Patents

Literature

91 results about "Cellulose preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing effective bacterial cellulose-containing formulations

A new method to produce formulations of bacterial cellulose that exhibit improved viscosity-modifying properties particularly with low energy applied to effectuate viscosity changes therewith is provided. Such a method includes the novel co-precipitation with a water soluble co-agent that permits precipitation in the presence of excess alcohol to form an insoluble fiber that can than be utilized as a thickener or suspension aid without the need to introduce high energy mixing. Such bacterial cellulose properties have been available in the past but only through highly labor and energy intensive processes. Such an inventive method as now proposed thus provides a bacterial cellulose-containing formulation that exhibits not only properties that are as effective as those for previous bacterial celluloses, but, in some ways, improvements to such previous types. Certain end-use compositions and applications including these novel bacterial cellulose-containing formulations are also encompassed within this invention.

Owner:CP KELCO U S INC

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Bacterial cellulose-containing formulations

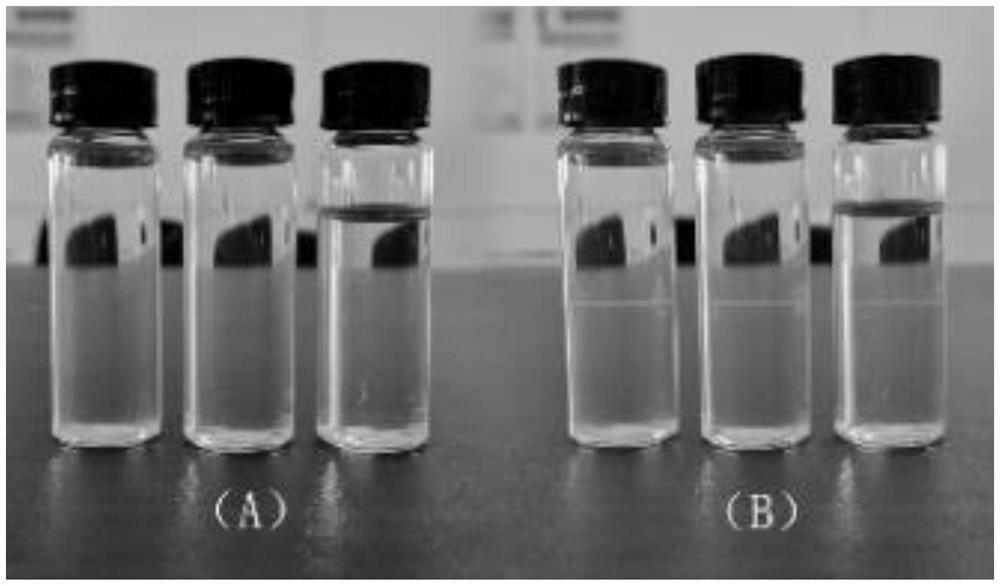

ActiveUS20070197779A1Need for networkReserved functionNatural cellulose pulp/paperStarch adhesivesAlcoholHigh energy

A new method to produce formulations of bacterial cellulose that exhibit improved viscosity-modifying properties particularly with low energy applied to effectuate viscosity changes therewith is provided. Such a method includes the novel co-precipitation with a water soluble co-agent that permits precipitation in the presence of excess alcohol to form an insoluble fiber that can than be utilized as a thickener or suspension aid without the need to introduce high energy mixing. Such bacterial cellulose properties have been available in the past but only through highly labor and energy intensive processes. Such an inventive method as now proposed thus provides a bacterial cellulose-containing formulation that exhibits not only properties that are as effective as those for previous bacterial celluloses, but, in some ways, improvements to such previous types. Certain end-use compositions and applications including these novel bacterial cellulose-containing formulations are also encompassed within this invention.

Owner:CP KELCO U S INC

Method for producing seaweed protein feed through synergistic effect of enzymolysis and fermentation

InactiveCN103549130AImprove conversion utilizationImprove enzymatic hydrolysis efficiencyAnimal feeding stuffDrug biological activityFermentation

The invention discloses a method for producing a seaweed protein feed through the synergistic effect of enzymolysis and fermentation. The method comprises the steps of fully mixing seaweed residue (the water content is 38%) and a feed enzyme preparation according to a certain proportion and performing the enzymolysis for 4-7h with the pH of 6.2-7.0 at the temperature being 35-45 DEG C to obtain a seaweed residue-feed enzyme preparation mixture; inoculating compound microorganisms and performing solid fermentation. The method has a simple process and is easy to operate; an external source is added to degrade a cellulose preparation to produce nutrition beneficial to microbial growth through the enzymolysis and make up the deficiency of enzyme produced by using the compound microorganisms, so as to stabilize the solid fermentation process and the product quality, greatly reduce the content of cellulose and increase the protein content; the seaweed protein feed is rich in multiple minerals, bioactive constituents and unknown somatomedin, and can be used as a protein feed for livestock and poultry and an aquatic feed; the method provides a technical support for growing tensions on developing novel protein resources and relieving a feed protein source.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES +1

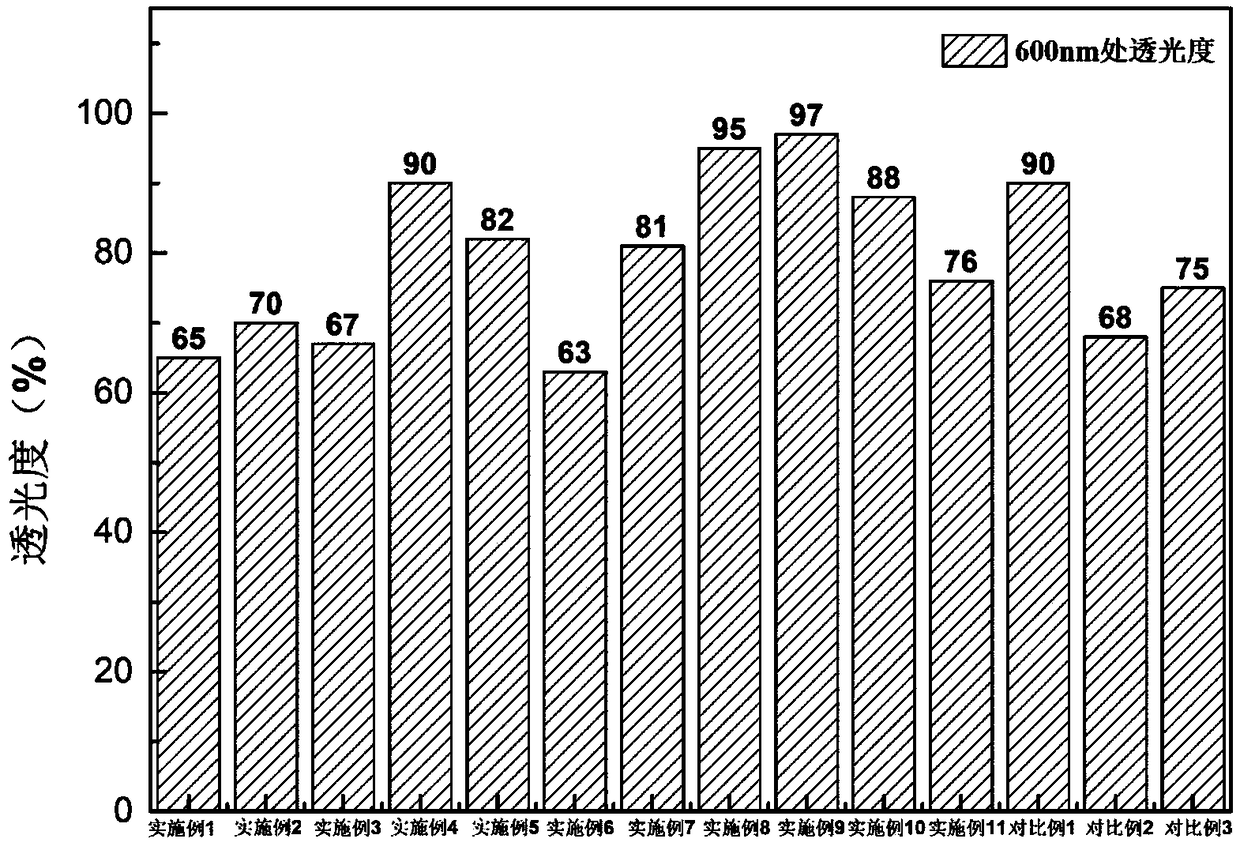

Separating and analyzing method for high purity cellulose without pollution

The invention relates to a separation and analyzing method for high purity cellulose without contamination, it uses wood fiber as material; it decomposes the wood cellulose and semi-cellulose in system with acetic acid and nitric acid but without chlorine and contamination, acquires the cellulose with high purity. The invention uses acetic acid and nitric acid as catalyst, the weight percentage density of acetic acid is 80%, the weight of nitric acid is 1-8% of the acetic acid weight, they are processed for 18-22 minutes in 100-120deg.C, separates them and acquires the cellulose preparations; then carries on detection to the cellulose preparations with special viscosity, molecular weight, FT-IR, CP-MAS13C-NMR and energetics analysis. The process is simple and quick, has no contamination, the cellulose has a high purity, which can be applied to the separation and analysis of cellulose in wood fiber material.

Owner:SOUTH CHINA UNIV OF TECH

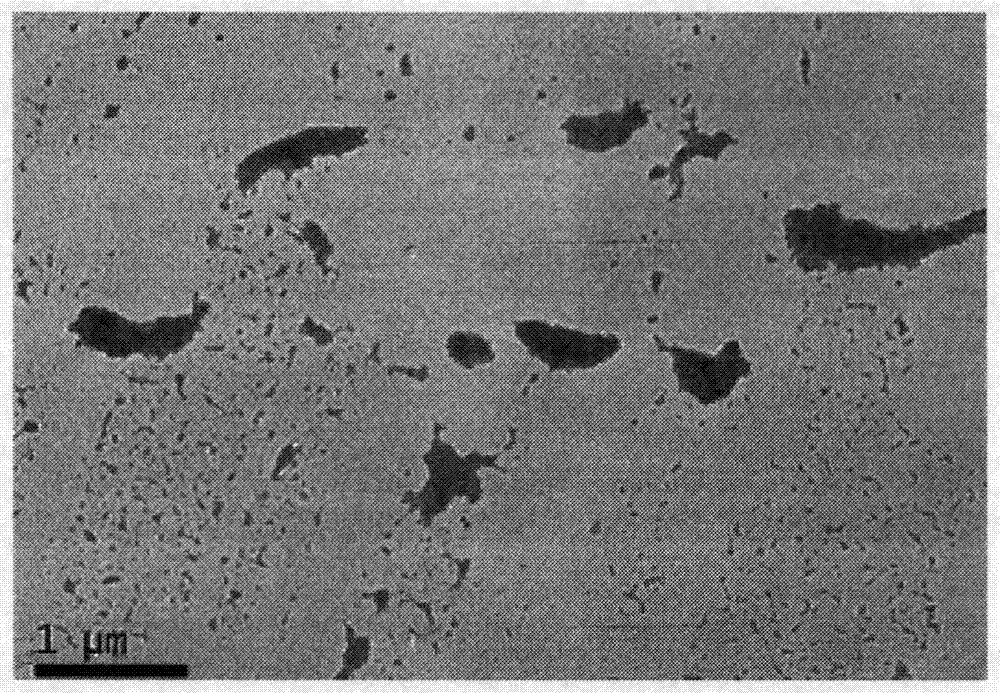

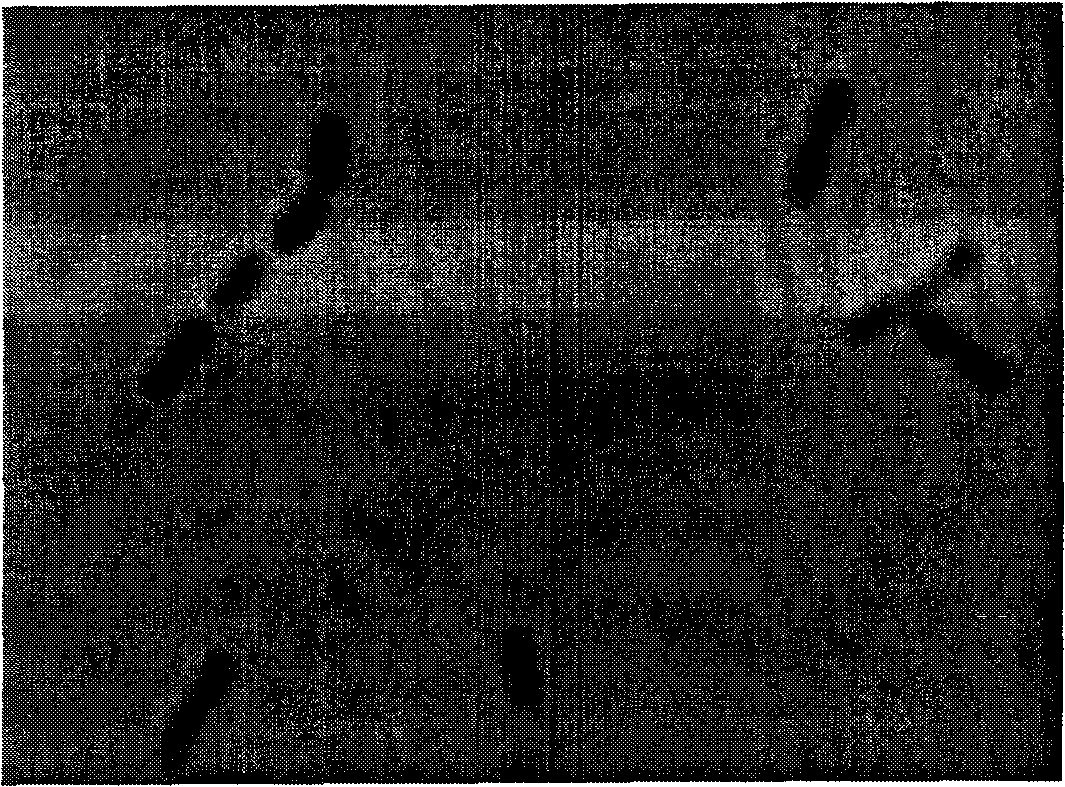

Micro-nano cellulose preparation method

The invention relates to a micro-nano cellulose preparation method, and especially relates to a micro-nano cellulose preparation method using pure physical method. According to the method, first natural cellulose is irradiated by high-energy electron beam, the internal structure is destructed, the irradiated cellulose material is coarsely crushed by mechanical dry method, and then is finely crushed by water grinding method to finally obtain micro-nano cellulose; and the aqueous dispersion liquid concentration is 0.01-1% (wt%). A water grinding fine crushing device is a colloid mill, or a colloid mill modified with a power ultrasonic pretreatment feed cavity, the final micro-nano cellulose fineness can reach 5-600nm, and the preparation process is environment-friendly without any chemical wastewater, and has the advantages of simple process and good repeatability.

Owner:施波波

Production method of spherical cellulose acetate butyrate

The invention belongs to the technical field of organic acid ester cellulose preparation, in particular relates to a production method of spherical cellulose acetate butyrate, and solves the technical problem of low product yield. The production method comprises the following steps: a, treating velvet wood pulp or cellulose acetate grade refined cotton by acetic acid; b, mixing butyric anhydride, acetic anhydride and concentrated sulfuric acid, cooling to obtain cooled mixed liquid, adding the treated velvet wood pulp or cellulose acetate grade refined cotton into the cooled mixed liquid, and adding a solvent for acylation; c, adding hydrolysis liquid into acylation reaction liquid for hydrolysis, and neutralizing; d, precipitating, hardening, performing solid-liquid separation, washing, stewing, and drying to obtain a spherical cellulose acetate butyrate product. According to the method provided by the invention, the apparent viscosity of materials in reaction liquid can be effectively reduced, the mixing effect of the materials can be improved, the reaction performance of the materials can be improved, and the reaction yield of the materials can be increased.

Owner:SICHUAN NITROCELLULOSE CORP

Method for fermenting soybean by virtue of lactobacillus

The invention relates to a method for fermenting soybean by virtue of lactobacillus, comprising the following steps of: taking soybean as a raw material, uniformly mixing soybean with water, and performing pre-treatment; then inoculating lactobacillus culture solution, and fermenting in the existence of a cellulose preparation; and then obtaining a soybean fermented product disclosed by the invention. The method disclosed by the invention is simple to operate, low in cost, less in the used time, and easy to realize large-scale commercialized production; and moreover, the obtained soybean fermented product is high in nutritional value, good in taste and smell, and has the function of adjuvant therapy for various diseases and a healthcare function.

Owner:胡玮

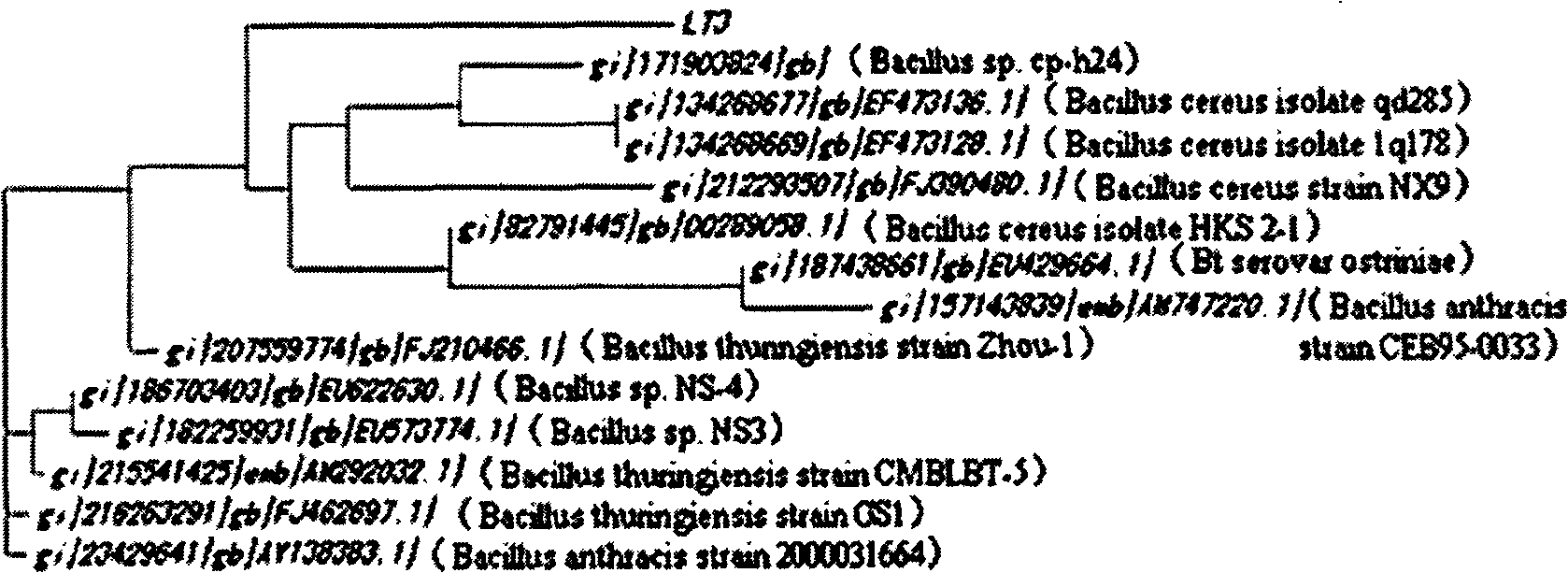

Bacterial strain LT3 producing alkalescence cellulase and breeding method and initial optimization of cellulase production conditions thereof

InactiveCN101555461AAlkaline resistantAdapt to a wide range of pHBacteriaMicrobiological testing/measurementBacillus cereusCellulase

The invention provides a bacterial strain LT3 producing alkaline cellulose and a breeding method and an initial optimization of cellulose production conditions thereof. The bacterial strain LT3 with higher secretory volume of alkaline cellulose is obtained by steps of conducting accumulation culture, separation and purification, identification of Congo red dye and liquid fermentation on samples obtained from rotten wood or nearby soil thereof; the bacterial strain is identified to be bacillus cereus by initial identification, sequence clone and phylogenetic analysis; and 16s and r DNA sequences are shown as sequence list SEQ ID NO.1. The invention has potential theoretical and application values for research on the action mechanism of the alkaline cellulose and the production of the alkaline cellulose preparation; and the bacterial strain LT3 of the alkaline cellulose can produce the alkaline cellulose of single component and is convenient for separation and purification, thus being an ideal material for gene clone of the alkaline cellulose and having potential theoretical and practical significances for constructing alkaline cellulose fibrinolysis engineered bacterial strain and questing the action mechanism of the alkaline cellulose, and the method is simple, fast and easy for implementation.

Owner:FUZHOU UNIV

Hydrophobic modified nano cellulose preparation method

A hydrophobic modified nano cellulose preparation method includes steps: (1) using excessive sodium hydroxide solution for alkali swelling treatment of fiber materials, adding acrylamide being 5-15% of the dry weight of the fiber materials, performing reaction for 2-6h at 60-90 DEG C, washing and filtering to obtain carboxyethyl cellulose; (2) under an organic solvent system at 55-95 DEG C, subjecting the carboxyethyl cellulose and a hydrophobic compound to reaction for 2-4h to generate hydrophobic modified carboxyethyl cellulose; (3) adopting a high-pressure homogenizer for mechanical treatment of the hydrophobic modified carboxyethyl cellulose to finally obtain the hydrophobic modified nano carboxyethyl cellulose. The hydrophobic modified nano cellulose prepared according to the method is high in dispersity, transparency, compatibility and thermal stability and can be applied to industries of petroleum drilling, construction mortar, textile dyeing and printing, electronic paste, paint, ceramics, papermaking, daily chemicals and the like.

Owner:胡云

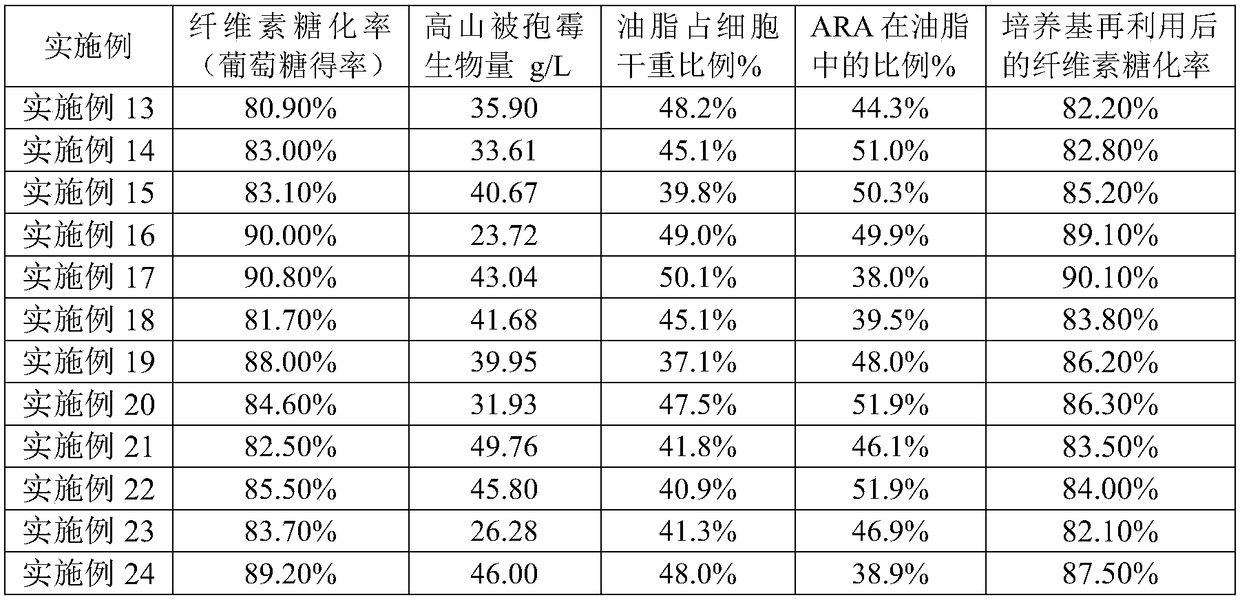

Method for producing grease containing rich polyunsaturated fatty acid by adopting lignocellulose

ActiveCN108977470ASolve market needsReduce the cost of using enzymesMicroorganism based processesFermentationFiberFermentation

The invention provides a technology for preparing grease containing rich polyunsaturated fatty acid by taking lignocellulose type agricultural and forest wastes as raw materials through fermenting mortierella alpine, aiming at the problems in the prior art. The technology comprises the steps of pre-treating, saccharifying, carrying out mortierella alpine fermentation, extracting the grease and thelike. According to the technology provided by the invention, a fermentation phase of the mortierella alpine adopts a temperature gradual reduction method and the yield of ARA (Arachidonic Acid) can be remarkably improved; the ratio of the ARA in the total grease can reach 48 percent. Compared with the prior art, the technology adopts a cellulose preparation based on fiber-production globule bacteria to realize the saccharifying of lignocellulose, so that the cost of a carbon source and the enzyme utilization cost of a saccharifying phase are remarkably reduced; the cellulose saccharifying efficiency is 80 to 90 percent. Furthermore, a culture medium at a lignocellulose saccharifying phase and a fermentation culture medium in the technology can be circularly utilized, so that water can beremarkably reduced and the dosage of chemicals also can be remarkably reduced; the technology has remarkable effects of reducing wastewater emission and reducing the cost.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Cellulose-containing resin composition and cellulosic ingredient

ActiveCN108884272AFull mechanical propertiesSufficient physical stabilityAdditive ingredientCellulose fiber

The present invention relates to: a resin composition which shows satisfactory flowability and mechanical properties; a cellulosic ingredient which gives the resin composition; and resin pellets and amolded resin object which are formed from the resin composition. One embodiment of the resin composition comprises a thermoplastic resin and a cellulosic component, wherein the cellulosic component comprises cellulose whiskers and cellulose fibers. Another embodiment of the resin composition comprises a thermoplastic resin and a cellulosic component, has a coefficient of variation of a linear expansion coefficient of 15% or less and a coefficient of variation of tensile rupture strength of 10% or less. One embodiment of the cellulosic ingredient comprises cellulose particles and an organic component. A still another embodiment of the resin composition comprises a thermoplastic resin, cellulose particles, an organic component, and a surfactant. In a further embodiment, the organic component has a static surface tension of 20 mN / m or higher and a higher boiling point than water.

Owner:ASAHI KASEI KK

Raw material composition and preparation method of anti-retroviral, freeze-proofing and refreshing biomembrane preparation

ActiveCN102388926AAvoid pollutionReduce evaporationBiocidePlant growth regulatorsBiotechnologyMedicinal herbs

The invention relates to the raw material composition and a preparation method of an anti-retroviral, freeze-proofing and refreshing biomembrane preparation. The anti-retroviral, freeze-proofing and refreshing biomembrane preparation comprises the following raw materials in part by weight: 30 to 50 parts of oligosaccharide, 15 to 30 parts of tissuemat E, 15 to 20 parts of cellulose preparation, and 20 to 30 parts of bacteriacide, adhesive and synergist. The prepared anti-retroviral, freeze-proofing and refreshing biomembrane preparation is safe and non-toxic, and pollution-free, and has the characteristics that the preparation can prevent fruits and vegetables from being frozen and protect fruits and vegetables from retroviral, disinfect and nourish the fruits and vegetables, improve fruit setting, and protect plant to grow through the winter safely. The preparation is particularly suitable for retroviral and frostbite prevention of plants such as fruit trees, vegetables, flowers, grain, cotton, medicinal materials and the like and has durability and controllability in the aspects of preventing plants from being frozen and supplying nutrients to the plants.

Owner:武兴战

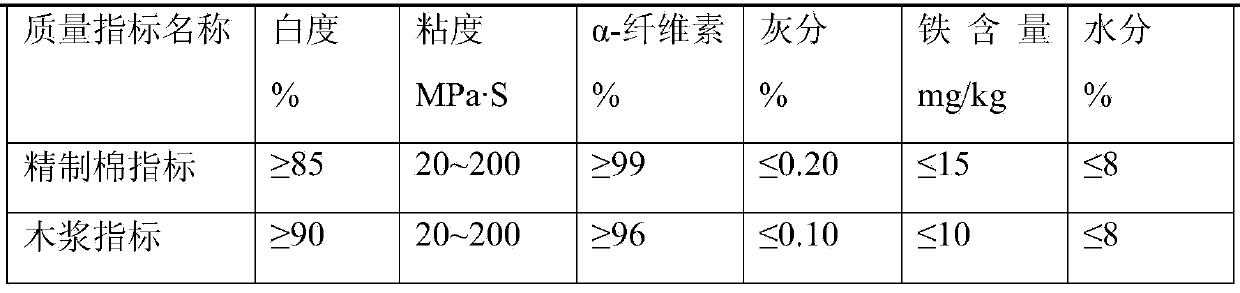

Method for preparing cellulose nitrate for explosive from wood pulp

InactiveCN102219861ASolve the costPrice stabilityNitrocellulose explosive compositionsEnvironmental resistanceNitrocellulose

The invention relates to a method for preparing cellulose nitrate for an explosive from wood pulp, in particular relates to a preparation method of cellulose nitrate for an explosive and belongs to the technical field of cellulose preparation. The method is characterized by comprising the following steps: adding 20-30 parts by weight of wood pulp in 500 parts by weight of mixed acid, carrying outmiddle-low temperature nitration reaction and then washing; and then successively carrying out boil washing, shredding and refine washing so as to obtain the cellulose nitrate for the explosive. In the preparation method of the cellulose nitrate, the wood pulp is used as a raw material, which is not a precedent in the field of military cellulose nitrate, thereby broadening the use range of the raw material in nitrated cellulose production, and simultaneously, the wood pulp is cheaper than cotton linter and can be used as the raw material of energy-containing nitrated cotton for production, thereby greatly solving the cost problem of the raw material; and at the same time, the environmental protection pressure problem brought by a large amount of cotton dust, black liquid and acidic wastewater which are generated in the processes of cotton opening, boiling, bleaching and drying refined cotton when a nitrated cotton product is prepared by utilizing the cotton linter as the raw material is solved.

Owner:SICHUAN NITROCELLULOSE CORP

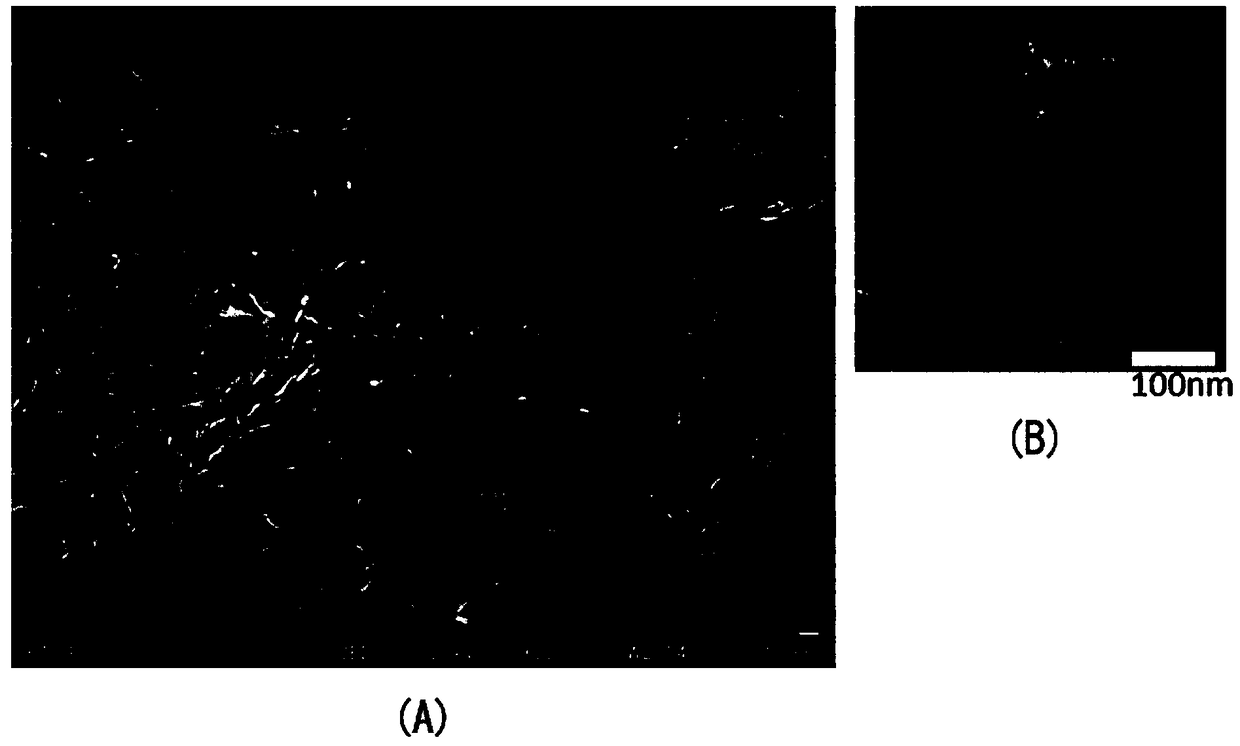

Nanocrystalline cellulose preparation method

A nanocrystalline cellulose preparation method includes steps: using an acetic acid-sodium acetate buffer solution with pH being 4.8 to prepare a cellulose solution with the concentration being 0.03-0.05g / mL, adding cellulase for enzymolysis, and performing ultrasonic treatment at intervals of 12h in the enzymolysis process, wherein the concentration of the cellulose in the solution is 10-15U / mL, and ultrasonic treatment lasts 30-60min each time; after reaction is finished, taking out a sample, separating centrifugally, centrifugally washing precipitates, freezing and drying to obtain nanocrystalline cellulose. The one-dimension rodlike nanocrystalline cellulose is prepared by combination of cellulose endonucleases and the ultrasonic physical method. The nanocrystalline cellulose preparation method has advantages of safety, avoidance of pollution, high efficiency and low energy consumption; the nanocrystalline cellulose prepared according to the method has the advantages of high yield, high crystallinity, high thermostability and small particle size.

Owner:QINGDAO AGRI UNIV

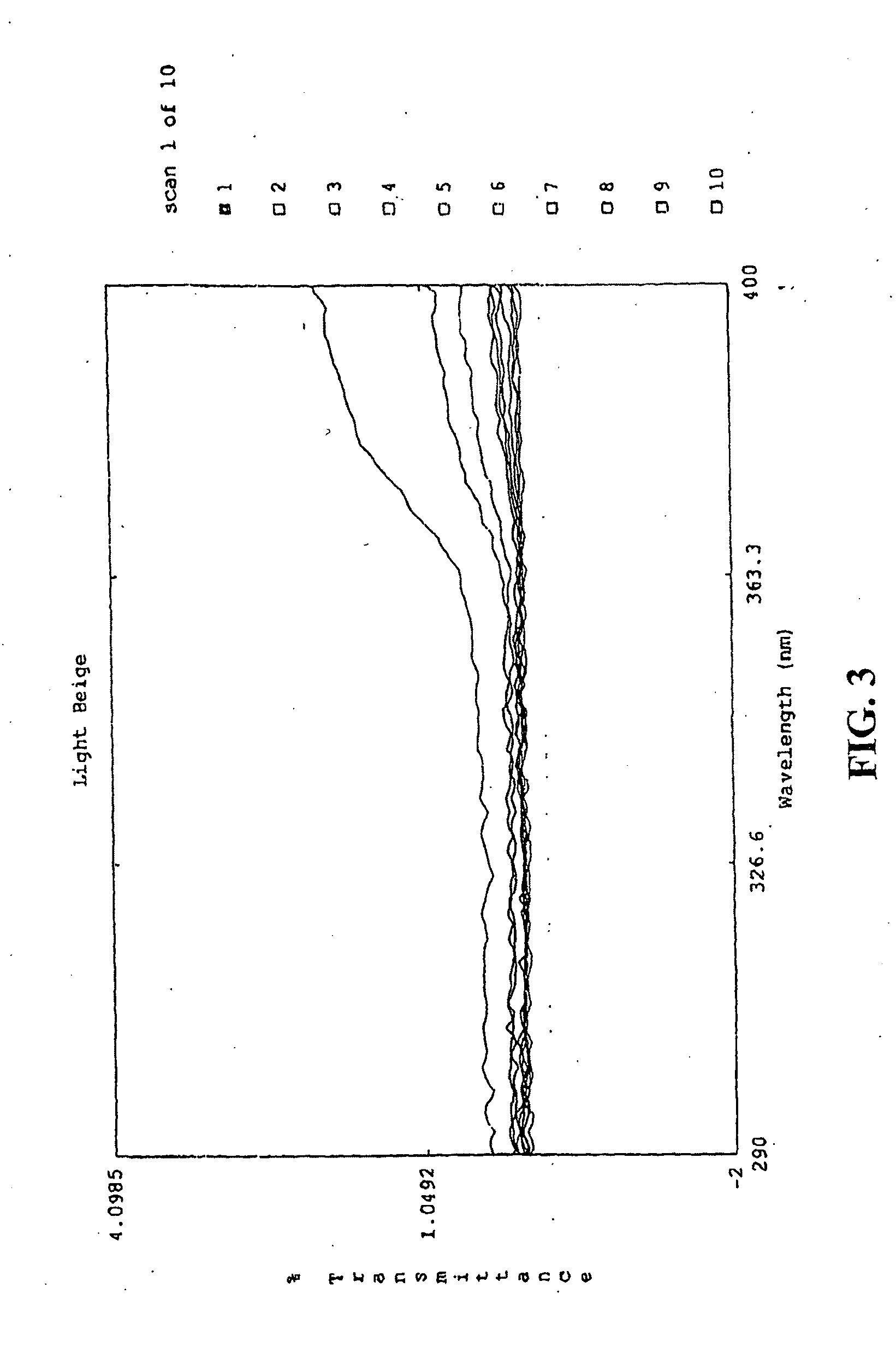

Skin Coating Composition and Uses Thereof

InactiveUS20090004252A1Increased durabilityViscosity be optimisedCosmetic preparationsMake-upShellacSunscreen agents

The present invention relates to a composition for coating the skin wherein the composition forms a water-proof flexible film on the skin. Preferably, the flexible film is durable and is capable of remaining adhered to the skin for 1 to 3 days. The composition may include (i) one or more pigments and / or dyes, or (ii) one or more sunscreen agents or (iii) one or more therapeutic agents for preventing or treating disorders of the skin. The coating composition comprises resin and flexibilizer (platicizer). Any suitable type of natural or synthetic resin may be used, preferably the resin is shellac or other natural gum derivative. A suitable flexiblizer is an animal, vegetable, mineral or synthetic oil, preferably castor oil, pine oil, rosehip oil or soya bean oil or mixture thereof. The composition optionally includes a diluent such as ethanol, a cellulosic preparation such as ethyl cellulose, an anti-agglomerating or dispersing agent and a thickener. The composition may be in the form of a paste, cream, gel, liquid or aerosol and may be used as a bandage or artificial skin.

Owner:BLONDE HLDG PTY LTD

Biomass organic fertilizer for soil improvement

InactiveCN105837381AHigh nutrient contentHigh nitrogen contentExcrement fertilisersBioloigcal waste fertilisersEcological environmentProtease preparation

The invention discloses a biomass organic fertilizer for soil improvement. The fertilizer is prepared from, by weight, 1-3 parts of zinc sulfate powder, 4-5 parts of tourmaline powder, 6-8 parts of wood bits, 4-6 parts of ammonium chloride, 2-3 parts of calcium ammonium nitrate, 14-15 parts of bagasse, 10-12 parts of cotton seed shells, 79-81 parts of crop straw, 24-25 parts of wormcast, 3-4 parts of pyroligneous liquor, 53-57 parts of waterweed, 2-4 parts of cellulose preparation, 2-3 parts of protease preparation, 7-8 parts of tamarind fruits and a proper amount of water. The biomass organic fertilizer has good biochemical stability and degradation resistance, and can be reserved in soil for a long time, the organic matter content of the soil is remarkably improved, the content of effective nitrogen phosphorus and potassium in the soil is adsorbed and kept, the moisture and fertility preserving effect is remarkable, the granular structure of the soil is optimized, the ecological environment of the soil is improved, the utilization rate of the fertilizer efficiency is increased, and the effects of increasing the yield and guaranteeing the quality are achieved.

Owner:ANHUI HAOLI FERTILIZER IND CO LTD

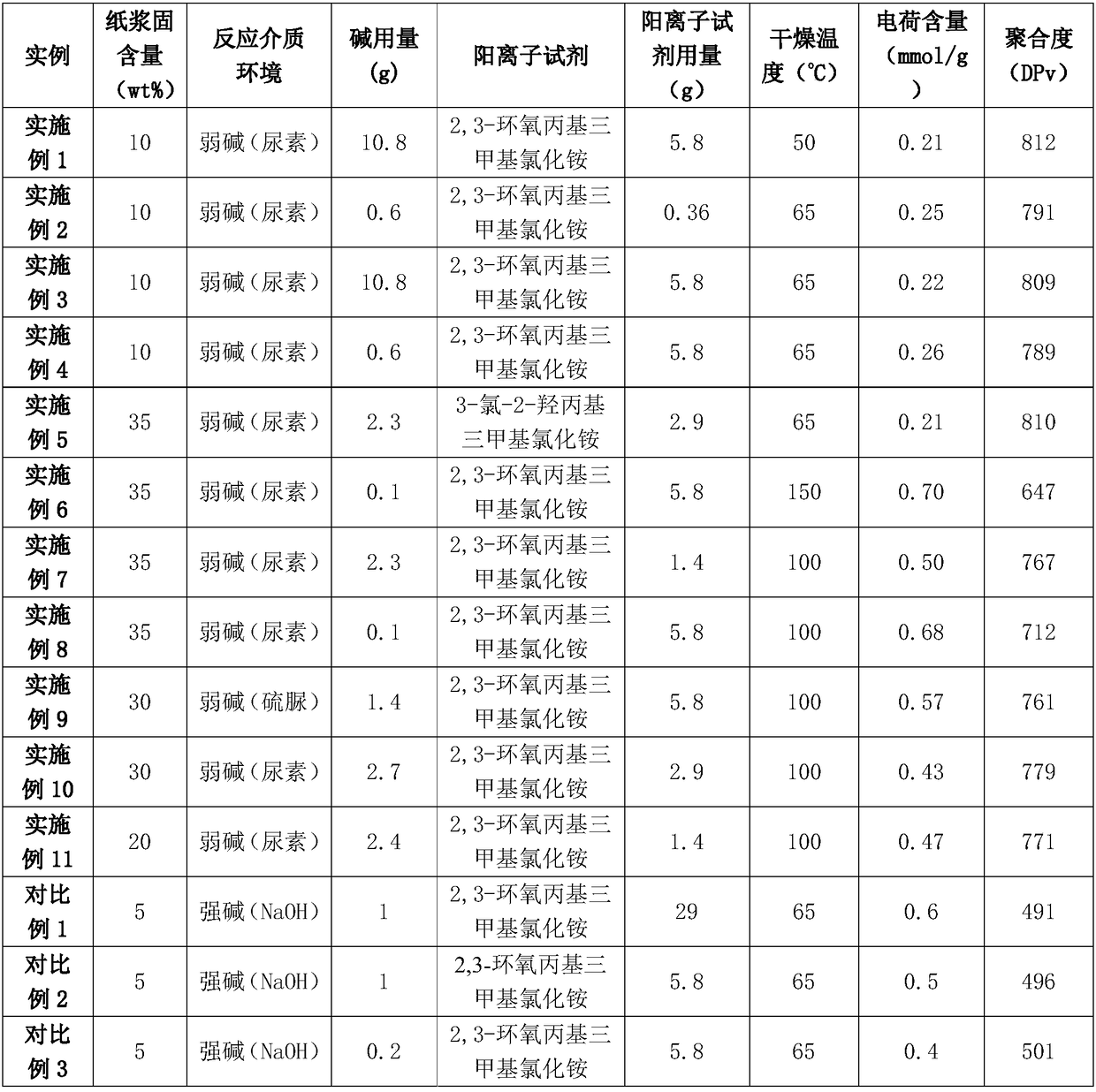

High-efficiency environment-friendly cationic fibrillating cellulose preparation method

ActiveCN109487546ASolve problemsSolve the problem of low degree of polymerization of the obtained celluloseVegetal fibresEnvironmental resistanceCellulose fiber

The invention discloses a high-efficiency environment-friendly cationic fibrillating cellulose preparation method. The method includes: in a chemical pretreatment step, using a warm and environment-friendly weakly-alkaline reagent to replace corrosive strong alkali to serve as an activating agent of natural cellulose fiber; performing quaternary ammonium salt pretreatment on paper pulp at medium temperature, performing mechanical separation to prepare Q-NFC water dispersion liquid high in polymerization and fibrillating degree and controllable in surface charge content. The preparation methodis simple, efficient, mild in reaction condition, environment-friendly and suitable for large-scale production, and Q-NFC prepared by the method can be used in the field of paper and plastic reinforcement, food packing, paint, cosmetics, electronic materials, biomedicine and environment purifying.

Owner:ZHEJIANG FORESTRY UNIVERSITY

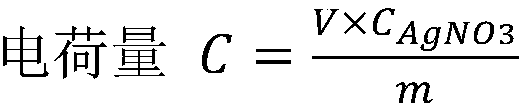

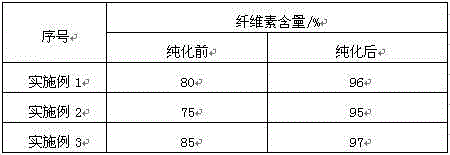

Deep purification method of crude cellulose

InactiveCN104631178AIncreased alpha-cellulose contentSmall difference in alpha-cellulose contentCellulose treatment using microorganisms/enzymesCooking & bakingPurification methods

The invention discloses a deep purification method of crude cellulose. The method is characterized by comprising the following steps: mixing crude cellulose; carrying out purifying treatment; inactivating biological enzyme; washing; dewatering; and baking. The technology disclosed by the invention is simple, mild in treatment condition, low in time and energy consumption, and free of a chemical assistant, and is capable of effectively improving alpha-cellulose content in a cellulose preparation material; and the structure and the performance of the cellulose are not affected.

Owner:SHAOXING UNIVERSITY

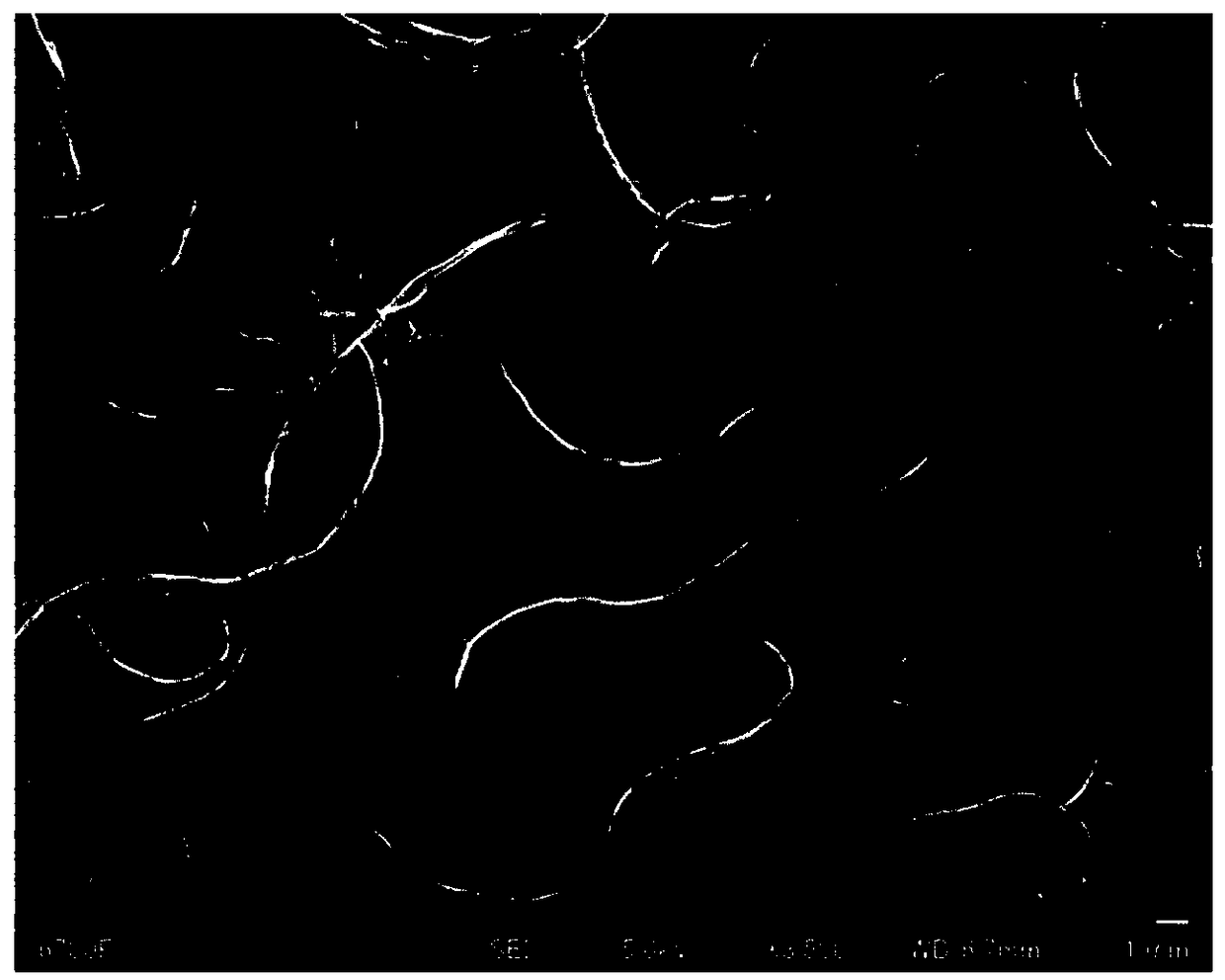

Preparation method of nanometer fibrillated cellulose capable of being re-dispersed in water after drying

The invention discloses a preparation method of nanometer fibrillated cellulose capable of being re-dispersed in water after drying, and belongs to the technical field of nanometer cellulose preparation. According to the present invention, nanometer fibrillated cellulose is physically modified with an anionic polymer electrolyte sodium carboxymethyl cellulose, and the obtained nanometer fibrillated cellulose and sodium carboxymethyl cellulose mixed solution is dried by an experimental fluidized bed granulator and a freeze drying machine to prepare powdery or microparticle-like nanometer fibrillated cellulose solid, wherein the nanometer fibrillated cellulose solid can be uniformly re-dispersed in an aqueous medium due to the weakening of the agglomeration caused by hydrogen bonding; and the preparation of the re-dispersible nanometer fibrillated cellulose provides convenience in storage, transportation and subsequent applications.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

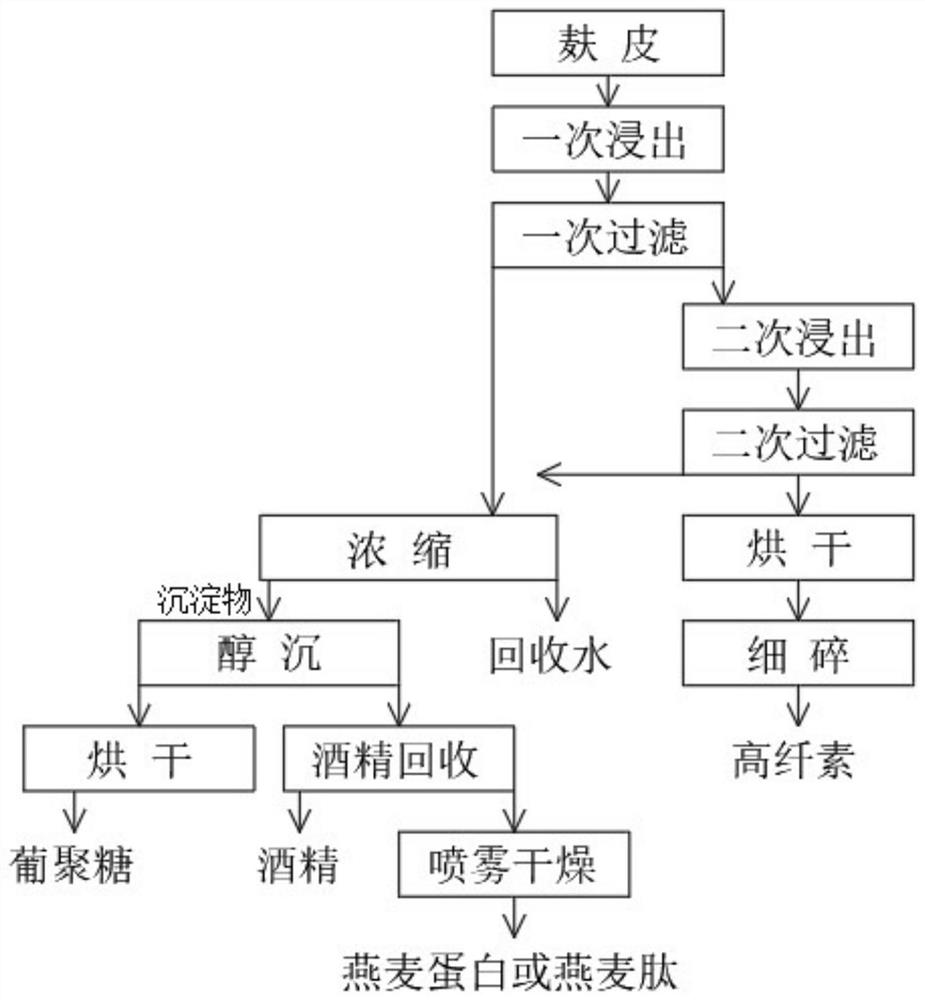

Preparation technology of high-content oat beta-glucan dietary fiber powder

InactiveCN113519859AImprove the rate of dissolution and leachingEasy extractionPeptide preparation methodsFood ingredient functionsBiotechnologyFiber

The invention provides a preparation technology of high-content oat beta-glucan dietary fiber powder, and relates to the technical field of food processing. The preparation process of the high-content oat beta-glucan dietary fiber powder comprises the following steps: 1, primary leaching; 2, primary filtration and secondary leaching; 3, secondary filtration and high cellulose preparation; 4, mixed concentration and alcohol precipitation preparation; 5, alcohol recovery and spray drying. According to the method disclosed by the invention, beta-glucan in the oat can be fully hydrolyzed into water through two times of leaching and two times of filtering; meanwhile, the beta-glucan in the oat hulls can be fully extracted. Beta-glucan can be well prepared through the steps of mixing, concentration and alcohol precipitation, and beta-glucan in the oat bran can be fully extracted; wherein the beta-glucan cannot be wasted, the high yield is ensured, and the method is worthy of vigorous popularization.

Owner:内蒙古阴山优麦食品有限公司

Immobilization method of xylanase

InactiveCN105154426AImprove hydrophilicityImprove stabilityOn/in organic carrierXylanaseCellulose pulp

The invention provides an immobilization method of xylanase, which comprises the processes of immobilization carrier preparation and immobilized xylanase preparation. The immobilization carrier preparation process mainly comprises the following steps: bacteria cellulose seed culture, bacteria cellulose preparation, bacteria cellulose pulping, and bacteria cellulose / chitosan composite microsphere preparation. The immobilized xylanase preparation process comprises the following steps: crosslinking the bacteria cellulose / chitosan microsphere and glutaric dialdehyde, carrying out crosslinking reaction on the crosslinked-formyl-containing bacteria cellulose / chitosan microsphere and a xylanase solution at 4 DEG C, centrifuging, precipitating and carrying out vacuum drying to obtain the immobilized xylanase. The activity recovery rate of the immobilized enzyme is up to 75.3%, and the relative enzyme activity reaches 80.5%. After the immobilized enzyme is continuously used 5 times, the enzyme activity is kept at 83.6%, and thus, the immobilized enzyme has favorable stability and higher application value.

Owner:TIANJIN MODERN VOCATIONAL TECH COLLEGE

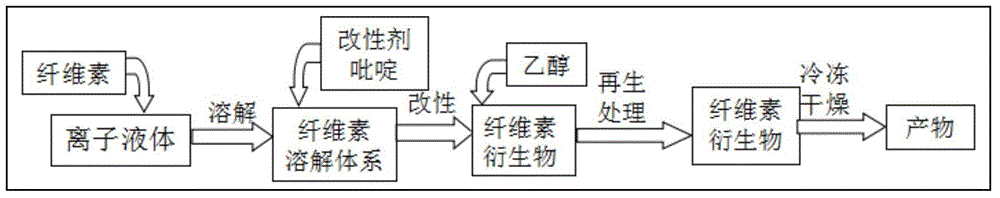

Method for preparing water-soluble cellulose and water-soluble cellulose prepared by the same

The present invention provides a method for preparing water-soluble cellulose. The method uses linter pulp board as a raw material, which is dissolved by an ionic liquid, and then supplemented with a modifier and a catalyst for chemical modification, so as to prepare a water-soluble cellulose derivative. The water-soluble cellulose derivative prepared by the method has the advantages of good solubility and high degree of polymerization, and has broad application prospects in medical engineering, food industry and cellulosic functional materials. The preparation method is simple and convenient for operation, has easily controlled process conditions, greatly simplifies the production process and reduces costs; and the method for the first time reports water-soluble cellulose preparation based on the ionic liquid dissolving system.

Owner:BEIJING FORESTRY UNIVERSITY

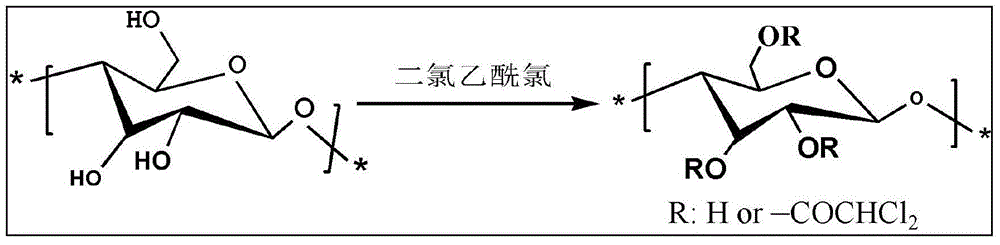

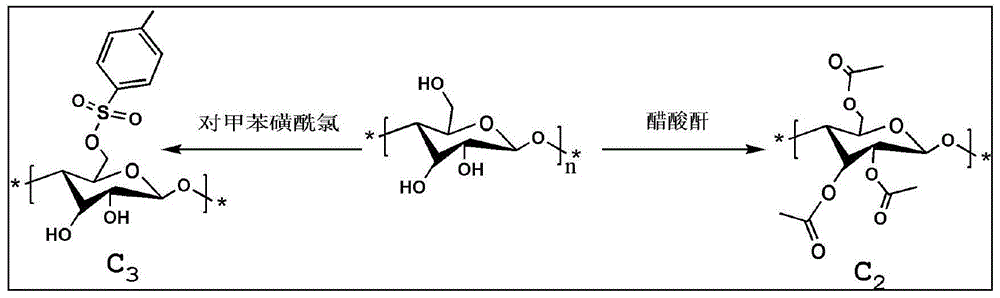

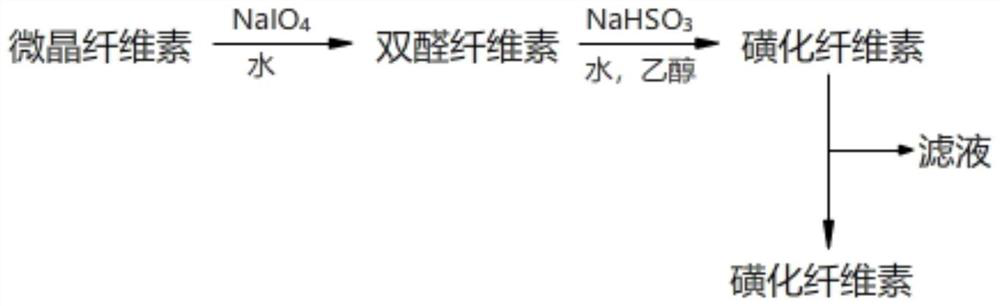

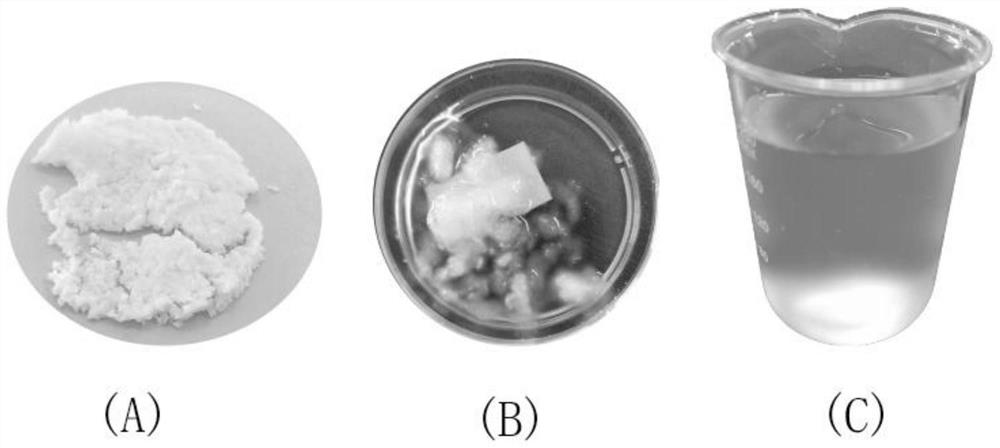

Preparation method of sulfonated cellulose

The present invention relates to a sulfonated cellulose preparation method, which comprises that dialdehyde cellulose and a sulfonating agent are subjected to an addition reaction to prepare sulfonated cellulose, wherein the reaction medium of the addition reaction contains ethanol. According to the invention, a reaction medium containing ethyl alcohol is used for an addition reaction of dialdehyde cellulose and a sulfonating agent, so that the sulfonated cellulose can be easily separated from a reaction system even if the highly hydrophilic sulfonated cellulose is prepared from the dialdehydecellulose with the high aldehyde group content; and the yield of sulfonated cellulose is high by adopting the reaction medium containing ethanol.

Owner:GUANGDONG IND TECHN COLLEGE

Biomass organic fertilizer for supplementing rice with calcium

InactiveCN105837382AHigh nutrient contentHigh nitrogen contentCalcareous fertilisersDi-calcium phosphate fertilisersCalcium in biologyProtease preparation

The invention discloses a biomass organic fertilizer for supplementing rice with calcium. The biomass organic fertilizer is prepared from, by weight, 16-19 parts of tea powder, 1-2 parts of cobaltous chloride, 1-2 parts of aluminum polychlorid, 23-24 parts of vinegar residues, 4-5 parts of calcium hydrophosphate, 7-9 parts of land plaster, 68-72 parts of waterweed, 5-6 parts of ground phosphate rock, 8-9 parts of xylose powder, 4-6 parts of dipotassium phosphate, 58-62 parts of crop straw, 13-14 parts of oyster shell piece powder, 2-4 parts of cellulose preparation, 3-4 parts of protease preparation, 10-12 parts of tamarind fruits and a proper amount of water. According to the biomass organic fertilizer, the raw materials are reasonably combined according to the growth law of the rice, it is guaranteed that nutrients are sufficient in the growing process of the rice, the oyster shell piece powder, the land plaster and the like are added and combined with organic humus and chelate nutrients, the rice can absorb calcium better, the quality of the rice is enhanced, the stress resistance of the rice is improved, the rice is further converted into calcium-rich rice through absorbed calcium, and the rice is suitable for being eaten by people with calcium deficiency, especially the old.

Owner:ANHUI HAOLI FERTILIZER IND CO LTD

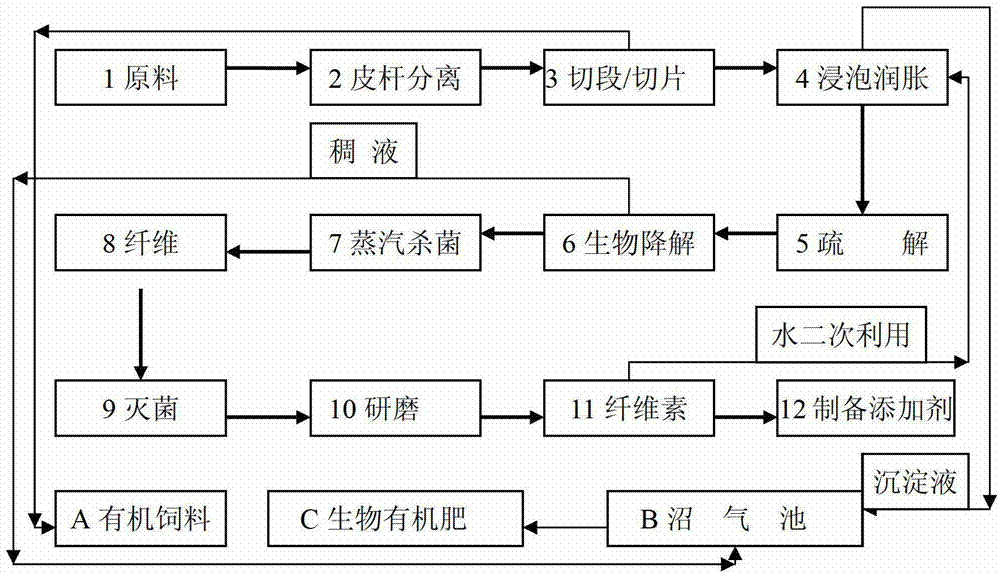

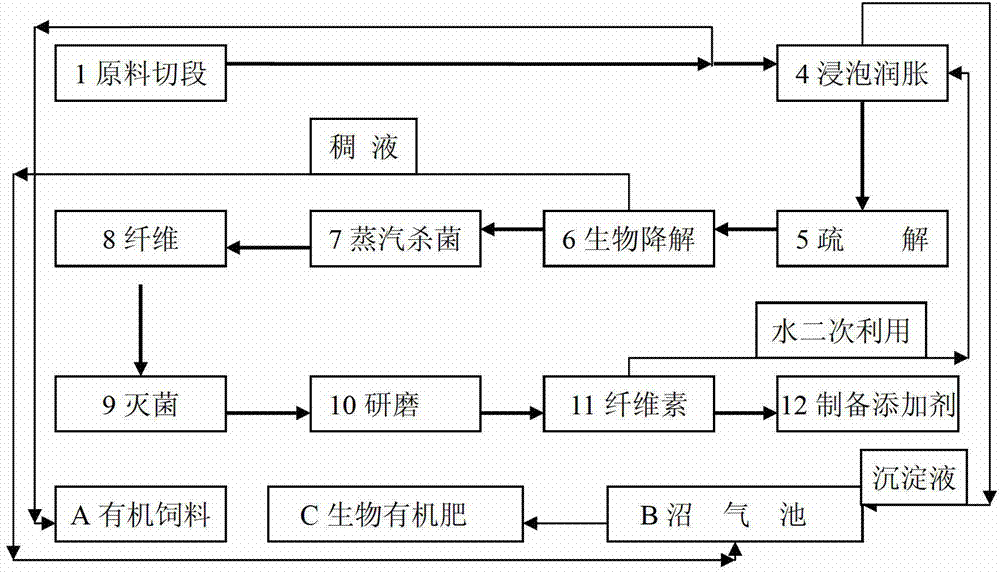

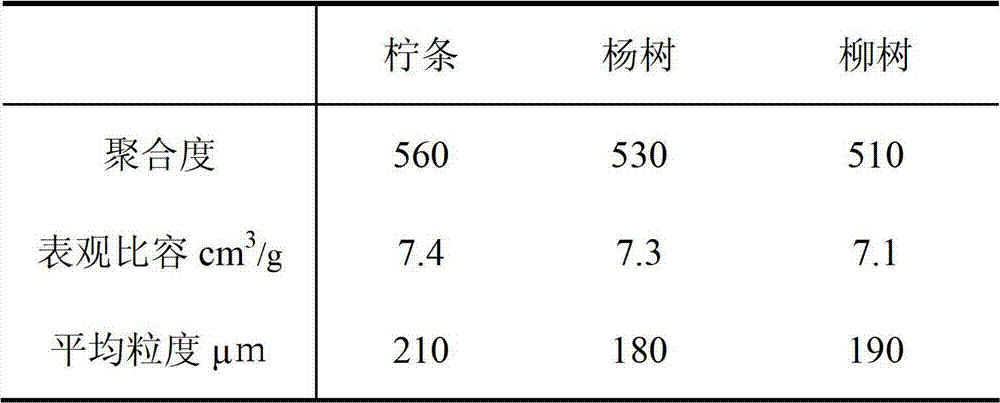

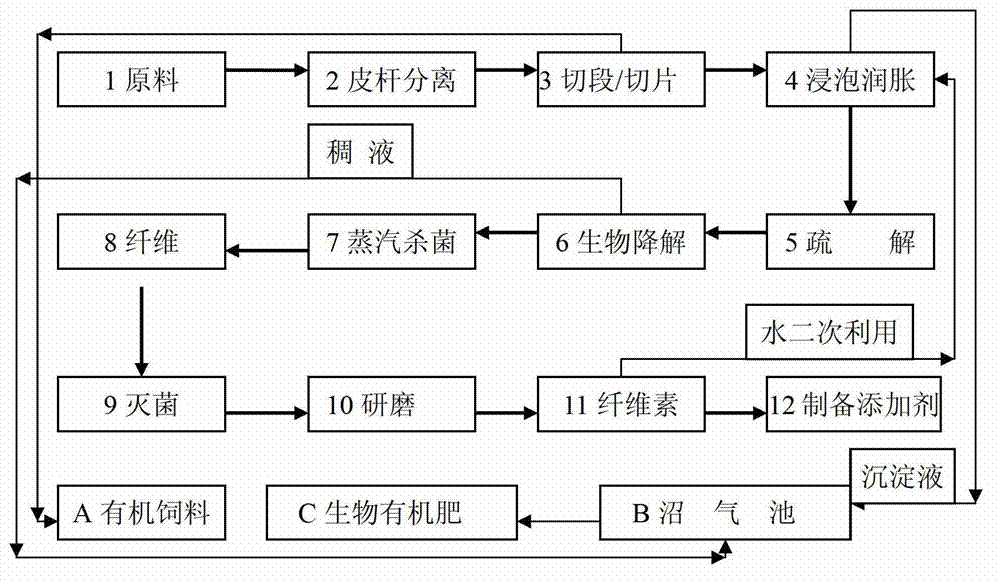

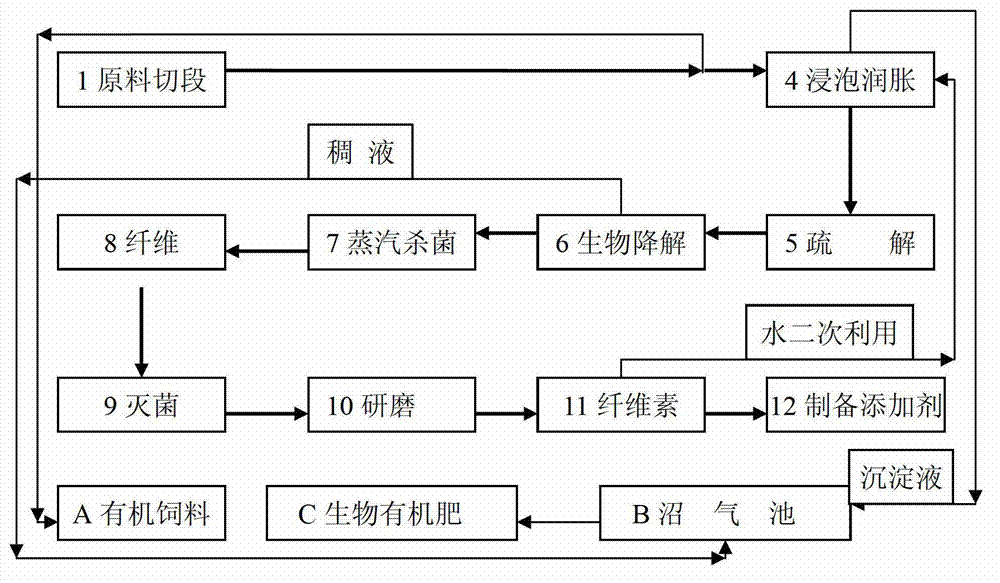

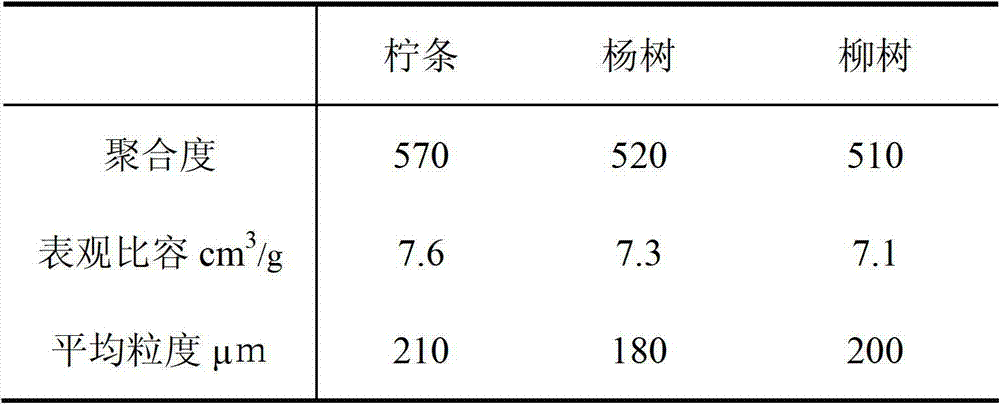

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074219APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberPollution

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Method for preparing biomass graphene by extracting cellulose from wheatgrass

InactiveCN107686106ASolve complexityFix security issuesSingle layer grapheneCarbonizationCvd graphene

The invention belongs to the technical field of graphene materials and particularly provides a method for preparing biomass graphene by extracting cellulose from wheatgrass. The method comprises the steps of S1, cellulose preparation, S2, catalyst solution preparation, S3, precursor preparation by high-temperature deoxidation, S4, carbonization heat treatment and S5 acid treatment and drying. Themethod takes the cheap cellulose with a wide source as a carbon source to prepare the graphene; when the yield is increased, the production cost is lowered; and the method has a series of advantages that a preparation technology is simple, the method is low in cost and high in yield, the production safety is high, the product size and physical properties are controllable, and industrial productioncan be achieved.

Owner:杨子中

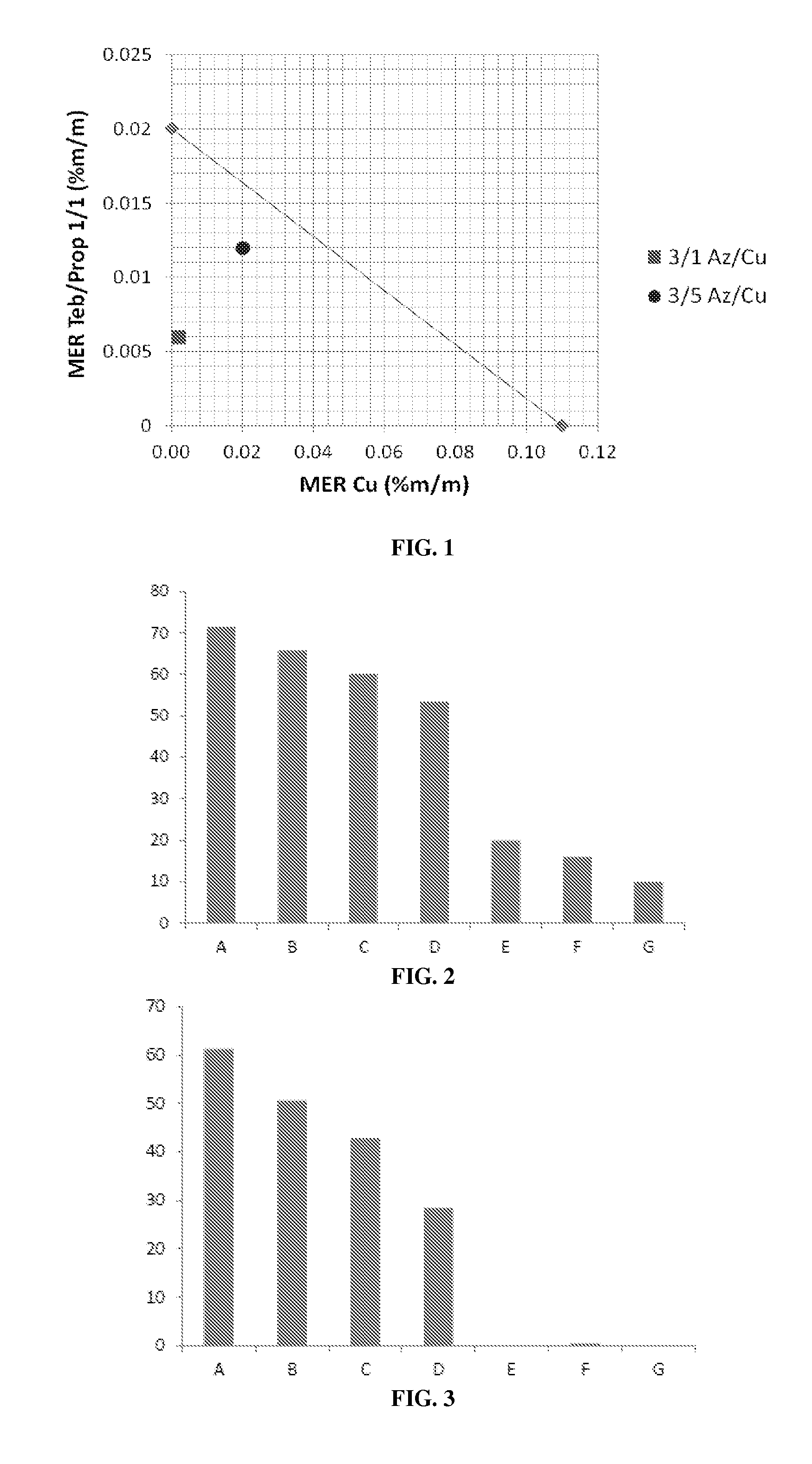

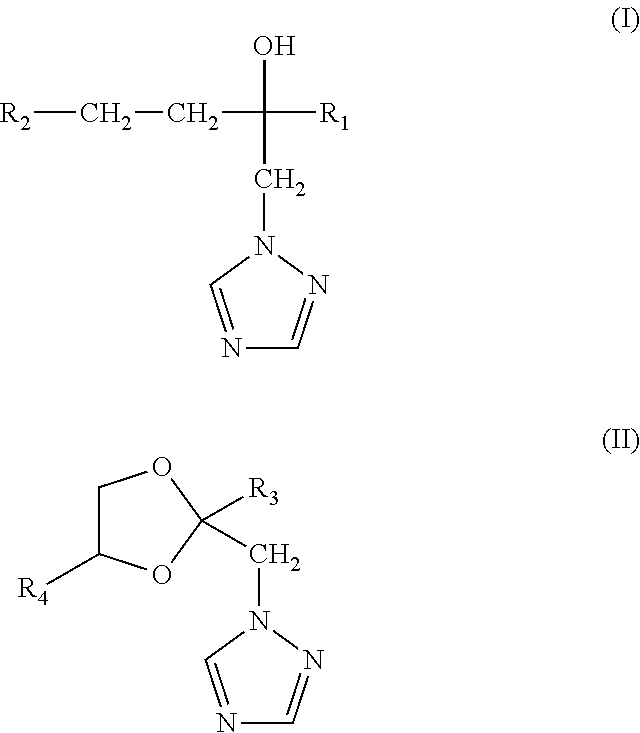

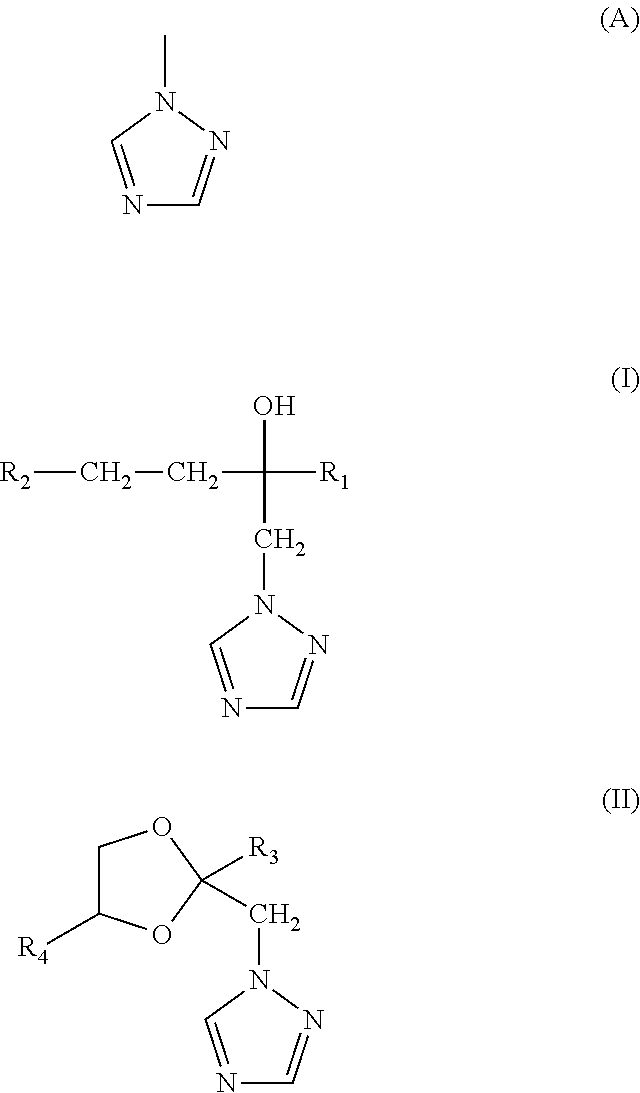

Wood preservative

InactiveUS20140370320A1High bactericidal activityImprove permeabilityBiocideWood treatment detailsPropiconazolePreservative

According to the present invention there is provided a preservative formulation for use in treating wood or other cellulosic formulations, said formulation comprising: at least one biocidal metal compound; at least one organic compound; and a carrier. Preferably, the preservative formulation is copper / (tebuconazole / propiconazole) in a ratio of about 1:3 w / w; the carrier is preferably aqueous or spirit-based.

Owner:ARCH WOOD PROTECTION

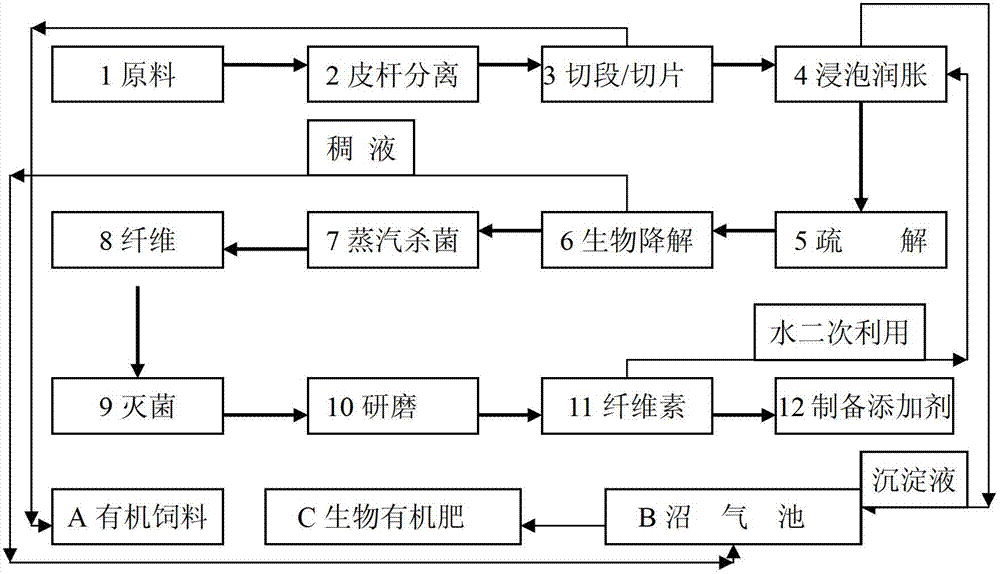

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074256APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

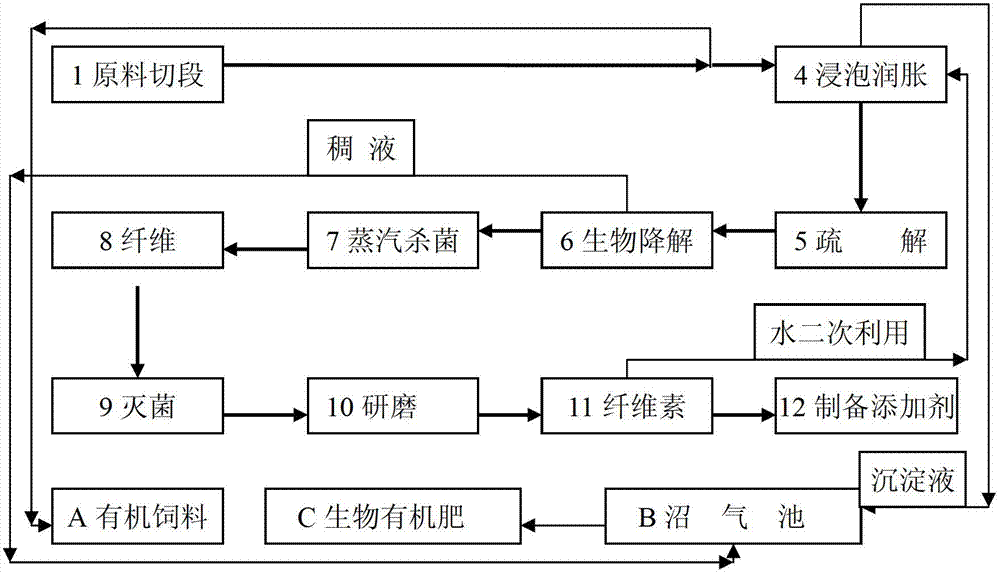

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074254APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com