Method for producing long-distance transmission optical cable made of manganese and cupronickel special alloy

A technology of digital optical fiber and production method, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of intolerance to bending and extrusion, restricting mass use, and high communication costs, achieving long service life, light weight, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0018] A digital optical fiber cable for long-distance transmission of manganese and cupronickel special alloys, characterized in that the manganese and cupronickel special alloy cores are manganese and nickel added to the manganese cupronickel alloy, and the obtained preform is passed through After high-speed wire drawing, it becomes the core of the optical fiber, and the suitable ratio range of manganese and nickel is manganese Mn (1%~9%) and nickel Ni (40%~44%).

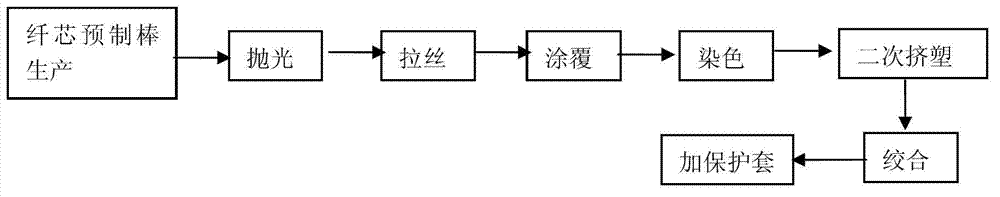

[0019] refer to figure 2 Shown is a digital optical fiber cable for long-distance transmission of the manganese and cupronickel special alloys, the steps of the method are as follows:

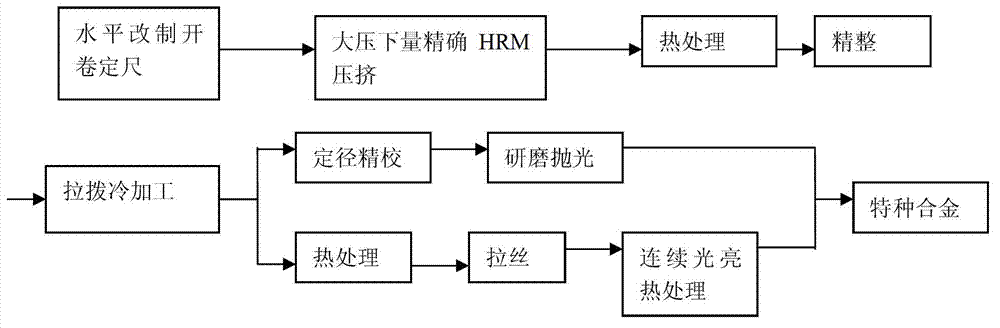

[0020] Step 1: Manufacture of special alloy fiber core (refer to figure 1 ), compared with the core of ordinary silica optical fiber, this process increases the treatment process of alloy rods, such as ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com