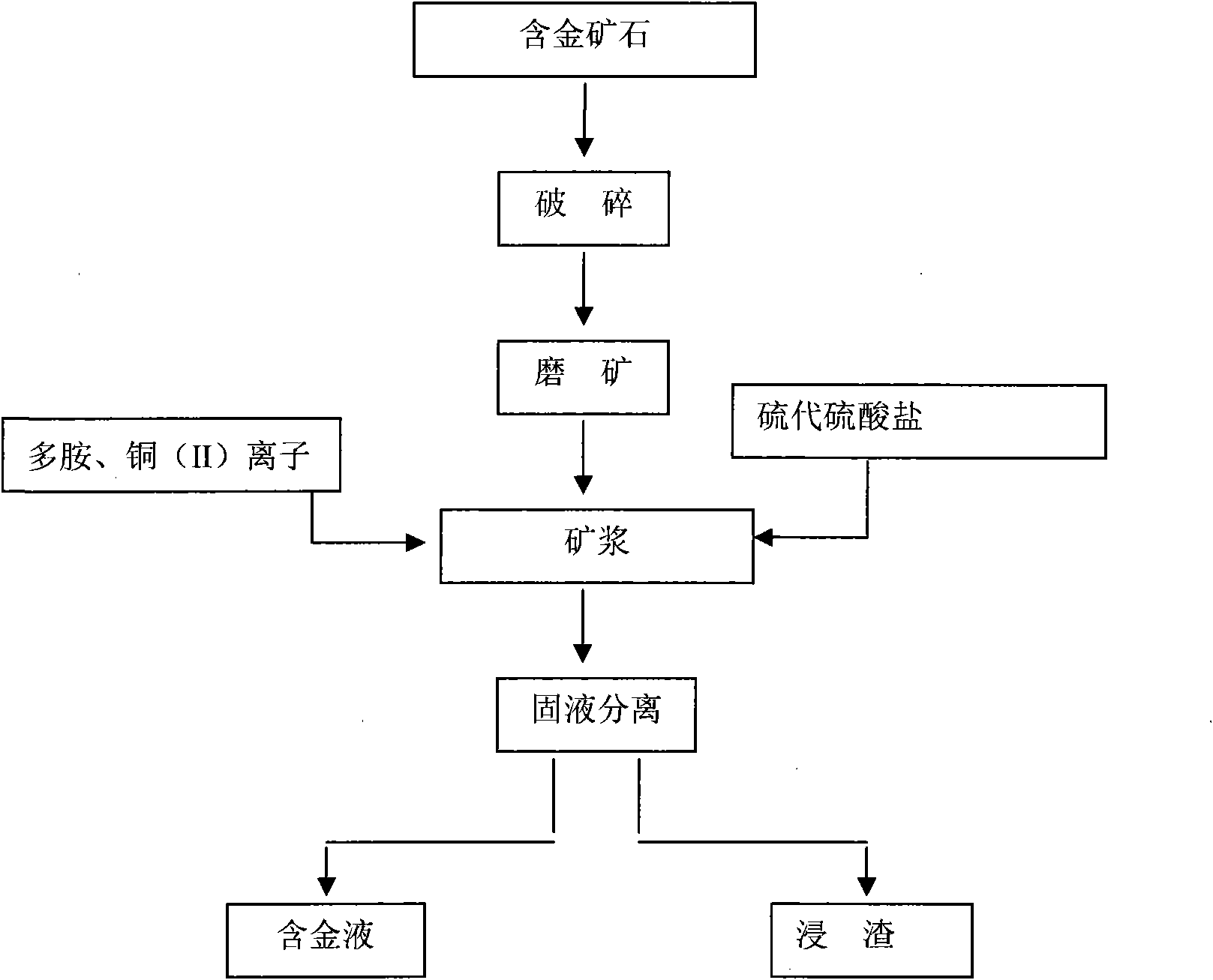

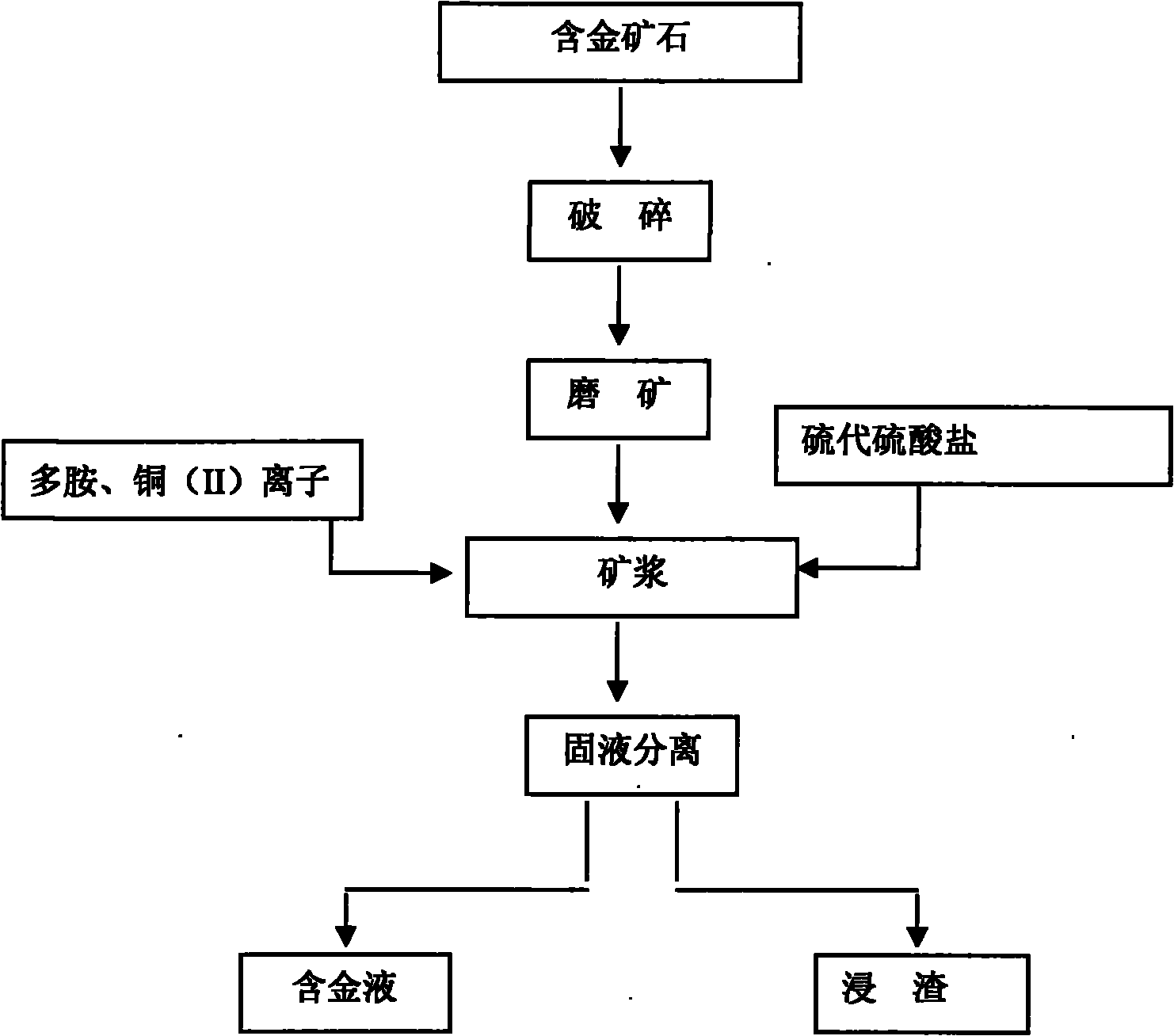

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com