A micro-nanotube array nickel biomimetic material and its preparation method

A technology of micro-nanotubes and biomimetic materials, applied in nanotechnology, nanotechnology, metal material coating process and other directions, can solve the problems of high energy consumption, difficult control of material structure, etc., achieve excellent electrical conductivity, overcome difficult structure control, Overcome the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a micro-nanotube array type nickel biomimetic material, comprising the steps of:

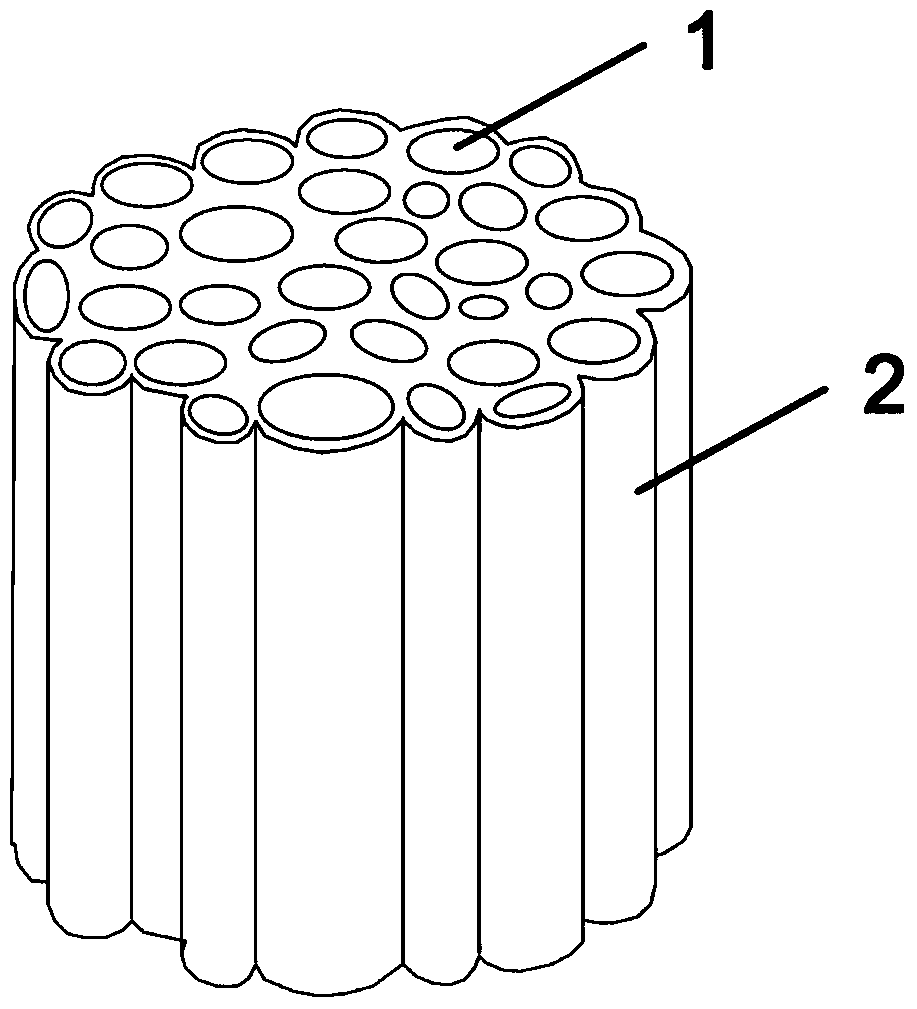

[0037] 1) Use a biological slicer to cut abaca fiber bundles (hemp fiber bundles) into samples with a length of 1mm, and then immerse the samples in 1% sodium hydroxide aqueous solution for 0.5 hours at 30°C. Rinse 1-5 times with deionized water, and then dry at 60°C for 16 hours to obtain figure 1 The shown tube-shaped abaca fiber bundle template sample (tube-shaped hemp fiber bundle template);

[0038] 2) Immerse the above-mentioned tube-shaped abaca fiber bundle template sample in an ethanol solution with a mass fraction of 0.05% aminopropyltrimethoxysilane (APTMS) for 24 hours, then rinse with ethanol and deionized water respectively, and heat it at 110° C. Drying for 60min at lower temperature obtains the abaca fiber bundle template after surface grafting modification;

[0039] 3) The 1mmol / L NiSO 4 or AgNO 3 After adsorption at 20°C for 30min, take it out ...

Embodiment 2

[0044] A method for preparing a micro-nanotube array type nickel biomimetic material, comprising the steps of:

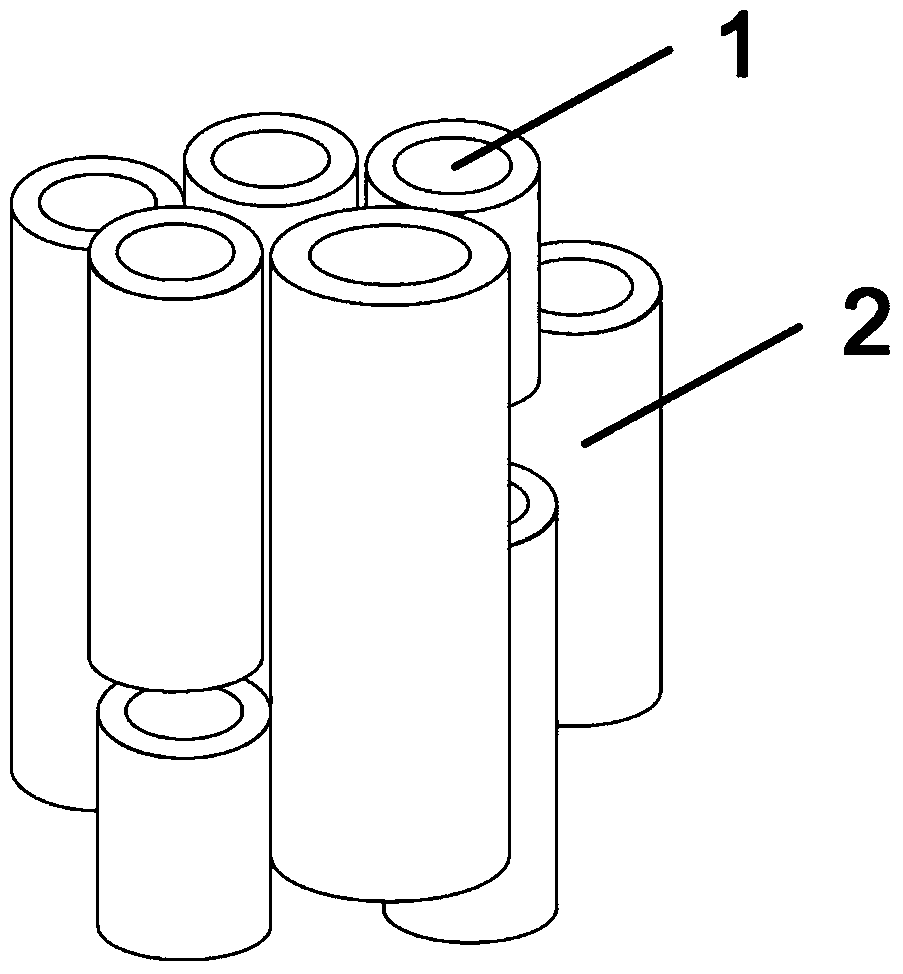

[0045] 1) Cut abaca fiber bundles (hemp fiber bundles) into samples with a length of 4 mm using a biotome, and then at 60° C., the samples were sequentially immersed in 75° C., pH=4.5 (using a mass fraction of 10% acetic acid Aqueous solution adjustment) mass fraction is 5~10% sodium chlorite aqueous solution 120min and 20 ℃, mass fraction is 18% sodium hydroxide aqueous solution 120min, then carries out deionized water and dehydrated alcohol cleaning respectively at normal temperature 1- 5 times, dried (dried at 60°C for 16 hours), to obtain figure 2 The single-tubular abaca fiber bundle template sample shown (single-tubular hemp fiber bundle template);

[0046] 2) Immerse the above-mentioned single-tubular abaca fiber bundle template sample in an ethanol solution with a mass fraction of 0.05% aminopropyltrimethoxysilane (APTMS) for 24 hours, then wash it with et...

Embodiment 3

[0052] A method for preparing a micro-nanotube array type nickel biomimetic material, comprising the steps of:

[0053] 1) Cut the sisal fiber bundle (hemp fiber bundle) into a sample with a length of 10mm, and then immerse the sample in a 1% sodium hydroxide aqueous solution at 30°C for 1 hour, using deionized water Rinse 1-5 times, and then dry at 60°C for 12 hours to obtain a tube-shaped sisal fiber bundle template sample;

[0054] 2) Immerse the above-mentioned tubular sisal fiber bundle template sample in an ethanol solution with a mass fraction of 0.05% aminopropyltrimethoxysilane (APTMS) for 24 hours, and then wash it with ethanol and deionized water for 1-5 times respectively , dried at 110°C for 60 minutes to obtain a sisal fiber bundle template after surface graft modification;

[0055] 3) The 1mmol / L NiSO 4 or AgNO 3 After adsorption at 20°C for 30min, take it out and wash it with deionized water, then immerse the sample in 0.1mol / L sodium borohydride solution, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com