Patents

Literature

187 results about "ULTRAMARINE BLUE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

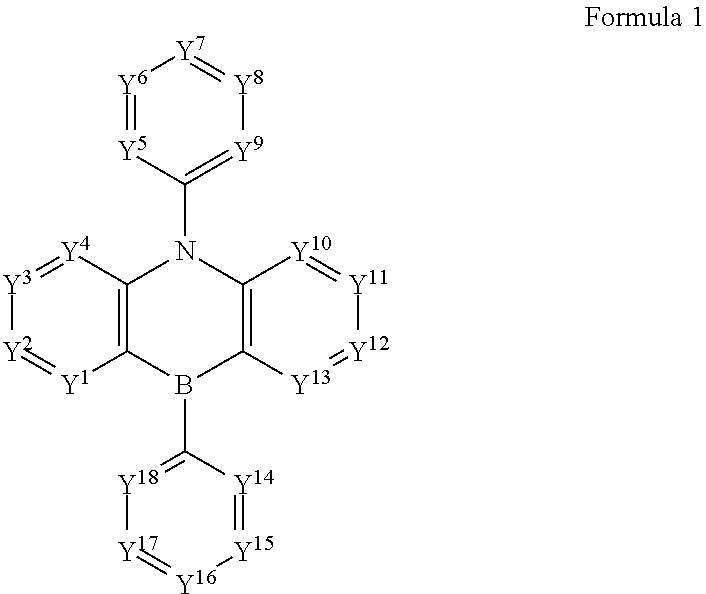

Dark blue organic light-emitting material and preparation method and application thereof

InactiveCN110790782AHigh color purityImprove stabilitySilicon organic compoundsSolid-state devicesBond energyULTRAMARINE BLUE

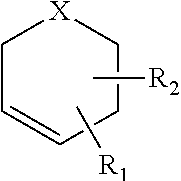

The invention discloses a dark blue organic light-emitting material and a preparation method and application thereof. The dark blue organic light-emitting material contains a structural unit disclosedin the invention, wherein, M is B or Bi; X is O, S or NR4; R1-R4 are independently selected from connecting bonds or groups obtained from H-H, H-F, H-O-H, H-S-H, H-CN, saturated hydrocarbons, unsaturated hydrocarbons, fluorinated hydrocarbons, heterocyclic compounds, organoboron, organosilicone, alcohols, mercaptans, ethers, thioethers, phenols, thiophenol, aldehydes, ketones, amines, amides, nitriles or sulfones losing one or more H; R1-R3 are located at any substitution position on rings of the structural unit where R1-R3 are located, and the bond energy between the ring where R3 is locatedand M is greater than or equal to the bond energy between the ring where R2 is located and M. The dark blue organic light-emitting material containing the B / Bi-N main body structure has very narrow light-emitting spectrum and TADF properties; the color purity is high, and the stability is good.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

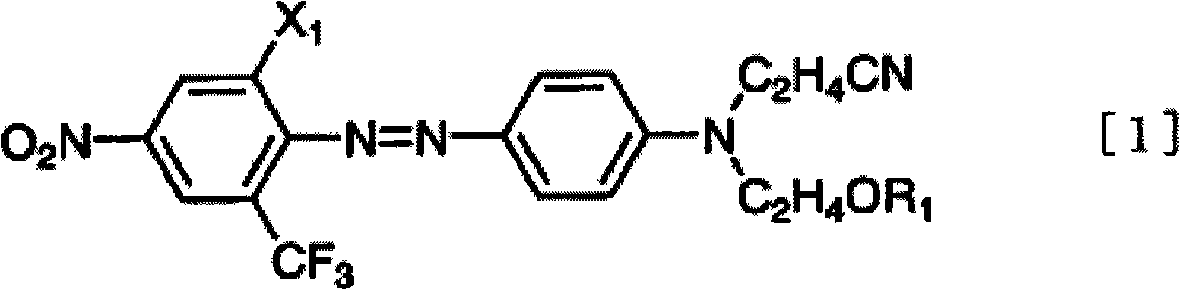

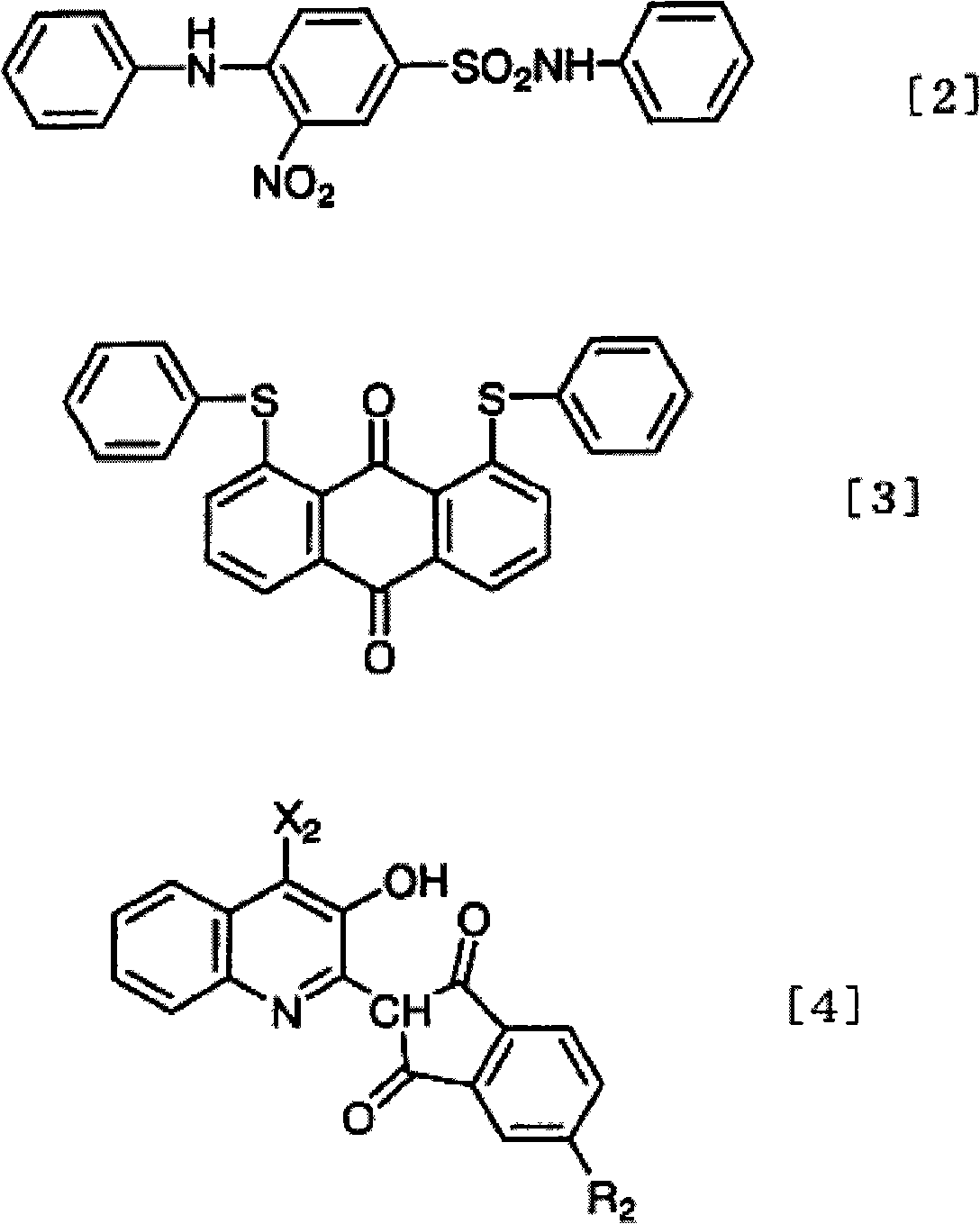

Disperse die, disperse die composition, ink for ink-jet printing, and staining method and stained material using the die, composition or ink

InactiveCN101309975AImprove dyeing propertiesExcellent sublimation fastnessMonoazo dyesIsothiazolanthrone/isoxazolanthrone/isoselenazolanthrone dyesDisperse dyePolymer science

Disclosed are: a novel orange-colored disperse dye which has excellent staining properties onto a hydrophobic fiber material, a high light-resistant color-fastness, an excellent sublimation fastness, and a good buildup property, and is useful as a dye for use in an automotive interior sheet; a disperse dye composition for yellow-to-orange, brown, dark blue and black colors which comprises the disperse dye; an ink for ink-jet printing; a staining method or a stained material using the disperse die, the composition or the ink. The orange-colored disperse dye is represented by the formula (1) below and can stain a hydrophobic fiber material (e.g., a polyester) into orange color. [Chemical formula] (1) wherein X1 represents a chlorine or bromine atom; R1 represents a benzoyl group, a cyanoethyl group, a C1-C4 alkyl group, a phenyl group or a phenyl group substituted by at least one C1-C4 alkyl group.

Owner:KIWA CHEM IND CO LTD

Pigmented polymerizable compositions and optical articles prepared therefrom

Provided is a polymerizable composition including: (a) a polymerizable component; and (b) a pigment component the pigment component includes: (i) an ionic or amphoteric dispersant material; and (ii) pigment nanoparticles uniformly dispersed in the dispersant material (i). The nanoparticles have a particle size of up to 500 nanometers. Also provided is a polymerizable composition of: (a) a polymerizable component including: (i) diethylene glycol bis(allyl carbonate); and (ii) a radical initiator; and (b) a pigment component which includes: (i) an ionic or amphoteric dispersant material derived from polycaprolactone; and (ii) pigment nanoparticles of ultramarine blue having an average particle size of up to 500 nanometers, uniformly dispersed in the dispersant material.

Owner:PPG IND OHIO INC

One-time forming high-strength decorative slab and manufacturing process thereof

InactiveCN101602223AHigh strengthImprove toughnessDomestic articlesFlat articlesULTRAMARINE BLUETemperature resistance

The invention discloses a one-time forming high-strength decorative slab and a manufacturing process thereof. The slab comprises the following compositions in portion by weight: 100 portions of 40-to-120-mesh wood powder, 8 to 25 portions of melamine, 0.5 to 2.0 portions of titanium pigment, 0.1 to 1.2 portions of ultramarine blue powder, 0 to 12 portions of active carbon, 0 to 62 portions of fire retardant, 0 to 13.5 portions of aromatizer and 0 to 12 portions of antistatic agent. The manufacturing process comprises the following steps: (1) weighing and respectively storing the compositions according to the weight portions in the formula; (2) setting the temperature of a stirrer between 80 and 110 DEG C, and drying wood powder in the stirrer for 30 to 120 minutes; (3) then, adding the melamine, the titanium pigment, the ultramarine blue powder and auxiliary materials including the fire retardant and / or the aromatizer and / or the antistatic agent to stir again for 15 to 30 minutes, and finally adding active carbon to stir continuously for 10 minutes; (4) obtaining a mixture after heat preservation at a temperature of between 20 and 80 DEG C; (5) maintaining the temperature of the mixture, paving the mixture in a die cavity and covering a decorative film before and after paving the mixture; (6) carrying out sulfuration for 15 to 35 minutes by a flat sulfuration machine at a temperature of between 160 and 170 DEG C under a clamping pressure ranging from 1.4 to 2.6MPa; and (7) transferring the mixture to a cooling machine to cool down the mixture to less than 40 DEG C. The one-time forming high-strength decorative slab has the characteristics of high strength, high toughness, high temperature resistance, aging resistance, waterproofness, environmental protection, no deformation, and the like.

Owner:SUZHOU GOODTIME TECH DEV

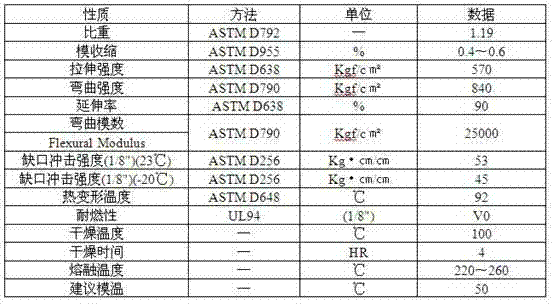

Cold resistant polycarbonate/ABS alloy for intelligent ammeter shell and preparation method thereof

ActiveCN102311628AImprove performanceConvenient amountTime integral measurementFluorescenceULTRAMARINE BLUE

The invention discloses a cold resistant polycarbonate / ABS alloy for an intelligent ammeter shell and a preparation method thereof. Raw materials of the cold resistant polycarbonate / ABS alloy for an intelligent ammeter shell comprise the following components of: by weight, 25-50 parts of PC, 20-50 parts of a PC reworked material, 20-30 parts of an ABS reworked material, 5-10 parts of MBS, 5-8 parts of triphenyl phosphate, 0.3-0.5 part of an FR 2025 fire retardant, 0.5-2 parts of titanium dioxide, 0.1-0.5 part of an anti-oxidant 1010, 0.1-0.5 part of an anti-oxidant 168, 0.1-0.5 part of an ultraviolet resistance agent UV-531, 0.03-0.08 part of a diffusion powder EBS, 0.02-0.06 part of an ultramarine blue powder, 0.02-0.04 part of an iron oxide red powder, 0.005-0.01 part of a high temperature resistance fluorescent yellow powder, and 2-5 parts of a cold resistant agent 2602. The alloy provided by the invention has characteristics of high performance, high cold resistance, high flame retardation, high impact resistance, high stability, antistatic performance and the like, and is suitable for the preparation of an intelligent ammeter shell in a cold region as well as a terminal row.

Owner:江苏振东电气设备有限公司

Boron and nitrogen containing heterocyclic compounds

ActiveUS20190211038A1Narrow emission spectrumHigh saturated deep blue emissionSolid-state devicesSemiconductor/solid-state device manufacturingElectricityOrganic light emitting device

Boron and nitrogen containing heterocyclic compounds are disclosed, which can be used as emitters, hosts, charge blocking materials, charge transporting materials, etc. in an electroluminescent device. These novel compounds can offer very narrow emissive spectrum, and obtain high saturated deep blue emission. Also disclosed are an organic light-emitting device and a formulation.

Owner:BEIJING SUMMER SPROUT TECH CO LTD

Polycarbonate (PC)/glass fiber (GF) alloy for intelligent water meter housing and preparation method thereof

The invention discloses a PC / GF alloy for the housing of an intelligent water meter and a preparation method thereof. The raw material formula of the PC / GF alloy for the housing of the intelligent water meter comprises the following components, by weight, 30-50 parts of PC, 30-50 parts of a recycled material of the PC, 0.5-2 parts of titanium dioxide, 9.5-11.5 of a GF, 2-6 parts of a cold resistant agent E920, 0.1-0.5 parts of an antioxidant 1010, 0.1-0.5 parts of an antioxidant 168, 0.3-0.5 parts of an ultraviolet resistant agent UV-531, 0.03-0.08 parts of diffusion powder EBS, 0.04-0.08 parts of ultramarine blue powder, 0.02-0.04 parts of iron oxide red powder, and 0.005-0.01 parts of high temperature resistant fluorescein powder. All performance indexes of the PC / GF alloy for the housing of an intelligent water meter reach or exceed standards of a national water reticulation system, and the PC / GF alloy which has the characteristics of high performance, high shock resistance, high stability, good cold resistance, stable body, high toughness, standard compliant color, and accordance of environmentally friendly standards and the like can be applied to cold regions.

Owner:浙江恒成高分子材料股份有限公司

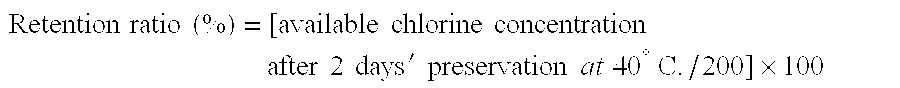

Microbicide compositions

InactiveUS20030155549A1High bactericidal effectImprove securityBiocideDead animal preservationParticulatesHypochlorite

A colored liquid hypochlorite bleach composition is provided, comprising a particulate pigment such as Ultramarine Blue, which is stably suspended in the composition by means of a flocculate, such as calcium soap flocs.

Owner:KAO CORP

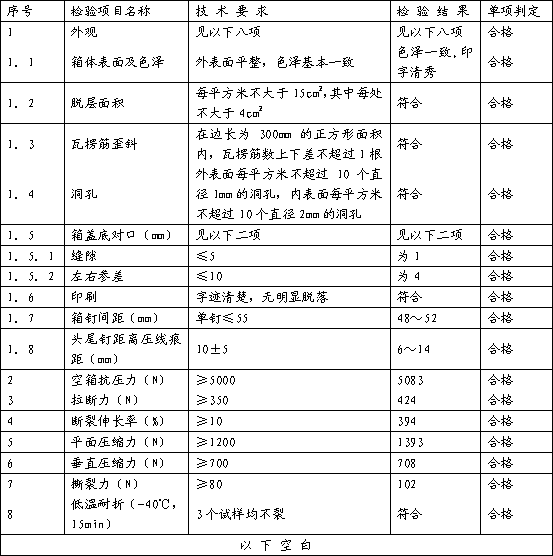

Calcium plastic corrugated board and production method thereof

InactiveCN102700213AHigh breaking forceImprove tear strengthLayered productsWhitening AgentsModified carbon

The invention provides a calcium plastic corrugated board. The calcium plastic corrugated board has a layer structure, consists of a surface calcium plastic paper layer, a core calcium plastic corrugated paper layer and a bottom calcium plastic paper layer, has the total thickness of 3.6 to 4.2mm and the corrugated rib number of 18 to 20 pieces / 100mm, and is prepared from the following raw material components in part by weight: 7 to 8 parts of polyethylene, 20 to 30 parts of modified calcium carbonate, 20 to 25 parts of calcium plastic return material, 0.4 to 0.6 part of stearic acid, 0.01 to 0.03 part of white oil, 0.3 to 0.5 part of titanium dioxide, 0.08 to 0.12 part of ultramarine blue and 0.08 to 0.12 part of whitening agent. A method comprises the following steps of: preparing the modified calcium carbonate, and preparing the calcium plastic board according to the conventional process for producing the calcium plastic corrugated board. The calcium plastic board is low in raw material cost, the process is simple, various performance indexes of a calcium plastic box prepared from the calcium plastic board meet the national standard requirements, and the raw material cost of the calcium plastic box is greatly reduced.

Owner:ANHUI TIANHE PACKAGE MATERIALS

Polycarbonate/glass fiber alloy used for cold resistant housing of intelligent water meter and preparation method thereof

ActiveCN102311625AImprove performanceSave energyTime integral measurementGlass fiberULTRAMARINE BLUE

The invention discloses polycarbonate / glass fiber alloy used for the cold resistant housing of an intelligent water meter and a preparation method thereof. The polycarbonate / glass fiber alloy comprises, by weight, 30 to 50 parts of PC, 30 to 50 parts of an PC recycled material, 0.3 to 0.5 part of a fireproof agent FR2025, 0.5 part to 2 parts of titanium dioxide, 9.5 to 11.5 part of glass fiber, 2 to 5 parts of EMA, 0.1 to 0.5 part of an anti-oxidant1010, 0.1 to 0.5 part of an anti-oxidant 168, 0.3 to 0.5 part of an ultraviolet resistant agent UV-531, 0.03 to 0.08 part of diffusion powder EBS, 0.04 to 0.08 part of ultramarine blue powder, 0.02 to 0.04 part of iron oxide red powder 0.005 to 0.01 part of high temperature resistant florescent yellow powder and 2 to 5 parts of a cold resisting agent 2602. The alloy has the characteristics of high performance, high cold resistance, high fire retardancy, high impact, high stability, resistance to static electricity and the like, and can be used for preparing the housing of intelligent water meters used in chilly regions and for preparing terminal rows.

Owner:江苏百凌电器有限公司

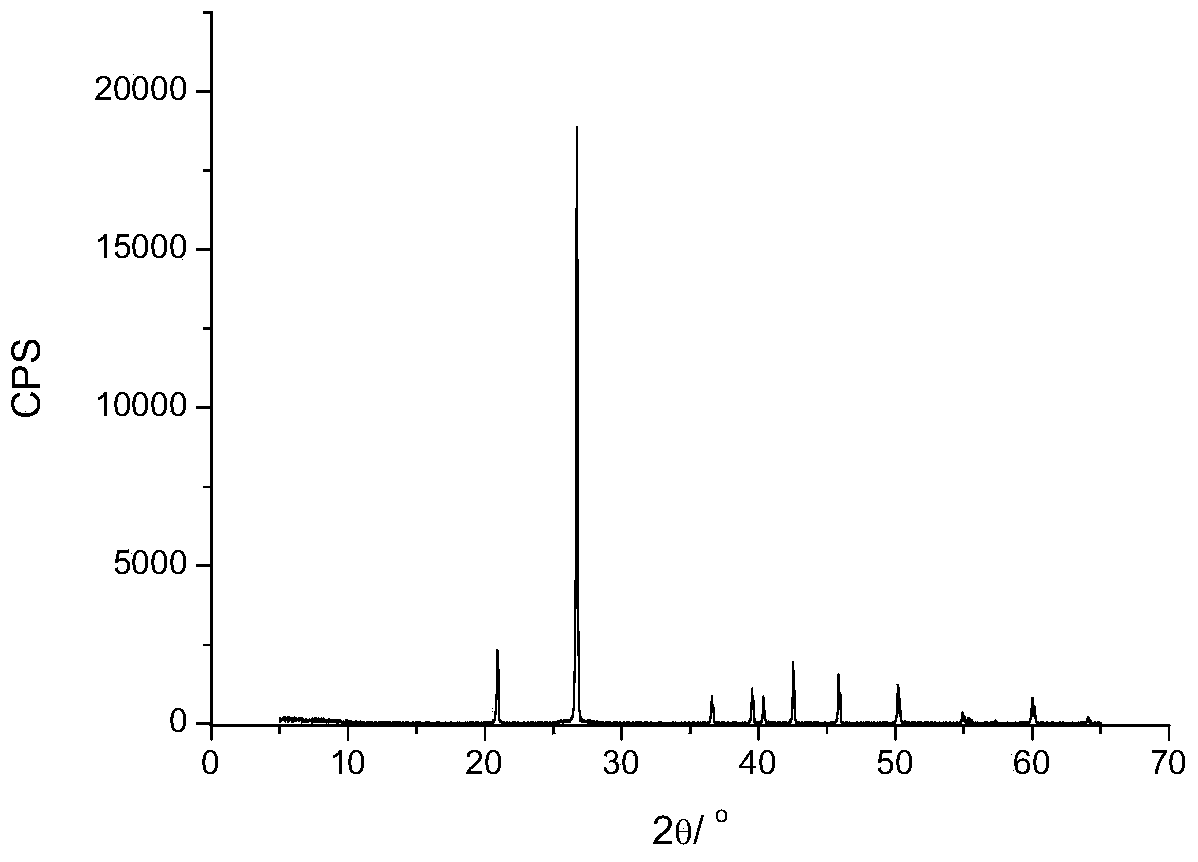

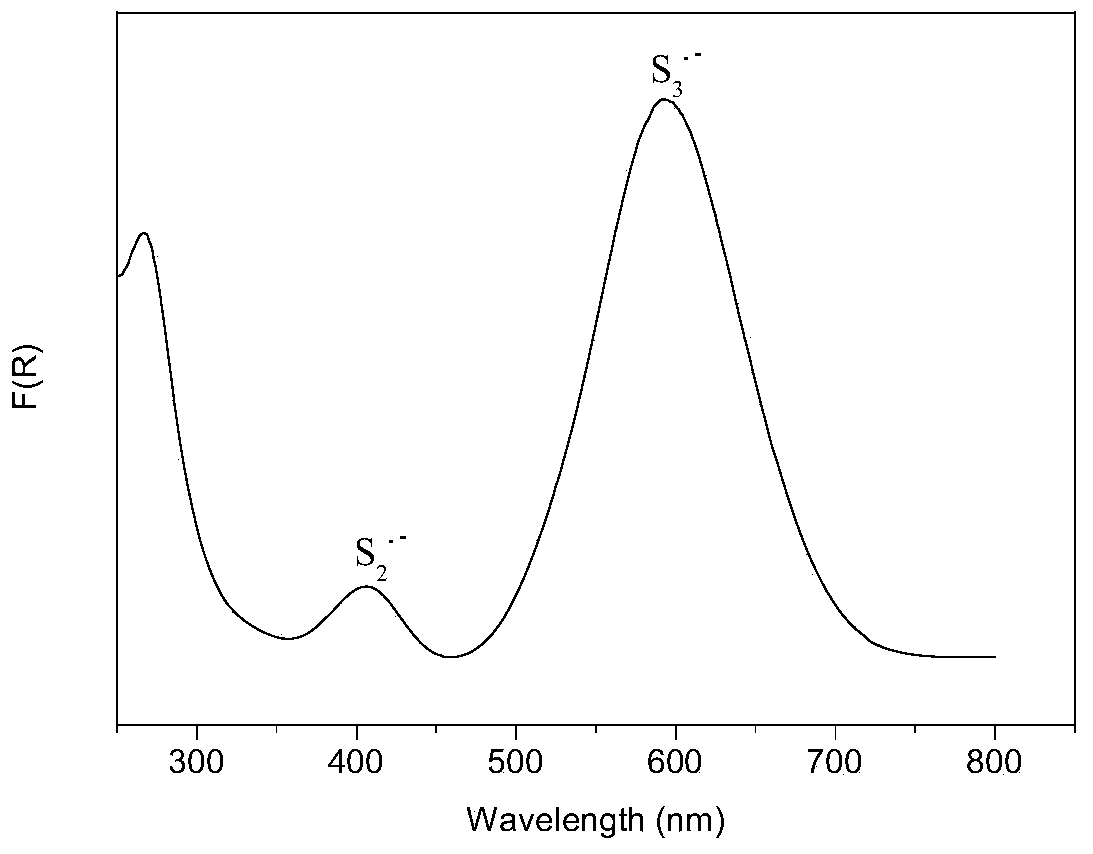

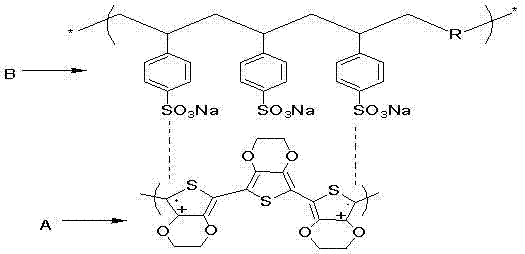

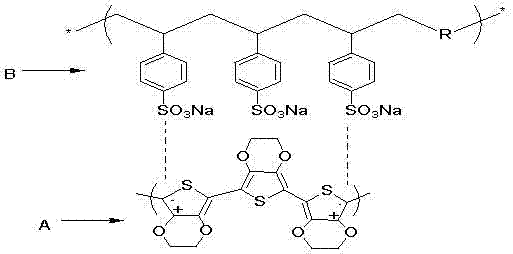

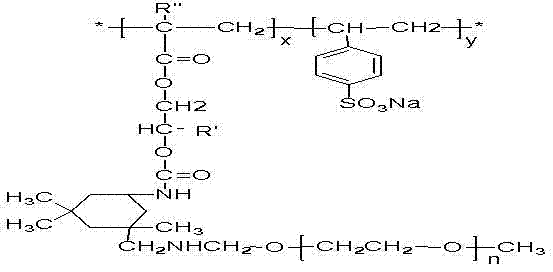

Crosslinkable poly-(3,4-ethylenedioxythiophene) aqueous dispersoid and preparation method thereof

ActiveCN102443250ASmall particle sizeImprove dispersion stabilitySemiconductor materialsPtru catalyst

The invention provides a crosslinkable poly-(3,4-ethylenedioxythiophene) aqueous dispersoid and a preparation method thereof, relating to the fields of organic semiconductor material preparation technology and application thereof. The crosslinkable (3,4-ethylenedioxythiophene) aqueous dispersoid is prepared by carrying out reaction on monomer, oxidant, a catalyst, a template and adulterant in de-ionized water, wherein the template and the adulterant functionalize sodium polystyrene sulfonate and blocking aqueous polyurethane; the aqueous dispersoid is dark blue in color, and the prepared aqueous dispersoid is subjected to post treatment in a centrifuging manner; and the film formed from the dispersoid can be deblocked and crosslinked at high temperature, so that the water-absorbing capacity of the film is greatly reduced and the film-forming effect is improved. Ultraviolet spectrophotometer tests show that the formed film has no obvious absorption in the visible wavelength range, thereby ensuring that the formed film is suitable for being used as a transparent electrode.

Owner:溧阳常大技术转移中心有限公司

Polypropylene composite material for outdoor sport floor and preparation method thereof

The invention provides a polypropylene composite material for an outdoor sport floor and a preparation method thereof. The raw material formula of the polypropylene composite material for the outdoor sport floor comprises the following components in parts by weight: 40-60 parts of polypropylene, 30-50 parts of polypropylene reclaimed material, 5-40 parts of calcium carbonate, 5-10 parts of toughening agent POE (polyolefin elastomer), 0.1-0.5 part of antioxidant 1010, 0.1-0.5 part of antioxidant 168, 0.3-0.5 part of uvioresistant agent UV-531, 0.03-0.08 part of diffusion powder EBS (ethylene bis stearamide), 0-0.02 part of sunproof bright-red powder, 0-0.3 part of ultramarine blue powder, 0-0.04 part of permanent yellow GR and 2-6 parts of linear low-density polyethylene. The polypropylenecomposite material provided by the invention has the characteristics of high performance, scratch resistance, low-temperature resistance, high fire resistance, fireproofing property, anti-aging property and the like and is easy to lay and reproducible, six basic indexes in the sport industry can be met, buffer action during sports is good, the composite material can endure high temperature of 80 DEG C and low temperature of minus 40 DEG C, service life can reach up to more than 20 years, and colour is beautiful.

Owner:浙江省嘉名染整有限公司

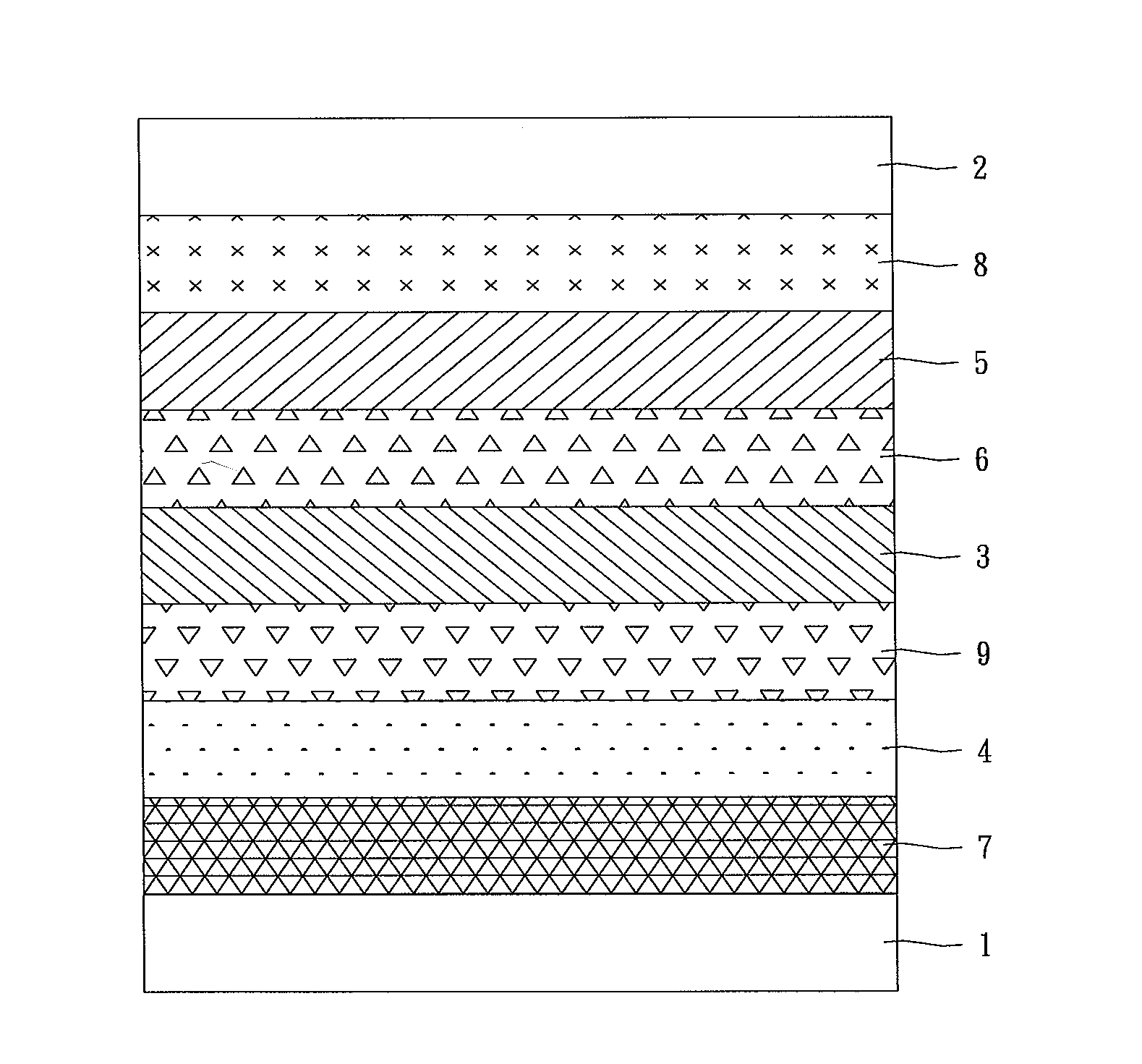

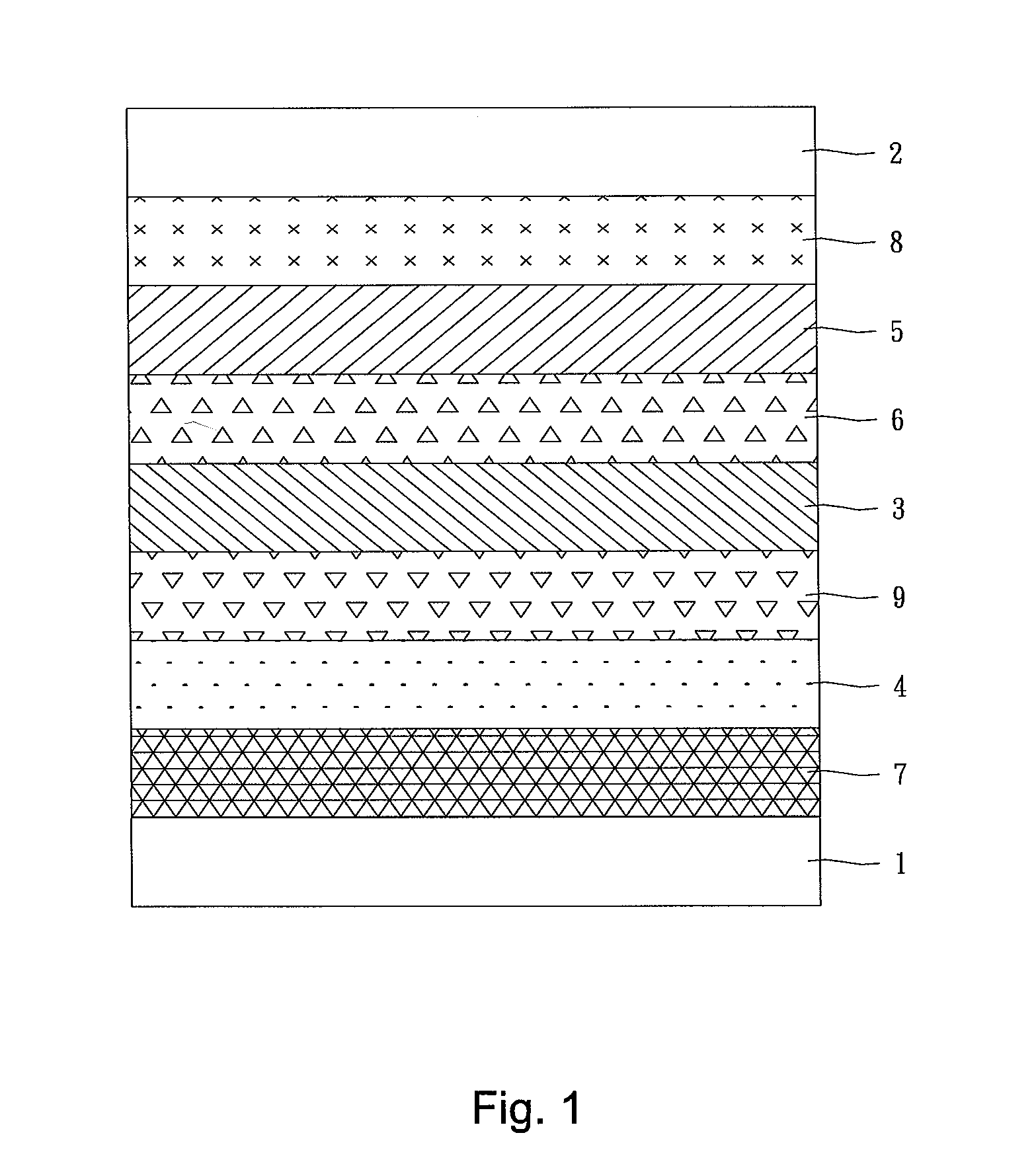

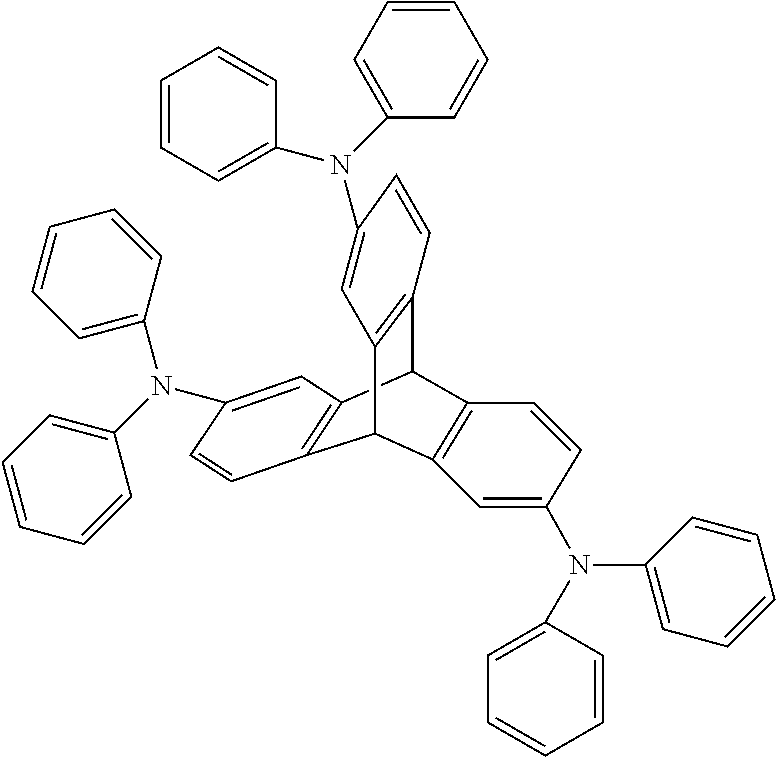

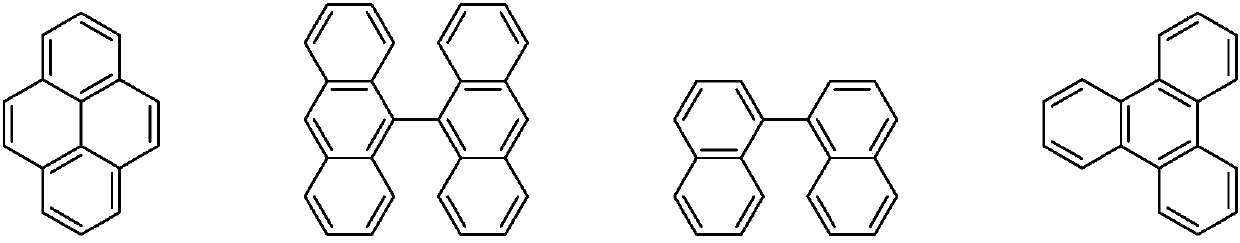

Triptycene derivatives having symmetric or asymmetric substituents and organic light emitting diode using the same

ActiveUS20150137084A1High performance and efficiencySolid-state devicesSemiconductor/solid-state device manufacturingULTRAMARINE BLUEMaterials science

Triptycene derivatives having symmetric or asymmetric substituents are provided. The triptycene derivatives of the present invention may be applied in phosphorescent lighting devices ranging from deep blue to red and may be applied as a host material, an electron transporting material or a hole transporting material. An OLED device is also herein disclosed.

Owner:NATIONAL TSING HUA UNIVERSITY

Co-extruded PVC colorized wood-grain profile and preparation method thereof

The invention discloses a co-extruded PVC colorized wood-grain profile which mainly comprises a main body and a colorized co-extruded wood-grain layer formed on the surface of the main body, wherein the colorized co-extruded wood-grain layer consists of a grain material and a base material. The grain material comprises the following components: polyvinyl chloride I, chlorinated polyethylene, filler, a stabilizer, an ultraviolet light absorber, an antioxidant, ACR and a pigment I and the base material comprises the following components: polyvinyl chloride II, chlorinated polyethylene, filler, a stabilizer, an ultraviolet light absorber, an antioxidant, ACR and a pigment II, wherein the relative molecular weight of the polyvinyl chloride I is greater than that of the polyvinyl chloride II, and the pigments I and II are respectively one or more of inorganic yellow, red, carbon black, titanium dioxide and ultramarine blue. According to the co-extruded PVC colorized wood-grain profile, the raw material of the co-extruded layer is re-designed based on the original profiled bar, so that the wood grain is clear and well matched with the window so as to satisfy the requirements on high-end decoration.

Owner:TIANJIN ZHONGCAI PROFILES

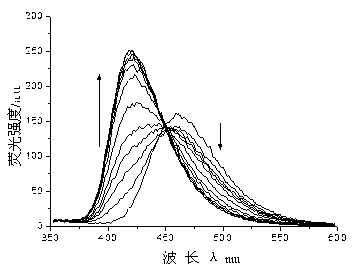

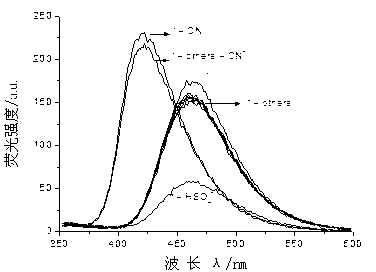

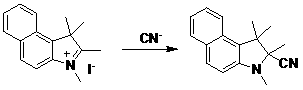

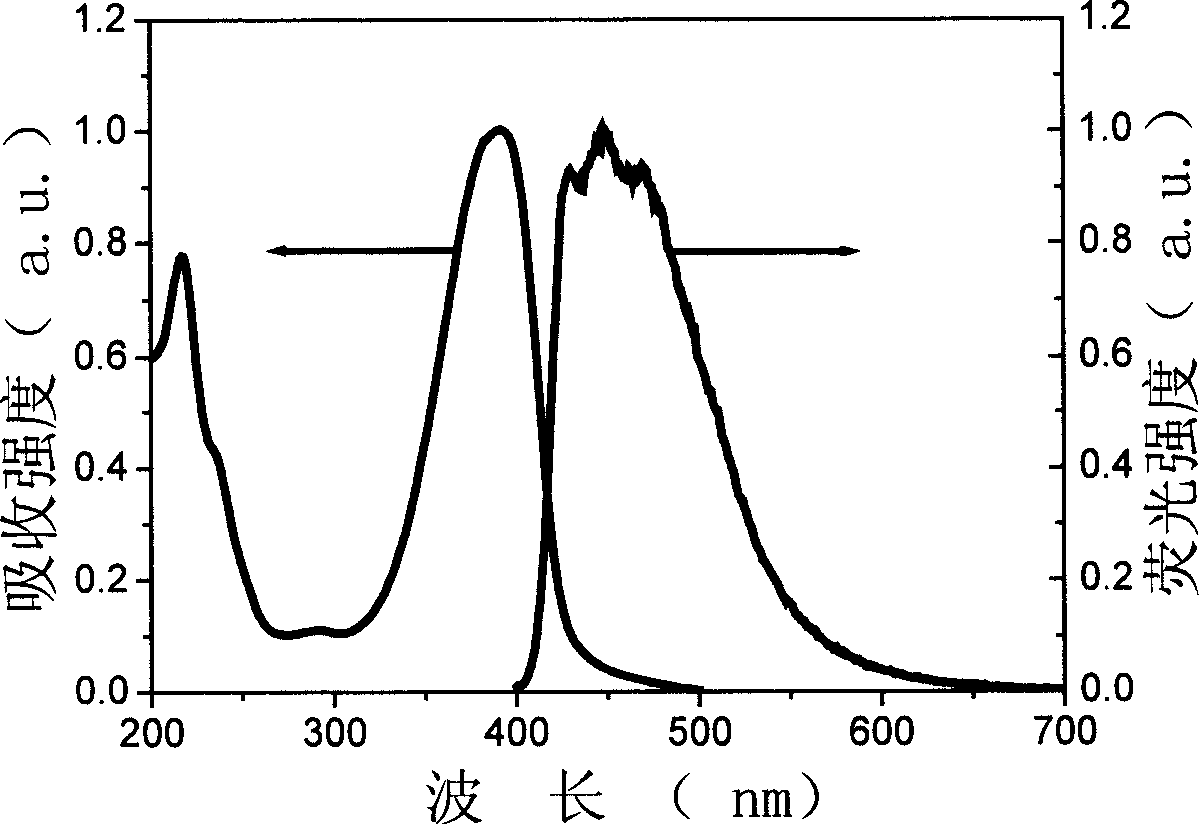

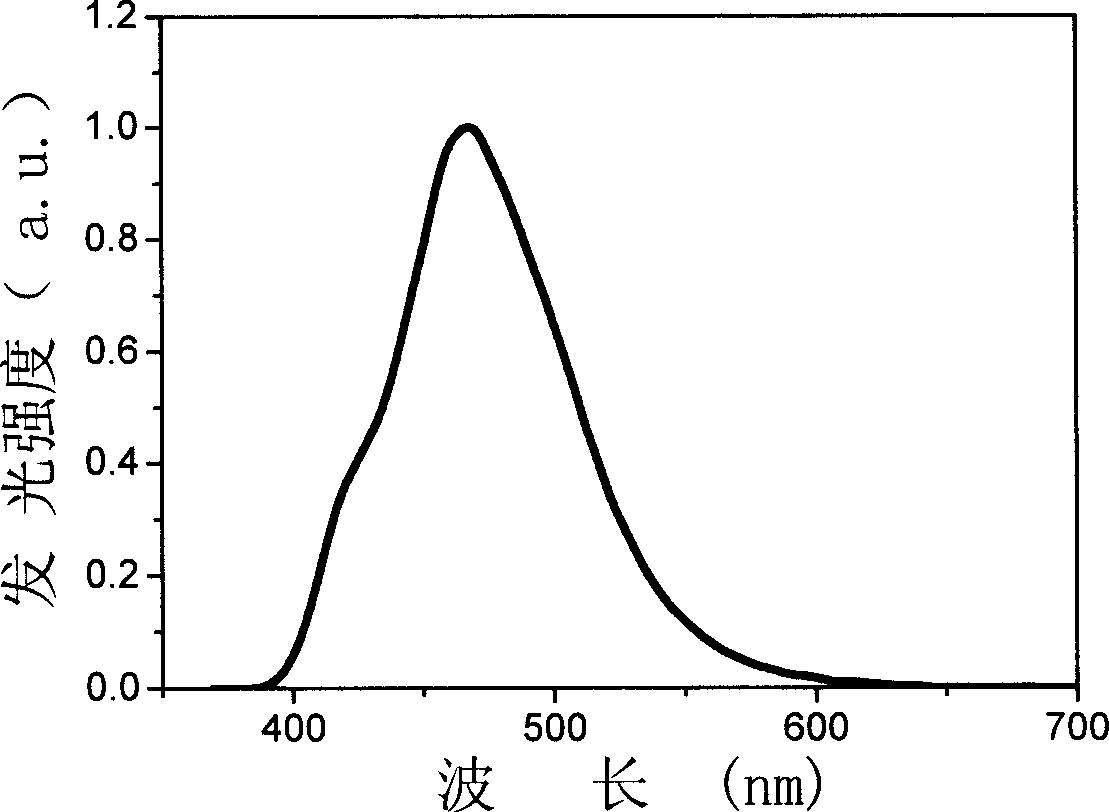

Application method of ratio-type cyanide ion fluorescent probe molecule

InactiveCN103134787ATo achieve specific identificationHigh electron deficiencyFluorescence/phosphorescenceFluoProbesFluorescence

The invention relates to an application method of a ratio-type cyanide ion fluorescent probe molecule. The invention belongs to the technical field of anion detection. The method is characterized in that the method is an application of a ratio fluorescent probe molecule, which is 1,2,2,3-tetramethyl-4,5-benzoindoline, used in cyanide ion detection. The probe molecule is obtained by a one-step process of periodic methane alkylation of 2,3,3-trimethyl-4,5-benzindole. In a system where DMF:H2O=1:1 (V / V), the probe molecule is excited by using 320nm light, and emission occurs at 461nm. When cyanide ion is added, intra-molecular charge transfer (ICT) process is broken, emission peak at 461nm is reduced, and new emission peak occurs at 425nm. Therefore, solution fluorescence is turned from bluish green to deep blue. In a system wherein cyanide ion coexists with other anions, the probe molecule shows high interference resistance, high specificity, and high sensitivity.

Owner:TAIYUAN UNIV OF TECH

Recovery culturable viable but non culturable (VBNC) arthrobacterium DSC4 strain and recovering method and application thereof

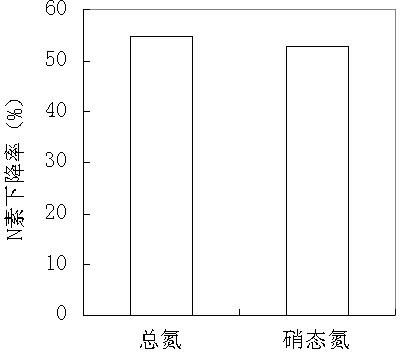

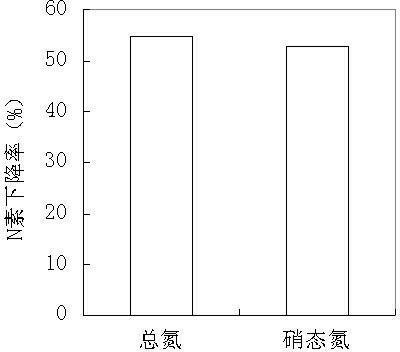

ActiveCN102604870AObvious effect of denitrification and denitrificationBacteriaMicroorganism based processesGenus ArthrobacterULTRAMARINE BLUE

The invention belongs to the fields of agricultural biotechnology and environmental protection and relates to a 'viable but non culturable (VBNC)' arthrobacterium strain which is obtained through separation by using recovery culturable technology, a recovering method of the strain and application of the strain. The preservation number of the strain is CCTCC No: M2011406; the preservation organization is China Center for Type Culture Collection; the preservation address is Wuhan University, Wuhan Province, China; and the preservation date is 25th Nov. 2011. The viable but non culturable (VBNC) arthrobacterium DSC4 can turn the color of the reaction liquid of a Giltay culture medium to dark blue from green and generate gas. At the same time, the conversion rate of nitrate nitrogen is detected to be 54.7 percent, the total nitrogen depletion rate is 52.9 percent, and residue of ammoniacal nitrogen and nitrite nitrogen is not detected. The strain has an obvious denitrification effect.

Owner:郎溪品旭科技发展有限公司

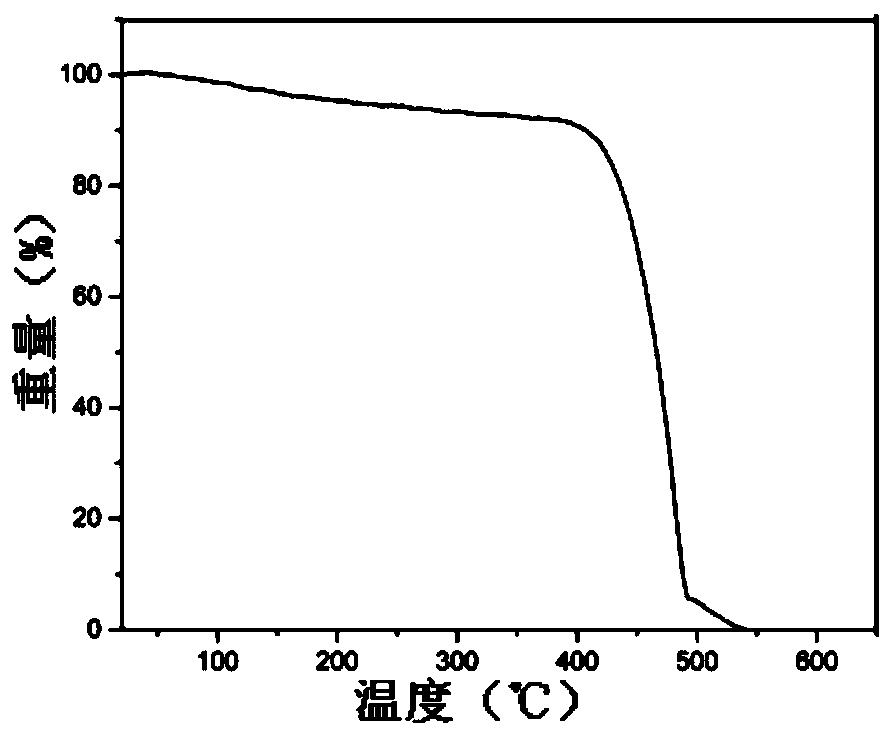

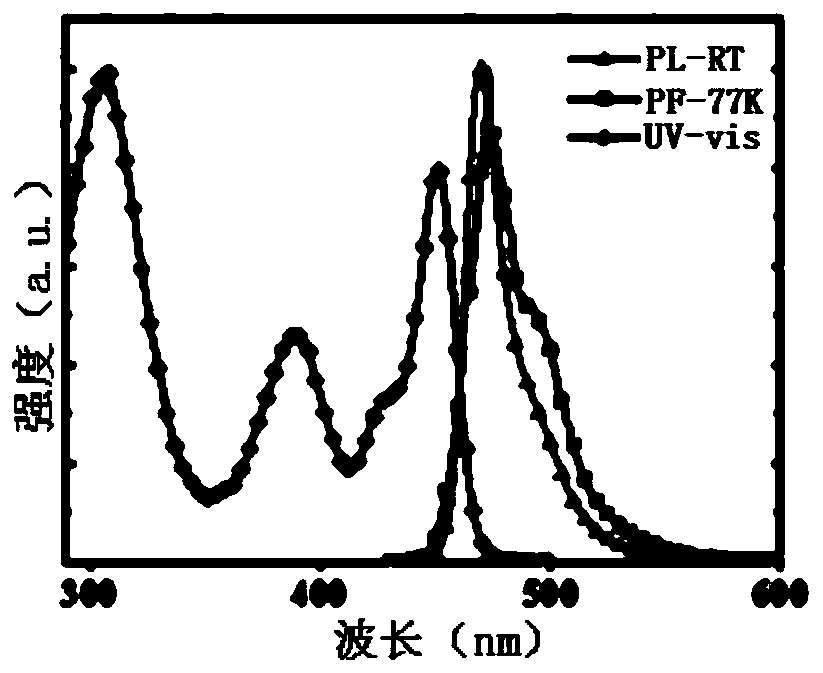

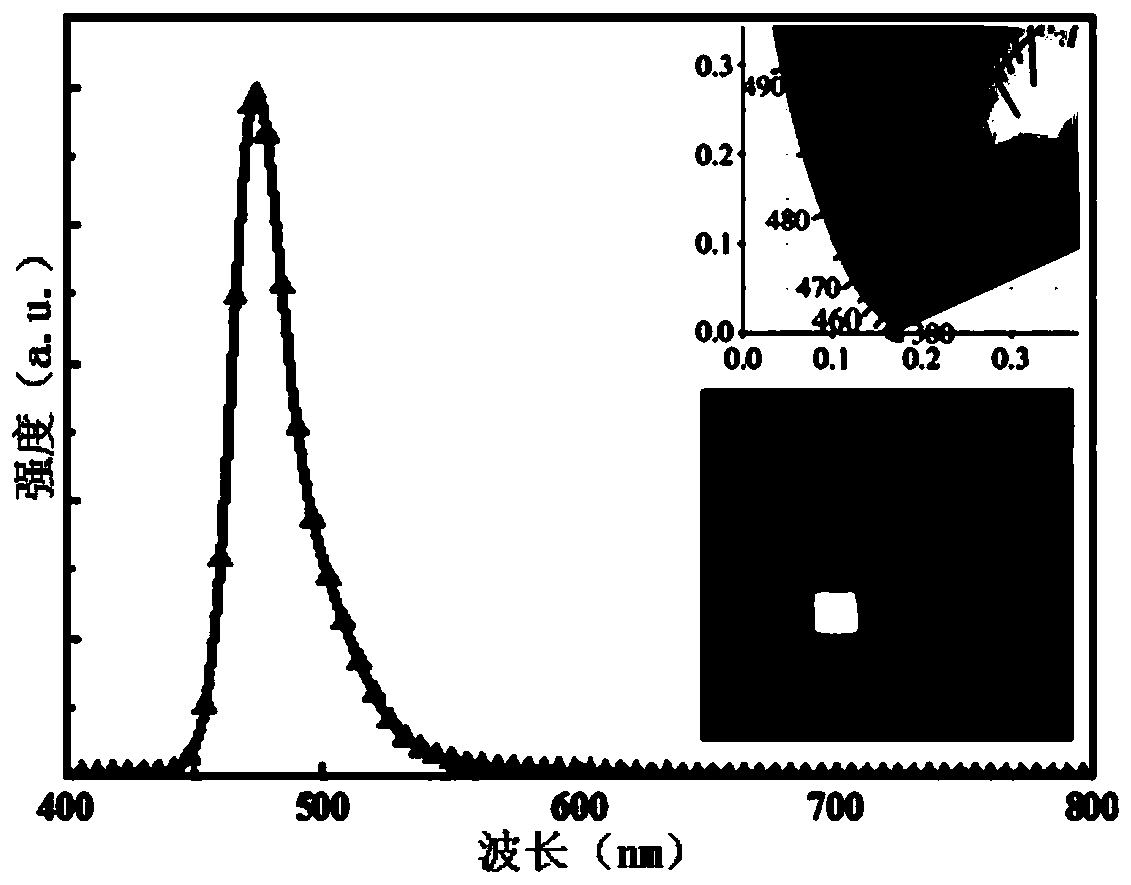

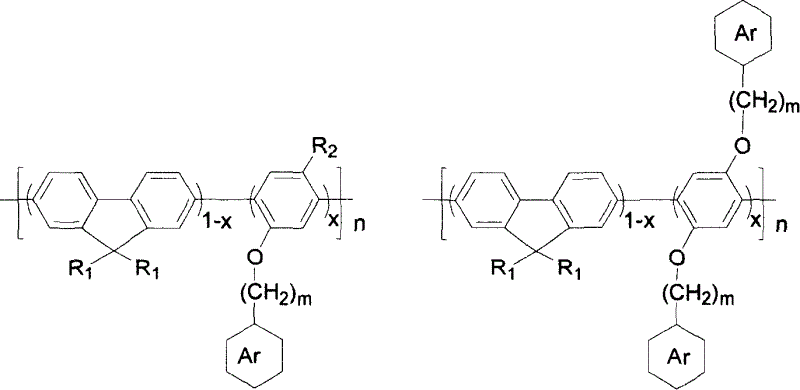

Blue color electroluminescent macromolecular material and method for making same

The invention relates to a blue color electroluminescent macromolecular material and method for making same, which comprises chemically grafting blue light or blue-green light fluorescent dye molecules with high fluorescence quantum efficiency to the parent body of the prussian blue macromolecules, dispersing at molecular level, regulating the relative content of the blue light or blue-green light fluorescent dye molecules in the parent body of the prussian blue macromolecules, thus realizing the part or complete energy transfer of prussian blue macromolecules to blue light or green light fluorescent dye molecules, enhancing the light emission of blue light or blue-green light fluorescence dye molecular elements, and achieving the ethereal blue electroluminescence of the macromolecular material, and constructing a categories of molecular dispersive type blue electroluminescent macromolecular materials.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

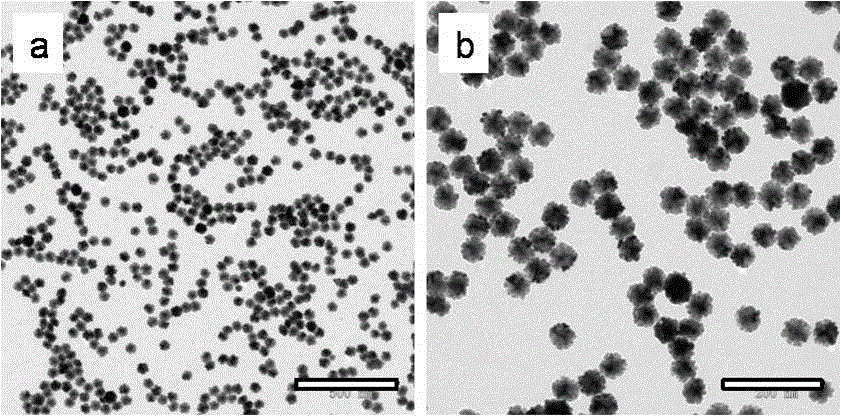

Flower-like gold palladium heterogeneous nano particle with good electro-catalytic property and preparing method thereof

InactiveCN104907557AUniform particle sizeGood dispersionMaterial nanotechnologyOrganic compound preparationAlcohol fuelReaction temperature

The invention relates to a flower-like gold palladium heterogeneous nano particle with a good electro-catalytic property and a preparing method thereof. The preparing method of the particle includes the following steps that firstly, under the condition of magnetic force stirring, ascorbic acid (AA), sodium citrate, dehydrate (C6H5Na3O7.2H2O), an aurum (Au) decahedron colloidal solution and a disodium tetrachloropalladate (Na2PdC14) water solution are added to an ethylene glycol solution in sequence; secondly, a reaction polymeric precursor solution is placed at the reaction temperature of 25-75 DEG C for 0.2-1 hour, and then centrifuging is conducted for 15-50 minutes under the condition of the rotation speed of 5000-15000 turns per minute; thirdly, solvent ultrasonic is used for cleaning dark blue precipitate products, and therefore the flower-like gold palladium heterogeneous nano particle is prepared. The flower-like gold palladium heterogeneous nano particle has important application value in the aspects of direct alcohol fuel batteries, surface enhanced Raman scattering (SERS), chemical and biological sensors and the like.

Owner:UNIV OF JINAN

Projection coating, projection curtain surface and manufacturing method of projection curtain surface

The invention discloses a projection coating, a projection curtain surface and a manufacturing method of the projection curtain surface. The projection coating comprises, by mass, 0.5-1.5 parts of ultramarine blue, 40-60 parts of titanium dioxide and 80-120 parts of polymer resin. The projection coating comprises the ultramarine blue and the titanium dioxide, the blue and white effect is generated, after a blue and white projection is projected, the projection picture is clearer, meanwhile a certain light adsorption function is achieved, and eyes can be protected quite well.

Owner:深圳市石代科技集团有限公司

High-definition transparent household purifying film and preparation method thereof

The invention discloses a high-definition transparent household purifying film and a preparation method thereof. The high-definition transparent household purifying film is prepared from the following raw materials in parts by weight: PVC (polyvinyl chloride) resin, a plasticizer, a cold-resistant agent, talc powder, a liquid flame retardant, a PVC stabilizer, a nontoxic plasticizer, a co-solvent, cypermethrin, a dispersant, a wetting agent, silver ion powder, a color master batch, titanium dioxide powder, and ultramarine blue powder, wherein the nontoxic plasticizer is epoxidized soybean oil, the plasticizer is p-phenyl dioctyl dimethyl, and the cold-resistant agent is dioctyl adipate. The raw materials selected by the invention are nontoxic and harmless and accord with environmental protection requirements, the obtained purifying film is high in transparency, is clear and glossy, is good in softness and strong in toughness, has flame-retardant and cold-resistant properties, is soft and plump in tactile impression and exquisite in texture, and master batches are prepared from cypermethrin, silver ion powder, titanium dioxide powder and the like, so that the high-definition transparent household purifying film has the characteristics of decomposing formaldehyde, removing peculiar smells, sterilizing, preventing mildew and insects, and prolonging the service life of a floor or furniture.

Owner:GUANGDONG SHANG XIN NEW MATERIALS CO LTD

White edge strip and production method thereof

The invention provides a white edge strip comprising the following raw materials in parts by weight: 90-110 parts of 1# glue, 3-5 parts of zinc oxide, 1.1-1.9 parts of stearic acid, 2.5-3.5 parts of diethylene glycol, 2-3 parts of a yellowing-resistant accelerant, 1.1-1.8 parts of an anti-aging agent RDZ, 1.7-2.3 parts of a thermal antioxidant, 2.6-3.4 parts of a brightener, 1.7-2.3 parts of sulphur, 78-88 parts of superfine calcium carbonate, 35-45 parts of titanium dioxide, 0.35-0.48 part of ultramarine blue, 0.45-0.58 part of permanent violet masterbatch and 28-38 parts of white carbon black. The white edge strip has the advantage of good yellowing resistance. The invention also provides a production method of the white edge strip.

Owner:河南荣光鞋业有限公司

Method for preparing ultramarine blue pigment

InactiveCN104059394ABright colorMild roasting reaction conditionsInorganic pigment treatmentSulfite saltULTRAMARINE BLUE

The invention belongs to the technical field of inorganic pigment preparation, and in particular relates to a method for preparing ultramarine blue pigment. The method comprises the following steps: drying a NaA type molecular sieve, sodium carbonate, elemental sulfur, sodium hydroxide and a reducing agent, weighing the dried raw materials, grinding, mixing, putting into a ceramic crucible, tightly compressing, and sealing up; putting the pre-sealed crucible into an electric oven for first stage of roasting so as to obtain green solid powder; preparing the green solid powder into granules, sealing in the presence of oxygen, and performing second stage of roasting so as to obtain a crude ultramarine blue pigment product; and repeatedly washing the crude ultramarine blue pigment product in hot water, adding the washed crude ultramarine blue pigment product into a hot sodium sulfite solution, stirring, subsequently adding water to wash, and drying, thereby obtaining the ultramarine blue pigment. The ultramarine blue pigment prepared by using the method is bright in color, the yield can be greater than 85%, the roasting reaction conditions are gentle, the production process is simple, the reaction period is short, and the pigment is non-toxic, is good in light resistance, alkali resistance and weather resistance, and is free of environmental pollution.

Owner:慧科高新科技股份有限公司

Polyether poly(3,4-ethylenedioxythiophene) (PEDOT) water dispersion and preparation method thereof

InactiveCN102399416AImprove dispersion stabilityGood film formingFunctionalized polystyreneSemiconductor materials

The invention relates to the field of preparation technologies and applications of organic semiconductor materials, and concretely relates to a polyether PEDOT water dispersion and a preparation method thereof. The preparation of the crosslinkable EDOT water dispersion is completed by carrying out a reaction on a monomer, an oxidant, a catalyst, a template, and a doping agent in deionized water, wherein the template and the doping agent are a copolymer of functionalized polystyrene sulfonate and terminated aqueous polyurethane. The water dispersion is dark blue in color, and is post-processed in a centrifuging mode after the preparation. A film prepared from the dispersion can release the crosslinking at a high temperature, so the water absorption capability of the film is substantially reduced, and the film forming effect is improved. The formed film is tested by an ultraviolet spectrophotometer, and results show that there is no obvious absorption in the visible light wavelength range, so the film is suitable for being a transparent electrode.

Owner:CHANGZHOU UNIV

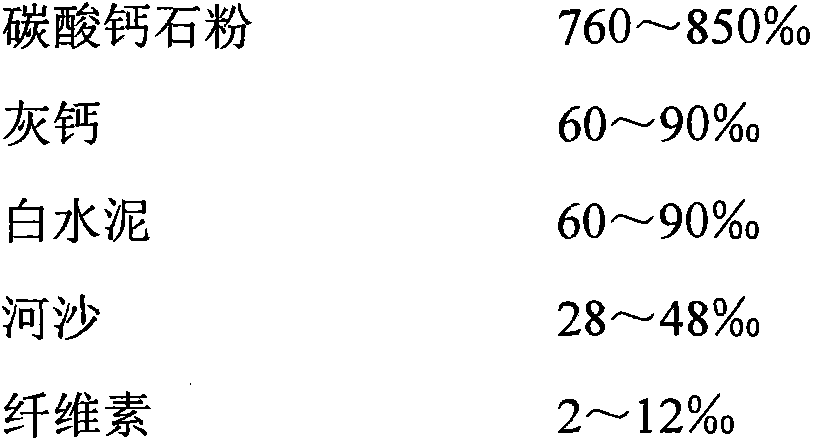

Alkali-free interior wall putty powder

InactiveCN103113776AGuaranteed aestheticsLess prone to yellowingFilling pastesEnvironmental resistanceAlkali free

The invention discloses an alkali-free interior wall putty powder, and relates to the interior wall putty powder of a wall decorative material. The alkali-free interior wall putty powder is prepared from calcium carbonate powder, polyvinyl alcohol powder, carboxymethyl cellulose, soluble starch and ultramarine blue. The alkali-free interior wall putty powder has the characteristics of simple preparation technology, low transportation cost, low cost of raw materials and high bonding strength, has no any volatile and pungent odor and the like. A yellowing phenomenon is difficult to appear by painting the putty powder on a wall surface for too long time; and the yellowing and floating phenomena are difficult to appear by constructing on an old wall surface. Other emulsion paints or wallpapers are added in the putty powder again, and the floating condition of emulsion paints or wallpapers is unlikely to be caused, so that the putty powder belongs to green and environment-friendly wall decoration. The putty powder can be widely used for the wall decoration of new and old interior walls, and particularly suitable for interior wall decoration of places such as an upscale guild hall, a hotel, a restaurant, a conference center and a family.

Owner:CHONGQING UNIV

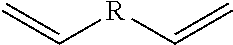

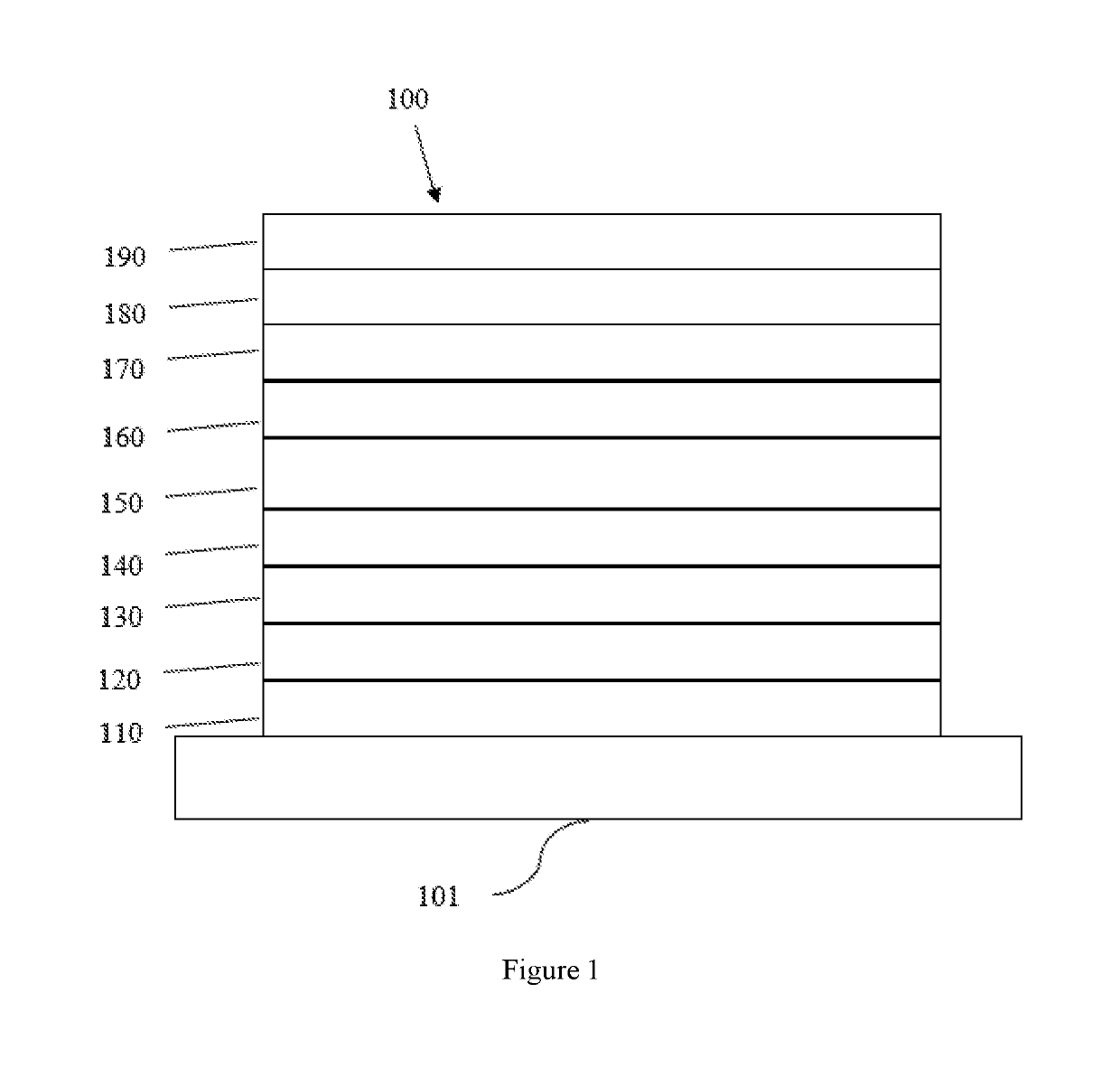

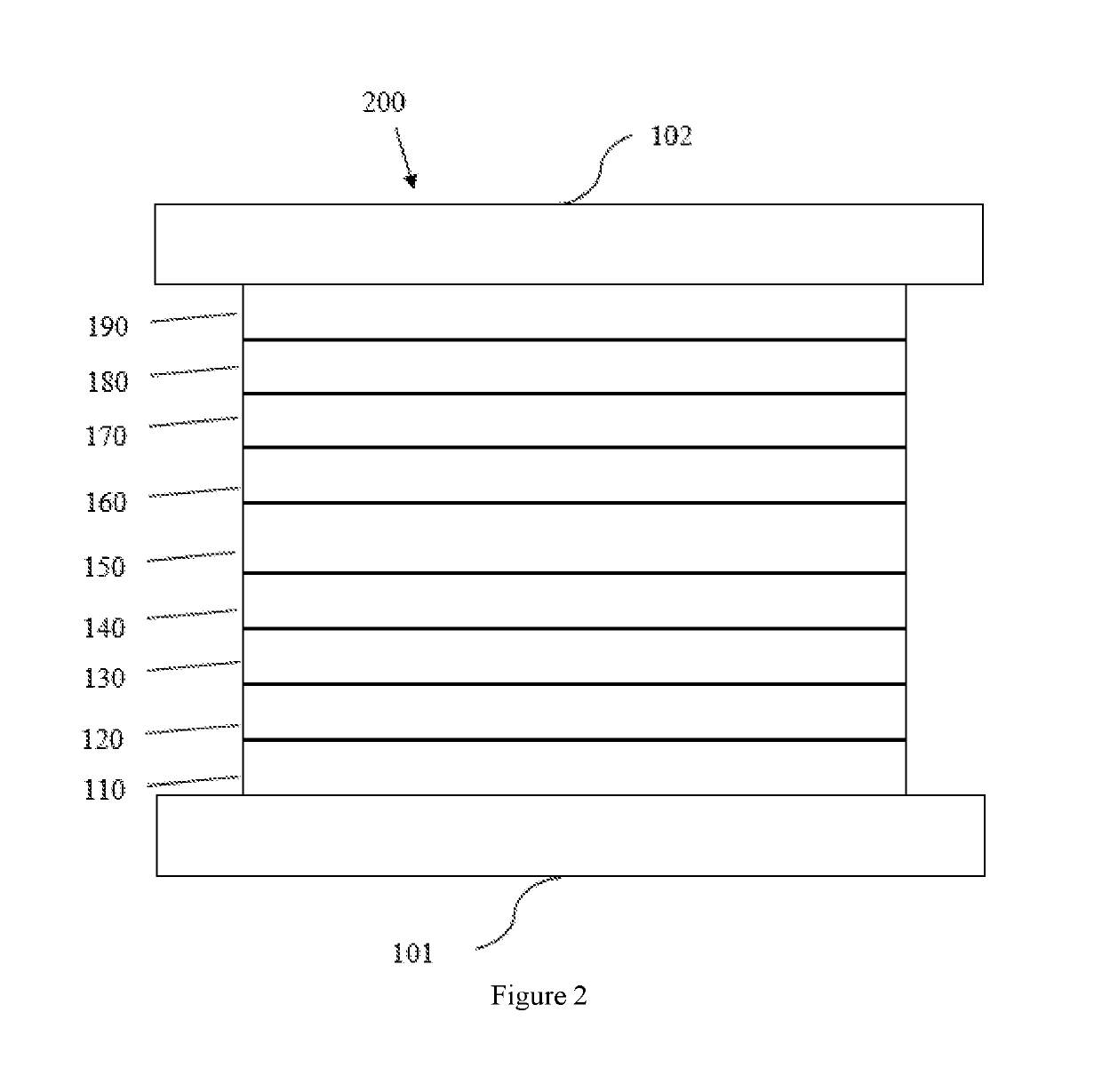

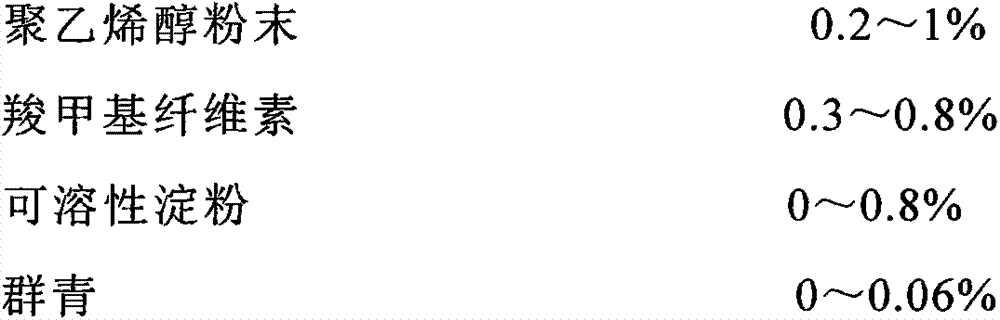

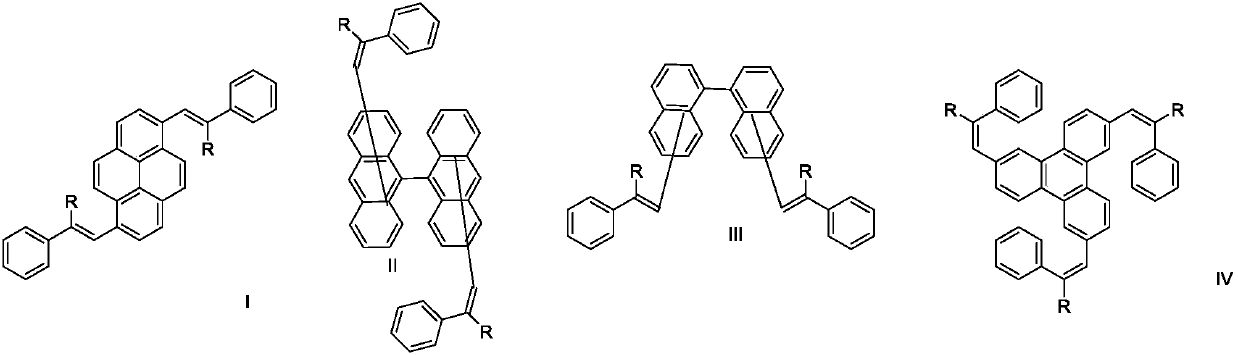

Organic electroluminescence material and organic light-emitting diode

InactiveCN107739606AExpand the range of conjugationAdjust the energy band widthOrganic chemistrySolid-state devicesBenzo(c)phenanthreneOrganic light emitting device

The invention provides an organic electroluminescence material and an organic light-emitting diode, which belong to the technical field of organic photoelectric materials. The material has a general structural formula as shown in a formula A; a mother nucleus part of the material is of dinaphthalene, dianthranide, benzophenanthrene, pyrene and other structures; the material has a blue-black emission spectrum; a conjugate range in a molecule is enlarged through a double bond, the bandwidth is adjusted, and a light-emitting range is turned into sky blue from blue black. An experimental result shows that by adopting the organic light-emitting diode prepared by the organic electroluminescence material, the light-emitting efficiency is 5.9cd / A maximally, the service life is remarkably prolonged, and the material is an excellent OLED (Organic Light-emitting Diode) material.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

Boron and nitrogen containing heterocyclic compounds

ActiveUS20190214564A1High saturated deep blue emissionNarrow emission spectrumSolid-state devicesSemiconductor/solid-state device manufacturingElectricityOrganic light emitting device

Boron and nitrogen containing heterocyclic compounds are disclosed, which can be used as emitters, hosts, charge blocking materials, charge transporting materials, etc. in an electroluminescent device. These novel compounds can offer very narrow emissive spectrum, and obtain high saturated deep blue emission. Also disclosed are an organic light-emitting device and a formulation.

Owner:BEIJING SUMMER SPROUT TECH CO LTD

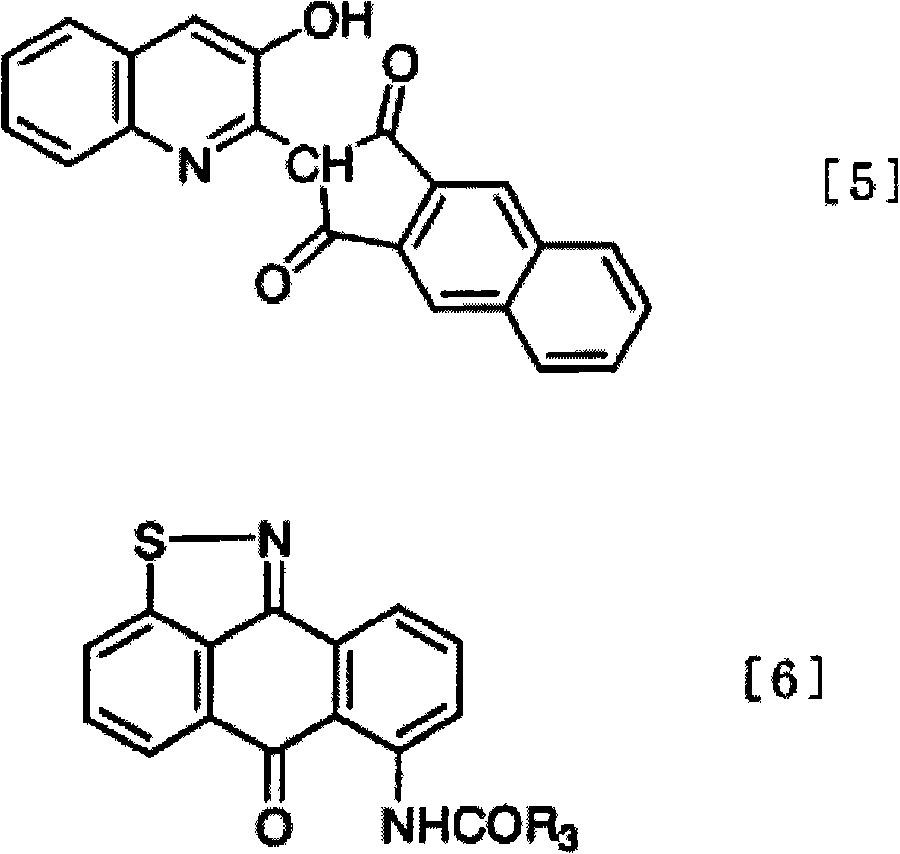

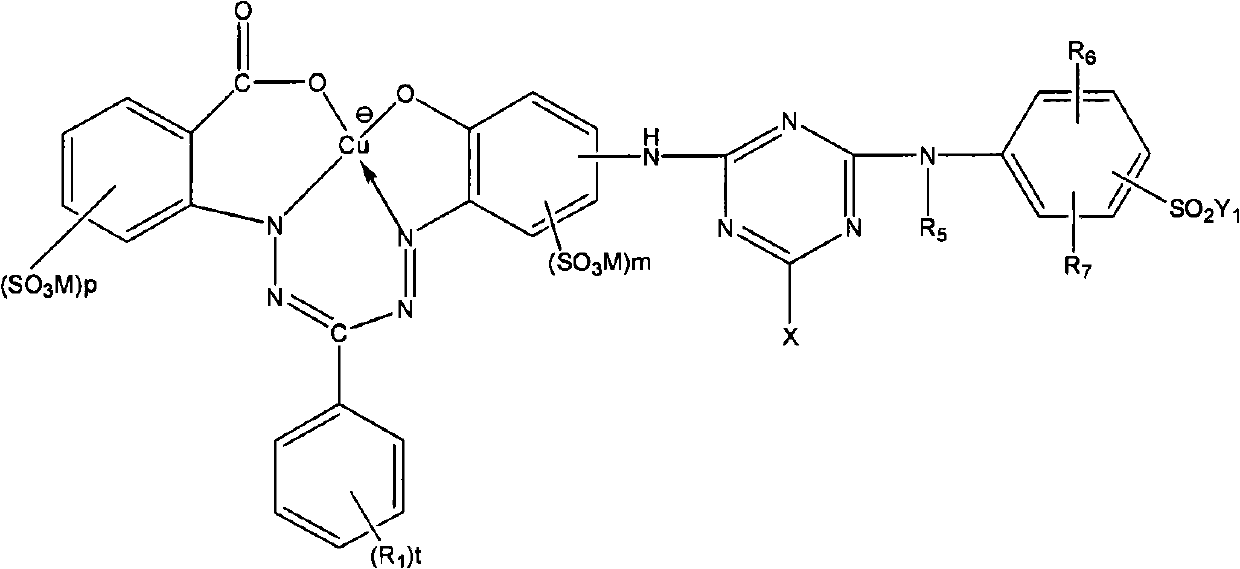

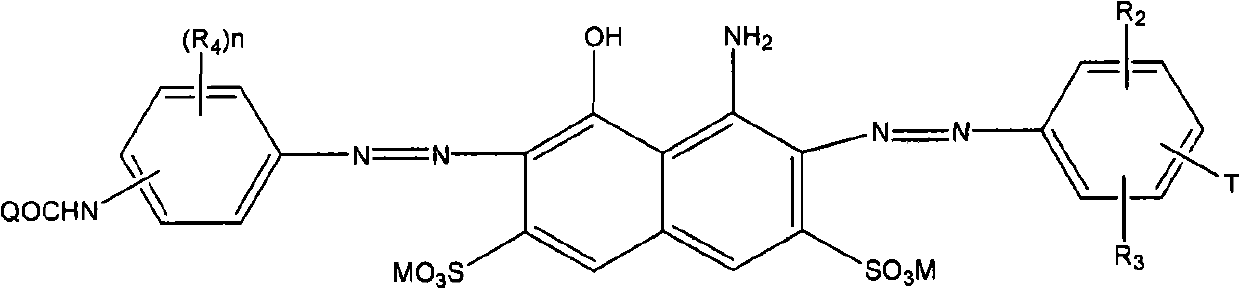

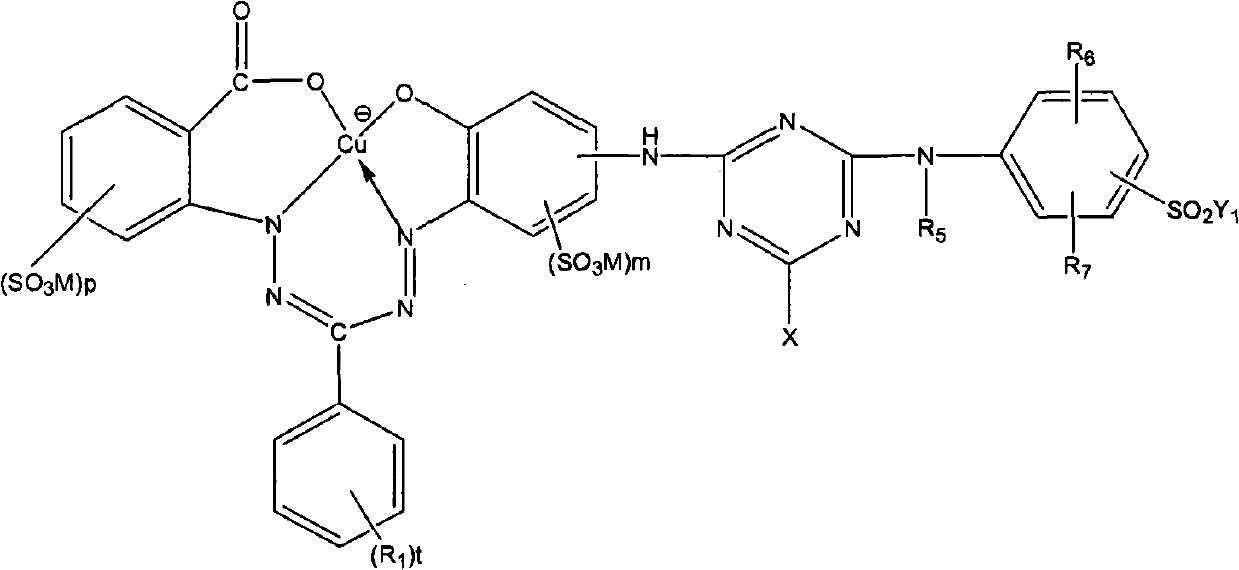

Dark blue active dye composition and application thereof in dyeing fibers

ActiveCN102115612AImprove dyeing effectHigh color fastnessOrganic dyesDyeing processFiberPhotochemistry

The invention provides a dark blue active dye composition and application thereof in dyeing fibers. The dye composition comprises one or more of dye compounds shown in a general formula (1), and one or more of dye compounds shown in a general formula (2). The dark blue active dye composition has excellent dyeing property and various items of dyefastness, and excellent compatibility with other common red and yellow active dyes. Substituent groups in the general formulas (1) and (2) are shown in the specifications.

Owner:ARGUS SHANGHAI TEXTILE CHEM

Pigmented polymerizable compositions and optical articles prepared therefrom

Provided is a polymerizable composition including: (a) a polymerizable component; and (b) a pigment component the pigment component includes: (i) an ionic or amphoteric dispersant material; and (ii) pigment nanoparticles uniformly dispersed in the dispersant material (i). The nanoparticles have a particle size of up to 500 nanometers. Also provided is a polymerizable composition of: (a) a polymerizable component including: (i) diethylene glycol bis(allyl carbonate); and (ii) a radical initiator; and (b) a pigment component which includes: (i) an ionic or amphoteric dispersant material derived from polycaprolactone; and (ii) pigment nanoparticles of ultramarine blue having an average particle size of up to 500 nanometers, uniformly dispersed in the dispersant material.

Owner:PPG IND OHIO INC

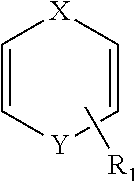

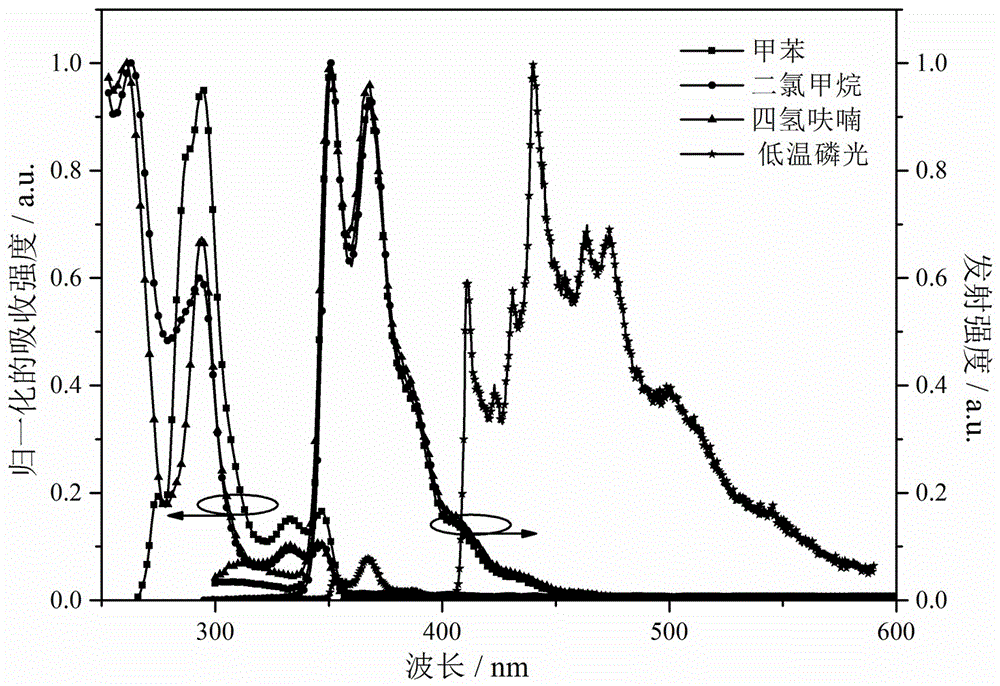

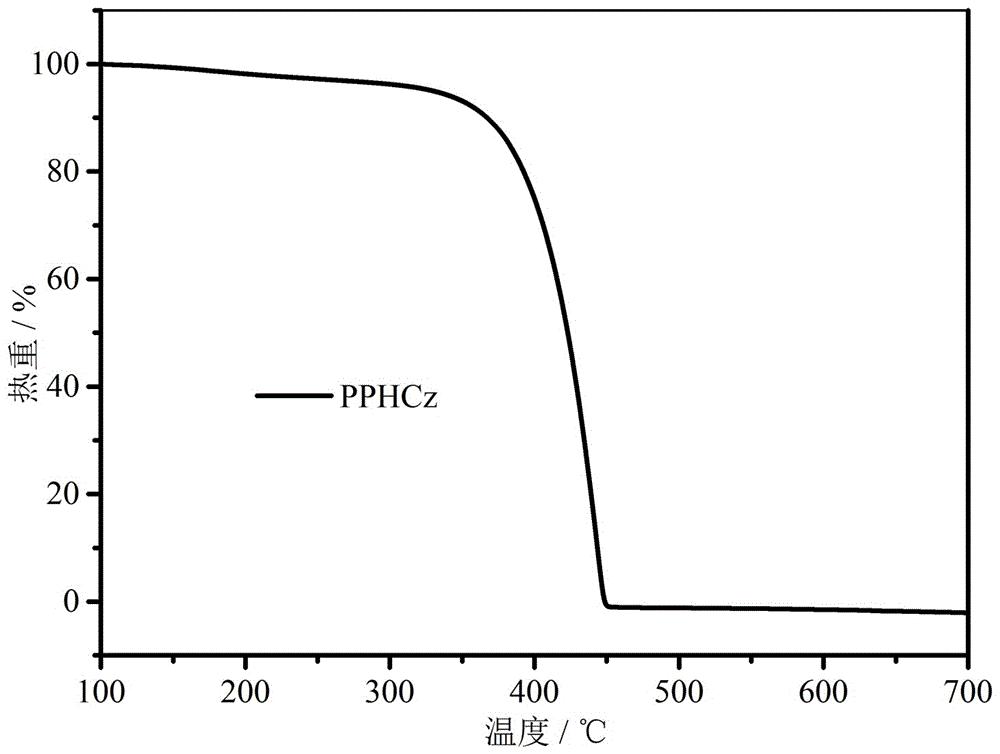

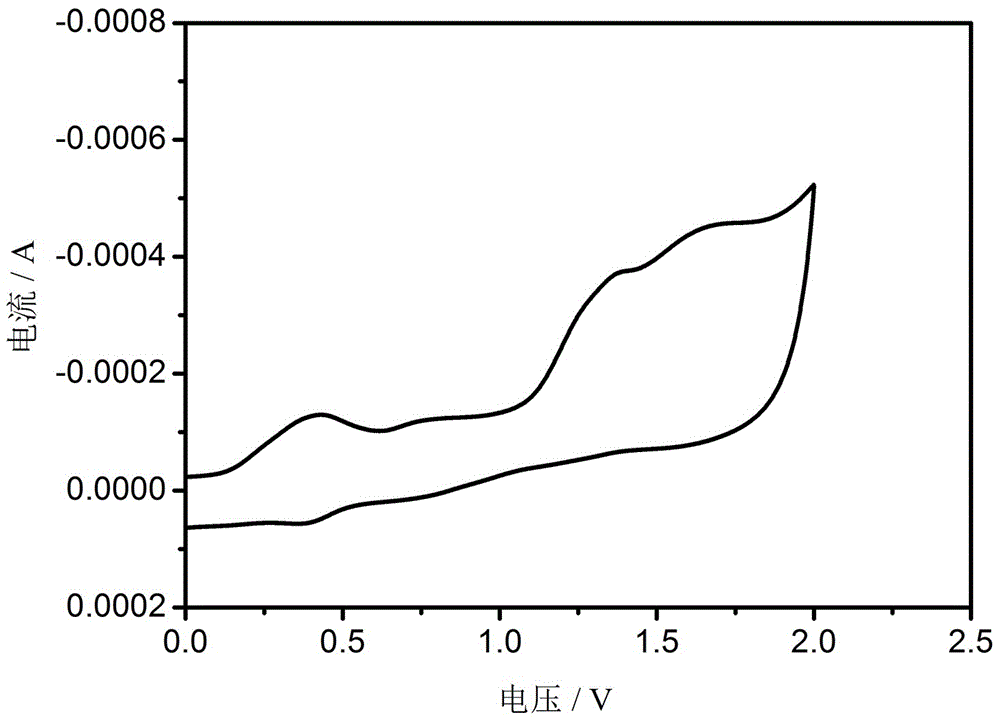

Bipolar blue phosphorescent host material based on carbazole and 1,2,4-triazole

ActiveCN106045977AHigh triplet energy levelImprove luminous efficiencyOrganic chemistrySolid-state devicesCarbazoleHost material

The invention discloses a bipolar blue phosphorescent host material which is as shown in a structural general formula (I) and takes carbazole and 1,2,4-triazole as a donor and a receptor respectively. The triplet-state energy level of the host material is improved by introducing an alkyl chain into the portion between carbazole and 1,2,4-triazole to prevent a conjugated structure between the donor and the receptor. When the bipolar blue phosphorescent host material is applied to dark blue phosphorescent organic electroluminescence devices, energy return between a host and a guest in the blue phosphorescent devices can be effectively prevented, and the luminous efficiency of the devices is improved. Please see the formula in the description.

Owner:TAIYUAN UNIV OF TECH

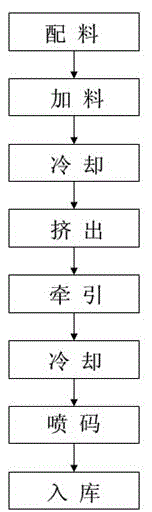

Highly weather-resistance co-extruding material PVC pipe and production method thereof

The present invention discloses a highly weather-resistance co-extruding material PVC pipe, which is prepared from the following raw materials: polycarbonate, PMMA, insulating ceramic particles, glass fibers, titanium dioxide, talc powder, magnesium oxide, a stabilizer, ACM, sodium stearate, cupric oxalate, dimethyl trimethylsilylmethylphosphonate, an antistatic agent, a coloring pigment, a lubricant, a dispersant, an antioxidant, an ultraviolet absorber, acid-resistant ultramarine blue, a fluorescent whitening agent, a PVC lubricant, a smoke inhibitor, and the balance of PVC. The production method comprises eight steps such as material preparing, material adding, cooling, extrusion, traction, cooling, code spraying, and warehousing. According to the present invention, the pollution of the heavy metal lead is effectively avoided, the impact resistance, the stress distribution performance, the thermal expansion and cold contraction performance, and the electrical insulation property of the PVC pipe material are substantially improved, and the waste insulating ceramic and other materials are effectively utilized so as to reduce the pipe material production cost and improve the resource recycling rate.

Owner:JIAOZUO HAOTONG PIPE IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com