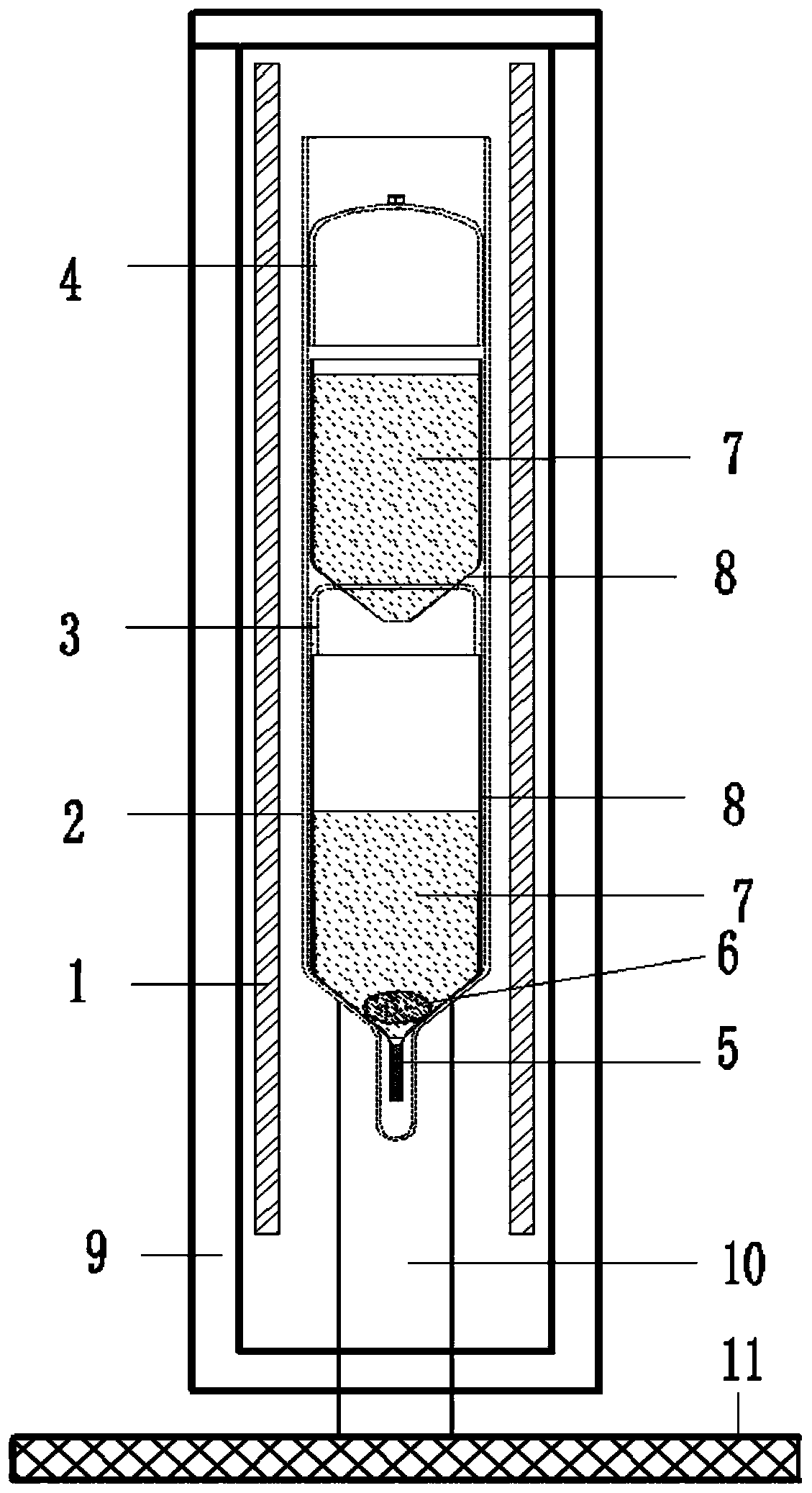

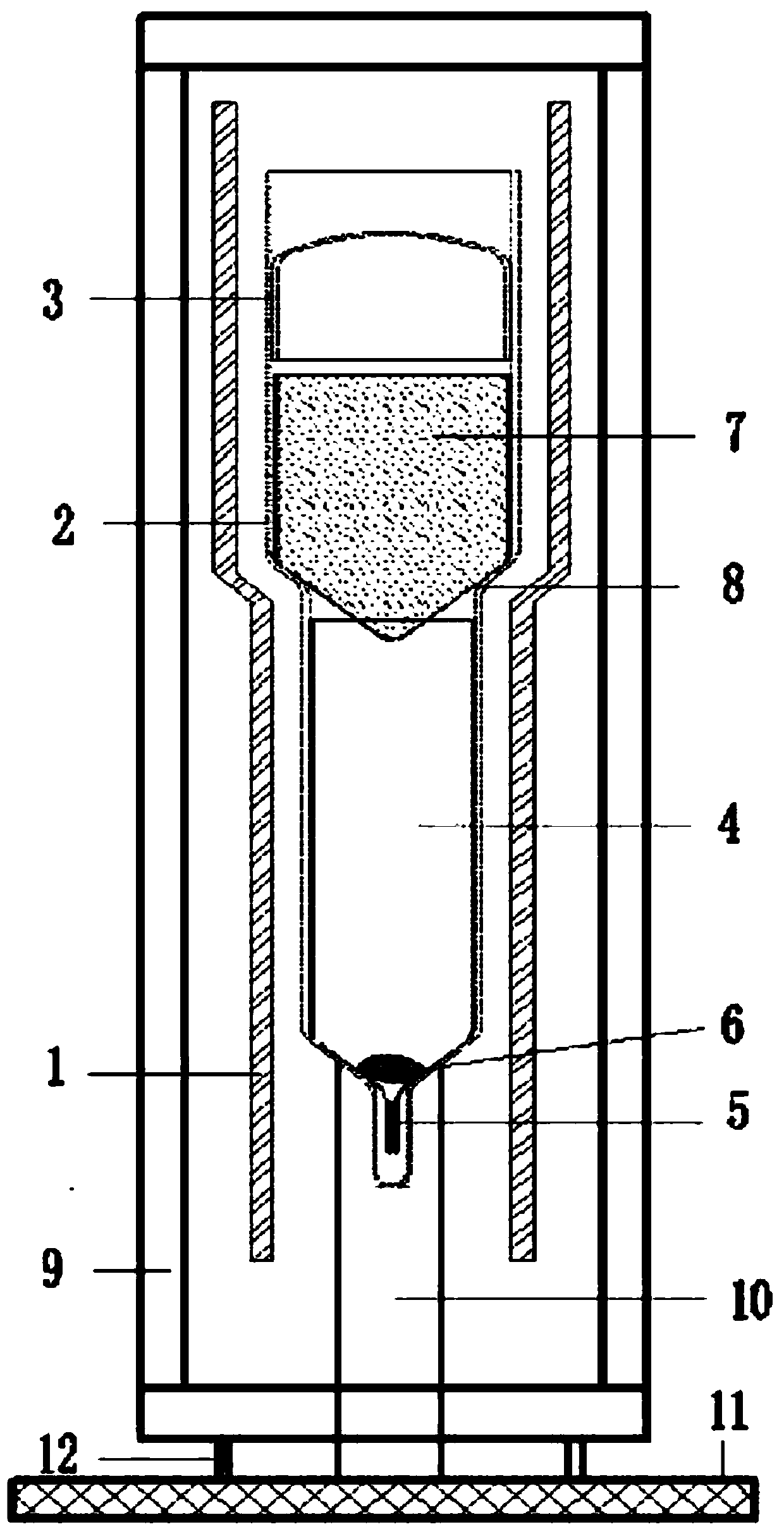

A device and method for preparing gallium arsenide crystal by vgf method

A gallium arsenide and gallium arsenide seed technology, which is applied in the field of devices for preparing gallium arsenide crystals by VGF method, can solve problems affecting the yield of crystal growth, twinning, uneven heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Put the gallium arsenide seed crystal into a 4-inch PBN crucible that has been baked and oxidized at 900°C and cover it with boron oxide, and put 12kg of gallium arsenide polycrystalline material into a 6-inch PBN crucible that has been baked and oxidized at 900°C , then put the 4-inch PBN crucible into the lower part of the quartz tube, put the 6-inch PBN crucible on the upper part of the quartz tube, and add a quartz cap on the top of the quartz tube; then vacuumize the quartz tube to 0.1MPa, and seal the quartz tube while vacuuming.

[0054] (2) Place the sealed quartz tube in the VGF furnace body, adjust the temperature of the upper part of the quartz tube in the VGF furnace body to 1250 °C through the heater, so that all the gallium arsenide polycrystalline materials in the 6-inch PBN crucible are melted and dropped to 4 inches In the PBN crucible; then adjust the temperature so that the temperature of the lower part of the quartz tube is 1240 ° C, so that the t...

Embodiment 2

[0056] (1) Put the gallium arsenide seed crystal into a 4-inch PBN crucible that has been baked and oxidized at 900°C and cover it with boron oxide, and put 14kg of gallium arsenide polycrystalline material into a 6-inch PBN crucible that has been baked and oxidized at 900°C , then put the 4-inch PBN crucible into the lower part of the quartz tube, put the 6-inch PBN crucible on the upper part of the quartz tube, and add a quartz cap on the top of the quartz tube; then vacuumize the quartz tube to 0.1MPa, and seal the quartz tube while vacuuming.

[0057] (2) Place the sealed quartz tube in the VGF furnace body, adjust the temperature of the upper part of the quartz tube in the VGF furnace body to 1280°C through the heater, so that all the gallium arsenide polycrystalline materials in the 6-inch PBN crucible are melted and dropped to 4 inches In the PBN crucible; then adjust the temperature so that the temperature of the lower part of the quartz tube is 1250 ° C, so that the to...

Embodiment 3

[0059] (1) Put the gallium arsenide seed crystal into a 4-inch PBN crucible that has been baked and oxidized at 900°C and cover it with boron oxide, and put 15kg of gallium arsenide polycrystalline material into a 6-inch PBN crucible that has been baked and oxidized at 900°C , then put the 4-inch PBN crucible into the lower part of the quartz tube, put the 6-inch PBN crucible on the upper part of the quartz tube, and add a quartz cap on the top of the quartz tube; then vacuumize the quartz tube to 0.1MPa, and seal the quartz tube while vacuuming.

[0060] (2) Place the sealed quartz tube in the VGF furnace body, adjust the temperature of the upper part of the quartz tube in the VGF furnace body to 1300°C through the heater, so that all the gallium arsenide polycrystalline materials in the 6-inch PBN crucible are melted and dropped to 4 inches In the PBN crucible; then adjust the temperature so that the temperature of the lower part of the quartz tube is 1270 ° C, so that the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com