Metal-modified eutectic zeolite catalyst with EUO (Europium Oxide) structure as well as preparation method and application thereof

A eutectic zeolite and metal modification technology, which is applied in the direction of catalyst activation/preparation, isomerization to hydrocarbons, molecular sieve catalysts, etc., can solve the problems of low conversion ability, low activity and selectivity, and achieve simple preparation process, The effect of good catalytic performance and good mechanical crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

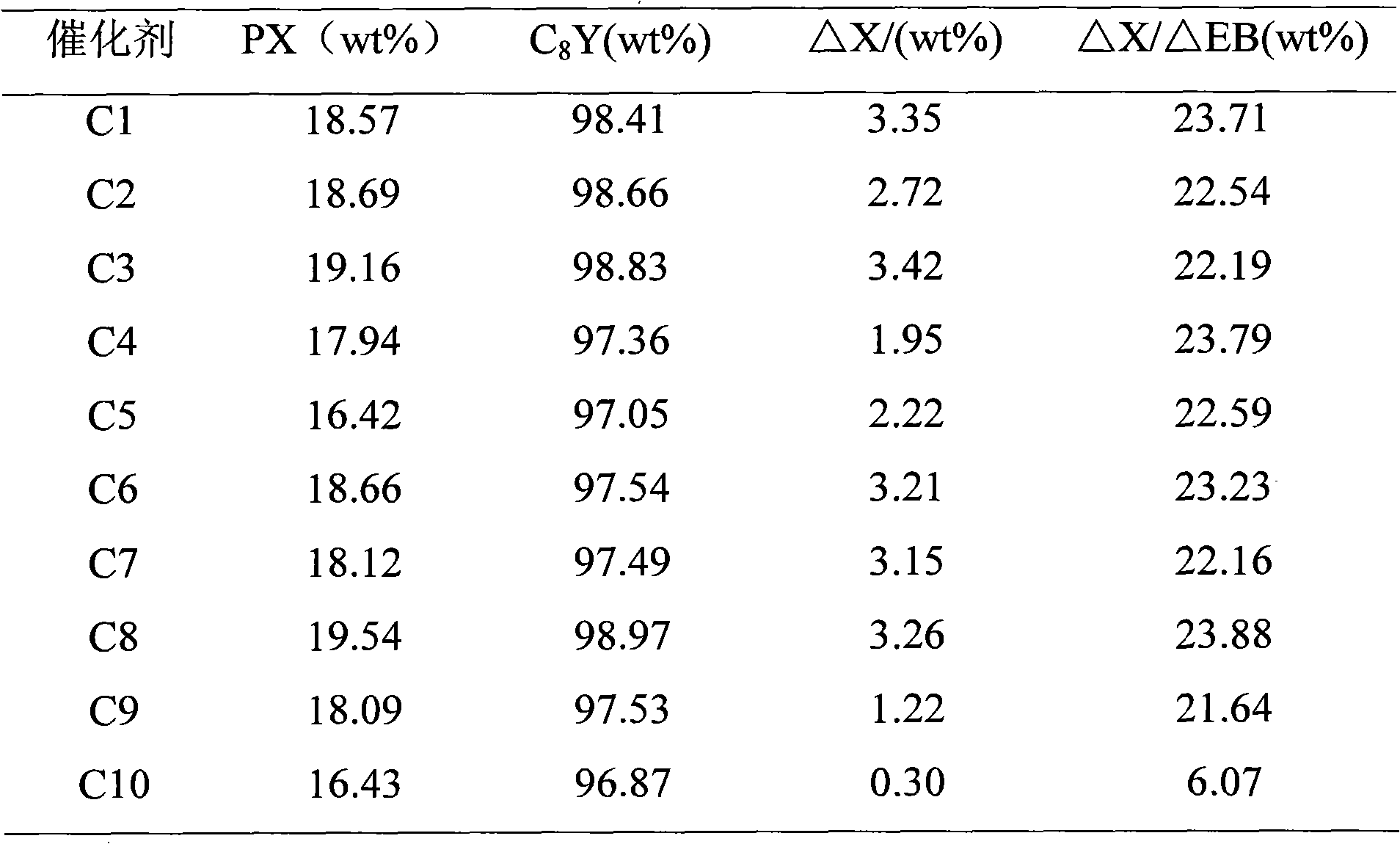

[0017] Preparation of catalyst C1 containing 35.0 wt% EU-1 / MOR eutectic zeolite with a Si / Al ratio of 30, 63.15 wt% alumina and 0.35 wt% platinum and 1.50 wt% cerium.

[0018] The EU-1 / MOR eutectic zeolite with a Si / Al ratio of 30 is fully mixed with aluminum hydroxide powder, the prepared 3wt% nitric acid aqueous solution is added to the powder mixture and mixed evenly, and then the mixture is extruded into rods. The strip mixture was allowed to stand at room temperature for 4 hours, and then dried at 120°C for 6 hours, then the strips were cut into pellets with a length of 3 to 8 mm (wherein the particles of 4 to 6 mm accounted for more than 80%), and dried in air. It was calcined at 500° C. for 4 hours under an atmosphere to prepare a support. According to zeolite: NH 4 The ratio of Cl=1:0.26 was used to prepare a 3wt% ammonium chloride aqueous solution, and then ion-exchange the prepared support with the ammonium chloride aqueous solution for 2 hours under the condition o...

Embodiment 2

[0020] Preparation of catalyst C2 containing 50.0 wt% EU-1 / MOR eutectic zeolite with a Si / Al ratio of 60, 48.15 wt% alumina, 0.35 wt% platinum and 1.50 wt% cerium.

[0021] The EU-1 / MOR eutectic zeolite with a Si / Al ratio of 60 was calcined at 350°C for 4 hours in nitrogen with 5% oxygen concentration, then fully mixed with aluminum hydroxide powder, and the prepared 3wt% nitric acid aqueous solution was added to the Mix well in the powder mixture, then extrude the mixture into bars. The strip mixture was allowed to stand at room temperature for 4 hours, and after drying at 110°C for 6 hours, the strips were cut into pellets, with a length of 3 to 8 mm (wherein the particles of 4 to 6 mm accounted for more than 80%). It was calcined at 550° C. for 4 hours under an atmosphere to prepare a support. According to zeolite: NH 4The ratio of Cl=1:0.26 was used to prepare a 3wt% ammonium chloride aqueous solution, and then ion-exchange the prepared support with the ammonium chloride...

Embodiment 3

[0023] Preparation of catalyst C3 containing 35.0 wt% EU-1 / MOR eutectic zeolite with a Si / Al ratio of 30, 64.40 wt% alumina and 0.10 wt% platinum and 0.50 wt% cerium.

[0024] The EU-1 / MOR eutectic zeolite with a Si / Al ratio of 30 is fully mixed with aluminum hydroxide powder, the prepared 3wt% nitric acid aqueous solution is added to the powder mixture and mixed evenly, and then the mixture is extruded into rods. The strip mixture was allowed to stand at room temperature for 4 hours, and then dried at 120°C for 6 hours, then the strips were cut into pellets with a length of 3 to 8 mm (wherein the particles of 4 to 6 mm accounted for more than 80%), and dried in air. It was calcined at 500° C. for 4 hours under an atmosphere to prepare a support. Prepare an aqueous solution of 3wt% ammonium chloride at the ratio of zeolite:NH4Cl=1:0.26, then ion-exchange the prepared support with the aqueous solution of ammonium chloride in a water bath at 90°C for 2 hours, and wash until ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com