Nanometer microcrystalline cellulose preparation method

A technology of microcrystalline cellulose and nanocrystalline, which is applied in the fields of biochemical engineering and chemical engineering, can solve problems such as low efficiency, environmental pollution, and low production rate, and achieve simple and easy preparation process, reduce production cost, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

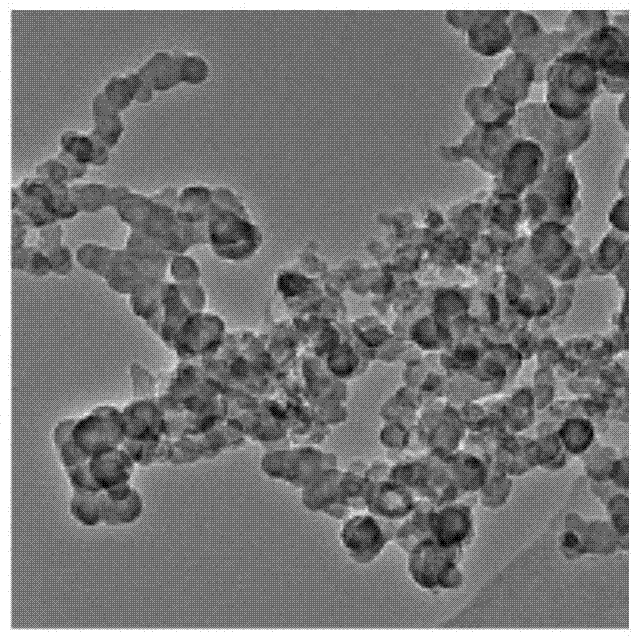

Image

Examples

Embodiment 1

[0020] Example 1: First, take 1 g of microcrystalline cellulose and add 100 g of an aqueous solution with a mass fraction of 10% N-methylmorpholine-N-oxide, and heat and stir at 50°C for 20 minutes to fully swell the fibers of the microcrystalline cellulose , to obtain a mixed solution; secondly, after treating the mixed solution with a 60w ultrasonic wave for 30 minutes, add 10 g of hydrogen phosphate ionic liquid, stir evenly, and then use a 60w ultrasonic wave for 30 minutes; then, add water and stir evenly, and the amount of water added is N-methyl? 0.5 times the volume of the morphine-N-oxide solution, the mixed solution naturally settles and is divided into upper and lower layers, collects the lower layer, removes impurities, and freeze-dries to obtain nano-microcrystalline cellulose; finally, the treatment agent is recovered, and the supernatant is taken, Centrifuge at 10000r / min for 5min, distill under reduced pressure at 80°C for 30min to remove water and low-boiling i...

Embodiment 2

[0021] Example 2: First, take 1 g of microcrystalline cellulose and add 200 g of an aqueous solution with a mass fraction of 50% N-methylmorpholine-N-oxide, and heat and stir at 70°C for 5 minutes to fully swell the fibers of the microcrystalline cellulose , to obtain a mixed solution; secondly, after treating the mixed solution with an 80w ultrasonic wave for 25min, add 5g of bisulfate ionic liquid, stir evenly, and then use an 80w ultrasonic wave for 25min; The volume of -N-oxide solution is equal, the mixed solution naturally settles and is divided into upper and lower layers, the lower layer is collected, impurities are removed, and nano-microcrystalline cellulose is obtained by freeze-drying; finally, the treatment agent is recovered, and the supernatant is taken, 10000r / min Centrifuge for 5 minutes, distill under reduced pressure at 90°C for 30 minutes; heat and distill under reduced pressure at 150°C for 30 minutes to remove water, and sublimate N-methylmorpholine-N-oxid...

Embodiment 3

[0023] First, take 1 g of microcrystalline cellulose and add it to 100 g of an aqueous solution with a mass fraction of 80% N-methylmorpholine-N-oxide, and heat and stir at 60°C for 10 minutes to fully swell the fibers of microcrystalline cellulose to obtain a mixed solution ; Secondly, after treating the mixed solution with a 90w ultrasonic wave for 20 minutes, add 8g of hydrogen phosphate ionic liquid, stir evenly, and then use a 90w ultrasonic wave for 20min; then, add water and stir evenly, and the amount of water added is N-methylmorpholine-N- 0.6 times the volume of the oxide solution, the mixed solution naturally settles and is divided into upper and lower layers, collects the lower layer, removes impurities, freeze-dries to obtain nano-microcrystalline cellulose; finally, recovers the treatment agent, takes the supernatant, and centrifuges at 10,000r / min 5min, vacuum distillation at 85°C for 30min, heating and vacuum distillation at 145°C for 30min to remove water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com