Patents

Literature

39 results about "Depletion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

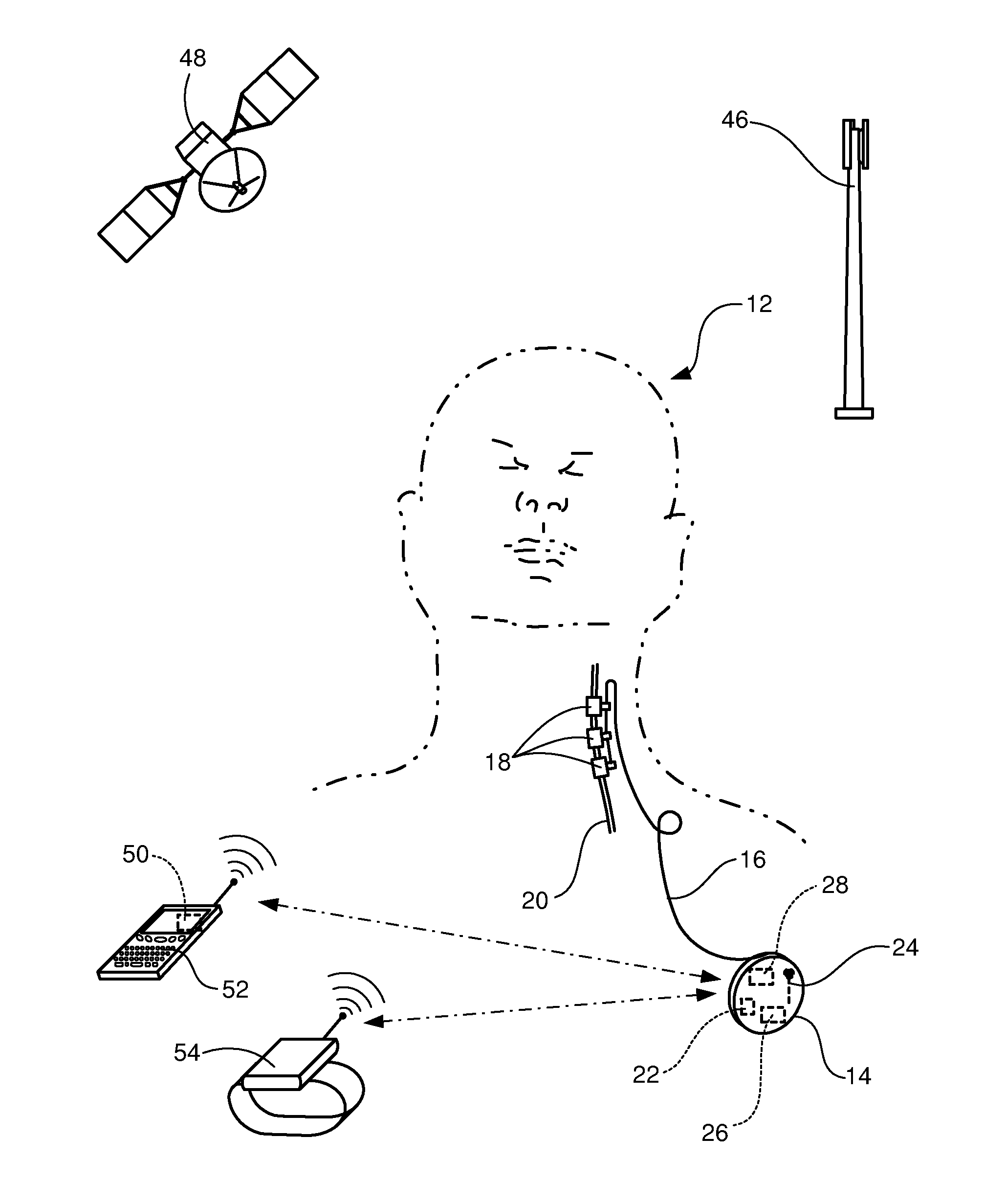

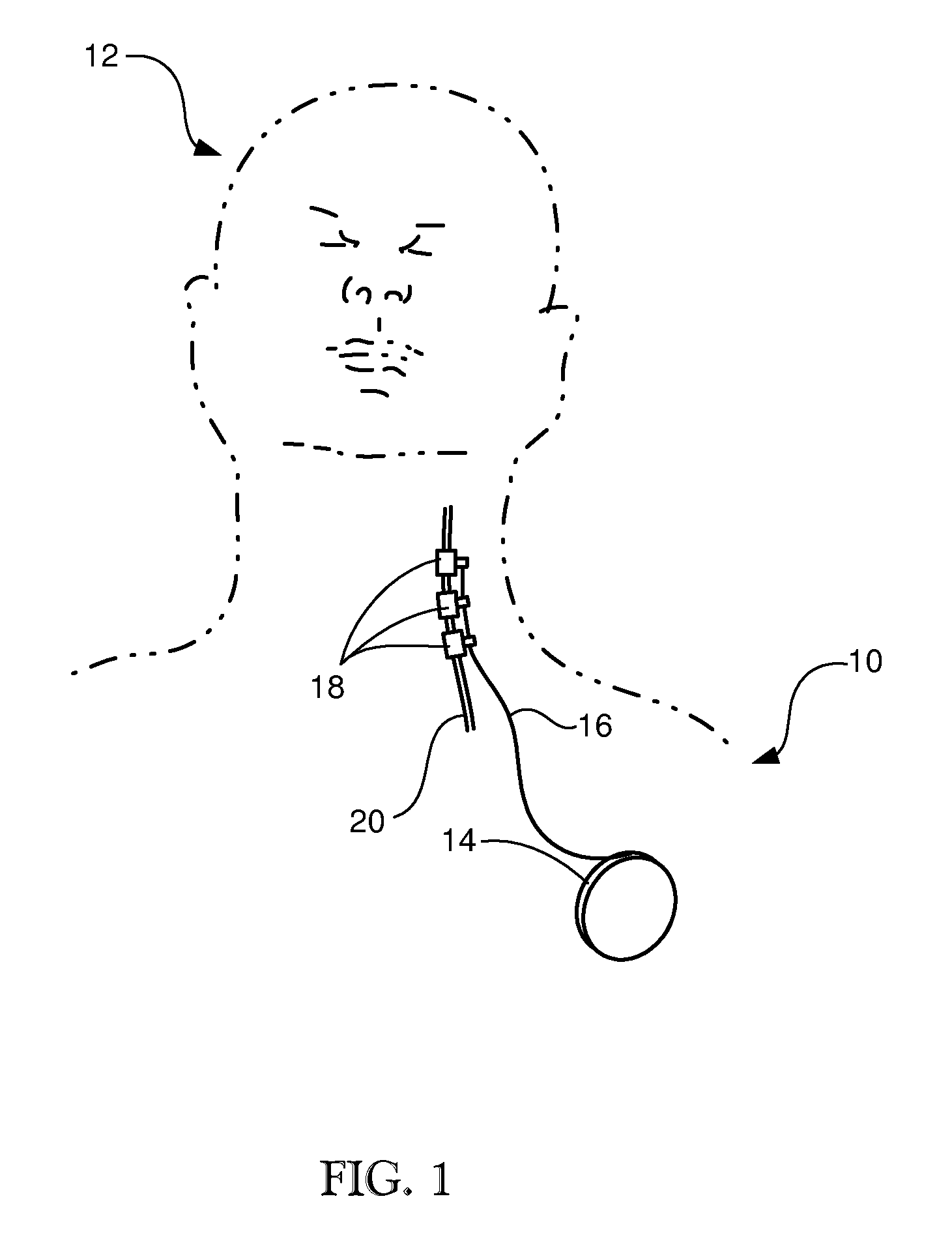

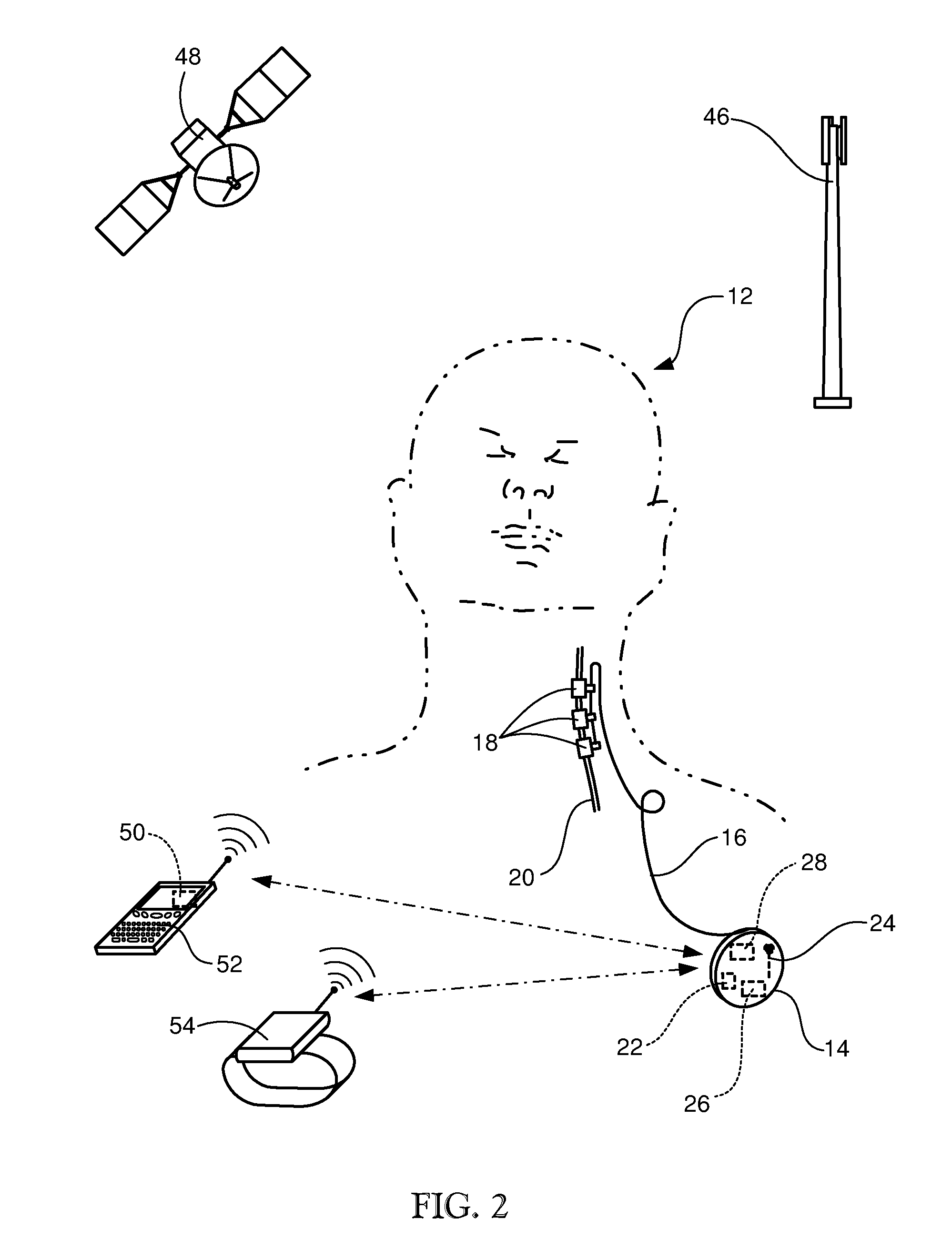

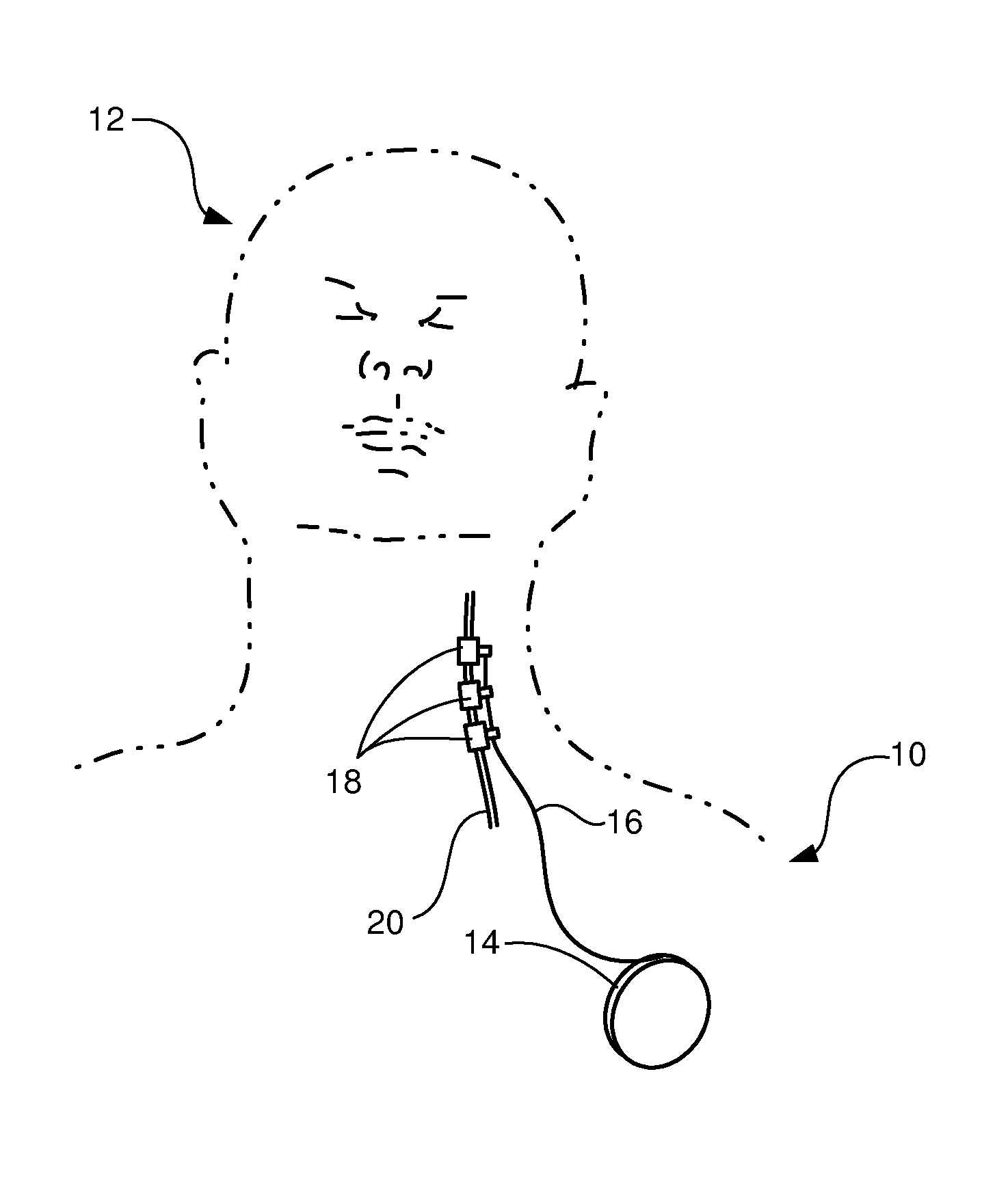

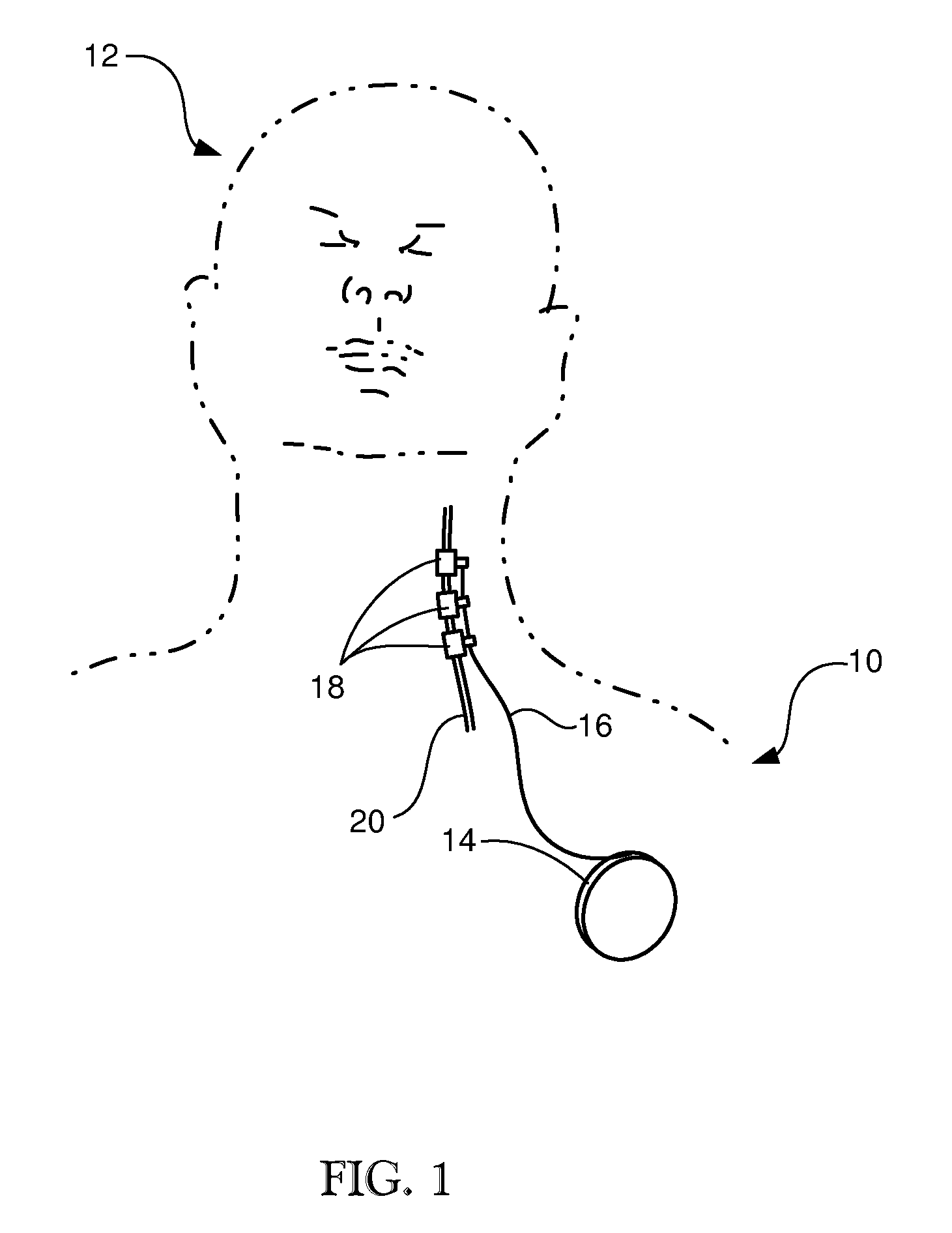

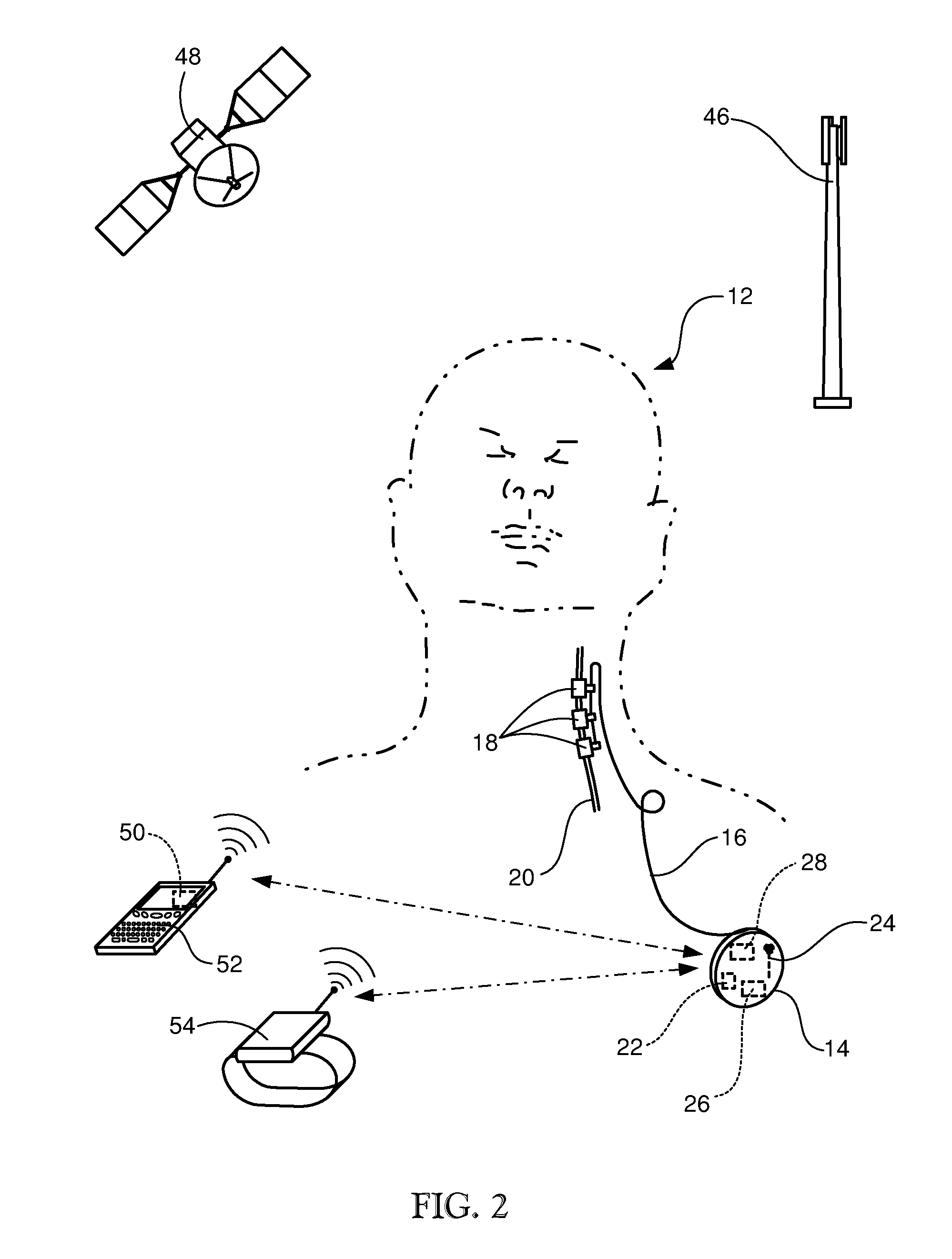

Battery life estimation based on voltage depletion rate

ActiveUS20120277832A1Simple and robust methodElectrotherapyElectrical testingTerminal voltageElectrical battery

Apparatus and methods for estimating the remaining life of a battery in an implantable medical device (“IMD”) are disclosed herein. The terminal voltage of the battery is measured and the measurements create a baseline curve of the battery voltage depletion. The points along the baseline curve can be linearly extrapolated to calculate the voltage depletion rate, which can estimate the remaining life of the battery.

Owner:LIVANOVA USA INC

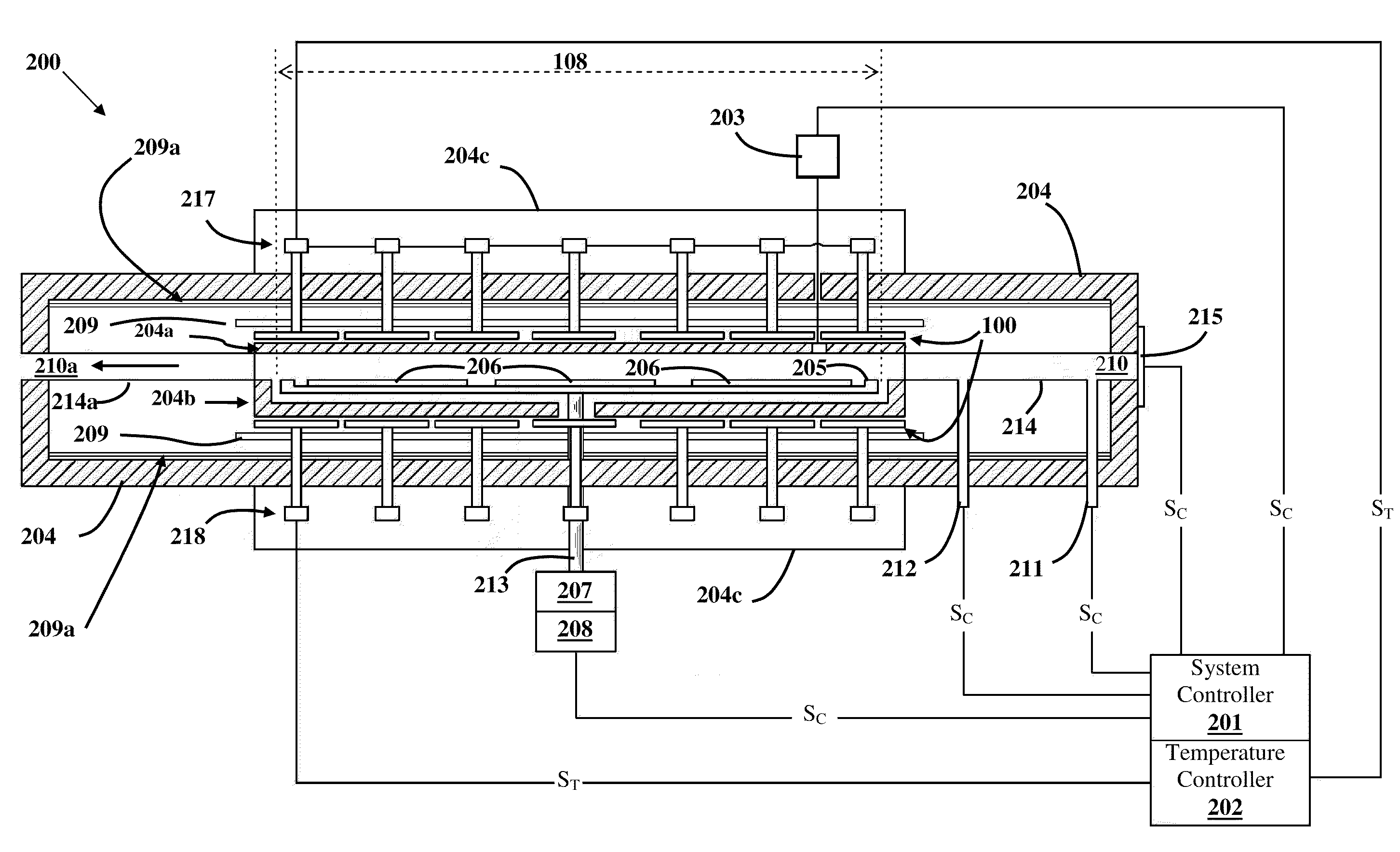

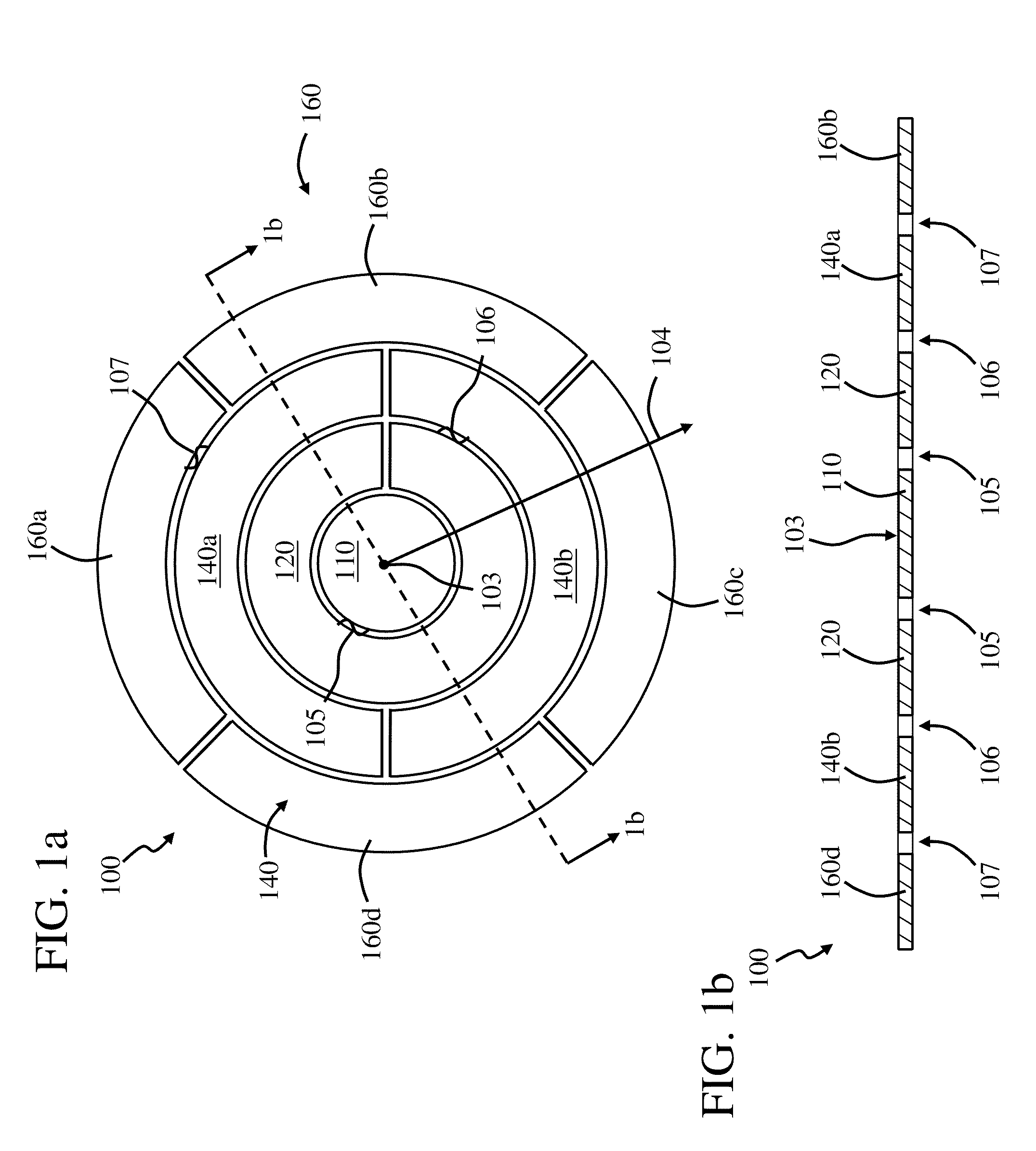

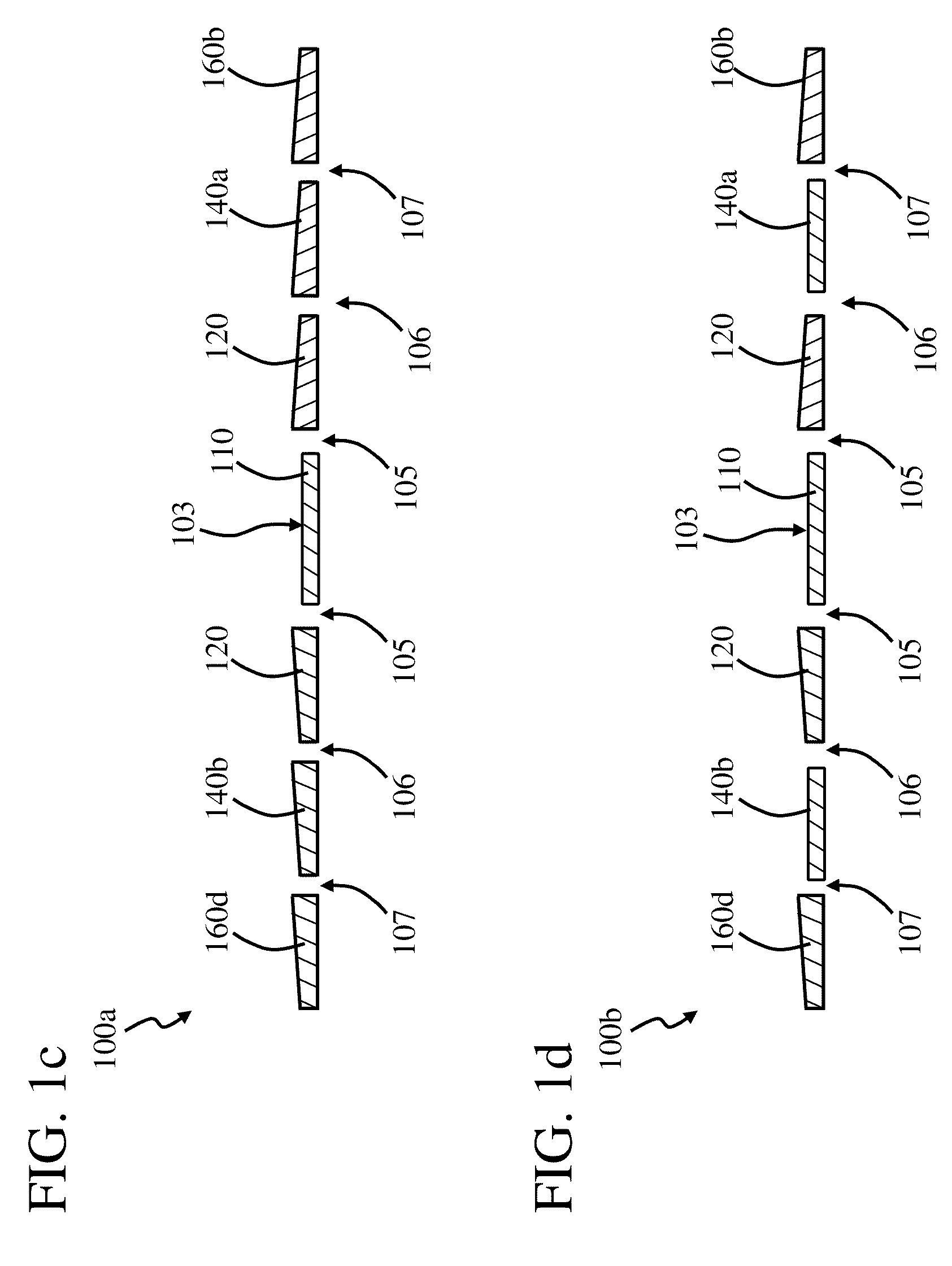

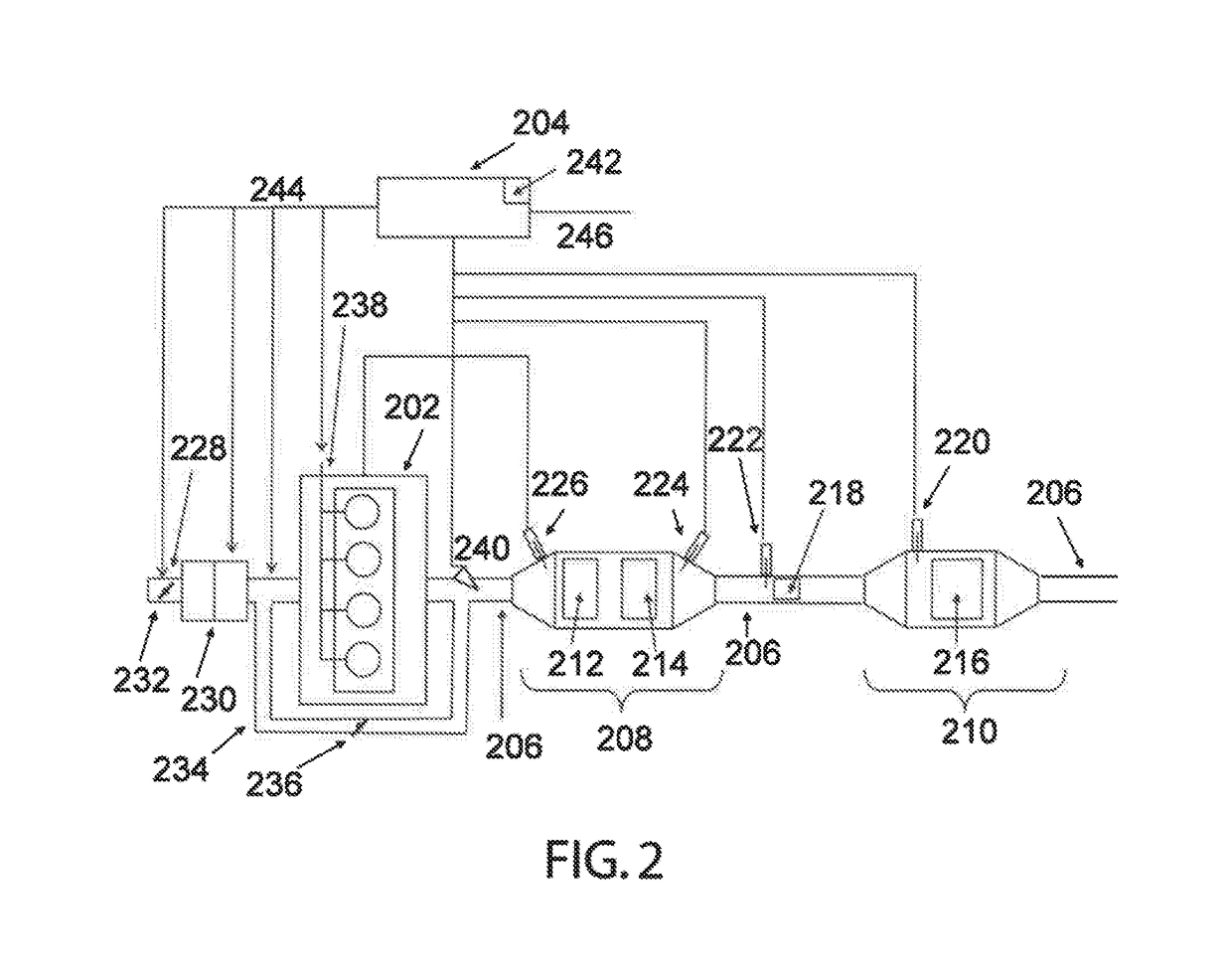

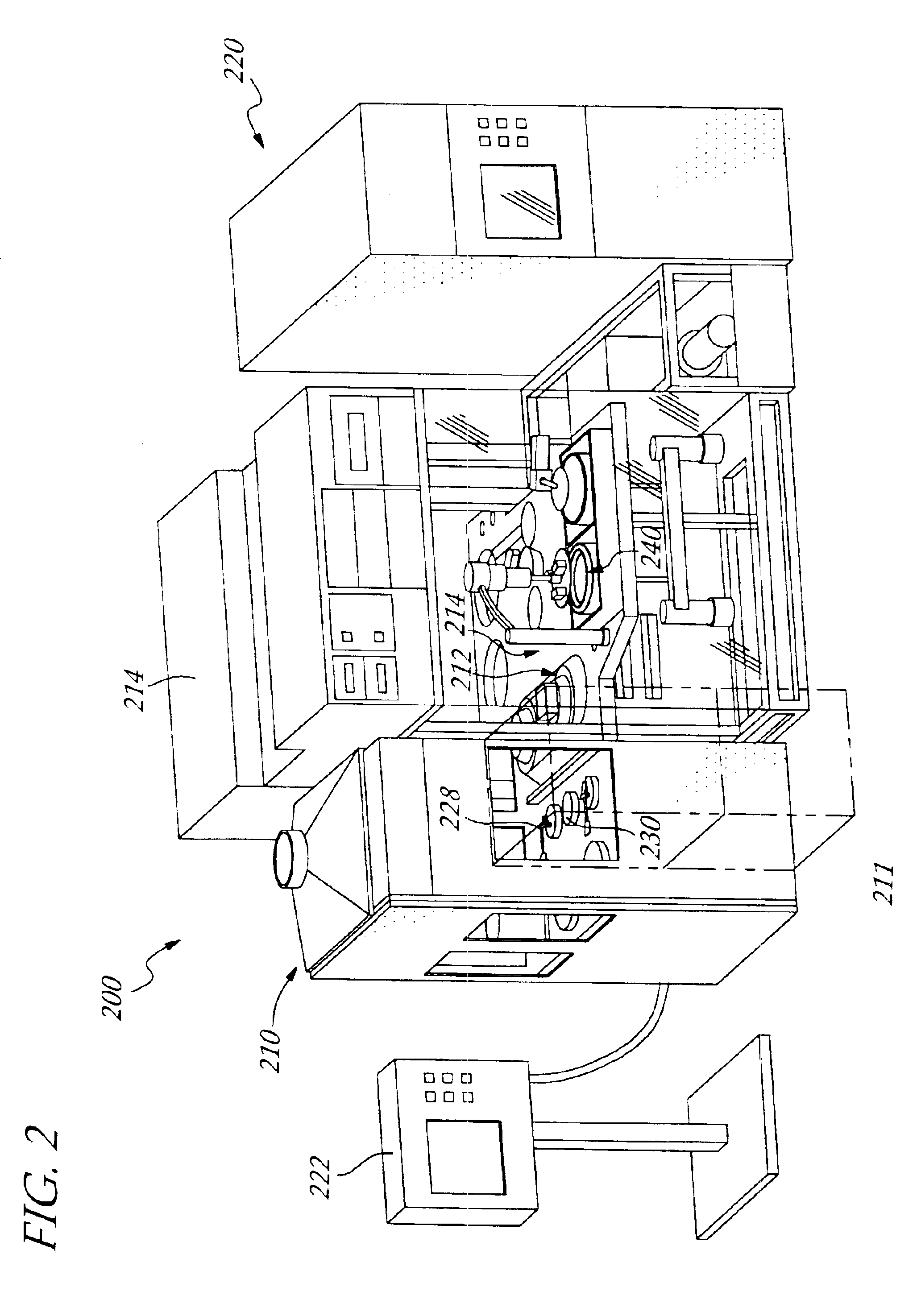

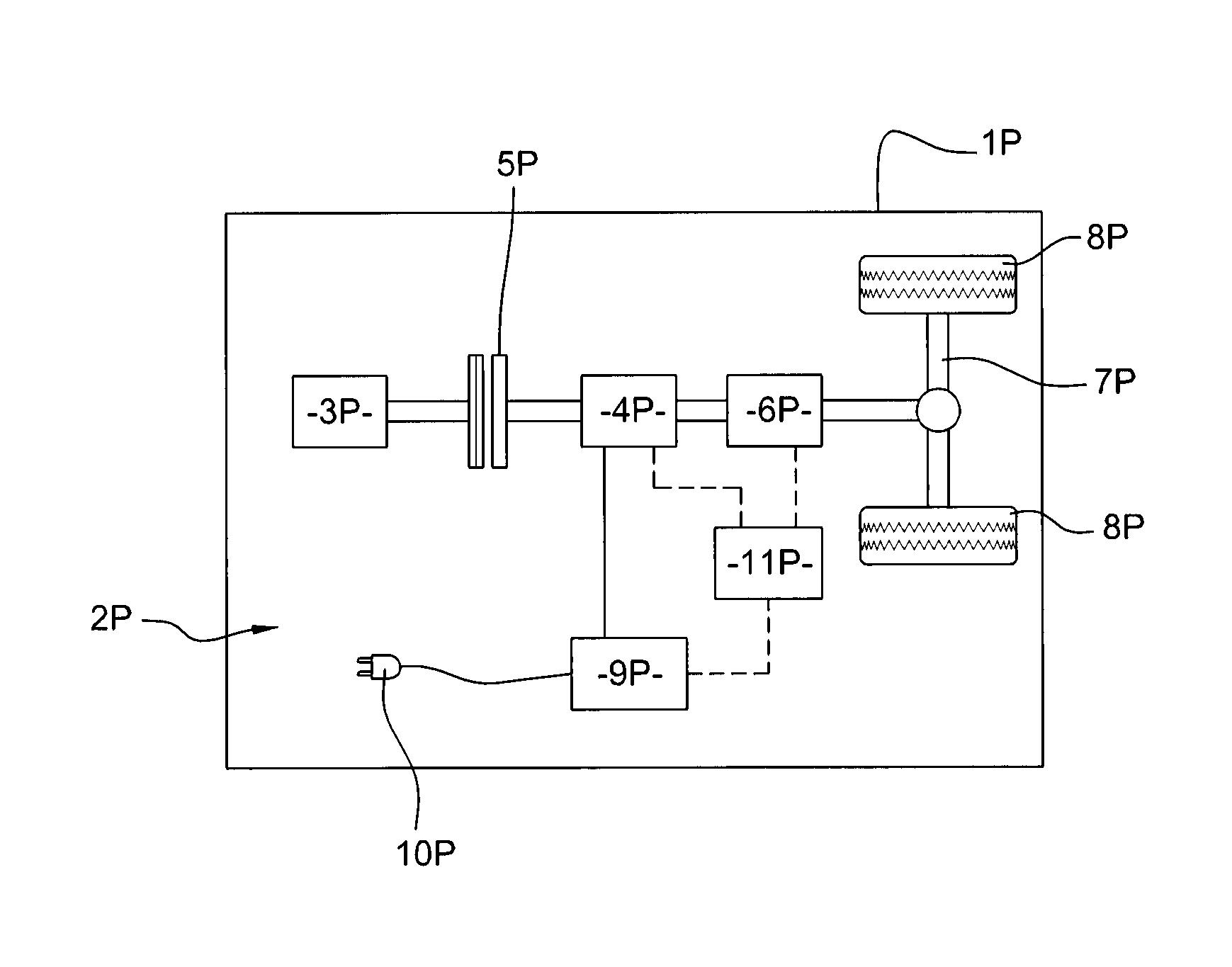

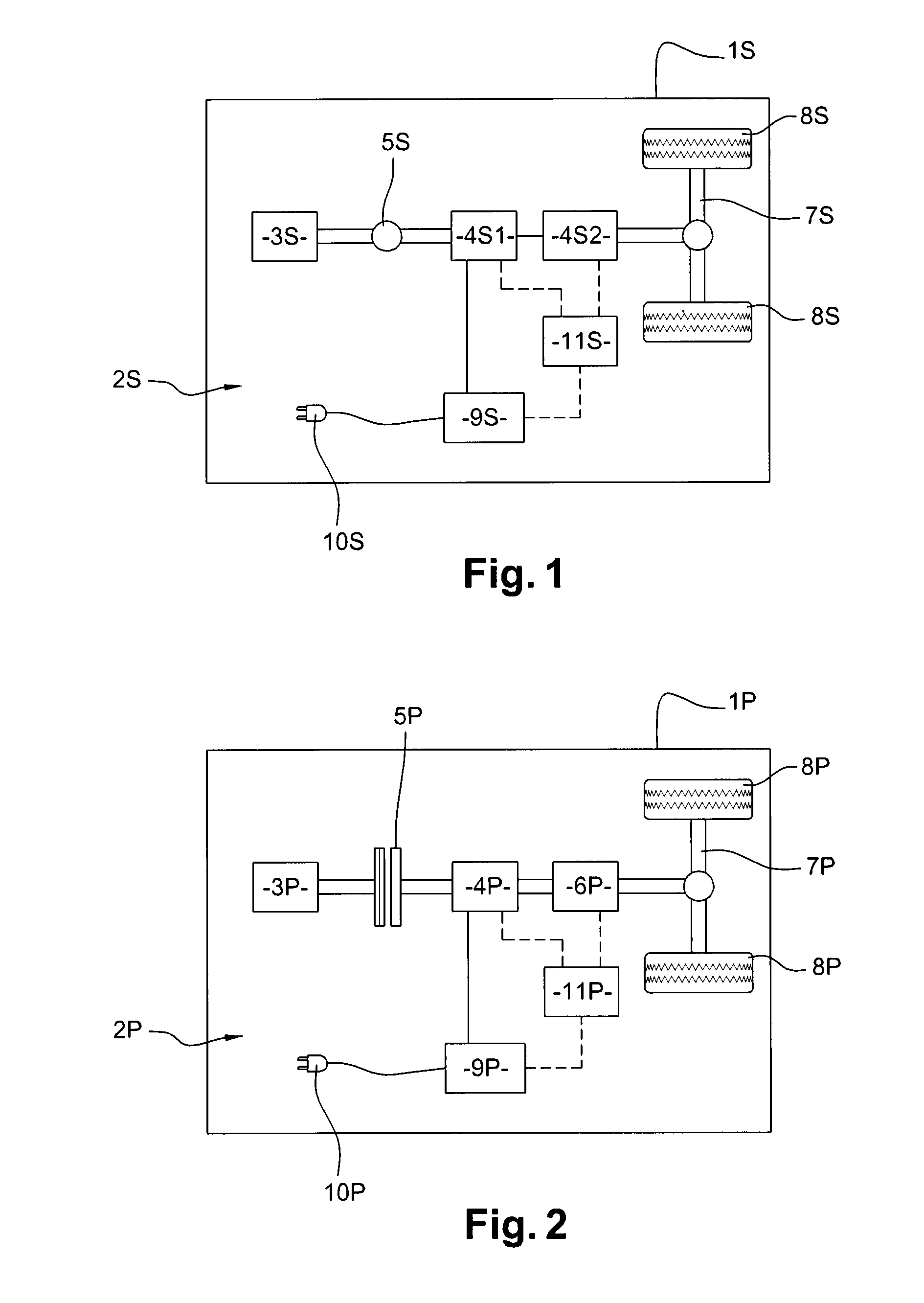

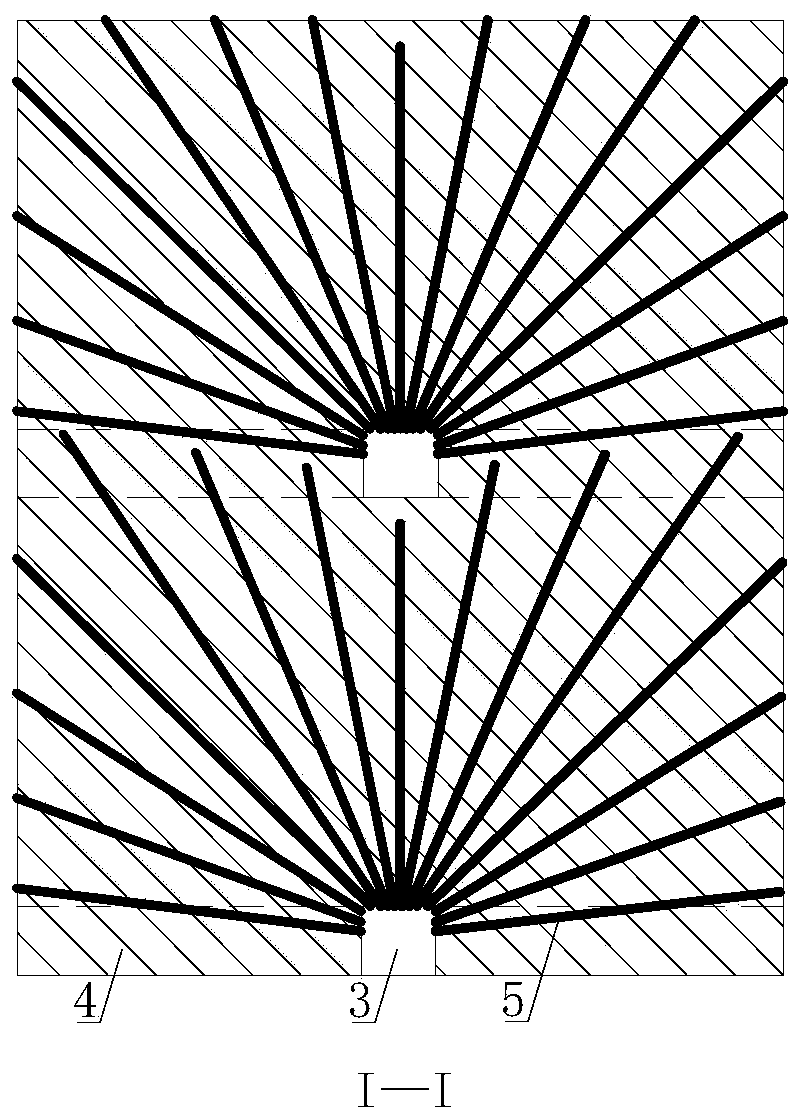

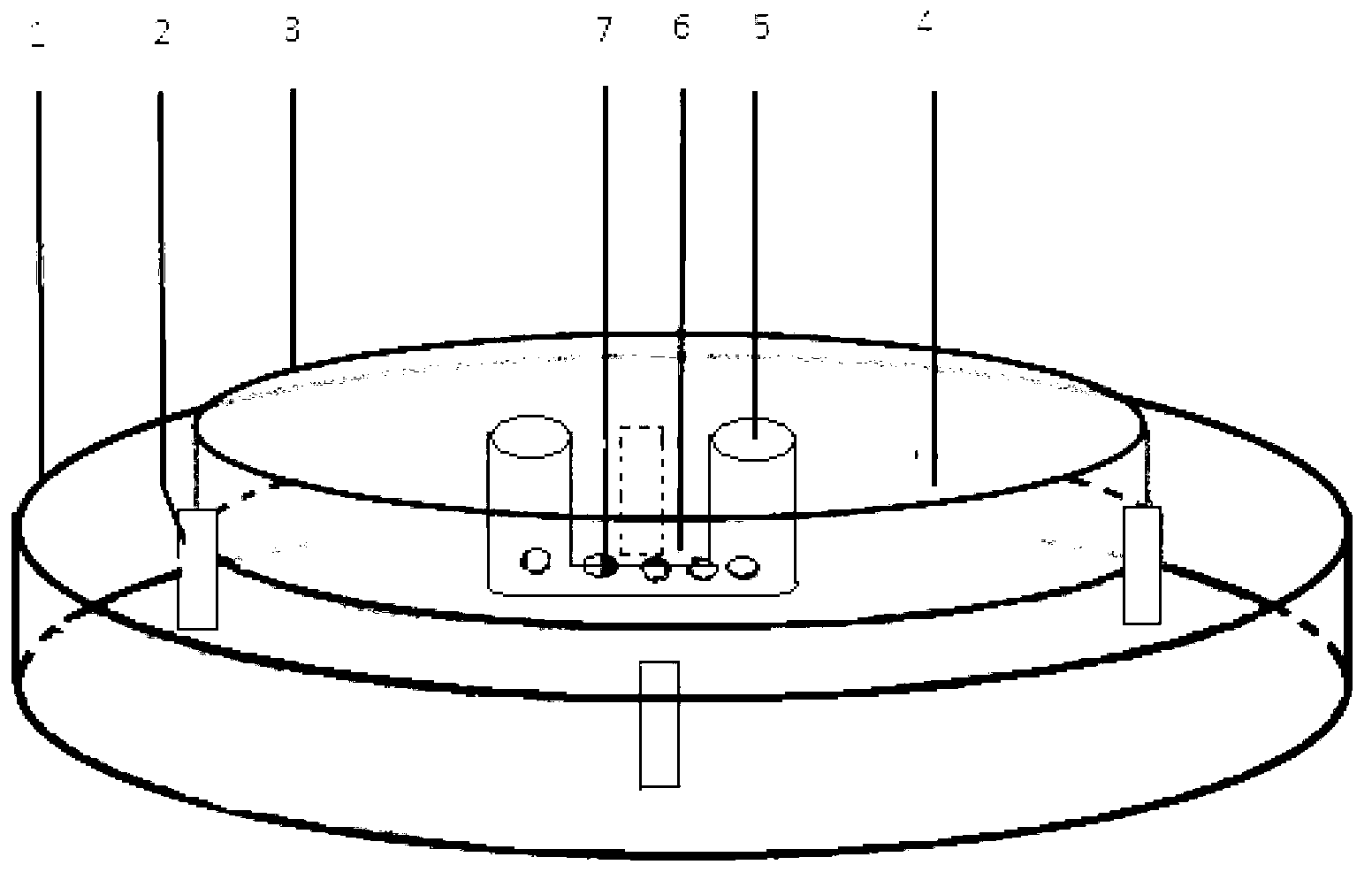

Semiconductor deposition system and method

InactiveUS20110073039A1Electric heatingSemiconductor/solid-state device manufacturingManufacturing cost reductionSilicon solar cell

A novel heating method and a novel gas inject schemes for a depositing semiconductor layers on wafers with improved disposition uniformity and disposition composition, deposition rates and decreased depletion rates. The novel heating and gas design can be readily changed in size to accommodate the ever increasing demand for larger substrates, increased batch sizes and increased deposition and heating efficiencies. The heating scheme can operate to 1500° C., and has a high resolution capability for tuning the temperature and gas flows for easy of setup and improved control and repeatability of the deposition process. This novel heating and gas inject scheme in conjunction with the unconventional usage of a non-quartz process chamber promises higher throughputs and higher wafer yields and reduced manufacturing costs for the manufacturing of silicon devices, silicon solar cells and white High Brightness LEDs.

Owner:STRATIS SEMI L L C

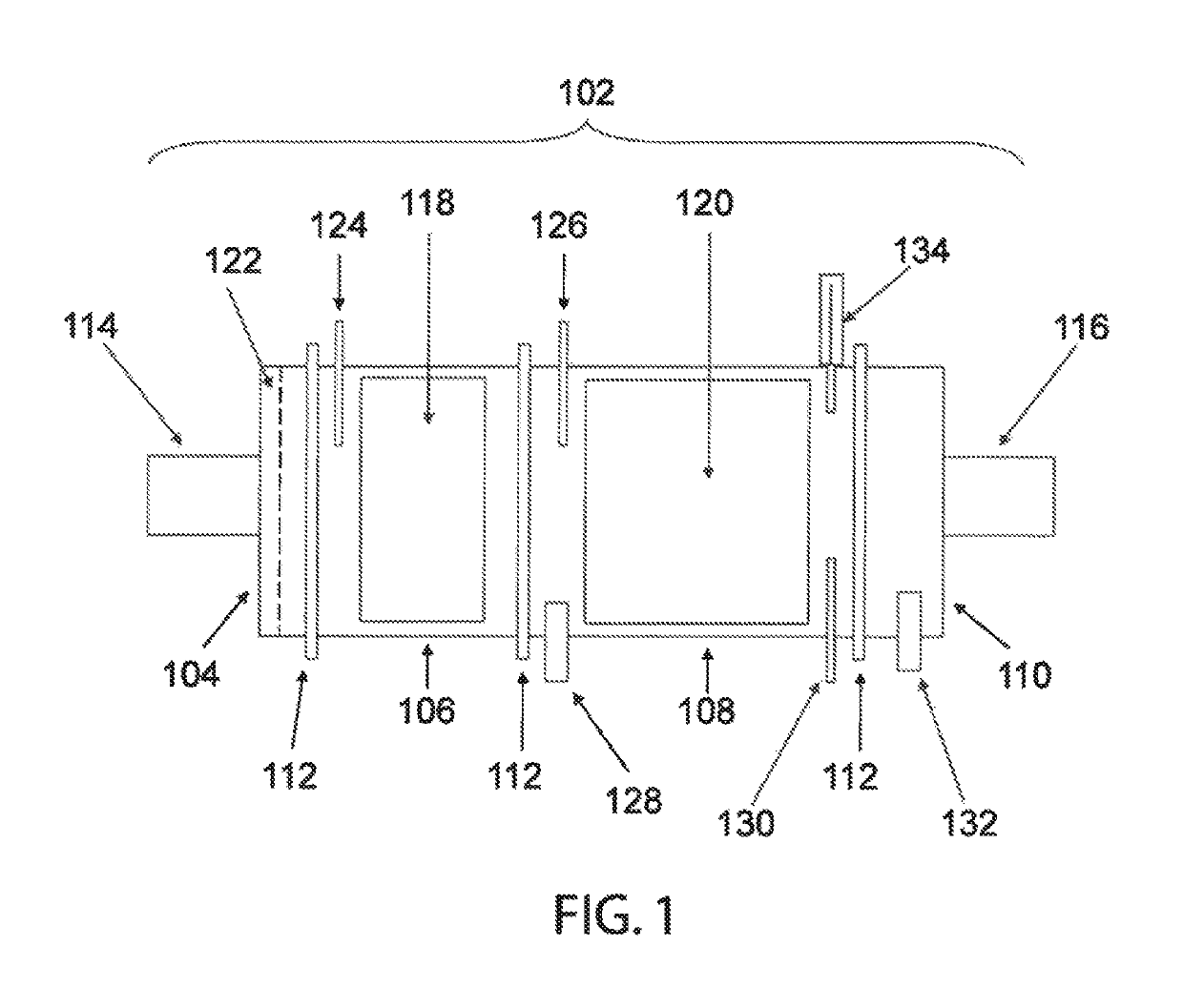

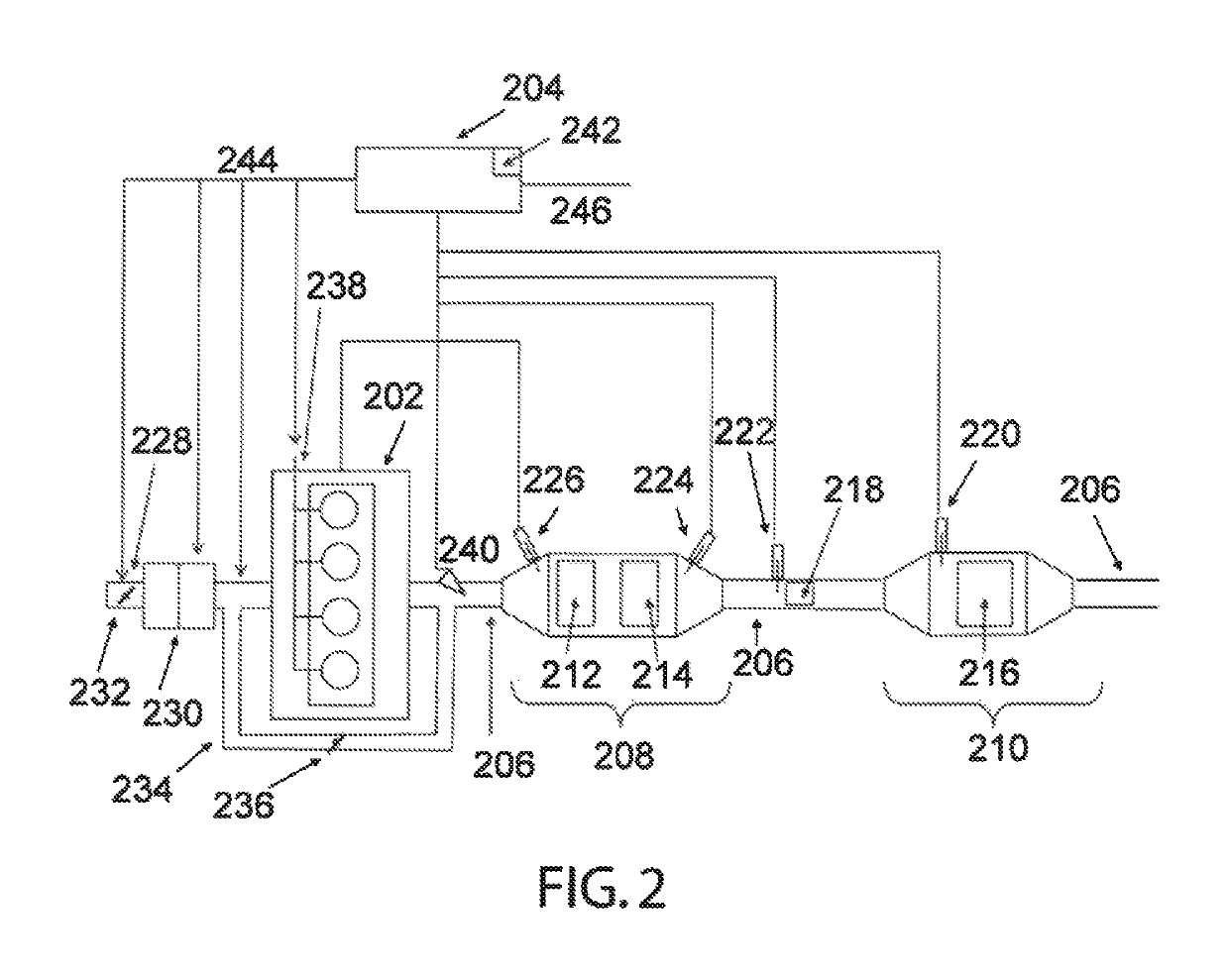

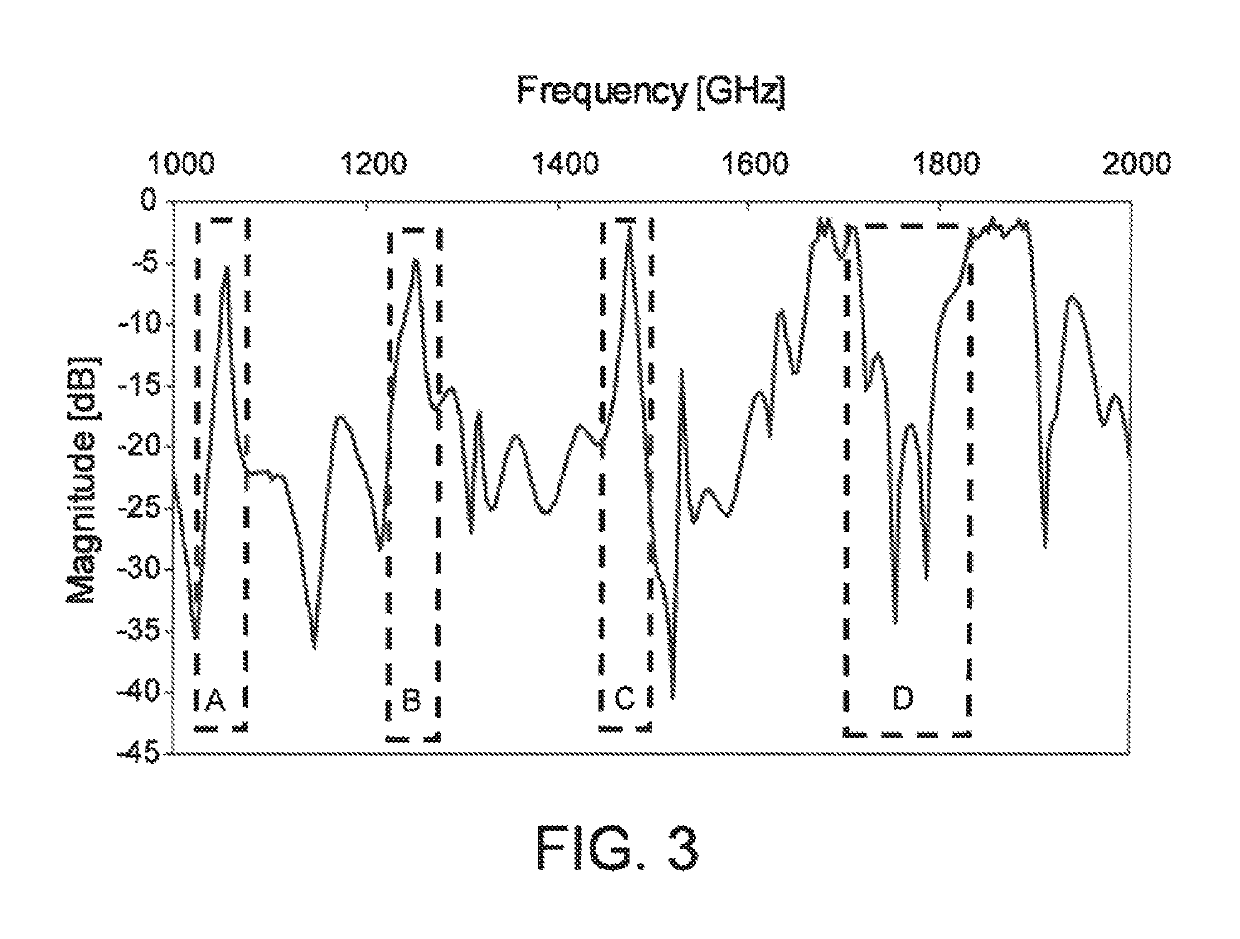

Radio Frequency System and Method for Monitoring Engine-Out Exhaust Constituents

ActiveUS20170211453A1Enhanced signalReduced measurement response timeTransmitters monitoringInternal combustion piston enginesRadio frequency signalEngineering

A radio frequency system and method for monitoring an engine-out exhaust emission constituent. The system comprises a housing containing the emission constituent, one or more radio frequency sensors extending into the housing and transmitting and receiving radio frequency signals, and a control unit for controlling the radio frequency signals and monitoring changes in the emission constituent based on changes in one or more parameters of the radio frequency signals. In one embodiment, the control unit measures a rate of change in one or more of the parameters of the radio frequency signals for monitoring a rate of change of the emission constituent including for example the emission rate, accumulation rate, and / or depletion rate of the emission constituent.

Owner:CTS CORP ELKHART

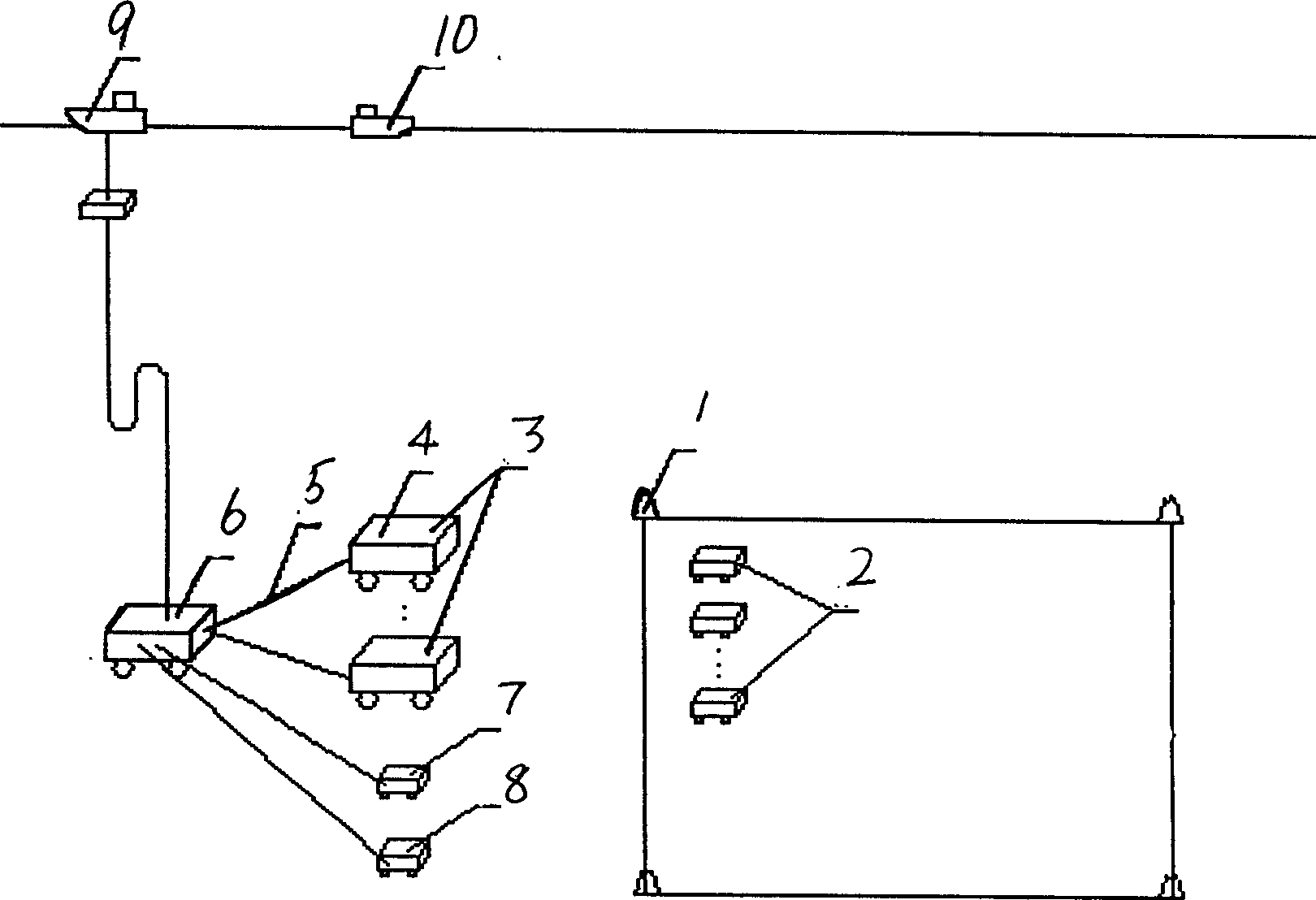

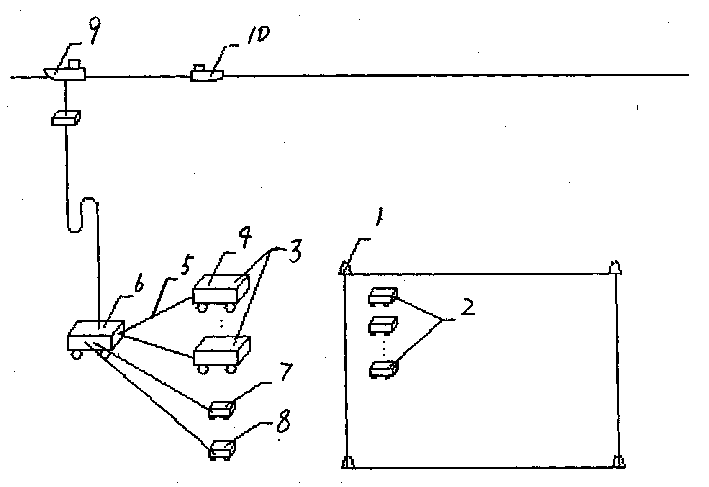

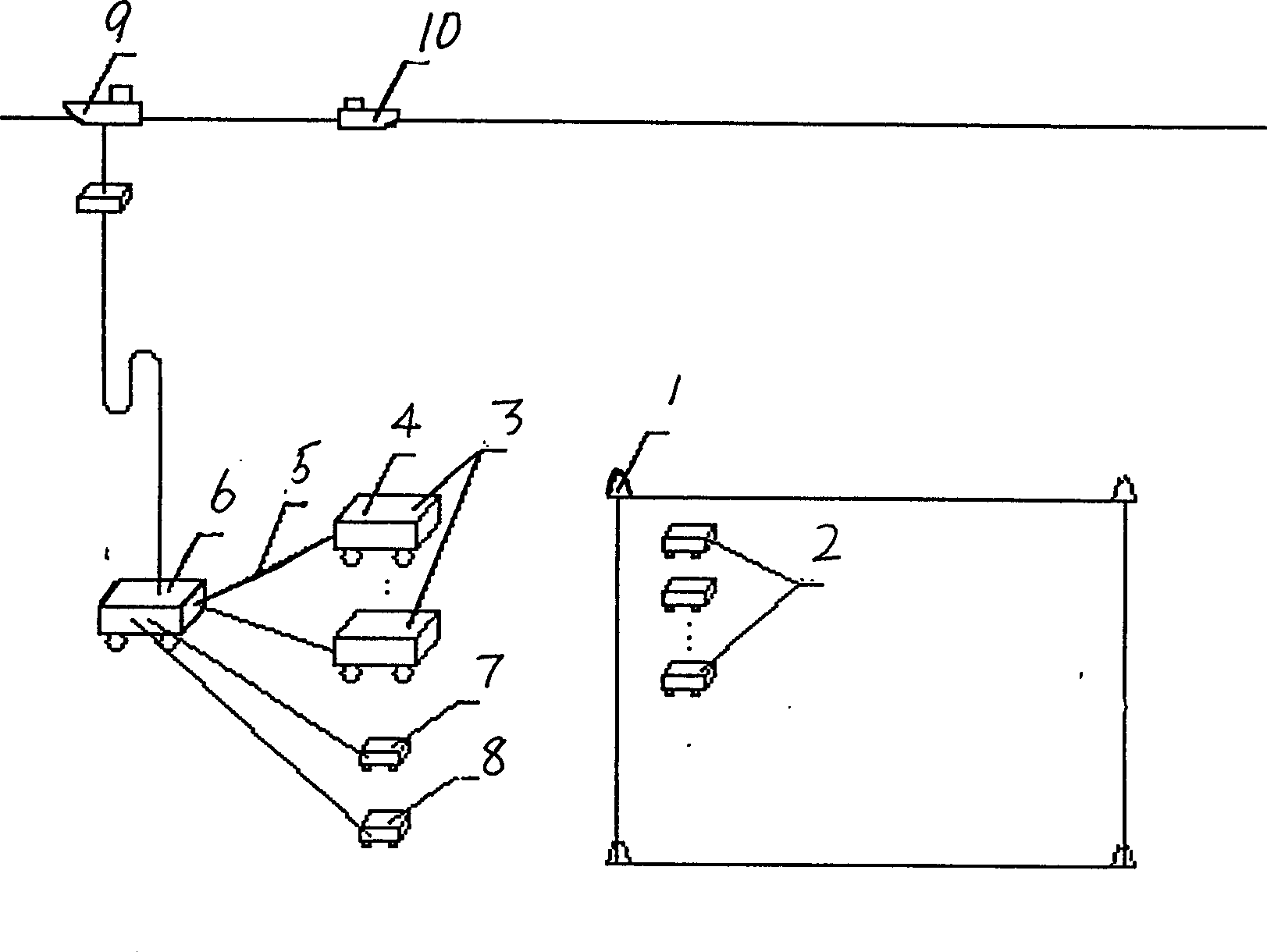

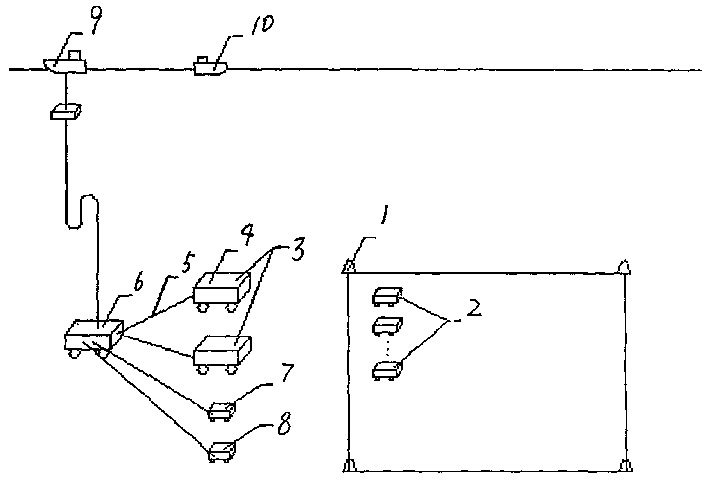

Movable distributive continuous exploitation method for deep sea mineral resources

InactiveCN1458391AIncrease collection rateBroken particle sizeMineral miningProduction rateMineral Sources

The movable deep sea mineral resource exploiting system consists of under water positioning base point in the marine mining area, movable distributing mining vehicle, movable ore bin matching the exploitation amount, initial separating and crushing unit capable of inhibiting depletion rate and matching mineral granularity, conveyer to the ore raising unit, movable ore raising unit with driving plant and pipeline, movable underwater power distributing station, movable main control station, surface exploitation ship, transportation ship, etc. The present invention is adaptable to the exploitation of deep sea mineral resources, especially base rock mineral resources and deposit mineral resources, and has high production rate, high collecting rate, low exploitation cost, high reliability, and less marine environmental pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

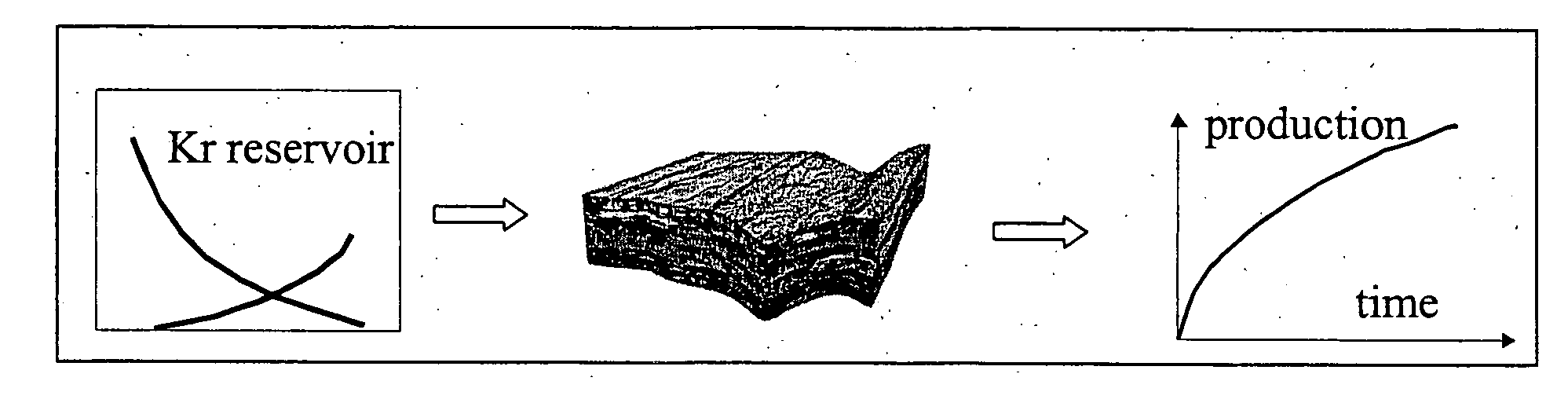

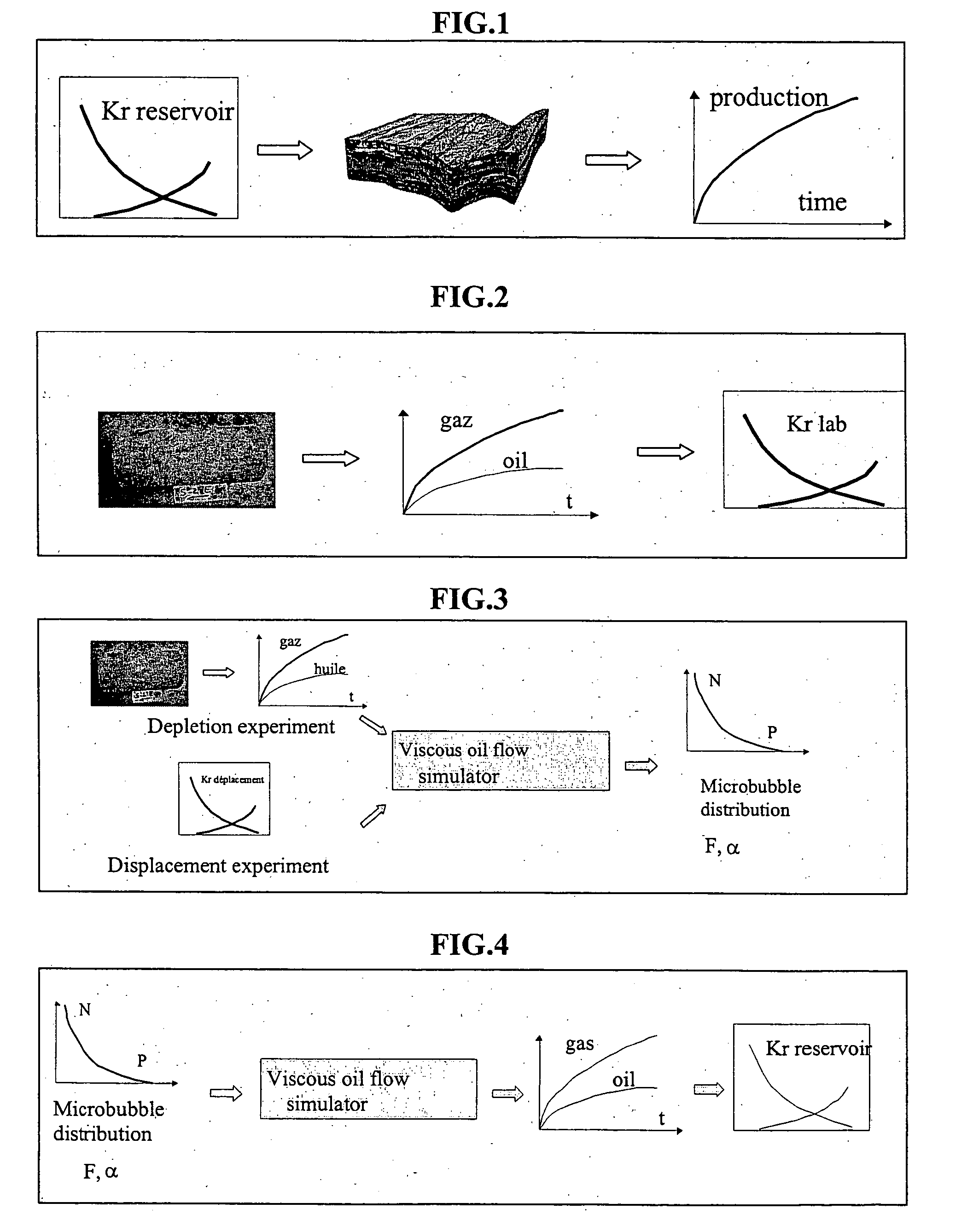

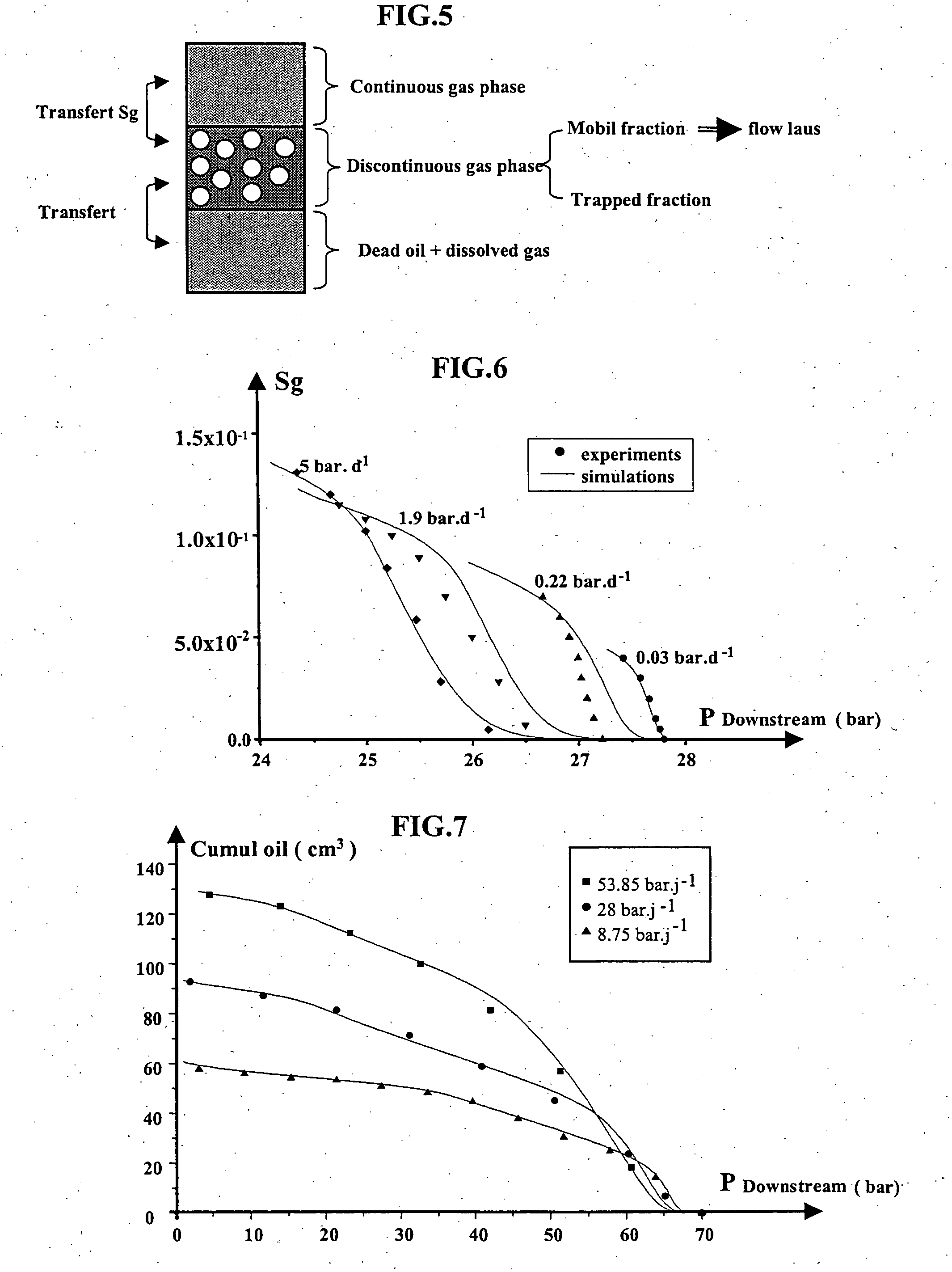

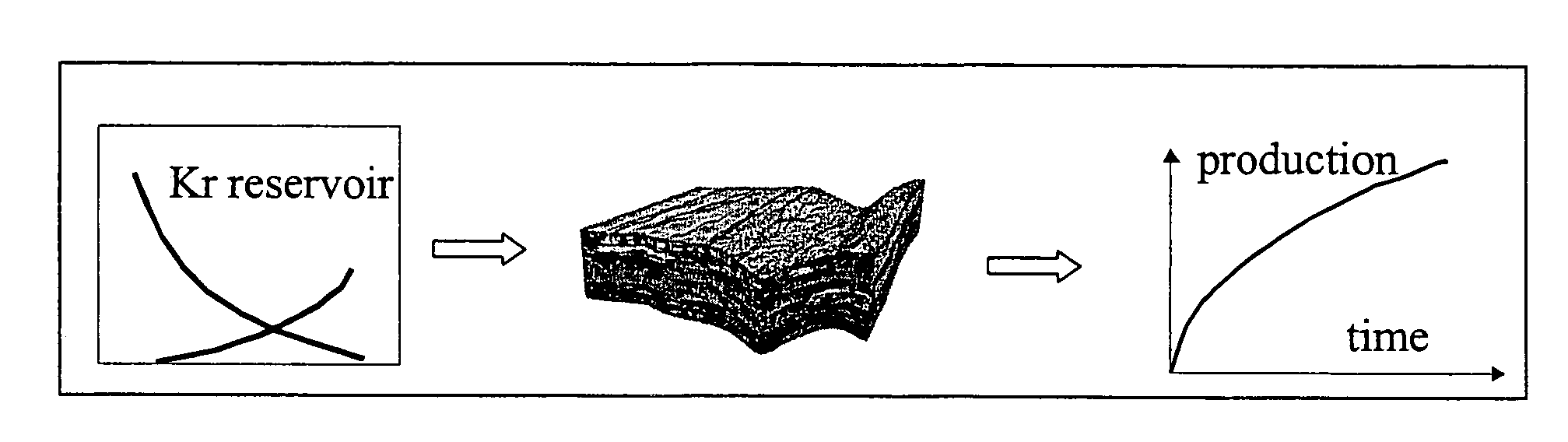

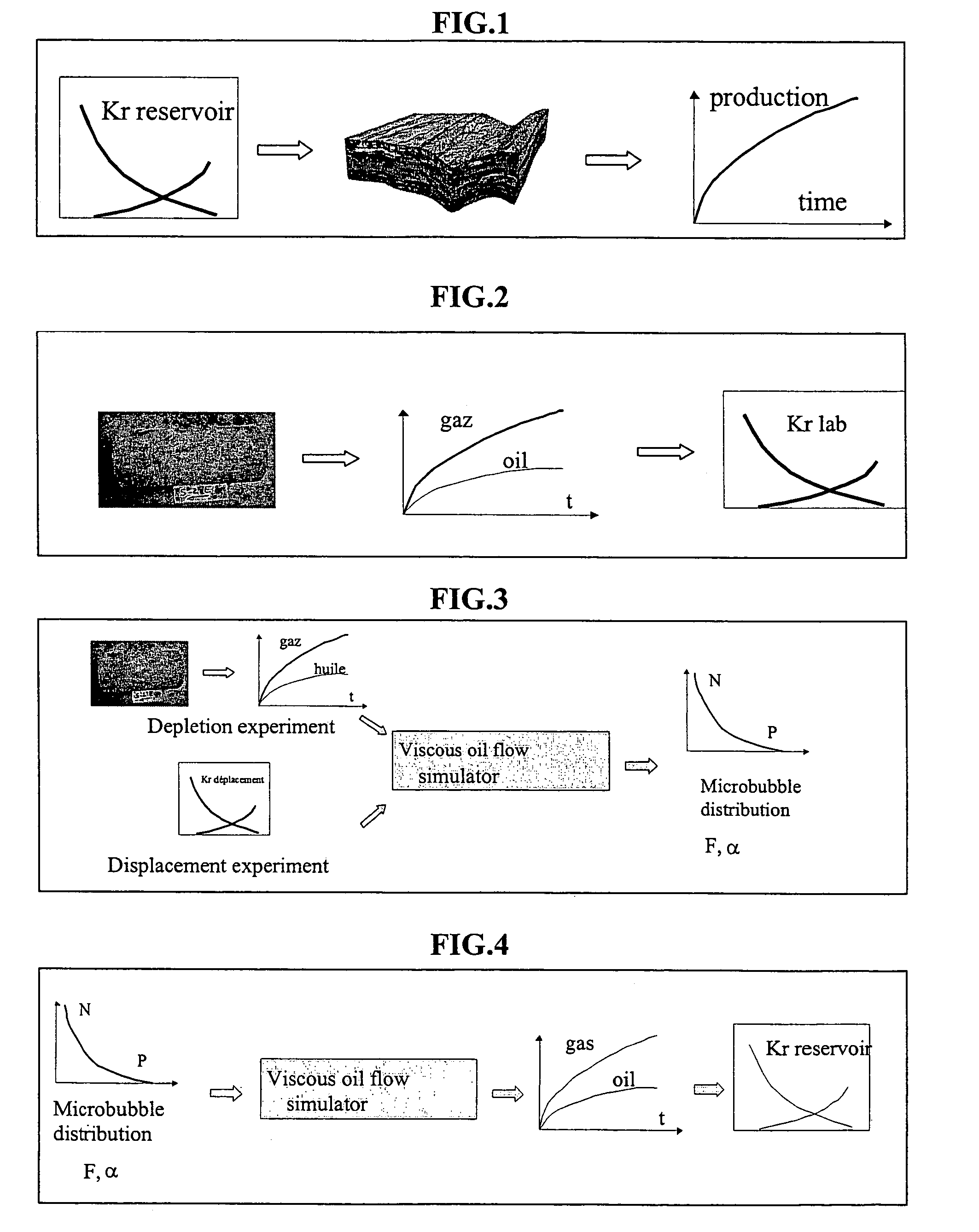

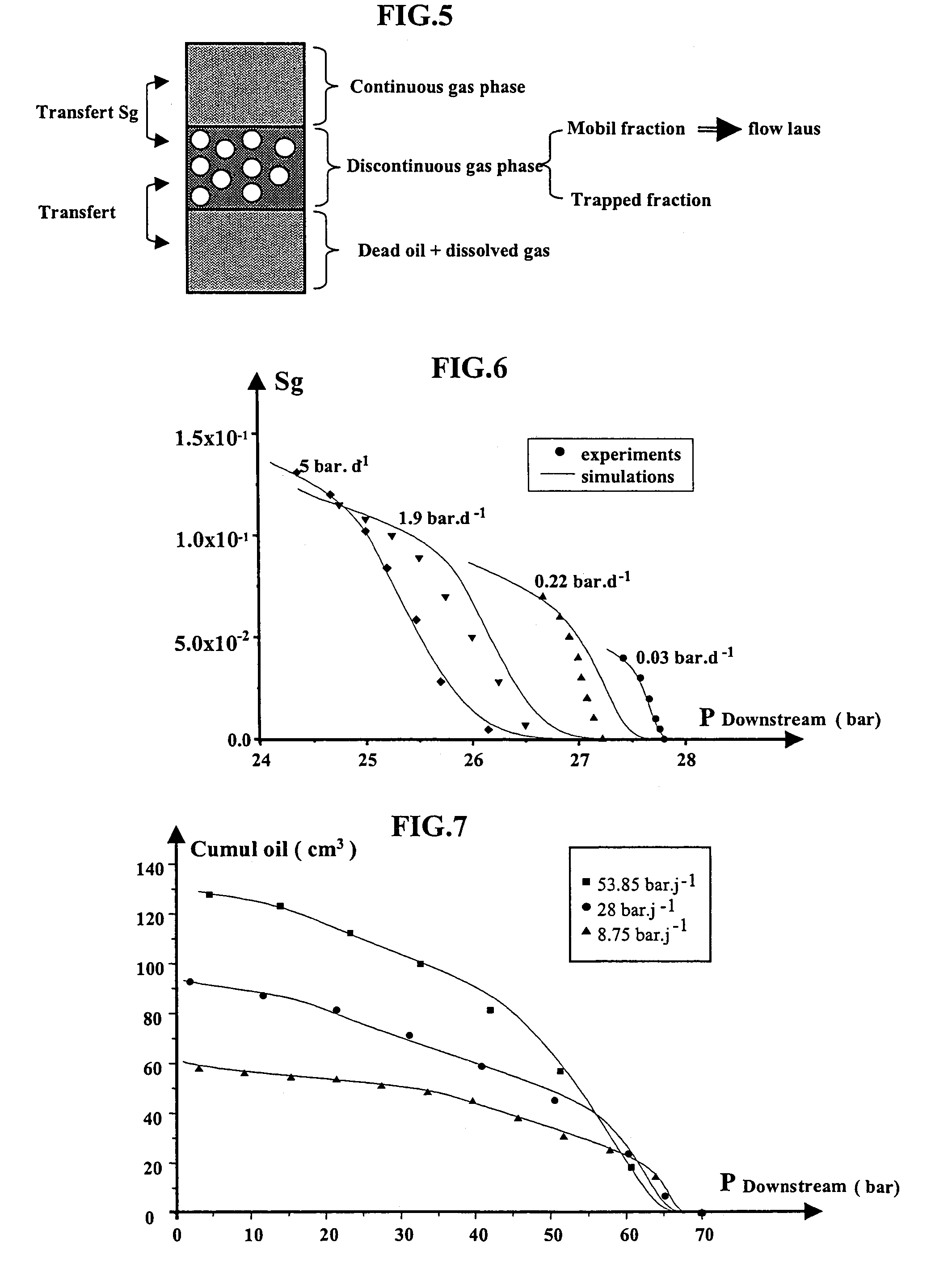

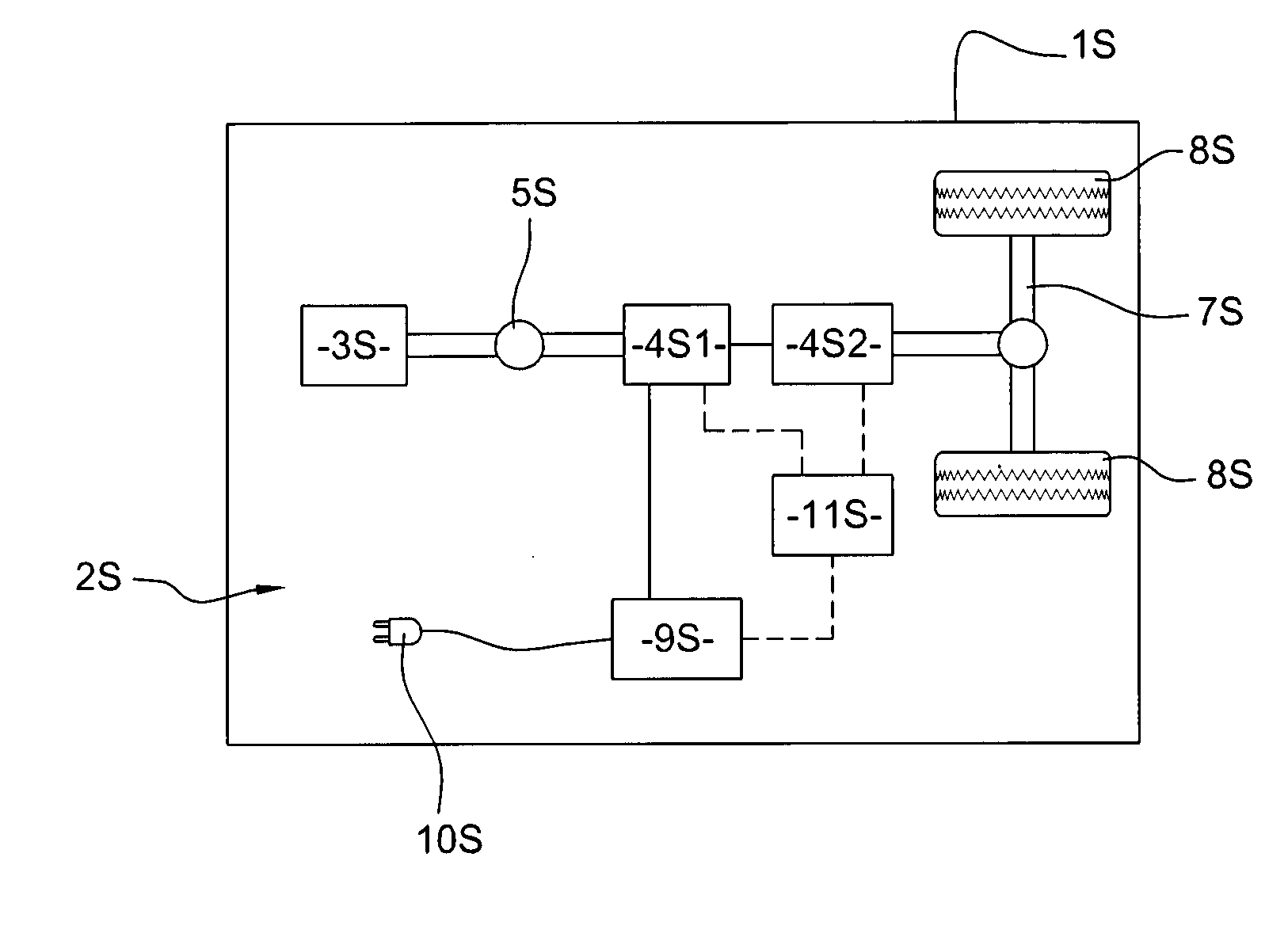

Method for modelling the production of hydrocarbons by a subsurface deposit which are subject to depletion

ActiveUS20050165593A1Realistic representationElectric/magnetic detection for well-loggingPermeability/surface area analysisHydrocotyle bowlesioidesRock sample

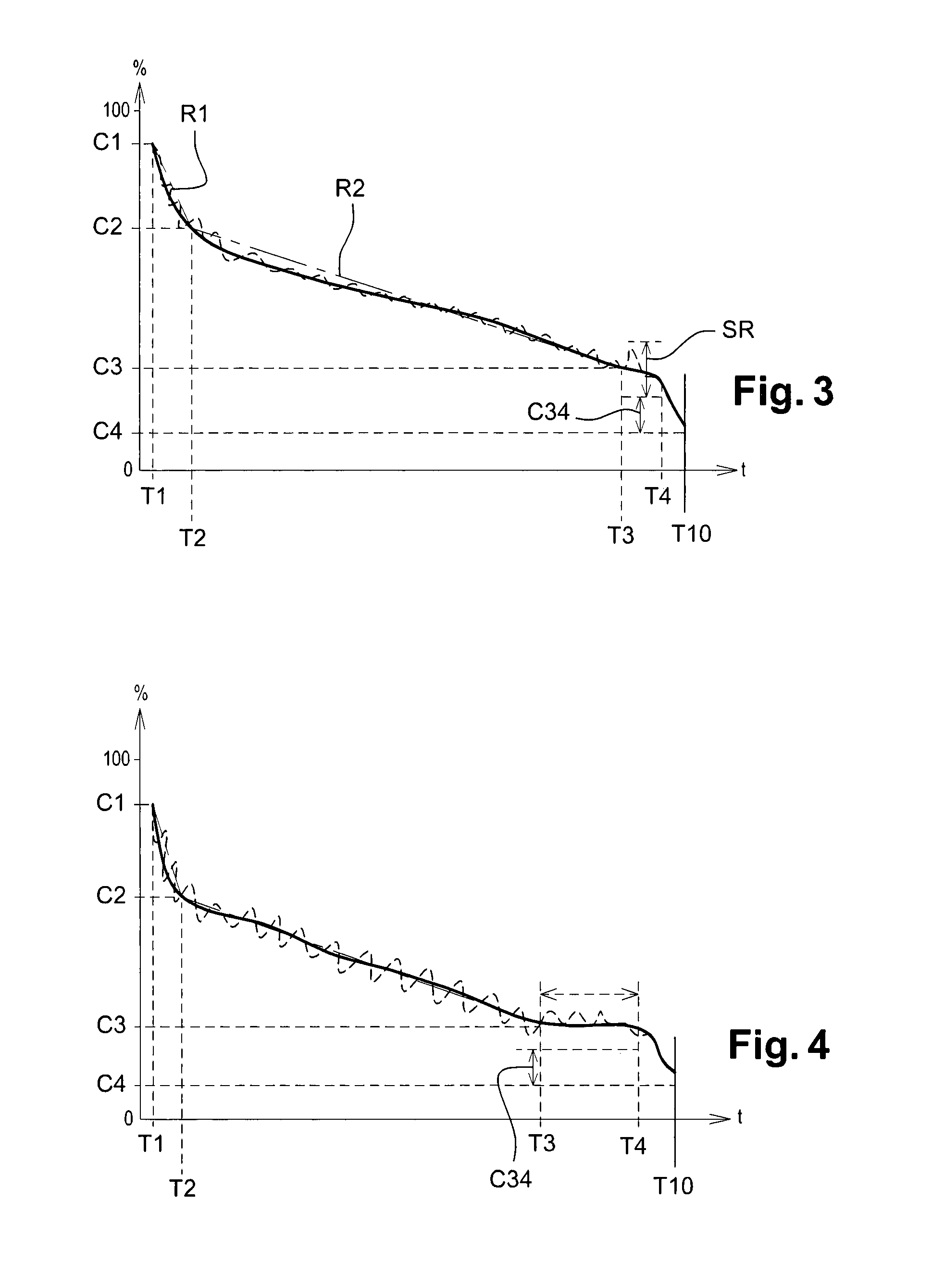

A method for forming a model simulating production, by an underground reservoir subject to depletion, of hydrocarbons comprising notably relatively high-viscosity oils. From laboratory measurements of the respective volumes of oil and gas produced by rock samples from the reservoir subject to depletion, and the relative permeabilities (Kr) of rock samples to hydrocarbons, a model of the formation and flow of the gas fraction is used to determine a volume transfer coefficient (hv) by means of an empirical function representing the distribution of nuclei that can be activated at a pressure P (function N(P)) which is calibrated with reference to the previous measurements. Considering that the nuclei distribution N(P) in the reservoir rocks is the same as the distribution measured in the laboratory, the numerical transfer coefficient corresponding thereto in the reservoir at selected depletion rates is determined using the gas fraction formation and flow model, which allows predicting the relative permeabilities in the reservoir and the production thereof which is useful for reservoir engineering. Method for forming a model allowing to simulate the production, by an underground reservoir subjected to depletion, of hydrocarbons comprising notably relatively high-viscosity oils. From laboratory measurements of the respective volumes of oil and gas produced by rock samples from the reservoir and subjected to depletion, and the relative permeabilities (Kr) of rock samples to hydrocarbons, a model of the formation and flow of the gas fraction is used to determine a volume transfer coefficient (hv) by means of an empirical function representing the distribution of nuclei that can be activated at a pressure P (function N(P)) which is calibrated with reference to the previous measurements. Considering that the nuclei distribution N(P) in the reservoir rocks is the same as the distribution measured in the laboratory, the numerical transfer coefficient corresponding thereto in the reservoir at selected depletion rates is determined using the gas fraction formation and flow model, which allows to predict the relative permeabilities in the reservoir and the production thereof. Applications notably reservoir engineering.

Owner:INST FR DU PETROLE

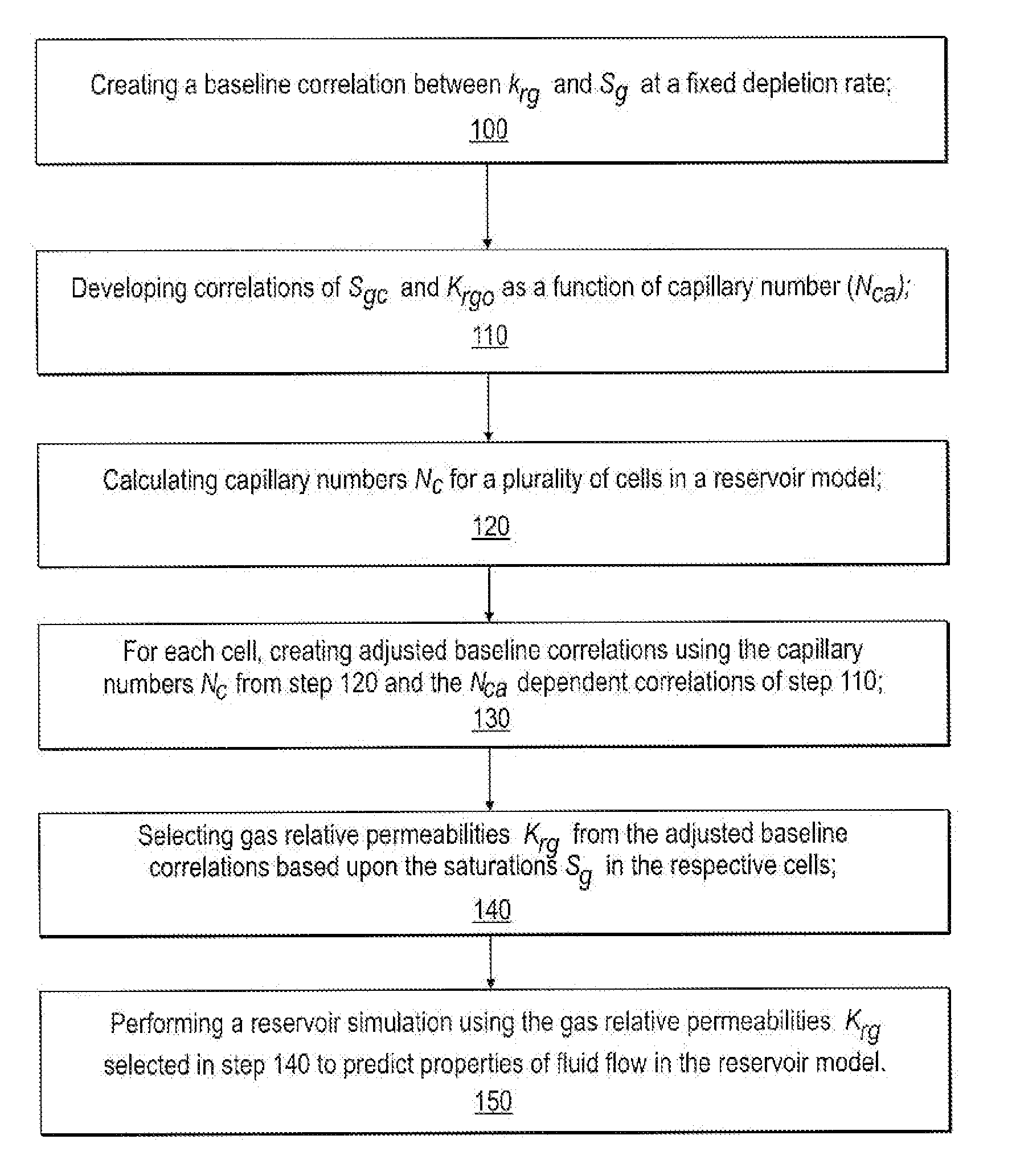

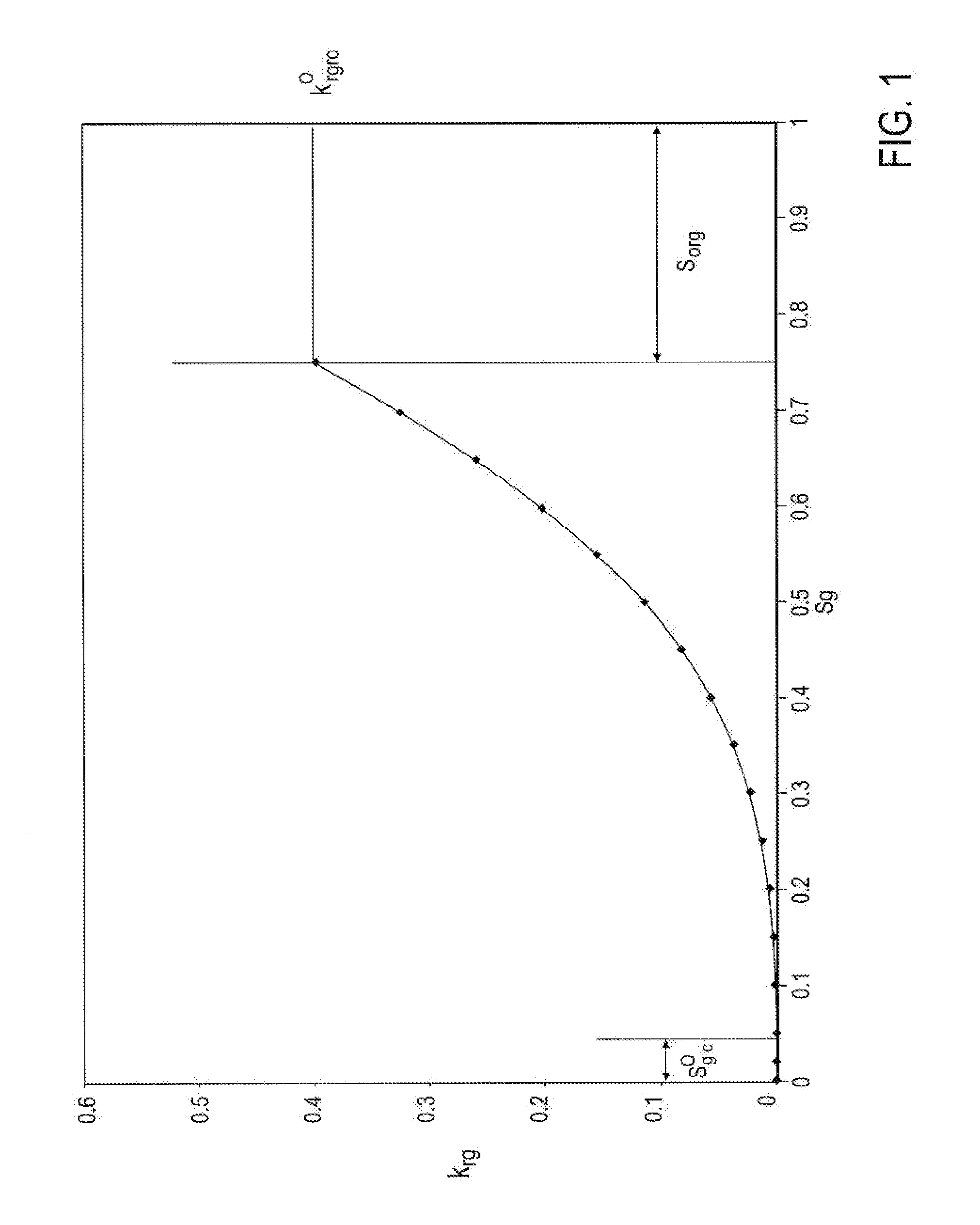

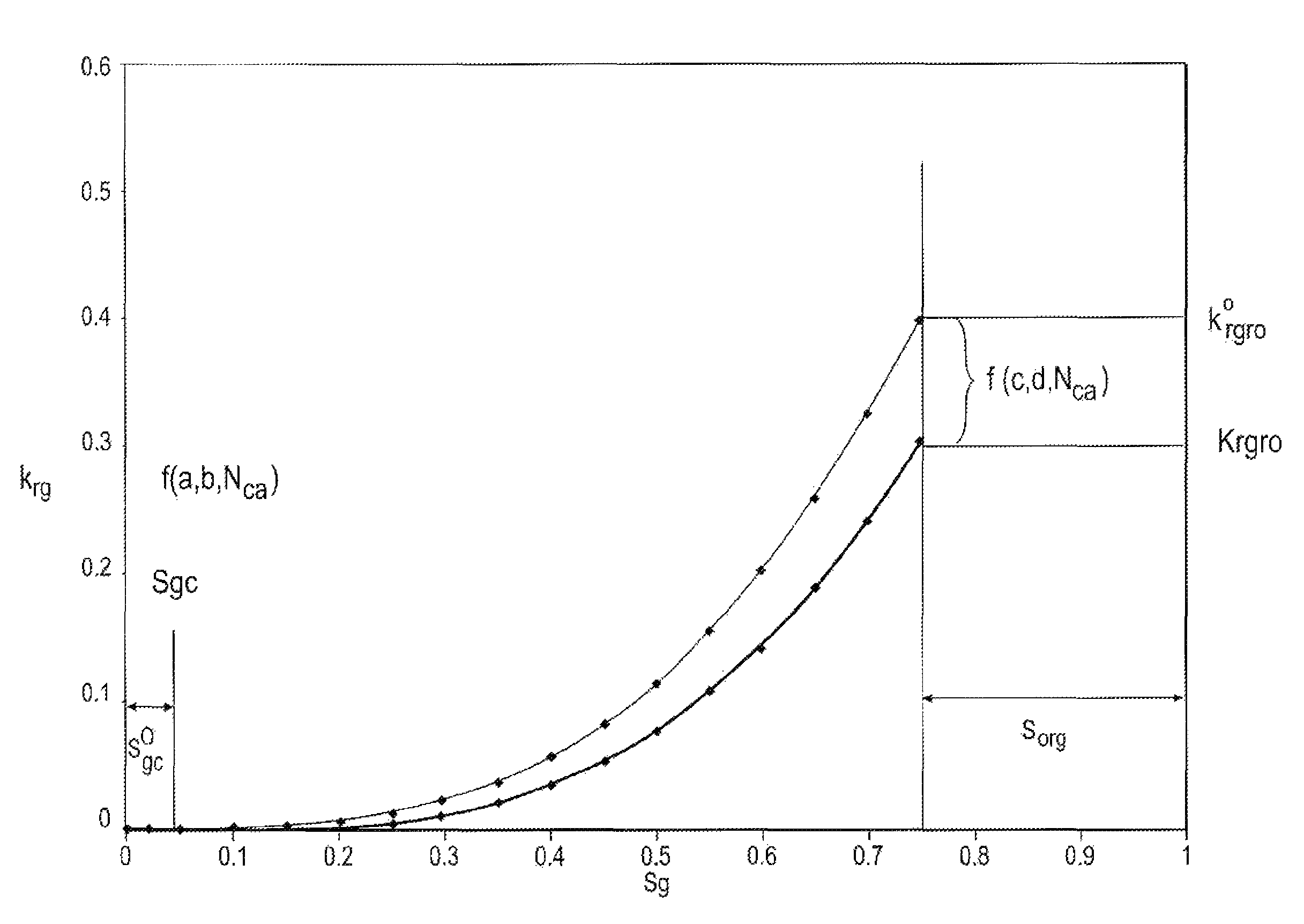

Method, system and program storage device for reservoir simulation utilizing heavy oil solution gas drive

ActiveUS20080154563A1Enhance reservoir performance forecastingImprove predictive performanceFluid removalDesign optimisation/simulationFuel oilProduct gas

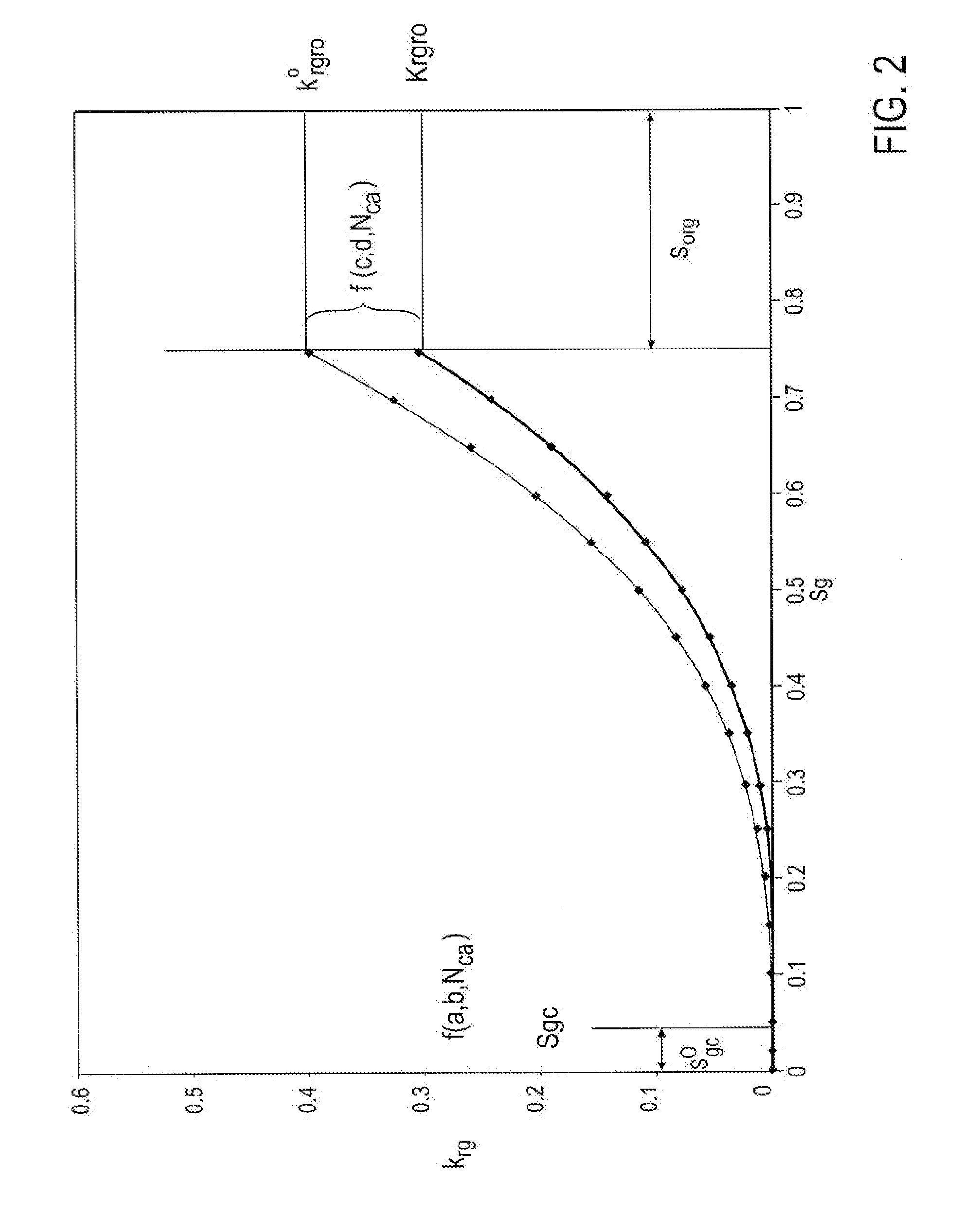

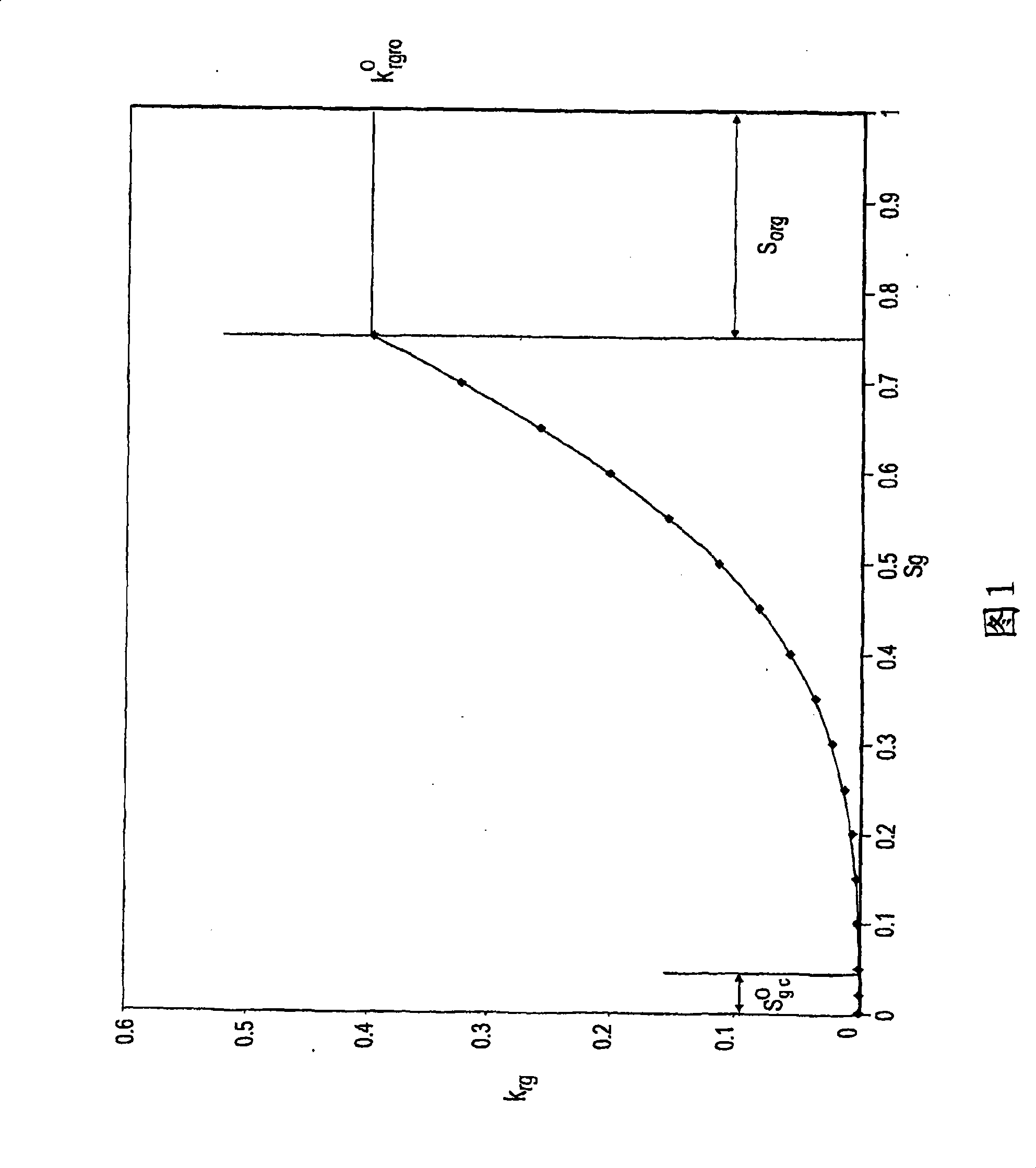

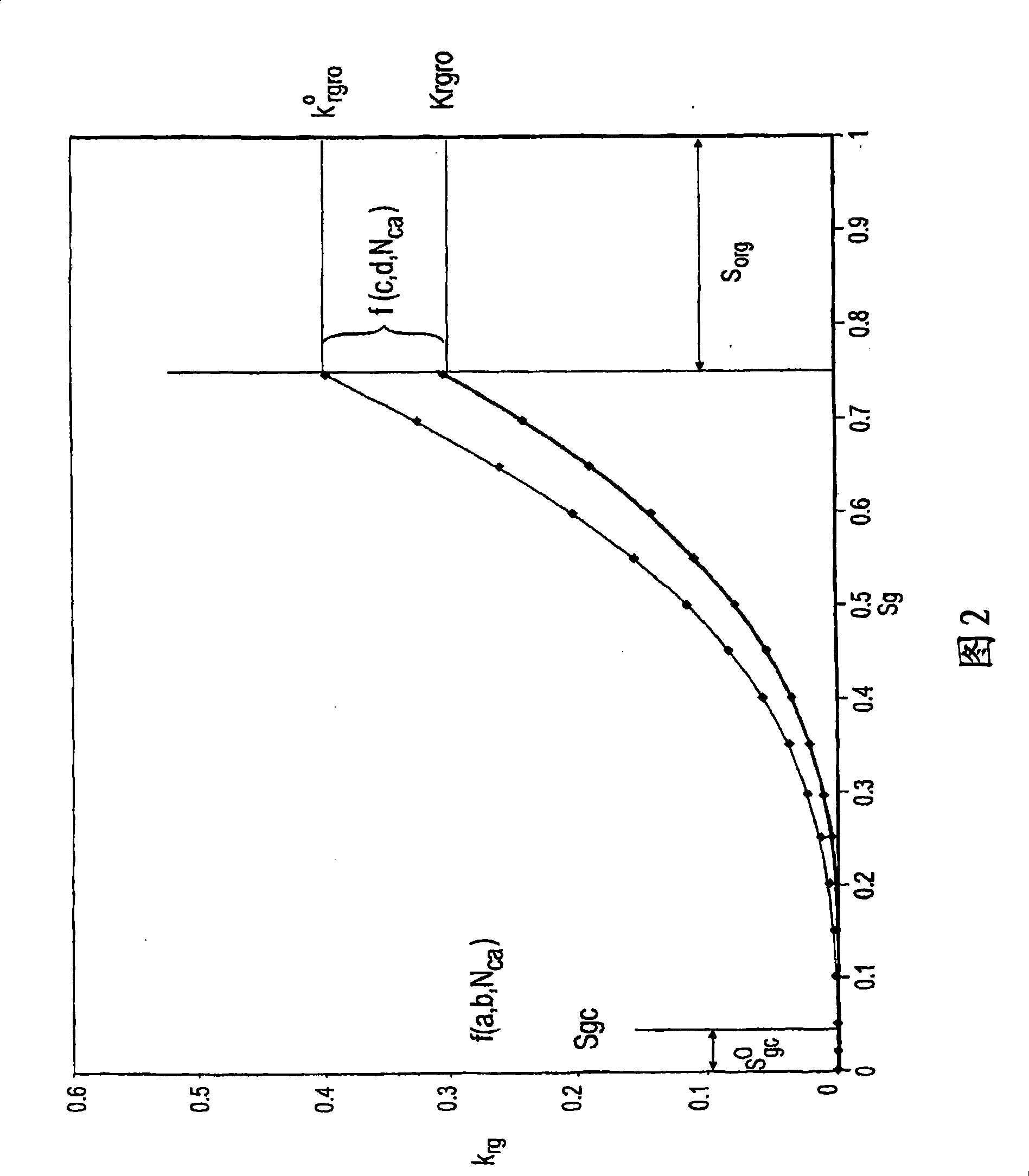

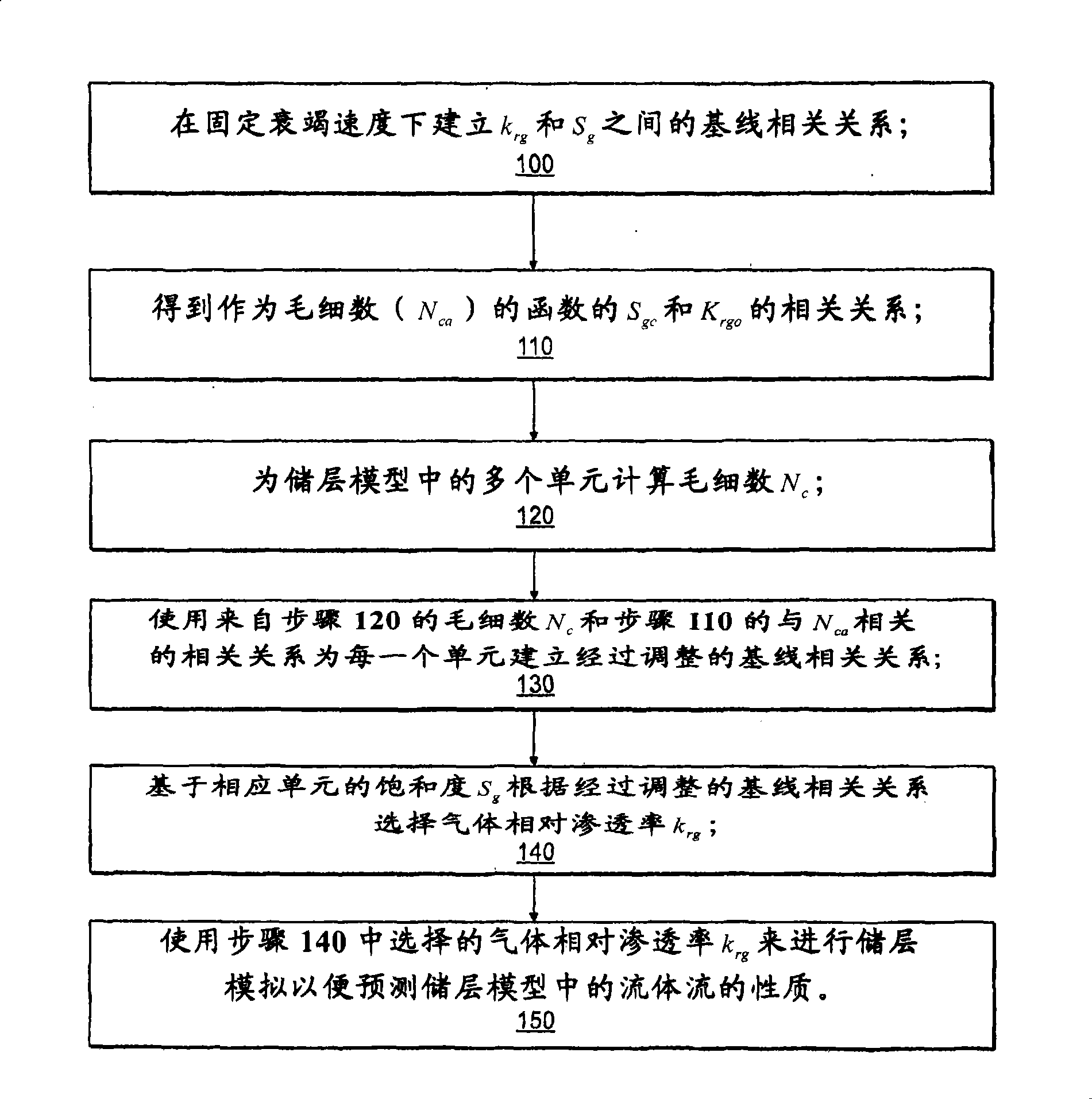

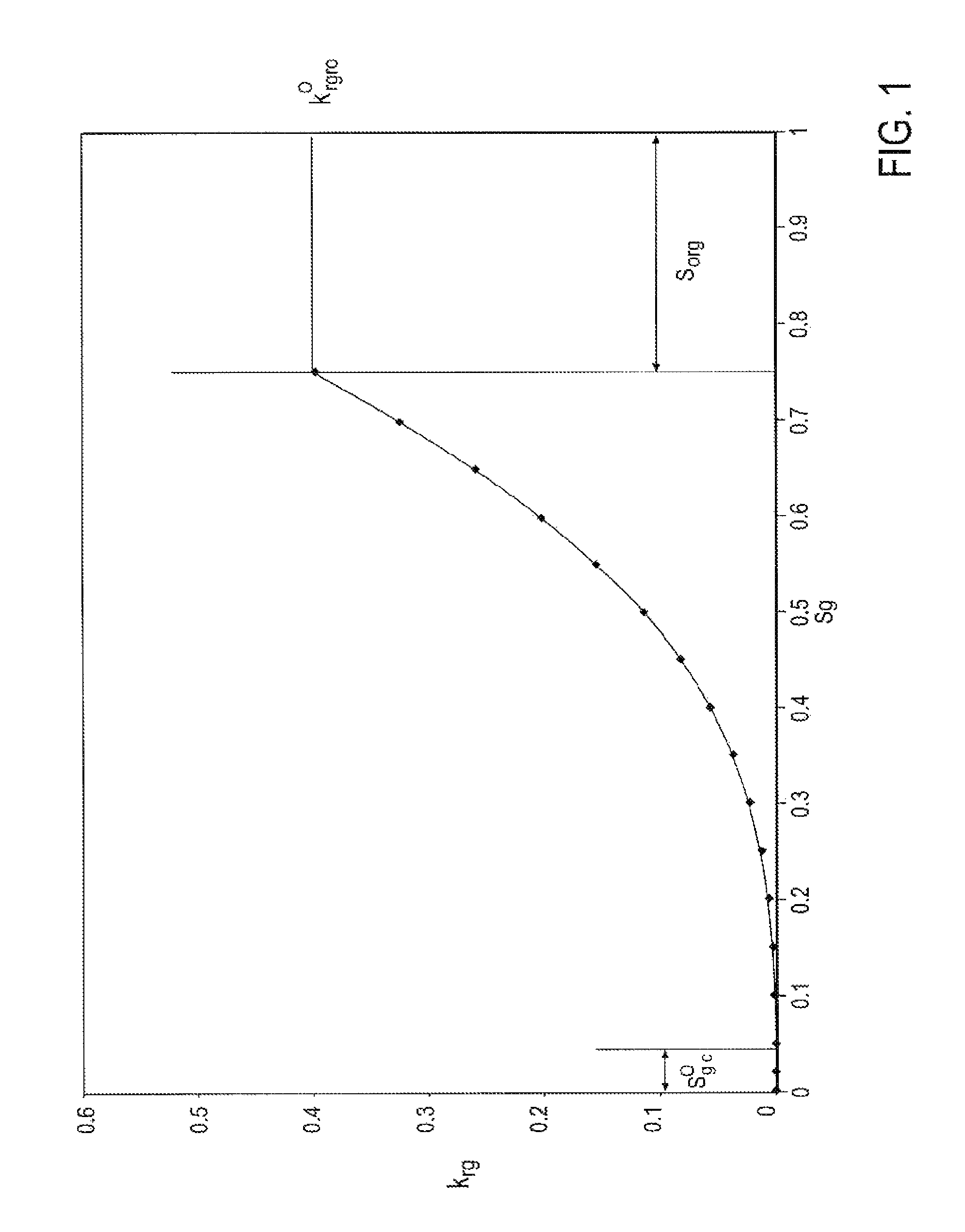

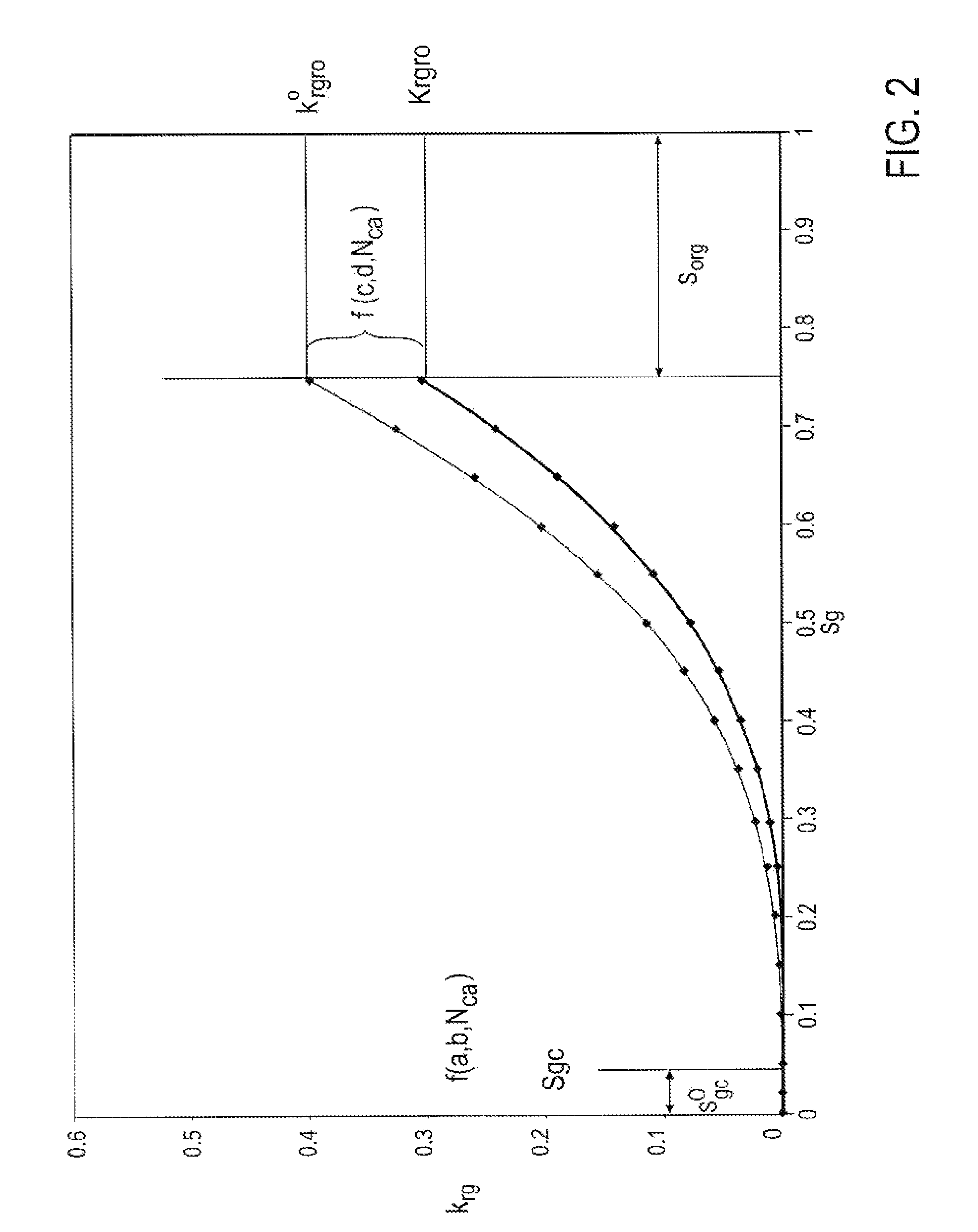

A method, a system and a program storage device for predicting a property of a fluid, such as fluid production from a subterranean reservoir containing heavy oil entrained with gas is described. The method includes developing a baseline correlation of gas relative permeability krg versus gas saturation Sg. A capillary number dependent correlation is determined capturing the relationship between at least one of critical gas saturation Sgc and capillary number Nca and gas relative permeability krgro and capillary number Nca phased upon a plurality of depletion rates. Capillary numbers Nc are calculated for a plurality of cells in a reservoir model representative of the subterranean reservoir. The baseline correlation is then adjusted to comport with at least one of Sgc and krgro selected from the capillary number dependent correlation to produce a plurality of corresponding adjusted baseline, correlations. Gas relative permeabilities krg for the plurality of cells are selected from the corresponding adjusted baseline correlations. A reservoir simulation is then run utilizing the selected relative permeabilities krg to predict a property of at least one fluid in a subterranean reservoir containing heavy oil entrained with gas.

Owner:CHEVROU USA INC

Method, system and program storage device for reservoir simulation utilizing heavy oil solution gas drive

InactiveCN101366041ASurveyAnalogue processes for specific applicationsProduct gasRelative permeability

A method a system and a program storage device for predicting a property of a fluid from a subterranean reservoir containing heavy oil entrained with gas. The method includes developing a baseline correlation between gas relative permeability k(rg) and gas saturation S(g), and capillary number N(c) calculated from a plurality of cells and at least one of critical gas saturation S(gc) and gas relative permeability k(rgro) based upon plurality of depletion rates. The baseline correlation is then adjusted to comport with at least one of S(gc) and k(rgro) to produce a plurality of corresponding adjusted baseline correlations where gas relative permeabilities k(rg) are selected. A reservoir simulation is then run utilizing the selected relative permeabilities k(rg) to predict a property of at least one fluid.

Owner:CHEVROU USA INC

Method for modelling the production of hydrocarbons by a subsurface deposit which are subject to depletion

ActiveUS7343275B2Realistic representationElectric/magnetic detection for well-loggingPermeability/surface area analysisReservoir engineeringOil and natural gas

A method for forming a model simulating production, by an underground reservoir subject to depletion, of hydrocarbons comprising notably relatively high-viscosity oils. From laboratory measurements of the respective volumes of oil and gas produced by rock samples from the reservoir subject to depletion, and the relative permeabilities (Kr) of rock samples to hydrocarbons, a model of the formation and flow of the gas fraction is used to determine a volume transfer coefficient (hv) by means of an empirical function representing the distribution of nuclei that can be activated at a pressure P (function N(P)) which is calibrated with reference to the previous measurements. Considering that the nuclei distribution N(P) in the reservoir rocks is the same as the distribution measured in the laboratory, the numerical transfer coefficient corresponding thereto in the reservoir at selected depletion rates is determined using the gas fraction formation and flow model, which allows predicting the relative permeabilities in the reservoir and the production thereof which is useful for reservoir engineering.

Owner:INST FR DU PETROLE

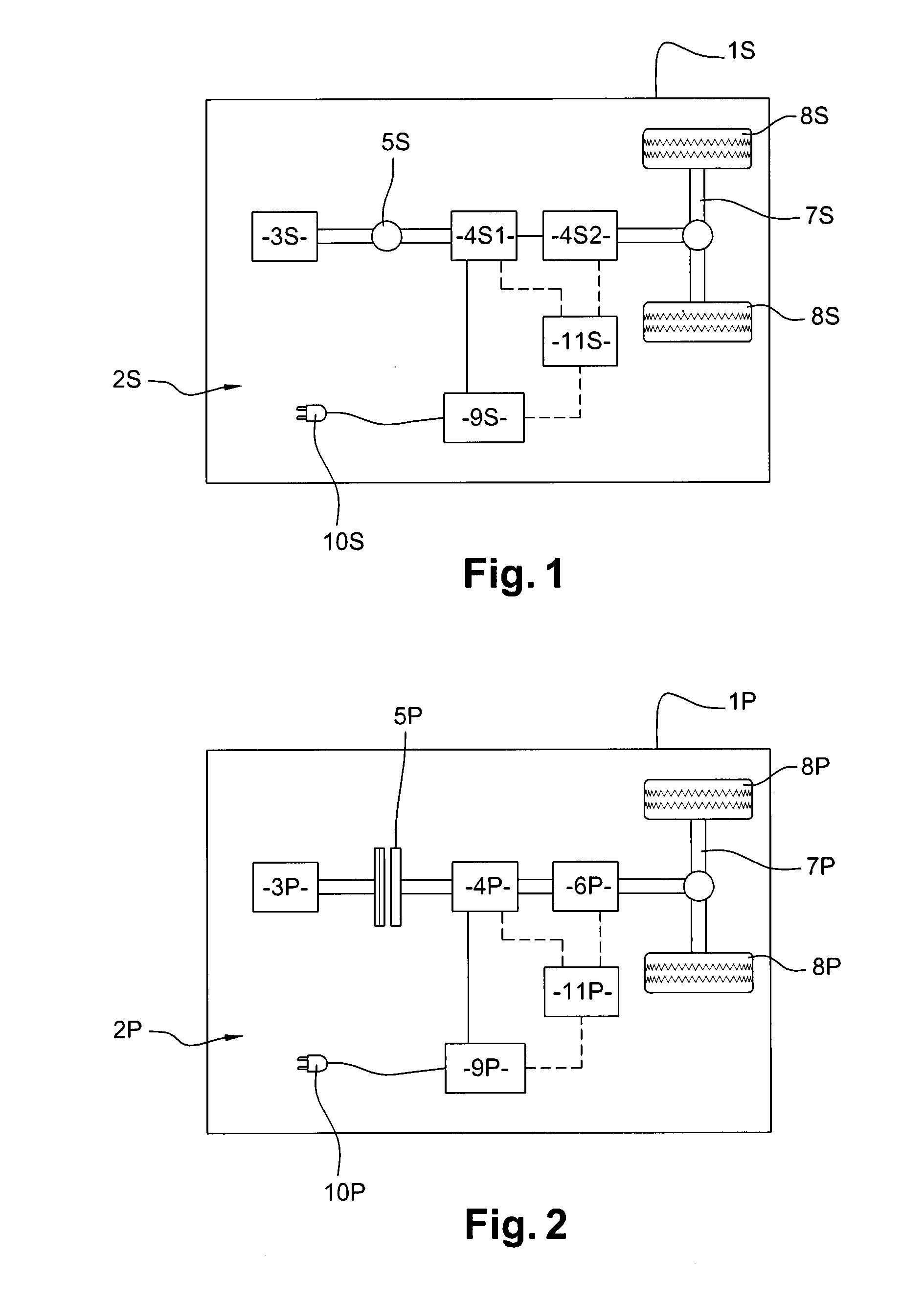

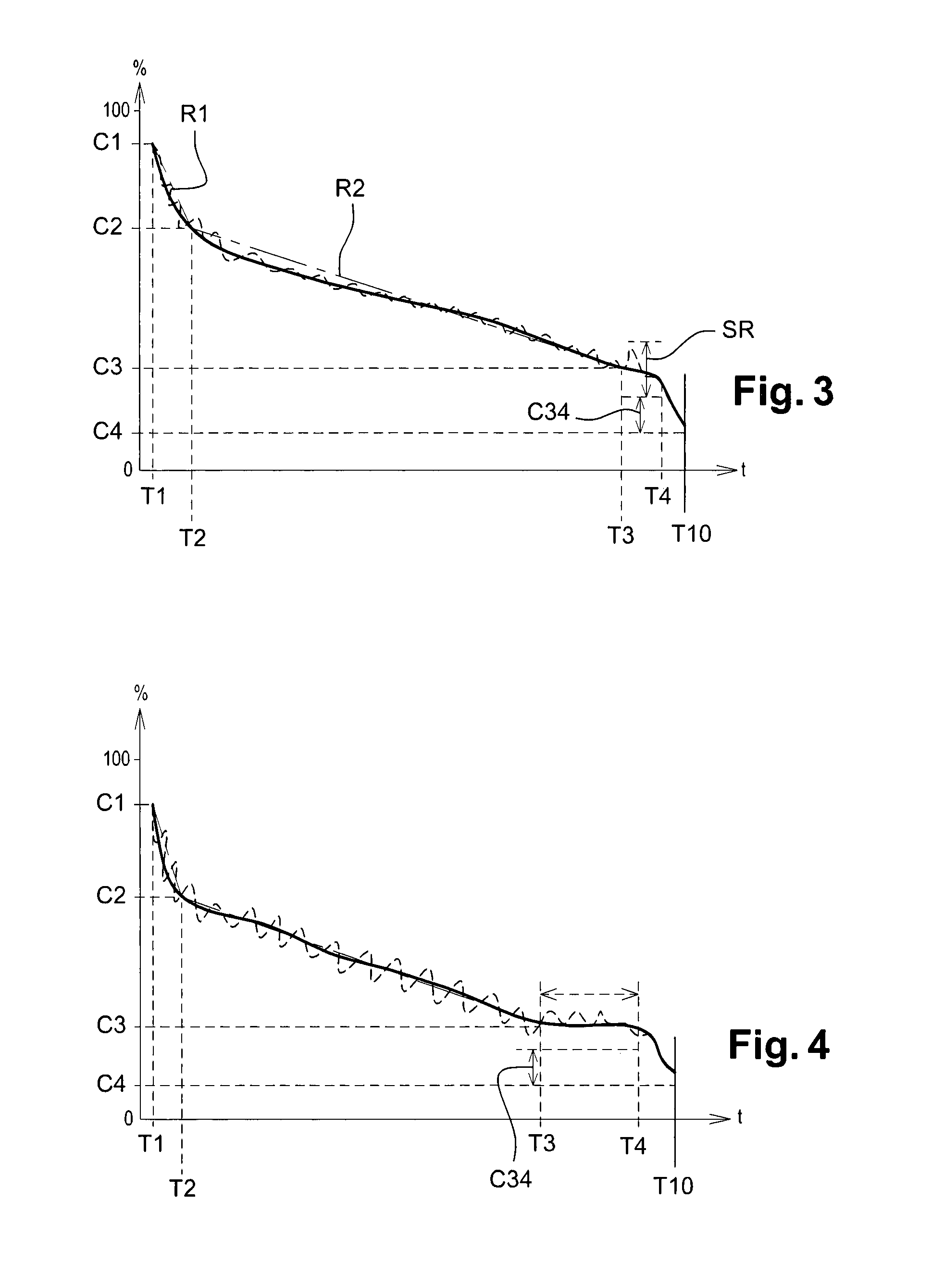

Method for controlling a hybrid traction assembly and hybrid vehicle controlled according to such a method

ActiveUS20130274984A1Avoid disadvantagesHybrid vehiclesDigital data processing detailsState of chargeHybrid vehicle

Owner:VOLVO LASTVAGNAR AB

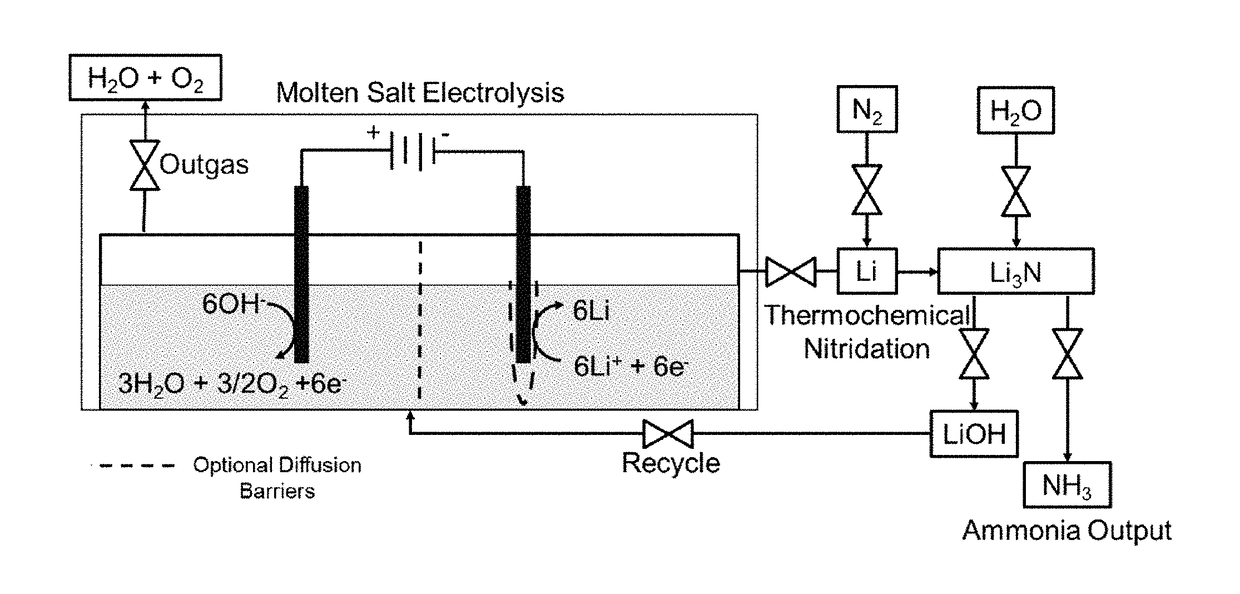

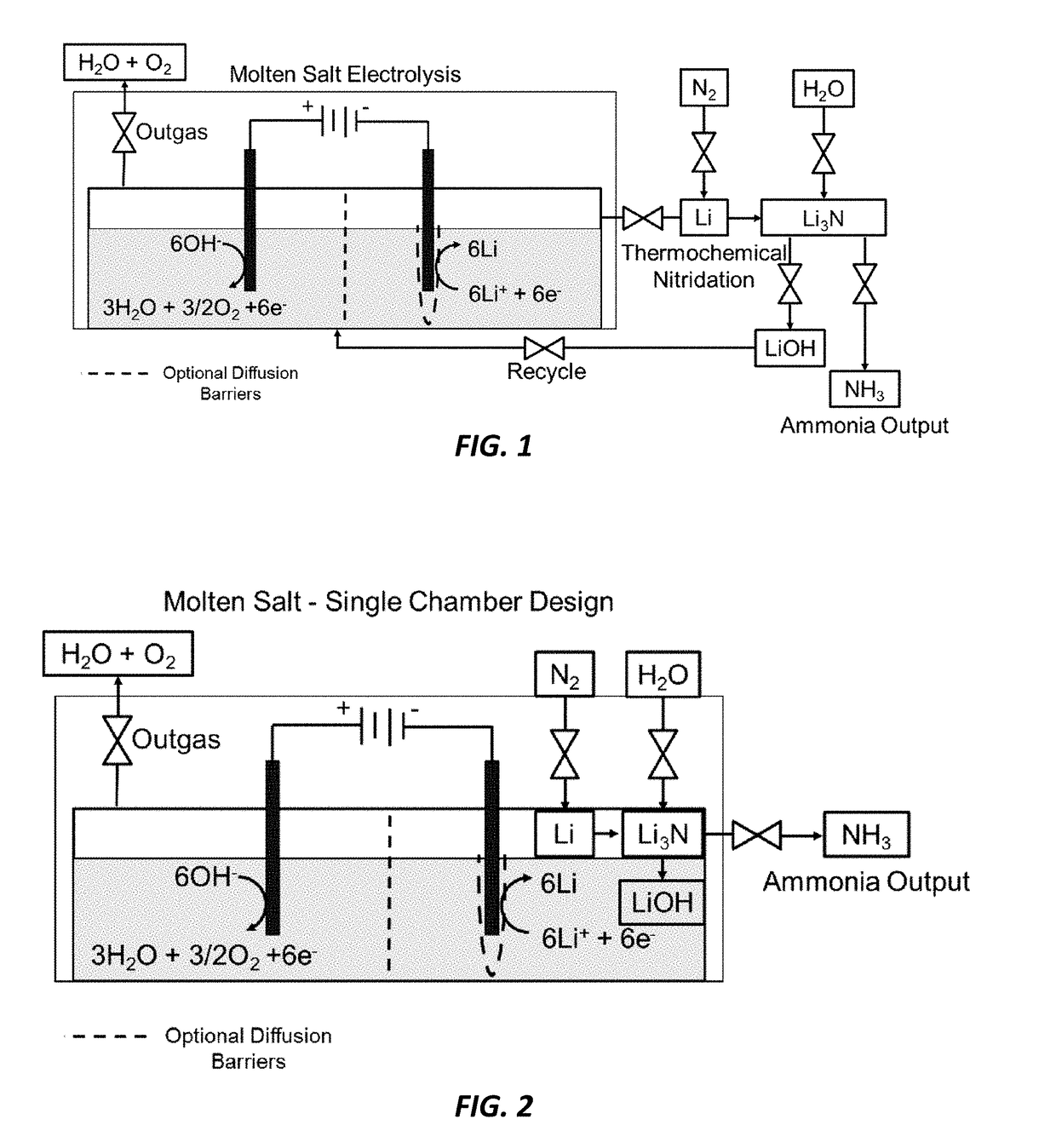

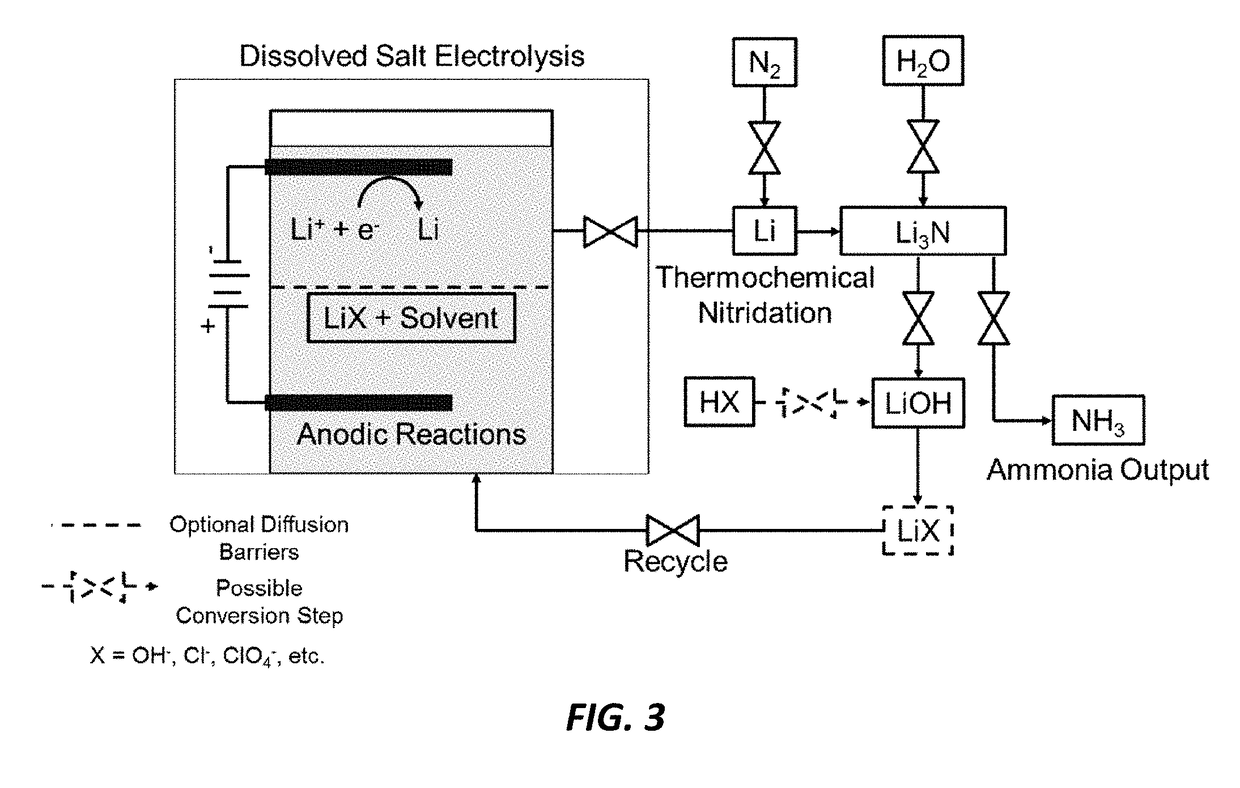

Electro-thermochemical Li Cycling for NH3 Synthesis from N2 and H2O

An electro-thermochemical cycling system for producing ammonia is provided that includes a reaction chamber having a metal compound input port, an anode suitable for oxidation in contact with the metal compound and configured for oxidation of hydroxide ions to water and oxygen, a cathode suitable for plating in contact with the metal compound and configured to electrolyze the metal compound to metal, a voltage source connecting the cathode and anode, a nitrogen port to the reaction chamber that combines nitrogen with the electrolyzed metal on the cathode to form a metal-nitrogen compound proximal to the nitrogen input, an atomic hydrogen port to the reaction chamber that combines with the metal-nitrogen compound to form ammonia, and an ammonia output port from the reaction chamber, where a metal compound input port inputs the metal compound to the reaction chamber according to a depletion rate of the metal compound in the reaction chamber.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

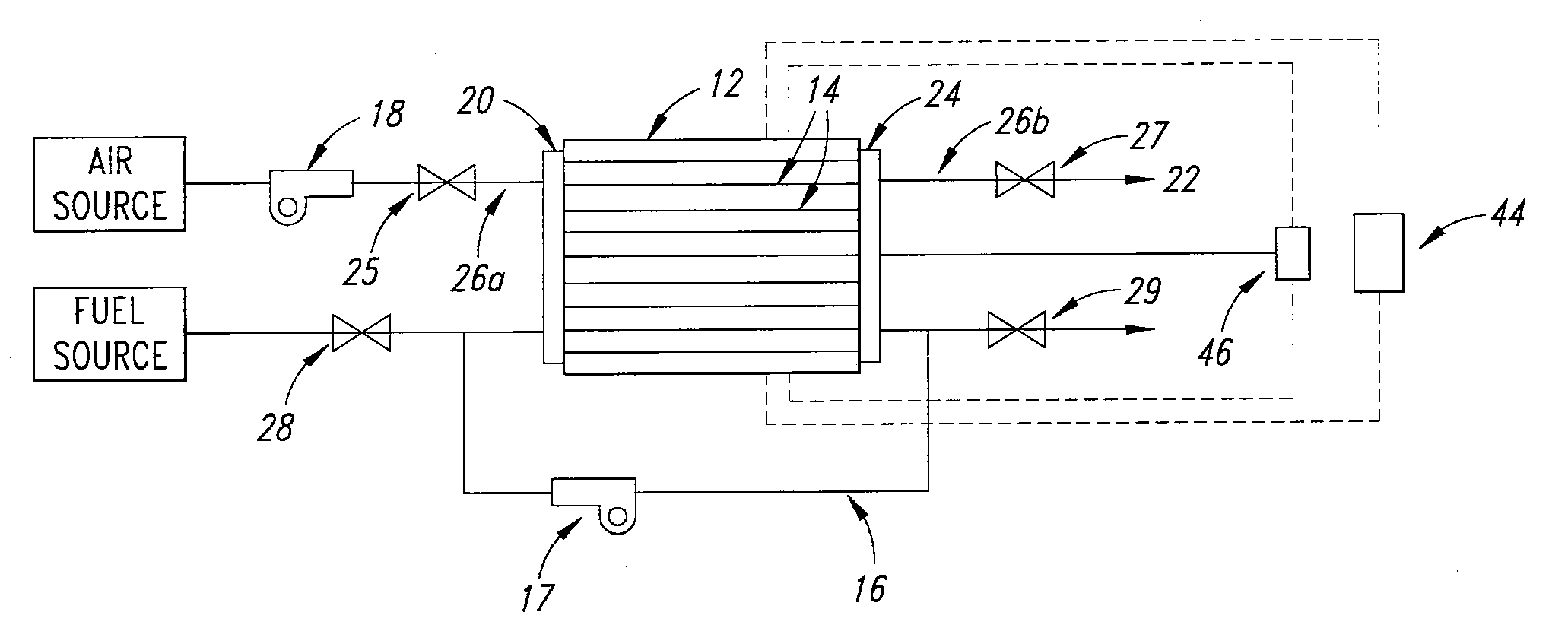

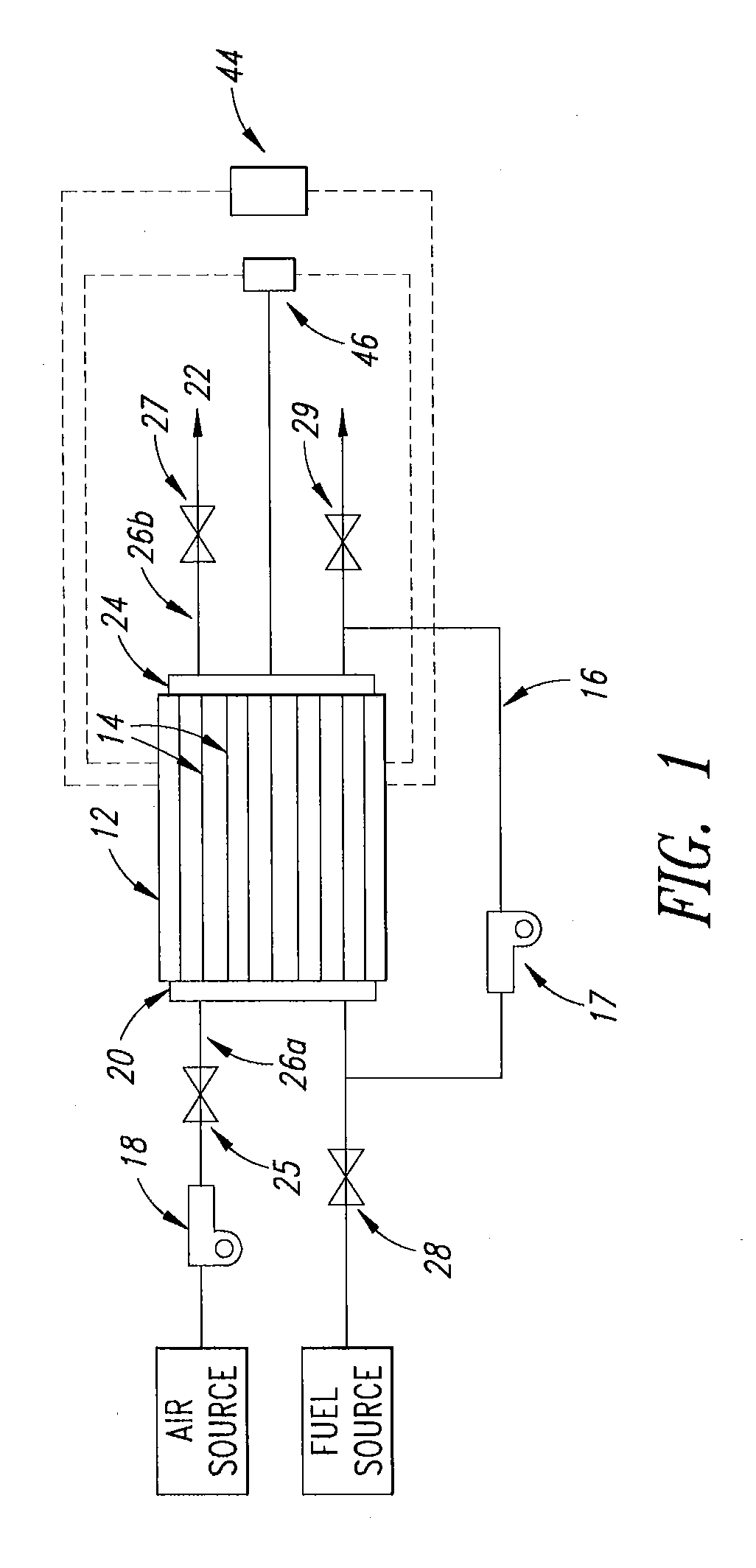

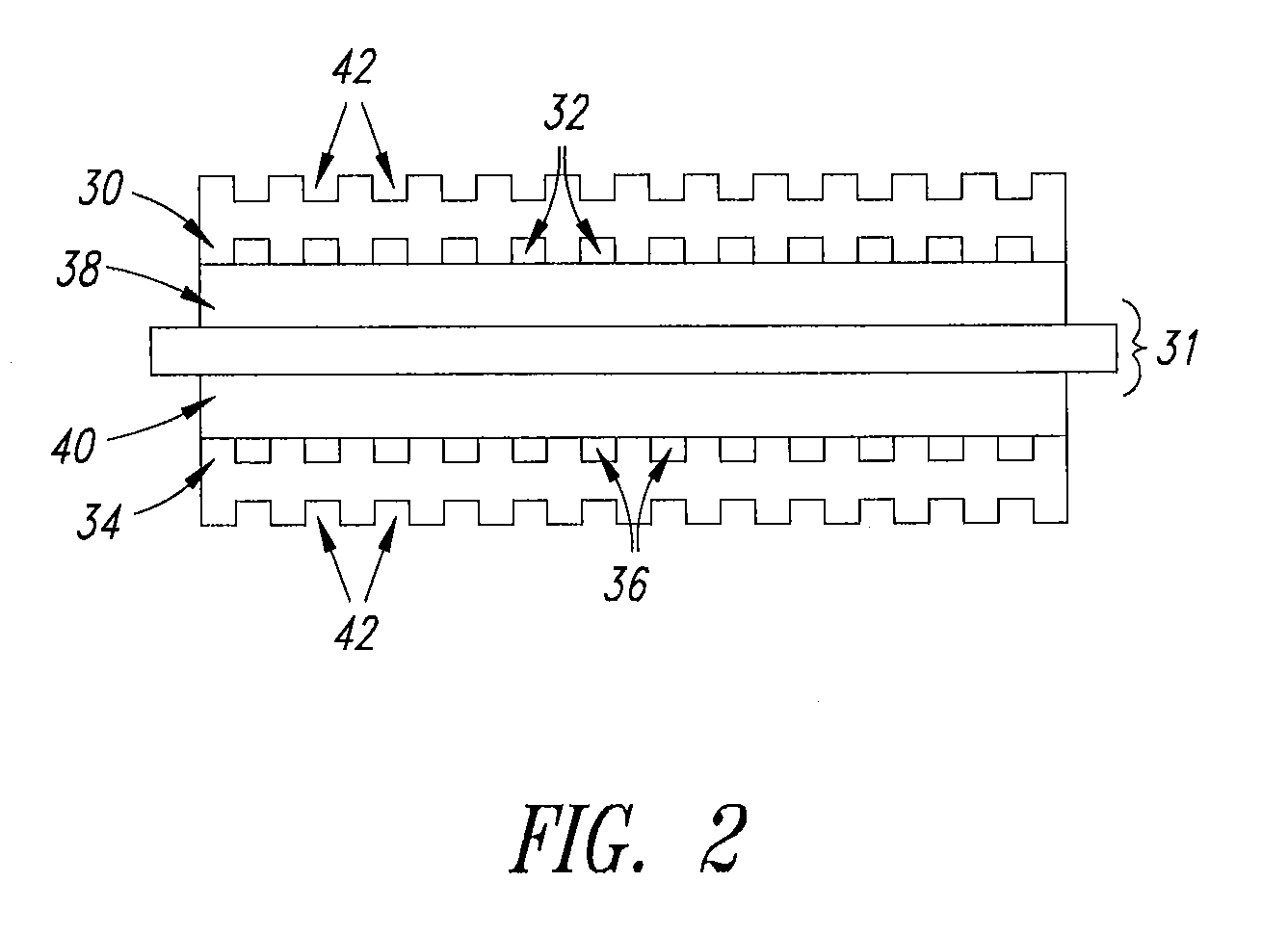

Shutdown procedure for fuel cell stacks

InactiveUS20070128474A1Reduce the temperatureFuel cell heat exchangeFuel cells groupingFuel cellsHydrogen

A method of ceasing operation of a fuel cell stack, the fuel cell stack comprising a plurality of fuel cells, each fuel cell comprising at least one anode flow field and at least one cathode flow field for supplying fuel and oxidant thereto, the fuel comprising hydrogen, the method comprising the steps of disconnecting a primary load from the fuel cell stack; terminating the supply of oxidant to the disconnected fuel cell stack; terminating the supply of fuel to the disconnected fuel cell stack; recirculating the fuel through the at least one anode flow field of each fuel cell until all of the oxygen in the oxidant is substantially consumed; and maintaining a hydrogen depletion rate of less than about 3.0% hydrogen / ° C. decrease in a fuel cell stack temperature as the fuel cell stack cools down to a predetermined temperature.

Owner:BDF IP HLDG

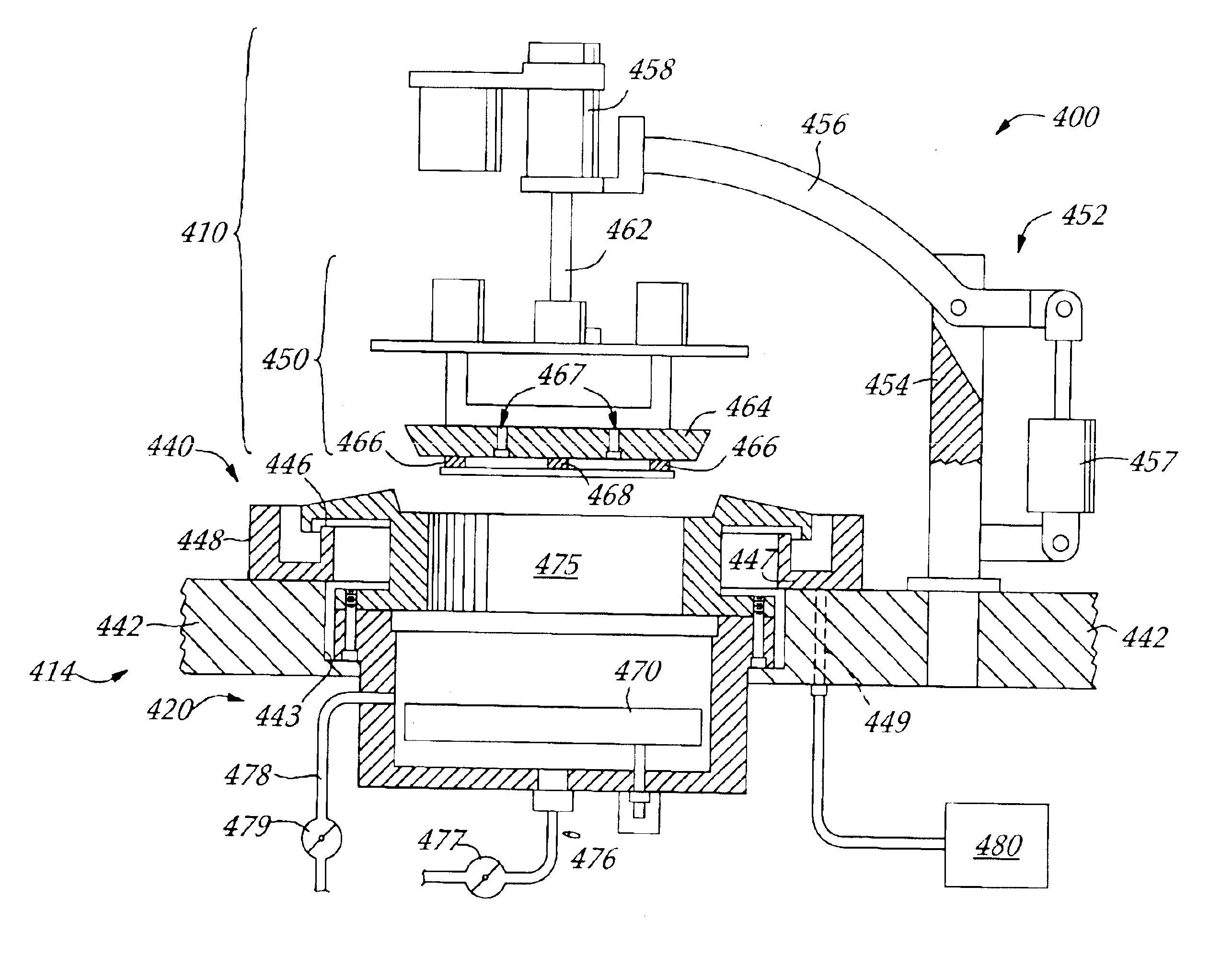

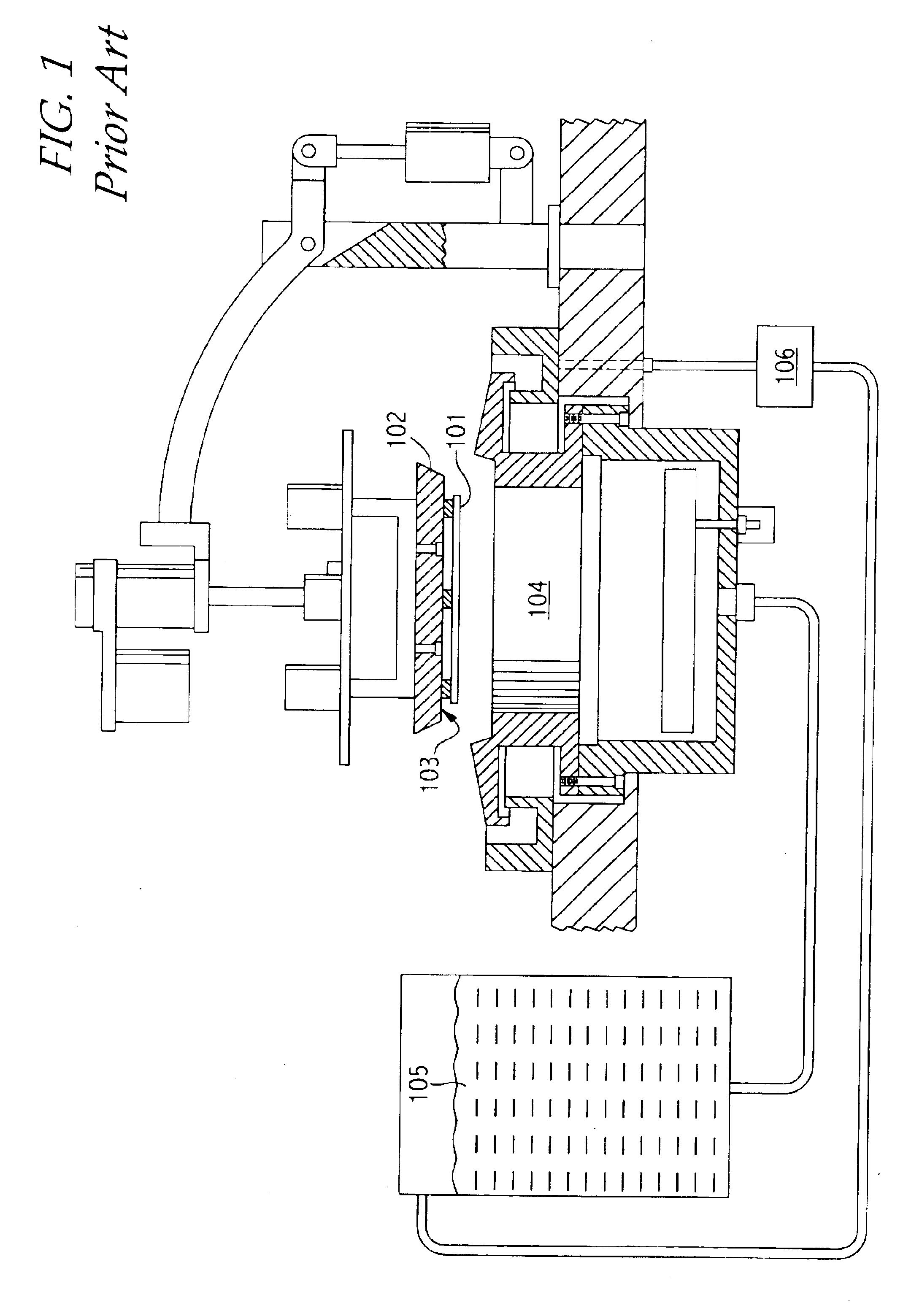

Method and apparatus for reducing organic depletion during non-processing time periods

InactiveUS6878245B2Reduce consumptionReducing organic depletionCellsElectrical-based auxillary apparatusUnit of timeEngineering

Embodiments of the invention generally provide an apparatus and method for replenishing organic molecules in an electroplating bath. The replenishment process of the present invention may occur on a real-time basis, and therefore, the concentration of organics minimally varies from desired concentration levels. The replenishment method generally includes conducting pre-processing depletion measurements in order to determine organic depletion rates per current density applied in the electroplating system. Once the organic depletion rates per current density are determined, these depletion rates may be applied to an electroplating processing recipe to calculate the volume of organic depletion per recipe step. The calculated volume of organic depletion per recipe step may then be used to determine the volume of organic molecule replenishment per unit of time that is required per recipe step in order to maintain a desired concentration of organics in the plating solution. The calculated replenishment volume may then be added to the processing recipe so that the replenishment process may occur at real-time during processing periods. The apparatus generally includes a selectively actuated valve in communicaiton with a fluid delivery line, wherein the valve is configured to fluidly isolate a plating cell during a non-processing time period. The valve may be controlled by a system controller, and thus, the fluid level in the cell may be controlled during a non-processing time period.

Owner:APPLIED MATERIALS INC

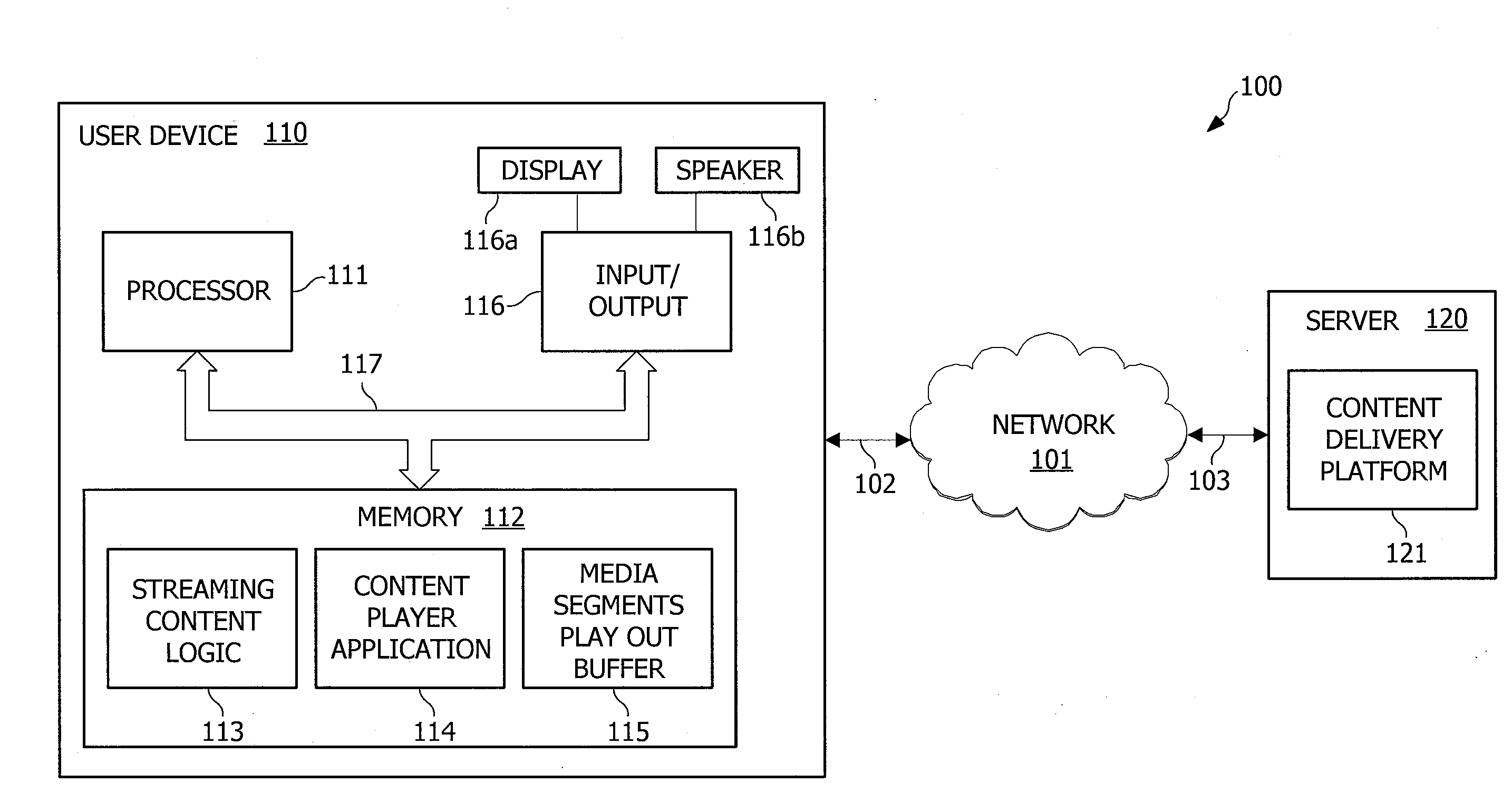

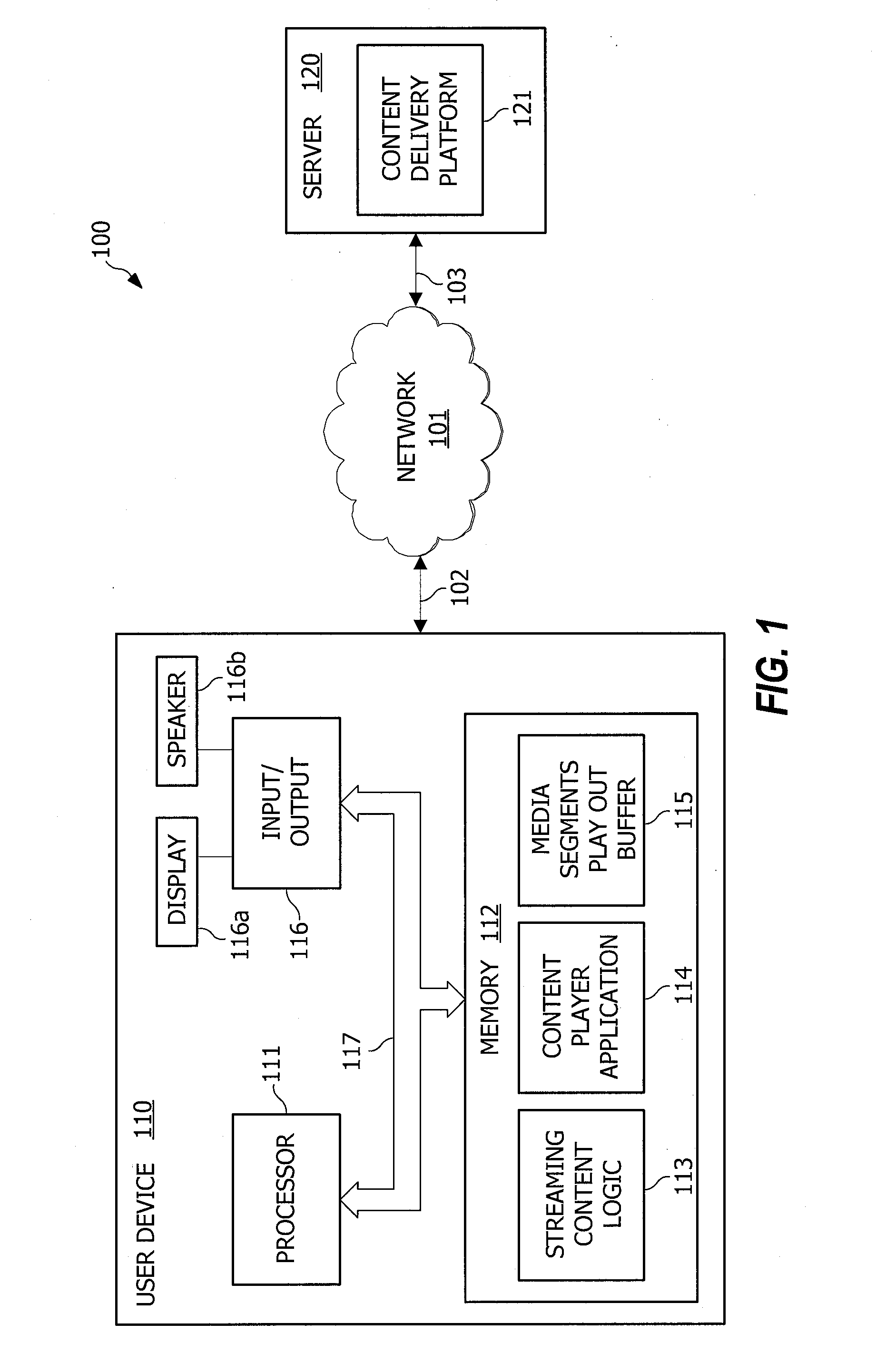

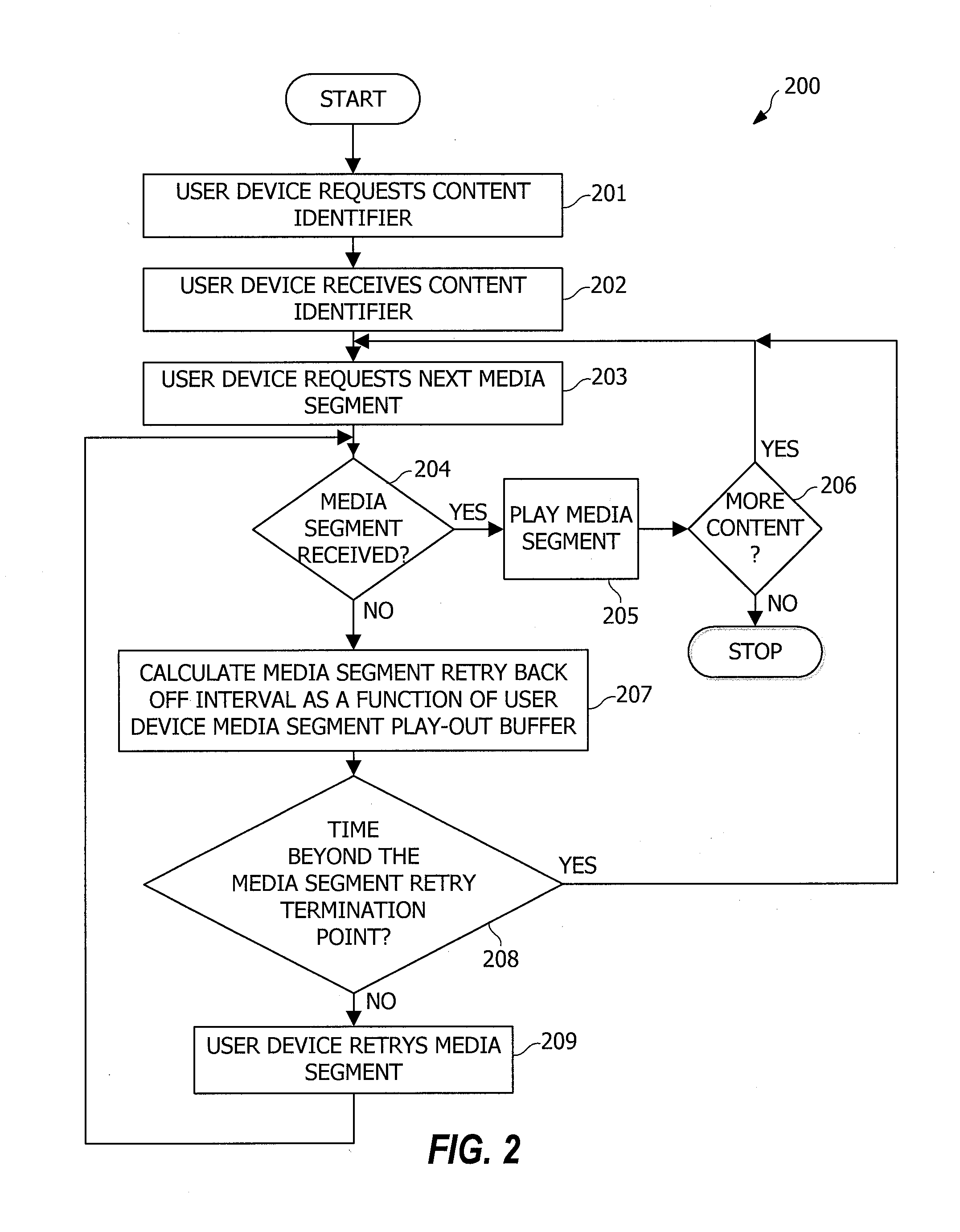

Method and apparatus for media segment request retry control

Methods and apparatus for media segment request retry control are disclosed. Embodiments implement one or more media segment retry back off interval calculated as a function of an aspect of a client media segments play-out buffer, wherein the media segment retry back off interval defines a period before a subsequent retry for a media segment is attempted. The retry back off interval may be calculated as a function of a depletion rate of content from the client media segments play-out buffer, a function of a change in size of the client media segments play-out buffer, or a combination thereof according to embodiments. Embodiments may implement a media segment retry termination point as a function of an estimated media segment transaction time and a next media segment availability time.

Owner:QUALCOMM INC

Method for controlling a hybrid traction assembly and hybrid vehicle controlled according to such a method

ActiveUS8725339B2Degradation of combustionReduced service lifeHybrid vehiclesDigital data processing detailsControl theoryHybrid vehicle

A method for controlling a hybrid traction assembly includes an initial depleting phase which begins at the beginning of the vehicle mission and where the hybrid traction assembly is controlled to cause depletion of the storage device at a high first mean depletion rate, at least one sustaining phase where the hybrid traction assembly is controlled so that the state of charge is maintained in a predetermined sustaining range. The method further includes a second depleting phase which extends between the initial depleting phase and the sustaining phase, wherein the hybrid traction assembly is controlled to cause depletion of the storage device at a second mean depletion rate, the second mean depletion rate being lower than the first mean depletion rate.

Owner:VOLVO TRUCK CORP

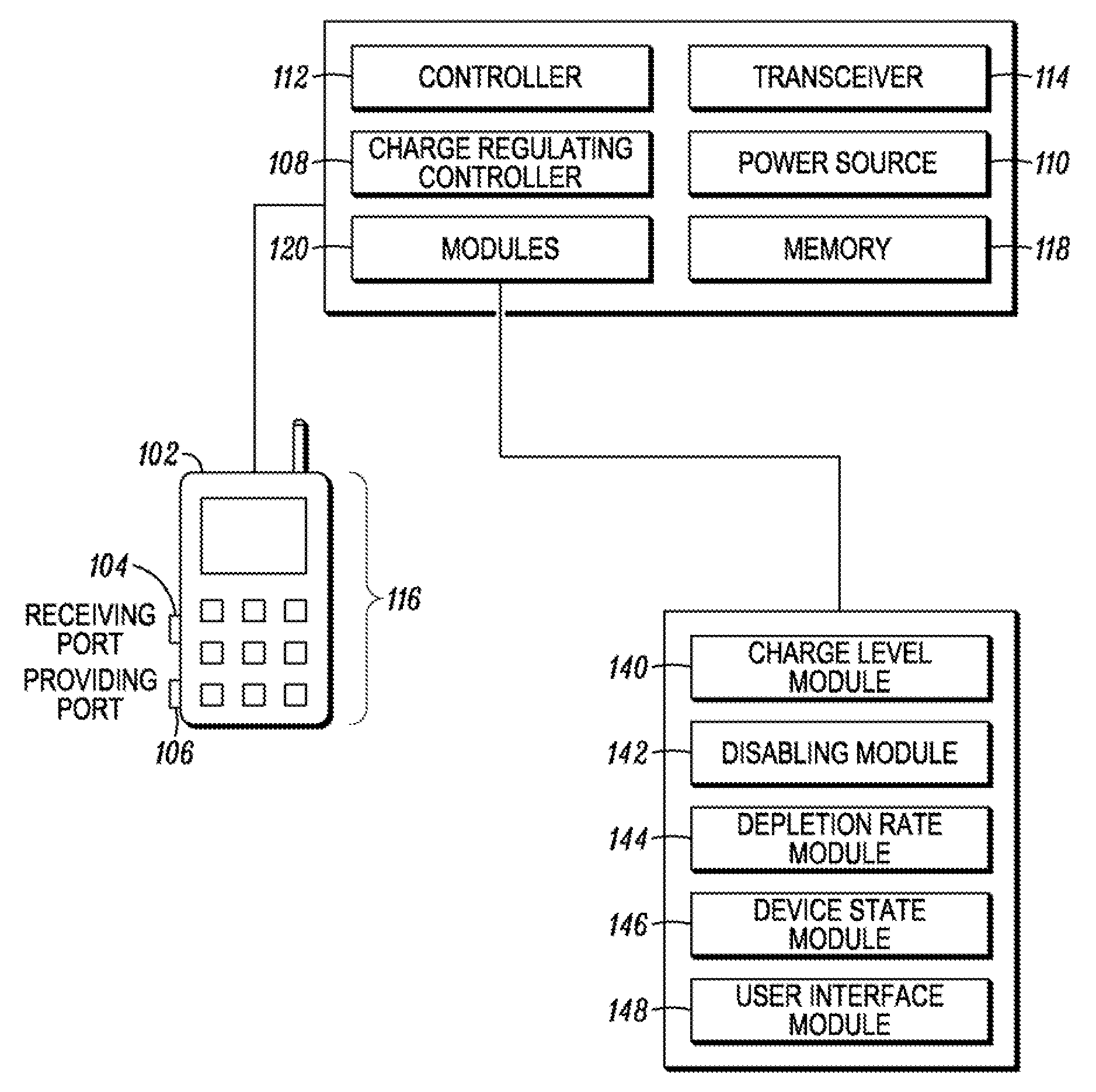

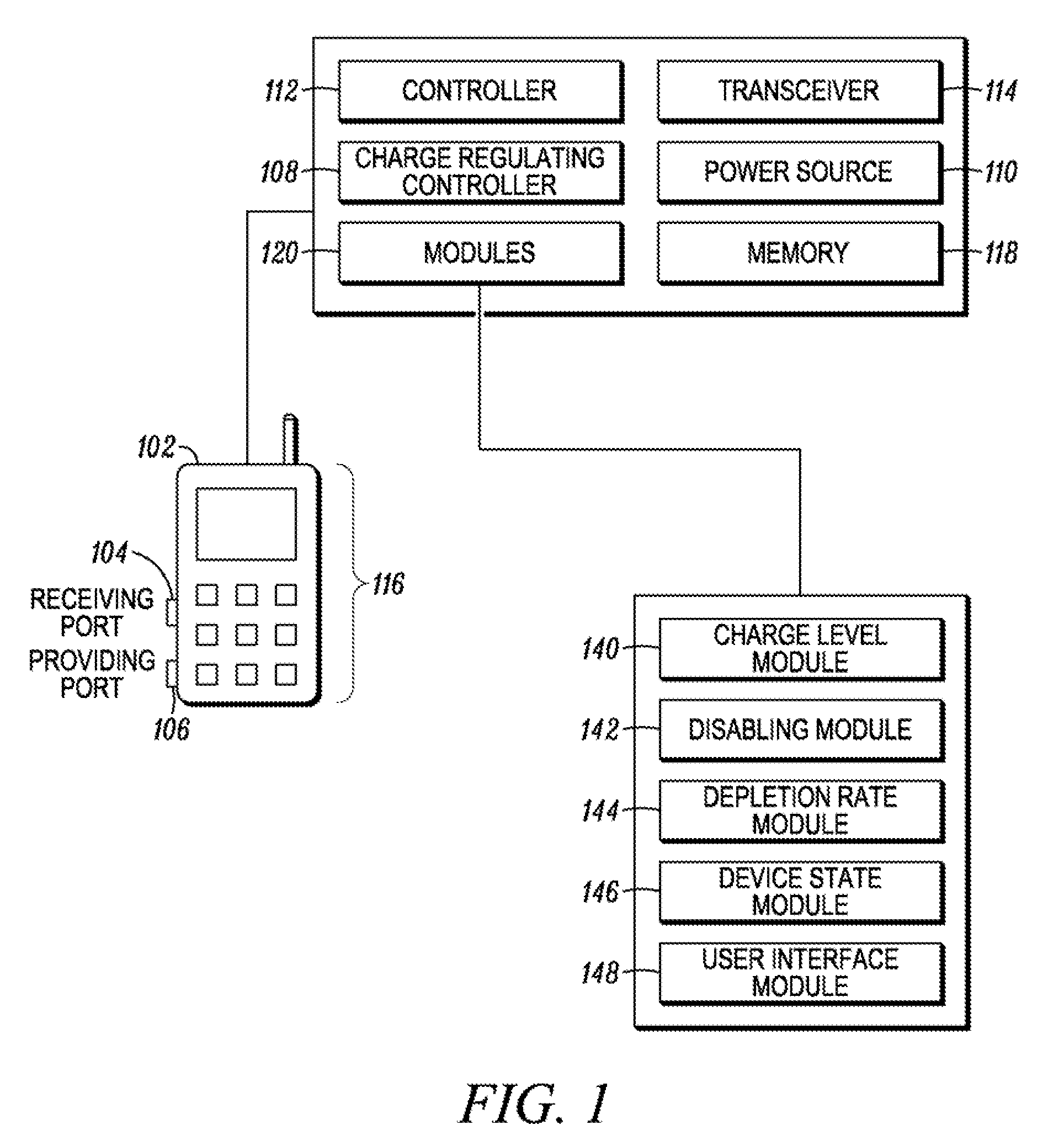

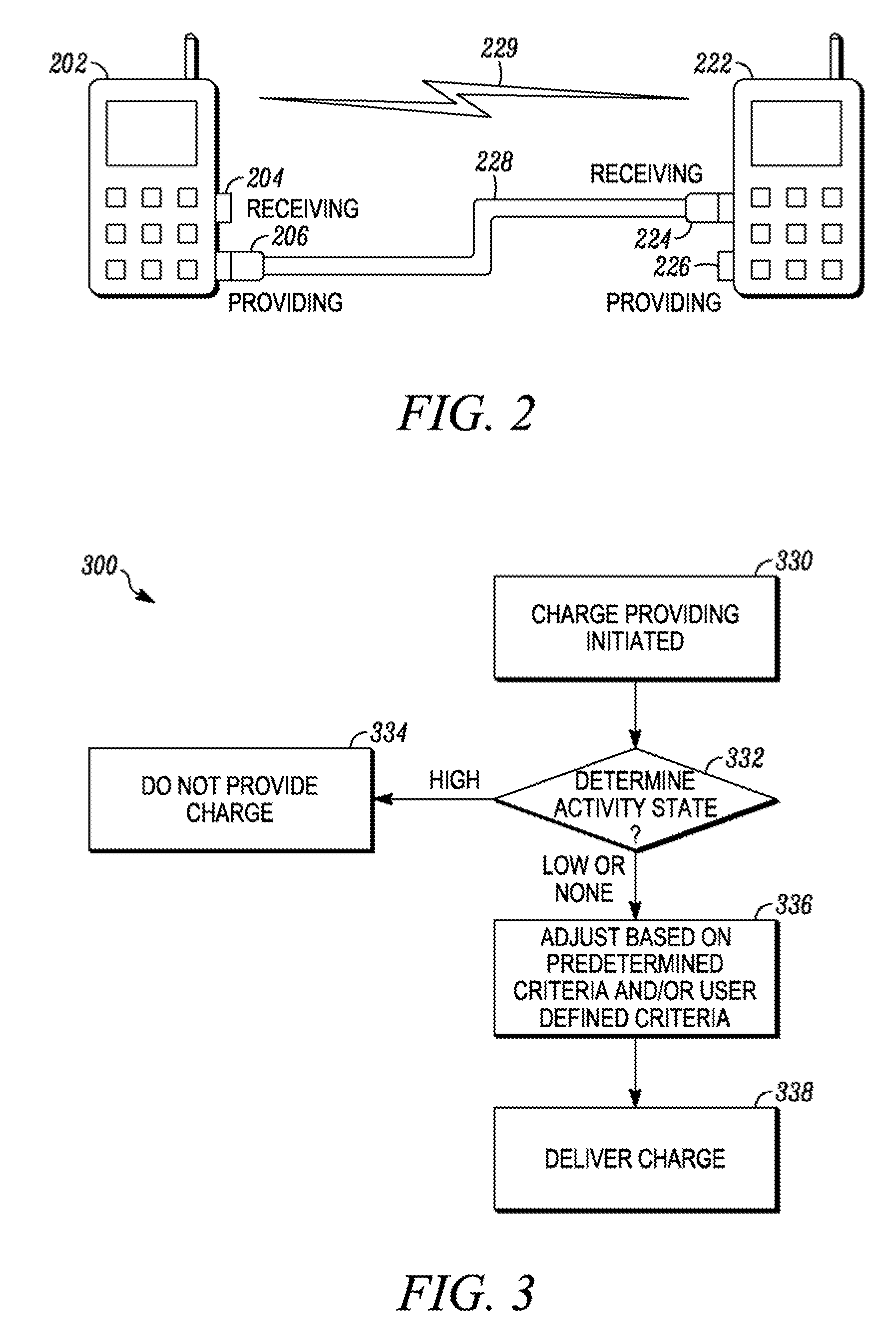

Devices and methods for electronic device recharging

InactiveUS20090134836A1Batteries circuit arrangementsElectric powerDepletion rateElectrical and Electronics engineering

Disclosed are devices and methods for regulating providing a charge via a charge receiving port of one device, the one device coupled to another device having a charge providing port. In one embodiment, the ports can be coupled by a cable. In another embodiment, the ports can be coupled wirelessly. The charge delivering device may regulate a charge providing process, controlled by a charge regulating controller of the charge providing device and based, for example, upon predetermined criteria. A charge regulating controller can disable the charging process, monitor the charge depletion rate, or the charging process may be based upon user established criteria. A charge regulating controller of the other device can regulate the charge accepting process. Each device may take on both roles, that is providing charge and receiving charge.

Owner:MOTOROLA MOBILITY LLC

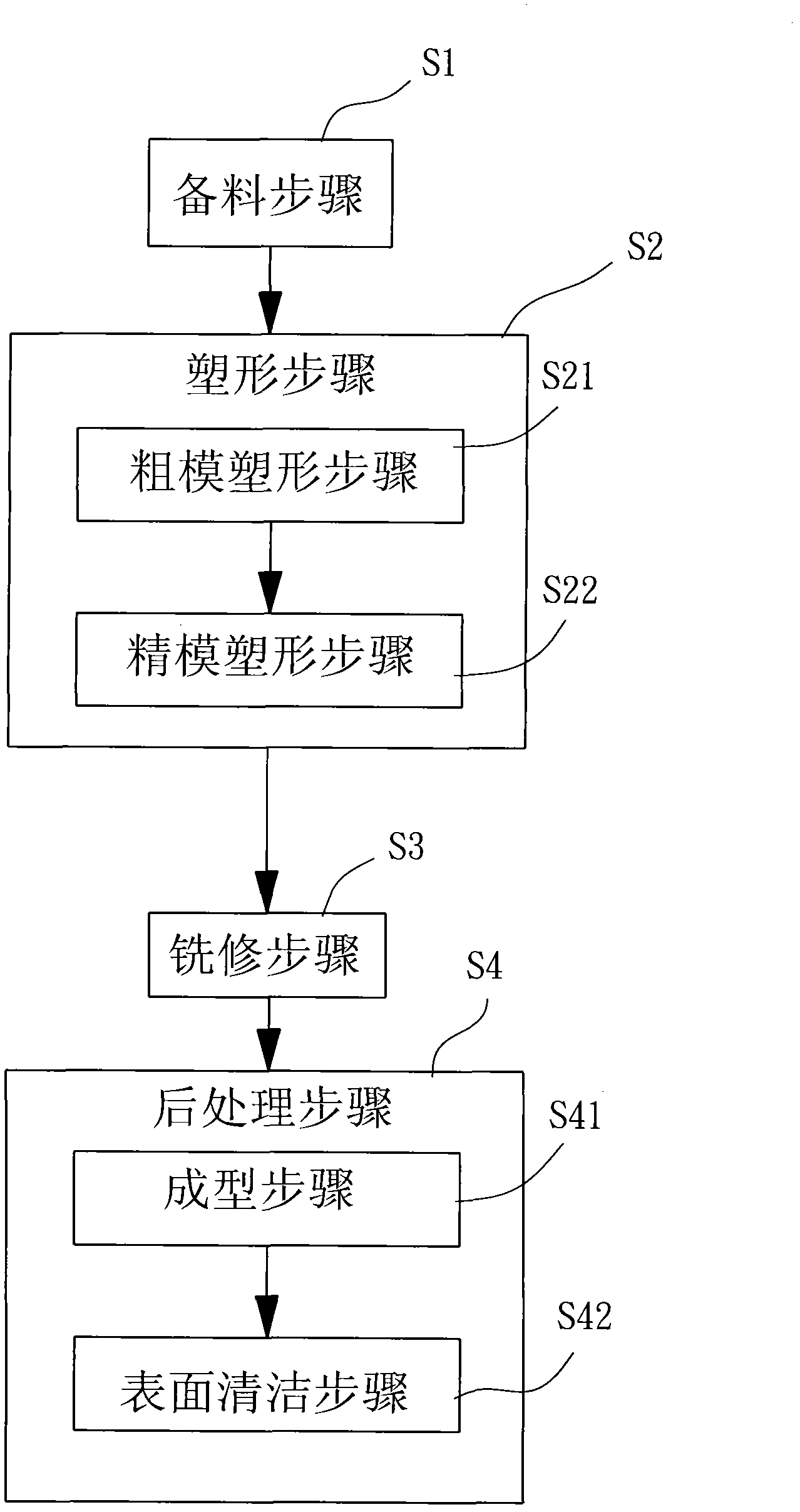

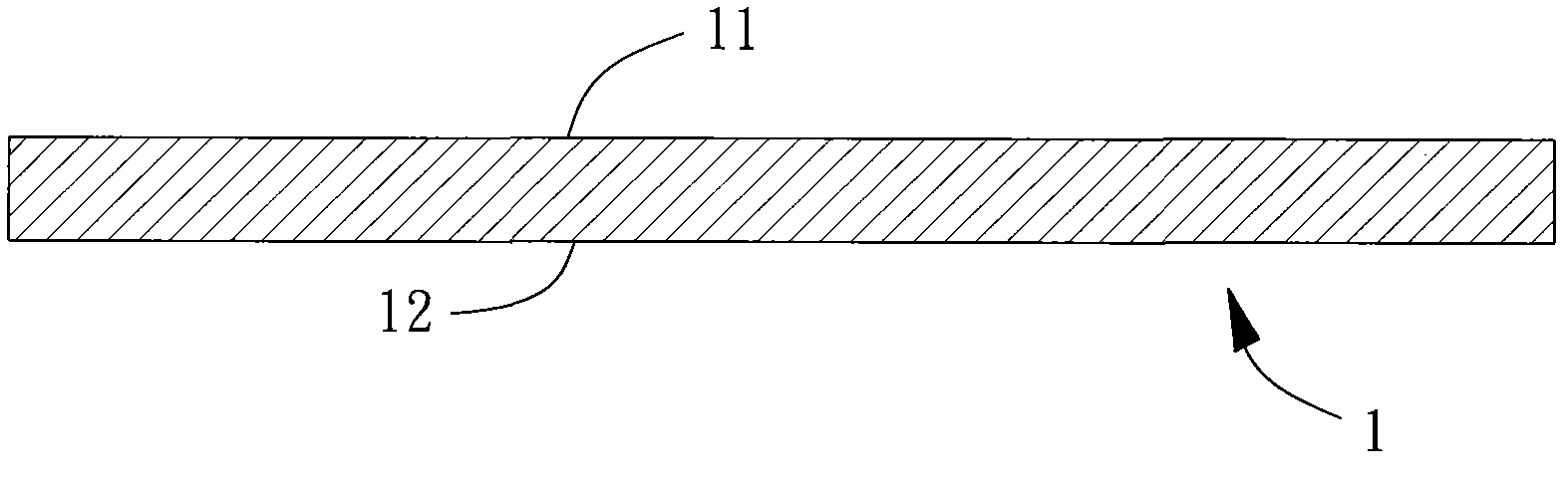

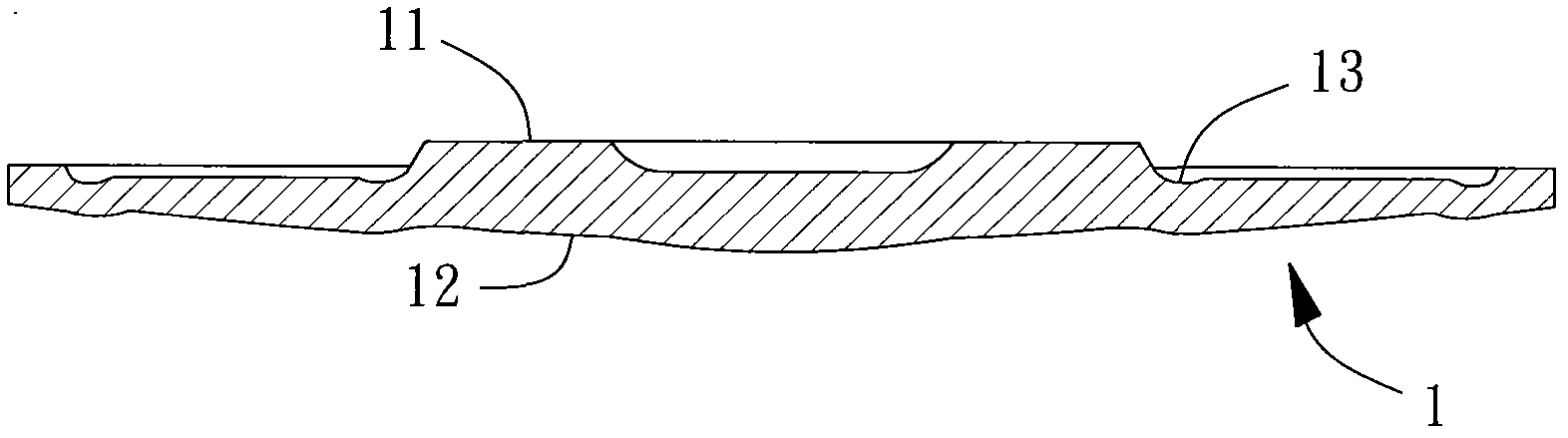

Manufacturing method for striking panel of golf club head

InactiveCN103007502AReduce consumption rateReduce processing timeGolf clubsRacket sportsEngineeringGolf Ball

The invention relates to a manufacturing method for a striking panel of a golf club head. The manufacturing method comprises the following steps: preparing materials: preparing a to-be-processed panel with a first surface and a second surface which are opposite to each other; molding: performing at least once pressing molding on the panel obtained from the step of preparing the materials through at least one mould, thereby forming a structure in different thickness on the first surface of the panel; and milling and trimming: milling and cutting the second surface of the panel obtained from the step of molding, thereby forming a striking surface and obtaining the striking panel of the golf club head. According to the manufacturing method for the striking panel of the golf club head provided by the invention, the structure in different thickness is molded on the first surface of the striking panel, and then the second surface of the striking panel is milled and trimmed, so that the cut-off panel waste materials are greatly reduced, the depletion rate of a cutter of a milling machine platform is reduced, the processing time is reduced, the manufacturing cost is saved and the effect of capacity is promoted.

Owner:FUSHENG IND CO LTD

Method, system and program storage device for reservoir simulation utilizing heavy oil solution gas drive

ActiveUS9020793B2Maintain relatively stableImprove predictive performanceFluid removalDesign optimisation/simulationProduct gasFuel oil

A method, a system and a program storage device for predicting a property of a fluid, such as fluid production from a subterranean reservoir containing heavy oil entrained with gas is described. The method includes developing a baseline correlation of gas relative permeability krg versus gas saturation Sg. A capillary number dependent correlation is determined capturing the relationship between at least one of critical gas saturation Sgc and capillary number Nca and gas relative permeability krgro and capillary number Nca phased upon a plurality of depletion rates. Capillary numbers Nc are calculated for a plurality of cells in a reservoir model representative of the subterranean reservoir. The baseline correlation is then adjusted to comport with at least one of Sgc and krgro selected from the capillary number dependent correlation to produce a plurality of corresponding adjusted baseline, correlations. Gas relative permeabilities krg for the plurality of cells are selected from the corresponding adjusted baseline correlations. A reservoir simulation is then run utilizing the selected relative permeabilities krg to predict a property of at least one fluid in a subterranean reservoir containing heavy oil entrained with gas.

Owner:CHEVROU USA INC

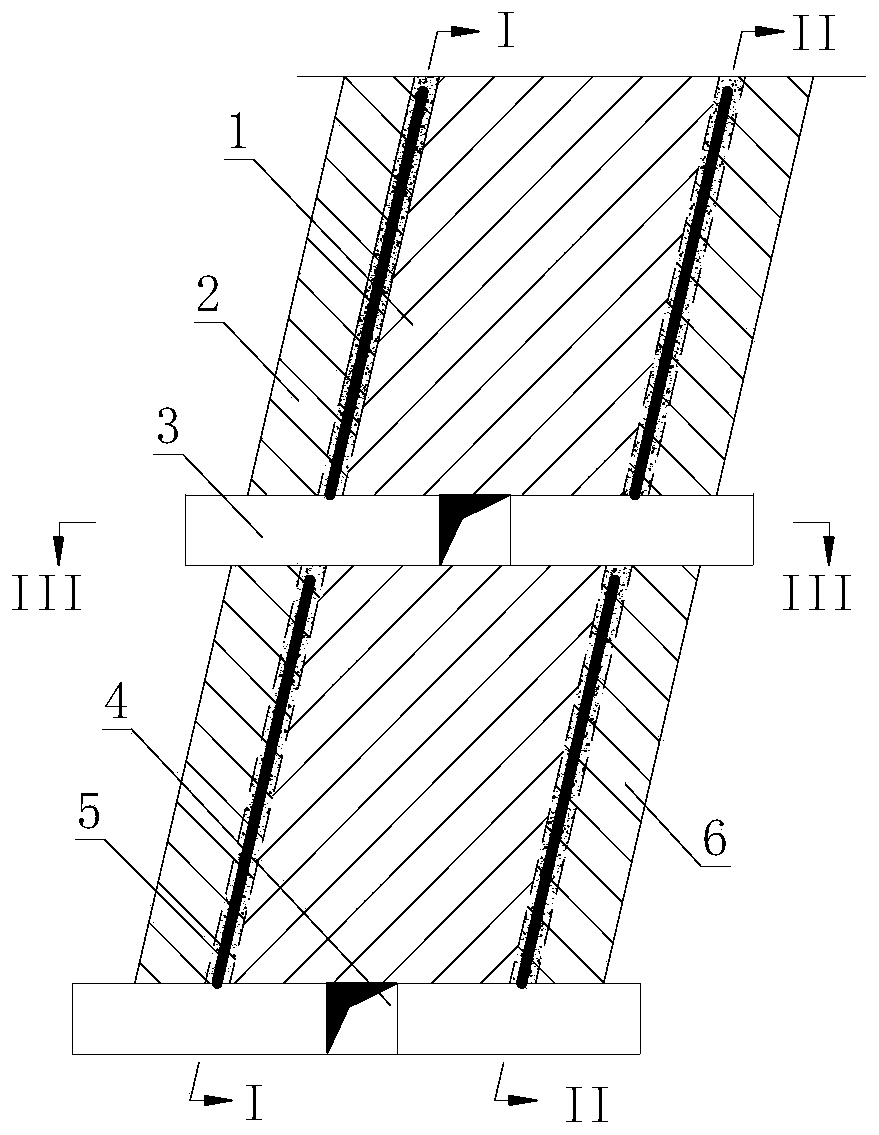

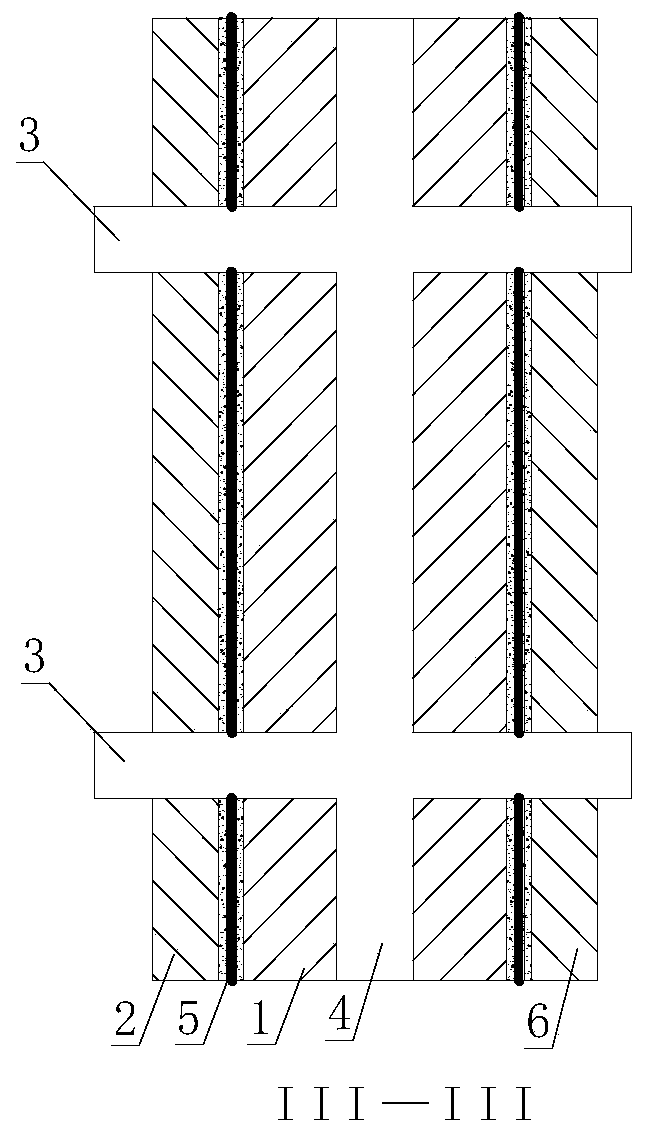

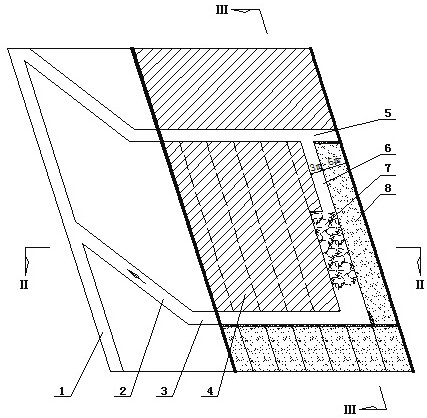

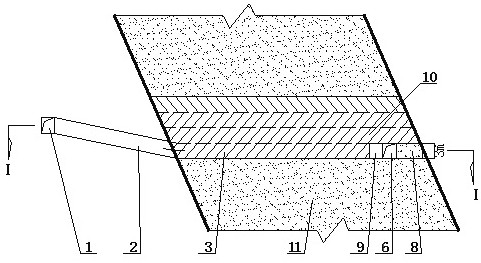

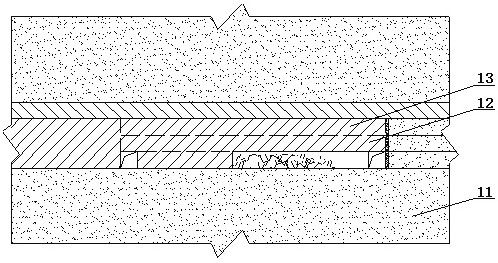

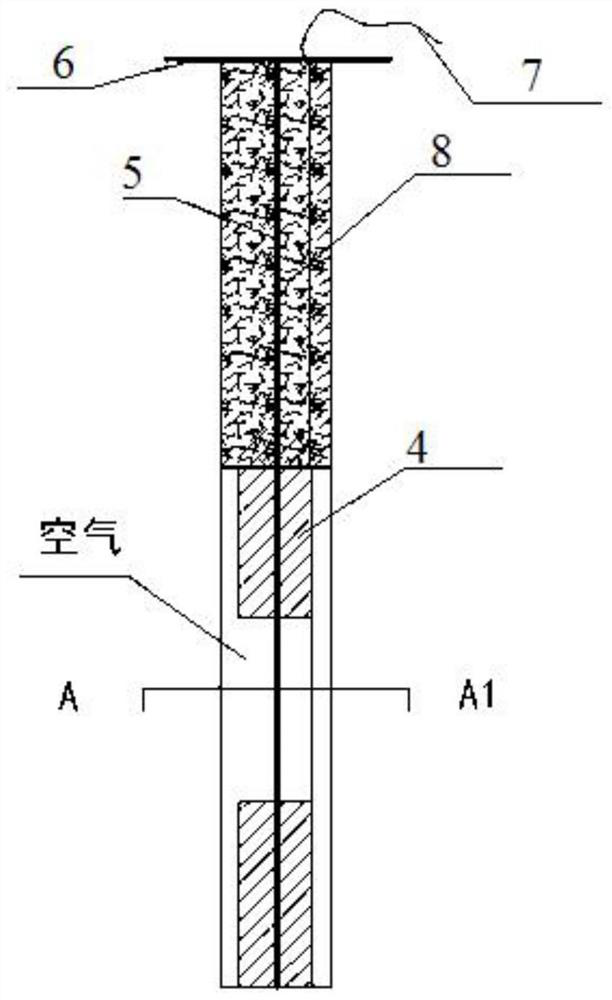

Method for controlling stope upper and lower disc surrounding rock through medium-deep hole pre-grouting

InactiveCN111005740AAvoid mixingImprove stabilityUnderground chambersUnderground miningMining engineeringOperation safety

The invention belongs to the technical field of metal mine, and particularly discloses a method for controlling stope upper and lower disc surrounding rock through medium-deep hole pre-grouting. The stope upper and lower disc crushed surrounding rock is strengthened in advance through the medium-deep hole pre-grouting technology, and the integral stability of the stope upper and lower disc surrounding rock is improved. The problem that under the situation of heavy pitch ore body upper and lower disc surrounding rock crushing, during medium-deep hole detonation, the upper and lower disc surrounding rock is mixed in, and consequently explored ore is depleted is solved. According to the method, the technical and safety guarantee is provided for reducing the depletion rate index, improving stability of the stope upper and lower disc surrounding rock and improving operation safety of equipment and personnel in the stope, and the method has the characteristics that the usage degree is wide,and safety and high efficiency are achieved.

Owner:CHANGCHUN GOLD RES INST

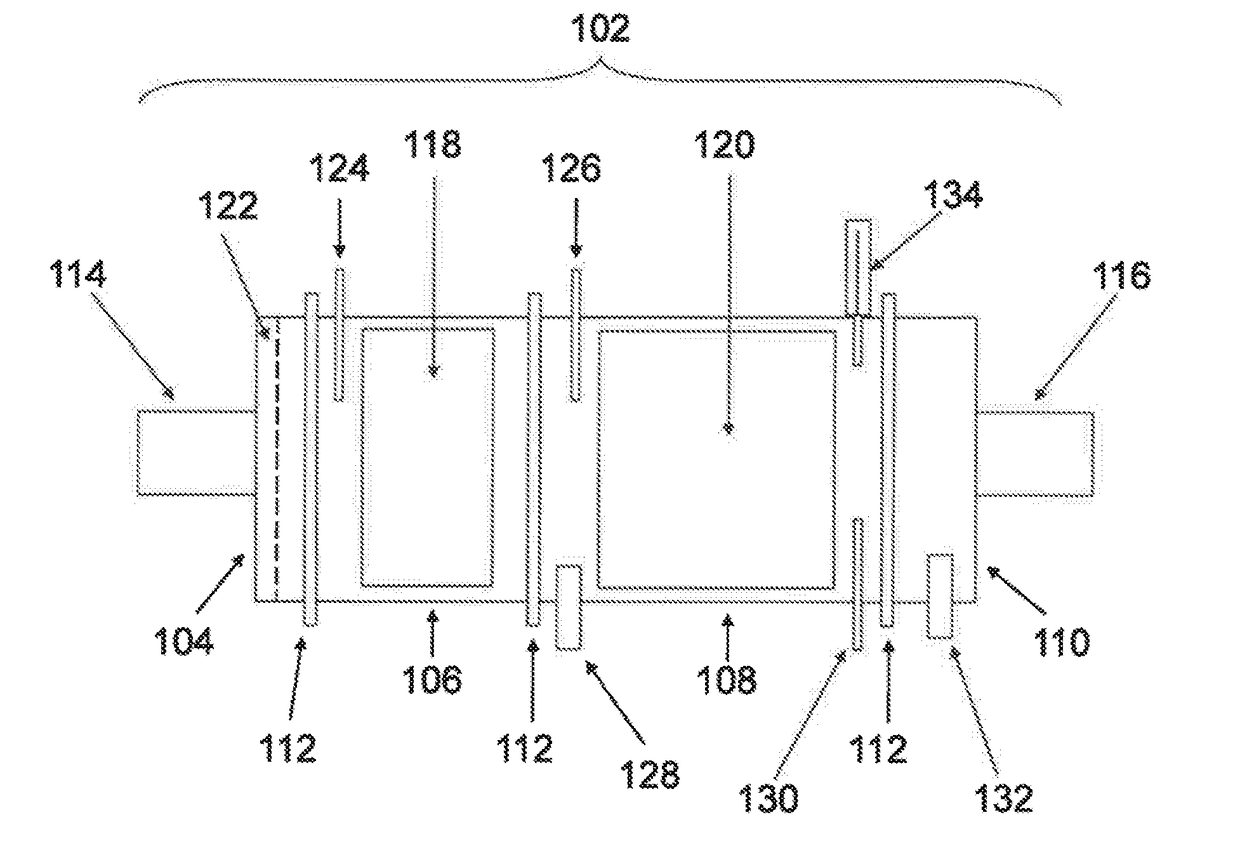

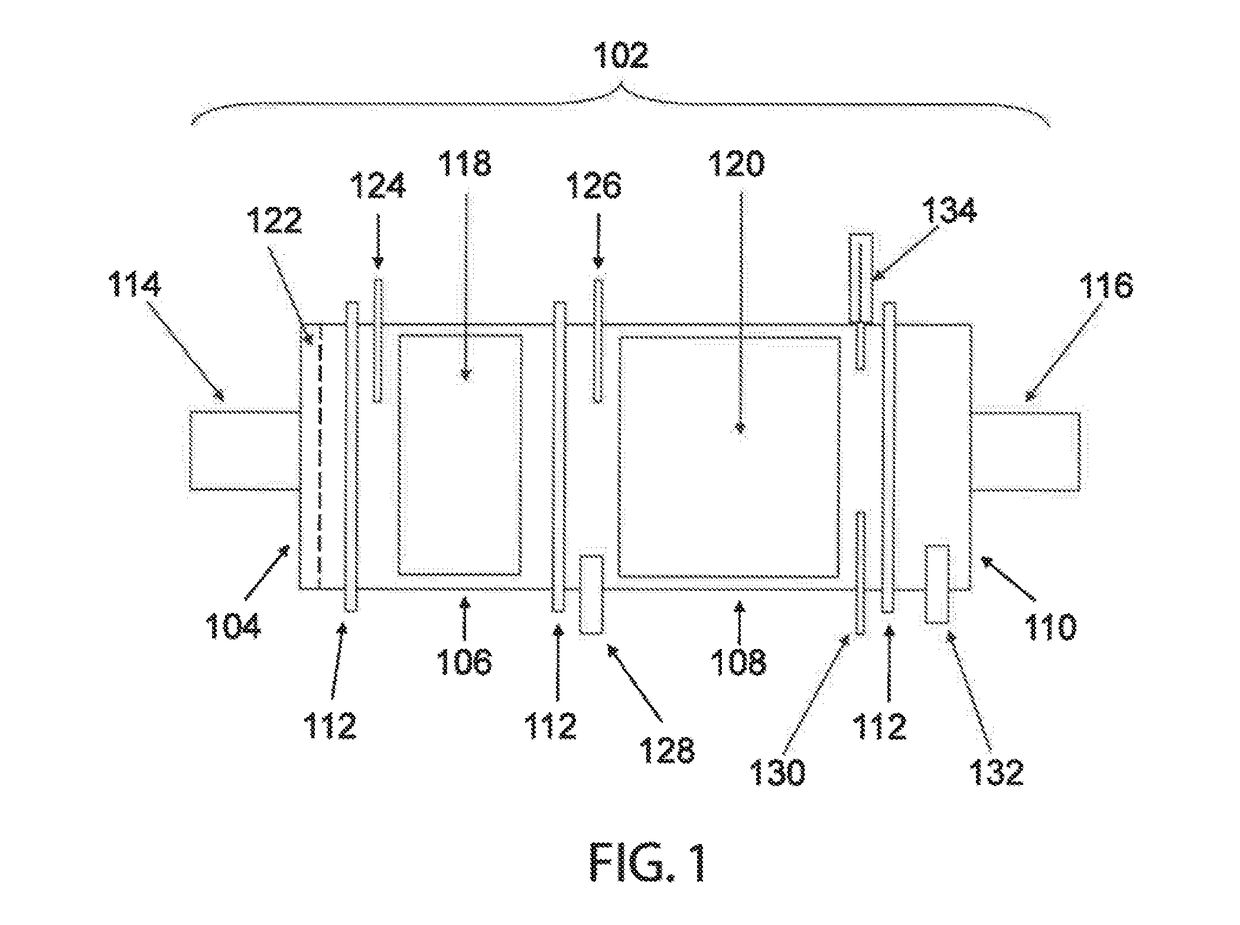

Radio frequency system and method for monitoring engine-out exhaust constituents

ActiveUS10260400B2Enhanced signalReduced measurement response timeTransmitters monitoringInternal combustion piston enginesRadio frequency signalVariation of parameters

A radio frequency system and method for monitoring an engine-out exhaust emission constituent. The system comprises a housing containing the emission constituent, one or more radio frequency sensors extending into the housing and transmitting and receiving radio frequency signals, and a control unit for controlling the radio frequency signals and monitoring changes in the emission constituent based on changes in one or more parameters of the radio frequency signals. In one embodiment, the control unit measures a rate of change in one or more of the parameters of the radio frequency signals for monitoring a rate of change of the emission constituent including for example the emission rate, accumulation rate, and / or depletion rate of the emission constituent.

Owner:CTS CORP ELKHART

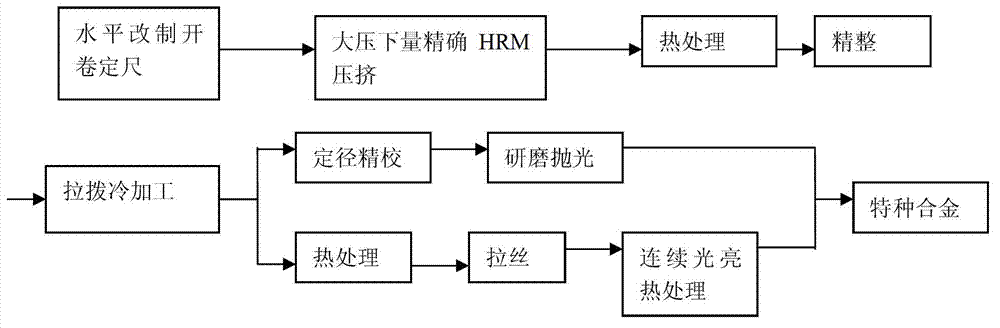

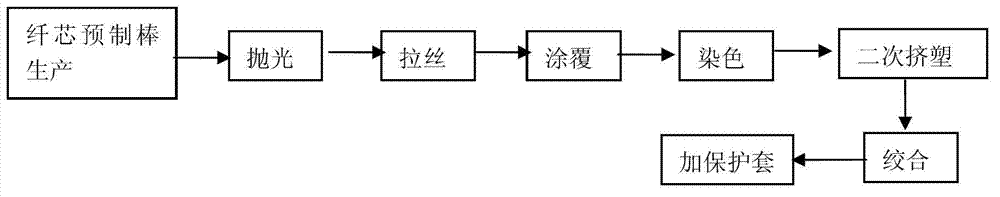

Method for producing long-distance transmission optical cable made of manganese and cupronickel special alloy

InactiveCN103163611AMeet the wire diameterMechanicsFibre mechanical structuresCable/conductor manufactureFiberCupronickel

The invention provides a method for producing long-distance transmission optical cables made of manganese and cupronickel special alloy. A preformed rod made of the manganese and cupronickel special alloy is subjected to high-speed wiredrawing and becomes a fiber core of an optical fiber. The fiber core is subjected to coating and cladding to obtain the optical fiber with the depletion rate of less than 3dB / km. The optical fiber with the depletion rate of less than 3dB / km reaches the international leading level of the manganese and cupronickel alloy optical fiber. The optical cable made of the manganese and cupronickel special alloy is an insulator material, has strong immunity on electromagnetic interference in the process of transmitting signals, and is free from natural thunder interference and interference of artificially released electromagnetism. Moreover, the optical cable made of the manganese and cupronickel special alloy is thin in wire diameter, light in weight, flexible, small in occupied space, little in pollution, high in electrical conductivity, corrosion-resistant, heat-resistant, simple in technological process, long in service life and wide in application range. Therefore, products developed through adoption of the method not only can be applied to main communication lines, but also can be applied to an electric power telecommunication control system for industrial monitoring and control. The application range of the optical cables is substantially expanded.

Owner:宁夏海洋线缆有限公司

Battery life estimation based on voltage depletion rate

ActiveUS8761885B2Simple and robust methodElectrotherapyElectrical testingTerminal voltageEngineering

Apparatus and methods for estimating the remaining life of a battery in an implantable medical device (“IMD”) are disclosed herein. The terminal voltage of the battery is measured and the measurements create a baseline curve of the battery voltage depletion. The points along the baseline curve can be linearly extrapolated to calculate the voltage depletion rate, which can estimate the remaining life of the battery.

Owner:LIVANOVA USA INC

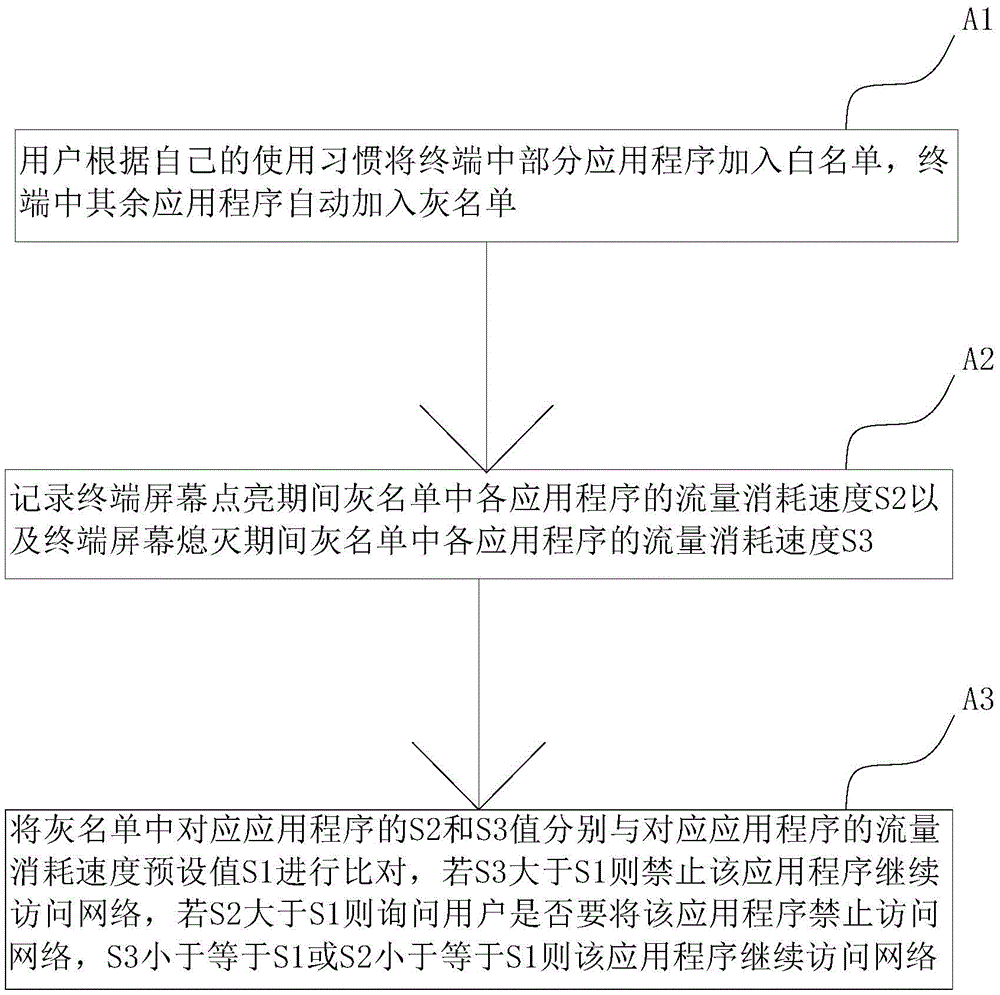

Method for preventing background traffic loss of application programs

ActiveCN105635447AAvoid consumptionAbnormal consumption monitoringSubstation equipmentWireless communicationPartial applicationHabit

The invention discloses a method for preventing background traffic loss of application programs. The method comprises the following steps: A1, adding part of application programs in a terminal into a white list by a user according to own use habit, and automatically adding the remaining application programs in the terminal into a grey list; A2, recording the traffic depletion rate S2 of each application program in the grey list during lightening of a terminal screen and the traffic depletion rate S3 of each application program in the grey list during turnoff of the terminal screen; and A3, separately comparing the S2 and S3 values of the corresponding application program in the grey list with a preset value S1 of the corresponding application program, forbidding the application program to continuously access a network if S3 is greater than S1, querying the user whether to forbid the application program to access the network or not if S2 is greater than S1, and allowing the application program to continuously access the network if S3 is smaller than or equal to S1 or S2 is smaller than or equal to S1. Compared with the prior art, the method has the advantages of effectively monitoring abnormal traffic depletion, avoiding unnecessary traffic depletion for users and reducing the loss of the users.

Owner:ANHUI ETUO COMM TECH GRP

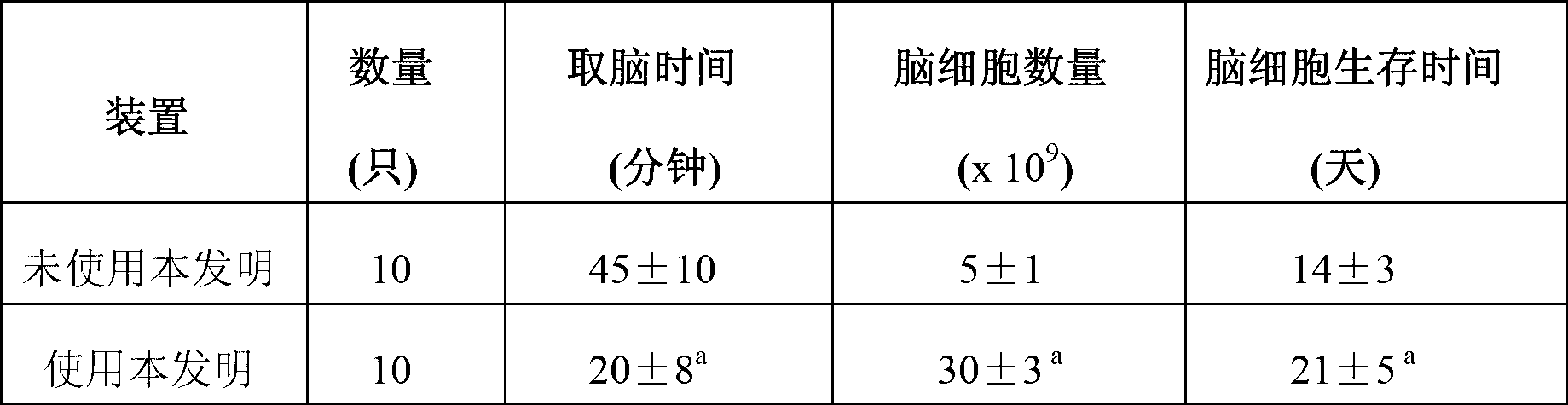

Fixing device for suckling mouse brain extraction

InactiveCN103006347AEffectively fixedFast and efficientAnimal fetteringSurgical veterinaryForcepsEngineering

The invention discloses a fixing device for suckling mouse brain extraction. The fixing device comprises a black base flat dish, wherein four brackets which are uniformly distributed are arranged at the center of the base flat dish, an operating flat dish is supported by the four brackets together, a rough soft plastic thick film covers the bottom of the operating flat dish, two upright columns made from soft plastics are arranged on a plane of the bottom of the operating flat dish, a clamping groove exists in the middle of the two upright columns, and holes communicated with the base flat dish are formed in the clamping groove. The fixing device for the suckling mouse brain extraction has the important significance that the quality for suckling mouse brain tissue extraction can be effectively improved, the time for extraction is shortened, the pollution is reduced, the depletion rate of fine forceps is reduced, the workload for researchers is reduced, the fixing device is reusable, the cost for experimental consumables is reduced, and the like. Shown by document retrieval carried out by the applicant, similar devices of the same type do not exist yet.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

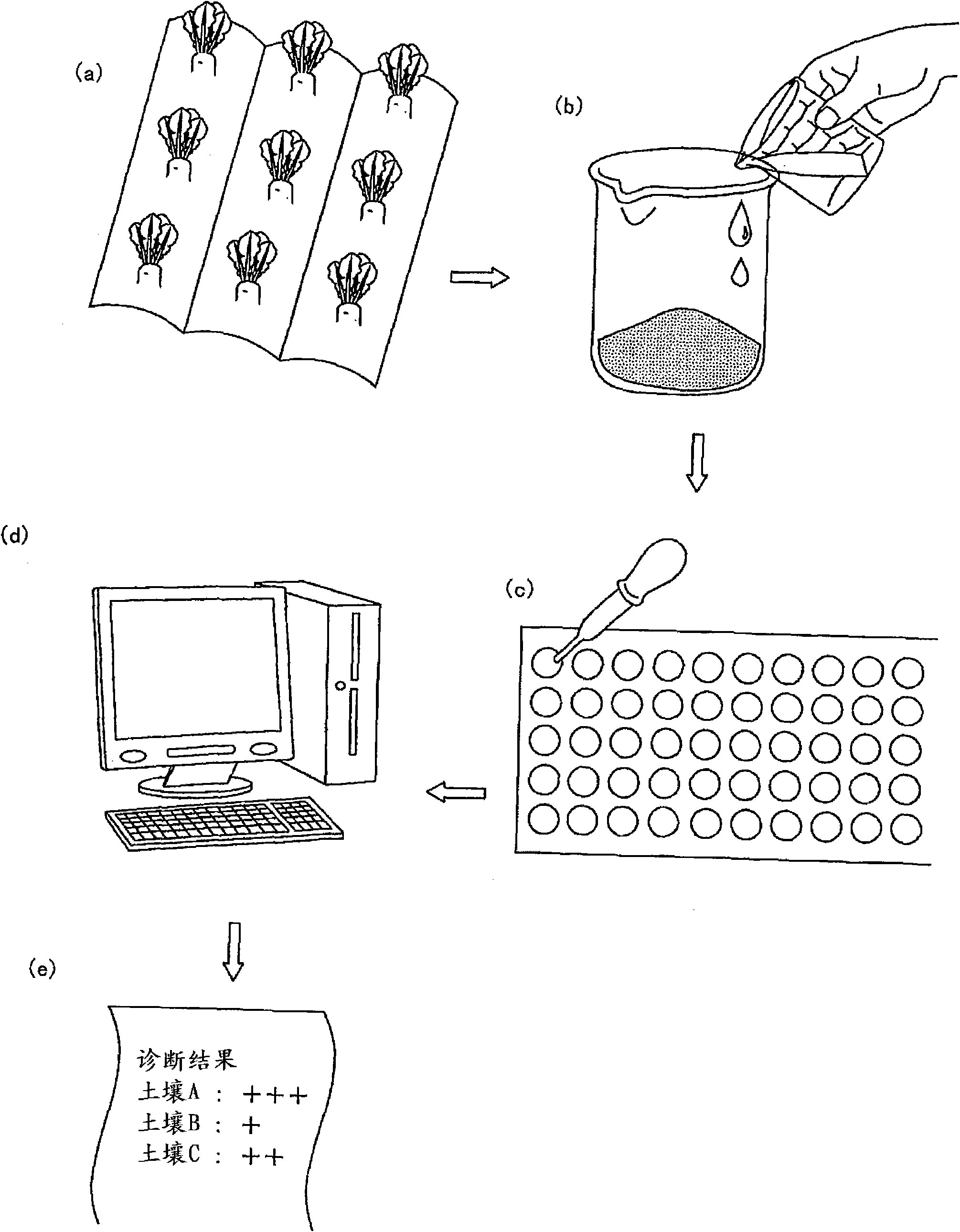

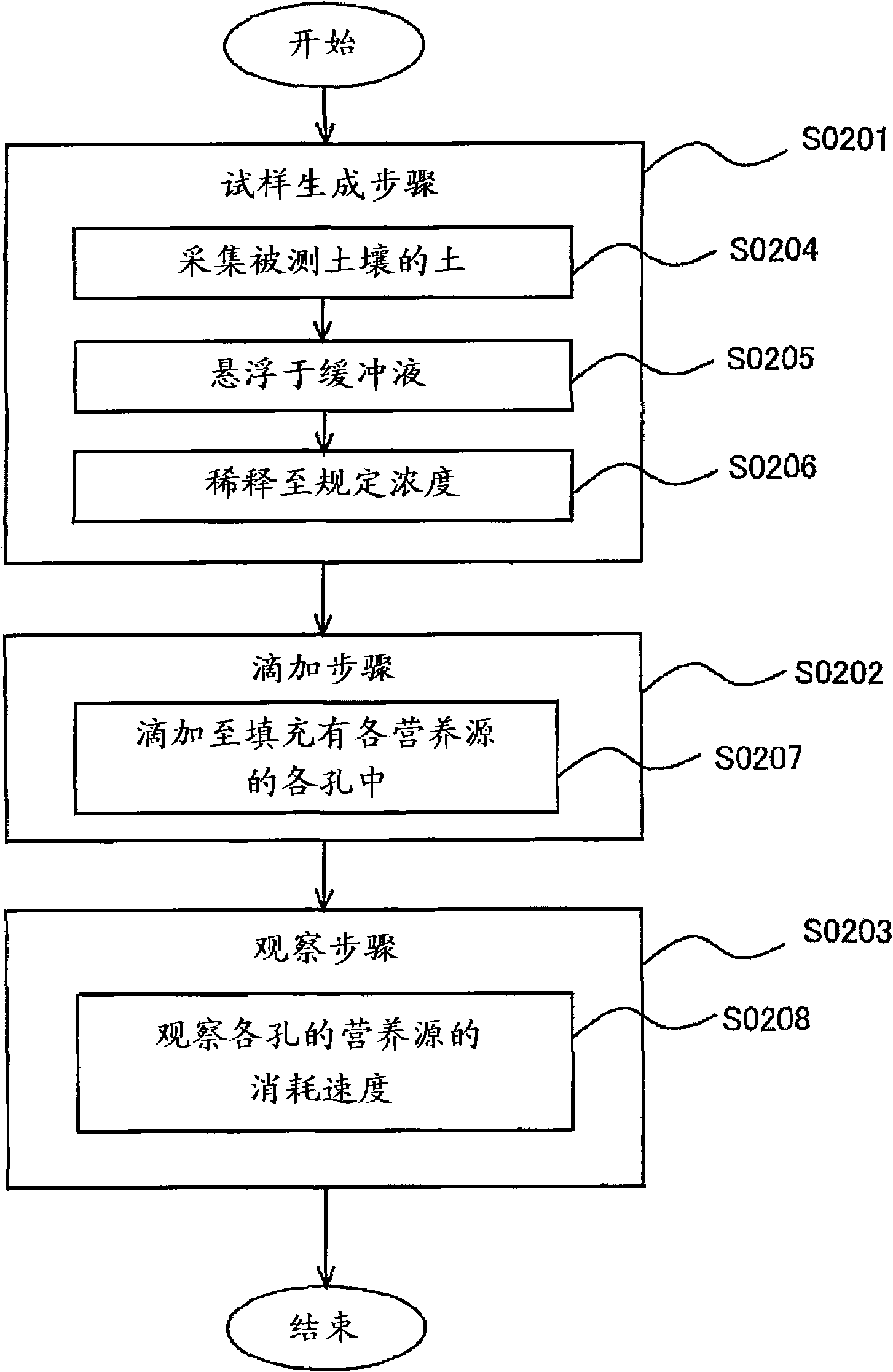

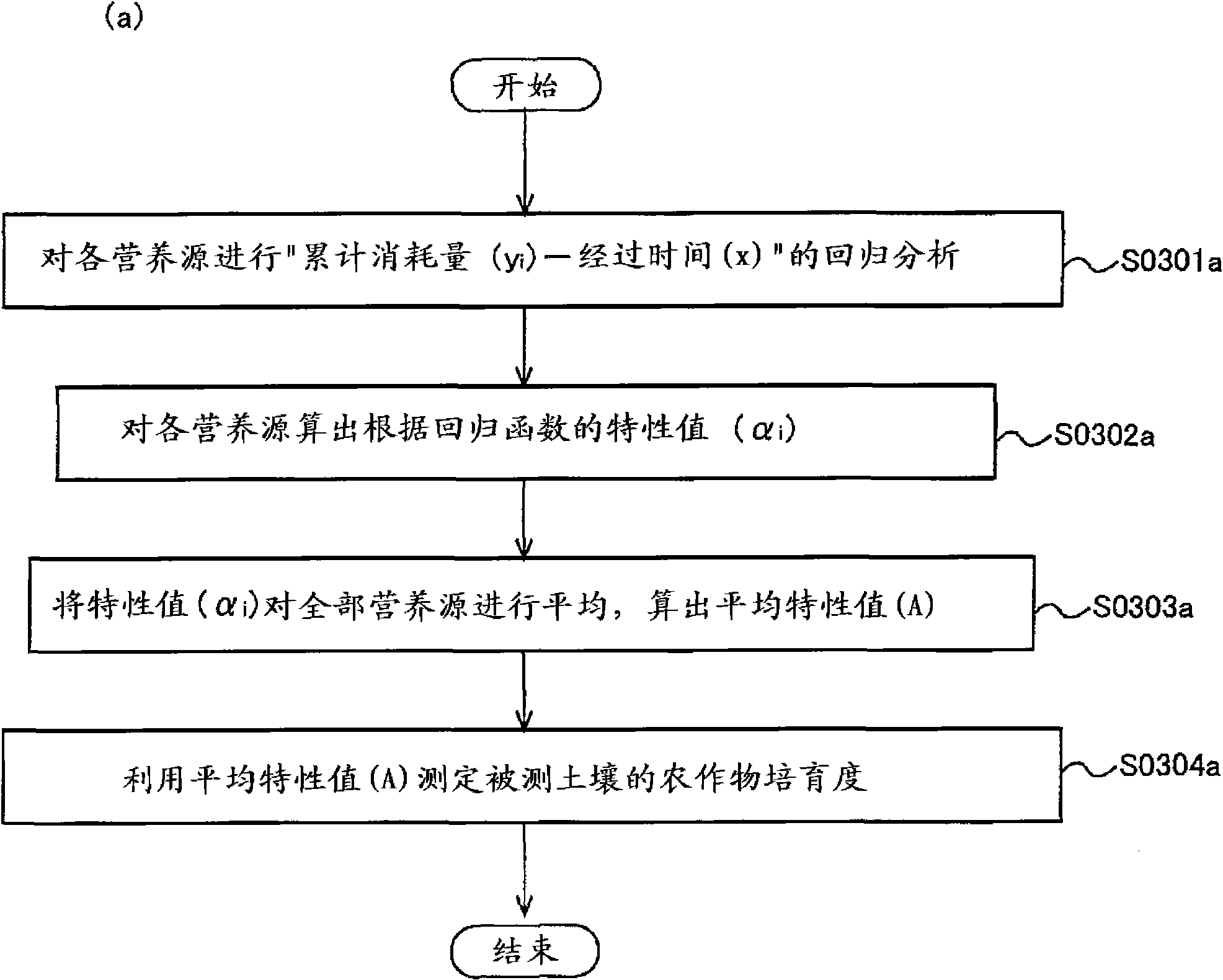

Crop culture degree measuring method for soil and judgment method for origin place camouflage

The invention relates to a crop culture degree measuring method for soil and a judgment method for origin place camouflage, and provides a method for diagnosing soil by using microbes perched in the soil and used as diagnosis objects and using a biological method. In addition, the truth of the origin place of agricultural products is judged by using the soil attached to the agricultural products. The crop culture degree measuring method for the soil comprises the following steps of: sample generation: generating suspension of the measured soil, wherein the suspension is used as a microbe sample; dripping: dripping the generated microbe sample, namely the suspension into multiple nutrient sources, at least one part of depletion rates of which are different according to the species of the microbes; and observation: observing the accumulated consumption of each nutrient source due to the microbes after dripping. In addition, the truth of origin place expression is judged by comparing the soil attached to the agricultural products with the expressed soil of the origin place.

Owner:DGC RES INST JAPAN CO LTD

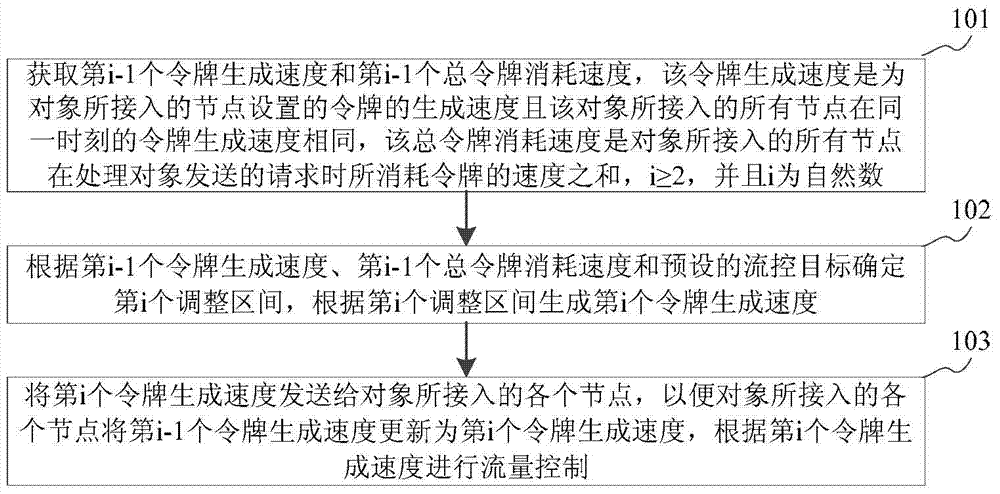

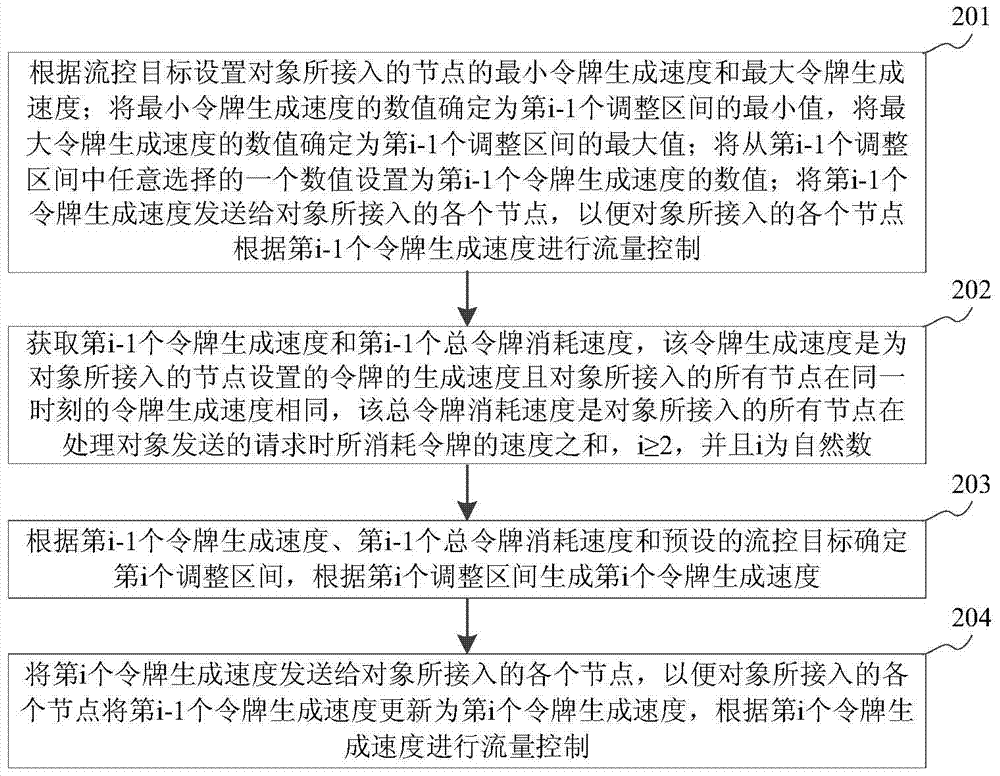

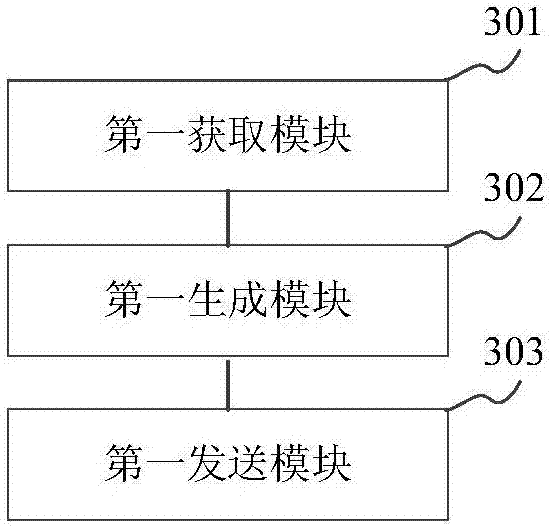

Flow control method, device and device

ActiveCN103929366BSolve load imbalanceBoot load balancingData switching networksHigh level techniquesComputer scienceDepletion rate

The invention discloses a flow control method and device and equipment, and belongs to the technical field of networks and storage. The flow control method comprises the steps that the generating speed of the (i-1)th token and the depletion rate of the (i-1)th total token are obtained; according to the generating speed of the (i-1)th token, the depletion rate of the (i-1)th total token and a preset flow control target, the ith adjusting interval is determined, and the generating speed of the ith token is generated according to the ith adjusting interval; the generating speed of the ith token is sent to all nodes to which an object has access so that all the nodes can update the generating speed of the (i-1)th token into the generating speed of the ith token, and flow is controlled according to the generating speed of the ith token. The flow control device comprises a first obtaining module, a first generating module and a first sending module. According to the flow control method and device and the equipment, the problem that the loads among all the nodes are unbalanced due to the fact that the number of processing requirements of the nodes with the large token generating speed is large is solved, and the loads are guided to be balanced among the nodes.

Owner:HUAWEI TECH CO LTD

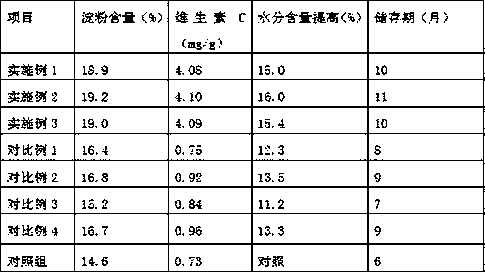

Potato storage method

InactiveCN108739999AInhibited breathing intensityExtended shelf lifeFruits/vegetable preservation by coatingParenchymaCell membrane

The invention relates to the technical field of modern agriculture industry and discloses a potato storage method. The potato storage method is characterized in that the potato surfaces are covered with a layer of a preservative material, so the respiratory intensity of the potatoes can be effectively inhibited, the depletion rate of starch, reducing sugar and other respiratory substrates in the potatoes is extremely low in the storage process, the water content of the potatoes is maintained, accumulation of active oxygen is reduced and prevented from generating toxic action on a body, the aging rate is reduced, the vitamin content is ensured not to be influenced by aging, the parenchyma cell membranes of the potatoes are protected, and the ascending speed of cell membrane permeability isreduced in the storage process. The potato storage method can improve the appearance of the potatoes during storage, can achieve the purpose of preservation, improves the shelf life of the potatoes, solves seasonal and regional problems, better meets the market demand, can realize sustainable development and utilization of potato resources and is a technical scheme worthy of popularization and utilization.

Owner:舒城县顺发蔬菜专业合作社 +1

Strip mining method of metal ore body horizontal pillar

ActiveCN110905510BReduce thicknessControl upper and lower boundariesUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a strip mining method for a horizontal ore pillar of a metal ore body. The beneficial effect of the invention is that the horizontal ore pillar is mined by the strip method, the mining engineering can well control the upper and lower boundaries of the ore body, and the dilution rate is low; the horizontal ore pillar The thickness is small, layered mining is adopted to control the height of the void, and the safety is good; there is no secondary ore pillar between the mining unit and the block, and the loss rate is small; using the characteristics of horizontal ore pillar layering, different bars are used Width, taking into account efficiency and safety, the effect is good.

Owner:安徽铜冠产业技术研究院有限责任公司

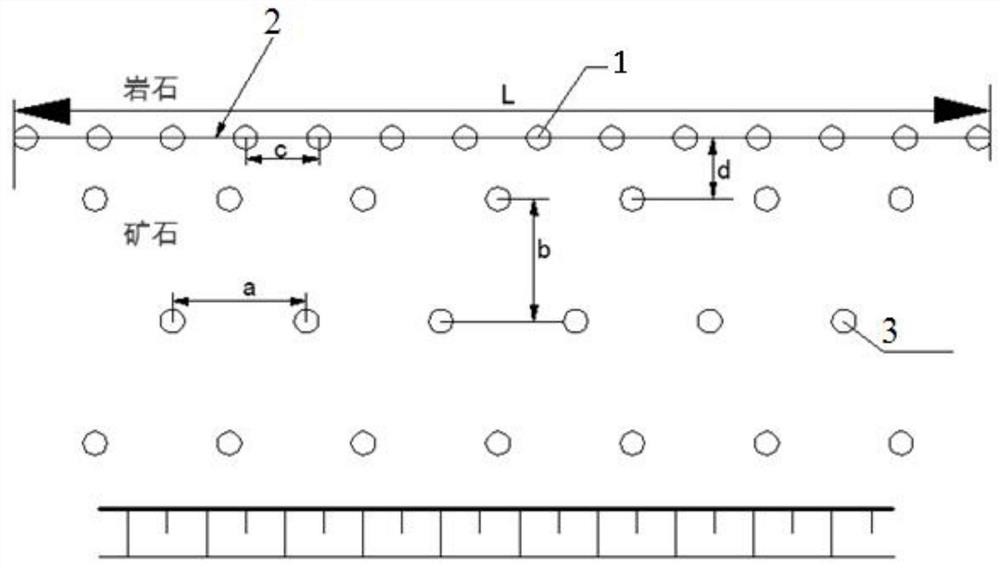

A Controlled Blasting Method for Reducing Loss and Depletion

The invention discloses a controlled blasting method for reducing loss and depletion. Conventional charge is carried out in the main charge blasting hole (3), and the ore-rock differentiation blasting hole (1) is arranged on the ore-rock boundary line (2). , the hole distance c of the ore-rock differentiation blasting hole (1) is 0.6~0.9 times the hole distance a of the main charge blasting hole (3), and the distance between the ore-rock differentiation blasting hole (1) and the nearest main charge blasting hole (3) The rejection d between the main charge blasting blastholes (3) is 0.6~0.9 times the row distance b; the ore-rock differentiation blasting blastholes (1) adopt radial uncoupled charges, and the uncoupling coefficient is 1.5 ~2. The invention sets ore-rock differentiation blasting holes at the boundary line of ore-rock, so that the ore body and rock mass can be separated efficiently and accurately at low cost, avoiding the mixing of ore or waste rock, and solving the technology of high loss rate and dilution rate in open-pit mining Difficulties, realize the separate mining and packaging of ore rocks, reduce the loss and dilution of ore, and create good economic benefits.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Movable distributive continuous exploitation method for deep sea mineral resources

InactiveCN1191423CIncrease collection rateBroken particle sizeMineral miningProduction rateMineral Sources

The movable deep sea mineral resource exploiting system consists of under water positioning base point in the marine mining area, movable distributing mining vehicle, movable ore bin matching the exploitation amount, initial separating and crushing unit capable of inhibiting depletion rate and matching mineral granularity, conveyer to the ore raising unit, movable ore raising unit with driving plant and pipeline, movable underwater power distributing station, movable main control station, surface exploitation ship, transportation ship, etc. The present invention is adaptable to the exploitation of deep sea mineral resources, especially base rock mineral resources and deposit mineral resources, and has high production rate, high collecting rate, low exploitation cost, high reliability, and less marine environmental pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

Method for mining tin mine

The invention discloses a method for mining tin mine, and relates to the technical field of mining. The method for mining tin mine comprises the steps of mining area layout, picking and cutting and recovery. The mining area layout is divided into a plurality of mining areas in an ore body direction, each mining area is divided into 3-7 ore blocks, and then the ore blocks are divided into mining houses and mining pillars, and the ore body is divided into middle sections in the height direction, and each middle section is subdivided into sections; the recovery step is carried out in the direction from the center to the sides, first returning to the mining houses and then back to the mining pillars. Thin ore bodies can be recovered, thick and extremely thick ore bodies can also be recovered.The method for mining tin mine has a wide application range, the ore recovery rate is larger than or equal to 88%, and the depletion rate is less than or equal to 10%, the ore loss rate is reduced.

Owner:广西华洋矿源材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com