Nanocrystalline cellulose preparation method

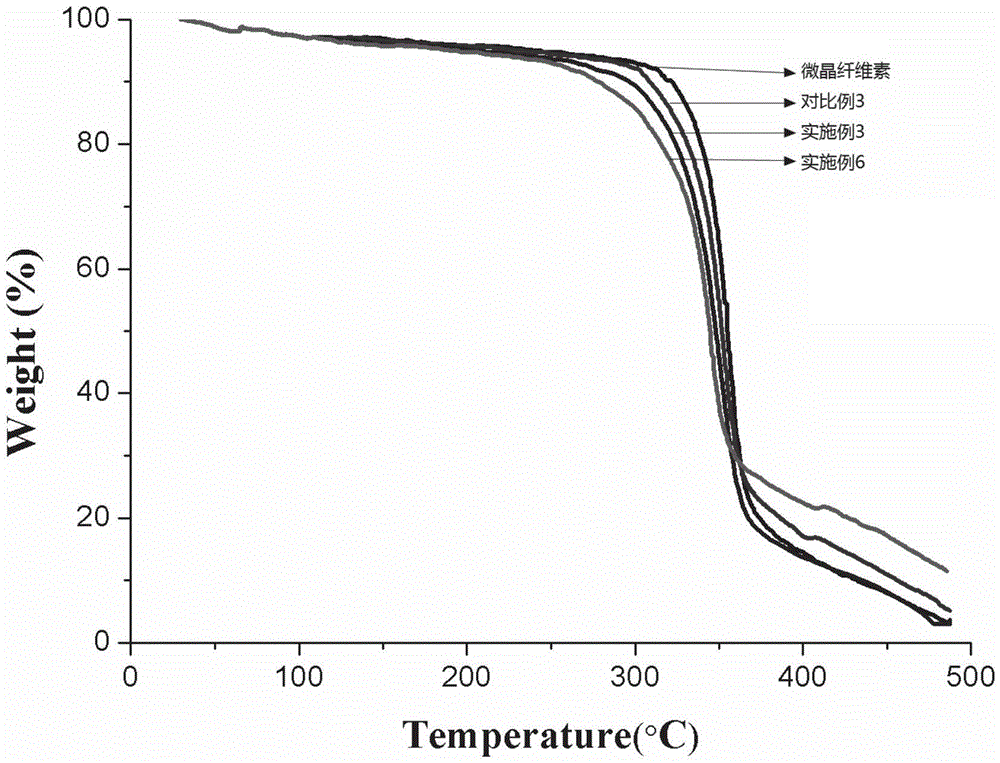

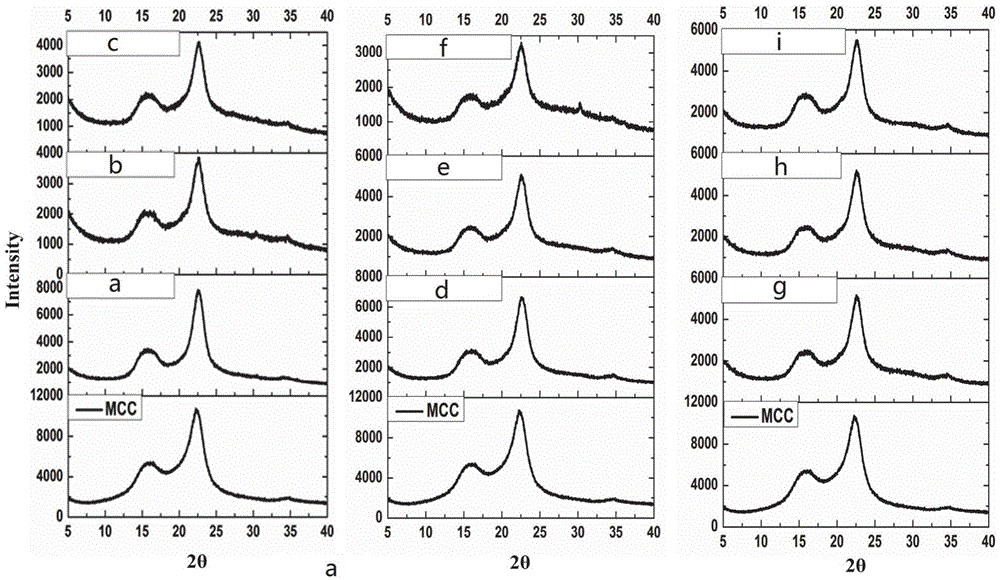

A technology of nanocellulose and cellulase, which is applied in fermentation and other directions, can solve the problems of large nanocellulose crystal particle size, high energy consumption for high-pressure homogenization, uncontrollable particle size, etc., and achieve good thermal stability and low energy consumption. The effect of low and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

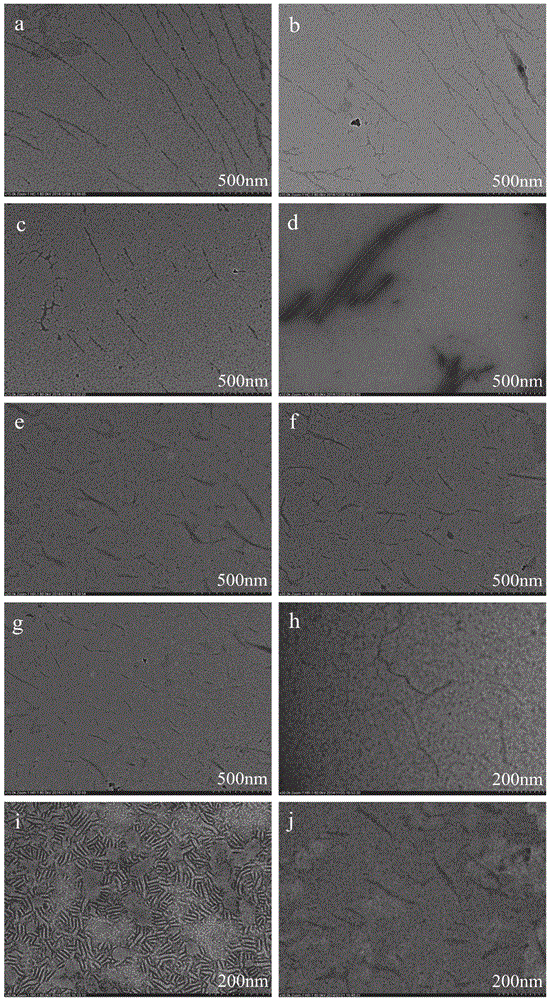

[0020] Accurately weigh 6g of straw cellulose into the Erlenmeyer flask, add the required amount (the total volume of the final mixture is 200mL) of acetic acid-sodium acetate buffer solution into the Erlenmeyer flask, and then add Place the cellulase solution in a shaker, adjust the temperature to 50°C, and the oscillation frequency is 126rpm, react for 72h to enzymatically hydrolyze the cellulose, and ultrasonically 30min at intervals of 12h during this period (that is, 12.5h is a cycle), the ultrasonic power is 300W, a total of 5 times of ultrasound during the whole enzymatic hydrolysis process. After the reaction, the sample was taken out, centrifuged at 10,000rpm for 20min, washed with water until the pH was 7, and a stable cellulose colloid was obtained. The colloid solution was poured into a plate and frozen at -20°C for 24h, then freeze-dried at -80°C for 48h to obtain a powder Nanocellulose crystals.

Embodiment 2

[0022] Accurately weigh 10 g of straw cellulose and put it into the Erlenmeyer flask, add the required amount (the total volume of the final mixture is 200 mL) of acetic acid-sodium acetate buffer solution into the Erlenmeyer flask, and then add Place the cellulase solution in a shaker, adjust the temperature to 55°C, and the oscillation frequency is 130rpm, react for 96 hours to enzymatically hydrolyze the cellulose, and ultrasonically 30min at intervals of 12h during this period (that is, 12.5h is a cycle), and the ultrasonic power is 320W, a total of 7 times of ultrasound during the whole enzymatic hydrolysis process. After the reaction, the sample was taken out, centrifuged at 11000rpm for 15min, washed with water until the pH was 7, and a stable cellulose colloid was obtained. The colloid solution was poured into a plate and frozen at -24°C for 20h, then freeze-dried at -85°C for 45h to obtain a powder Nanocellulose crystals.

Embodiment 3

[0024] Accurately weigh 8 g of straw cellulose and put it into an Erlenmeyer flask, add the required amount (total volume of the final mixture is 200 mL) of acetic acid-sodium acetate buffer solution into the Erlenmeyer flask, and then add Place the cellulase solution in a shaker, adjust the temperature to 45°C, and the oscillation frequency is 120rpm, react for 120h to enzymatically hydrolyze the cellulose, during which time, ultrasonic for 30min at intervals of 12h (that is, 12.5h is a cycle), the ultrasonic power is 340W, a total of 9 times of ultrasound during the whole enzymatic hydrolysis process. After the reaction, the sample was taken out, centrifuged at 12000rpm for 10min, washed with water until the pH was 7, and a stable cellulose colloid was obtained. The colloid solution was poured into a plate and frozen at -18°C for 28h, then freeze-dried at -75°C for 50h to obtain a powder Nanocellulose crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com