Method of Recovering Aqueous N-Methylmorpholine-N-Oxide Solution Used in Production of Lyocell Fiber

a technology of lyocell fiber and aqueous solution, which is applied in the field of recovery method of lyocell fiber recovery solvent, can solve the problems of high processing cost, large amount of lyocell fiber, and high cost of primary nmmo dissolving solvent, so as to reduce material cost, promote purity of concentrated aqueous solution, and reduce waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment example 1

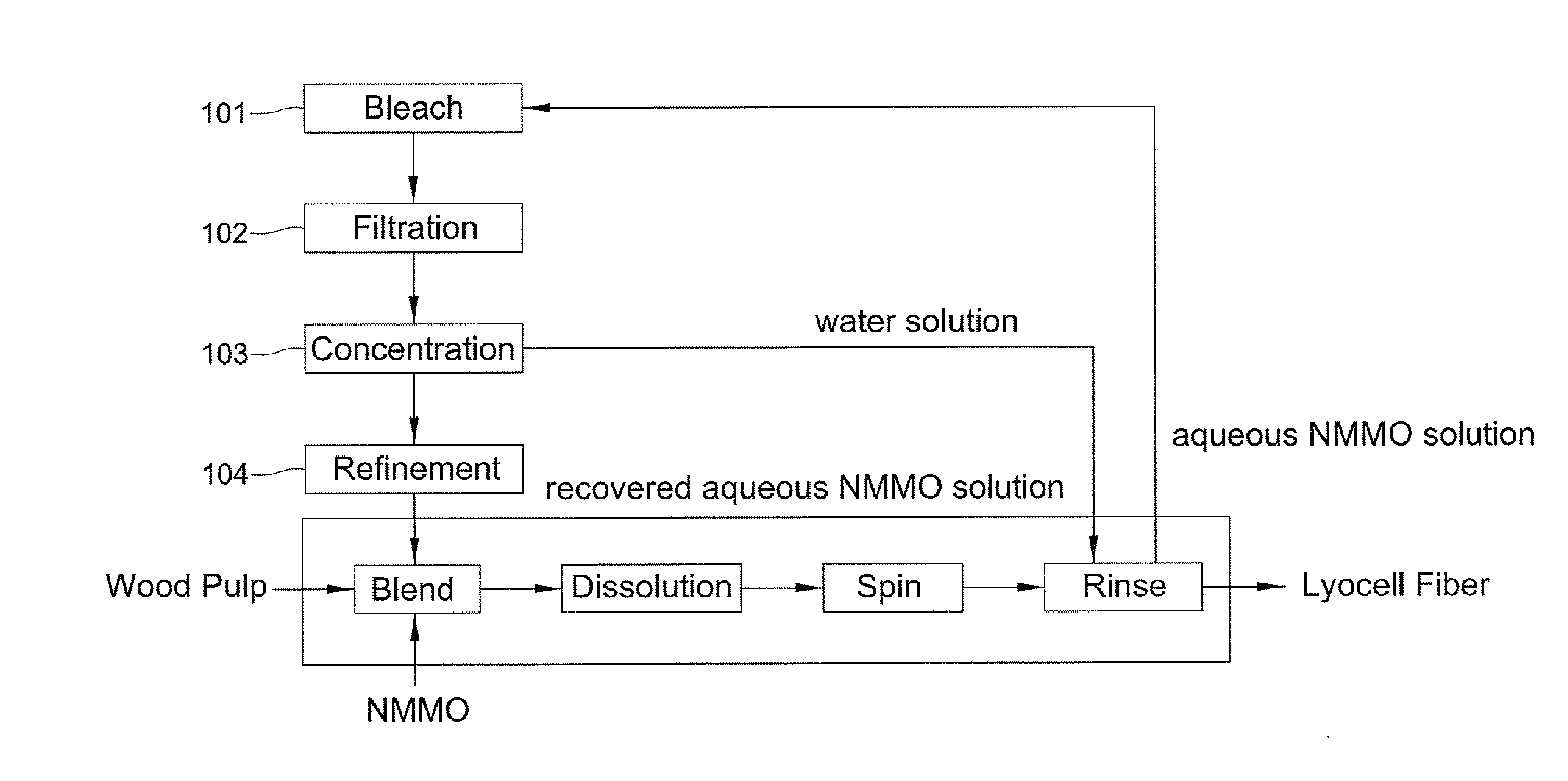

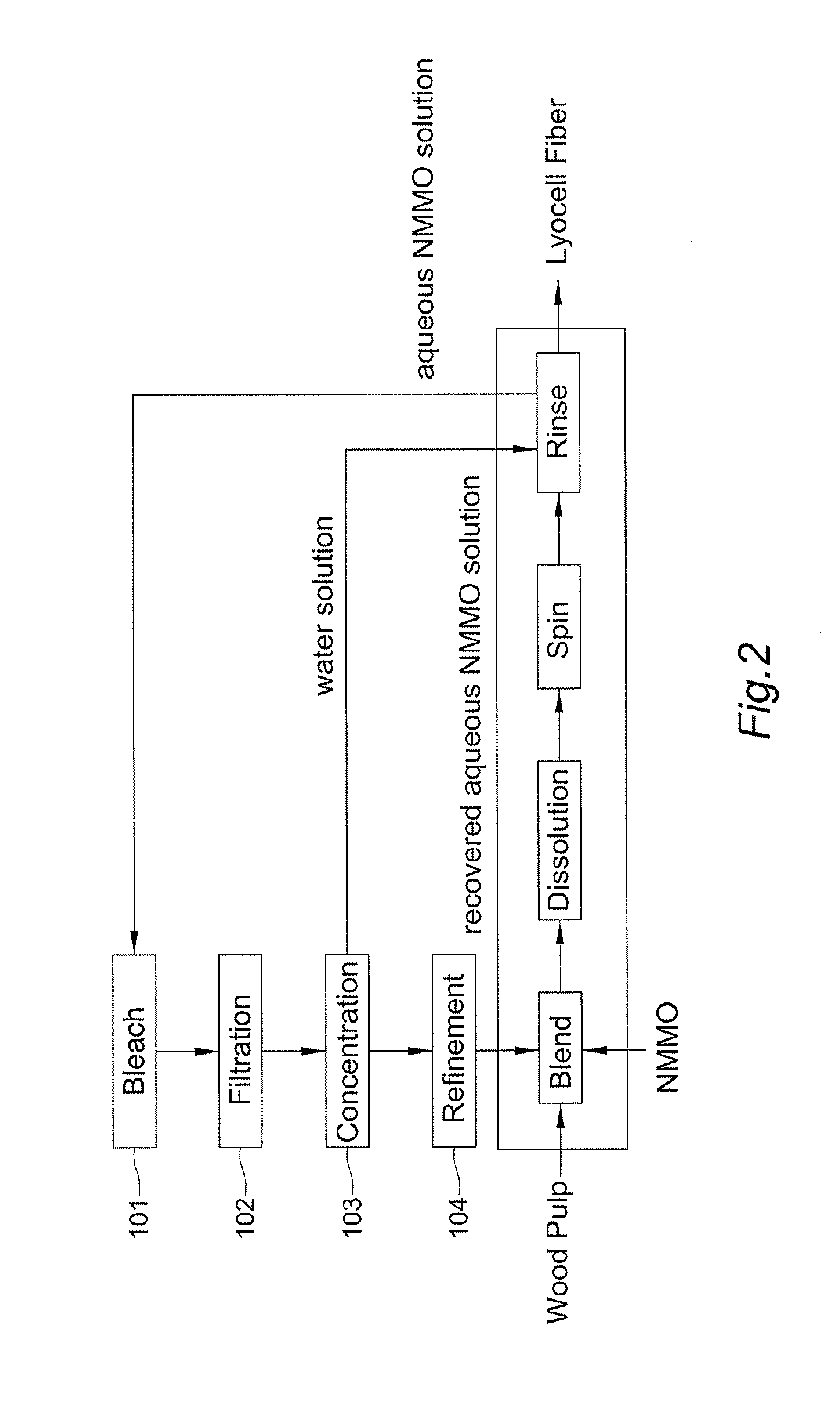

[0044]Please refer to FIG. 3, which is a schematic diagram of a preferred exemplary embodiment in a bleach step showing the addition of activated carbon powder therein in association with a disposition of an agitation blower for the present invention. After previous processes of bleach (step 101) and filtration (step 102), the collected aqueous NMMO solution 1 of the Lyocell fiber will contain NMMO in 3.92 wt % weight percentage. Then, the collected aqueous NMMO solution 1 is input into the first evaporating vessel 10 via input pipe 50 by orderly passing third steam tank 31, second steam tank 21 and first steam tank 11 as well as heat exchanger 6 and input pump 51. Because the aqueous NMMO solution 1 has orderly passed third steam tank 31, second steam tank 21 and first steam tank 11, the steam evaporated by the recovered aqueous solution at the outlets of the first evaporating vessel 10, second evaporating vessel 20 and third evaporating vessel 30 can be fed back to the first evapo...

embodiment example 2-9

[0070]The processing procedure of bleach step for preferred exemplary embodiment example 2-9 in the present invention is the same as that for preferred exemplary embodiment example 1 but with following differences.

[0071]Outlet Concentration: In range of 10-20 wt % for the recovered aqueous NMMO solution 1 of the first evaporating vessel 10 (measured by first concentration meter 15).

[0072]Outlet Concentration: In range of 22-38 wt % for the recovered aqueous NMMO solution 1 of the second evaporating vessel 20 (measured by second concentration meter 25).

[0073]For other operating parameters such as outlet concentration (OC), degree of vacuum (DV) and operating temperature (OT), they are listed in the Table-1. Moreover, for other key operating parameters such as inlet quantity before recovery (IQBR), outlet quantity after recovery (OQAR), concentration before recovery (CnBR) and concentration after recovery (CnAR), they are also listed in the Table-2. Thus, the recovery efficiency (RVEf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Dimensionless property | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com