Polyether poly(3,4-ethylenedioxythiophene) (PEDOT) water dispersion and preparation method thereof

A technology of ethylenedioxythiophene and polyether polyurethane is applied in the field of poly(3,4-ethylenedioxythiophene) (PEDOT) aqueous dispersion and its preparation, and can solve the problems of poor film-forming property, high water absorption and the like, achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

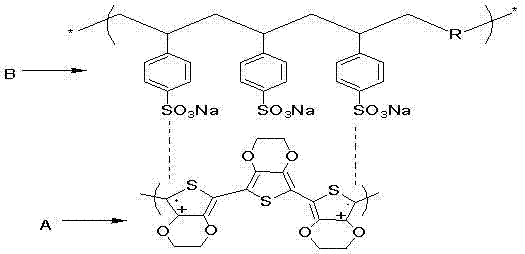

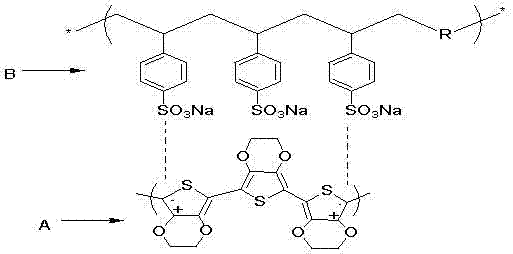

[0041] Example 1 ( Preparation of poly(3,4-ethylenedioxythiophene) water dispersion Ⅰ)

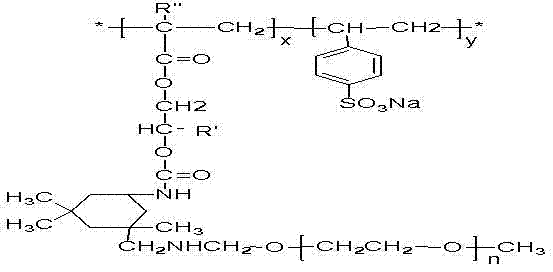

[0042] Poly(3,4-ethylenedioxythiophene) (ie PEDOT) water dispersion Ⅰ template and dopant are SSS and polyether (Mn=5000) type polyurethane copolymer, and end-capping agent in the preparation process of polyether type polyurethane The molar ratio of HPA dosage to diisocyanate is 1:1. The molar ratio of SSS to polyether (Mn=5000) polyurethane is 10:1; the molar ratio of initiator to SSS during the preparation process is 0.001:1. The mass ratio of template and dopant to EDOT is 0.01:1. During the reaction of the two, the molar ratios of oxidant, catalyst and EDOT are 1.5:1 and 0.002:1, respectively.

[0043] The specific preparation method and steps are as follows:

[0044] 1. MPEG (Mn=5000, 25.0000g, 0.005mol), methyl ethyl ketone (5.4600g) was put into a 100ml four-necked flask equipped with a spherical condenser, and heated and stirred. After the MPEG was completely dissolved, IPDI (0.1380g,...

Embodiment 2

[0049] Example 2 (Preparation of PEDOT water dispersion II)

[0050] The template and dopant in PEDOT water dispersion II are SSS and polyether (Mn=1000) polyurethane copolymer. The molar ratio of HPA and diisocyanate used in the preparation of polyether polyurethane is 2:1. The molar ratio of SSS to polyether (Mn=1000) polyurethane is 39:1; the molar ratio of initiator to SSS is 0.005:1. The mass ratio of template and dopant to EDOT is 3:1. During the reaction of the two, the molar ratios of oxidant, catalyst and EDOT are 4:1 and 0.005:1 respectively.

[0051] The specific preparation method and steps are as follows:

[0052] 1. MPEG (Mn=1000, 5.000g, 0.005mol), butanone (5.4600g) were put into a 100ml four-necked flask equipped with a spherical condenser, and heated and stirred. After the MPEG was completely dissolved, IPDI (0.1380g, 0.0053mol) and a small amount of glacial acetic acid (0.6400g) were added. React at 80°C for 5 hours. When the temperature drops to 60°C, add HPA ...

Embodiment 3

[0058] Example 3 (Preparation of PEDOT water dispersion Ⅲ)

[0059] The template and dopant in PEDOT water dispersion III are sodium styrene sulfonate and polyether (Mn=200) polyurethane copolymer. The amount of blocking agent HEA and the molar ratio of diisocyanate in the preparation of polyether polyurethane is 1.5:1 . The molar ratio of SSS to polyether (Mn=200) polyurethane is 87:1; the molar ratio of initiator to SSS is 0.002:1. The mass ratio of template and dopant to EDOT is 3:1. During the reaction of the two, the molar ratios of oxidant, catalyst and EDOT are 0.5:1 and 0.005:1, respectively.

[0060] The specific preparation method and steps are as follows:

[0061] 1. MPEG (Mn=200, 0.5000g, 0.005mol), methyl ethyl ketone (5.4600g) was added to a 100ml four-necked flask equipped with a spherical condenser, and heated and stirred. After the MPEG was completely dissolved, IPDI (0.1380g, 0.0053mol) and a small amount of glacial acetic acid (0.6400g) were added. React at 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com