Self-assembly preparation method of noble metal-graphene double-layer composite conductive film

A double-layer composite, precious metal technology, applied in metal material coating process, coating and other directions, can solve the problems of high equipment requirements, high cost, and difficult structure control of chemical vapor deposition method, and achieve reliable preparation method and good electrical conductivity. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

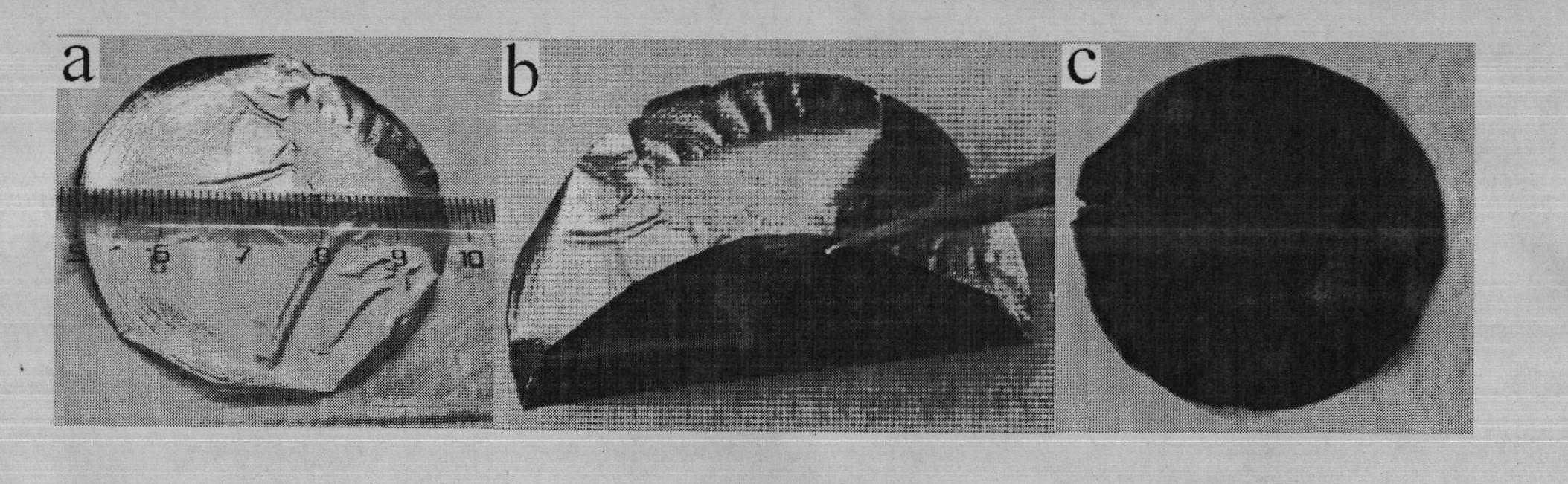

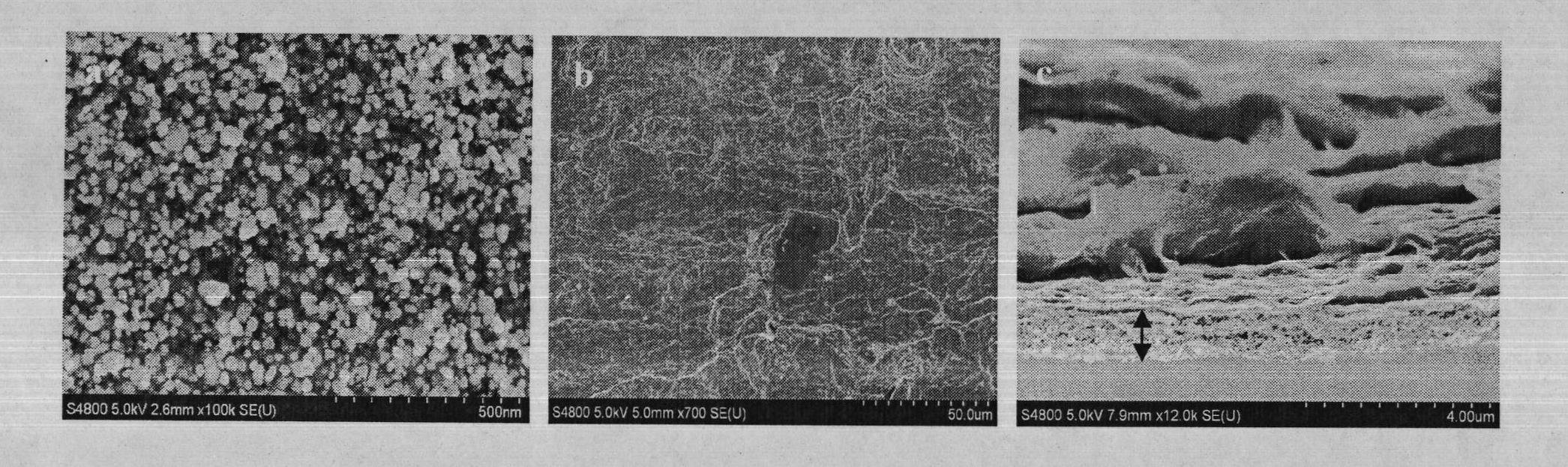

[0014] Example 1: Mix 1 mL of silver nitrate aqueous solution (5 mg / mL) with 8 mL of graphene oxide ethanol dispersion (2 mg / mL), then add 0.1 mL of dispersant solution (0.1 mg / mL), ultrasonically disperse for 10 minutes, and mix liquid was transferred to a glass substrate. The solvent was evaporated at a constant temperature at 50° C. to form a film, and the obtained film was treated with hydrazine vapor for 24 hours to obtain a silver-graphene double-layer composite conductive film.

Embodiment 2

[0015] Example 2: Mix 2 mL of silver nitrate solution (5 mg / mL) with 7 mL of graphene oxide aqueous dispersion (2 mg / mL), then add 0.2 mL of dispersant (0.1 mg / mL), ultrasonically disperse for 10 minutes, and dissolve the mixture Transfer to a Teflon substrate. The solvent was evaporated at a constant temperature at 30° C. to form a film, and the obtained film was treated with hydrazine vapor for 24 hours to obtain a silver-graphene double-layer composite conductive film.

Embodiment 3

[0016] Example 3: Mix 6 mL of silver ammonia solution (5 mg / mL) with 3 mL of graphene oxide methanol dispersion (2 mg / mL), then add 0.05 mL of dispersant (0.1 mg / mL), ultrasonically disperse for 10 minutes, and dissolve the mixture onto polycrystalline silicon substrates. The solvent was evaporated at a constant temperature at 50° C. to form a film, and the obtained film was treated with hydrazine vapor for 24 hours to obtain a silver-graphene double-layer composite conductive film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com