Deep purification method of crude cellulose

A purification method and cellulose technology, which is applied in the field of deep purification of crude cellulose, can solve the problems of cellulose denaturation, affecting the application performance of cellulose and fibril structure, etc., and achieve the improvement of α-cellulose content, easy control, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

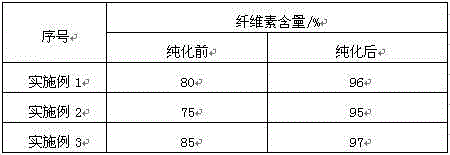

Examples

Embodiment 1

[0047] A kind of crude cellulose advanced purification method of the present embodiment, comprises the following steps:

[0048] (1) Mixing crude cellulose:

[0049] mixing different batches of crude cellulose extracted from wheat straw;

[0050] (2) Purification treatment:

[0051] Adjust the bath ratio to 1:15, adjust the pH value to 6.5 with a buffer solution composed of sodium acetate and acetic acid, then put in 6g / L of biological enzyme, and treat it at 55°C for 80min under the action of ultrasonic waves, the ultrasonic frequency is 53kHz, and the power is 120W.

[0052] The biological enzyme is configured by component A and component B at a mass ratio of 1:3, the component A is lignin peroxidase and laccase, and the mass ratio of lignin peroxidase to laccase 1:2, component B is xylanase.

[0053] (3) Biological enzyme inactivation:

[0054] Raise the temperature of the cellulose purification treatment bath to 80°C for 20 minutes.

[0055] (4) Washing, dehydration ...

Embodiment 2

[0057] A kind of crude cellulose advanced purification method of the present embodiment, comprises the following steps:

[0058] (1) Mixing crude cellulose:

[0059] mixing different batches of crude cellulose extracted from rice straw;

[0060] (2) Purification treatment:

[0061] Adjust the bath ratio to 1:15, adjust the pH value to 6.5 with a buffer solution composed of sodium acetate and acetic acid, then put in 4g / L of biological enzyme, and treat it at 55°C for 60min under the action of ultrasonic waves, the ultrasonic frequency is 53kHz, and the power is 100W.

[0062] The biological enzyme is composed of component A and component B in a mass ratio of 1:2, the component A is lignin peroxidase, manganese peroxidase and laccase, lignin peroxidase The mass ratio of manganese peroxidase and laccase is 1:1:2, and component B is xylanase.

[0063] (3) Biological enzyme inactivation:

[0064] Raise the temperature of the cellulose purification treatment bath to 80°C for 15 ...

Embodiment 3

[0067] A kind of crude cellulose advanced purification method of the present embodiment, comprises the following steps:

[0068] (1) Mixing crude cellulose:

[0069] Blending different batches of crude cellulose extracted from jute fibers;

[0070] (2) Purification treatment:

[0071] Adjust the bath ratio to 1:10, adjust the pH value to 6.5 with a buffer solution composed of sodium acetate and acetic acid, then put in 3g / L of biological enzyme, and treat it at 60°C for 60min under the action of ultrasonic waves, the ultrasonic frequency is 53kHz, and the power is 120W.

[0072] The biological enzyme is composed of component A and component B in a mass ratio of 1:2, the component A is lignin peroxidase and laccase, and the mass ratio of lignin peroxidase to laccase 1:1, component B is xylanase.

[0073] (3) Biological enzyme inactivation:

[0074] Raise the temperature of the cellulose purification treatment bath to 80°C for 15 minutes.

[0075] (4) Wash at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com