Low-mercury catalyst used for synthesizing vinyl chloride

A low-mercury catalyst and vinyl chloride technology, which is applied in the direction of physical/chemical process catalysts, hydrogen halide addition preparation, chemical instruments and methods, etc., can solve the problems of catalyst activity and stability reduction, environmental pollution, high consumption of mercury chloride, etc. problem, to achieve high catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

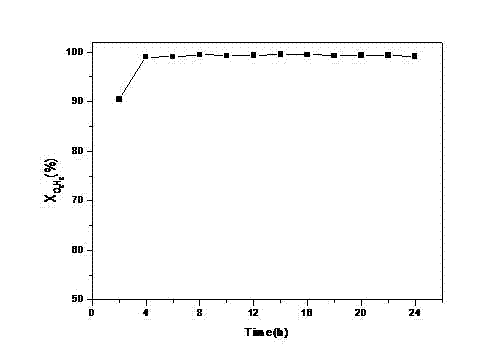

Embodiment 1

[0030] Soak 10g of activated carbon in 1% sodium hypochlorite at room temperature for 2h, filter, wash with deionized water several times until the filtrate is neutral, and dry at 120°C for 8h for later use. 0.2g mercuric chloride, 0.0029g H 2 PtCl 6 ·6H 2 O, 0.9654g FeCl 3 ·6H 2 O was dissolved in 15ml of deionized water, added dropwise into the pretreated activated carbon after clarification, soaked at room temperature for 4 hours, and dried at 120°C for 8 hours for later use.

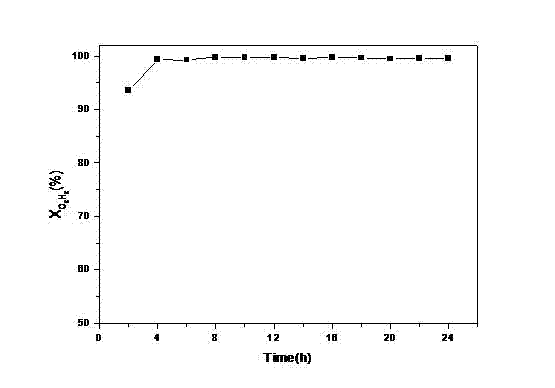

Embodiment 2

[0032] Soak 10g of activated carbon with 1% calcium hypochlorite at room temperature for 2h, filter, wash with deionized water several times until the filtrate is neutral, and dry at 120°C for 8h for later use. 0.05g mercuric chloride, 0.0128g RhCl 3 ·3H 2 O, 0.6253 gZnCl 2 Dissolve in 15ml of deionized water, add dropwise into the pretreated activated carbon after clarification, soak at room temperature for 4 hours, and dry at 120°C for 8 hours for later use.

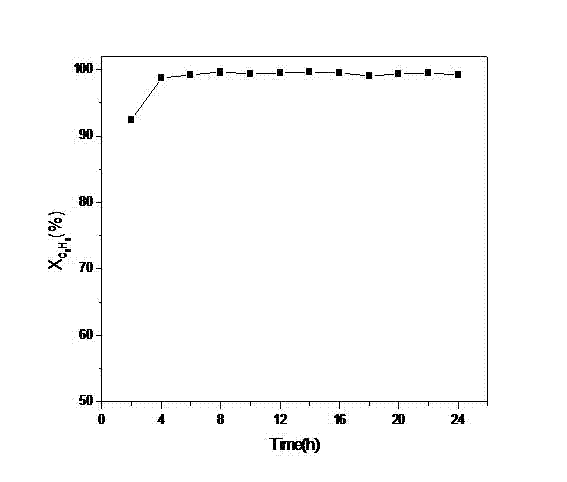

Embodiment 3

[0034] Soak 10g of activated carbon with 1% hypochlorous acid at room temperature for 2h, filter, wash with deionized water several times until the filtrate is neutral, and dry at 120°C for 8h for later use. 0.1g mercuric chloride, 0.0042g HAuCl 4 4H 2 O, 0.2685g CuCl 2 2H 2 O was dissolved in 15ml of deionized water, added dropwise into the pretreated activated carbon after clarification, soaked at room temperature for 4 hours, and dried at 120°C for 8 hours for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com