Aqueous coating material, method for the production thereof, and use thereof

A water-based coating, unsaturated technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of tributyl phosphate toxicity and other problems, and achieve the effect of easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0082]Preparation of gray water-based base coat material 1

[0083] To better assess any film defects exhibited, a gray waterborne basecoat material prepared according to the following instructions was used:

[0084] Mixture 1a:

[0085] 26 parts by weight of an inorganic thickener (sodium magnesium phyllosilicate, 3 wt% concentration in water) is installed in the dissolver. To this initial charge are then added with stirring 30 parts by weight of deionized water, 107.5 parts by weight of butyl glycol, 4.5 parts by weight according to German patent application DE 44 37 535 A1, page 7, line 55-page , the polyurethane-modified polyacrylate prepared in line 23, and 0.6 parts by weight of the commercial defoamer Nopco at a concentration of 20.5 wt% Solution of DSX 1550. This gives mixture 1a.

[0086] Mixture 1b:

[0087] Separately, 3.2 parts by weight of an aqueous polyester resin dispersion prepared according to Example D of German patent application DE 4009858A1, colu...

Embodiment 1-7

[0108] Embodiment 1-7 (the present invention) and C1 (comparison)

[0109] Preparation of water-based base coat material 2-8 (embodiment 1-7) and water-based base coat material C1 (embodiment C1)

[0110] Water-based base coat material C1:

[0111] Aqueous undercoat material C1 was prepared by adding 0.5 wt% of N-methylpyrrolidone to aqueous undercoat material 1 obtained in Preparation Example 1.

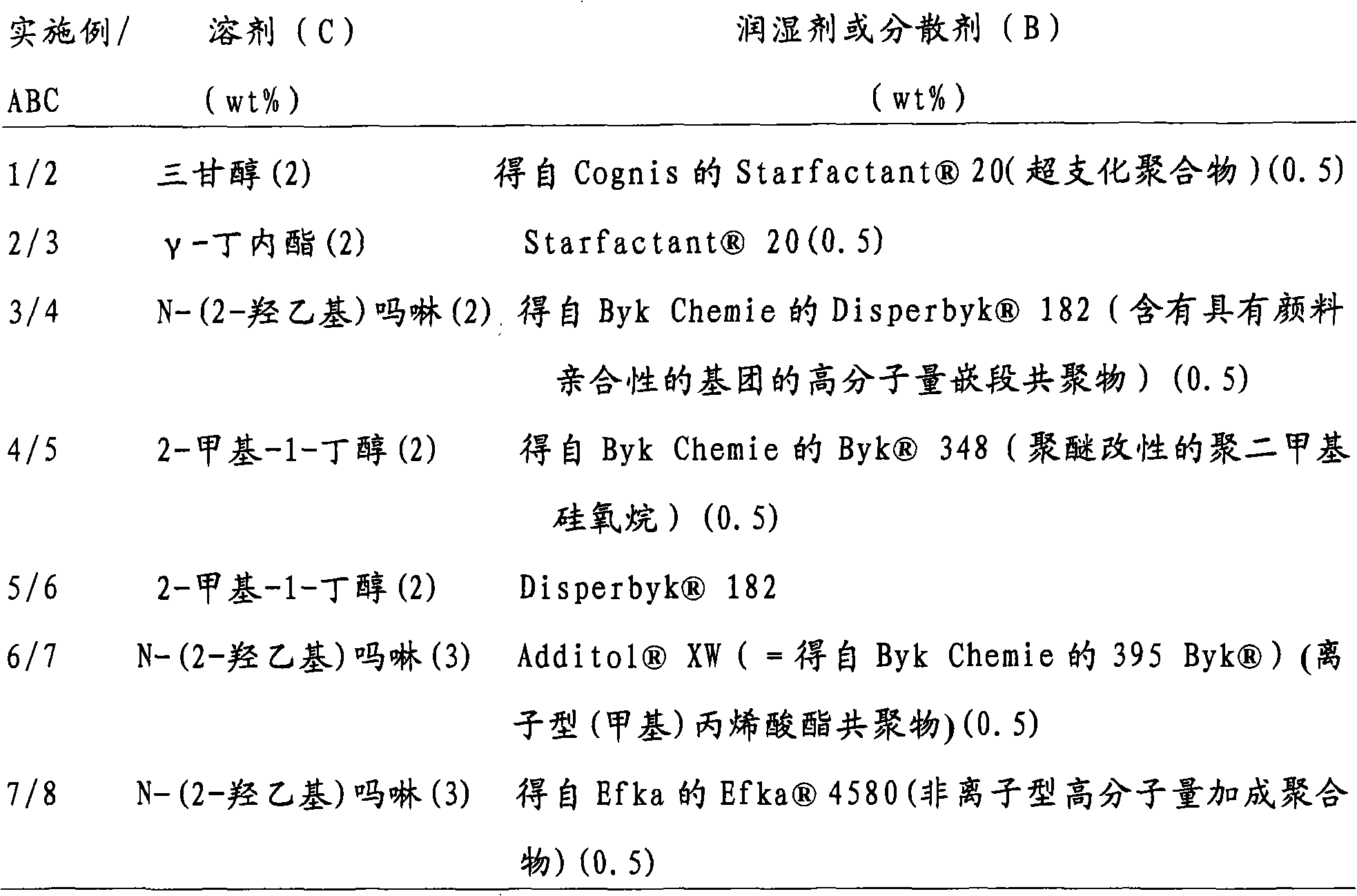

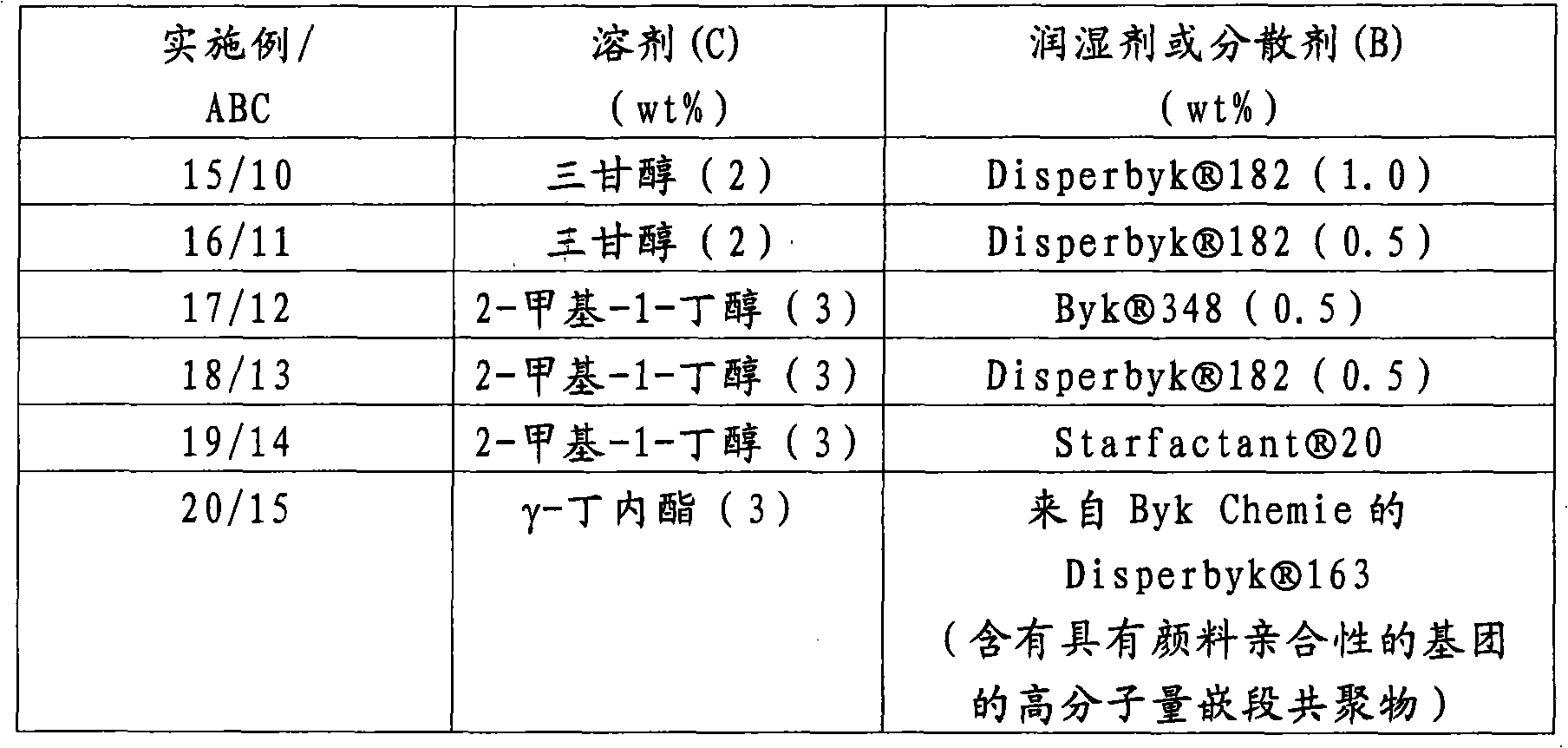

[0112] Aqueous undercoat materials 2-8 were prepared by adding the organic solvent (C) and wetting agent or dispersant (B) specified in Table 1 to the aqueous undercoat material 1 obtained in Preparation Example 1.

[0113] Table 1: Composition of the waterborne basecoat materials (ABC) of Examples 1-7

[0114]

[0115] The weight percentages in Table 1 are based on the corresponding waterborne basecoat material.

Embodiment 8-14

[0116] Embodiment 8-14 (the present invention) and C2 (comparison)

[0117] Preparation of Multicoat Paint System 2-8 (Examples 8-14) and Multicoat Paint System C1 (Example C2)

[0118] The multicoat coating system C1 of Example C2 was prepared using the aqueous basecoat material C1 from Example C1.

[0119] In the manner shown in Table 2, the multicoat coating systems 2-8 of Examples 8-14 were prepared using the aqueous basecoat materials 2-8 from Examples 1-7.

[0120] Table 2: Multicoat Coating Systems 2-8 of Examples 8-14

[0121] water-based base coat material

[0122] Spray blocking was measured by preparing multicoat paint systems C1 and 2-8 according to the following general guidelines:

[0123] A steel plate with a size of 30 x 50 cm and with a surface coating was sprayed for 30 seconds from a distance of 1.5 meters with a spray of an aqueous basecoat material. After a flash off time of 2 minutes, the aqueous basecoat material was spray coated at 1.5 cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com