Method for extracting copper from scrap copper through wet process

A waste miscellaneous copper and wet process technology, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high energy consumption, high environmental protection pressure, and difficulty in directly obtaining cathode copper products, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

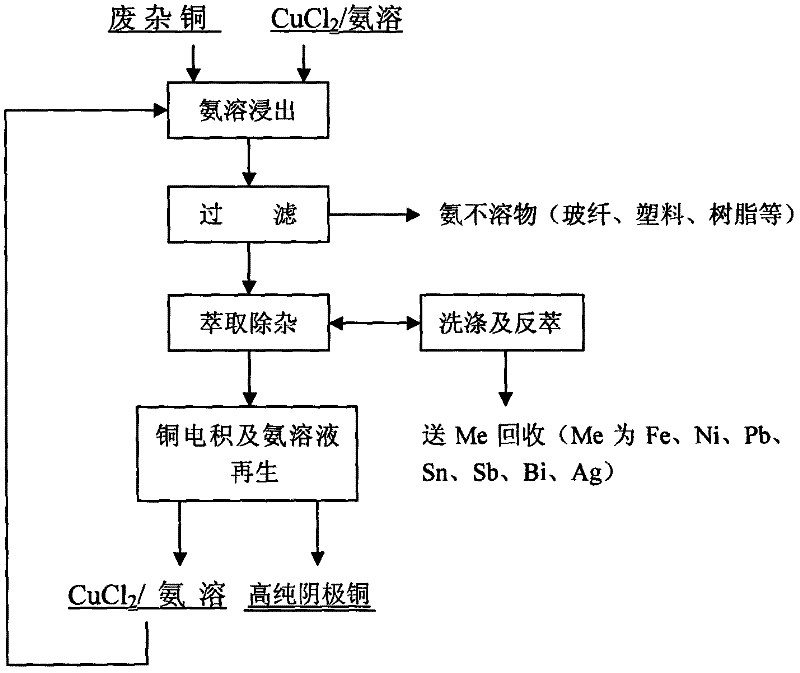

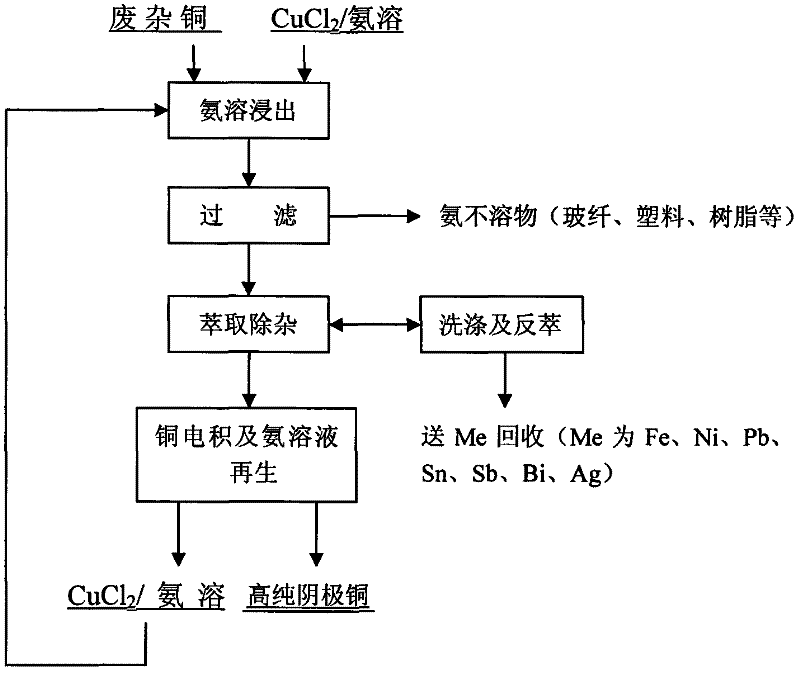

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 Shown, a kind of waste miscellaneous copper wet method extracts copper, comprises the steps:

[0033] A) ammonia leaching

[0034] Waste miscellaneous copper forms a suitable potential in the multi-component solution composed of ammonia, ammonia salt, monovalent copper chloride salt, and divalent copper chloride salt, and reacts with ammonium complex ions, and dissolves in the multi-component solution. Generate stable monovalent copper ammonium complex ions, filter most of the impurity metal elements Fe, Ni, Al, Sn, Pb in the scrap copper into the slag to separate from copper, and a small amount of impurities undergo oxidation reaction and react with ammonia molecules Complex ions with different coordination numbers are generated and exist in the solution.

[0035] The reaction that takes place in the ammoniacal leaching step is:

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com