Patents

Literature

1931 results about "Copper chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper forms two stable chlorides: Copper chloride, CuCl, mineral name nantokite. Copper chloride, CuCl₂, mineral name eriochalcite.

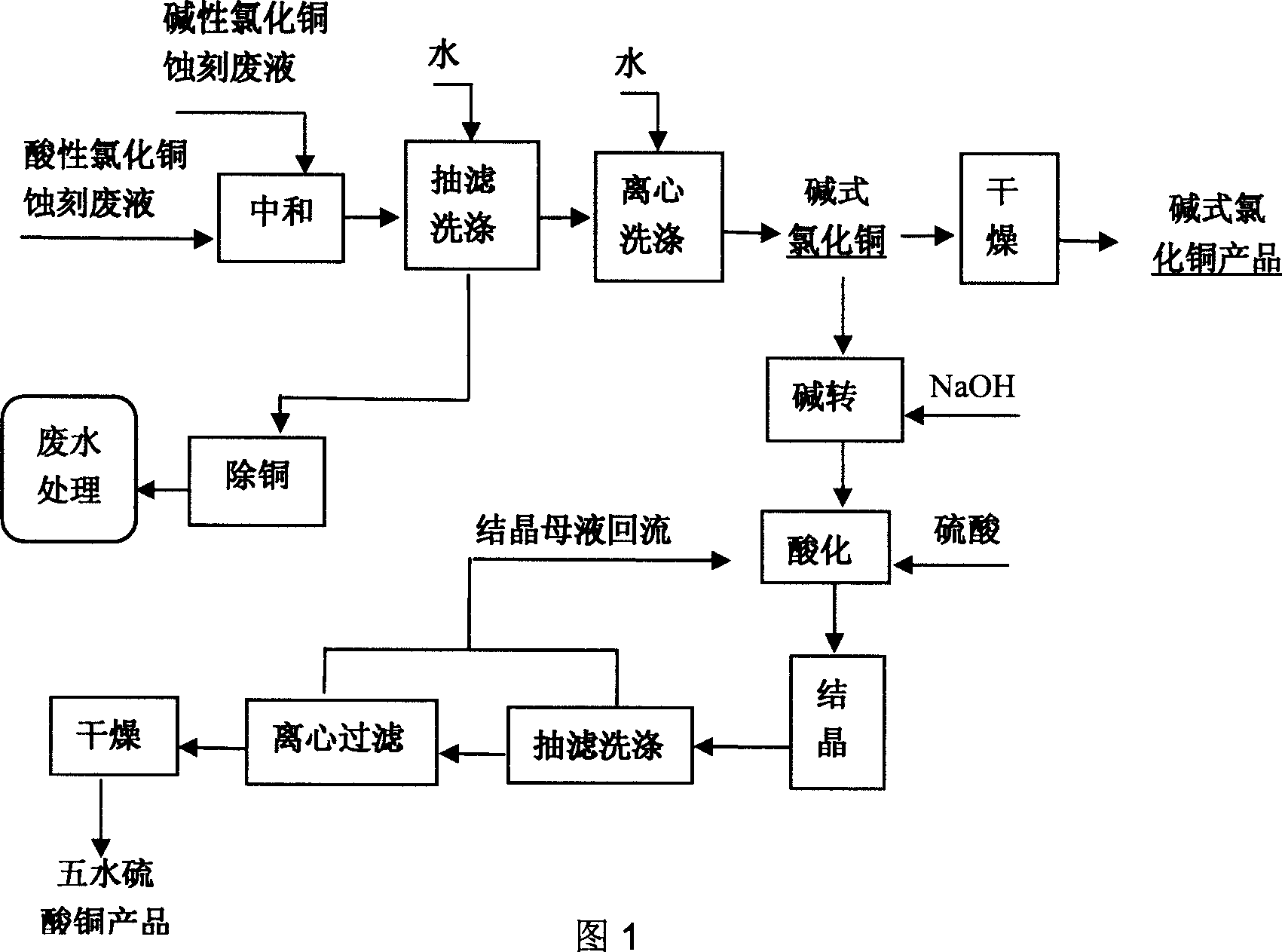

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

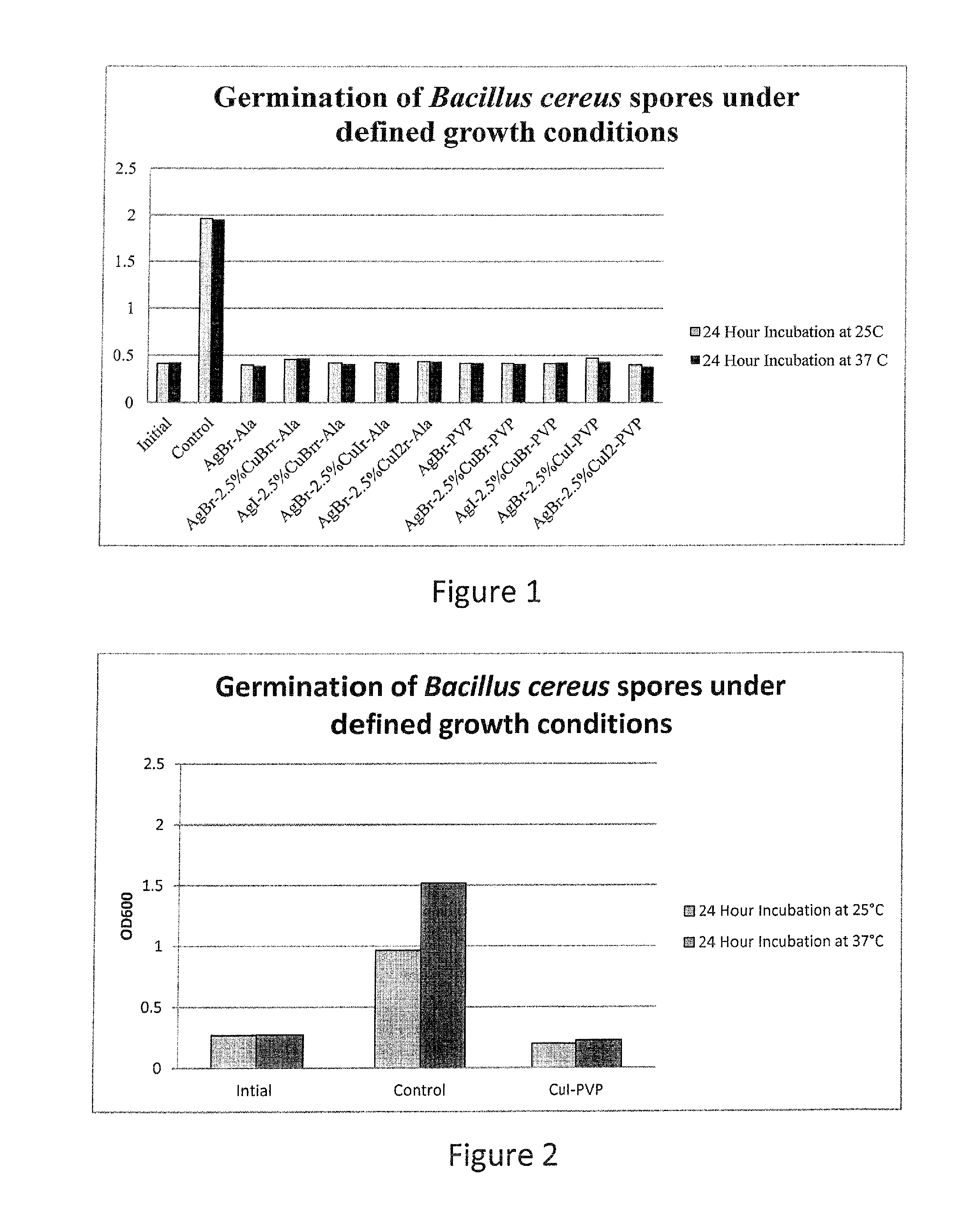

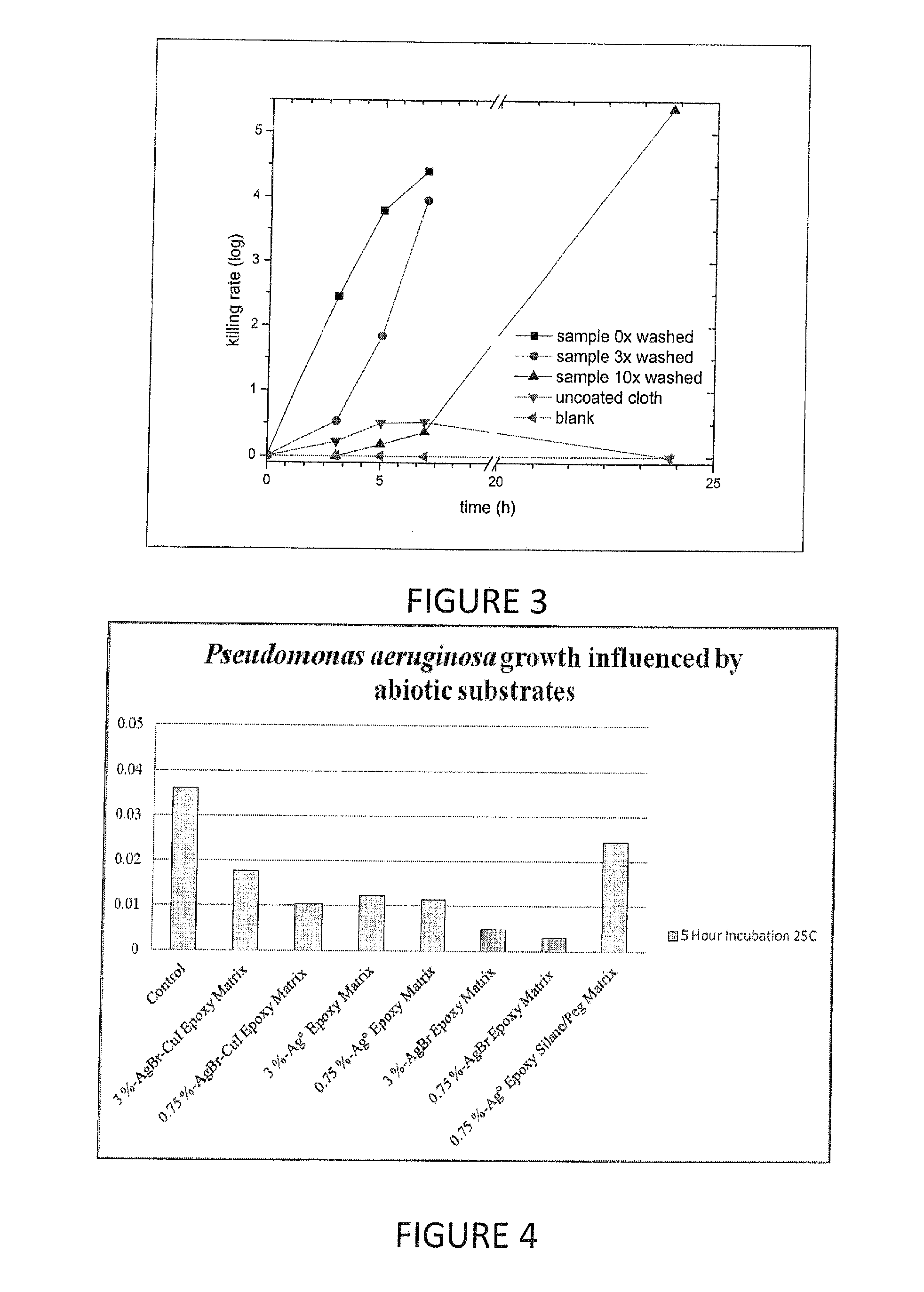

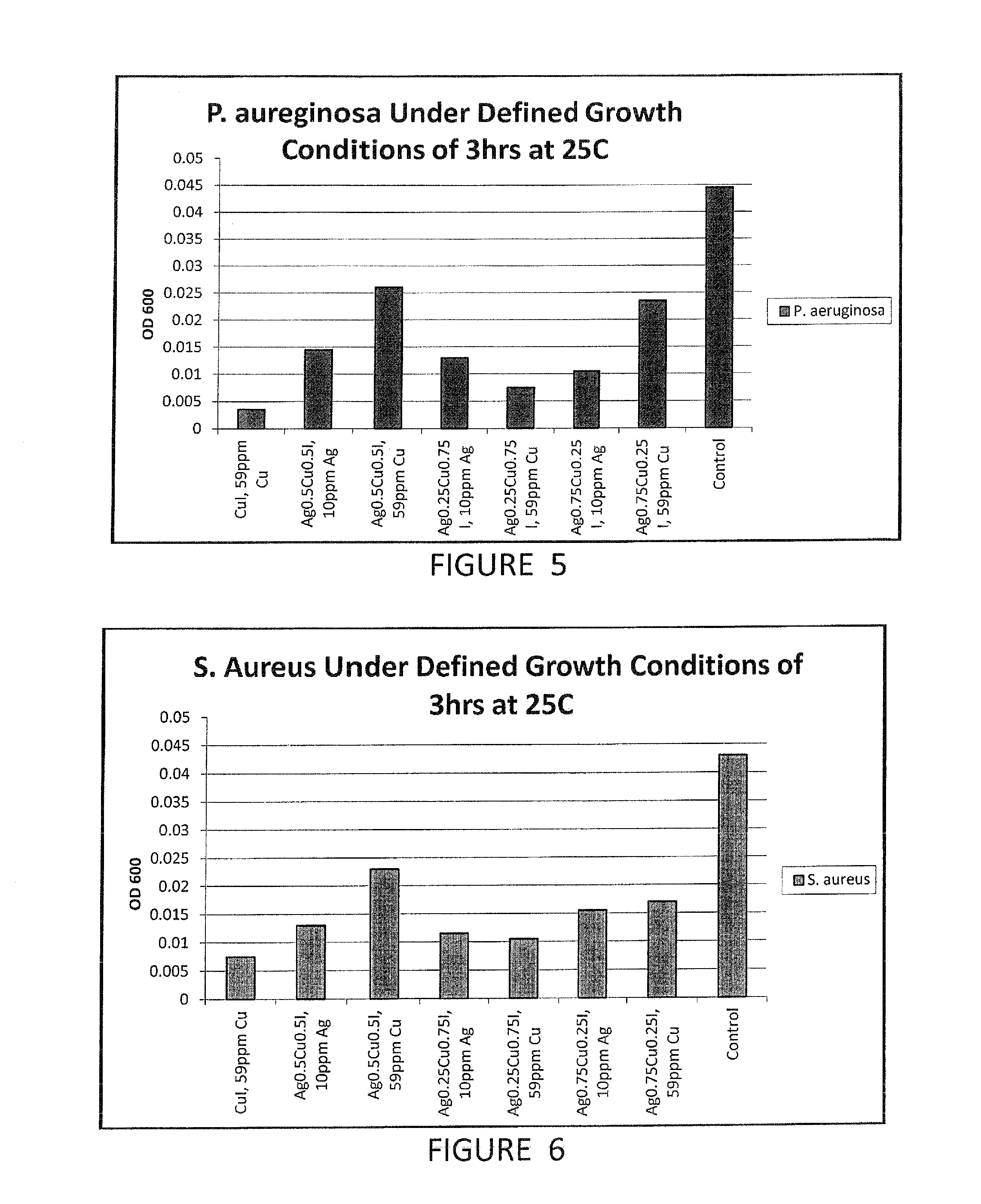

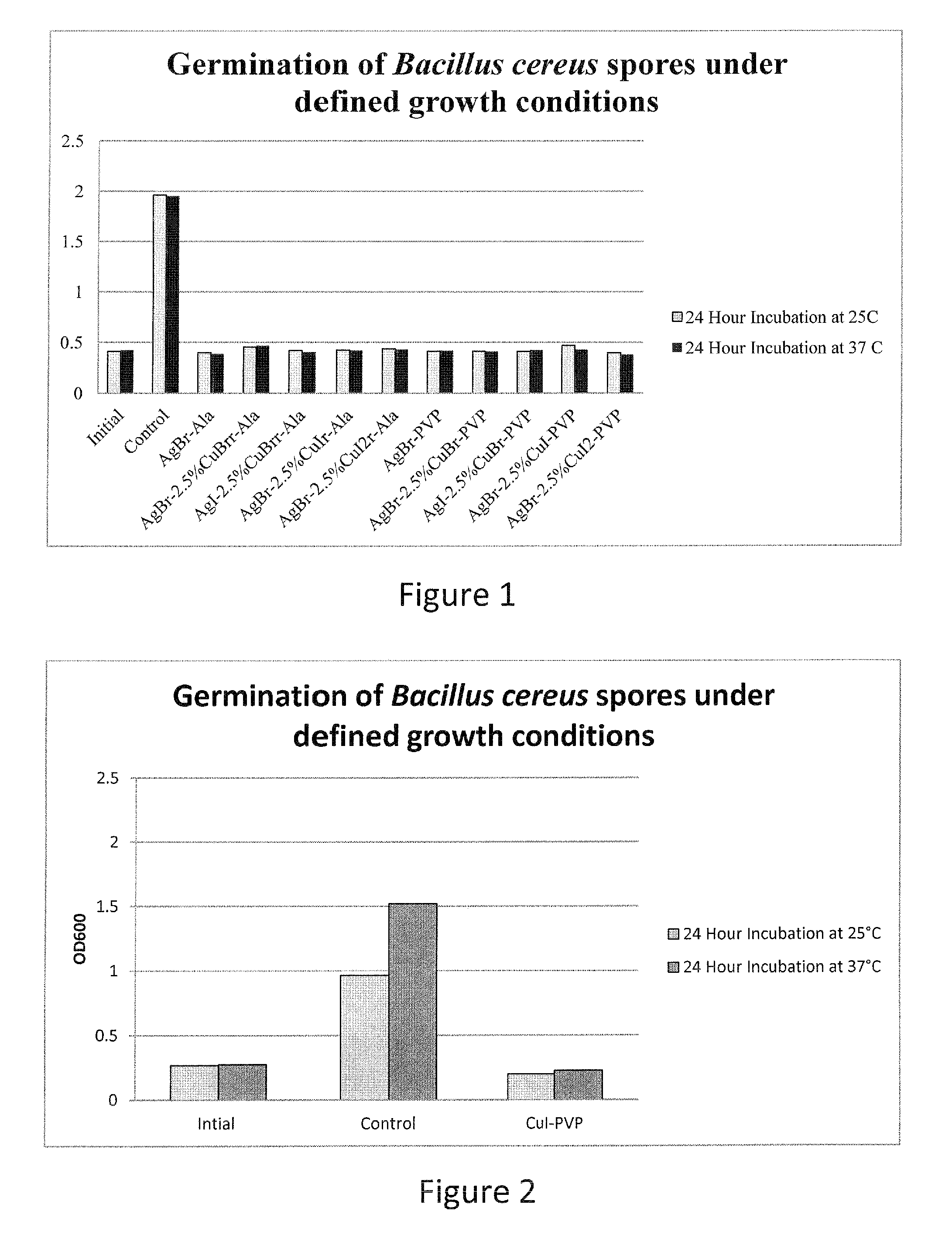

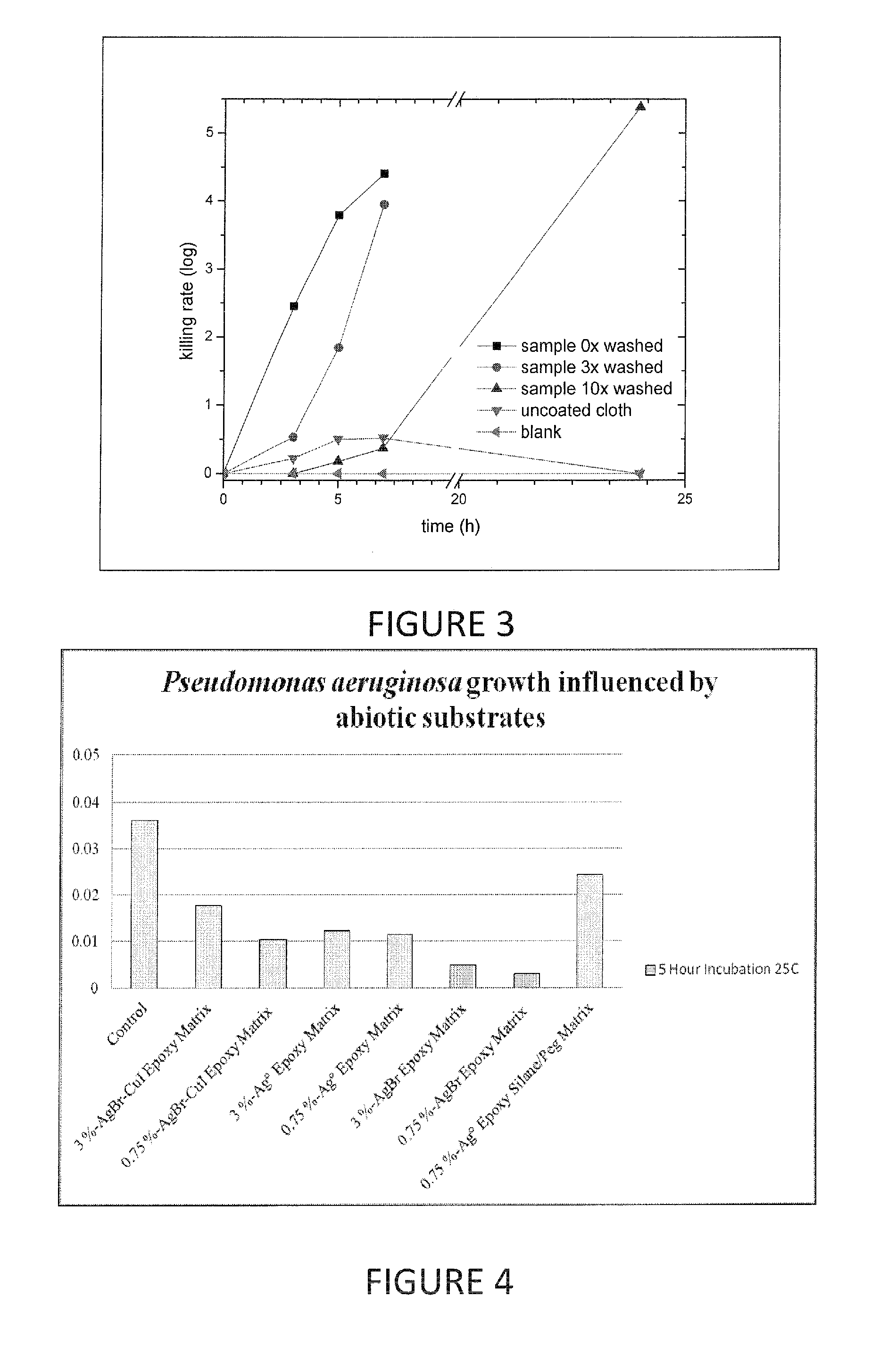

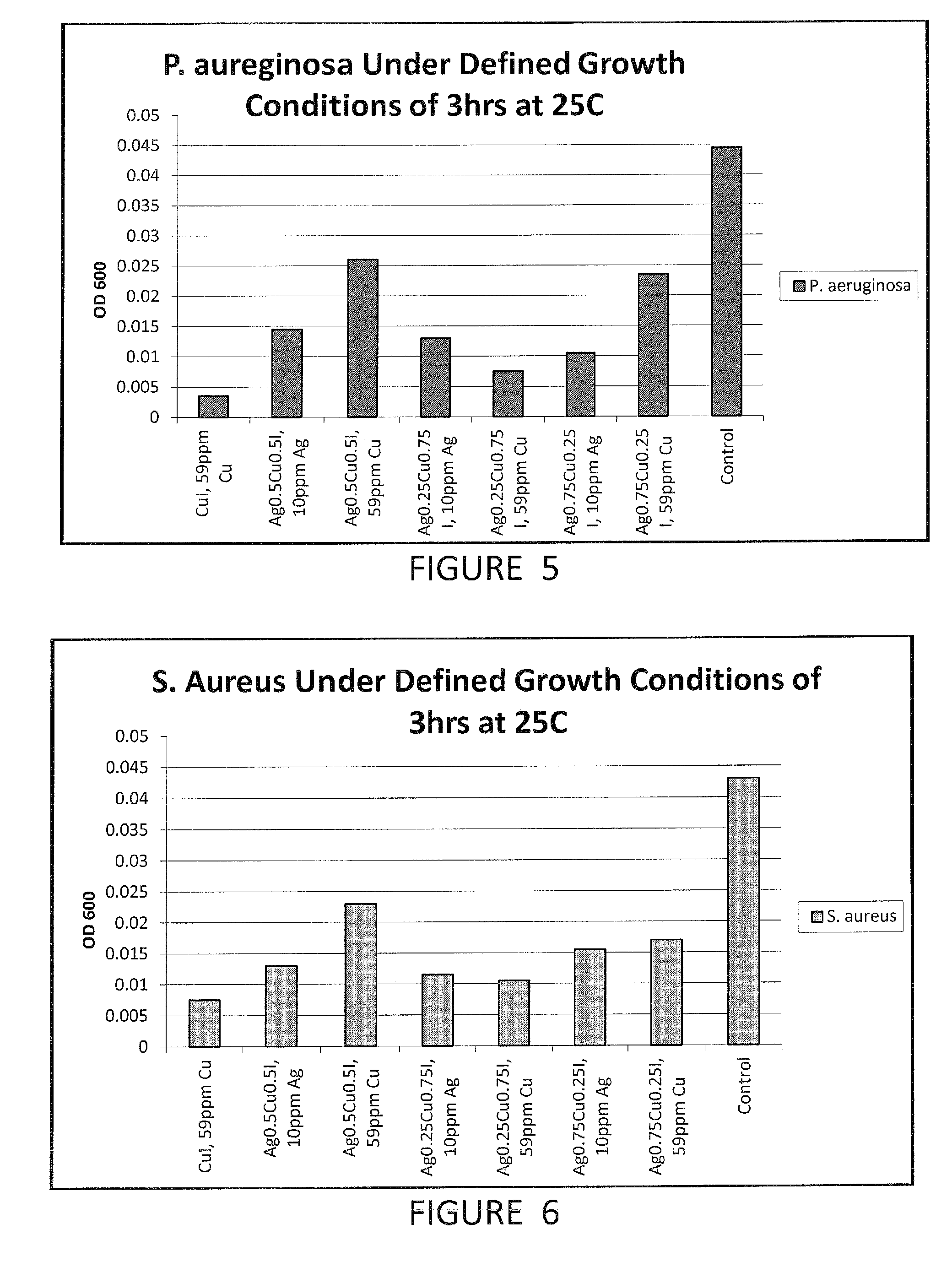

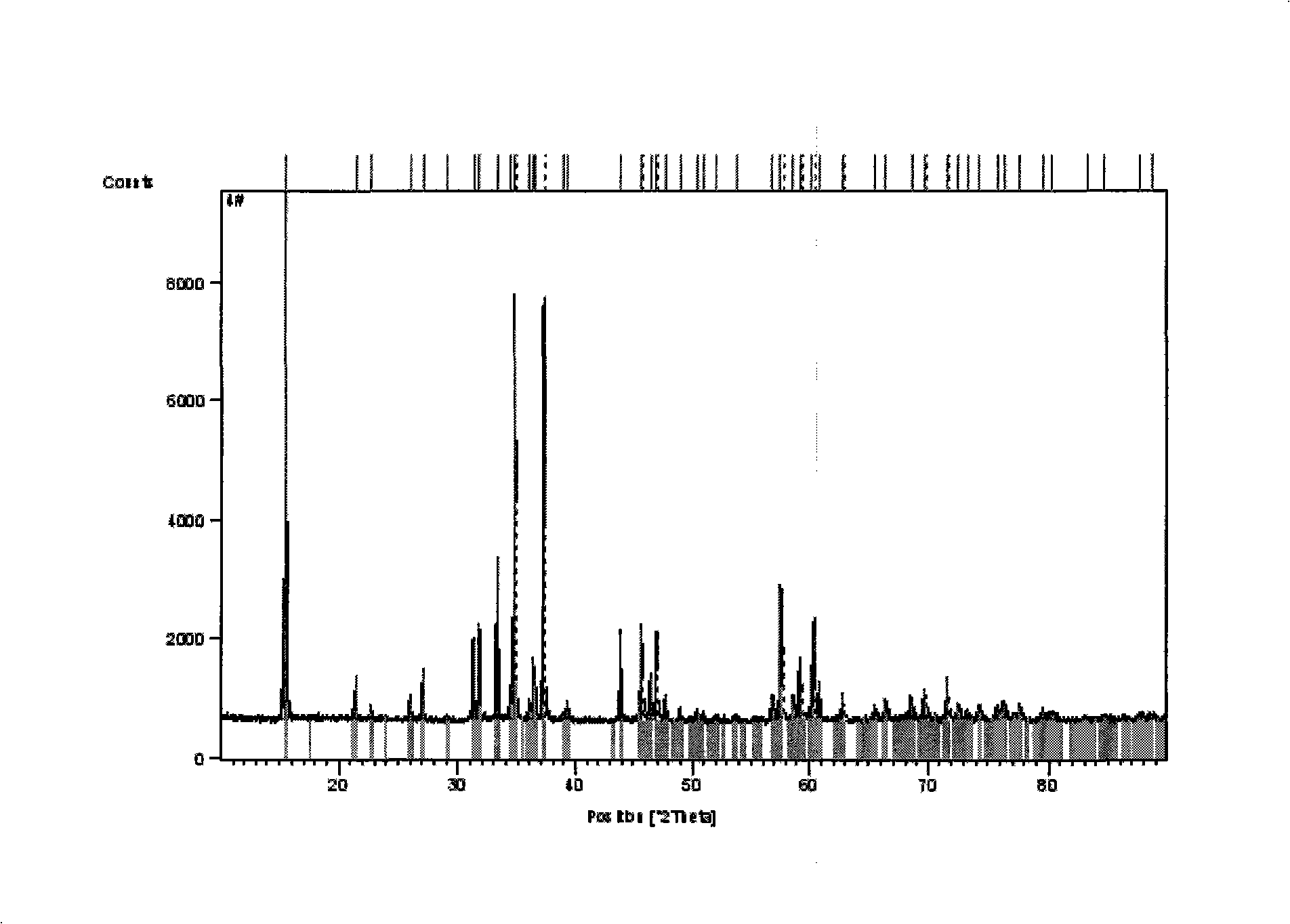

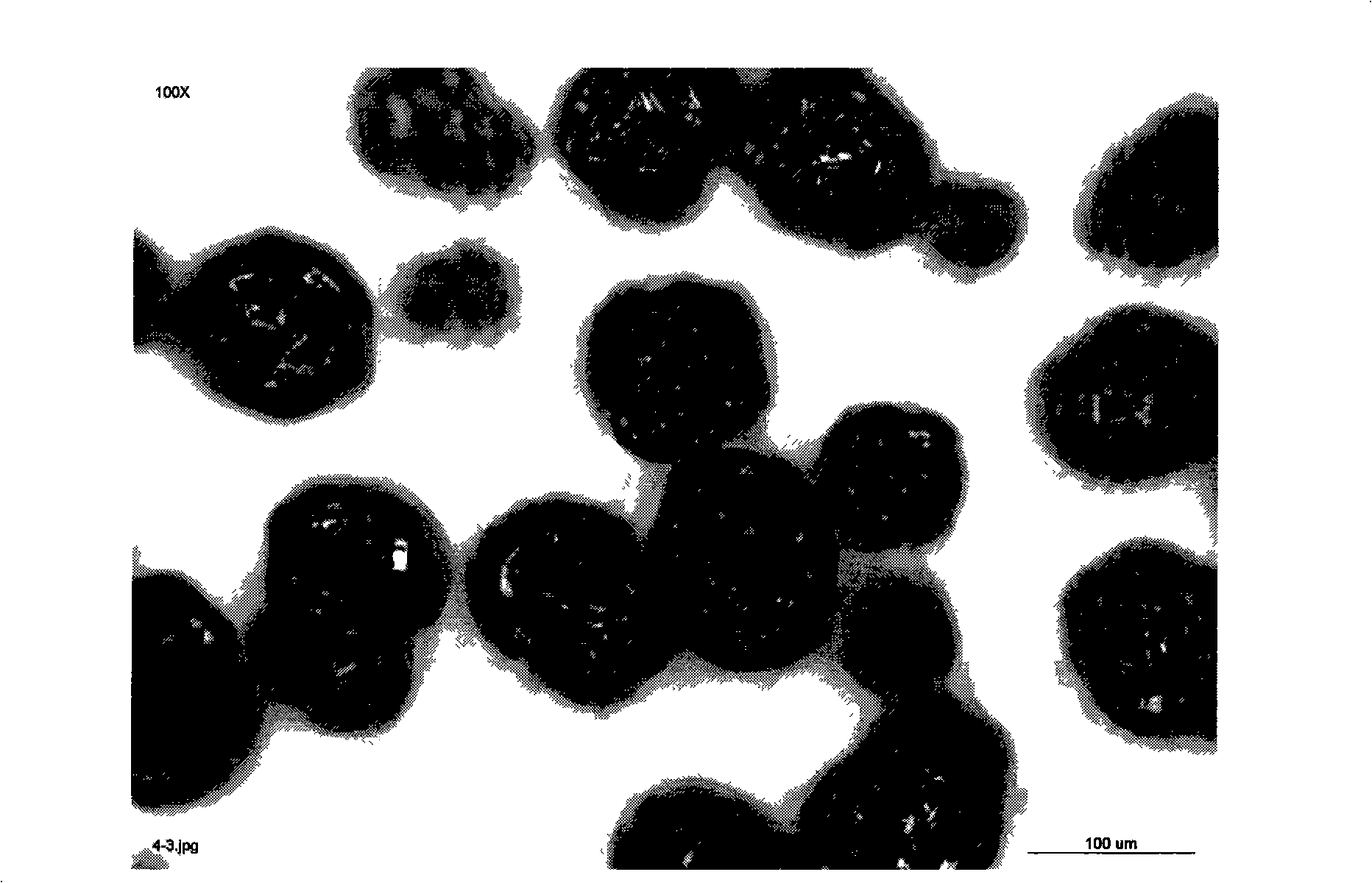

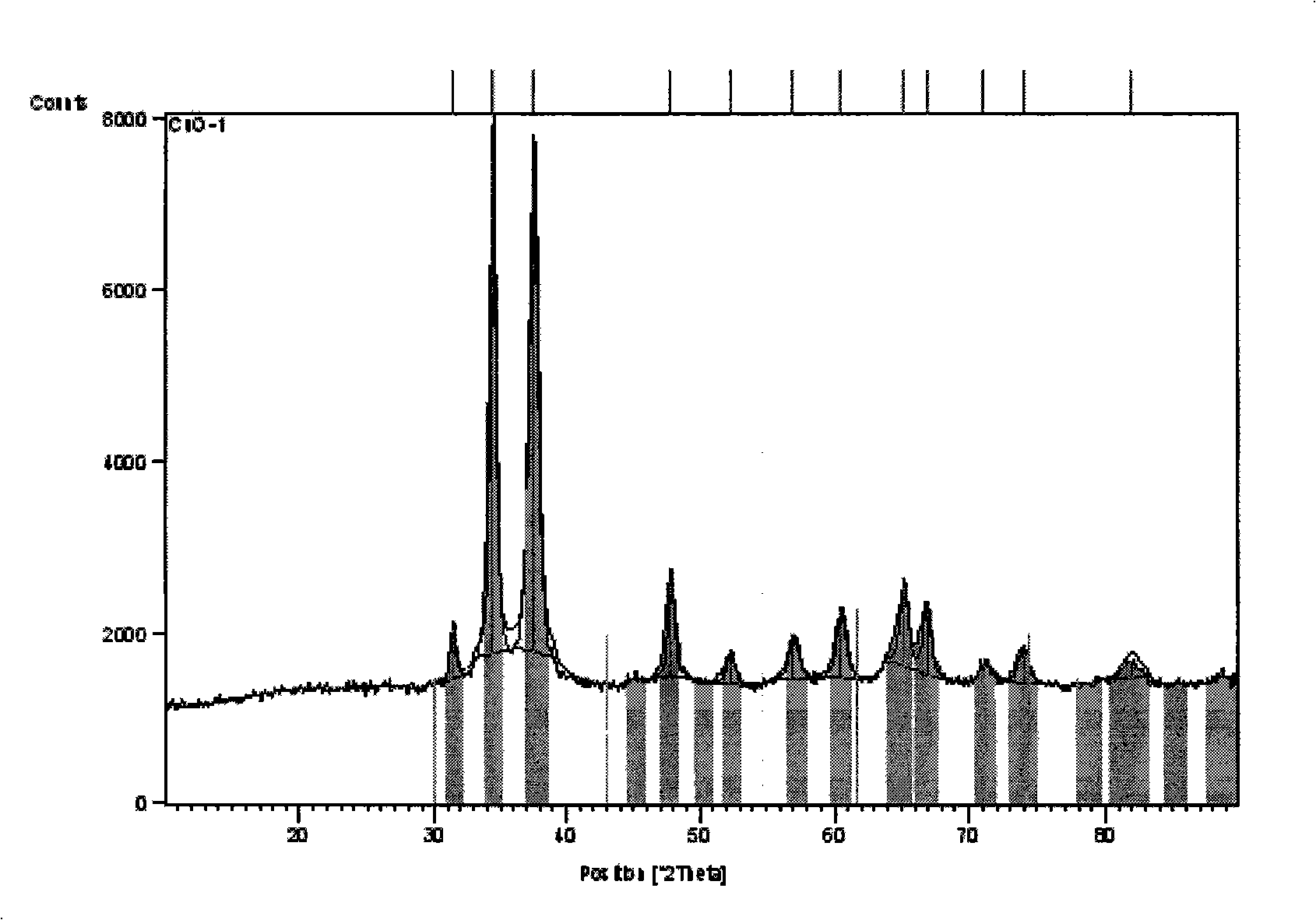

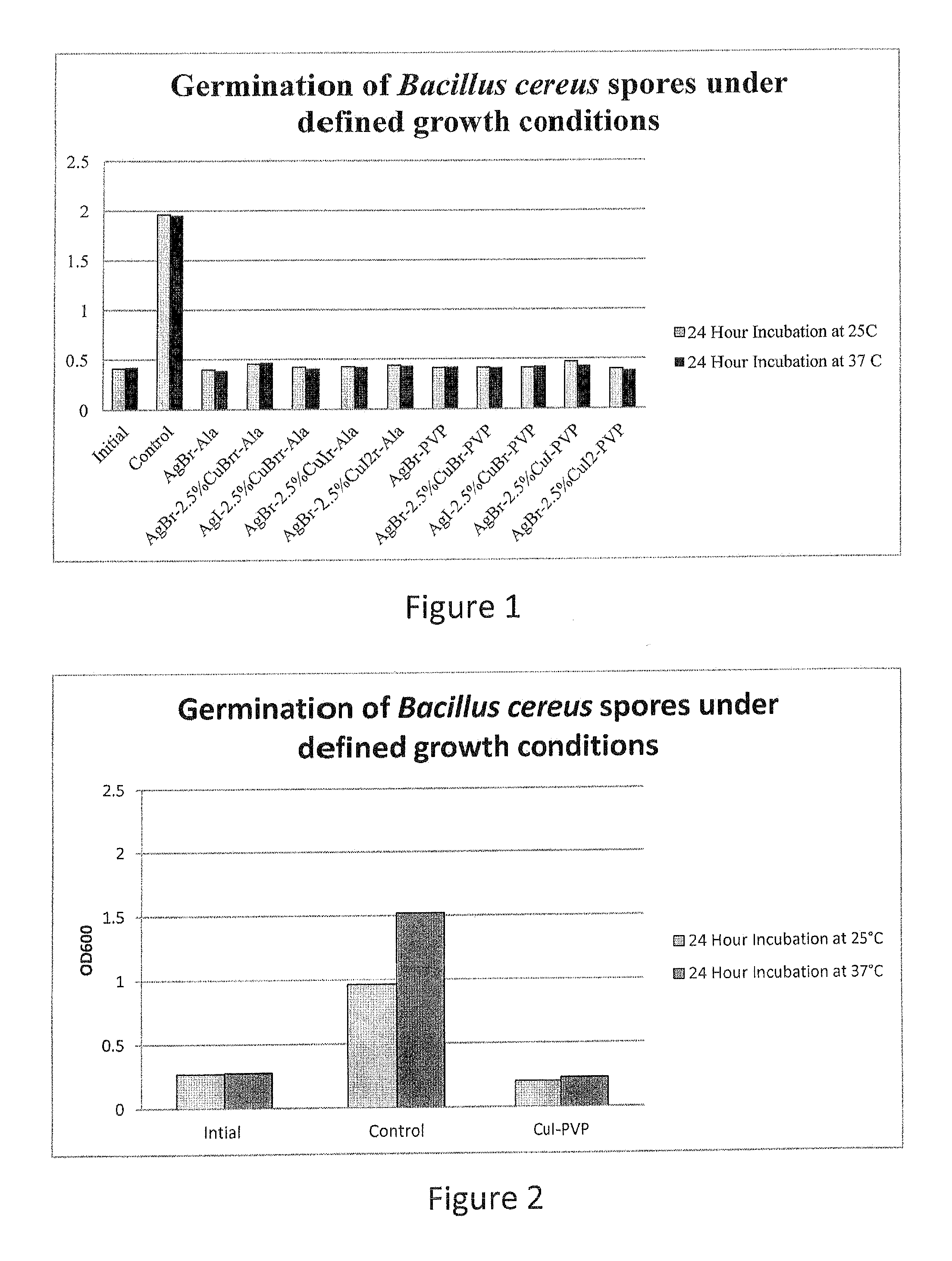

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20130315972A1Improve efficacyImprove utilizationBiocideInorganic active ingredientsHydrophilic polymersHydrophobic polymer

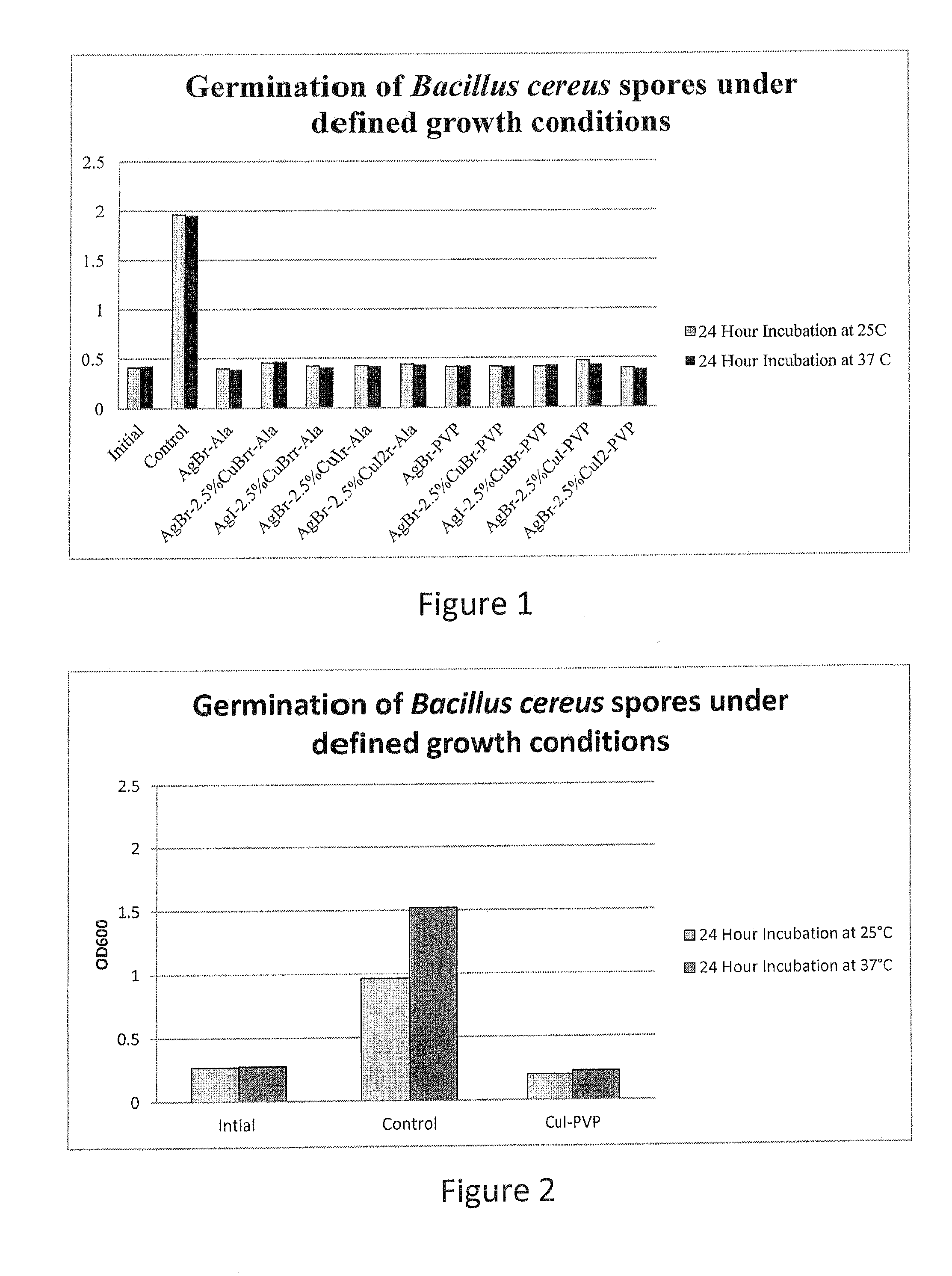

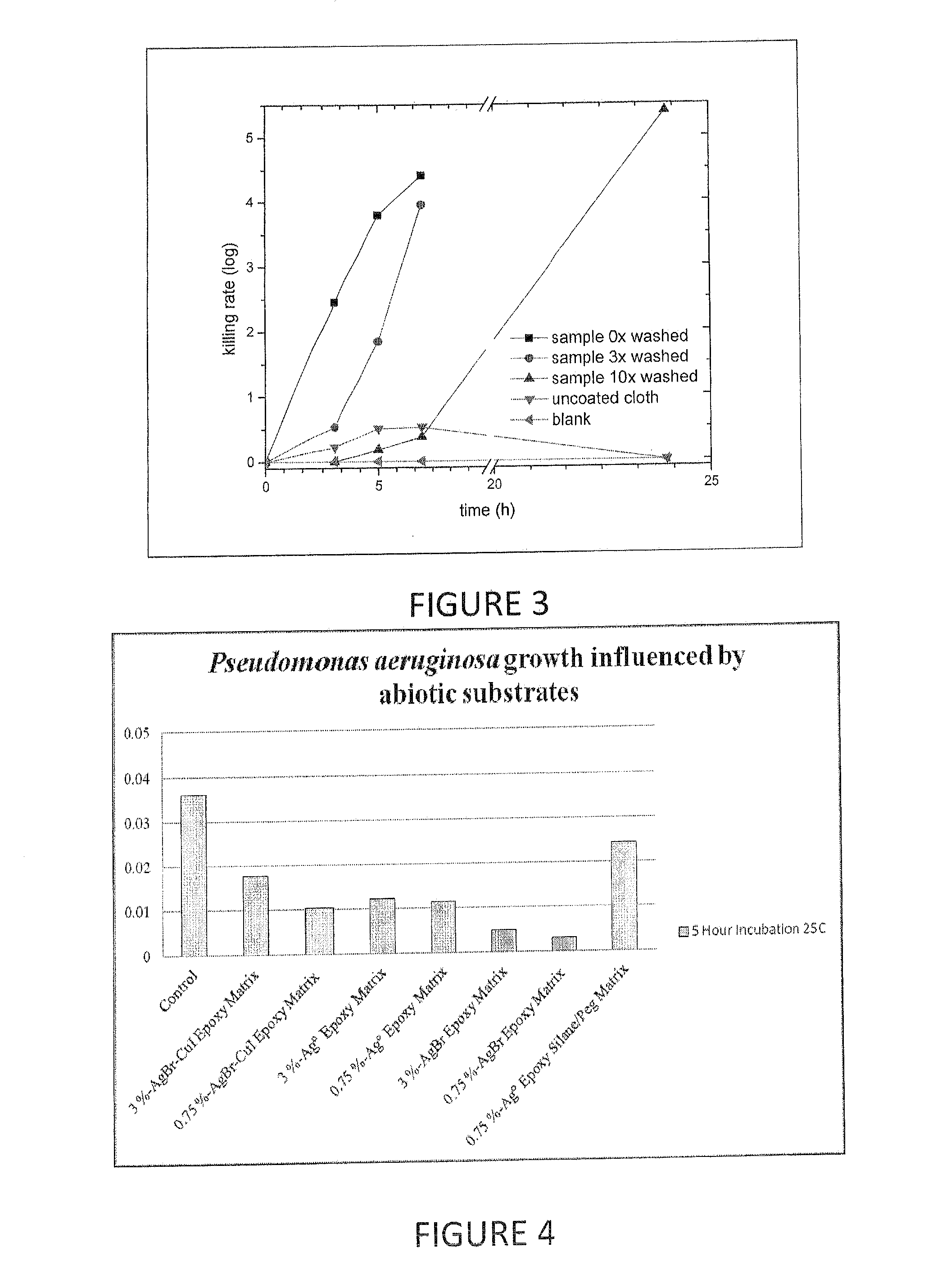

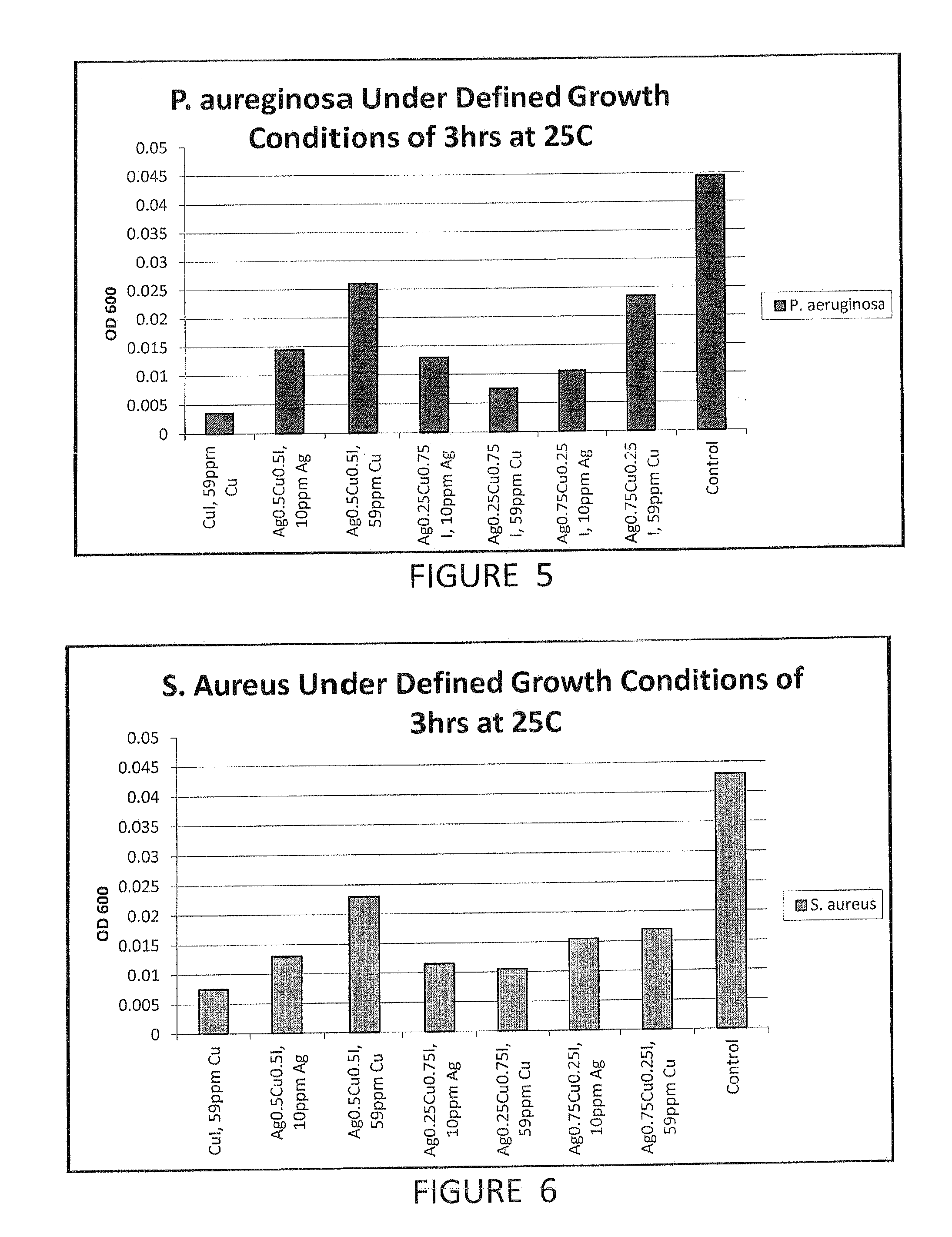

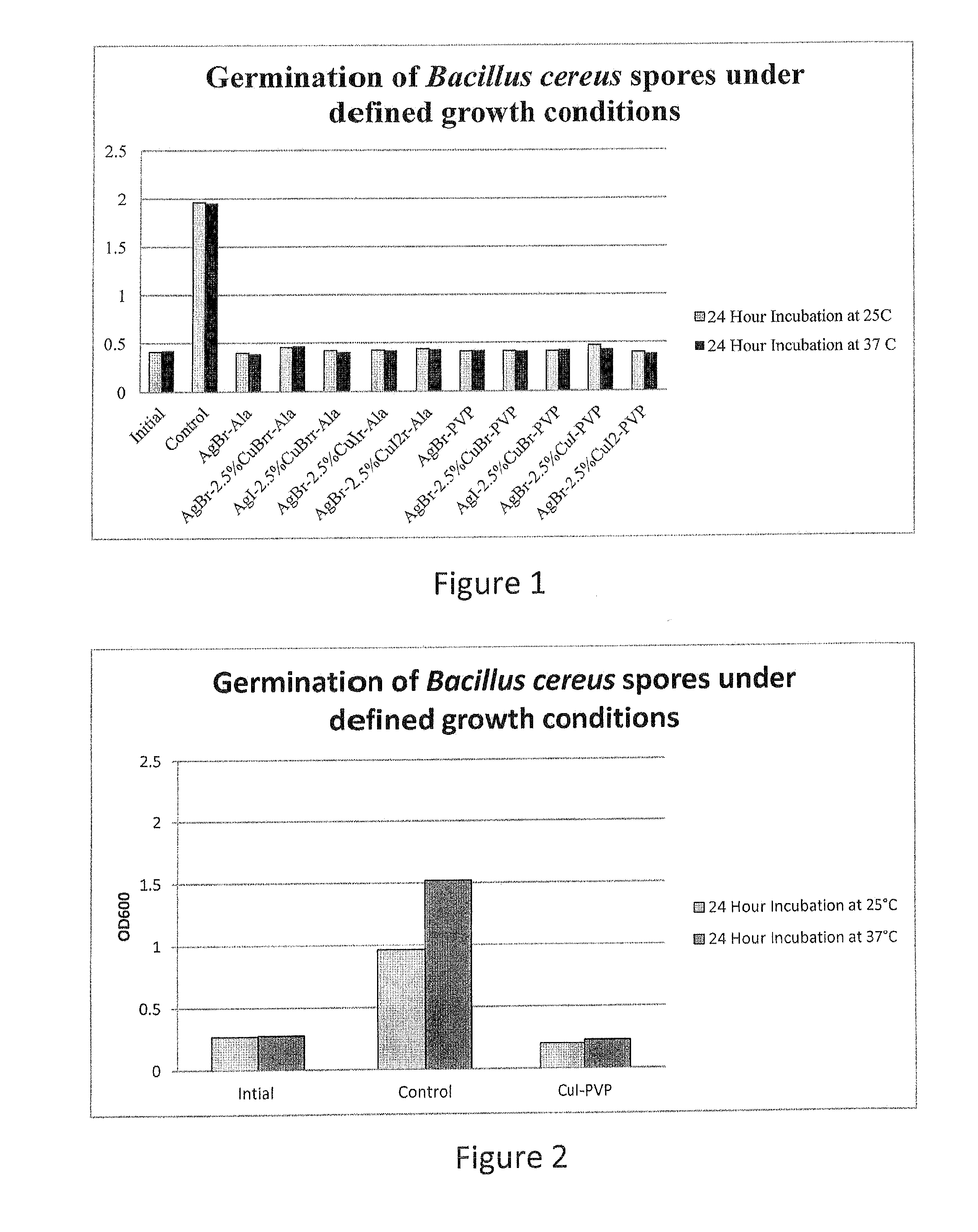

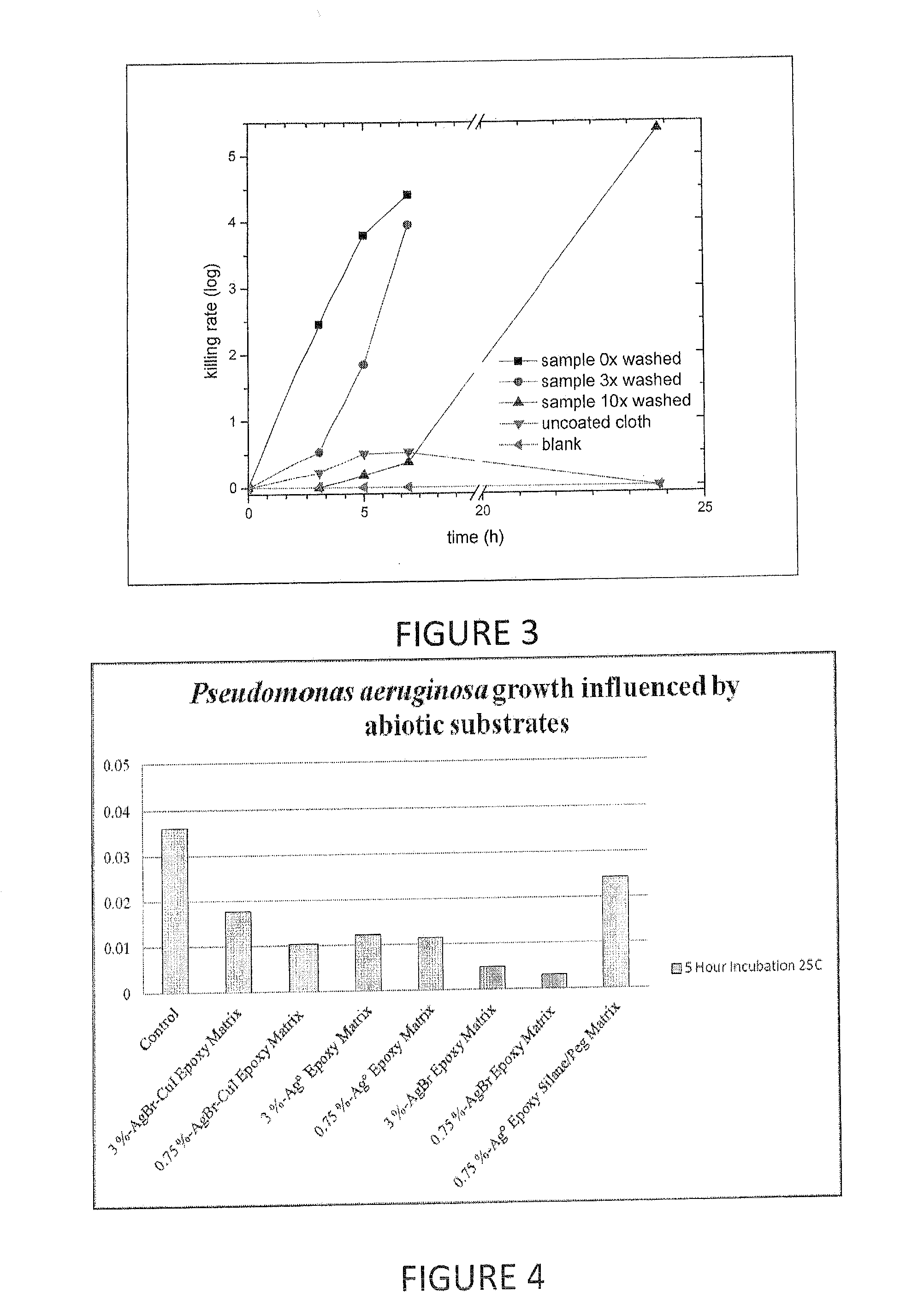

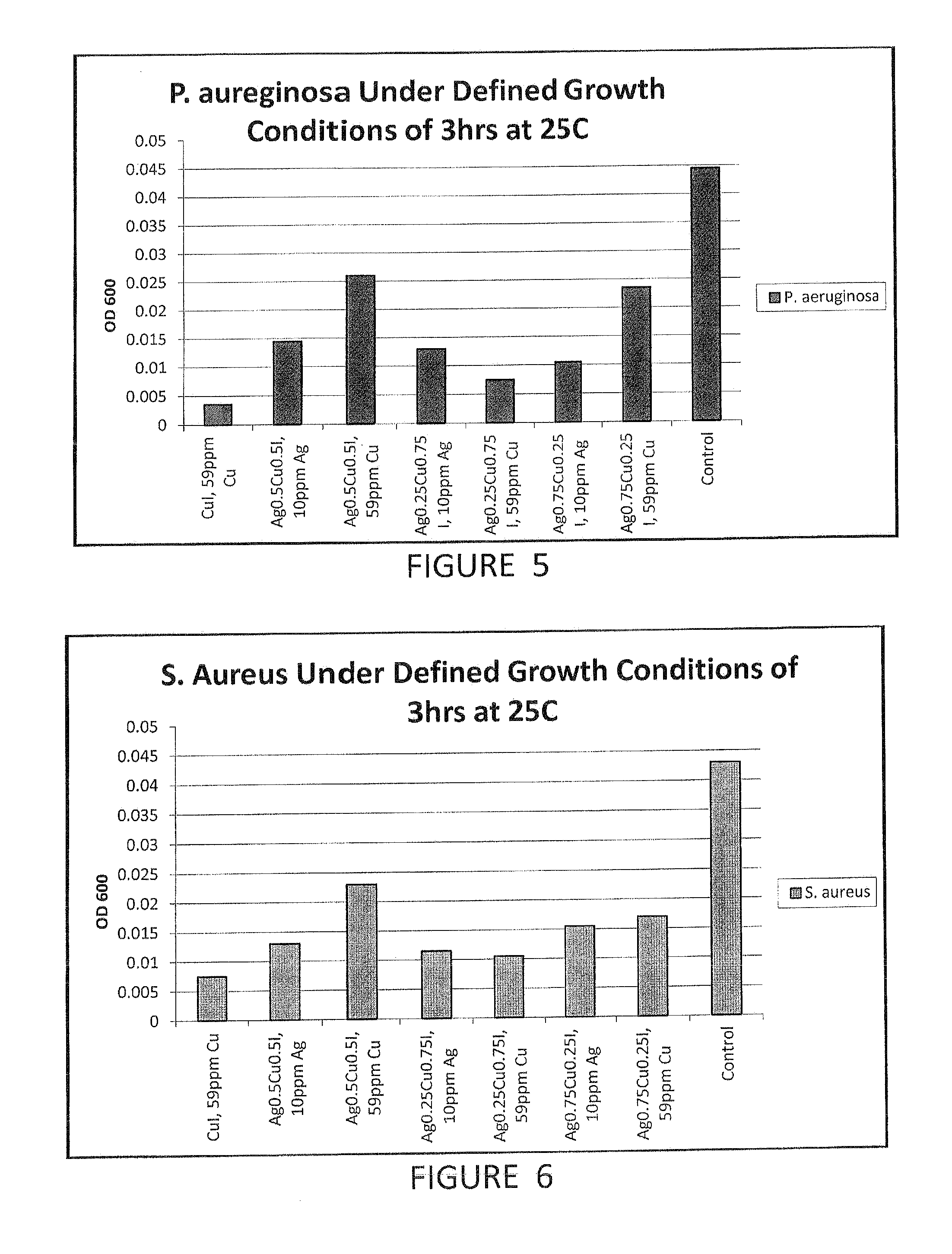

Compositions having antimicrobial activity contain particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 3 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride, most preferred being copper iodide. Preferred functionalizing agents comprise materials with a molecular weight of 60 or above, which include amino acids, other acidic materials, thiols, hydrophilic polymers, emulsions of hydrophobic polymers and surfactants. The functionalized particles are preferably made by a grinding process.

Owner:AGIENIC

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20120301528A1Good effectBiocideCosmetic preparationsHydrophilic polymersHydrophobic polymer

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers, emulsions of hydrophobic polymers and surfactants.

Owner:AGIENIC

Preparation method of nano cuprous oxide

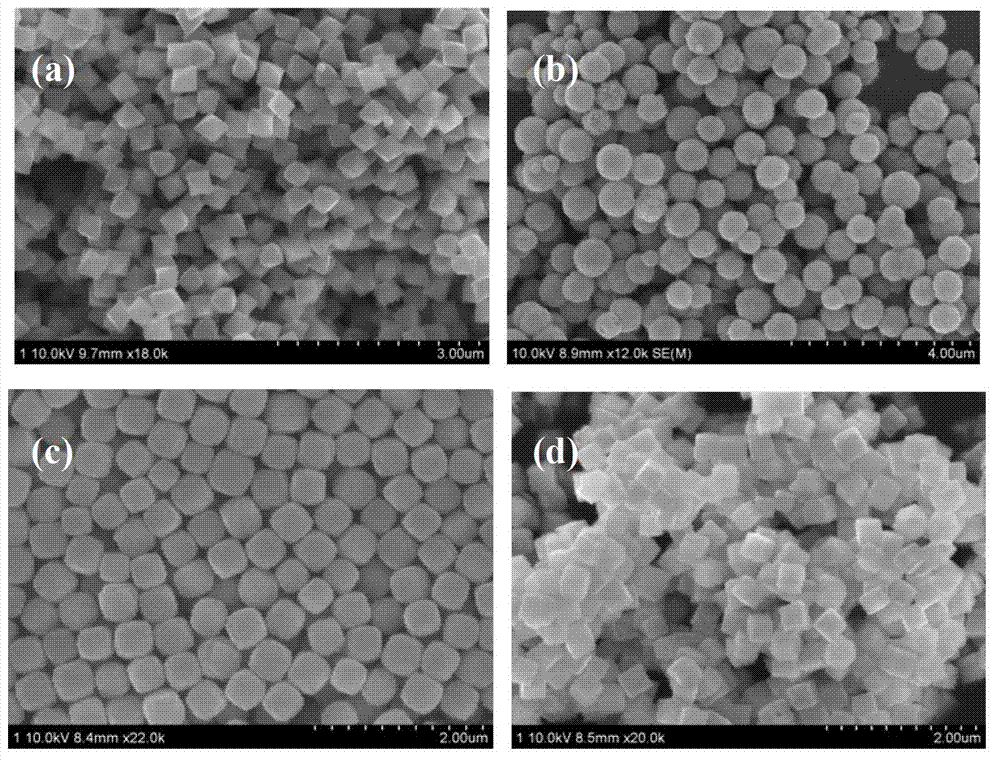

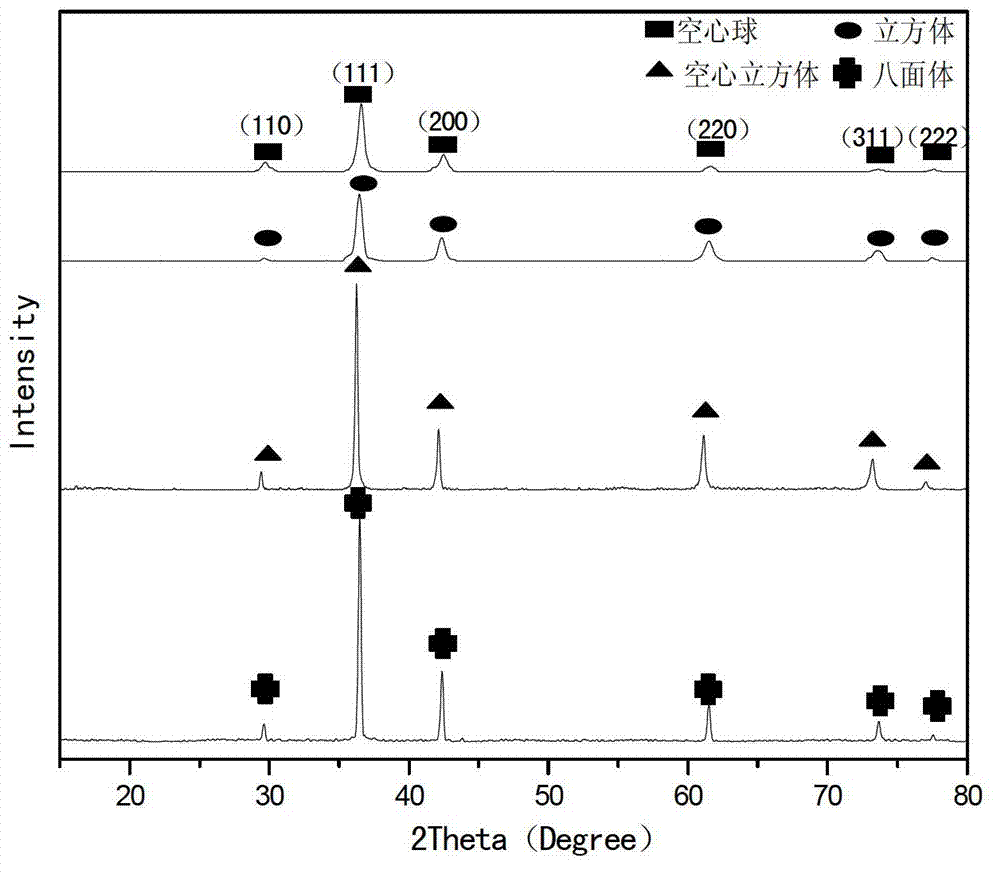

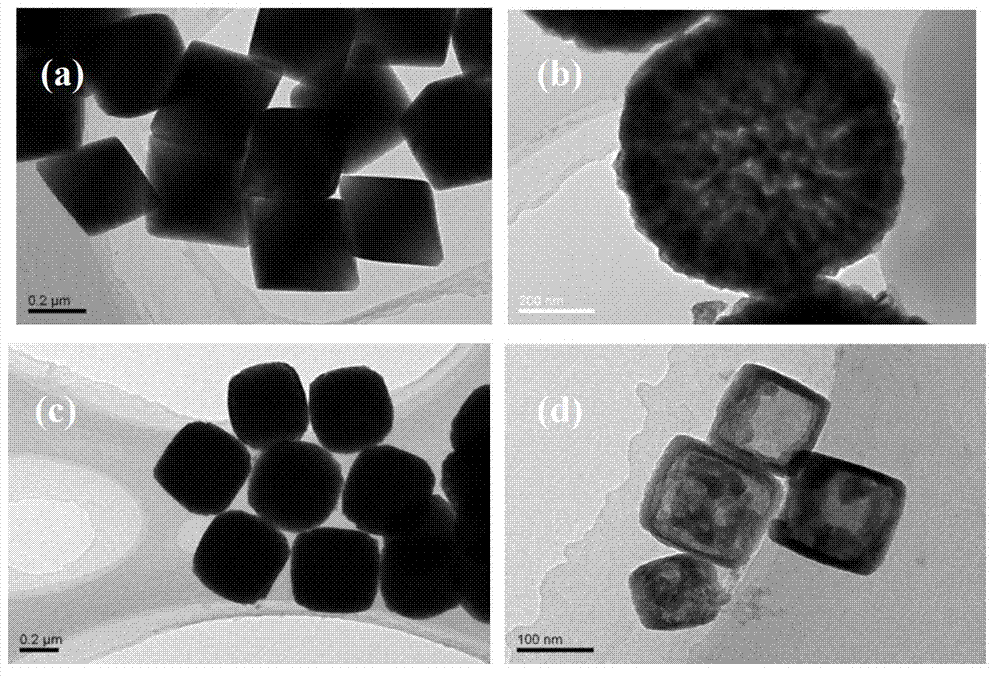

InactiveCN103172104AHigh purityNothing producedMaterial nanotechnologyCopper oxides/halidesOctahedronCopper nitrate

Owner:ZHEJIANG SCI-TECH UNIV

Process for production of gypsum/fiber board

ActiveUS20050161853A1Increase ratingsIncreased rehydration rateSolid waste managementWood working apparatusSlurryCellulose fiber

An improved process calcining a gypsum / cellulosic fiber slurry to produce a composite gypsum / cellulosic fiber product resides in adding a selected crystal modifier to the gypsum / cellulosic fiber slurry prior to the heating step to reduce the time necessary to carry out the calcination process, to reduce the temperature at which the calcination process is run or to increase the aspect ratio of the acicular calcium sulfate alpha hemihydrate crystals formed during the calcination process. Useful crystal modifiers include aluminum sulfate, aluminum chloride, chlorine, zinc sulfate, iron (III) sulfate, aluminum sulfate hexadecahydrate, iron (II) sulfate heptahydrate, iron (III) sulfate pentahydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, copper chloride dehydrate, manganese sulfate monohydrate and trisodium phosphate.

Owner:UNITED STATES GYPSUM CO

Nursery pig concentrated feed

ActiveCN101606639AImprove orderImprove immunityFood processingAnimal feeding stuffAdditive ingredientThreonine

The invention relates to a pig feed, in particular to a nursery pig concentrated feed, comprising the following raw materials by weight proportion: 30-50 of sucking pig composite vitamin, 30-50 of low copper mineral element, 60-100 of peeled soybean meal, 100-180 of fermented soybean meal, 100-150 of extruded soybean, 110-180 of steam fish meal, 50-100 of dried porcine soluble, 60-120 of acid whey powder, 80-90 of glucose powder, 5-10 of glutamine, 80-100 of chyle fat powder, 40-49 of calcium carbonate, 12-14 of basic zinc chloride, 4-6 of salt, 55-60 of calcium biphosphate, 6-10 of sodium butyrate, 12-15 of lysine, 6-8 of threonine, 4-6 of TP-100 enzyme, 4-5 of cysteine, 5-7 of se-enriched yeast and 6-10 of copper chloride hydroxide. The nursery pig concentrated feed has the advantages of milk nutrition composition simulation, good palatability, high digestibility, large feed intake because the baby pigs like to eat and improvement of survival rate as well as immunity of the nursery pigs.

Owner:江西大佑农生物科技有限公司

Low-mercury catalyst for acetylene hydrochlorination

InactiveCN102380407AEasy to makeLow costPhysical/chemical process catalystsPreparation by halogen halide additionO-Phosphoric AcidPtru catalyst

Disclosed is a low-mercury catalyst for acetylene hydrochlorination. Mercuric chloride is carried on activated carbon. Raw materials comprise, by weight, 100 parts of activated carbon, 4-5 parts of mercuric chloride, 8-10 parts of total essential assistant, 1-5 parts of total non-essential assistant, wherein the essential assistant comprises 2-5 parts of bismuth chloride, 1-5 parts of cerium chloride, 1-5 parts of barium chloride and 2-5 parts of copper chloride; and the non-essential assistant comprises at least one of potassium chloride, phosphoric acid, zinc chloride and cuprous chloride. After being subjected to surface subtraction and drying on acid and oxidizing conditions, activated carbon is in reflux treatment with urea solution; and the catalyst can be prepared by soaking the treated activated carbon with HgC12 dissolved in hydrochloric acid and assistant solution sufficiently after urea is removed by steps of heating, washing the activated carbon with hydrochloric acid and finally drying the same. The carrying capacity of mercuric chloride in the catalyst is lower so that cost for the catalyst is reduced and consumption of mercury resources is decreased. Furthermore, activity and stability of the low-mercury catalyst are much higher than those of the existing high-mercury catalyst, and reforming rate and selectivity of reaction of vinyl chloride can be 99.7% and be higher than 99.8%. Accordingly, the low-mercury catalyst for acetylene hydrochlorination is suitable for industry production and is environment-friendly.

Owner:CHENGDU HUIEN FINE CHEM

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20120301531A1Good effectAntibacterial agentsBiocideHydrophilic polymersHydrophobic polymer

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers emulsions of hydrophobic polymers and surfactants.

Owner:UHLMANN DONALD R +3

Corrosive agent for displaying silicon steel coagulation tissue and its preparation method

InactiveCN101144762AReactive and restrictiveAvoid irritation hazardsPreparing sample for investigationChemical agentPrecipitation

The invention provides a corrosive for the revealing of the silicon steel solidification structure. The invention has the component and blending ratio of the corrosive that 0.9 to 1.2 gram of a picronitric acid and / or 0.9 to 1.2 gram of a stannous acid, 10 to 20 gram of a ferric chloride, 20 to 50 milliliter of an absolute ethyl alcohol, 15 to 18 milliliter of a hydrochloric acid, 0.2 to 0.5 gram of a copper chloride, 0.2 to 0.5 gram of a magnesium chloride and 80 to 100 milliliter of a distilled water. The invention has the dosing method of the corrosive that the picronitric acid and / or the stannous acid and the ferric chloride are put into a container; the distilled water is divided into two shares, and one share is added into a medicine container; the absolute ethyl alcohol is divided into two shares, one share is added into an aqueous solution which is mixed with medicine, and the other share is added into the distilled water; the hydrochloric acid is added into the ethyl alcohol aqueous solution; the aqueous solution containing ethyl alcohol and hydrochloric acid is poured into the aqueous solution which is mixed with medicine, and the copper chloride and the magnesium chloride are added in. The chemical agent which is used in the corrosive reciprocally reacts mutually and has the strong conditionality, the efficiency of the core corrosive is exerted without forming a surface precipitation membrane, and a clear tree like crystal shape can be directly observed; the corroding time of the corrosive is short, and is suitable for a large size continuous casting semi finished metal; the dosing method of the corrosive is scientific, and the operating procedure is simple, convenient and easy to operate.

Owner:ANGANG STEEL CO LTD

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

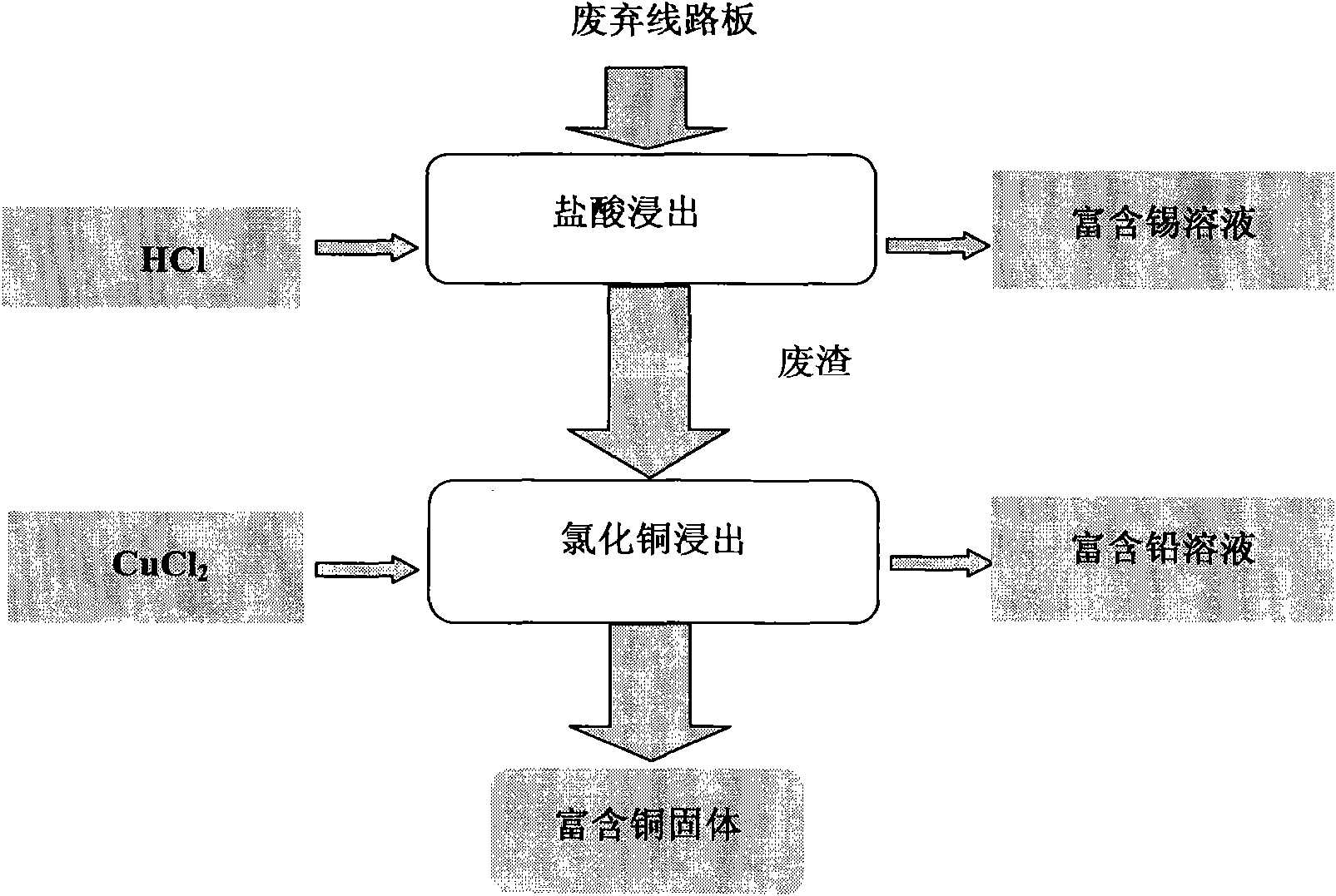

Method for selectively leaching and separating tin, lead and copper from waste circuit board

InactiveCN101864519AEfficient separationSave on subsequent separation operationsProcess efficiency improvementCopper chlorideHigh pressure

The invention discloses a method for selectively leaching and separating tin, lead and copper from a waste circuit board, which is characterized by comprising the following steps of: mixing and stirring particles of the waste circuit board and a leaching agent hydrochloric acid for a certain time at a certain temperature, and selectively dissolving the tin into the solution; and mixing and stirring residues and another leaching agent copper chloride for a certain time, selectively dissolving the lead into the solution, and keeping the residual copper in the circuit board. The technical process has the advantages of simplicity, no need of high temperature and high pressure, the capacity of effectively separating the tin, the lead and the copper from the waste circuit board and saving subsequent separation operation, no other introduced impurities and running cost saving.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Gold complex catalyst for hydrochlorinating acetylene

ActiveCN102631947AImprove stabilityHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsGold contentPotassium

The invention discloses a gold complex catalyst, and particularly relates to a non-mercury catalyst which is applicable to synthesizing vinyl chloride by acetylene hydrochlorination, and a preparation method of the non-mercury catalyst. The non-mercury catalyst comprises potassium aurate tetra-thiocyanate taken as a main active component, one or a combination of more than two of potassium chloride, copper chloride, cobalt chloride and zinc chloride taken as auxiliary active components, and carrier activated carbon, wherein gold complex accounts for 0.1-2.5% of the weight of the catalyst, and the auxiliary active components account for 0.05-15% of the total weight of the catalyst. According to the gold complex catalyst prepared by the invention, the gold content is lower, so that the cost of noble metal catalyst can be remarkably reduced; and the novel non-mercury catalyst is good in activity, high in stability and strong in selectivity. The gold complex catalyst has the advantages of being simple in production technology, short in production cycle and environment-friendly.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

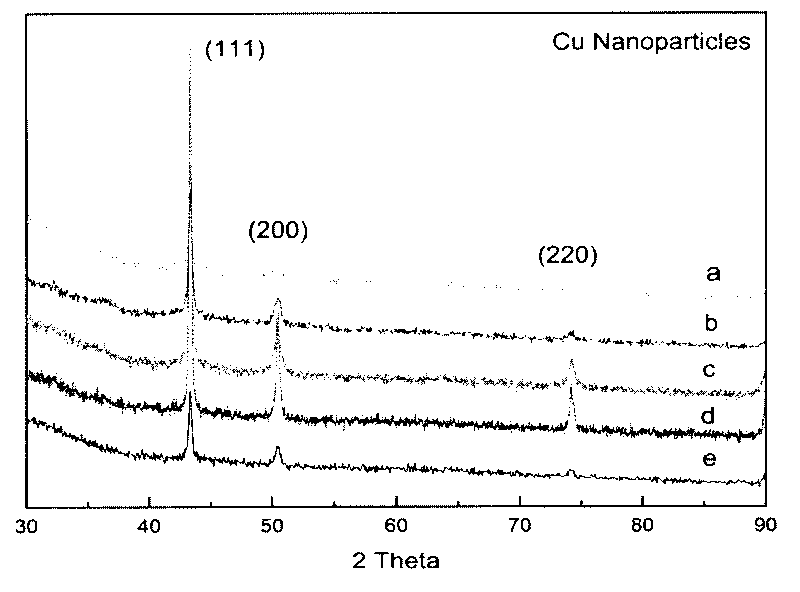

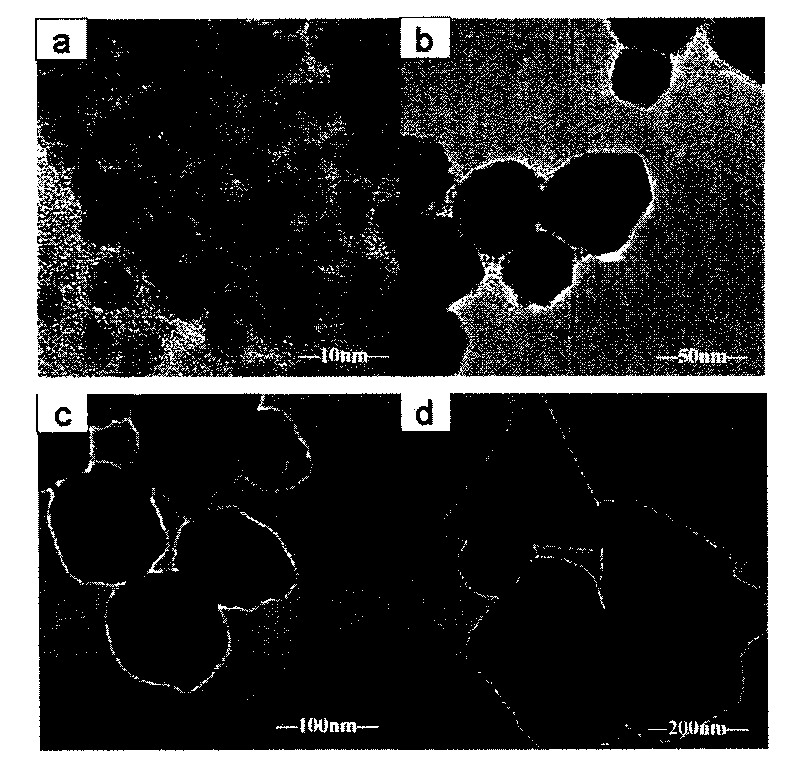

Preparation method of copper nanoparticles with different particle diameters

The invention discloses a preparation method of copper nanoparticles with different particle diameters and relates to a metal nanoparticle. The invention provides a preparation method of copper nanoparticles with different particle diameters, which has simple, economic, environment-friendly process. The preparation method comprises the following steps: adding metal salt of copper chloride or copper acetate, a solvent, a protective agent, a complexing agent and a surfactant in a vessel in sequence, and stirring to obtain a mixture, wherein the protective agent is polyvinylpyrrolidone, polyvinyl alcohol, polyacrylic acid, or the like, the complexing agent is oleic acid, hexadecylamine, oleamide, or the like, and the surfactant is hexadecyl dimethyl ammonium bromide, sodium dodecyl benzene sulfonate or the like; adding a reducing agent in the mixture for reacting, wherein the reducing agent is ascorbic acid, sodium formaldehyde sulphoxylate, sodium borohydride, or the like; cooling the reactant till the temperature is below 40 DEG C, then adding a precipitating agent, mixing, and centrifugally separating; then washing with the organic solvent, centrifugating, and extracting the precipitate; and then drying the precipitate to obtain red powder copper nanoparticles with different particle diameters.

Owner:XIAMEN UNIV

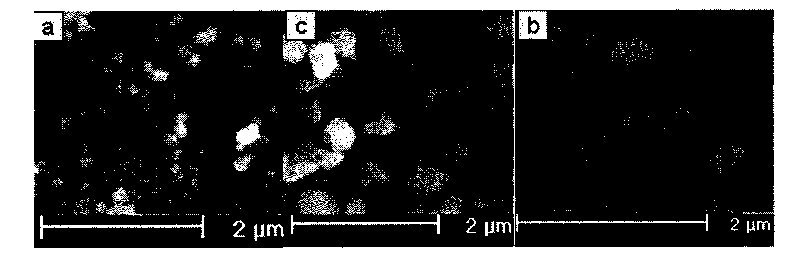

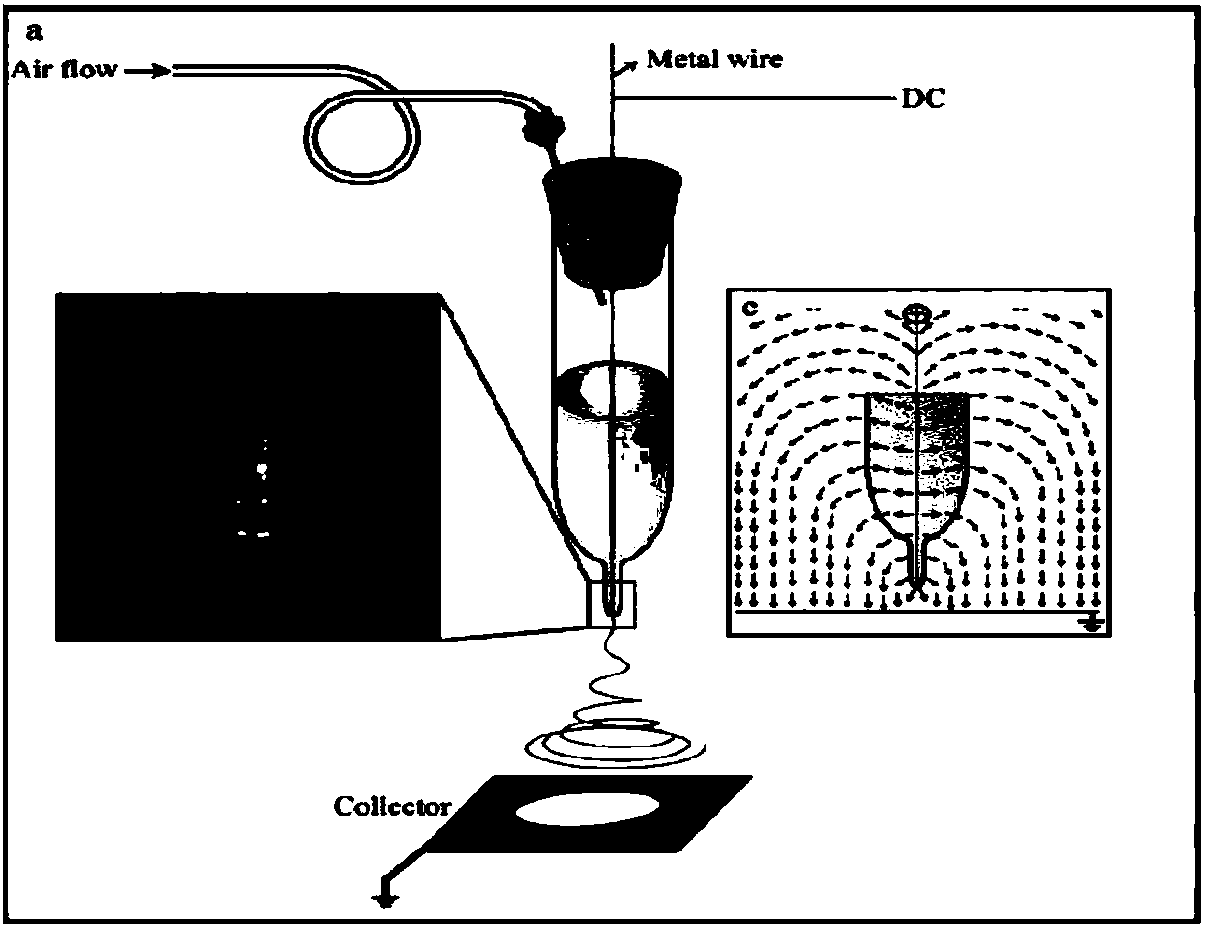

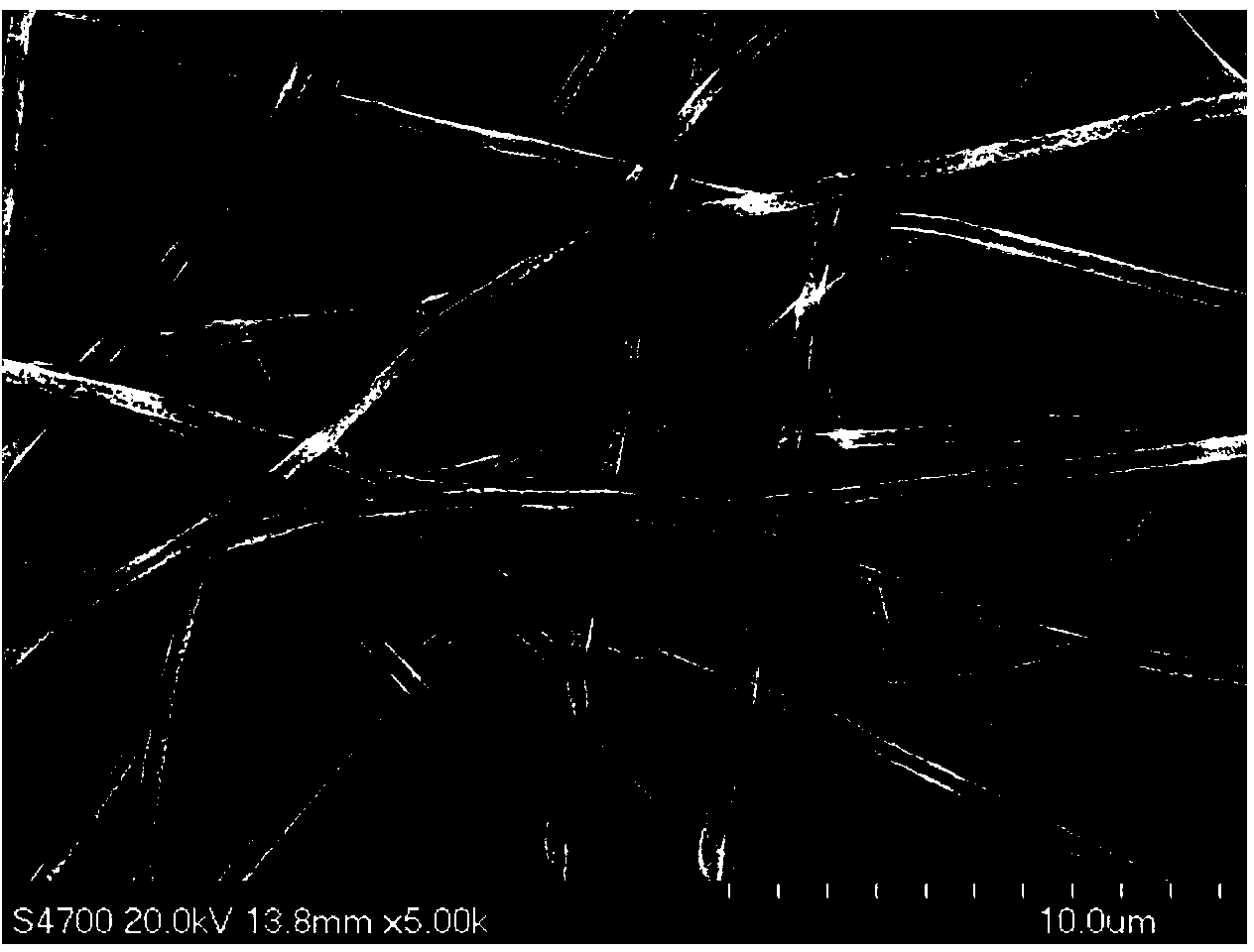

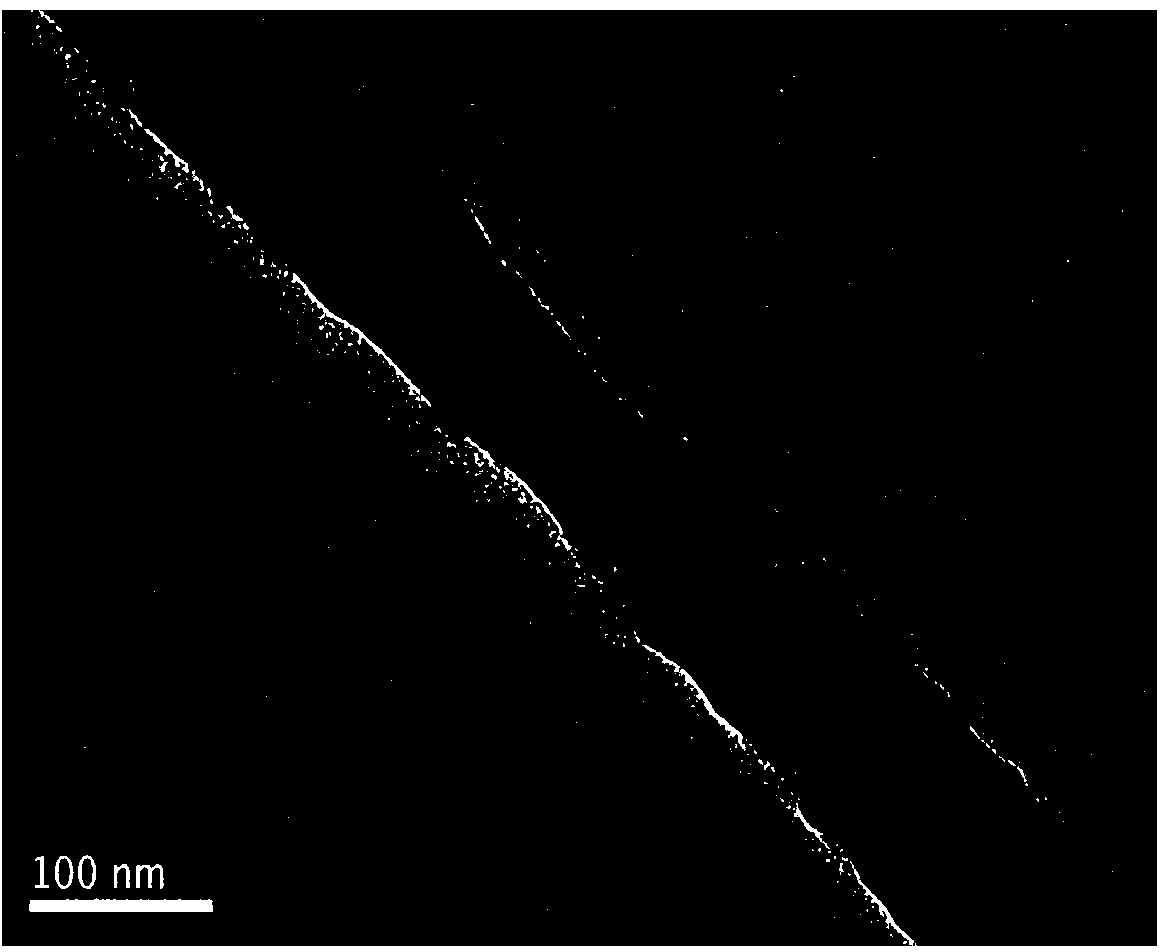

Core-shell structure metal/polymer nanofiber and preparation method thereof

InactiveCN103643347ASmall diameterEasy to form core-shell structureFilament/thread formingConjugated synthetic polymer artificial filamentsPolyvinyl alcoholSolvent

The invention relates to a method for preparing a core-shell structure metal / polymer nanofiber membrane. The prepared fiber membrane uses a polymer as a nuclear layer and uses a nano-metal as a shell layer; the polymer can be polyvinyl pyrrolidone, polyvinyl alcohol, polyoxyethylene, polylactic acid, polyacrylonitrile, hyaluronic acid, chitosan and the like; the nano-metal shell layer comes from metal salt silver nitrate or copper chloride. The core-shell structure metal / polymer nanofiber is prepared by utilizing the electrospinning technique; by controlling the process parameters, the concentration of polymer, the content of metal salt and the proportioning of solvents, the metal / polymer nanofiber membrane is prepared; the fiber membrane has high application value on tissue engineering, recovery of wound, drug transportation, photoelectricity and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

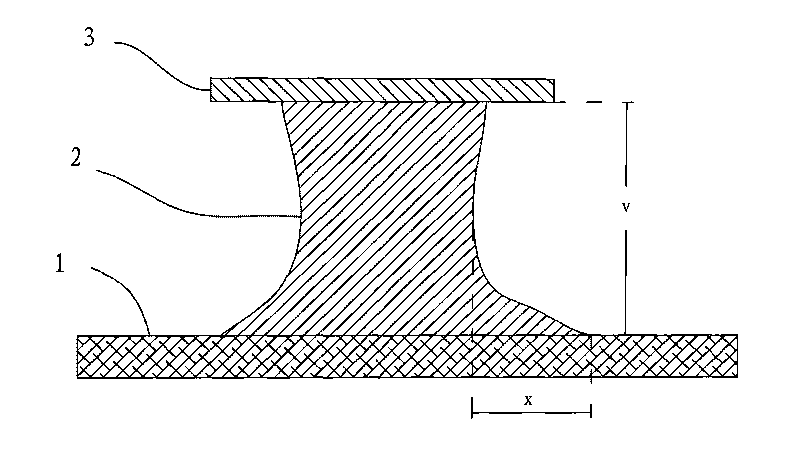

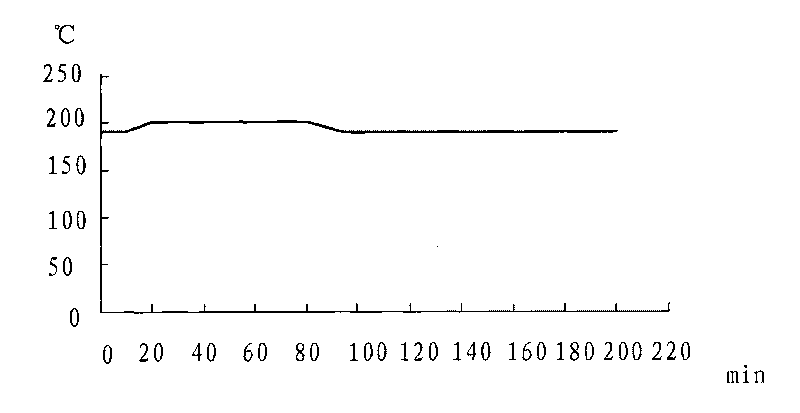

Process for manufacturing 12OZ thick copper multilayer circuit board

ActiveCN101692757AIncrease etch factorEvenly filledMultilayer circuit manufacturePlate pressureCopper chloride

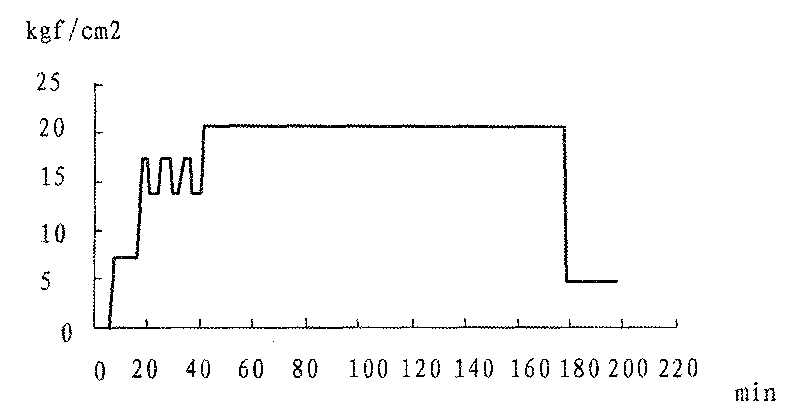

The invention discloses a process for manufacturing a 12OZ thick copper multilayer circuit board. In an inner layer etching process, the concentration of CU2+ in an acid copper chloride etching solution is controlled to be 150+ / -20g / l, the temperature is 50+ / -3 DEG C, total acidity is 2.8+ / -0.6N, specific gravity is 1.30+ / -0.10, etching speed is 1.2+ / -m / min, and the number of etching times is 4 times; a plate pressing process comprises a hot pressing step and a cold pressing step, wherein the hot pressing time is 200 minutes, a system is vaccumized at absolute pressure of 10mbar between the fifth minute and the ninety-fifth minutes, the maximum press plate pressure is controlled to be 21.42Kgf / cm2, and the temperature is 190 DEG C; the time for cold pressing is 110 minutes, and the maximum press plate pressure is controlled to be 18.36Kgf / cm2; when the diameter D of a prebored hole is more than or equal to 2.0mm and is less than 4.8mm, a drill bit with diameter d of less than or equal to 1.7mm is used to prebore 4 holes, and the holes are redrilled by using a drill bit with the diameter D. The process has the advantages of improving the etching factors of the plate material of the inner layer, reducing the side etching effect with good plate pressing effect and protecting the bored holes from the phenomenon that the holes are blocked by copper scarp.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

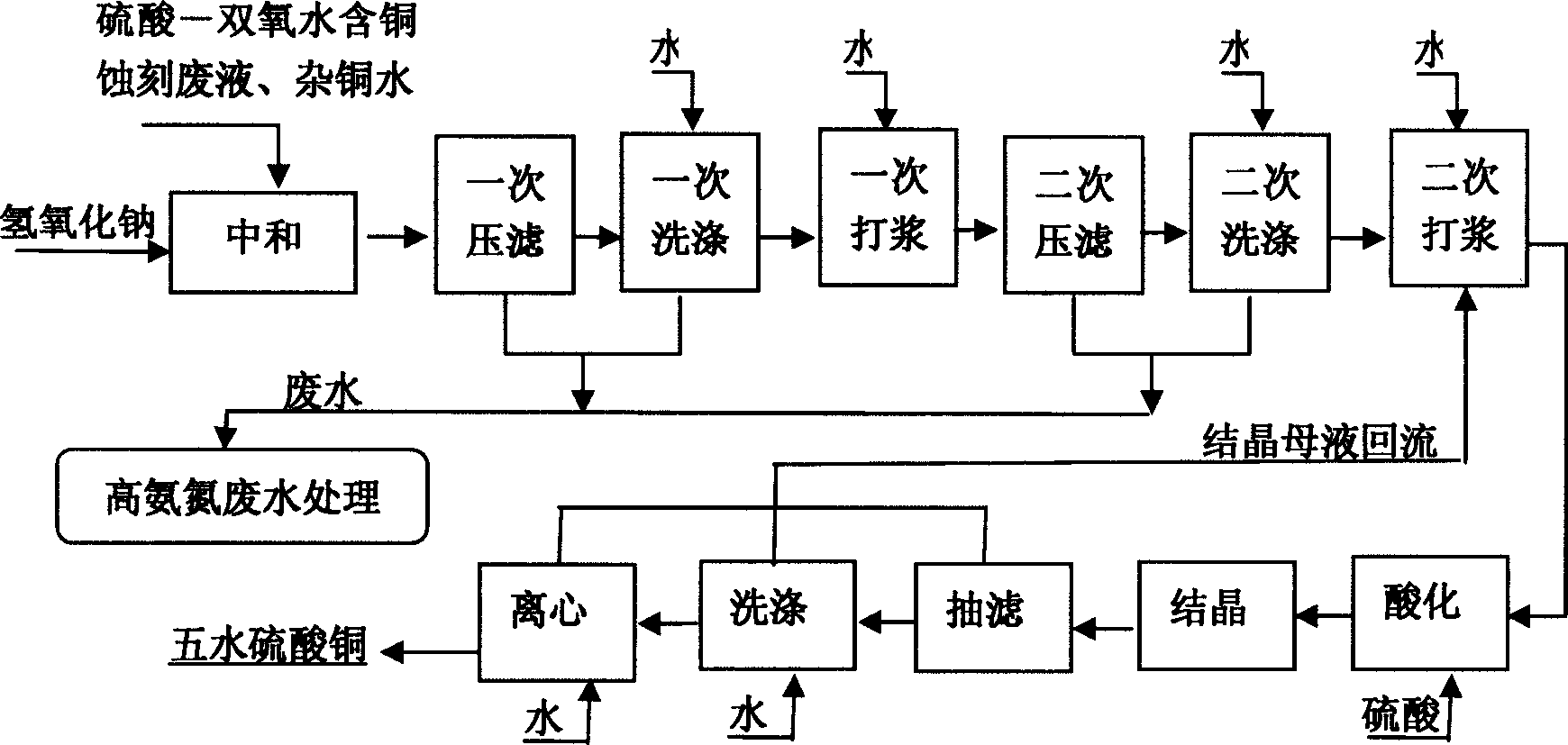

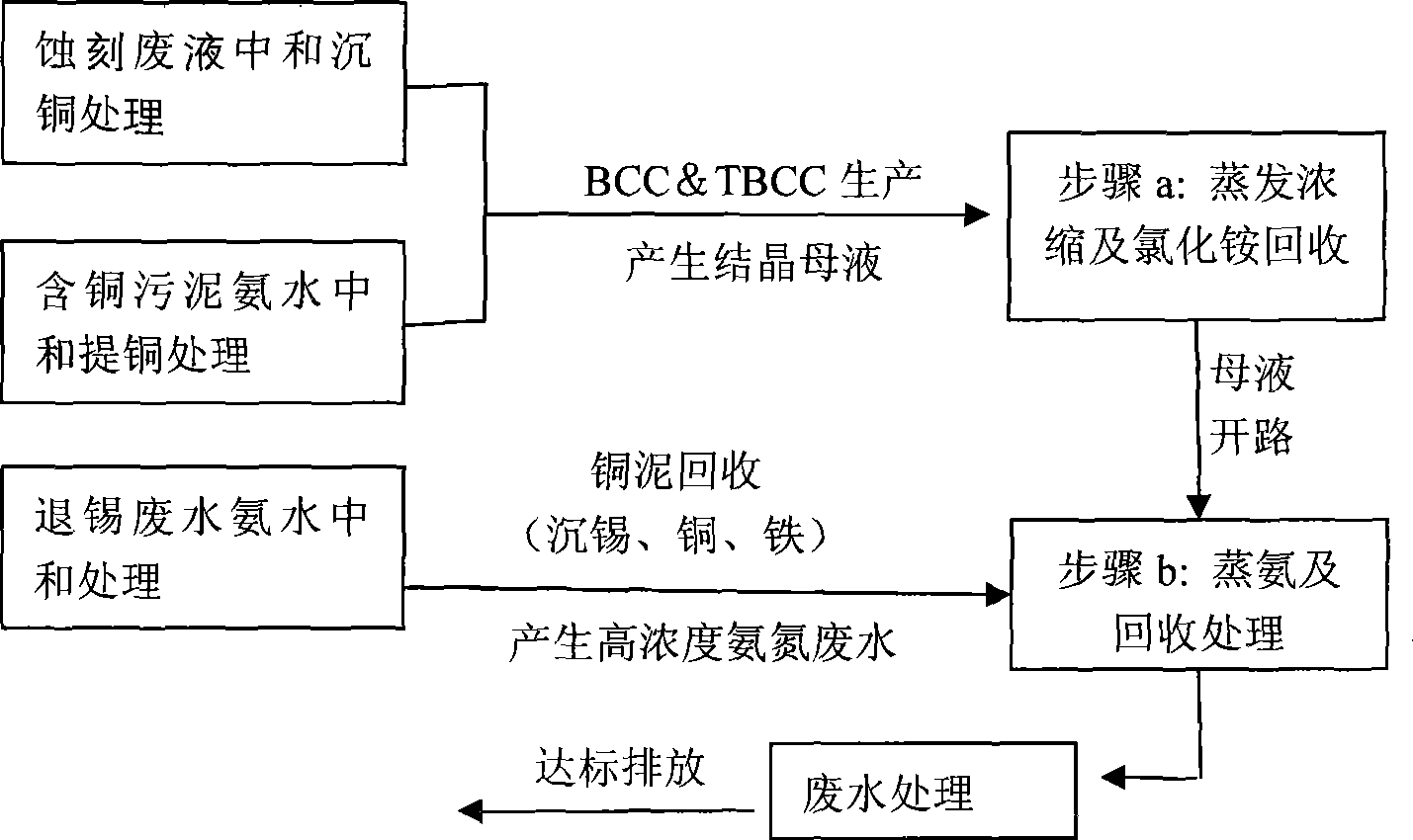

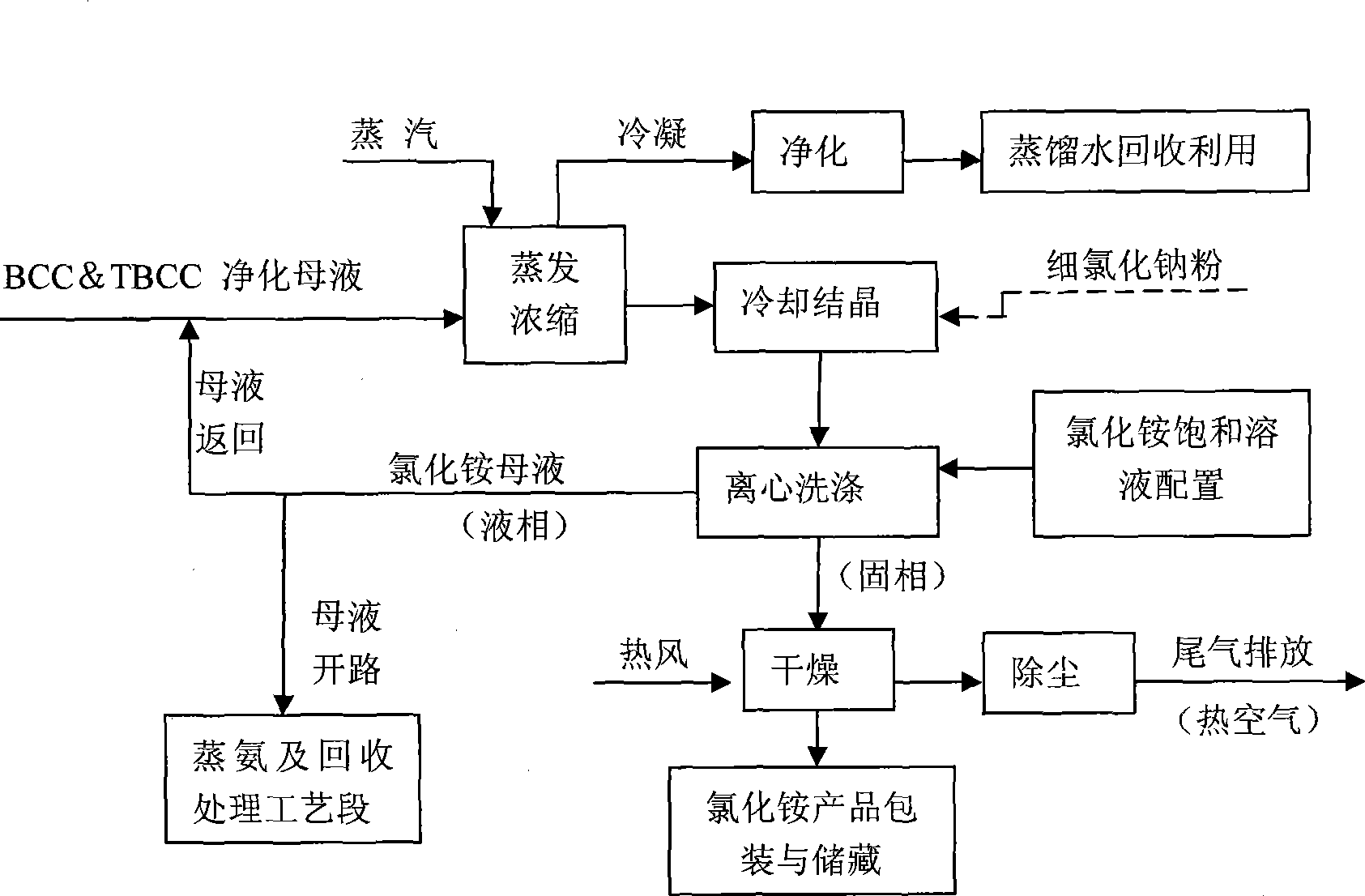

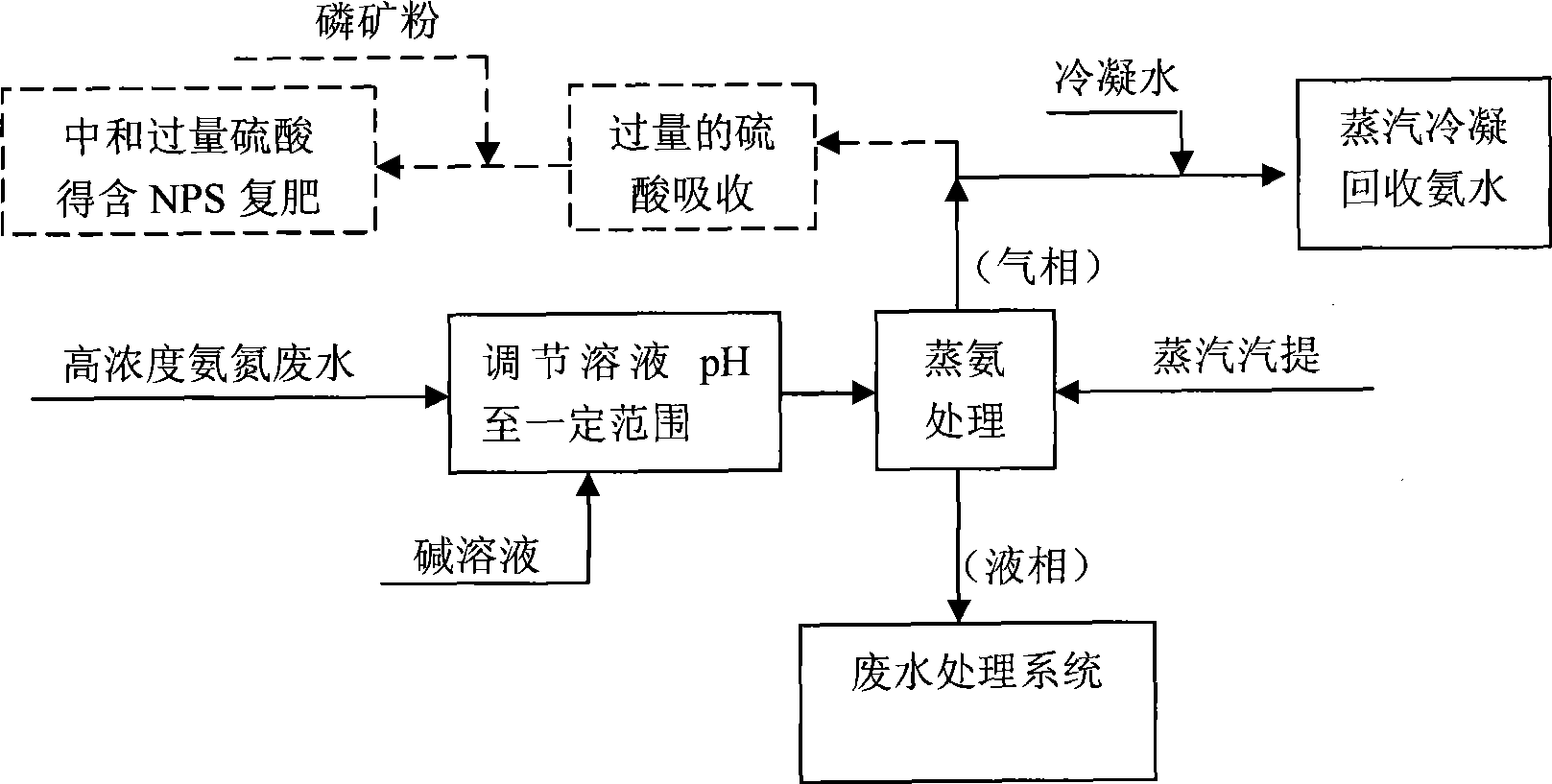

Method for recovery processing of ammonia nitrogen from printed circuit board waste liquid

ActiveCN101391799ARealize resource utilizationEasy to handleClimate change adaptationSewage/sludge fertilisersHigh concentrationLiquid waste

The invention relates to a method for recycling ammonian in ammonian waste water with high concentration, in particular to a method for recycling ammonian in printed wiring board waste water; crystallization mother liquid containing ammonium chloride with high concentration which is generated from processes such as producing alkaline copper chloride, Alpha crystallization type alkaline copper, blue vitriod and the like by using wiring board etching waster water, firstly is evaporated, concentrated and crystallized by one or two combination in multiple effect evaporation technique of mechanical compression, evaporating and compression with heat so as to recycle most ammonium chloride; secondly, Ph is adjusted and ammonian is evaporated so as to recycle ammonia or ammonium sulphate; ammonian waste water generated from removing tin water from ammonia and recycling tin mud are treated by evaporating ammoniac after directly adjusting Ph; and the residual sewage is further treated in the sewage treatment system. By using the method, both of the removal rates of ammonian waste water for wiring board and the recovery rate of ammonia are more than 99.8 percent; the method has good treatment effect, high efficiency, little amount of steam usage, low running cost, and good popularization and application prospect.

Owner:深圳市宝安东江环保技术有限公司

Compositions and methods for antimicrobial metal nanoparticles

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers emulsions of hydrophobic polymers and surfactants.

Owner:AGIENIC

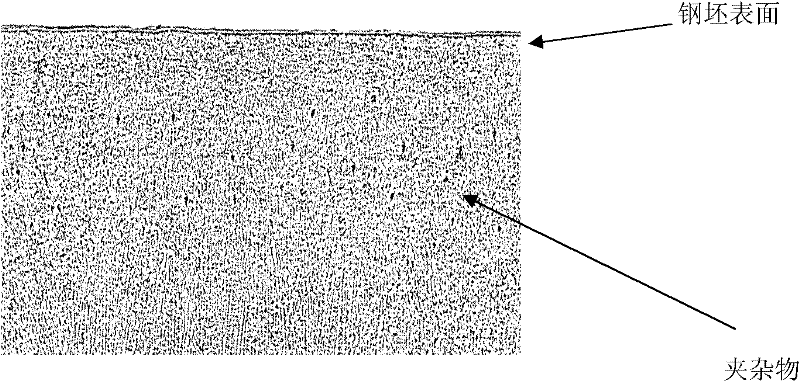

Corrosive capable of displaying ultra low carbon steel solidification arborescent structure and preparation method thereof

ActiveCN102023112ASimplify the manufacturing processReduced finish requirementsPreparing sample for investigationTin(II) chlorideMaterials science

The invention discloses a corrosive capable of displaying an ultra low carbon solidification arborescent structure and a preparation method thereof. The corrosive is prepared from the following components: picric acid, stannous chloride, copper chloride, hydrochloric acid, surfactant, absolute ethyl alcohol and distilled water. The preparation method is as follows: taking a specified amount of the distilled water, and equally dividing the distilled water into two parts; mixing and putting solid medicament into a glass container according to fixed quantity, and adding one part of the distilledwater into the solid mixed medicament to dissolve the medicament; adding a specified amount of the absolute ethyl alcohol into another part of spare distilled water; adding a hydrochloric acid solution into the absolute ethyl alcohol solution; mixing the ethyl alcohol and the hydrochloric acid solution which are poured into an aqueous solution containing the solid medicament; fully stirring; and finally adding the surfactant to finish preparing. By utilizing the reagent provided by the invention, the solidified arborescent structure forms of ultra low C, S, P continuous casting steel billets can be displayed clearly, a finish requirement on sample surface is lowered, the sample preparation working procedure is simplified and the larbour intensity of operators is lowered.

Owner:ANGANG STEEL CO LTD

Method for producing tribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

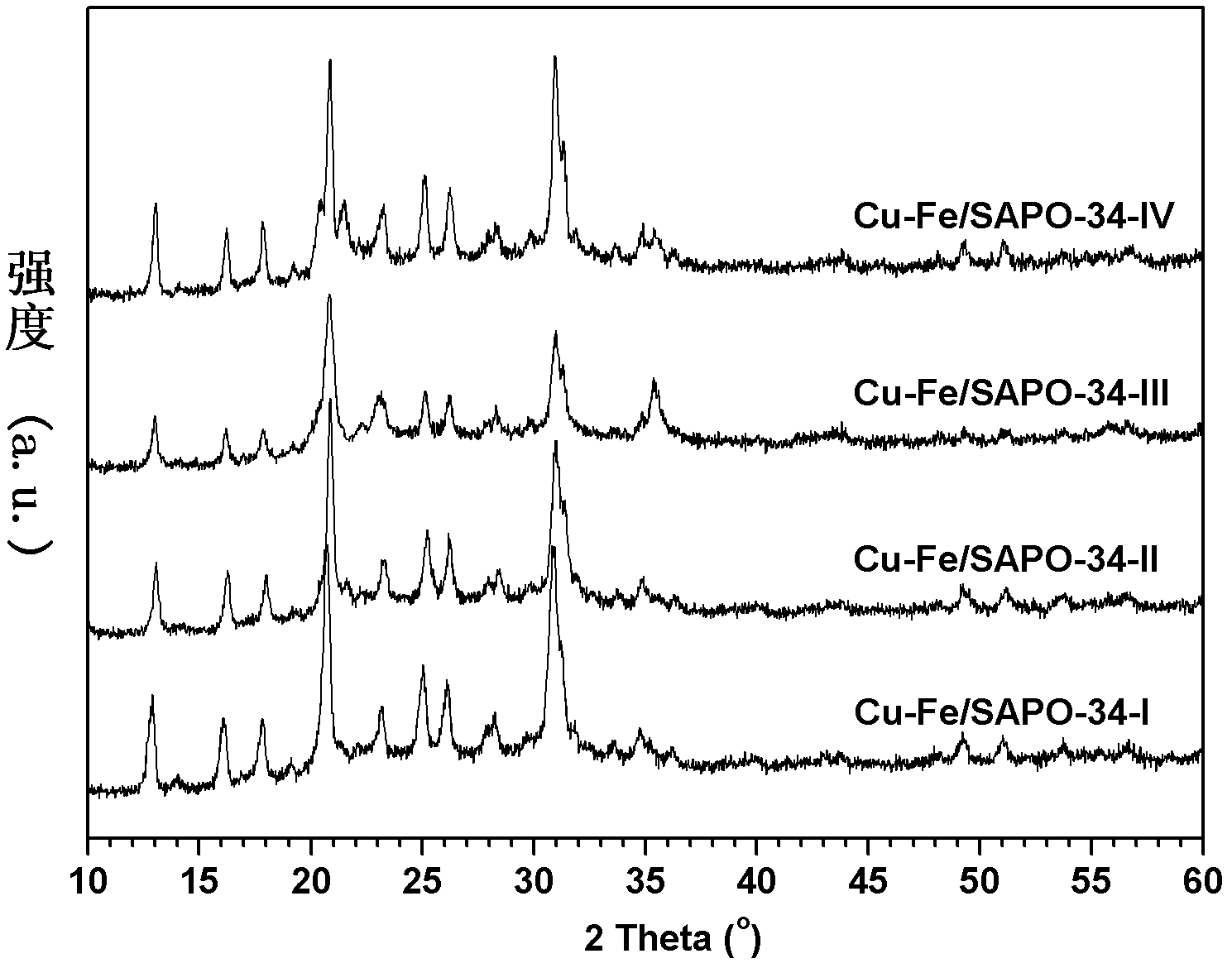

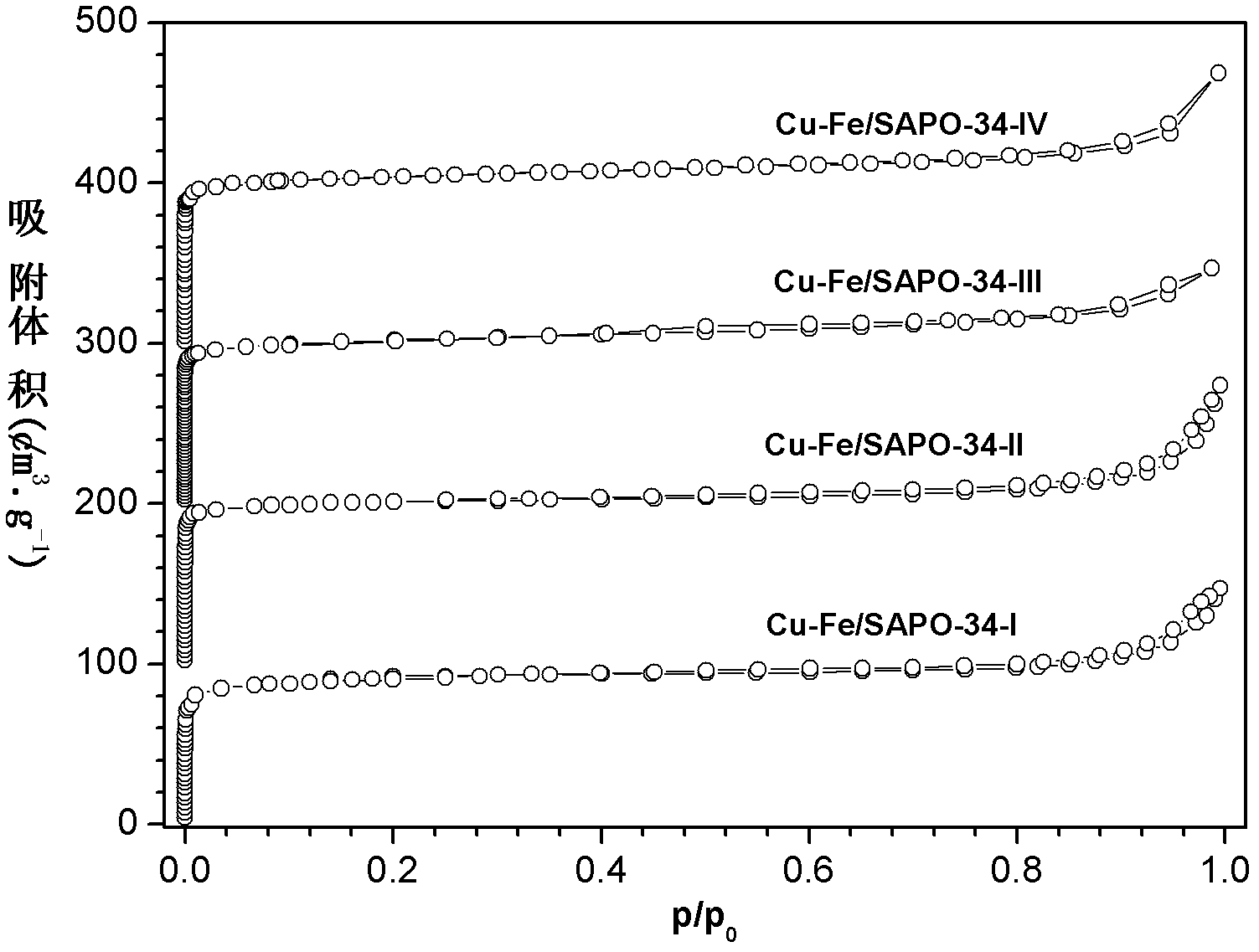

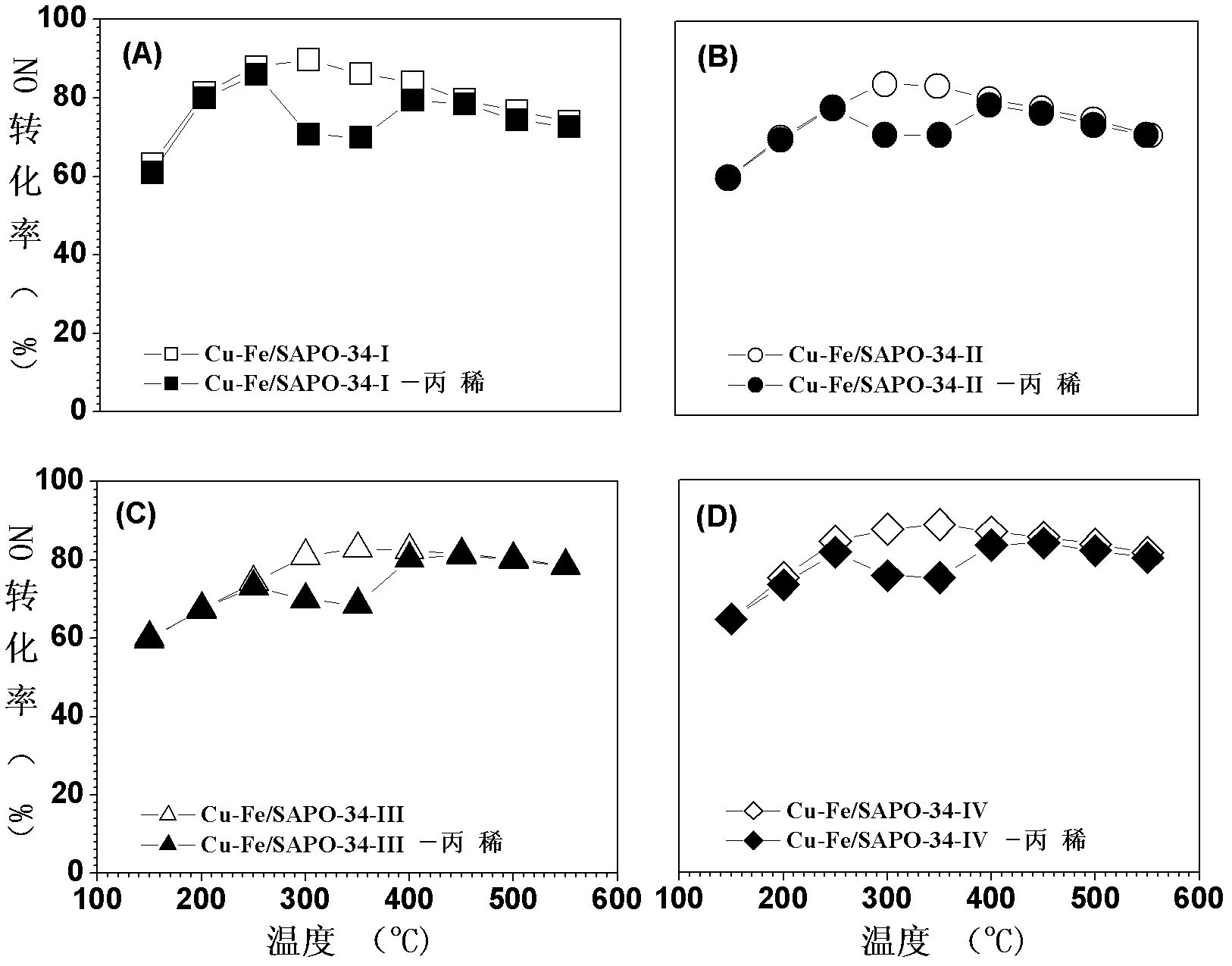

Ammonia-selective preparation method of SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx

InactiveCN102614910AHigh activityImprove anti-carbon performanceNitrous oxide captureMolecular sieve catalystsMolecular sieveCopper chloride

The invention relates to an ammonia-selective preparation method of an SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx. The catalyst is used for catalytically removing oxynitrides. A soft template method is used for preparing the SAPO-34 micropore molecular sieve carrier with high specific area (400-550m<2> / g); and an iron chloride-copper chloride mixed solution and an SAPO-34 molecular sieve ion-exchange method are utilized to prepare the SAPO-34 molecular sieve supported Cu-Fe composite catalyst. In a wide temperature range (150-550), the invention has high catalytic removal effect and high stability for pollutants with high air speed (120000-360000mL.(g.h)<-1>), high O2 concentration (10-10 vl.%), high H2O content (5-10 wt%) and low NO concentration (300-1000ppm). After adding hydrocarbons (300-1000ppm of propylene) into the reaction system, the catalyst provided by the invention has high anti-carbon performance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

Non-noble metal mercury-free catalyst for hydrochlorination of acetylene and preparation method thereof

InactiveCN103007972AHarm reductionAvoid inactivationPhysical/chemical process catalystsPreparation by halogen halide additionAlkaline earth metalVinyl chloride

The invention discloses a non-noble metal mercury-free catalyst for hydrochlorination of acetylene and a preparation method thereof. The catalyst mainly contains copper, chlorine, a carrier and the balance of catalysis-promoting metallic elements, wherein the copper exists in the form of copper chloride, the chlorine exists in the form of an inorganic salt of chlorine, the carrier is activated carbon or nitrided activated carbon which is subjected to acid cleaning, and the catalysis-promoting metallic elements are one of or a mixture of any of alkali metals, alkaline-earth metals and non-noble metals of which the chloride is non-volatile in transition metallic elements. The preparation method comprises the process steps of preparing impregnation motor liquor, adding a catalyst carrier to perform equivalent-volume impregnation, drying the mixture and the like. The non-noble metal mercury-free catalyst prepared by adopting the method is better in activity, high in selectivity, long in service life, low in cost and environment-friendly, and can be used for hydrochlorination of acetylene during the production of vinyl chloride by using a calcium carbide method.

Owner:TIANJIN UNIV

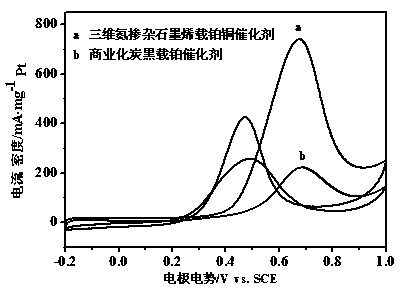

Three-dimensional nitrogen-doped graphene platinoid-loaded composite electro-catalyst and preparation method thereof

InactiveCN104353480ARaw materials are easy to getHigh yieldPhysical/chemical process catalystsCell electrodesNickel saltDoped graphene

The invention discloses a three-dimensional nitrogen-doped graphene platinoid-loaded composite electro-catalyst. A preparation method comprises the following steps of ultrasonically dispersing graphene oxide sheet in an aqueous solution, adding urea and soluble nickel salt for full and uniform mixing, transferring the mixture into a hydrothermal reaction kettle for reaction, performing freeze-drying to obtain three-dimensional nitrogen-doped graphene, dissolving the three-dimensional nitrogen-doped graphene in ethylene glycol, sequentially adding chloroplatinic acid, copper chloride dehydrate and glutamic acid, and performing microwave reaction to obtain the catalyst. The method has the characteristics of that energy is saved, the speed is high, and the operation is simple; the raw materials are easy to obtain, the yield is high, the capability of platinum in the direct electro-catalytic oxidation of methanol under an acidic condition can be remarkably improved, peak current is 3 to 4 times than that of a commercial carbon black platinum-loaded electro-catalyst and a commercial carbon black platinum-ruthenium-loaded electro-catalyst, and the prepared catalyst is widely applied to a methanol fuel cell.

Owner:GUANGXI NORMAL UNIV

Technique for extracting copper ions from industrial wastewater

ActiveCN104355474AHigh extraction rateGood removal effectWater contaminantsWater/sewage treatment by ion-exchangeIon exchangeIon-exchange resin

The invention discloses a technique for extracting copper ions from industrial wastewater, which comprises the following steps: 1) respectively pretreating an acidic coppery etching waste liquid and an alkaline coppery etching waste liquid; 2) neutralization and precipitation: carrying out neutralization reaction on the acidic coppery etching waste liquid and alkaline coppery etching waste liquid in a neutralizing tank, and precipitating to obtain a basic copper chloride precipitate and a filtrate; 3) adding the basic copper chloride precipitate into a reaction tank, and adding sulfuric acid to obtain a copper sulfate crystal; 4) sending the filtrate into an ion exchange resin tower to adsorb the rest unrecovered copper ions, thereby obtaining ammonia nitrogen wastewater; and 5) carrying out evaporative concentration on the ammonia nitrogen wastewater by a vapor recompression technique, crystallizing the concentrate to produce an ammonium chloride product, treating the condensation water by an ion-exchange process, and discharging after reaching the standard. The technique can greatly enhance the extraction rate of copper ions, solves the problem of environmental pollution caused by heavy metal ions, and can produce other products from the waste liquid to implement cyclic utilization, thereby saving the resources and protecting the environment.

Owner:清远市中宇环保实业有限公司

Low-mercury catalyst used for synthesizing vinyl chloride

InactiveCN102962082APlay a fixedActivePhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystCopper chloride

The invention discloses a low-mercury catalyst used for synthesizing vinyl chloride. The low-mercury catalyst takes mercuric chloride as a main active component, one or more of precious metals such as Au, Pd, Pt, Ru, Rh, Os and Ir salts or complexes thereof as active regulators, and one or more of potassium chloride, ferric chloride, zinc chloride and copper chloride as cocatalysts. By adding trace amount of precious metal salt into the mercuric chloride, the low-mercury catalyst forms a stable composite metal compound, plays a role in fixing and activating mercuric chloride, and still maintains very high catalytic activity and stability when the load capacity of the mercuric chloride is reduced to 0.1-2%.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

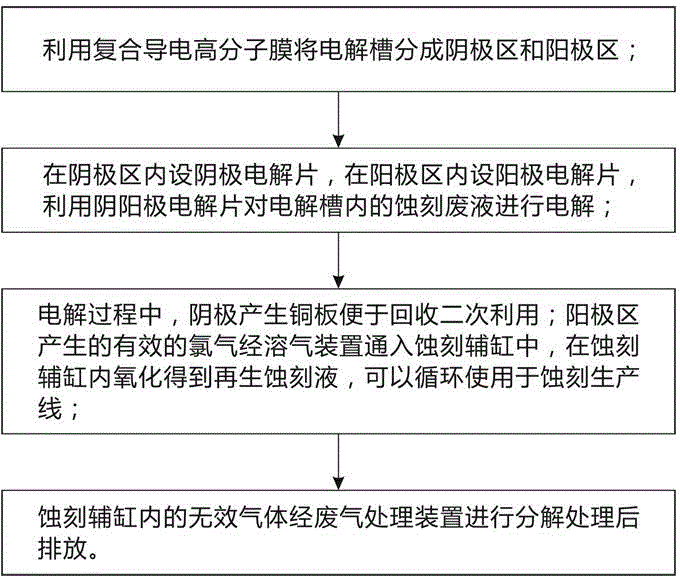

Acidic copper chloride etching liquid electrolytic regeneration recycling and copper plate recovery device and method

ActiveCN104152905AImprove reuse rateSolve the problem of energy consumptionPhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

The invention discloses an acidic copper chloride etching liquid electrolytic regeneration recycling and copper plate recovery device and method. The device comprises an electrolytic bath which is divided into a cathode region and an anode region by virtue of a composite conductive macromolecular membrane, an etching auxiliary cylinder, an etching liquid waste liquid collecting cylinder, a regenerated liquid collecting cylinder and an exhaust treatment device, wherein the cathode region is internally provided with a cathode electrolytic sheet, the anode region is internally provided with an anode electrolytic sheet, and the etching auxiliary cylinder is internally provided with a gas dissolving device; a waste liquid generated by the etching cylinder is fed to the cathode region of the electrolytic bath by virtue of the etching liquid waste liquid collecting cylinder, a water inlet and a gas outlet are formed in the anode region of the electrolytic bath, the water outlet is communicated with the etching auxiliary cylinder by virtue of the regenerated liquid collecting cylinder, gases generated by the anode region are introduced to the etching auxiliary cylinder by virtue of the gas dissolving device at the gas outlet, the etching auxiliary cylinder is communicated with the etching cylinder, and exhaust gases generated by the etching auxiliary cylinder are fed to the exhaust gas treatment device. The device and method disclosed by the invention solve the problem that an existing acidic copper chloride etching liquid is high in energy consumption of regeneration recycling, low in reuse rate, more in copper impurities of the cathode and the like.

Owner:SHENZHEN XINRUISI ENVIRONMENTAL PROTECTION TECH

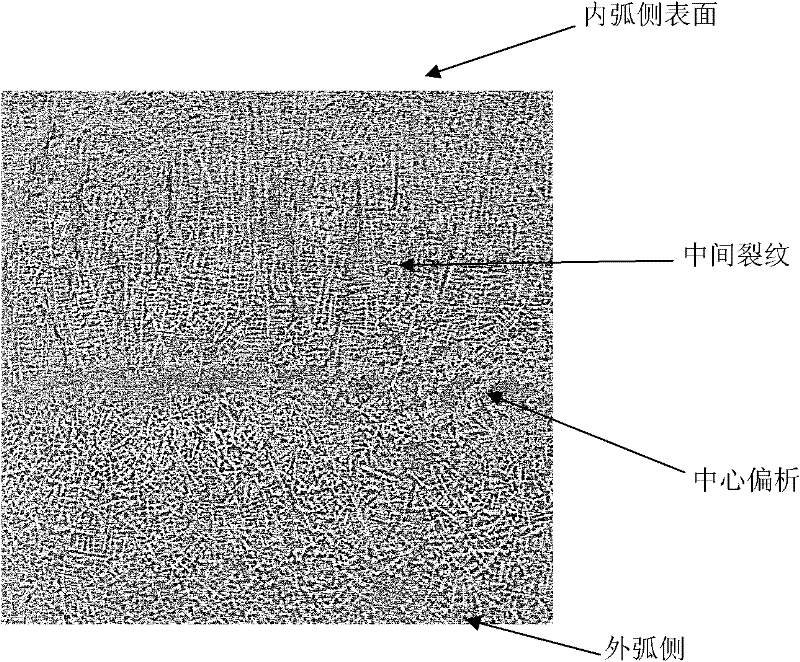

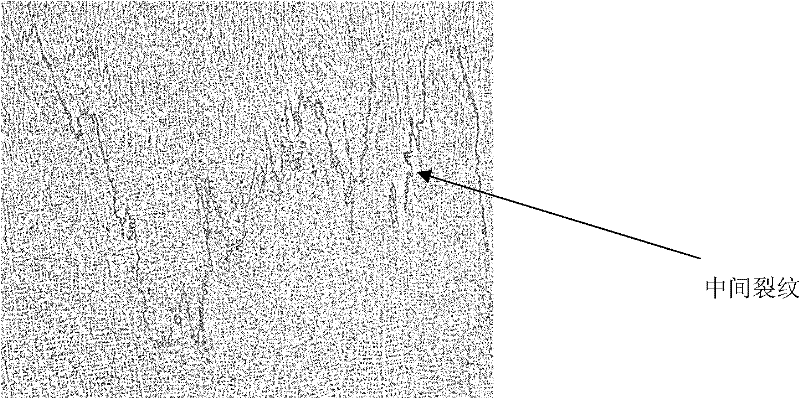

Dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of continuous cast blank and preparation method thereof

ActiveCN102174699ASolve the problem that the dendritic solidification structure of the continuous casting slab cannot be clearly displayedDisplay without reductionPreparing sample for investigationOptically investigating flaws/contaminationAlcoholCopper chloride

The invention discloses a dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of a continuous cast blank and a preparation method thereof. The reagent comprises the following components by mass percent: 0.28-1.09% of copper chloride, 0.17-0.27% of magnesium chloride, 0.56-1.60% of ferric chloride, 1.28-1.30% of hydrochloric acid with the mass concentration of 36-38%, 54.70-55.80% of absolute ethyl alcohol and the balance of water. The preparation method comprises the following steps: adding the water into a container, and then adding the copper chloride, magnesium chloride, ferric chloride and hydrochloric acid; and adding the absolute ethyl alcohol after all the added raw materials are fully dissolved, and evenly stirring. Compared with the prior art, the invention solves the problem that other corrosive reagents can not clearly display the dendritic crystal solidification structures of a continuous cast blank; and the reagent has the characteristic of original-size display without expansion or reduction for interior defects of a continuous cast blank when used for dendritic crystal corrosion macroscopic examination on the solidification structures and defects of the continuous cast blank.

Owner:苏州东大汉森冶金实业有限公司

Method for preparing monoclinic system crystalline state cupric oxide and uses thereof

The invention relates to a method for preparing monoclinic crystal system crystalline copper oxide and an application of the monoclinic crystal system crystalline copper oxide. The method comprises the following steps: a. a sodium hydroxide or potassium hydroxide water solution with a concentration of between 5 and 50 percent and a volume of between 30 and 80 percent of the volume of a reaction vessel is added into the reaction vessel, preheated to between 30 and 100 DEG C, added with crystalline copper chloride hydroxide with the addition between 1 / 6 and 1 / 3 of the mol number of sodium hydroxide, and reacted for 10 to 60 minutes at a reaction temperature of between 30 and 100 DEG C and under the condition of stirring; b. crystalline copper oxide is prepared after washing, pumping filtration, centrifugation and drying of reacted materials; and c. the crystalline copper oxide is crushed by the physical method, and the activated copper oxide with fine granularity are prepared. The method is easy to realize separation of the copper chloride hydroxide and the copper oxide with other water-soluble background salts, and has a simple technique and low production cost; and the crystalline copper oxide prepared has high yield, high purity, high activity, good quality and is suitable for mass production.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Non-mercury catalyst for production of vinyl chloride and preparation method thereof

InactiveCN102069000AAvoid pollutionEase of mass productionPhysical/chemical process catalystsPreparation by halogen halide additionBarium dichlorideCopper chloride

The invention discloses a non-mercury catalyst for the production of vinyl chloride and a preparation method thereof, belonging to the fields of chemical catalyst and the preparation thereof. The non-mercury catalyst of the invention uses cocoanut active charcoal as carrier and stannous chloride as main active substance, wherein the weight percentage of stannous chloride is 15%-30%; and at least one additive of barium chloride, zinc chloride and copper chloride is added and the total additive weight percentage is 0.5-2%. By using the non-mercury catalyst, the environmental pollution caused by the mercury-containing catalyst can be avoided; the large-scale production can be benefited, the conversion rate and selectivity of the catalyst can be increased, the yield of the product can be increased; by increasing the quality of the carrier, technical guarantee can be provided for the large-scale production device of vinyl chloride, the loss of the active matter can be slowed down, the service life of the catalyst can be prolonged; and the use efficiency of the catalyst can be increased by 500%.

Owner:YIBIN TIANYUAN GRP CO LTD

Compositions and methods for antimicrobial metal nanoparticles

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers emulsions of hydrophobic polymers and surfactants.

Owner:AGIENIC

Botallackite preparation method and uses thereof

ActiveCN1880225AHigh yieldQuality improvementAnimal feeding stuffAccessory food factorsSal ammoniacCopper chloride

A method for preparation and use of sloping atacamite belonging to the area of fine chemical engineering, the characters of which consist in the process steps as follows: preheating the ammonium chloride solution, copper chloride solution and ammonial solution to 65-100 degree centigrade separately; the concentration of ammonium chloride solution is 5-25%, the concentration of copper in copper chloride solution is 100-200g / L, the content of ammonial in ammonial solution is 5-20%; adding ammonium chloride solution to reactor equipped agitating device, at the same time, adding copper chloride solution and ammonial solution with the mole proportion of 2:3 to undergo neutralizing reaction during agitation for deposit of sloping atacamite. The invention has simple process, high reaction sensitivity and low cost; the sloping atacamite produced in the method has high yield, excellent quality, stable property and is suitable for mass production. So the sloping atacamite can be used for feed addictive on a large scale for the stable property

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com