System and method for producing pentose solution by series continuous hydrolyzation

A technology of pentose and solution, which is applied in the field of series and continuous hydrolysis to prepare pentose solution, which can solve the problems that cellulose can only be discarded or used as fuel, the extraction rate of xylose is not high, and it is difficult to realize automation, etc., so as to achieve full contact, Save the pretreatment step, which is beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the drawings and embodiments, but it should be noted that these embodiments are only used to illustrate the system and method of the present invention, but not limit the scope of the present invention thereto.

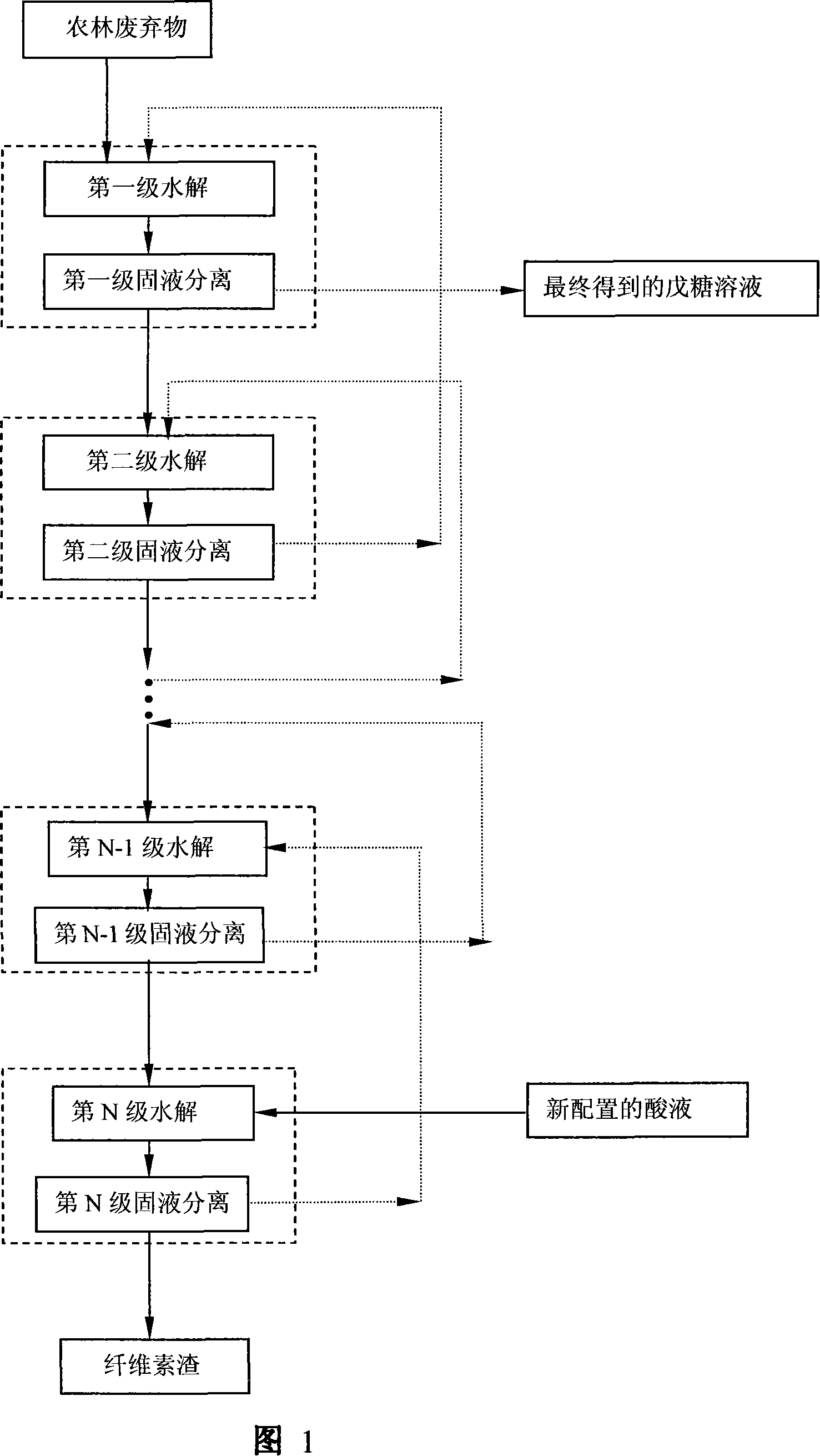

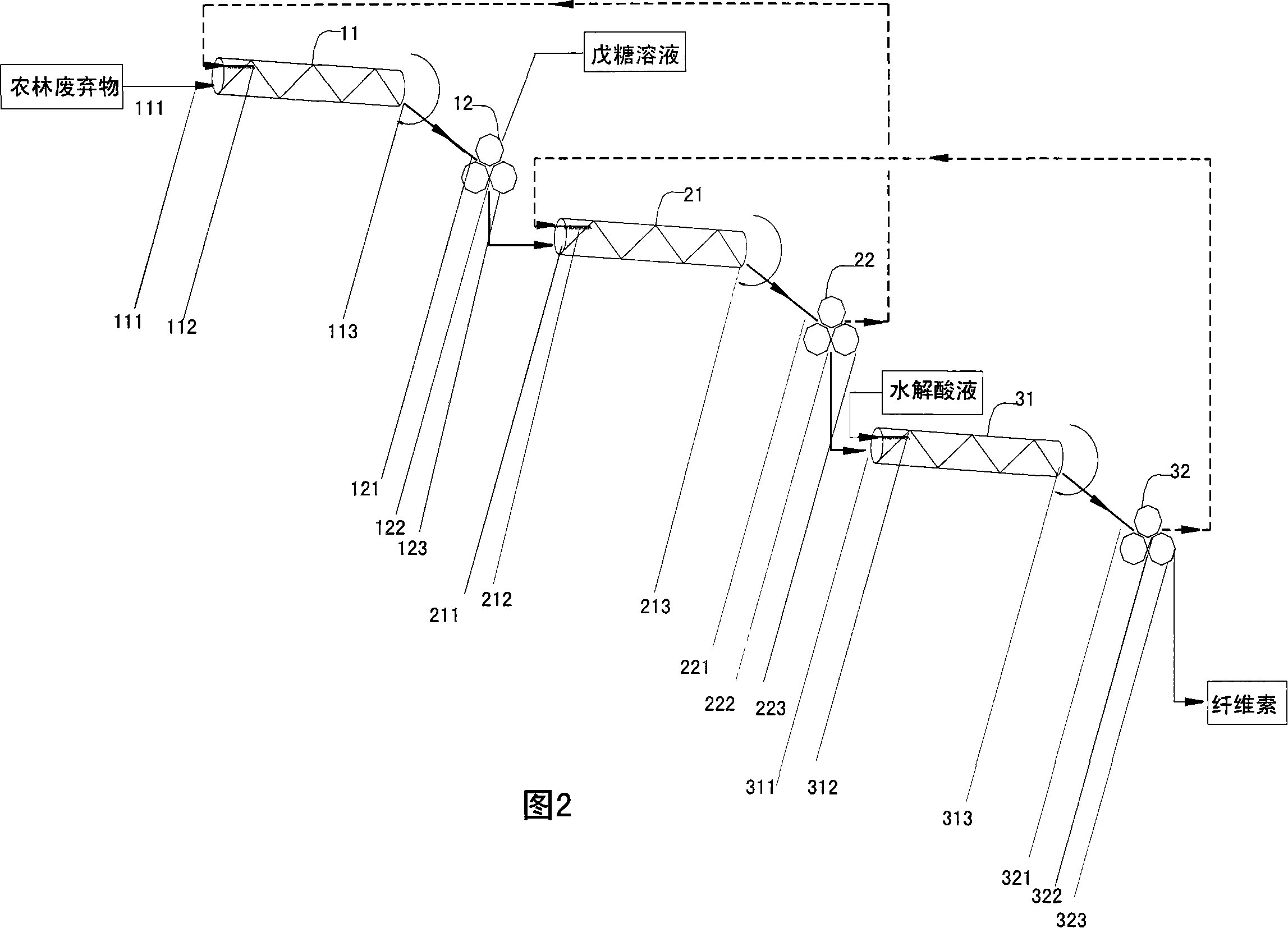

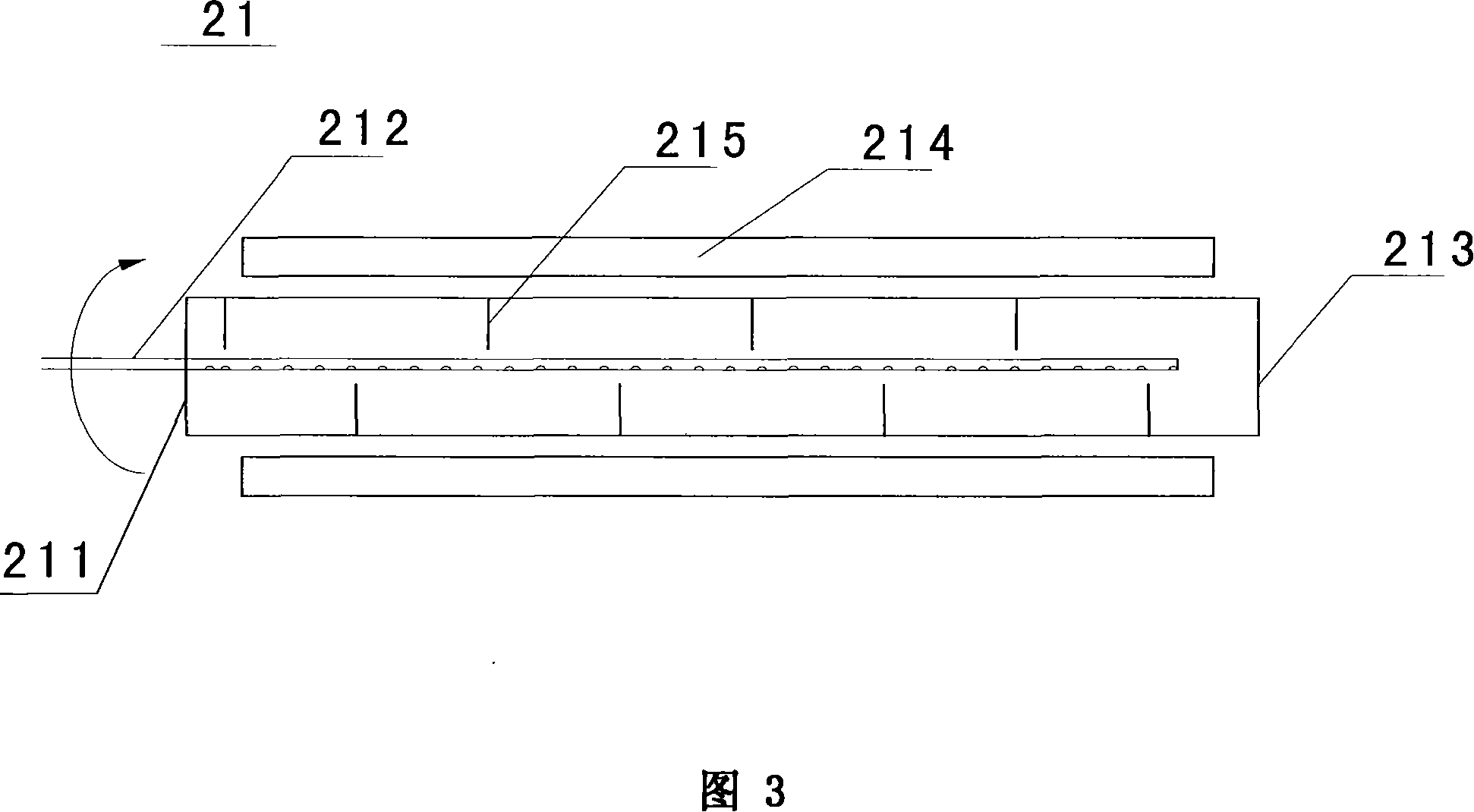

[0040] Fig. 1 is the method flow chart of the method for preparing pentose solution from agricultural and forestry wastes of the present invention, wherein the flow direction of the liquid obtained after solid-liquid separation is indicated by a dashed arrow, and the solid flow direction obtained after solid-liquid separation is represented by a solid line. The principle of the system and method of the present invention is briefly described as follows: multi-stage hydrolysis units connected in series are arranged, and each stage of hydrolysis unit includes a hydrolysis device and a solid-liquid separation device connected in series in turn, and each stage of hydrolysis reaction is correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com