Stone-imitated finishing material of building wall body and construction method of finishing layer

A technology for facing materials and building walls, which is applied in the field of imitation stone materials, can solve the problems of poor performance and weather resistance of imitation stone materials, high cost of imitation stone production, and large wall load, etc., to achieve high improvement costs and reduce infrastructure construction Good effect of investment and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

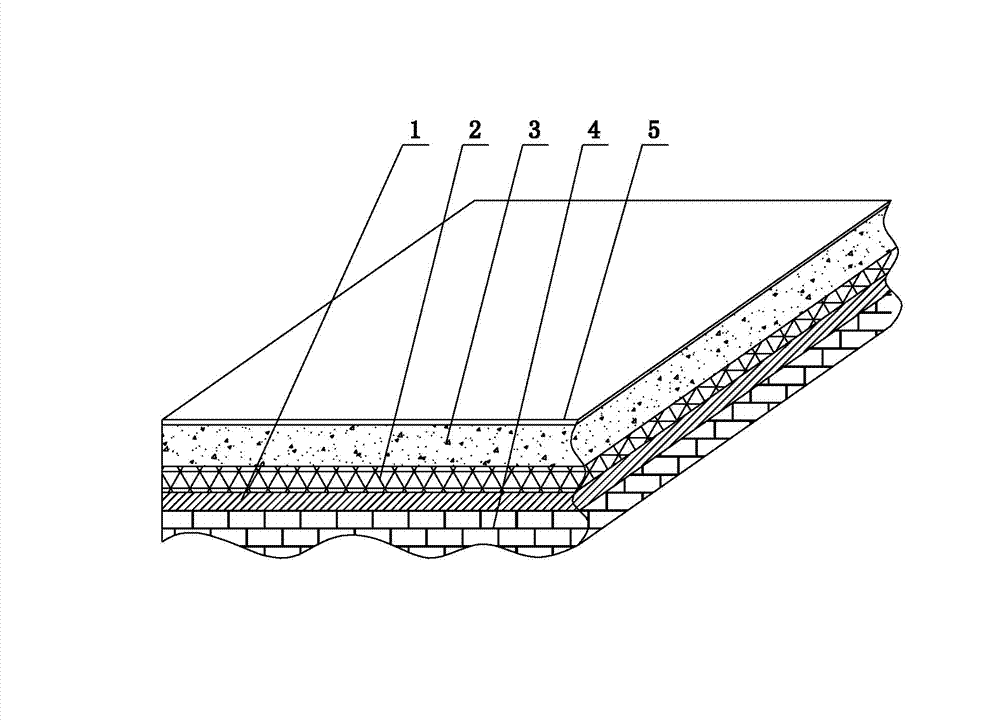

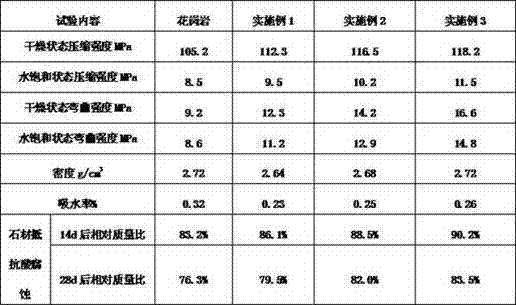

[0016] Example 1: Mix 100 parts of white cement, 8 parts of epoxy resin, and 0.3 parts of water reducer, add 40 parts of water and stir to make cement slurry, and cover the surface of wall body 4 with cement slurry to form interface layer 1; The outer surface is covered with a layer of steel wire mesh 2, and the steel wire mesh 2 is anchored to the wall with steel nails at regular intervals. Mix 100 parts of white cement, 58 parts of epoxy resin, 35 parts of acetone, 20 parts of acrylic resin emulsion (manufactured by Nanchang Huate Chemical Co., Ltd., the same below), 1 part of aluminum powder, inorganic pigments (such as iron oxide red, lead chromate , cadmium sulfide, chromium oxide green, iron blue, cobalt blue, ultramarine blue, brilliant blue, etc.) 20 parts, 40 mesh colored silica sand 10 parts, 40 mesh natural granite particles 10 parts, cobalt sulfate 0.5 part, water reducing agent 0.3 part and water 50 parts are mixed and stirred to make imitation stone material, app...

Embodiment 2

[0017] Example 2: Mix 100 parts of white cement, 9 parts of epoxy resin, and 0.4 parts of water reducing agent and add 42.5 parts of water reducer to make cement slurry, and cover the surface of wall 4 with the cement slurry to form interface layer 1 . A layer of steel wire mesh 2 is covered on the outer surface of the interface layer 1, and the steel wire mesh 2 is anchored to the wall by using steel nails at regular intervals. Mix 100 parts of white cement, 64 parts of epoxy resin, 40 parts of acetone, 23 parts of acrylic resin emulsion, 2 parts of aluminum powder, inorganic pigments (such as iron oxide red, lead chromate, cadmium sulfide, chromium oxide green, iron blue, cobalt blue, ultramarine blue, brilliant blue, etc.) 22.5 parts, 40 mesh colored silica sand 20 parts, 40 mesh natural granite particles 15 parts, cobalt sulfate 1.0 part, water reducing agent 0.4 part and water 55 parts and mix and stir to make imitation stone material. The imitation stone material is appl...

Embodiment 3

[0018] Example 3: Mix 100 parts of white cement, 10 parts of epoxy resin, and 0.5 parts of water reducer, add 45 parts of water and stir to make cement slurry, and cover the surface of wall 4 with the cement slurry to form interface layer 1 . A layer of steel wire mesh 2 is covered on the outer surface of the interface layer 1, and the steel wire mesh 2 is anchored to the wall by using steel nails at regular intervals. Mix 100 parts of white cement, 70 parts of epoxy resin, 45 parts of acetone, 26 parts of acrylic resin emulsion, 1.5 parts of aluminum powder, inorganic pigments (such as iron oxide red, lead chromate, cadmium sulfide, chromium oxide green, iron blue, cobalt blue, ultramarine blue, brilliant blue, etc.) 25 parts, 40-mesh colored silica sand 30 parts, 40-mesh natural granite particles 20 parts, cobalt sulfate 1.5 parts, water reducing agent 0.5 parts and water 60 parts to make imitation stone material after mixing and stirring The imitation stone material is appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com