Patents

Literature

161 results about "N-Methylmorpholine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

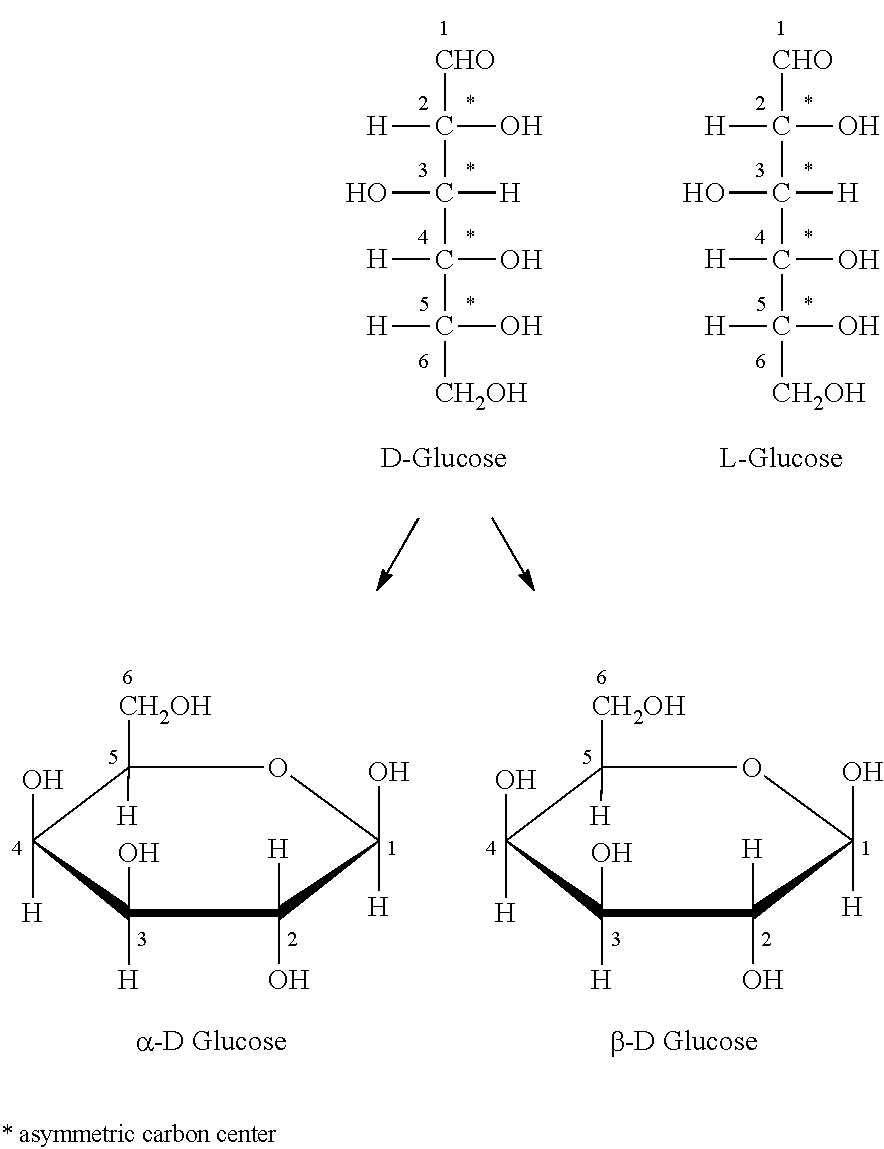

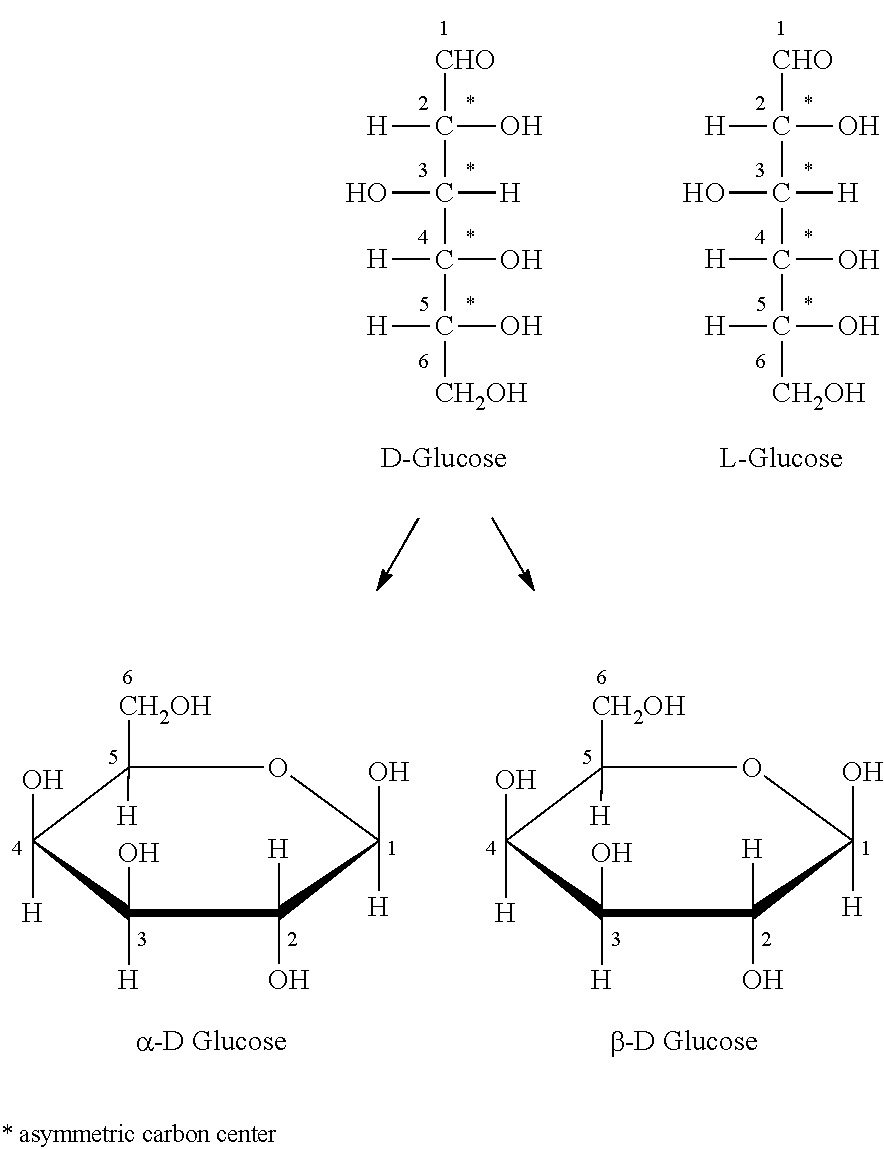

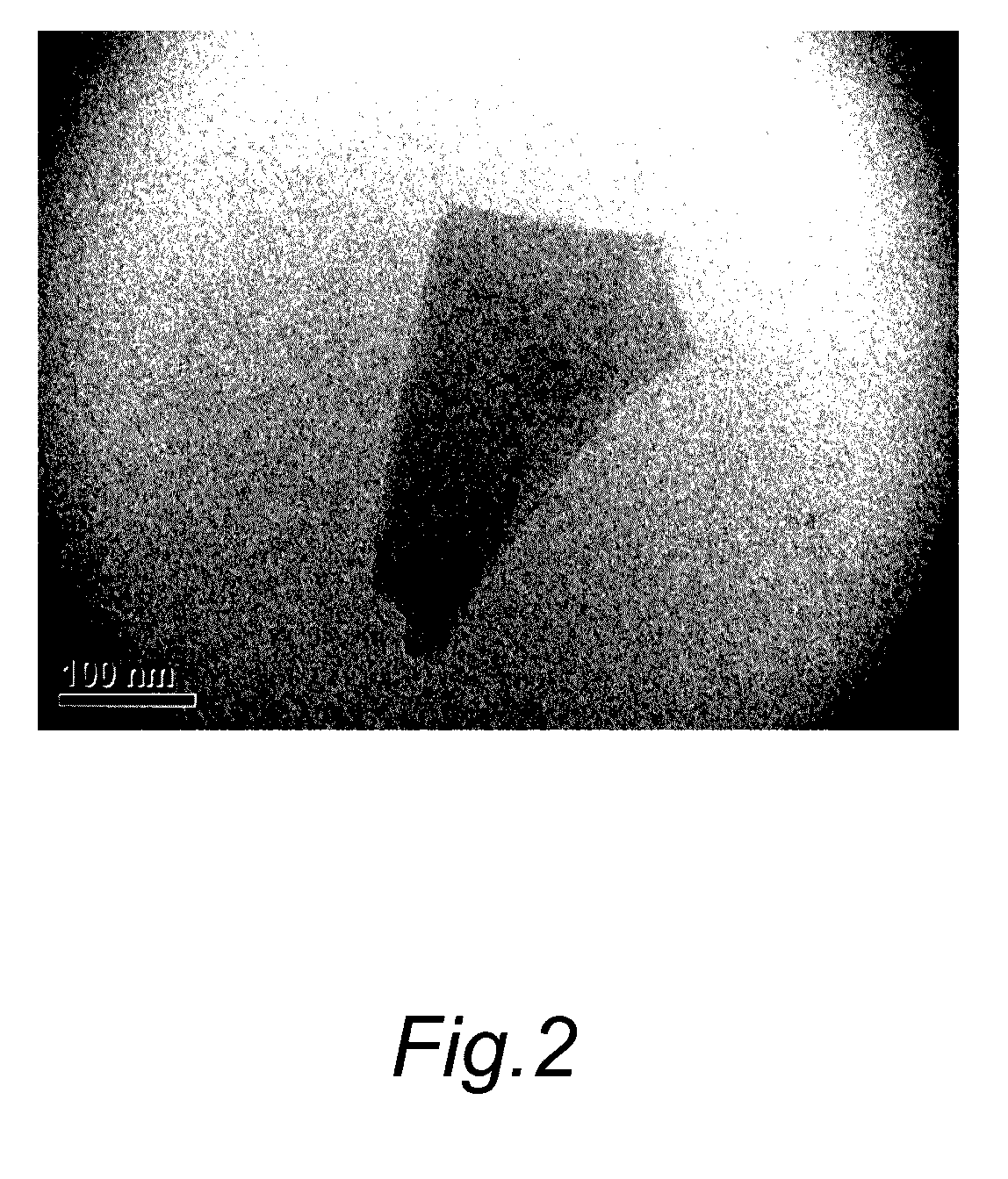

N-Methylmorpholine is the organic compound with the formula O(CH₂CH₂)₂NCH₃. It is a colorless liquid. It is a cyclic tertiary amine. It is used as a base catalyst for generation of polyurethanes. It is produced by the reaction of methylamine and diethylene glycol as well as by the hydrogenolysis of N-formylmorpholine. it is as the precursor to N-methylmorpholine N-oxide, a commercially important solvent.

Solution containing cellulose dissolved in n-methylmorpholine-n-oxide and high tenacity lyocell multifilament using the same

ActiveUS20050154093A1Solidifying temperatureIncrease flexibilityNon-fibrous pulp additionMonocomponent cellulose artificial filamentLiquid stateLyocell

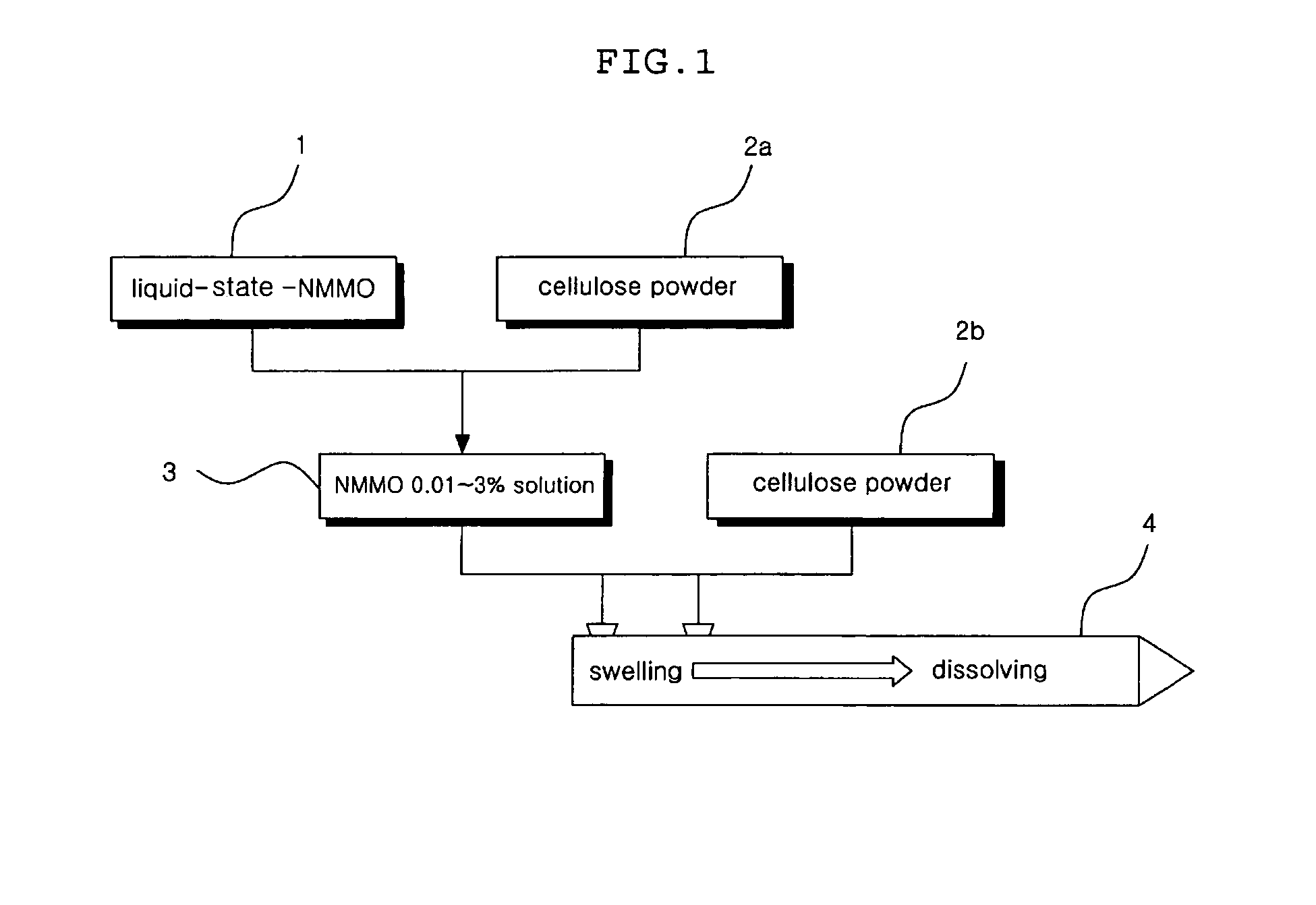

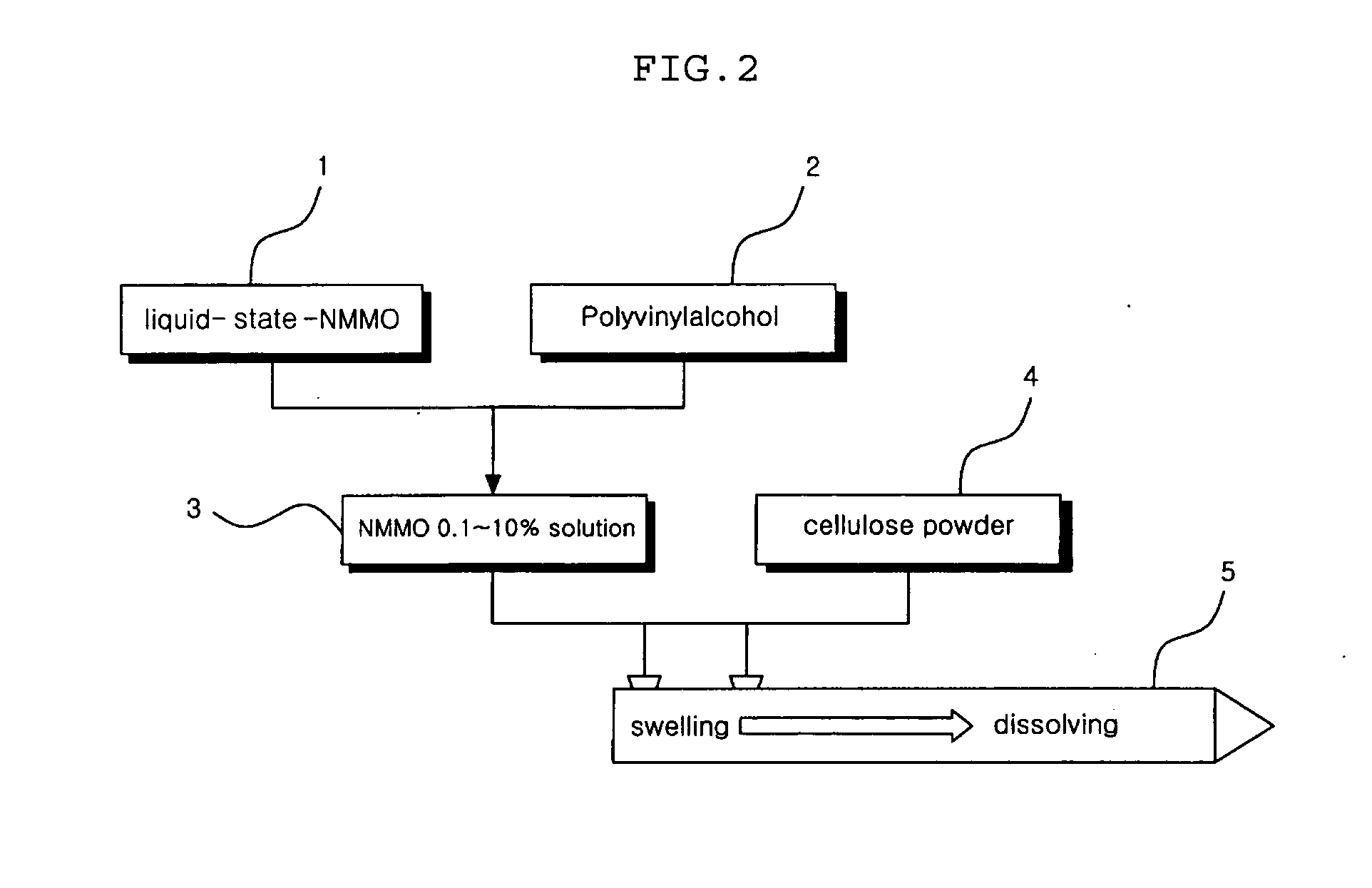

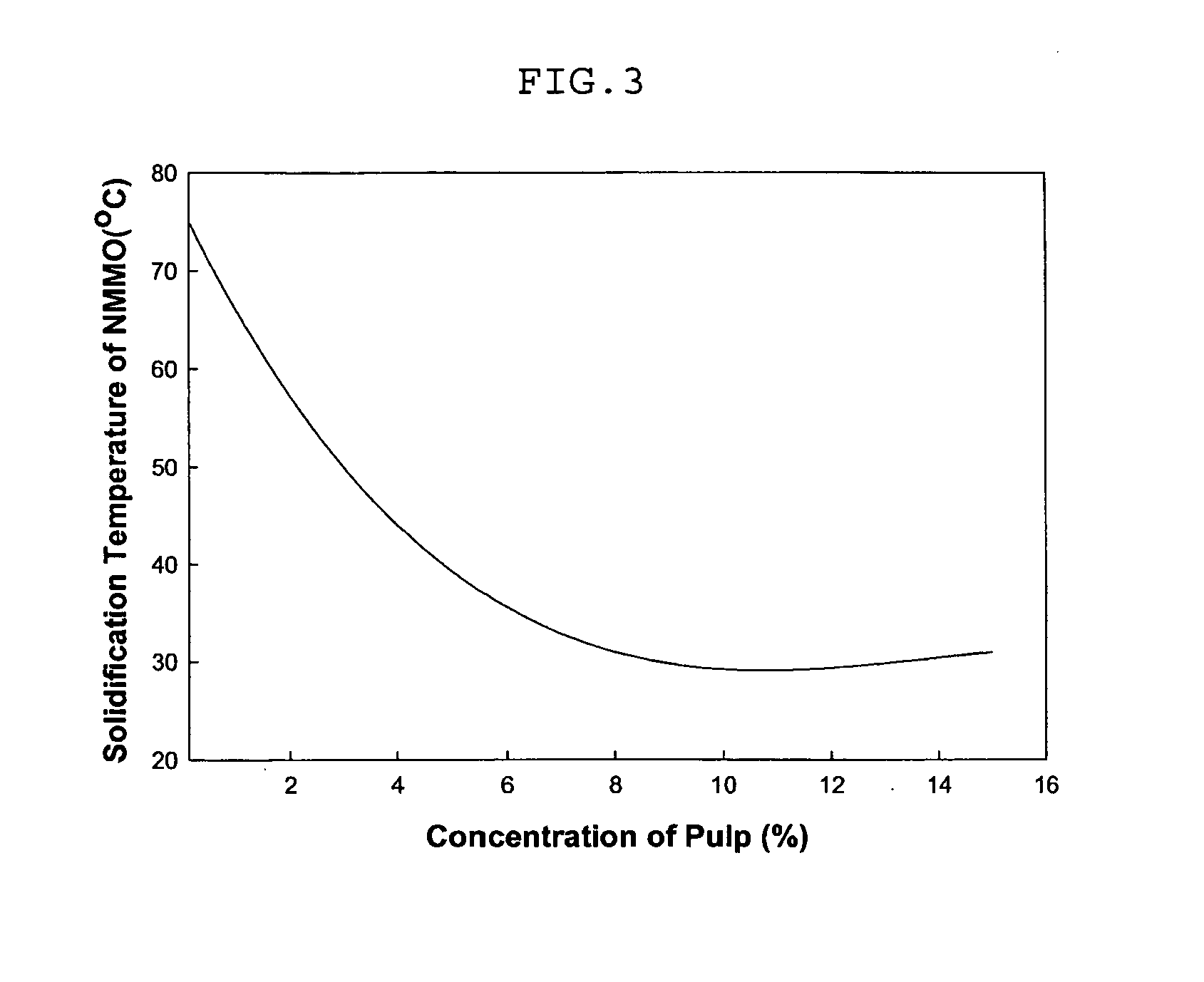

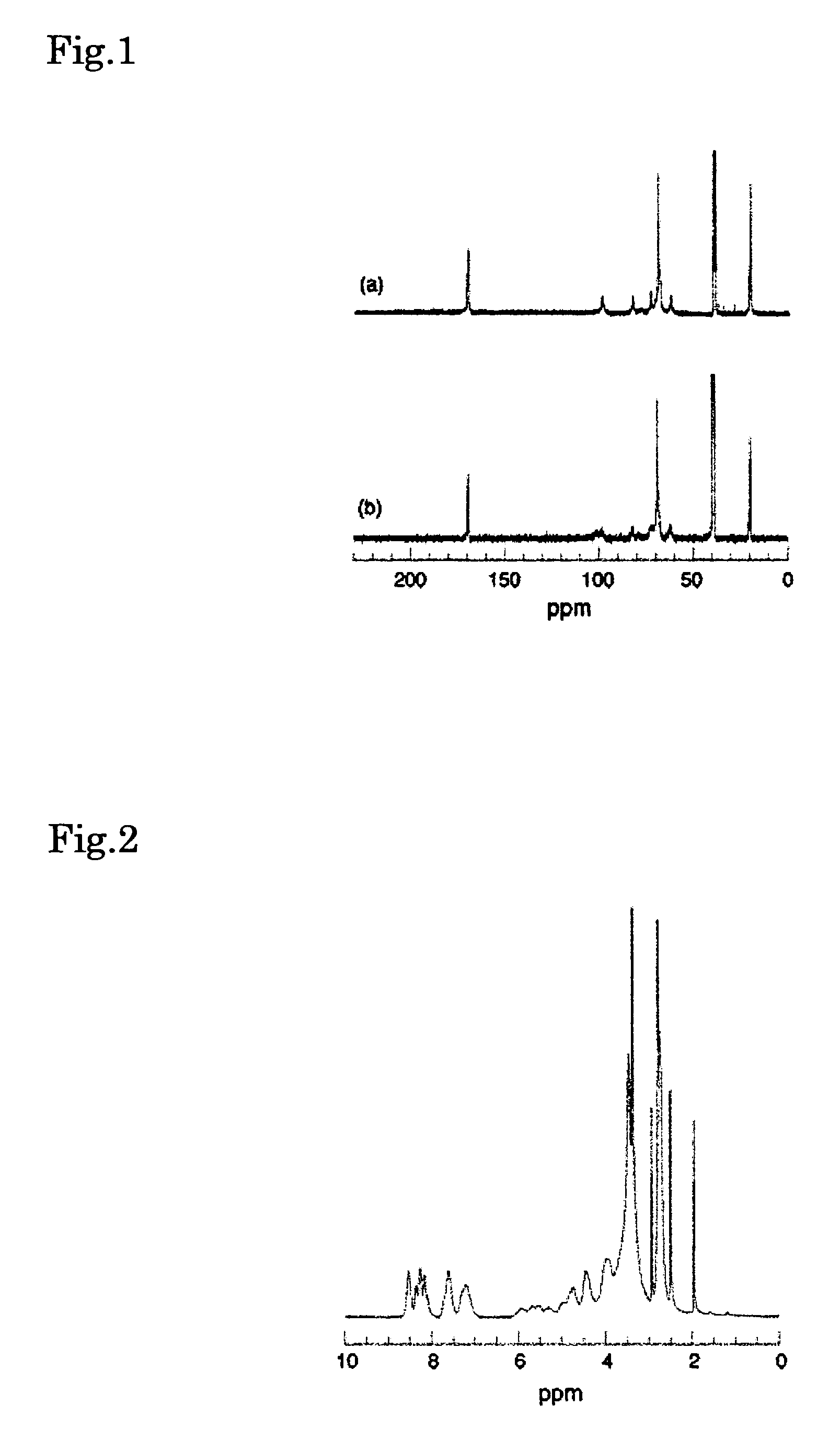

This invention relates to a method of preparing cellulose solution which is homogeneous at relatively low temperature, in which a small amount of cellulose powder or polyvinylalcohol is dissolved in the liquid-state, concentrated N-methylmorpholine-N-oxide (hereinafter, referred to as ‘NMMO’) so as to lower the solidifying temperature of NMMO, and then, the resulting solution and cellulose powder are fed into an extruder so as to be mixed, swollen and melted in the extruder.

Owner:HYOSUNG ADVANCED MATERIALS CORP

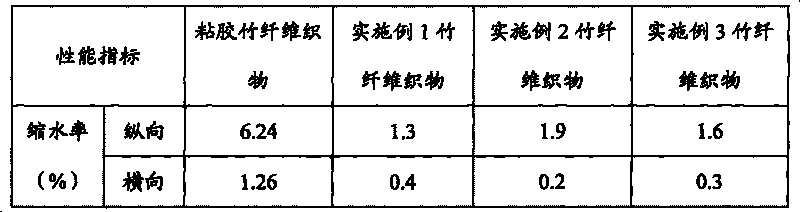

Solvent method high-wet-modulus bamboo fiber and preparation method thereof

ActiveCN101694019AEasy to operateReduce energy consumptionMonocomponent cellulose artificial filamentVegetable materialFiberCellulose

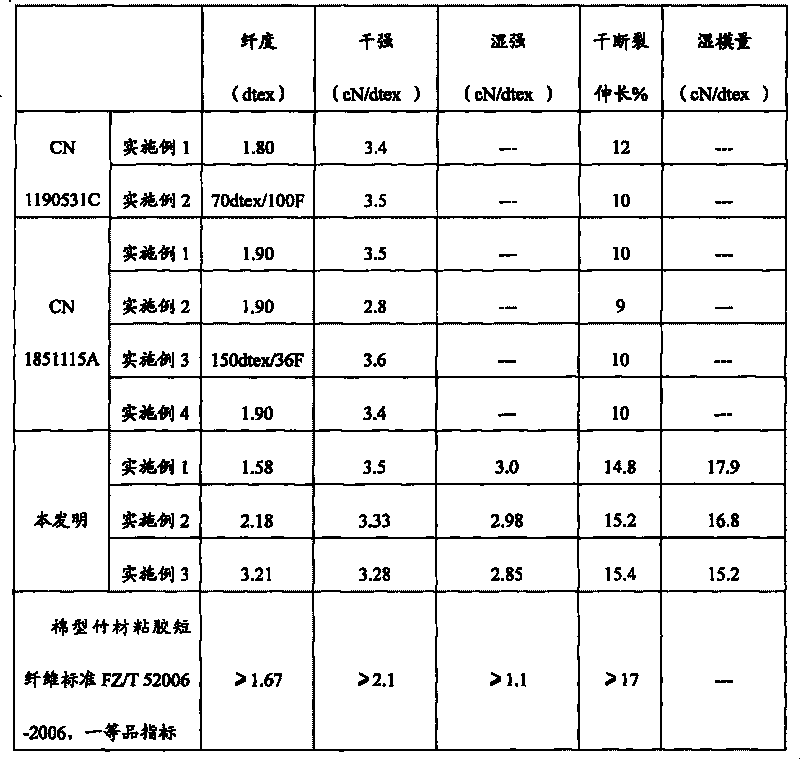

The invention discloses a solvent method high-wet-modulus bamboo fiber and a preparation method thereof. The preparation method of the bamboo fiber comprises the following steps: activation, adding bamboo pulp into deionized water, adjusting the pH value, adding cellulase for activation, and then adding alkali to adjust the pH value; squeezing, vacuum dewatering and squeezing; pre-dissolving, adding water solution containing 50-88% of N-methyl morpholine-N-oxide; dissolving, entering a dissolving machine, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning, spraying through a spinneret plate, and molding by adopting a dry wet spinning; washing; whitening; oiling; and drying. The preparation method has simple operation, no industrial pollution, low energy consumption and high safety performance, and is applicable to manufacturing the solvent method bamboo fiber by large-scale industrialized continuous production; furthermore, the bamboo fiber prepared by the method not only maintains the natural physical and chemical properties of the bamboo fiber, but also generates no harmful chemical residue and has higher wet modulus.

Owner:SHANGHAI LYOCELL FIBER DEV

Method for preparing cellulose spinning fluid

ActiveCN101240461AIncrease in sizeLow viscosityArtificial filaments from cellulose solutionsHigh concentrationOrganic solvent

The invention relates to a preparation method of cellulose spinning solution, including a mixed solvent with low boiling point, volatile, polar organic solvent as a promoter and the N-methylmorpholine-N oxides (NMMO) of 8-18% moisture content; the cellulose pulp is mixed with the mixed solvent forming a uniform mixed materials; the low boiling point volatile organic solvent is removed from the mixed materials and the low content is lower than 5%, the cellulose of mixed materials is dissolved in the NMMO forming the cellulose spinning solution under heating. The invention is used the promoter delaying swelling and preventing premature dissolution of cellulose to reduce the solvent viscosity, the cellulose is dissolved uniformly, completely, the advantage which the pulp is impregnated directly in the high concentration solvent, and overcomes the abuse of uneven mixed, the used promoter is easy to extract and to recycle.

Owner:CHINESE TEXTILE ACAD

Novel Composition for Preparing Polysaccharide Fibers

This invention pertains to a novel process for preparing fibers from poly(α(1→3) glucan). The fibers prepared according to the invention, have“cotton-like” properties, are useful in textile applications, and can be produced as continuous filaments on a year-round basis. The process comprises solution spinning from a novel solution of poly(α(1→3) glucan) in a mixture of water and N-methylmorpholine-N-oxide followed by coagulation in a liquid coagulant that comprises a liquid that is not water.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Chemical copper-plating solution and chemical copper-plating method

InactiveCN102191491AImprove stabilityImprove yieldLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention provides chemical copper-plating solution. The chemical copper-plating solution is the aqueous solution containing copper salt, N-methylmorpholine, formaldehyde, complexing agent, stabilizer and pH regulator and the pH value of the chemical copper-plating solution is 12-13. The invention also provides a chemical copper-plating method. The method comprises the following steps: directly contacting a part to perform chemical copper plating with the chemical copper-plating solution, cleaning and drying to obtain the plated part. By adopting the chemical copper-plating solution, the stability of the copper-plating solution can be greatly increased and the plating speed can be increased. By adopting the chemical copper-plating method provided by the invention to plate copper on the part to be plated, the yield of the copper-plating product can be increased largely and the work efficiency of chemical plating can be increased, thus the method is good for industrialized mass production.

Owner:BYD CO LTD

Vehicle high-methanol content gasoline

InactiveCN102161919AImprove starting performanceCold start problem solvedLiquid carbonaceous fuelsIsobutanolButanedioic acid

The invention discloses vehicle high-methanol content gasoline, relates to carbon-containing fuels and solves the problems of difficult low-temperature startup, serious metal corrosion, inadequate power and susceptibility to generating precipitates of the conventional methanol gasoline. The vehicle high-methanol content gasoline comprises the following components in part by volume: 70 to 86 partsof methanol, 14 to 30 parts of gasoline component oil, 0.5 to 1 part of cosolvent, 0.1 to 0.2 part of antiseptic and rubber swelling inhibitor, 0.2 to 0.3 part of detergent and 0.01 to 0.05 part of coloring agent. The cosolvent consists of isobutanol, isopropyl ether, 2-isobutanol and tetrahydrofuran, the antiseptic and rubber swelling inhibitor consists of propargyl alcohol, butanedioic acid, hexakis(dihydrogen phosphate), N-methyl morpholine, cyclohexane and dimethyl phthalate, the detergent consists of normal propyl alcohol, isopropanol, limonene and cyclohexane, and the coloring agent is Sudan IV solution. The vehicle high-methanol content gasoline has high startability, high dynamic performance, high environmental protection performance, obvious anticorrosion effect and high safety.

Owner:山西丰喜新能源开发有限公司

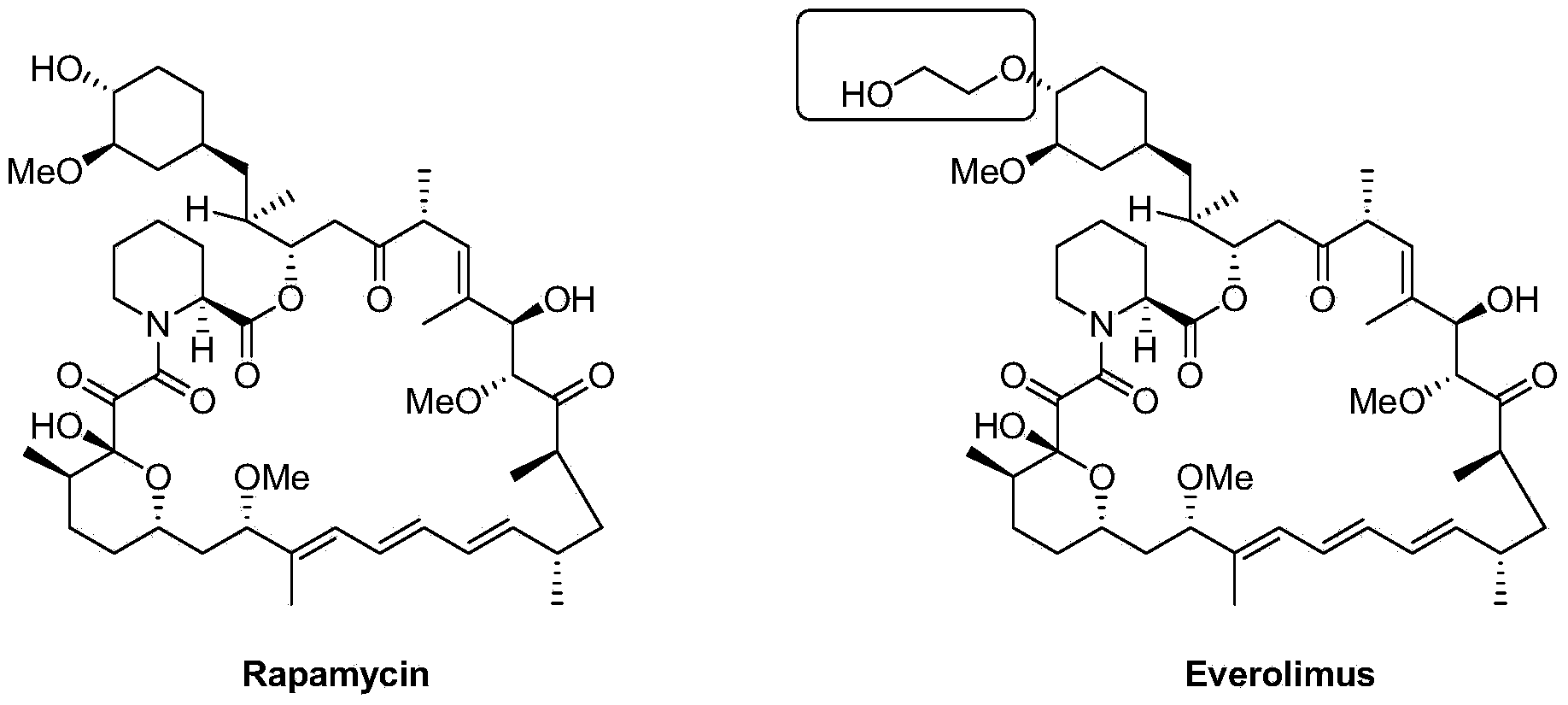

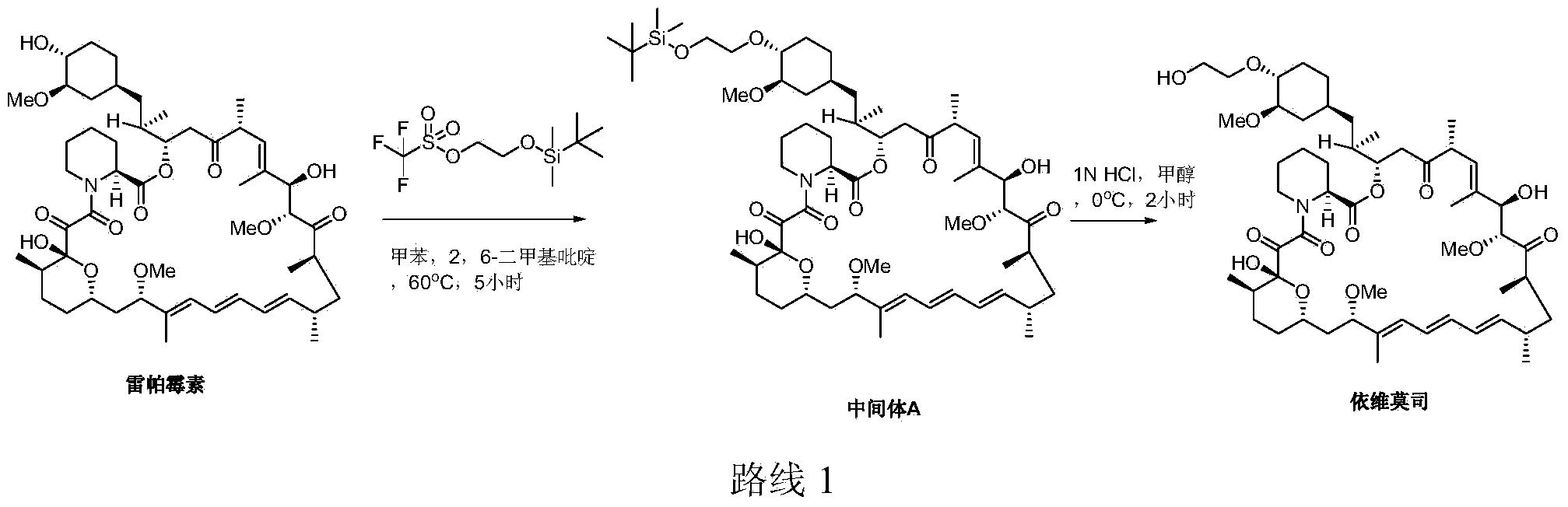

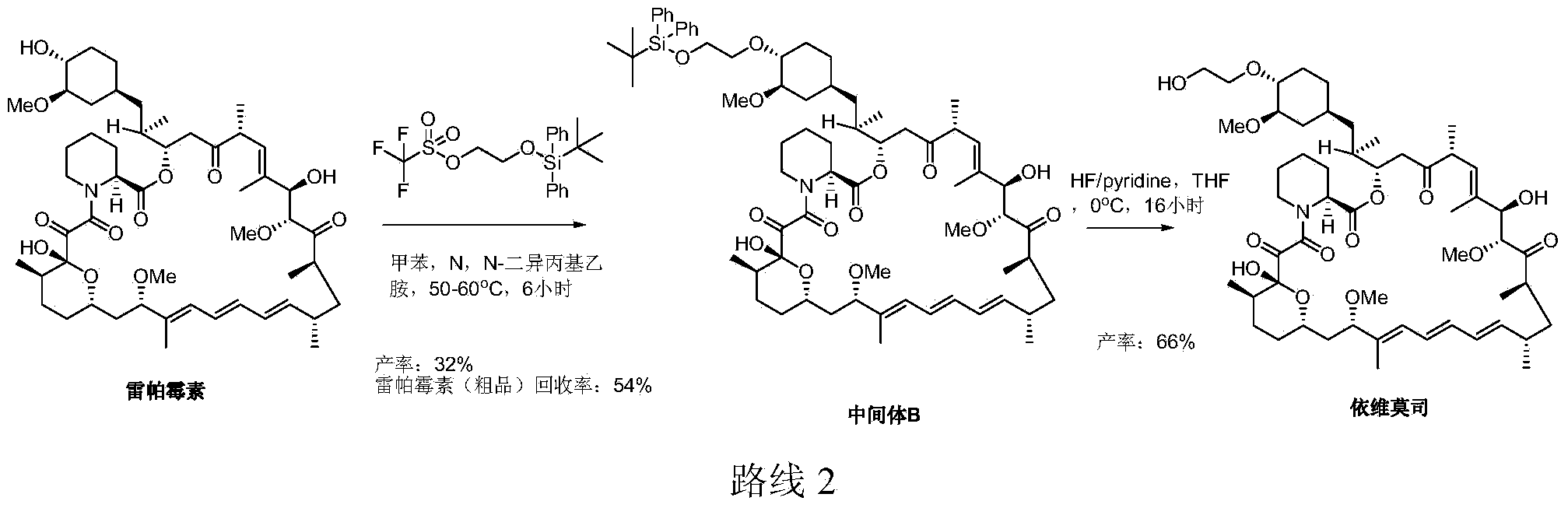

Preparation technology for everolimus

The invention provides a preparation technology for everolimus. The preparation method comprises the two steps of: 1) reacting sirolimus with 2-(tert-butyldiMethylsilyloxy) ethyl trifluoromethane sulfonate in the presence of proper solvent and organic base, to obtain an intermediate A; 2) reacting the intermediate A with inorganic acid in an organic solvent to obtain everolimus, wherein the organic base used in the step 1) is selected from large-steric hindrance or non-nucleophilic bases such as triethylamine, N,N-diisopropylethylamine, 1,8-diazabicycloundec-7-ene or N-methylmorpholine, acid used in the step 2) is hydrochloric acid, sulfuric acid or phosphoric acid. According to the technology, the total yield in the two steps and the purity of a final product are greatly improved as compared with those reported by the existing literature, the process route is short, the reaction conditions are mild, and the reaction result is also stable and reliable.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

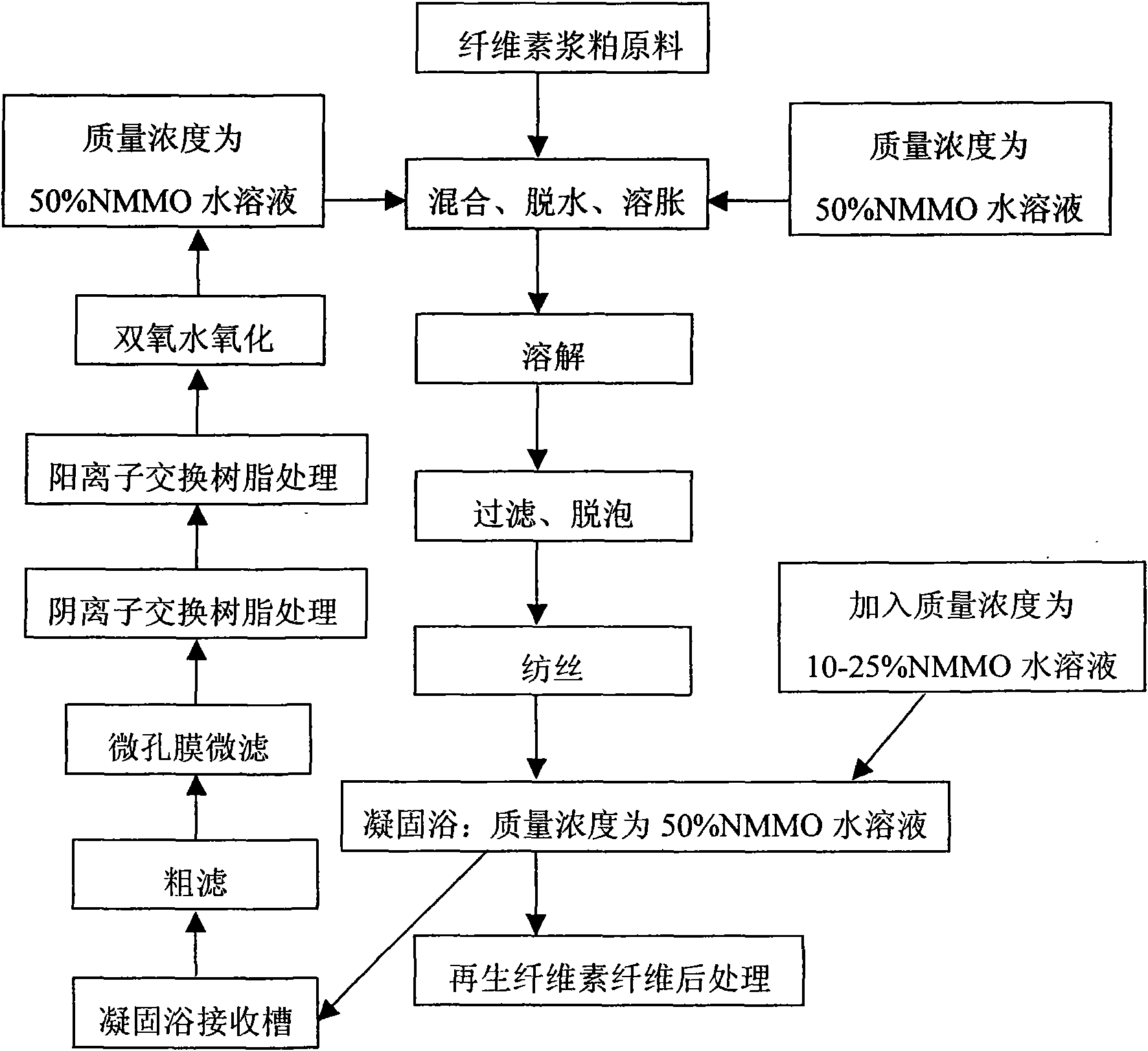

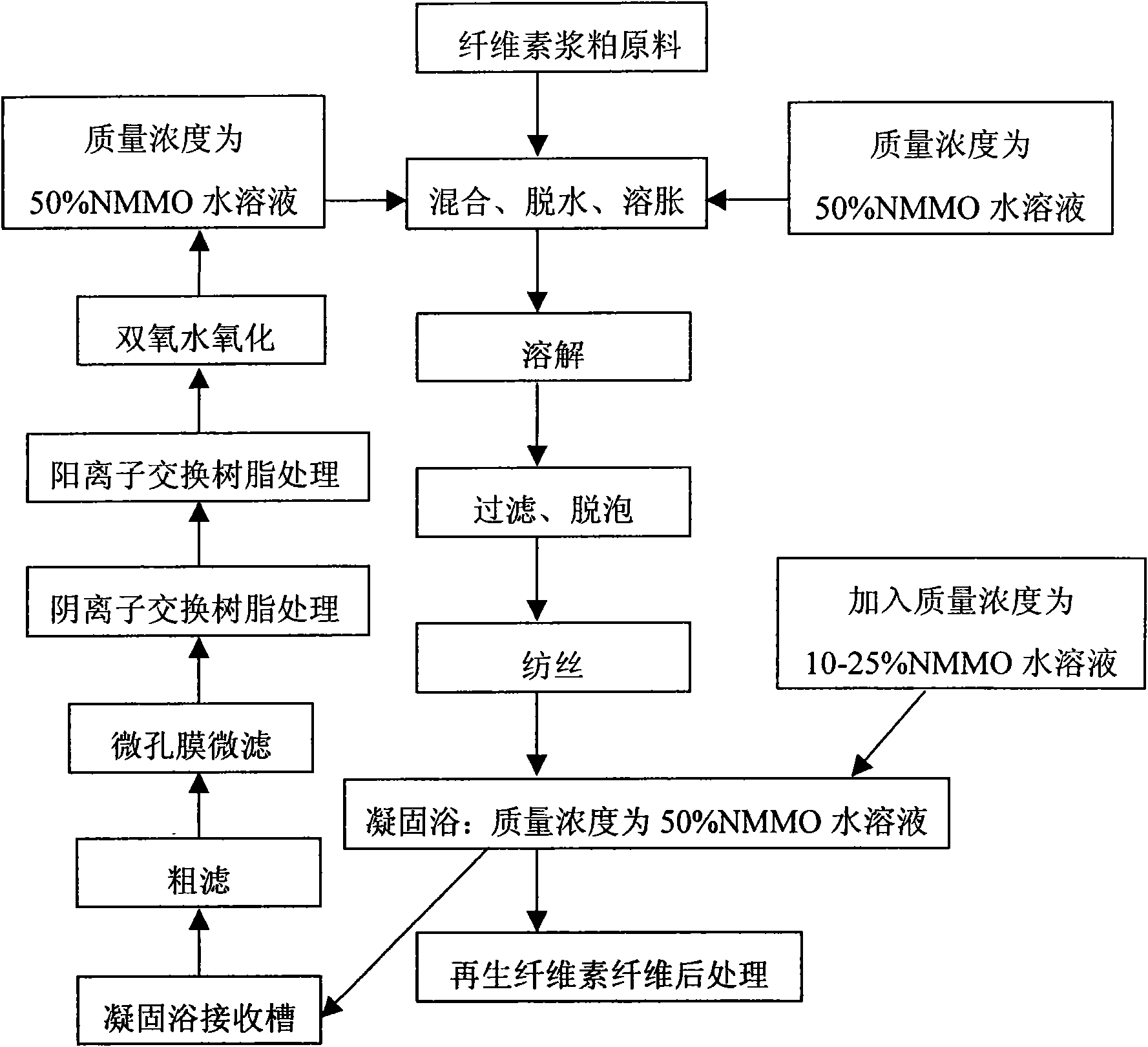

Recovery method of N-methylmorpholine oxide solvent in process of producing regenerated cellulose fibre by solvent method

InactiveCN101942712ARecycling method saves energyEasy to recycleArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiltration

The invention relates to a recovery method of an N-methylmorpholine oxide (NMMO) solvent in a process of producing regenerated cellulose fibre by a solvent method in a spinning technology. The technical scheme of the invention is designed as follows: a NMMO aqueous solution with the mass concentration of 50% is taken as a coagulating bath of the regenerated cellulose fibre; the circulation of the coagulating bath is optimally controlled so that the mass concentration of the coagulating bath of the NMMO aqueous solution in a coagulating bath-loading container is controlled to be 50%; and multiple impurities in recovery liquid, namely a coagulating bath solution, are removed through rough filtration, microporous membrane microfiltration, anion exchange resin treatment, cation exchange resin treatment and hydrogen peroxide oxidization, thereby achieving the recovery of the NMMO solvent.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Cellulose/polylactic acid blend material and preparation method thereof

The invention discloses a blend material of cellulose and a polylactic acid. The blend contains 0.1-99.9% of cellulose and 99.9-0.1% of polylactic acid. The method comprises the following steps: with a 30-100% N-methylmorpholine-N-oxide (NMNO) water solution as a solvent, adding cellulose and a polylactic acid to the NMMO solution; dissolving at constant temperature of 35-150 DEG C for 0.1-100 hours; completely dissolving the cellulose and the polylactic acid, so as to prepare the mixed solution of the cellulose and the polylactic acid; precipitating a molding product of the mixed solution by a precipitant; and pelletizing and drying the obtained blend in vacuum, so as to prepare the blend material of the cellulose and the polylactic acid. The raw material of the cellulose is any one or a mixture of more than two of straws, bagasse, wood fiber, jute fiber, beet pulp, bamboo fiber, cotton pulp, hemp pulp, bamboo pulp and recycled cellulose, and the polylactic acid is a homopolymer, a copolymer or a blend thereof.

Owner:NANJING FORESTRY UNIV

Composition for preparing polysaccharide fibers

This invention pertains to a novel process for preparing fibers from poly(α(1→3) glucan). The fibers prepared according to the invention, have “cotton-like” properties, are useful in textile applications, and can be produced as continuous filaments on a year-round basis. The process comprises solution spinning from a novel solution of poly(α(1→3) glucan) in a mixture of water and N-methylmorpholine-N-oxide followed by coagulation in a liquid coagulant that comprises a liquid that is not water.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

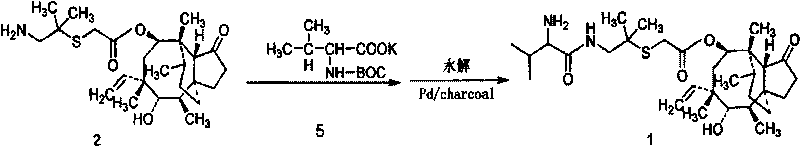

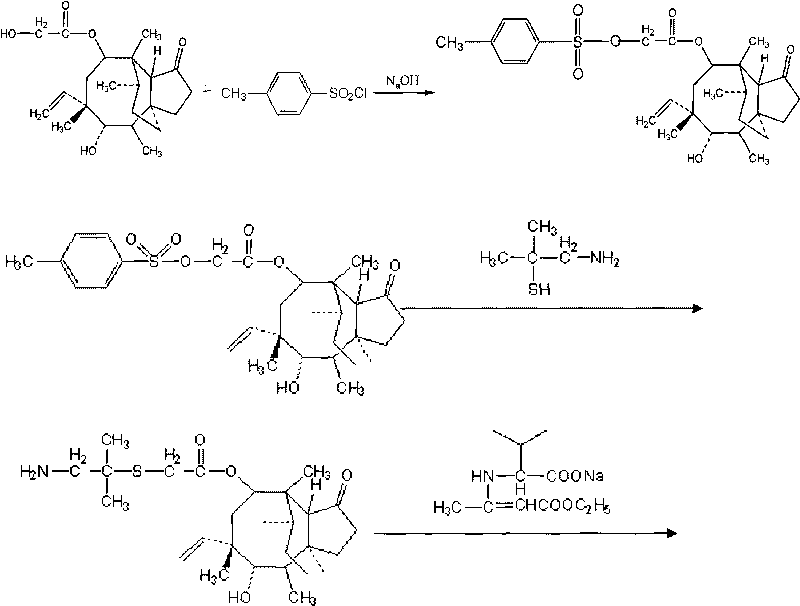

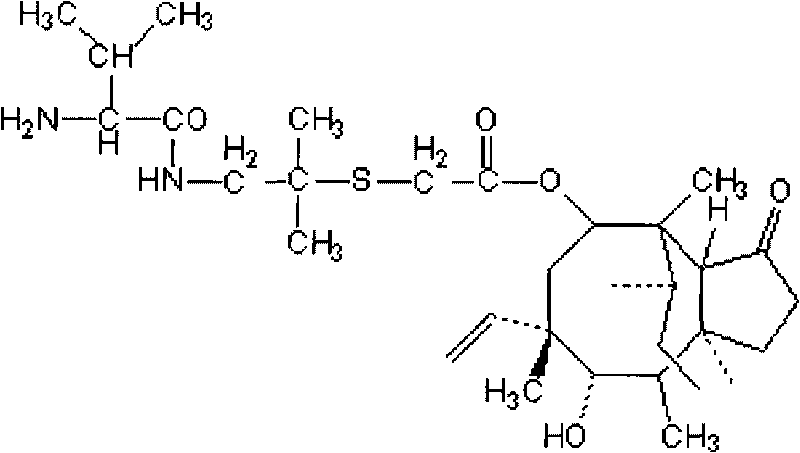

Method for synthesizing valnemulin hydrochloride

The invention discloses a method for synthesizing valnemulin hydrochloride. The method taking pleuromytilin a raw material comprises the following steps: synthesizing sulfonated pleurin; then, preparing 14-O-[(1-amido-2-methyl-propyl-2-yl)acetyl] mutelin by the sulfonated pleurin; synthesizing D-valine deng salt by D-valine; and finally, mixing the 14-O-[(1-amido-2-methyl-propyl-2-yl)acetyl] mutelin, the D-valine deng salt, N-methylmorpholine and allyl chloroformate by a certain sequence and a certain condition and reacting to generate mixed anhydride so as to obtain the valnemulin hydrochloride by the subsequent steps of acidylating, hydrolyzing, separating, drying and the like. The invention realizes the accurate control of the reaction by controlling the technological parameters of the reaction temperature, the drying condition, the reaction pH and the like and enhances the reaction efficiency and the quality and the purity of a product effectively. The obtained valnemulin hydrochloride can be used for medicines and meets the market requirement.

Owner:SHANDONG SHENGLI CO LTD

Process for separating acetic acid from water by salt-containing extracting, rectifying and separating

ActiveCN101306989ASmall number of theoretical platesReduce energy consumptionExtractive distillationCarboxylic compound separation/purificationSulfolaneAcetic acid

The invention relates to a method for separating acetic acid and water by salt addition, extraction and distillation. The method mainly solves the problems of low separating efficiency, the excess number of column plates and high energy consumption in the separation of the acetic acid and the water. The method adopts the technical proposal comprising the following steps that; an acetic acid aqueous solution enters an extraction and rectification tower and is added with salt, extracted and rectified; the water is extracted in a tower top; and a mixture of the acetic acid, the salt and solvent is obtained in a tower kettle, wherein, the solvent selects at least one of an N-methyl ketopyrrolidine, an N-methylmorpholine, a sulfolane or a tertiary amine organic alkali polar solvent; the salt added in the solvent is selected from at least one of thiocyanate, acetate or nitrate; the mixture of the acetic acid, the salt and the solvent enters to a solvent recovery tower; the distilled liquid in the tower top is the acetic acid with a concentration over 97 percent in mass by percentage; and a saline solvent is obtained in the tower kettle, thereby well solving the problems. The method can be used in industrial application of producing and reclaiming acetic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lyocell Fiber

The invention concerns a Lyocell fiber, containing a material selected from the group consisting of pearl powder, ground nacre and mixtures thereof. For the manufacture of the fiber according to the invention, a process is used comprising the steps ofmanufacturing a spinning solution of cellulose in an aqueous tertiary amine oxide, preferably N-methylmorpholine-N-oxide (NMMO)spinning the spinning solution to fibers,and being characterized in that a material selected from the group consisting of pearl powder, ground nacre and mixtures thereof is admixed to the spinning solution and / or to a precursor thereof.

Owner:LENZING AG

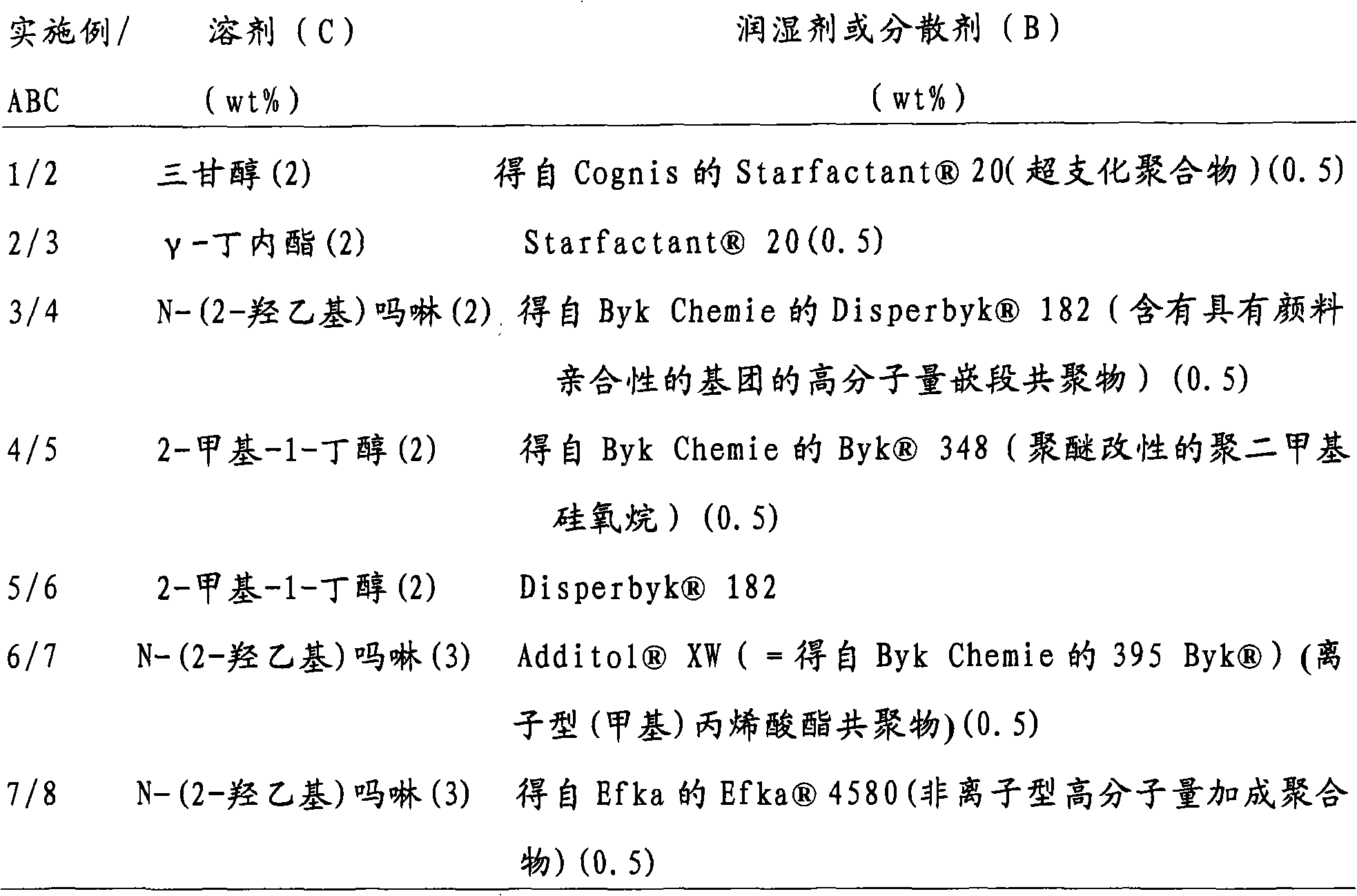

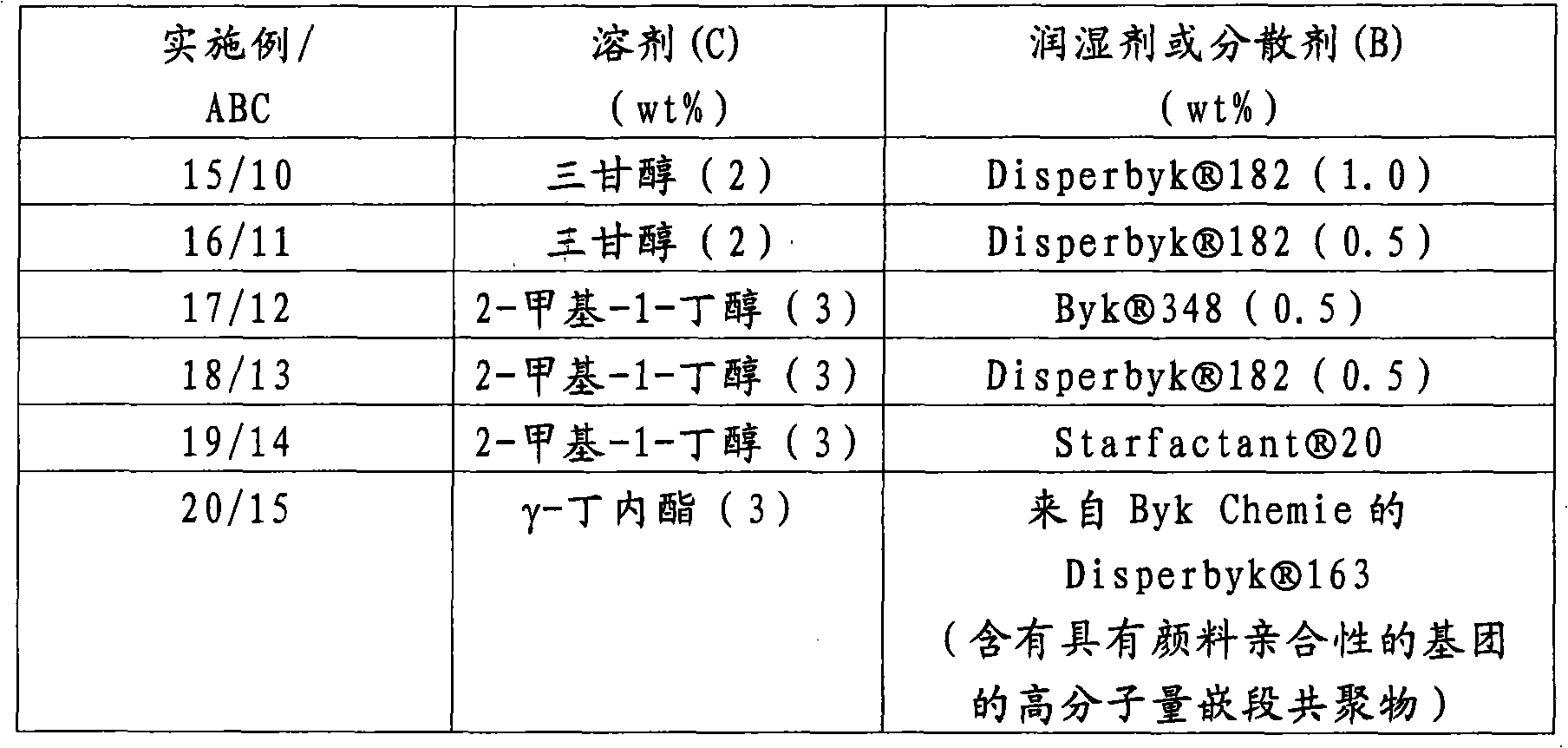

Aqueous coating material, method for the production thereof, and use thereof

ActiveCN101331196AEasy to manufactureLess spray cakingPolyurea/polyurethane coatingsSulfolane1-Pentanol

Disclosed is an aqueous coating material containing (A) at least one saturated and / or unsaturated polyurethane and / or an ionically and / or non-ionically stabilized polyurethane grafted with olefinically unsaturated compounds, (B) at least one wetting agent or dispersing agent, and (C) at least one organic solvent selected among the group comprising dimethylsulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexylglycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerin, trimethylolpropane solutions, pentaerythrite solutions, sorbit solutions, reactive polyether polyols having a number-average molecular weight of 110 to 6,000 Dalton and a hydroxyl number of 25 to 1,000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerin ethoxylate, ethyl-3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl); -piperidine, N-methylmorpholine, N-(2-hydroxyethyl)-morpholine, N-acetylmorpholine, N-cyclohexyl pyrrolidone, and N-octyl-2-pyrrolidone. Also disclosed are a method for producing said aqueous coating material and the use thereof.

Owner:BASF COATINGS GMBH

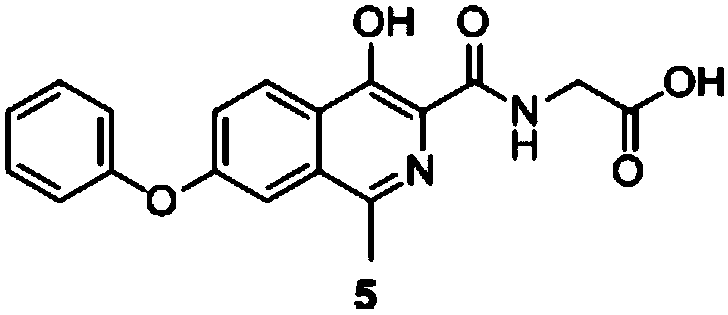

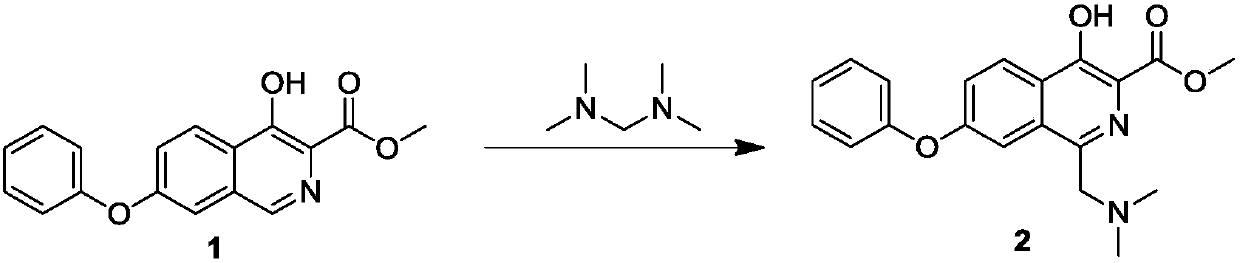

Preparation method of Roxadustat

ActiveCN108017583AEasy to prepareRaw materials are easy to getOrganic chemistryEthylenediamineAcetic anhydride

The invention discloses a preparation method of Roxadustat, compound 1 and bis(dimethylamino)methane are heated in a mixed solvent of acetic acid and trifluoroacetic acid for reaction to form compound2; acetic anhydride is added to the obtained reaction solution of the compound 2 for completing reaction by heating to form compound 3; the compound 3 is dissolved in ethyl acetate and heated, then is catalyzed by Pd / C, and reduced by hydrogen to obtain compound 4; the compound 4 and glycine are dissolved in a solvent, and heated under the action of an organic base for reaction to obtain compound5; wherein the solvent is one or more of dioxane, ethylene glycol monomethyl ether, toluene, acetonitrile and n-propanol, the organic base is one or more of triethylamine, 1,8-diazabicyclo undecane-7-ene, N,N-diisopropylethylamine, N-methylmorpholine, pyridine, and ethylenediamine; the preparation method has the advantages of shorter reaction time, low reaction temperature, low equipment condition requirements and high crude product purity, is suitable for large-scale industrial production, and has a good industrialization prospect.

Owner:XUZHOU WANBANG JINQIAO PHARMA +1

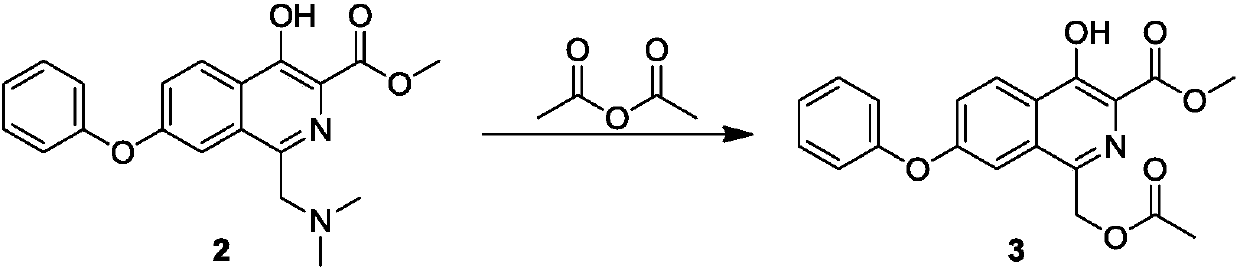

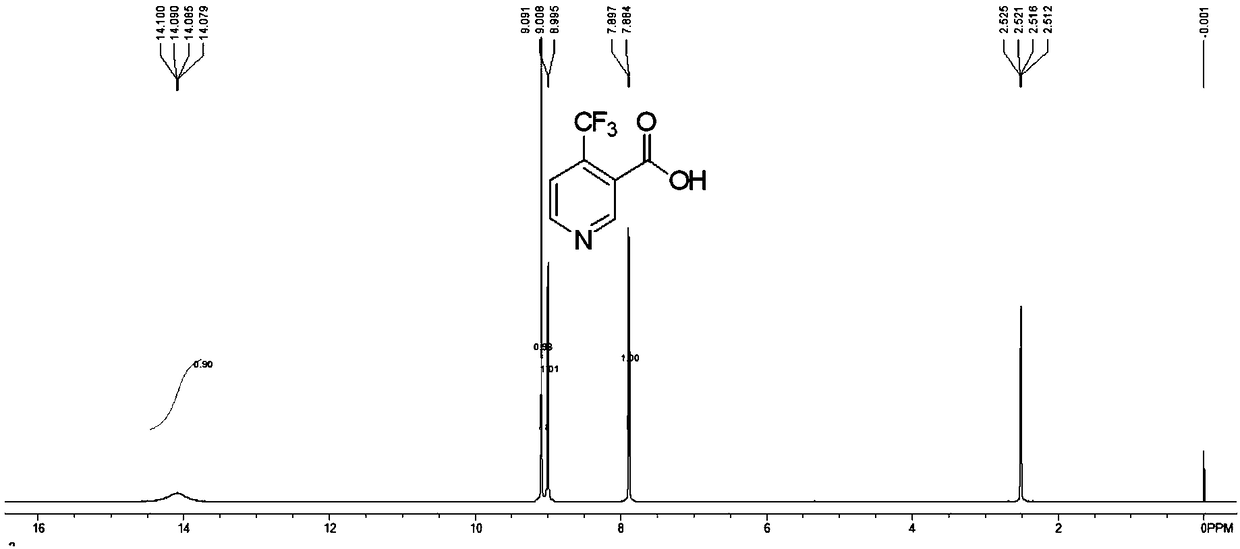

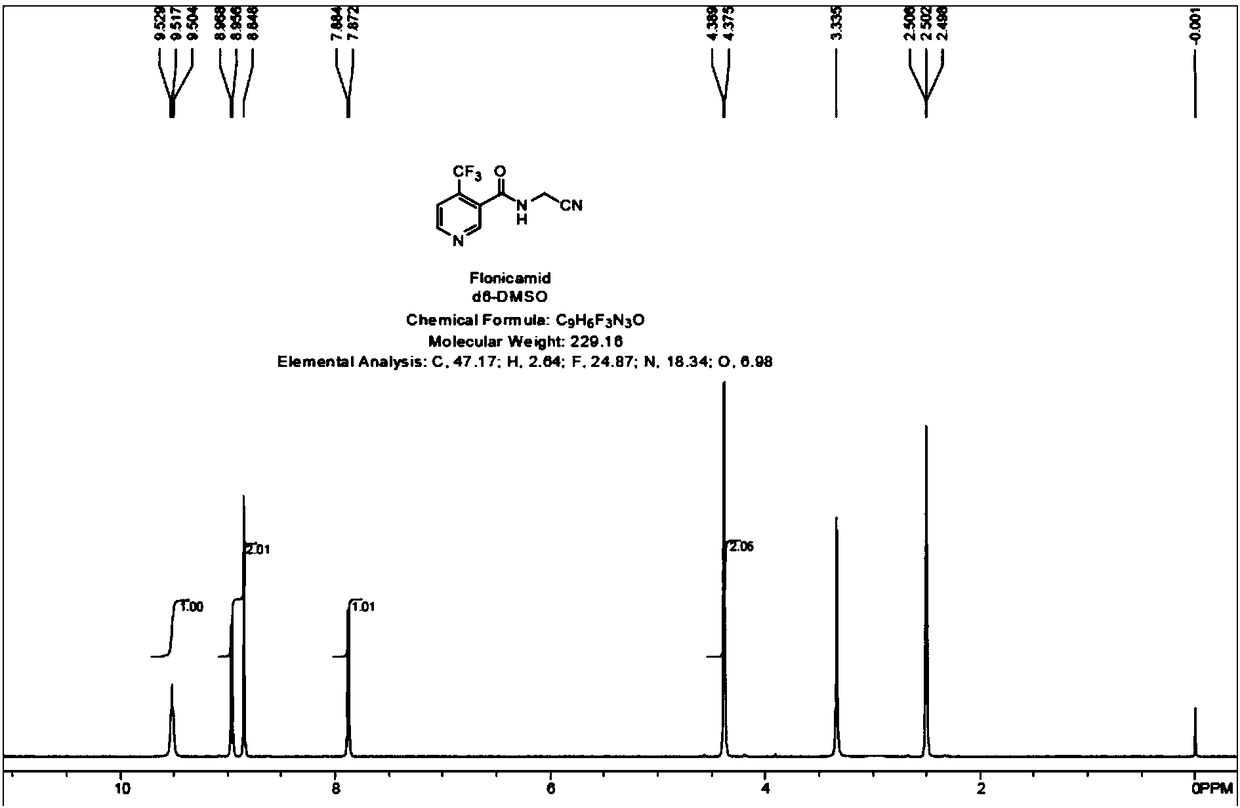

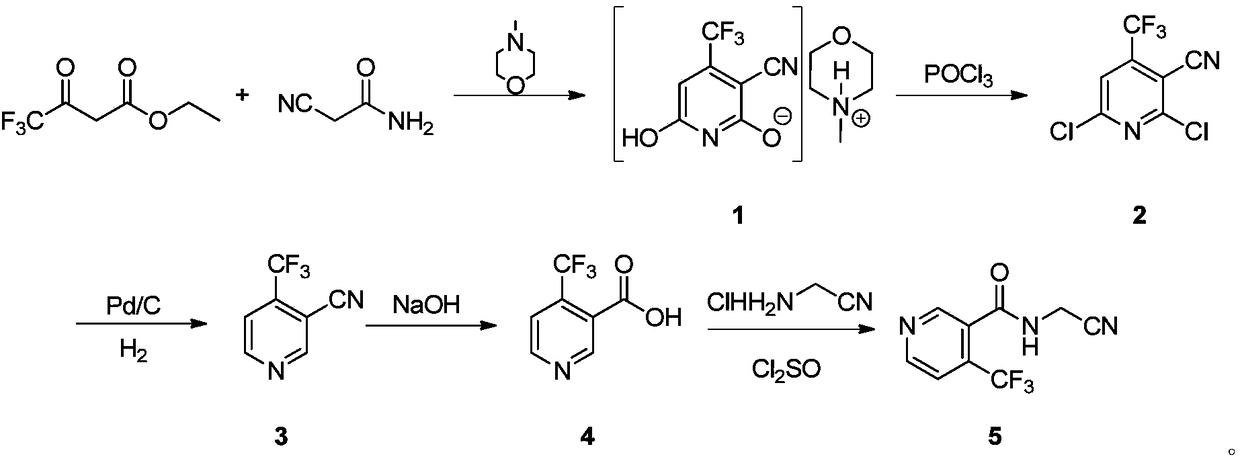

Preparation methods of flonicamid and intermediate 4-(trifluoromethyl)nicotinic acid thereof

The invention relates to preparation methods of flonicamid and an intermediate 4-(trifluoromethyl)nicotinic acid thereof. The preparation method of 4-(trifluoromethyl)nicotinic acid comprises the steps that cyanoacetamide, ethyl 4,4,4-trifluoroacetoacetate and organic alkali serve as the raw materials, 2,6-dyhydroxy-3-cyano-4-tirfluoromethylpyridine N-methylmorpholine salt is prepared first, and then phosphorus oxychloride chlorination, catalytic hydrogenation and hydrolyzation are conducted in sequence to obtain 4-(trifluoromethyl)nicotinic acid; the preparation method of the flonicamid comprises the steps that 4-(trifluoromethyl)nicotinic acid is prepared and then mixed with glycinonitrile hydrochloride, and after an amidation reaction is conducted, the flonicamid is obtained. Compared with the prior art, the total recovery of the prepared flonicamid is high, the cost is low, operation is easy, the equipment requirement is low, and the requirement of industrial production can be met;the technological process is simple, separation and purification are easy, and the reaction condition is mild.

Owner:SHANGHAI HETENG FINE CHEM

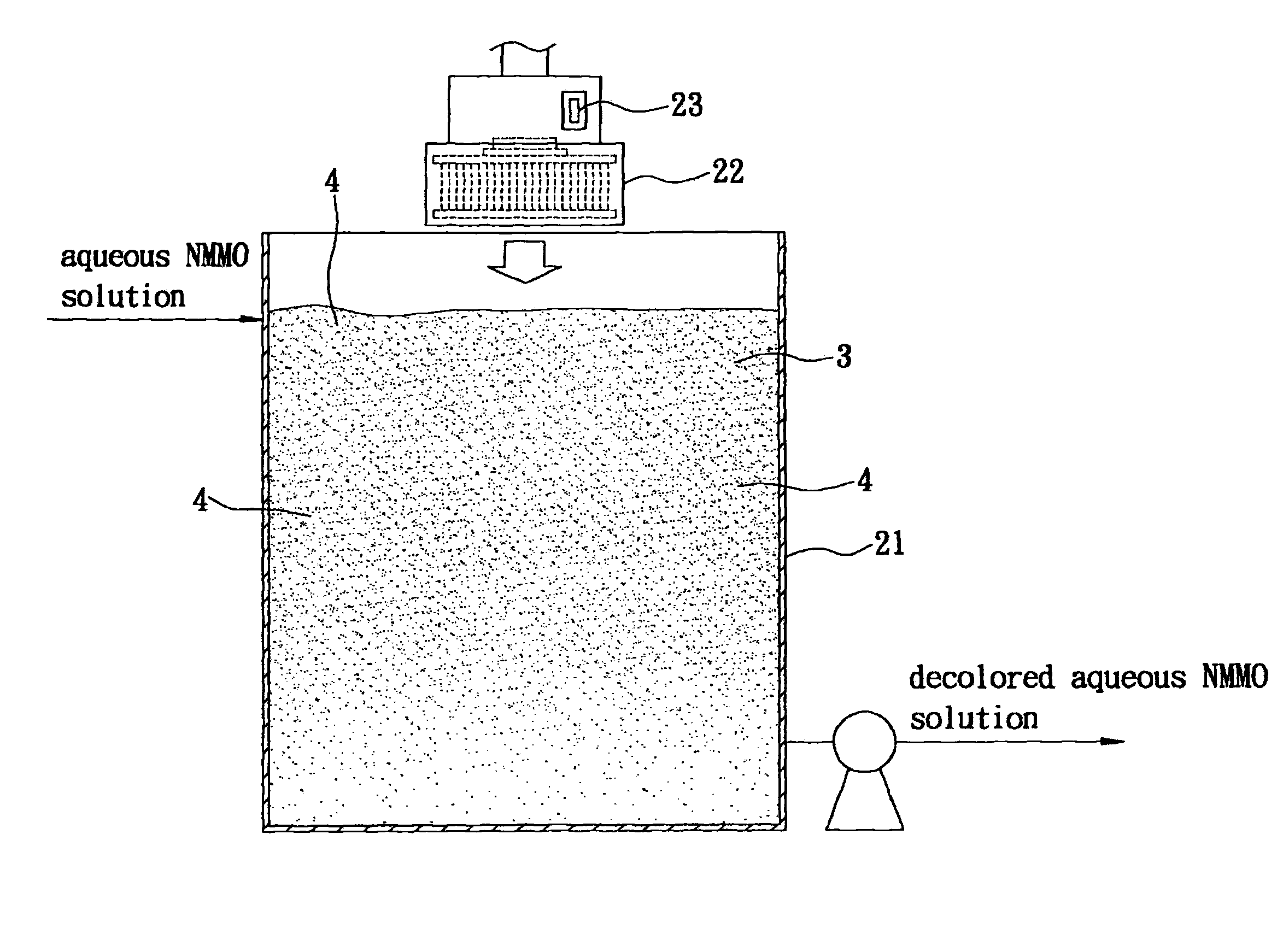

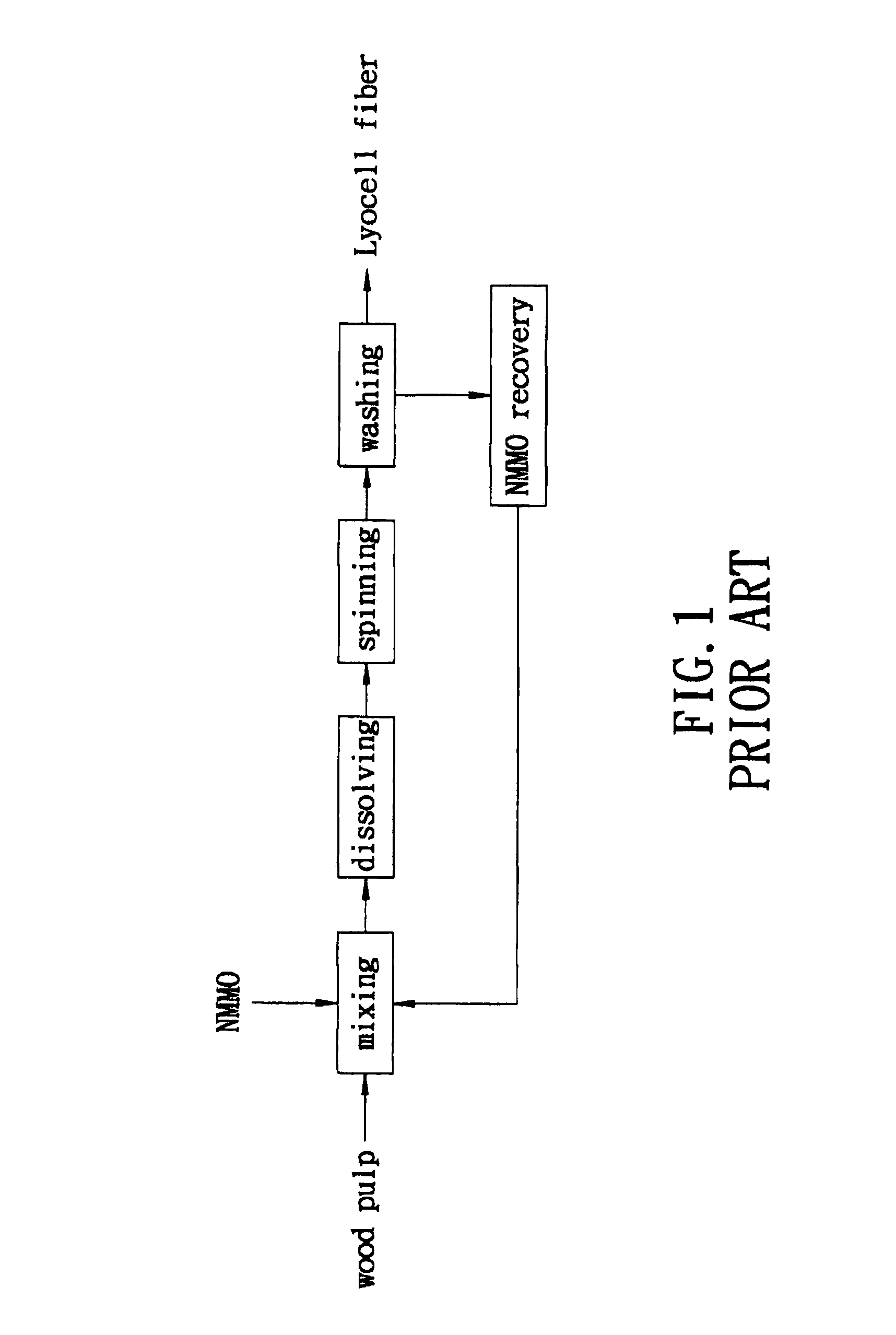

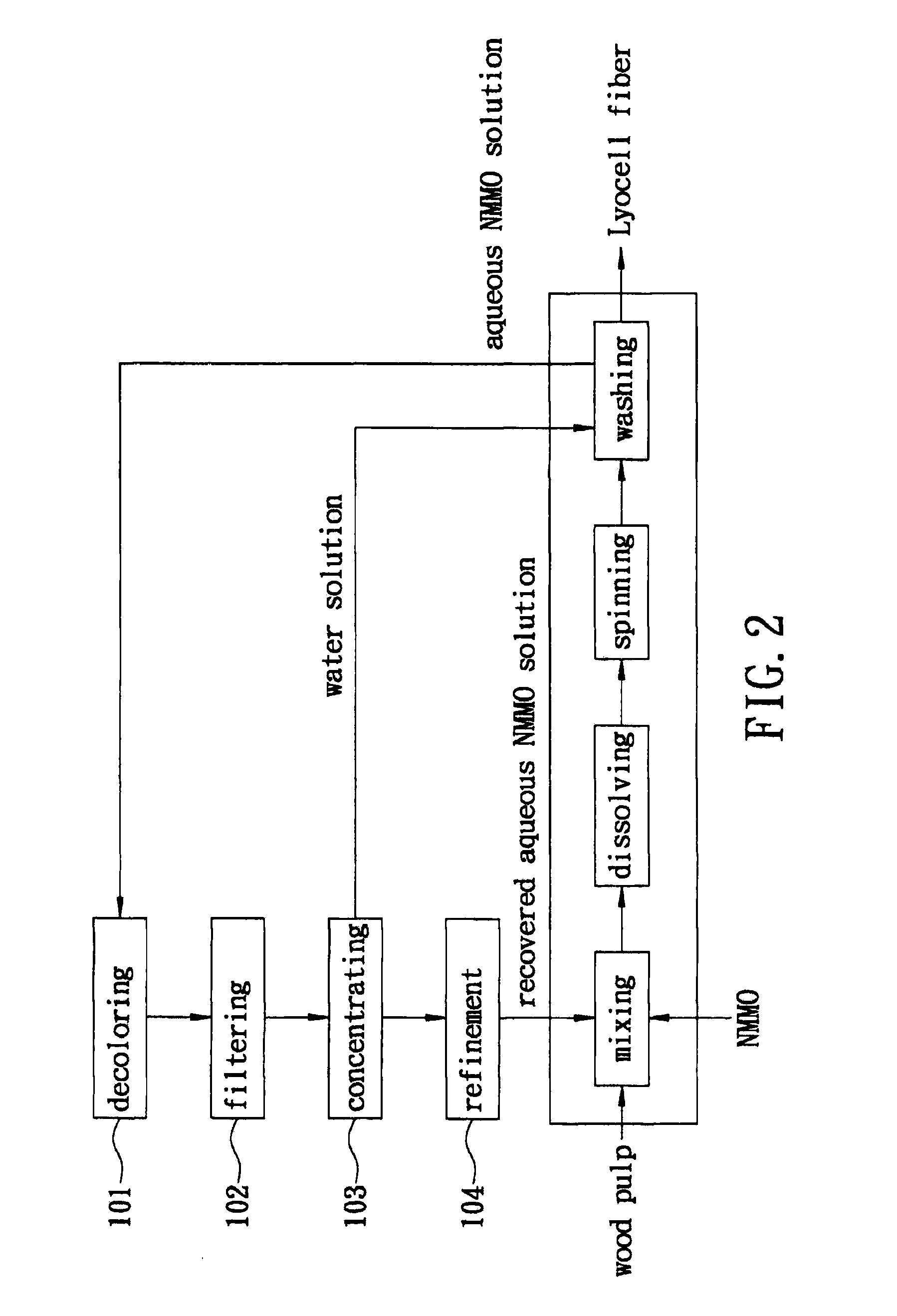

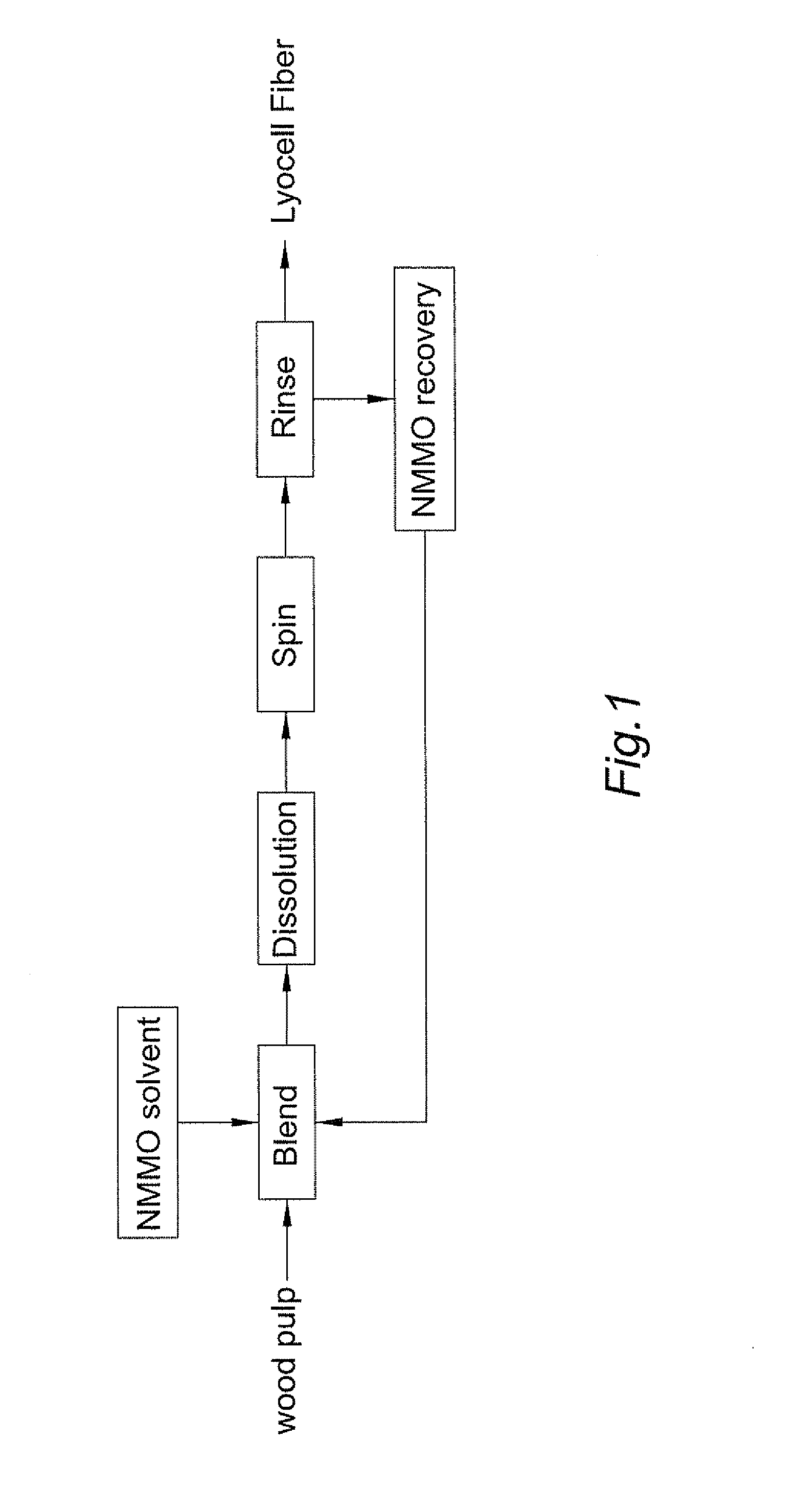

Method of Recovering Aqueous N-methylmorpholine-N-Oxide Solution Used in Production of Lyocell Fiber

InactiveUS20110226427A1Facilitate NMMO recoveryImprove recycling efficiencyArtificial filament recoveryTextile/flexible product manufactureFiberActivated carbon

A method of recovering an aqueous N-methylmorpholine-N-oxide (NMMO) solution used in production of Lyocell fiber includes: decoloring the aqueous NMMO solution by mixing the same with activated carbon using an agitation blower and by alternately energizing and de-energizing the agitation blower to contact the activated carbon with the aqueous NMMO solution thoroughly in an energy-efficient manner; filtering the aqueous NMMO solution which has been decolored through coarse filtration followed by ultrafiltration to remove the activated carbon and impurities from the aqueous NMMO solution; and concentrating the aqueous NMMO solution which has been filtered using one of a mechanical vapor recompression evaporator and a triple effect evaporator to remove water from the aqueous NMMO solution.

Owner:ACELON CHEM & FIBER

Polyrotaxane-containing solution and use thereof

InactiveUS20090149579A1Solve low usageLiquid carbonaceous fuelsBulk chemical productionAlkaline earth metalLithium chloride

An object of the present invention is to provide a polyrotaxane-containing solution by finding a good solvent for polyrotaxanes, and more particularly, to provide a polyrotaxane-containing solution by finding a good solvent for polyrotaxanes with a cyclodextrin as the cyclic molecule(s).The present invention provides a polyrotaxane-containing solution comprising polyrotaxane dissolved in a solvent selected from the group consisting of a nitrogen-containing organic solvent and an ionic liquid. In particular, a nitrogen-containing organic solvent such as N-methylmorpholine-N-oxide or hydrate thereof; a solution of a nitrogen-containing organic solvent such as N,N-dimethylacetamide containing as solute an alkali metal halide or alkaline earth metal halide such as lithium chloride; or an ionic liquid such as an N,N′-dialkylimidazolium salt or N-alkylpyridinium salt, is a good solvent for polyrotaxanes.

Owner:THE UNIV OF TOKYO

Method for synthesizing N-methylmorpholine with granular solid superacid as catalyst

InactiveCN101638397AHigh catalytic activityImprove catalytic stabilityOrganic chemistryPhysical/chemical process catalystsDesiccantFixed bed

A method for synthesizing N-methylmorpholine with granular solid superacid as a catalyst comprises the following steps: loading an SO4<2-> / MxOy super acidic catalyst into a fixed bed; heating the fixed bed to the temperature of 260-360 DEG C; pumping nitrogen into the fixed bed to ensure the catalysts under the protection of the nitrogen; introducing N-methyldiethanolamine aqueous solution into the fixed bed; dehydrating the N-methyldiethanolamine aqueous solution in the presence of the catalyst to generate the N-methylmorpholine; collecting mixed gas of the N-methylmorpholine and water, whichis discharged from the discharge hole of the fixed bed and passes through a condensing unit, into a flask, then adding solid NaOH for alkaline separation to separate supernatant; drying the supernatant with NaOH, removing the drying agent and carrying out rectification to collect distillates at a temperature of 104-106 DEG C to obtain the product of N-methylmorpholine. The invention has the effect as follows: the invention is fixed bed catalysis under normal pressure; the catalyst has stability and resistance to carbon deposition, and the method has the advantages of simple catalytic process,high product yield and purity, low cost and the like.

Owner:曲阜市圣泉催化应用科技有限公司

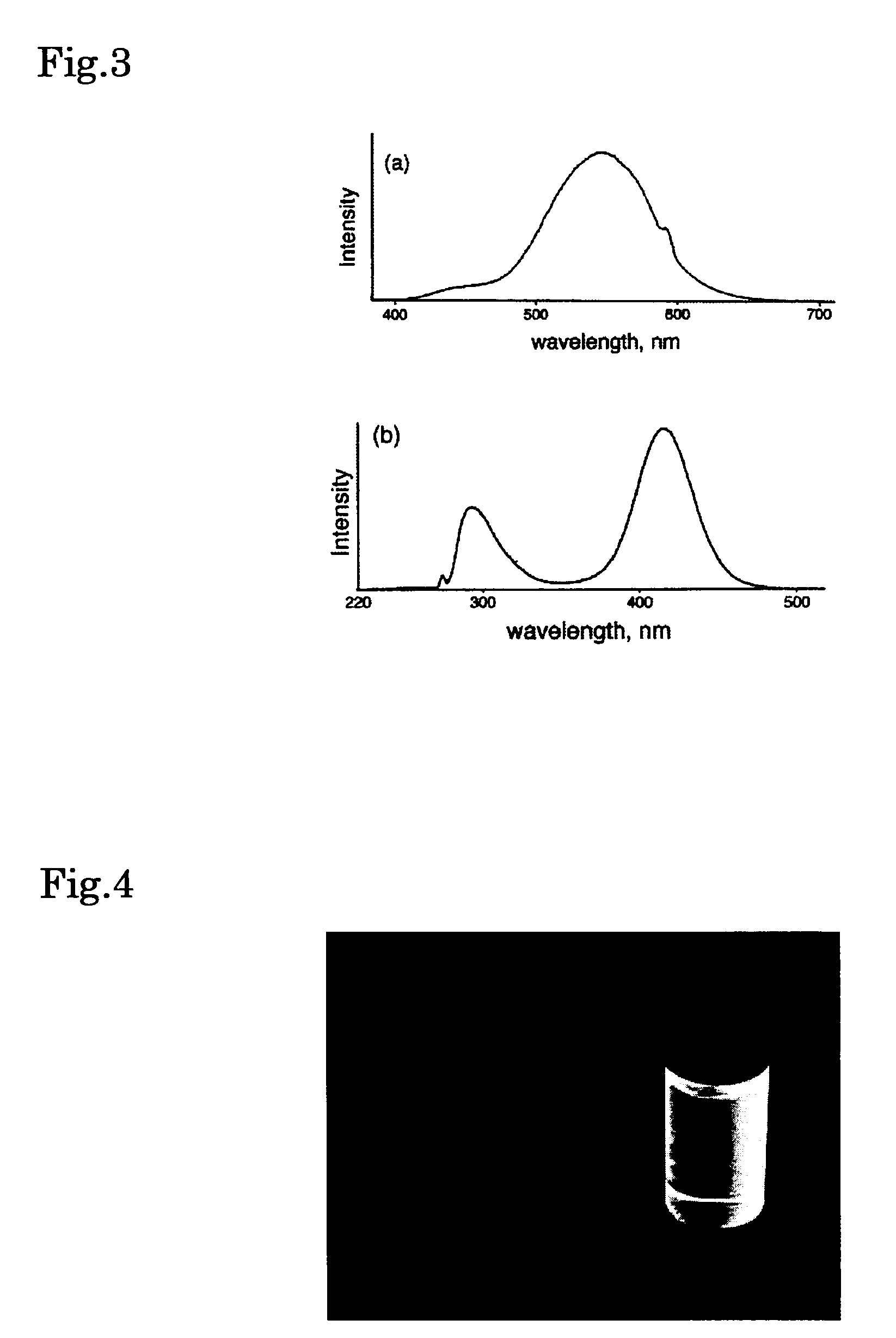

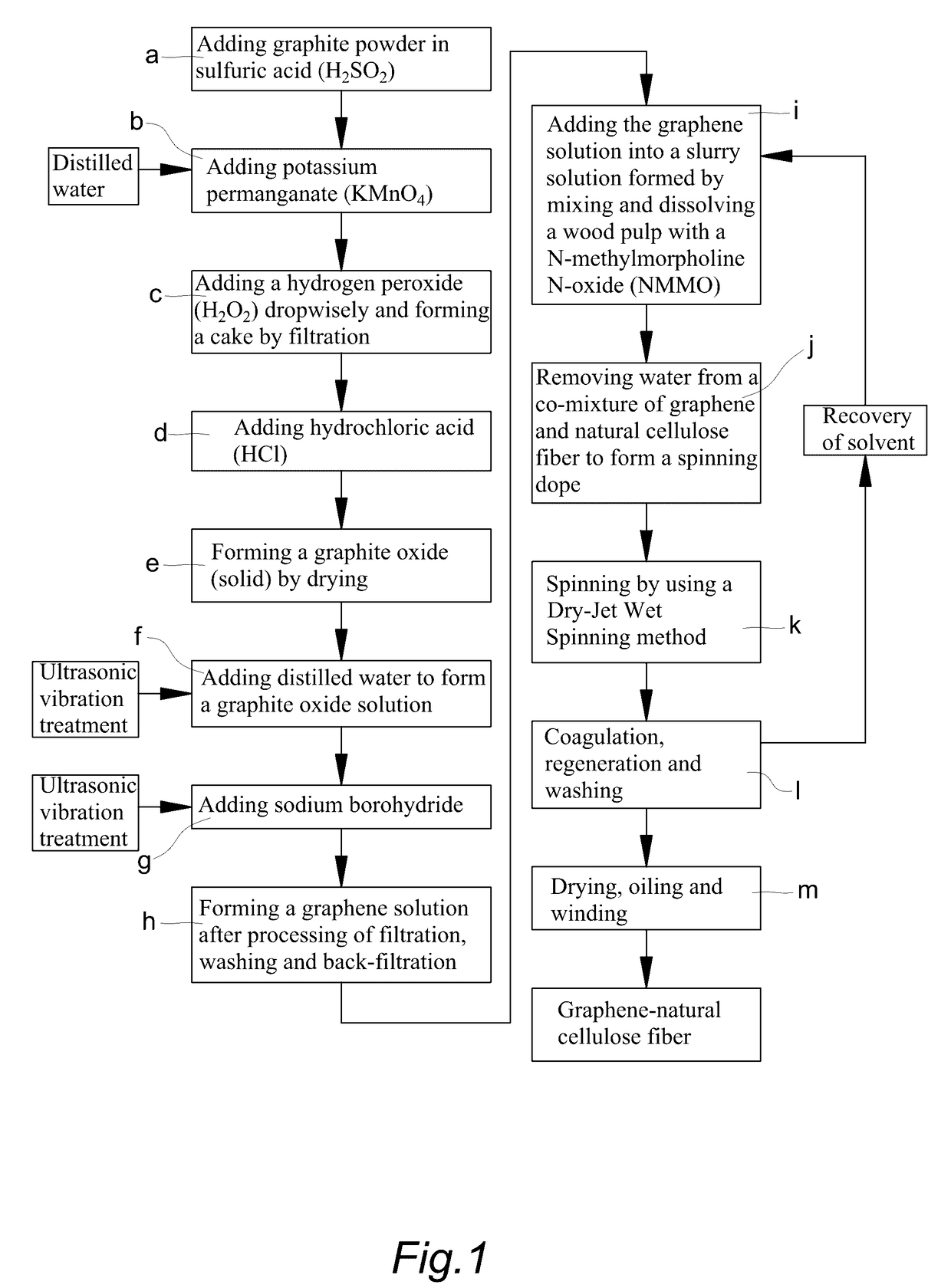

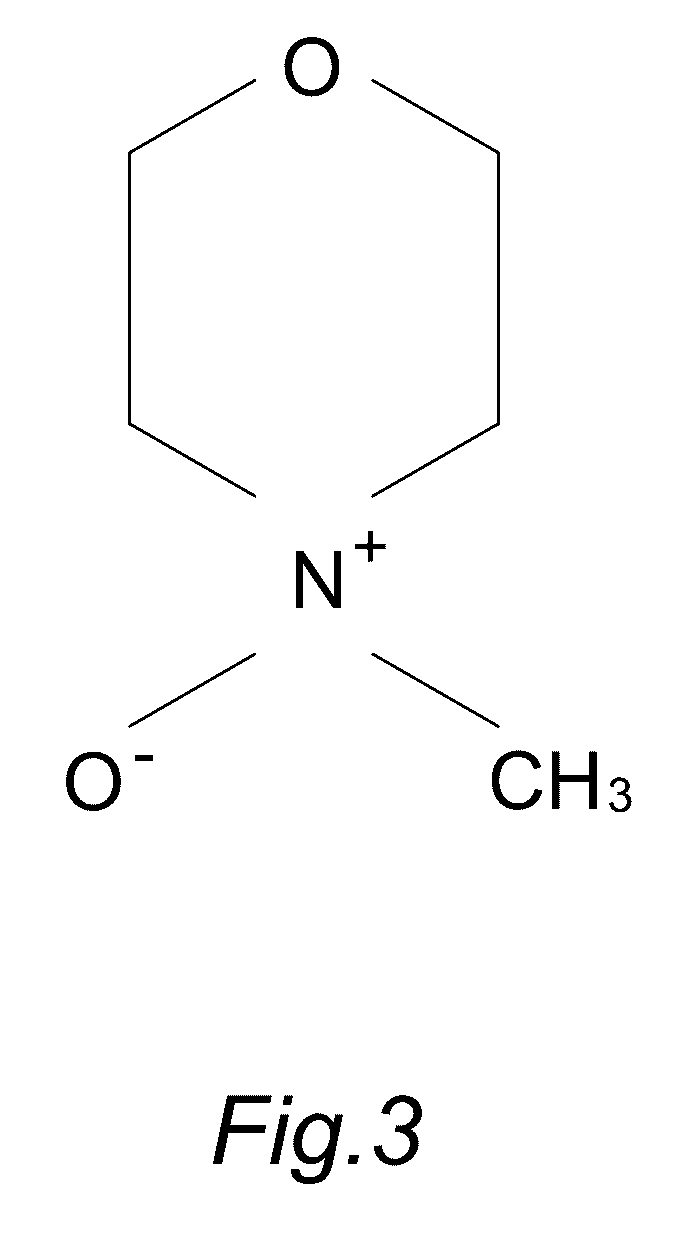

Method of preparing natural graphene cellulose blended fiber

This application describes a method of preparation of a natural graphene cellulose blended fiber, which comprises using a graphite powder as a raw material for preparing a graphene solution, adding the graphene solution to a slurry formed by mixing and dissolving a wood pulp with N-methylmorpholine N-oxide (NMMO), removing the water content thereof to form a spinning dope, and then spinning the spinning dope by a Dry-Jet Wet method to manufacture a natural graphene cellulose blended fiber. The present method does not require a highly toxic hydrazine hydrate solution. Further, by increasing the adding ratio of the graphene solution in the manufacturing process, control of the antistatic properties and thermal transferring functions can be achieved, and thereby various requirements of different consumers can be satisfied. Besides, the fibers can decompose naturally after being used, and thus the product is harmless, natural, and environmentally friendly.

Owner:LIN CHIH HSIN

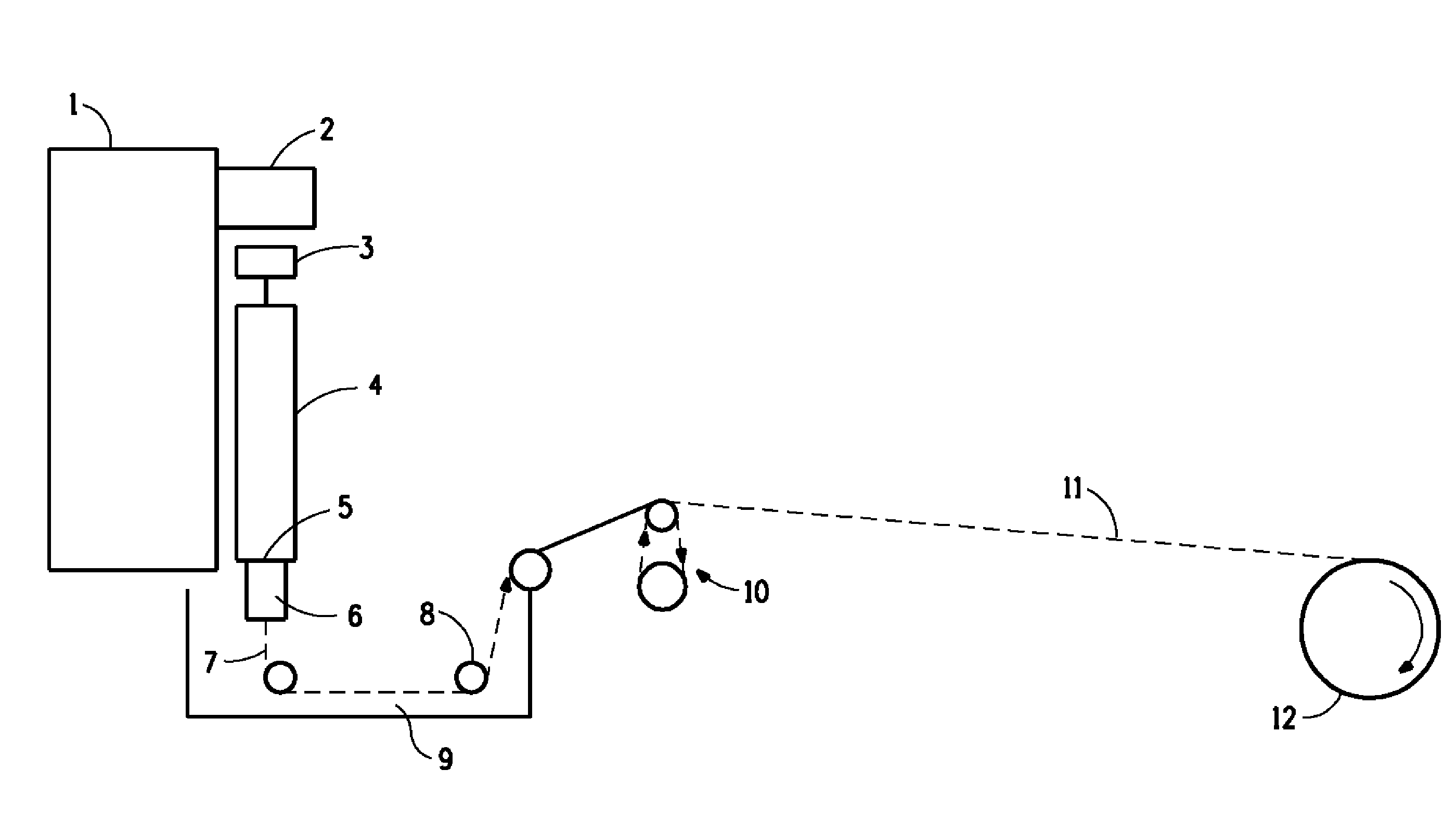

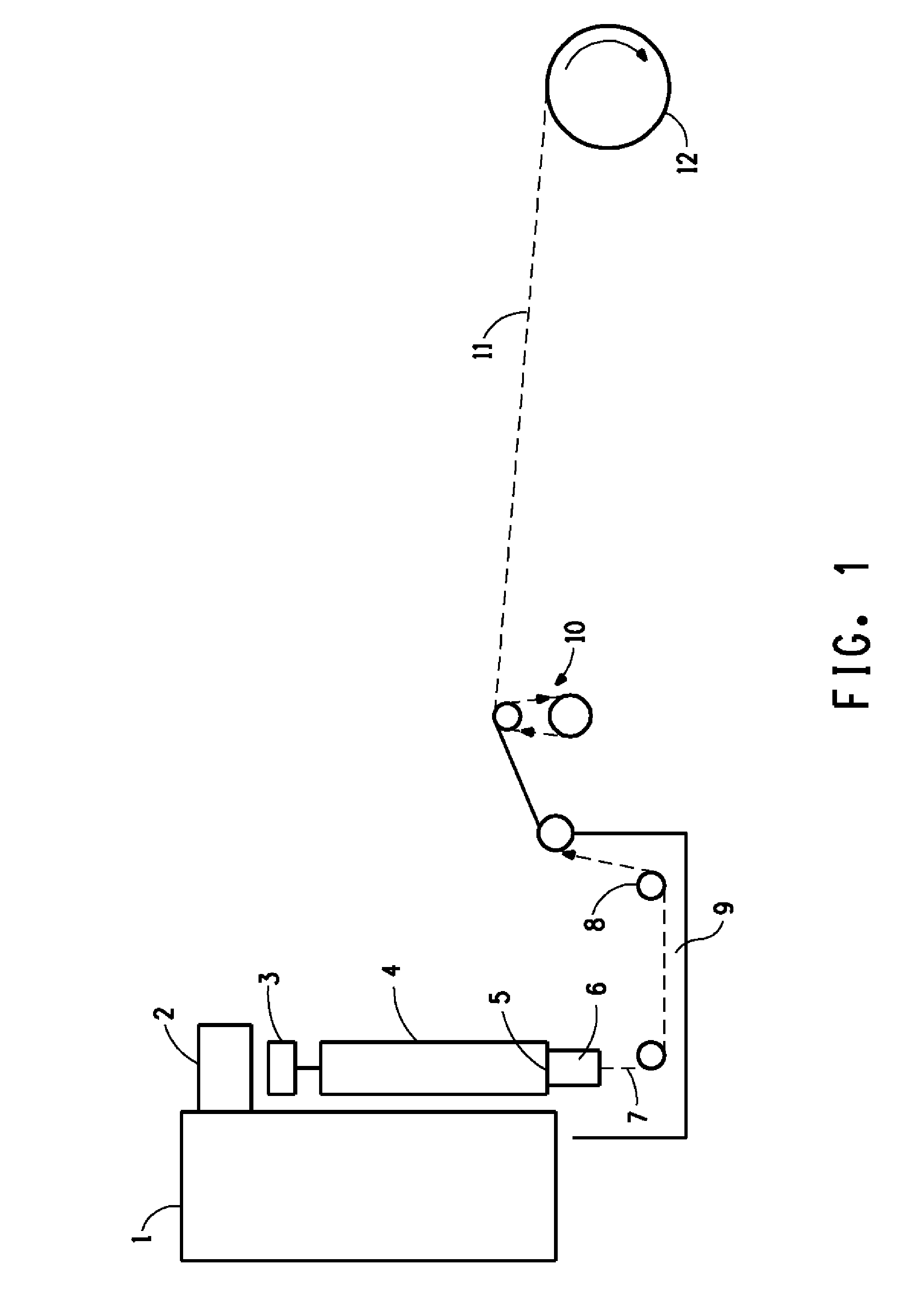

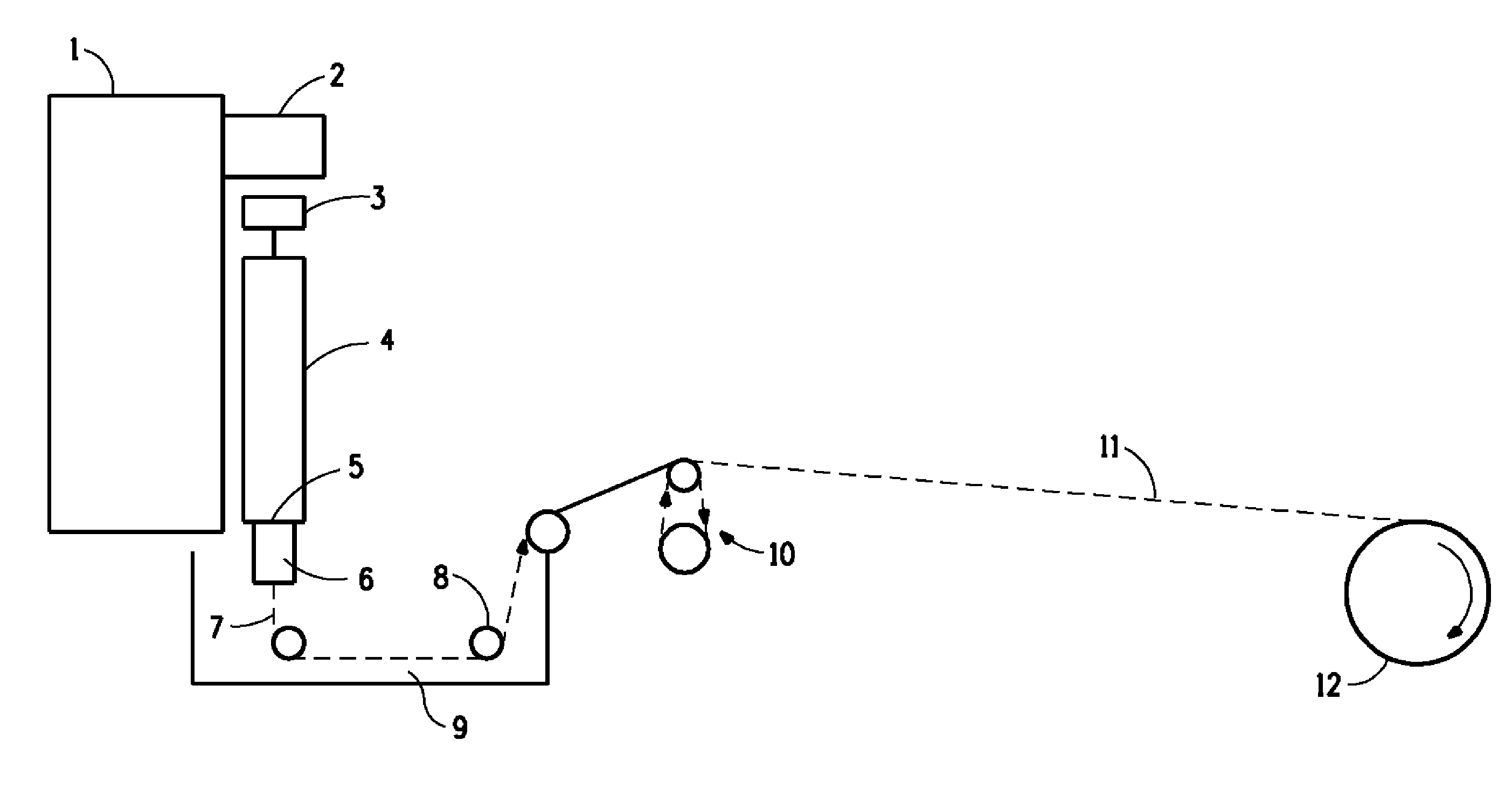

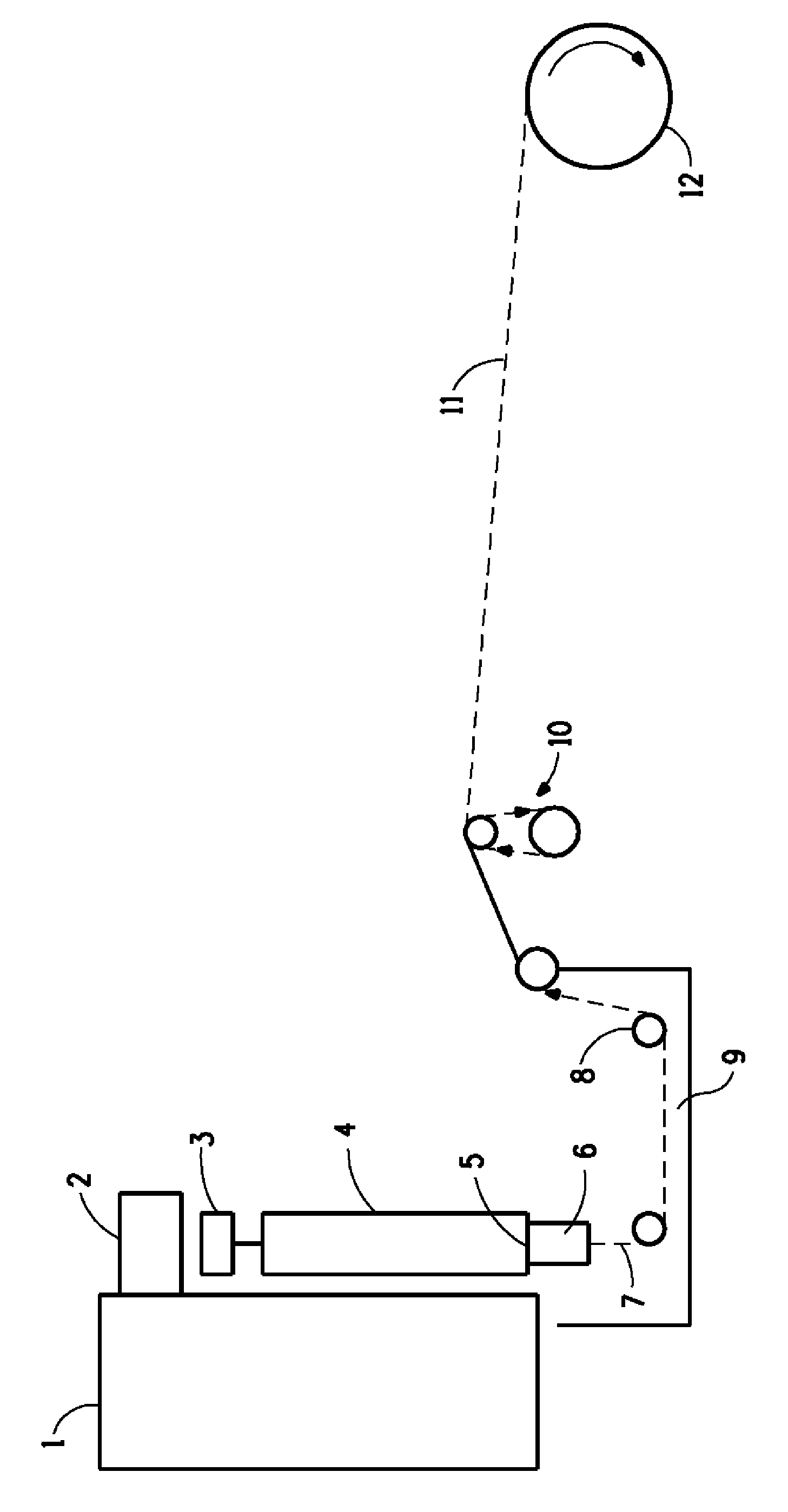

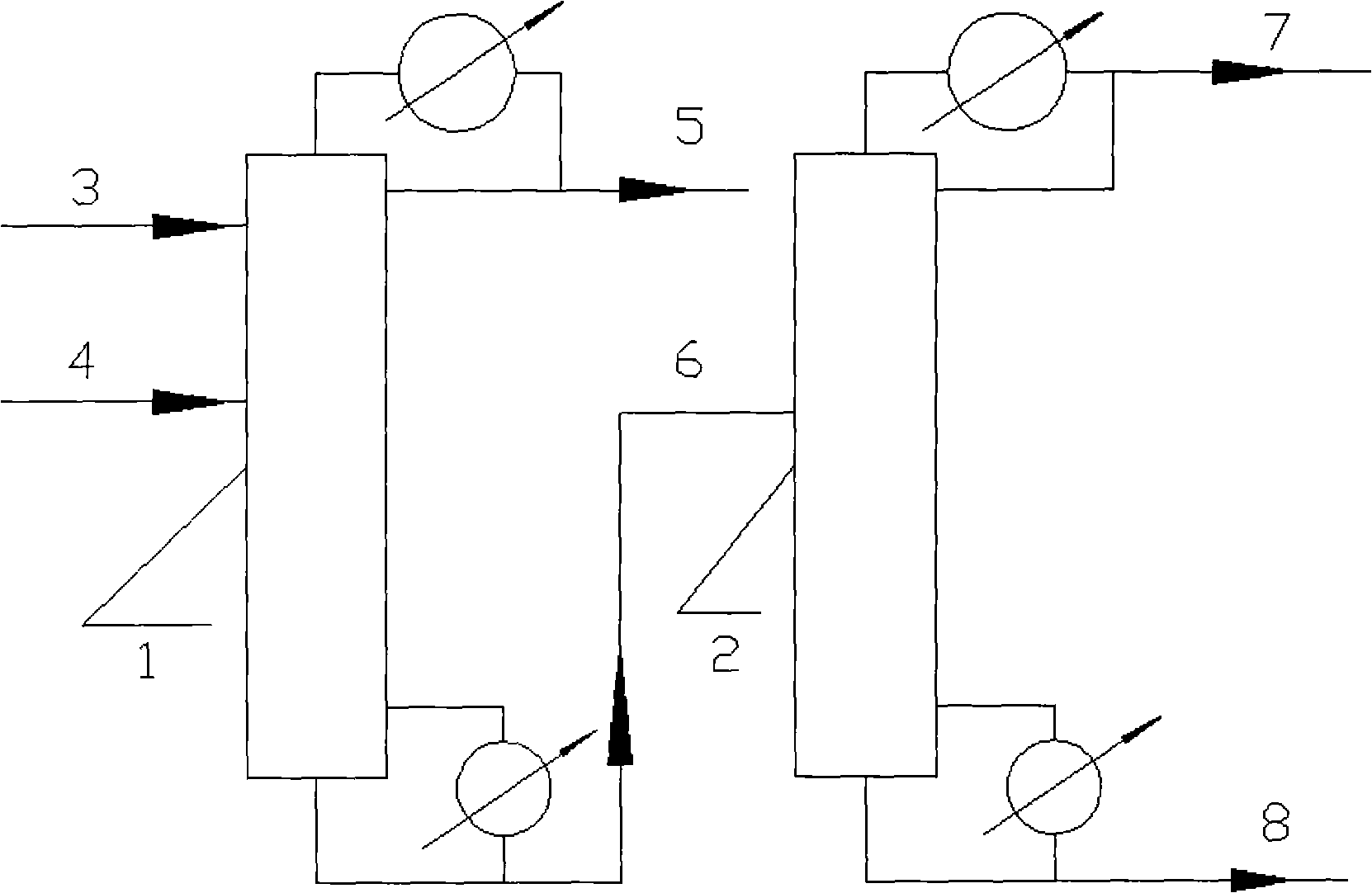

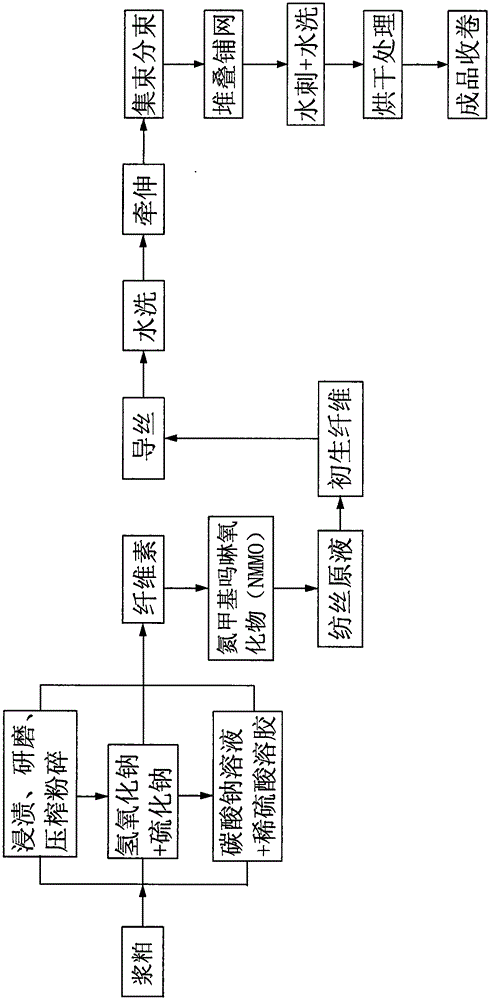

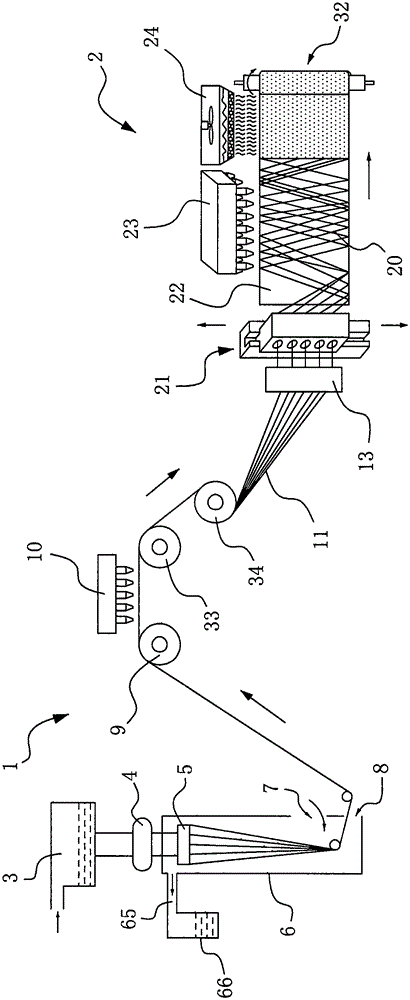

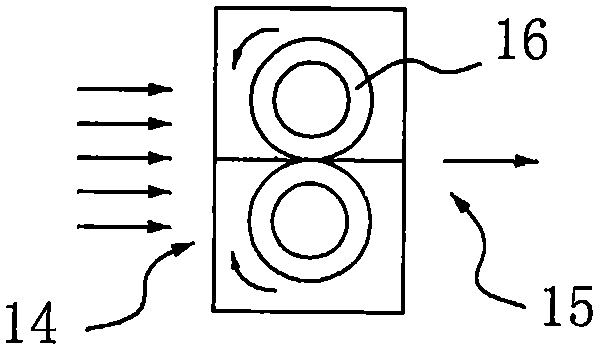

Technology and equipment for preparing artificial fiber filament non-woven fabric on basis of dry spinning technique

ActiveCN105350182AIncreased tangleEliminates the drying stepArtificial thread manufacturing machinesNon-woven fabricsFiber bundleEngineering

The invention discloses a technology for preparing an artificial fiber filament non-woven fabric on the basis of a dry spinning technique. The technology comprises a spinning technology including the steps of spinning solution preparing, liquid solidifying reacting and N-methylmorpholine oxide (NMMO) recycling, artificial fiber forming, washing and drafting and a non-woven fabric forming technology including the steps of web laying, wherein dried as-formed fiber bundles are evenly dispersed and laid on a web curtain of a web former to form filament fiber webs which are mutually stacked in a crossing mode; spunlace reinforcing; drying; rolling. Equipment is composed of a dry spinning device and a non-woven fabric forming device. According to the technology and the equipment, related steps in a traditional dry spinning technology are omitted, half-finished artificial fiber filaments are directly adopted for production of the non-woven fabric, and the traditional concept that finished fiber filaments are used for two times for non-woven fabric production is broken; the production cost is effectively saved, pollution to the environment in the technology process is reduced, and the production efficiency is improved.

Owner:QINGDAO UNIV

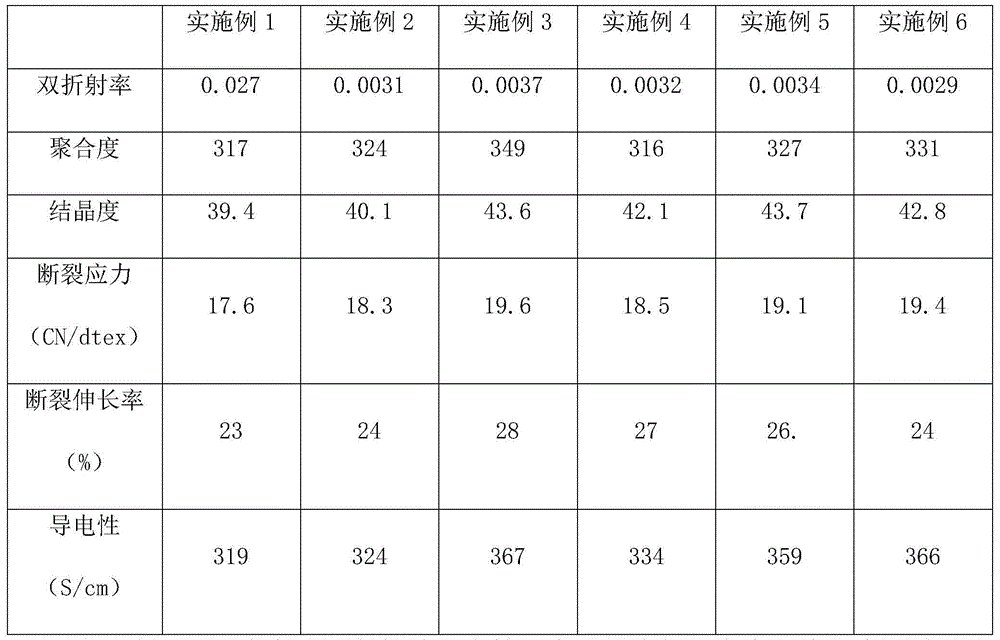

Carbon nanotube regenerated bamboo fibers and production method therefor

InactiveCN104878465AGood dispersionReduce reunionArtificial filaments from viscoseModified carbonViscose

The invention provides carbon nanotube regenerated bamboo fibers. The carbon nanotube regenerated bamboo fibers comprise hydrophilicity modified carbon nanotubes and regenerated bamboo fibers and are prepared by a viscose spinning process. A production method for the carbon nanotube regenerated bamboo fibers comprises the specific steps: (1) air-drying bamboo chips, then, submerging the bamboo chips in water for prehydrolysis, then, carrying out secondary cooking, then, carrying out pulp pulping, carrying out pulp washing, carrying out bleaching, carrying out neutralizing, carrying out impurity removal, carrying out pulping, and carrying out drying, so as to obtain regenerated bamboo fiber pulp; (2) submerging carbon nanotubes into a strongly acid solution, carrying out ultrasonic treatment for 5-10 hours at the temperature of 35 DEG C, cooling the solution to room temperature, then, filtrating to obtain filtrated residue, washing and filtrating the filtrated residue until the filtrate is neutral, and drying the filtrated residue so as to obtain the modified carbon nanotubes; (3) dispersing the modified carbon nanotubes into deionized water, carrying out ultrasonic dispersion, adding the dispersion into the regenerated bamboo fiber pulp, adding an aqueous solution of N-methyl morpholine, uniformly stirring so as to obtain a spinning stock solution, and obtaining the carbon nanotube regenerated bamboo fibers by the viscose spinning process. The carbon nanotube regenerated bamboo fibers prepared by the production method have the advantage that the mechanical properties and electrical conductivity of the fibers can be improved on the basis of not changing the comfort of the regenerated bamboo fibers.

Owner:SUZHOU WILDER IND & TRADE

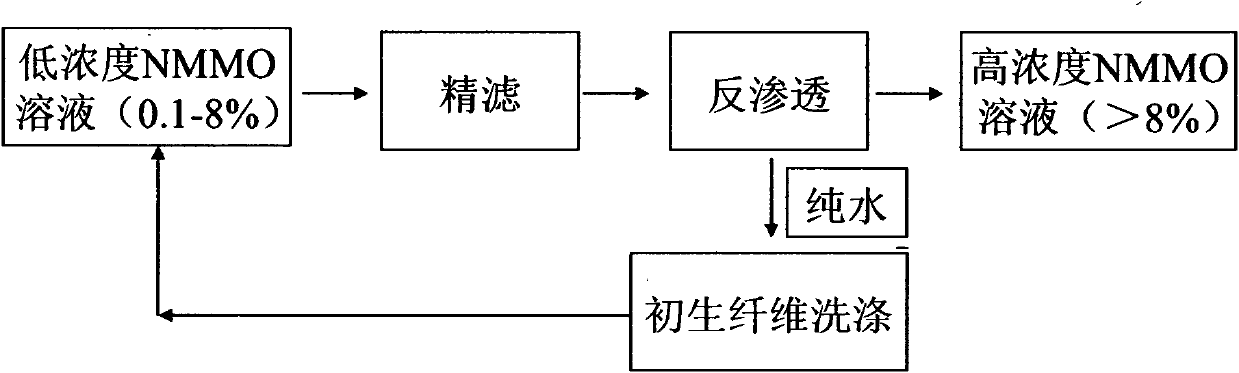

Recovery method of spinning waste liquor by means of concentrating

InactiveCN102167465ATake advantage ofRealize green productionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRecovery methodHigh concentration

The invention discloses a recovery method of spinning waste liquor by means of concentrating, which comprises the technical steps of: a. pretreating: pressurizing low-concentration NMMO (n-methylmorpholine oxide) solution with the weight percentage concentration of 0.1-8.0% to be the pressure of 0.2MPa under the water temperature condition of 20-35DEG C, and then being transported into a precision filter for pretreating by means of precision filtering; b. concentrating by means of reverse osmosis: feeding the pretreated filtered fluid by means of precision filtering into a reverse osmosis component for concentrating by means of the reverse osmosis, wherein the operation pressure is 0.7-6.0MPa when the reverse osmosis membrane component runs; and c. aftertreating: obtaining high-concentration NMMO solution with the weight percentage concentration which is more than 8.0% at an outlet of the concentrated water by means of the reverse osmosis, and feeding the high-concentration NMMO solution into a pressure-reducing distilling tower for further concentration, wherein pure water at the reverse osmosis pure water outlet is directly used for washing a nascent fiber, and the NMMO dissolvent quantity in the pure water is less than 0.1%.

Owner:TIANJIN POLYTECHNIC UNIV

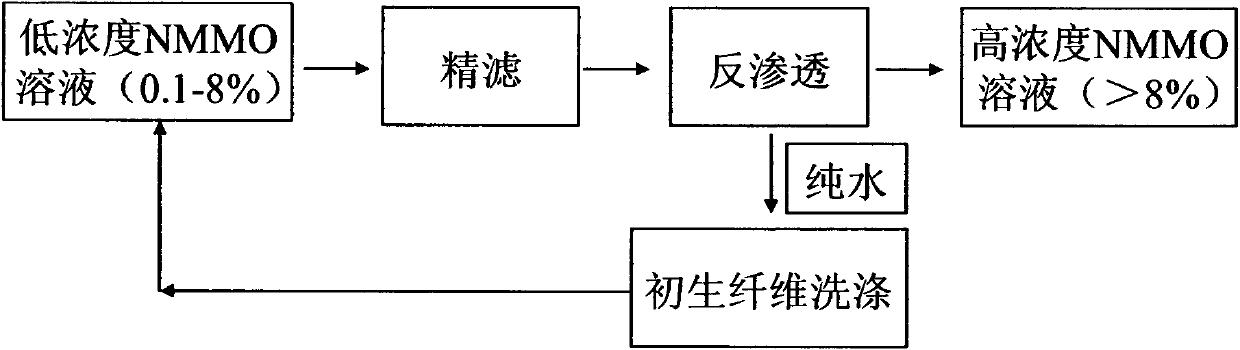

Nanometer microcrystalline cellulose preparation method

The present invention discloses a nanometer microcrystalline cellulose preparation method, which comprises: (1) adopting N-methylmorpholine-N-oxide and an ion liquid to treat microcrystalline cellulose; and (2) recovering the treatment agent. According to the present invention, the nanometer microcrystalline cellulose preparation method has the following advantages that: microcrystalline cellulose is adopted as a raw material, and can be extracted from plants, such that the source is wide, and the natural plant fiber utilization rate is substantially increased; the N-methylmorpholine-N-oxide and the ion liquid are subjected to coupling use, and the treatment is performed to obtain the fragmented nanometer microcrystalline cellulose; the N-methylmorpholine-N-oxide and the ion liquid can be recycled after being treated so as to reduce the nanometer microcrystalline cellulose production cost; and the nanometer microcrystalline cellulose preparation process has characteristics of simpleness, easy performing and green environmental protection, and no corrosion on equipment, environmental pollution and other problems exists.

Owner:JIANGSU UNIV OF SCI & TECH

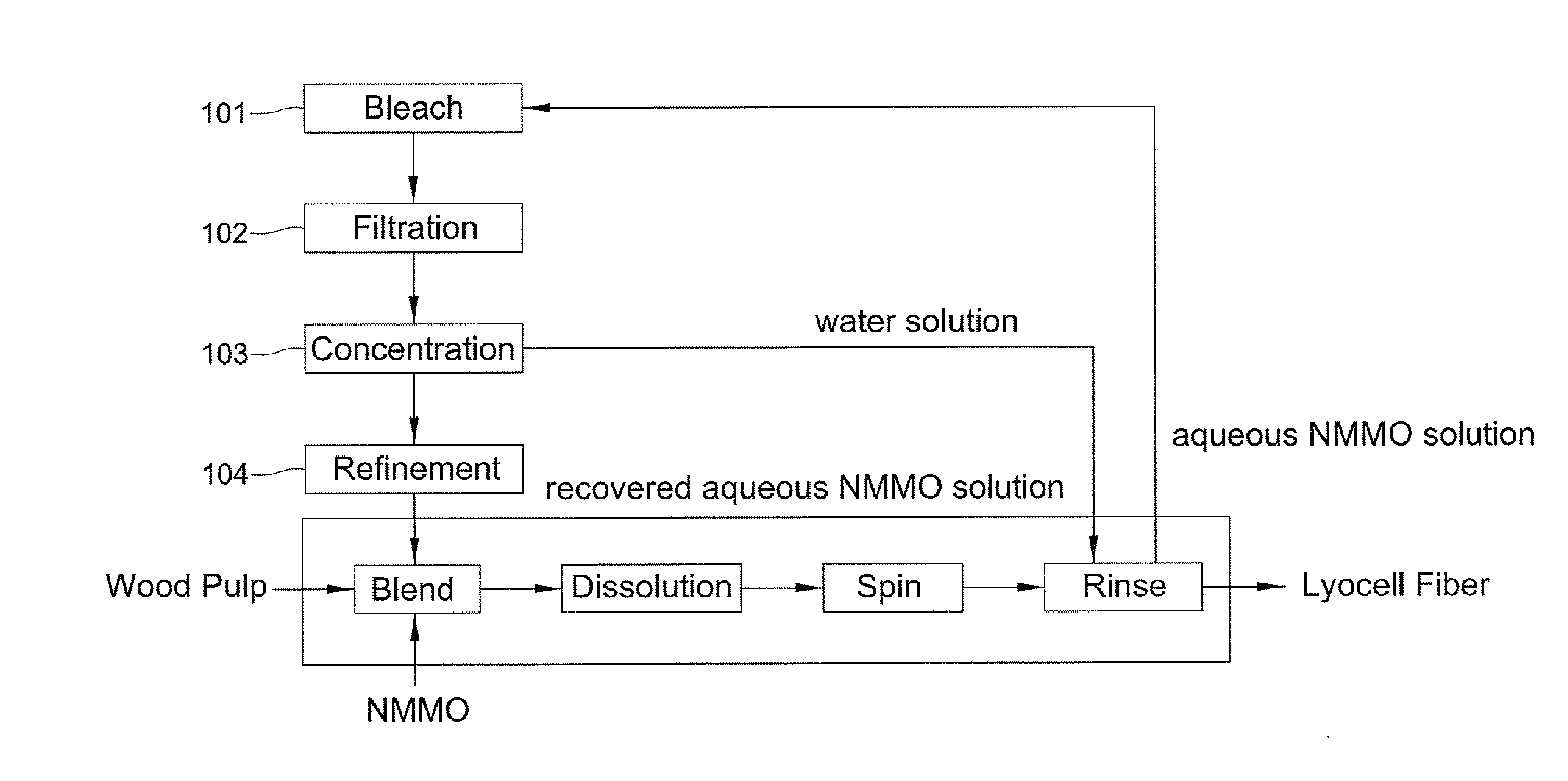

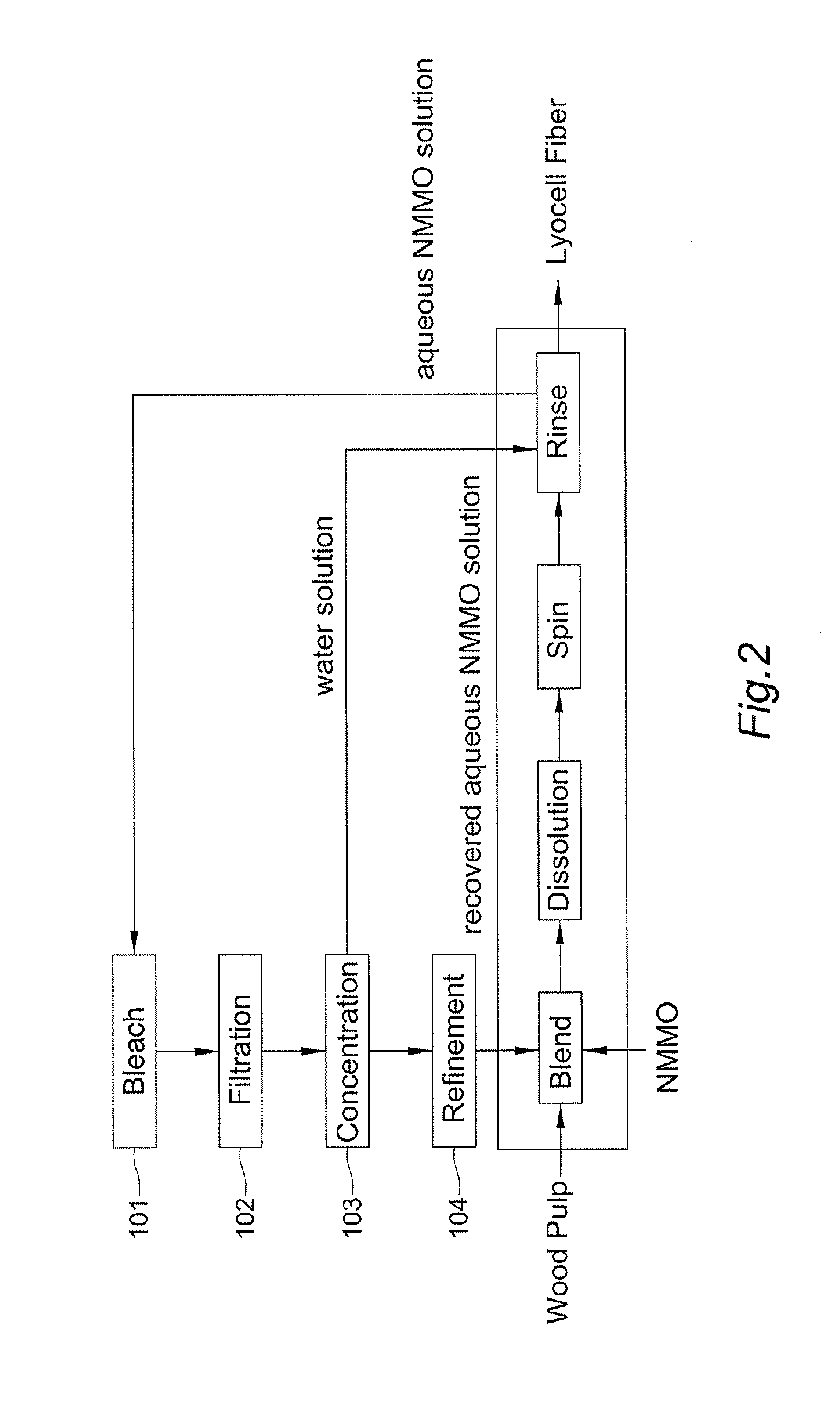

Method of Recovering Aqueous N-Methylmorpholine-N-Oxide Solution Used in Production of Lyocell Fiber

InactiveUS20140008577A1Facilitate purityReduce material costsArtificial filament recoveryTextile/flexible product manufactureFiberEnvironmental resistance

A method of recovering aqueous N-Methylmorpholine-N-Oxide solution used in production of Lyocell fiber comprises following steps. Bleach means for decoloring coloration in aqueous NMMO solution via alternate blow-mixing adsorption mode and static suspending adsorption mode reiteration. Filtration means for purifying the activated carbon powder and impurities by two filtering stages of first coarse filtering stage and second fine filtering stage. Concentration means for intensifying aqueous NMMO solution to obtain a condensed aqueous solution without NMMO solvent and a concentrated aqueous solution with NMMO solvent respectively by a sequential multi-stage evaporating system. Refinement means for purifying aqueous NMMO solution with promoting purity of concentrated aqueous solution to obtain required recovered aqueous solution by adding suitable agents in the redox reactions involved. Owing to streamlining and simplicity, the method not only has better competitiveness from promoted recovery cost, efficiency and quality but also meets regulations of environmental protection.

Owner:ACELON CHEM & FIBER

Preparation method of anti-bacterial and mite-proof sulfur-containing viscose fiber

ActiveCN105113033AGood long-lasting antibacterial and anti-mite effectEasy to useArtificial filaments from viscoseFiberAir filter

The invention discloses a preparation method of an anti-bacterial and mite-proof sulfur-containing viscose fiber. The method comprises steps as follows: an NMMO (N-methylmorpholine-N-oxide) spinning solvent with the certain moisture content is prepared in advance at a certain temperature; then cellulose powder with the certain mass fraction is added to the prepared spinning solvent, the mixture is stirred for a certain period while the certain temperature is kept, cellulose is fully dissolved, and a cellulose spinning solution is prepared; the cellulose spinning solution is quickly cooled to the specific temperature, certain sublimed sulfur is mixed to be used as an anti-bacterial and mite-proof functional component, blending and stirring are performed, and an evenly-dispersed sulfur-containing cellulose spinning solution is obtained; water is used as a solidification liquid, the spinning solution is extruded into the solidification liquid from a spinning orifice plate, the spinning solution is gradually lengthened and fine-drawn during quick solidification, and the sulfur-containing viscose fiber with anti-bacterial and mite-proof functions is prepared. The method solves problems that existing preparation methods are high in cost and low in safety and washability is poor, the functional component of the prepared fiber is evenly distributed, and the fiber is washable, safe, lasting in anti-bacterial and mite-proof effect and widely applicable to production of underwear, bedding and air filter materials.

Owner:河源市兴业卓辉实业有限公司

Method for preparing antibacterial nano-silver fiber with electrostatic spinning method

ActiveCN103668514AEasy to prepareLow costMonocomponent cellulose artificial filamentArtifical filament manufactureFiberHigh pressure

A method for preparing antibacterial nano-silver fiber with an electrostatic spinning method comprises steps as follows: 1), preparation of a spinning solution : a cotton fiber raw material and N-methylmorpholine oxide are mixed and dissolved at the temperature of 90-110 DEG C and stirred for 10-30 min, the cotton spinning solution is obtained, then, silver phosphate is added, and the mixture is stirred, so that silver phosphate is uniformly dispersed in the cotton spinning solution ; and 2), electrostatic spinning : the spinning solution prepared from the step 1 is added into a syringe with a needle, the needle is connected with a positive electrode of a high-voltage power supply, a grounded aluminum foil is paved under the syringe, the distance between the aluminum foil and the needle is 5-15 cm, the spinning solution is pulled into nanoscale fiber under the action of electric field force, and the nano-silver antibacterial fiber is obtained. According to the method, nano-silver and cotton fiber are blended and spun to obtain the fiber with an antibacterial function, the preparation method is simple, and the cost is low.

Owner:JIANGSU HONGSHUN SYNTHETIC FIBER TECH

Aqueous coating material, its preparation and use

ActiveUS20090270548A1Easy to prepareOutstanding performance propertyFilm/foil adhesivesPolyurea/polyurethane coatingsSulfolaneGlycerol

Disclosed herein is an aqueous coating material comprising (A) at least one polyurethane which is ionically stabilized, nonionically stabilized, or a combination thereof, and which is saturated, unsaturated, grafted with olefinically unsaturated compounds, or a combination thereof, (B) at least one wetting agent or dispersant; and (C) at least one organic solvent selected from the group consisting of dimethyl sulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexyl glycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerol, solutions of trimethylolpropane, solutions of pentaerythritol, solutions of sorbitol, reactive polyether polyols with a number-average molecular weight of 110 to 6000 daltons and a hydroxyl number of 25 to 1000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerol ethoxylate, ethyl 3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl)piperidine, N-methylmorpholine, N-(2-hydroxyethyl)morpholine, N-acetylmorpholine, N-cyclohexylpyrrolidone, N-octyl-2-pyrrolidone, and a combination thereof. Also disclosed is a process for preparing the foregoing aqueous coating material.

Owner:BASF COATINGS GMBH

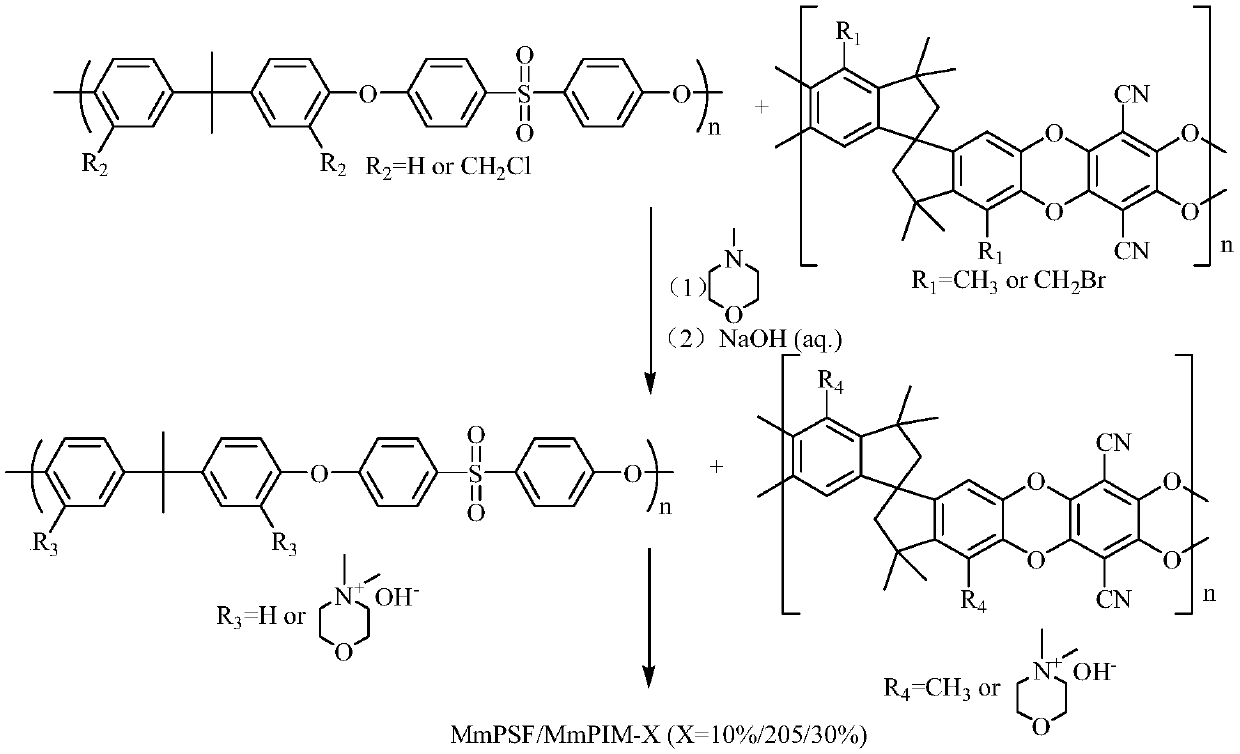

A blended anion exchange membrane and a preparation method thereof

ActiveCN109585888AImprove conductivityGood chemical stabilityFinal product manufactureFuel cellsFuel cellsIon-exchange membranes

A blended anion exchange membrane and a preparation method thereof belong to the field of fuel cell solid electrolyte membranes. The membrane material regards chloromethylated polysulfone as a polymerbase, bromomethylated PIM-1 as a blended component, and N-methylmorpholine as an ionic group. The two polymers are simultaneously subjected to a quaternization process to prepare a novel blended anion exchange membrane. The membrane blended with BrPIM has lower IEC and higher hydroxide ion conductivity and better dimensional stability than pure MmPSF membranes. In the present invention, the strong interaction force in the cyano-cyano and cyano-morpholine formed by the presence of cyano groups in the PIM polymer unit are used to maintain good dimensional stability of the membrane; and PIM rigid twisted main chains are used to construct micropores in the membrane to increase conductivity. The anion membrane prepared by the invention has the characteristics of controllability, relatively high alkali resistance stability, dimensional stability and electrical conductivity, and is important for exploring the influence of the free volume in the membrane on the electrical conductivity.

Owner:DALIAN UNIV OF TECH

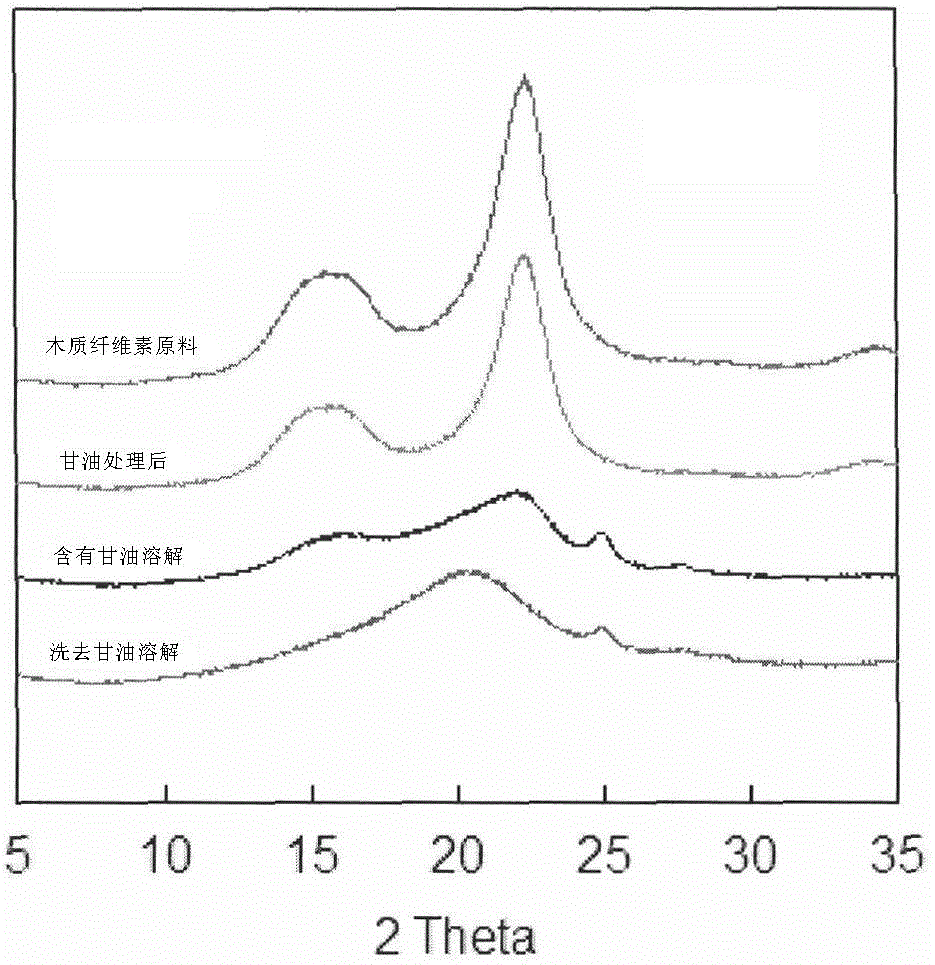

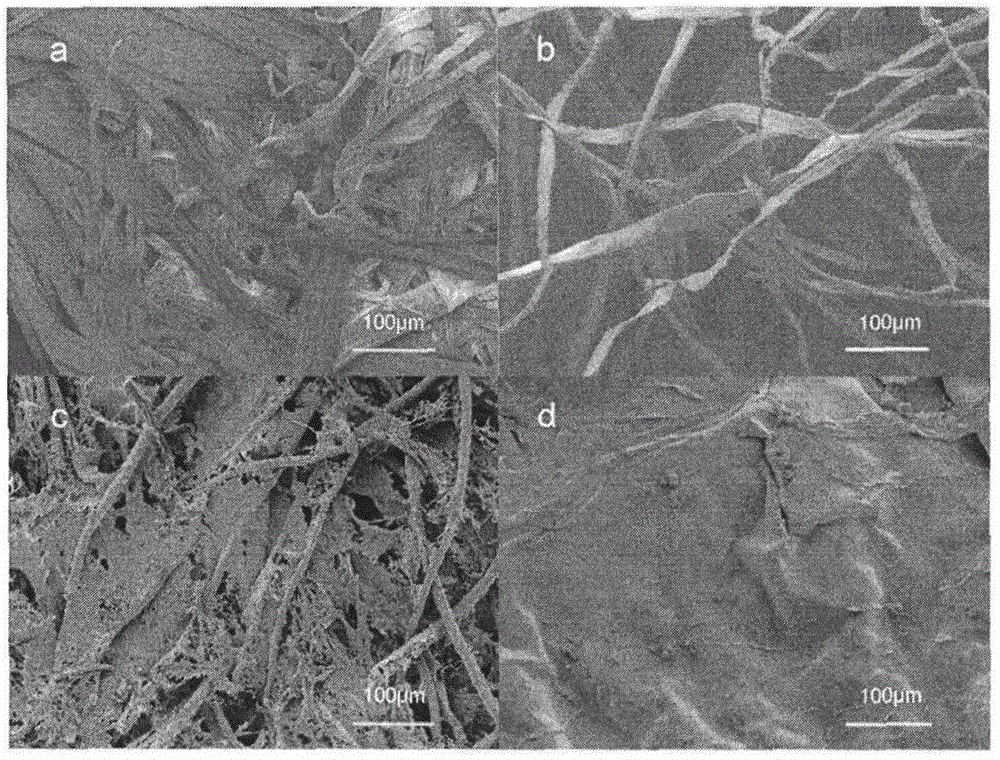

Dissolution method of lignocellulose

The invention relates to a dissolution method of lignocellulose with different lignin contents, belongs to the fields of lignocellulose processing and application and aims at providing a lignocellulose dissolution process which is simple, convenient and low in production cost. The method comprises the steps of adding the dried lignocellulose to a polyalcohol solution, conducting heating and stirring for 2-3 hours, then conducting mechanical pretreatment, obtaining a sample containing glycerine or a dry sample from which glycerine is washed away, mixing the sample with an N-methylmorpholine-N-oxide-hydration solution, conducting stirring and dissolution at the temperature of 85 DEG C, and obtaining a lignocellulose solution. The stable and homogeneous lignocellulose solution can be obtained no matter whether the glycerine is contained in a finished product obtained through dissolution or not. According to the dissolution method of the lignocellulose, through process improvement, N-methylmorpholine-oxide which only dissolves pure cellulose is applied to dissolution of a lignocellulose raw material containing lignin, and the scope of traditional pure cellulose dissolution is broken through. By means of the dissolution method, activation pretreatment is conducted on the lignocellulose, the crystal form of the lignocellulose raw material is not destroyed, meanwhile, production cost is lowered, and the process method is simplified.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com