Preparation method of agomelatine I crystal forms

A technology of crystal form and crude product, which is applied in the field of preparation of raw materials, can solve the problems of poor reproducibility and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

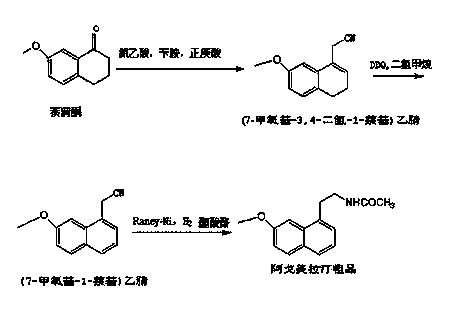

Method used

Image

Examples

Embodiment 1

[0032] Crude agomelatine was prepared according to the literature "Chinese Journal of Pharmaceutical Industry 2008, 39 (3) 161".

[0033] Add 1.15 kg of crude agomelatine to 2.88 kg of N, N-dimethylformamide (DMF) ethanol solution (5% ethanol, percent by mass), and stir at room temperature (0-35°C) until completely dissolved. Then, filter through an organic filter with a pore size of 0.2 μm. During the stirring process, add 28.8 kg of water to the filtrate, and filter after 2 hours of stirring and crystallization; the solid is beaten and filtered with 1.5 kg of water, a total of 3 times. The obtained solid was dried under normal pressure at 40-80°C to obtain about 1.06kg of solid. Yield: 92%, purity 99%.

[0034] The X powder diffraction data are:

[0035]

[0036] After the X powder diffraction data are indexed, the unit cell parameters are as follows:

[0037] Molecular formula: C 15 h 17 NO 2

[0038] Molecular weight: Mr=243.30

[0039] Crystal system: Orthorho...

Embodiment 2

[0049] The crude agomelatine was dissolved in the following mixed solvents with different concentrations, and the solid was precipitated according to the above-mentioned process (the process was the same as that in Example 1), and a crystalline solid of I was obtained.

[0050] 1. Methanol and DMF:

[0051] Methanol concentration

5%

25%

50%

75%

95%

crystal form

Form I

Form I

Form I

Form I

Form I

[0052] 2. Ethanol and DMF

[0053] Concentration of ethanol

5%

25%

50%

75%

95%

crystal form

Form I

Form I

Form I

Form I

Form I

[0054] 3. Isopropanol and DMF

[0055] Concentration of isopropanol

5%

25%

50%

75%

95%

crystal form

Form I

Form I

Form I

Form I

Form I

[0056] 4. Acetone and DMF

[0057] Concentration of acetone

5%

25%

50%

75%

95%

crystal form

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com