Method for preparing water-soluble cellulose and water-soluble cellulose prepared by the same

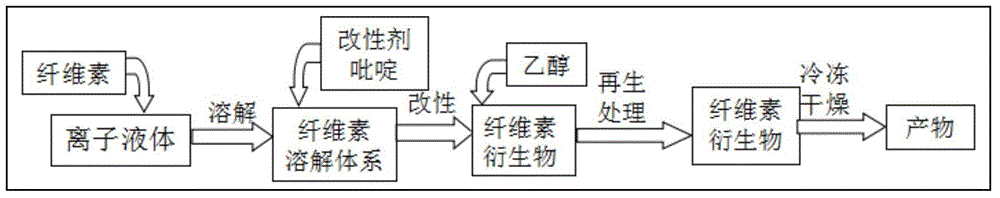

A technology for water-soluble cellulose and cellulose solution, applied in the field of preparation of water-soluble cellulose derivatives, can solve the problems of slow research progress, complicated preparation process and high price of water-soluble cellulose, and achieve reasonable and efficient utilization and dissolution. The effect of high rate and fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

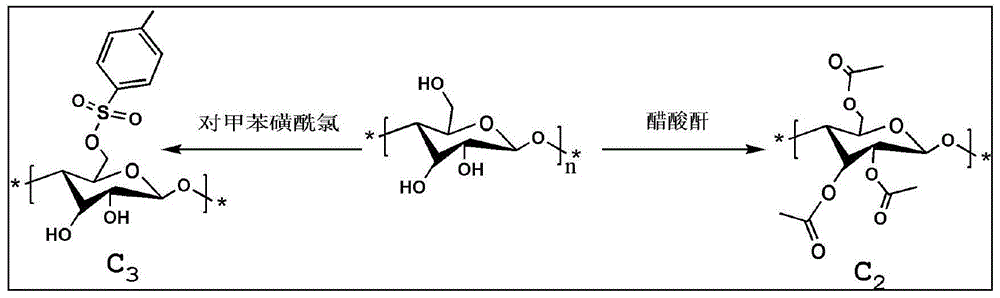

Method used

Image

Examples

Embodiment 1

[0051] 1. Crushed fiber pulp board

[0052] Put the cotton linter cellulose pulp board (purchased from Shandong Yinying Co., Ltd.) into a high-speed beater for cellulose crushing treatment. Generally, the fiber pulp board is crushed until it is completely fluffy, and there is no pulp board. A fluffy linter cellulose is obtained, wherein the pulverization time is 3-5 min.

[0053] The fluffy fiber pulp sheet is more conducive to the immersion of the solvent ionic liquid, which in turn facilitates the dissolution of cellulose.

[0054] 2. Dissolving treatment

[0055] Put fluffy linter cellulose (0.5g) and ionic liquid 1-ethyl-3-methylimidazole acetate (10g) into a 50mL beaker, and use a magnetic stirrer at 80°C under normal pressure, Stirring is carried out to dissolve the linter cellulose to obtain a transparent and viscous cellulose-ionic liquid solution, wherein the weight ratio of cellulose to ionic liquid is 1:20, the stirring time is 30min, and the stirring speed is 150...

Embodiment 2

[0066] 1. Crushed fiber pulp board

[0067] The cotton linter cellulose pulp board is placed in a high-speed beater for cellulose pulverization to obtain fluffy cotton linter cellulose, wherein the pulverization time is 3-5 minutes.

[0068] 2. Dissolving treatment

[0069] Put fluffy linter cellulose (0.5g) and ionic liquid 1-ethyl-3-methylimidazolium acetate (15g) into a 50mL beaker, seal the mouth of the beaker with plastic wrap, and store at 70°C, Under normal pressure, a magnetic device is used to stir the cotton linter cellulose to obtain a transparent and viscous cellulose-ionic liquid solution, wherein the weight ratio of cellulose and ionic liquid is 1:30, and the stirring time for 20min, the stirring speed is 200rpm.

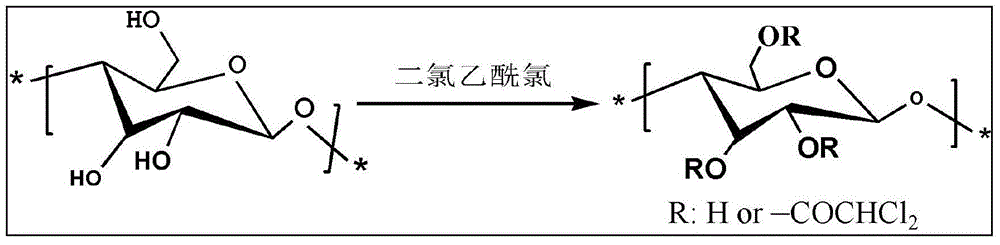

[0070] 3. Modification treatment

[0071] Under the condition of stirring and keeping the temperature of the cellulose-ionic liquid solution at 70°C, slowly add a chemical modifier (dichloroacetyl chloride, 2.5g) into the cellulose-ionic liquid solu...

Embodiment 3

[0077] 1. Crushed fiber pulp board

[0078] The cotton linter cellulose pulp board is placed in a high-speed beater for cellulose pulverization to obtain fluffy cotton linter cellulose, wherein the pulverization time is 3-5 minutes.

[0079] 2. Dissolving treatment

[0080] Put fluffy linter cellulose (0.5g) and ionic liquid 1-ethyl-3-methylimidazolium acetate (5g) into a 50mL beaker, seal the mouth of the beaker with plastic wrap, and store at 90°C, Under normal pressure, a magnetic device is used for stirring treatment to dissolve the linter cellulose to obtain a transparent and viscous cellulose-ionic liquid solution, wherein the weight ratio of cellulose and ionic liquid is 1:10, and the stirring time for 30min, the stirring speed is 200rpm.

[0081] 3. Modification treatment

[0082] Under the condition of stirring and keeping the temperature of the cellulose-ionic liquid solution at 90° C., slowly add a chemical modifier (dichloroacetyl chloride, 1.0 g) into the cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com