Patents

Literature

430 results about "Industrial utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrate chemical processes for industrial utilization of seed oils

ActiveUS20050154221A1Easy to operateHigh olefin conversionFatty oils/acids recovery from wasteOxygen-containing compound preparationPolyesterAmino esters

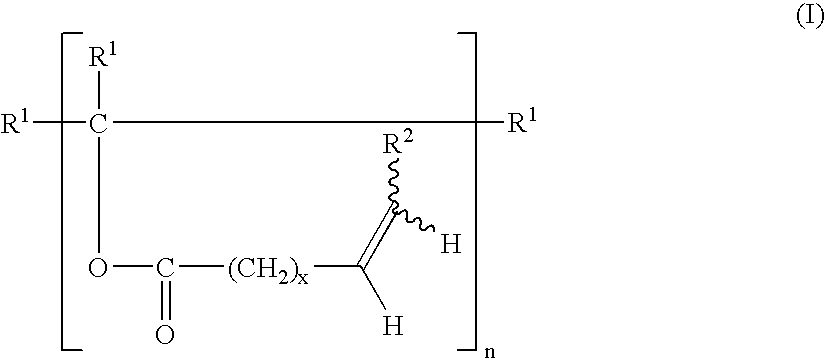

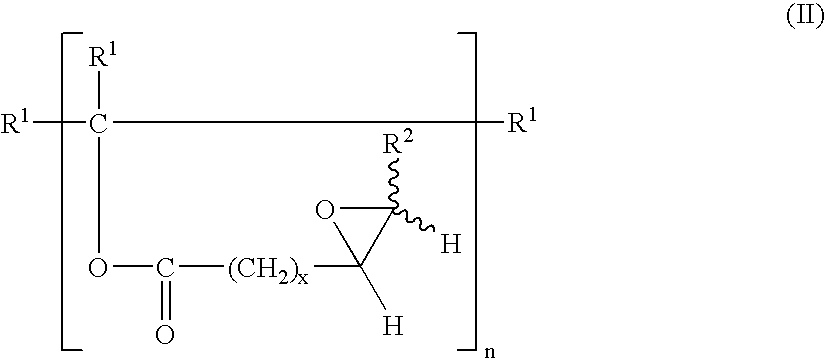

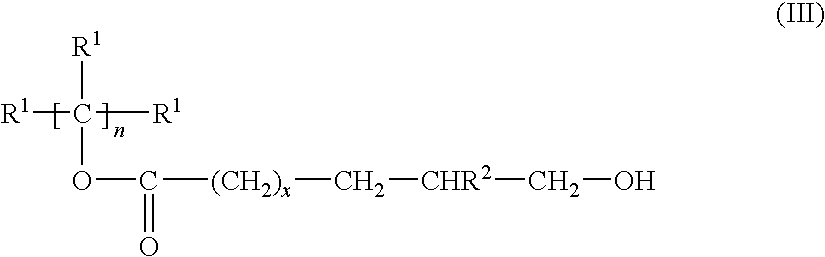

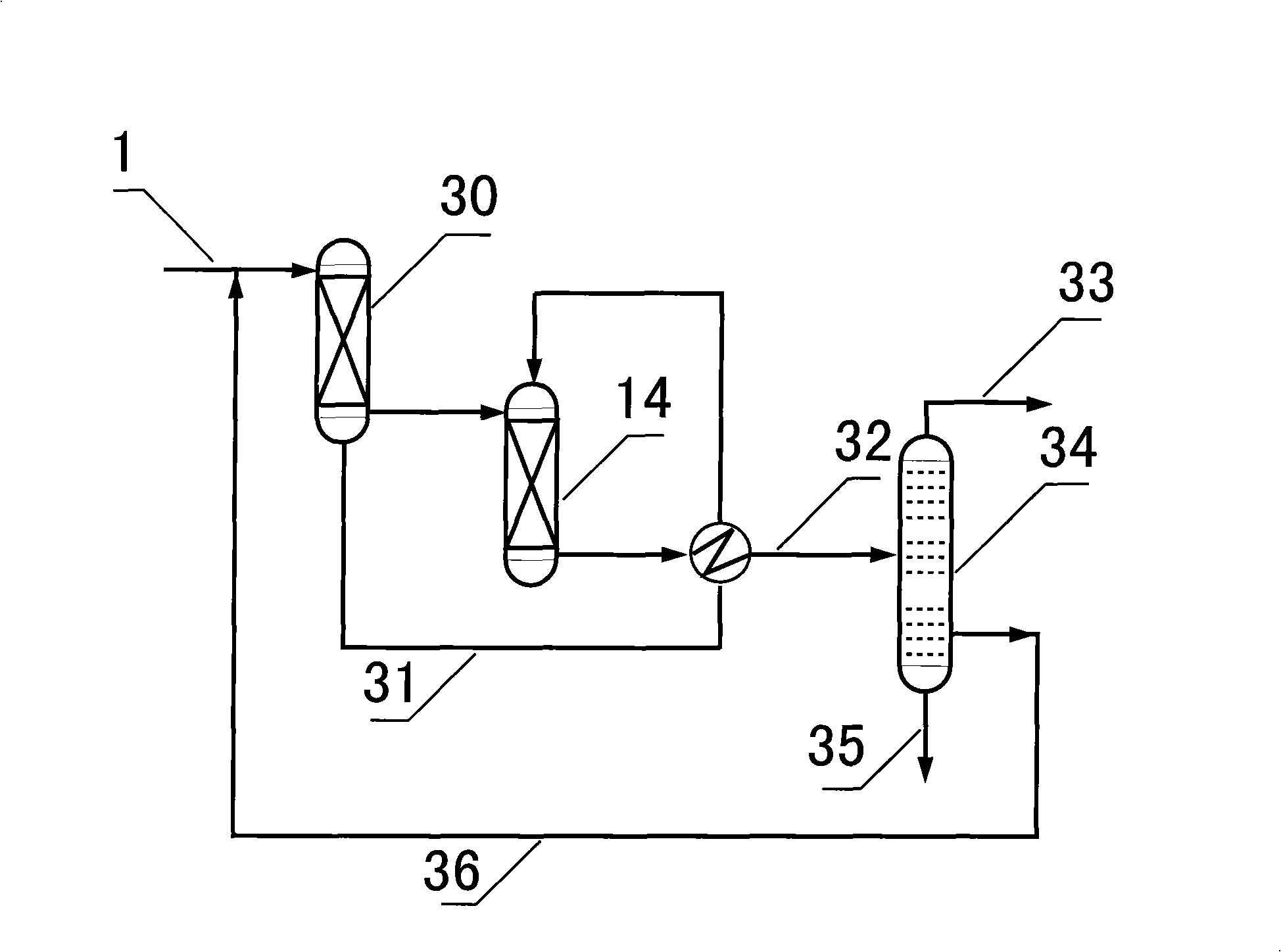

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,Ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,Ω-hydroxy acid or α,Ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,Ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,Ω-amino acid or α,Ω-amino ester, which may be (trans)esterified to form an α,Ωpolyester polyamine.

Owner:DOW GLOBAL TECH LLC

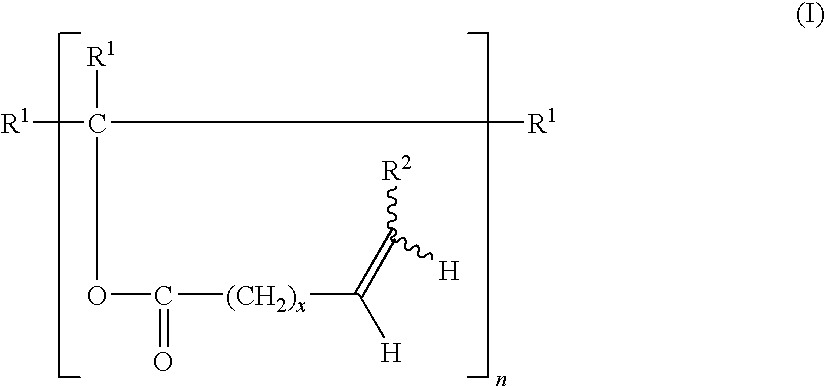

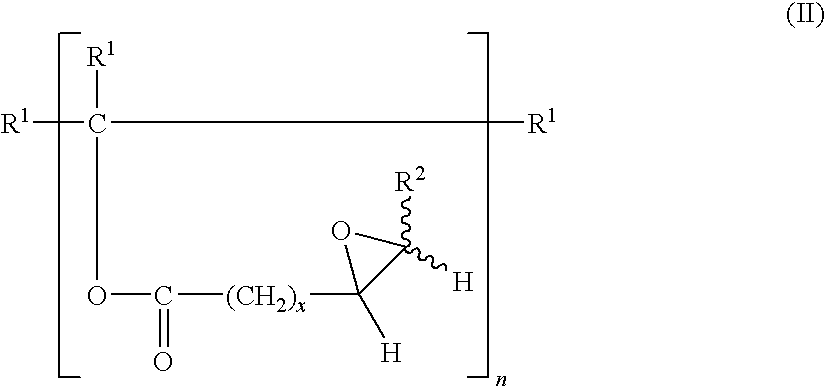

Curable resin composition

The object of the present invention is to provide a novel acrylic-modified silyl-terminated polyether resin composition which is advantageous not only in terms of the availability of raw materials and the ease of synthetic reaction, but also in fast-curing, good storage stability, good weatherability, high adhesiveness, thus promising high potentials of industrial utilization. Further, the object of the present invention is also to develop an environment-friendly curable composition which is a major social consideration. The composition is a curable composition comprising an oxyalkylene polymer (A) containing silyl functional group capable of crosslinking by forming a siloxane bond and a copolymer (B) having a molecular chain comprising alkyl acrylate and / or alkyl methacrylate monomer units and containing silyl functional group capable of crosslinking by forming a siloxane bond, said copolymer (B) having both dialkoxysilyl and trialkoxysilyl groups as said silyl functional group.

Owner:KANEKA CORP

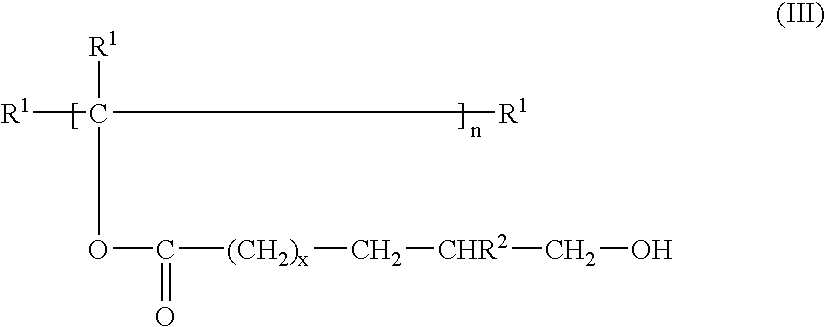

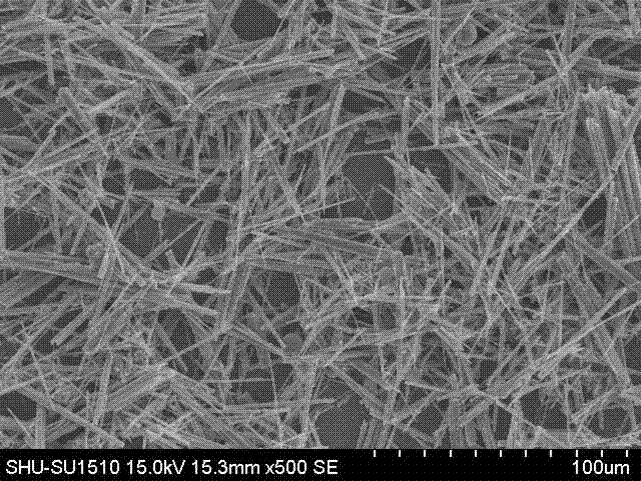

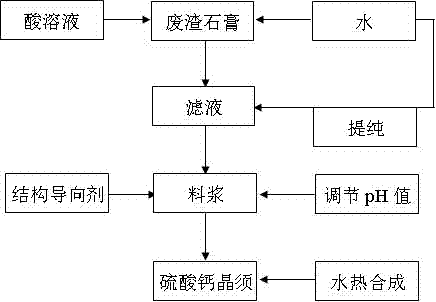

Method for preparing calcium sulfate crystal whisker from many kinds of industrial waste residue gypsum serving as raw materials

InactiveCN102212884AIncrease added valueTo achieve the purpose of turning waste into treasurePolycrystalline material growthFrom normal temperature solutionsSolubilityLiquid ratio

The invention relates to a method for preparing a high-quality calcium sulfate crystal whisker, which comprises the following steps of: purifying industrial waste residue gypsum serving as a raw material by utilizing the characteristic of the obvious change of the solubility of calcium sulfate in specific acid solution with temperature, adjusting the solid-to-liquid ratio and pH value of purified filter liquor, and synthesizing the high-purity and high-whiteness calcium sulfate crystal whisker in a hydrothermal mode under the action of a structural guiding agent. In a process for preparing the calcium sulfate crystal whisker from many kinds of industrial waste residue gypsum, the bottleneck problem of the large-scale industrial utilization of complex varieties of waste residue gypsum impurities is solved fundamentally, and the aims of saving energy, reducing emission and recycling waste materials are fulfilled, and the method has a bright application and market prospect.

Owner:SHANGHAI UNIV

Integrated chemical processes for industrial utilization of seed oils

InactiveUS20090143544A1Easy to operateImprove productivityFatty oils/acids recovery from wasteOrganic compound preparationPolyesterPolymer science

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,ω-hydroxy acid or α,ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,ω-amino acid or α,ω-amino ester, which may be (trans)esterified to form an α,ω-polyester polyamine.

Owner:DOW GLOBAL TECH LLC

Method for improving mixed C4 chemical industry exploitation value

ActiveCN101492334AIncrease valueChemical added value is highHydrocarbon by isomerisationHydrocarbon purification/separationChemical industryDisproportionation

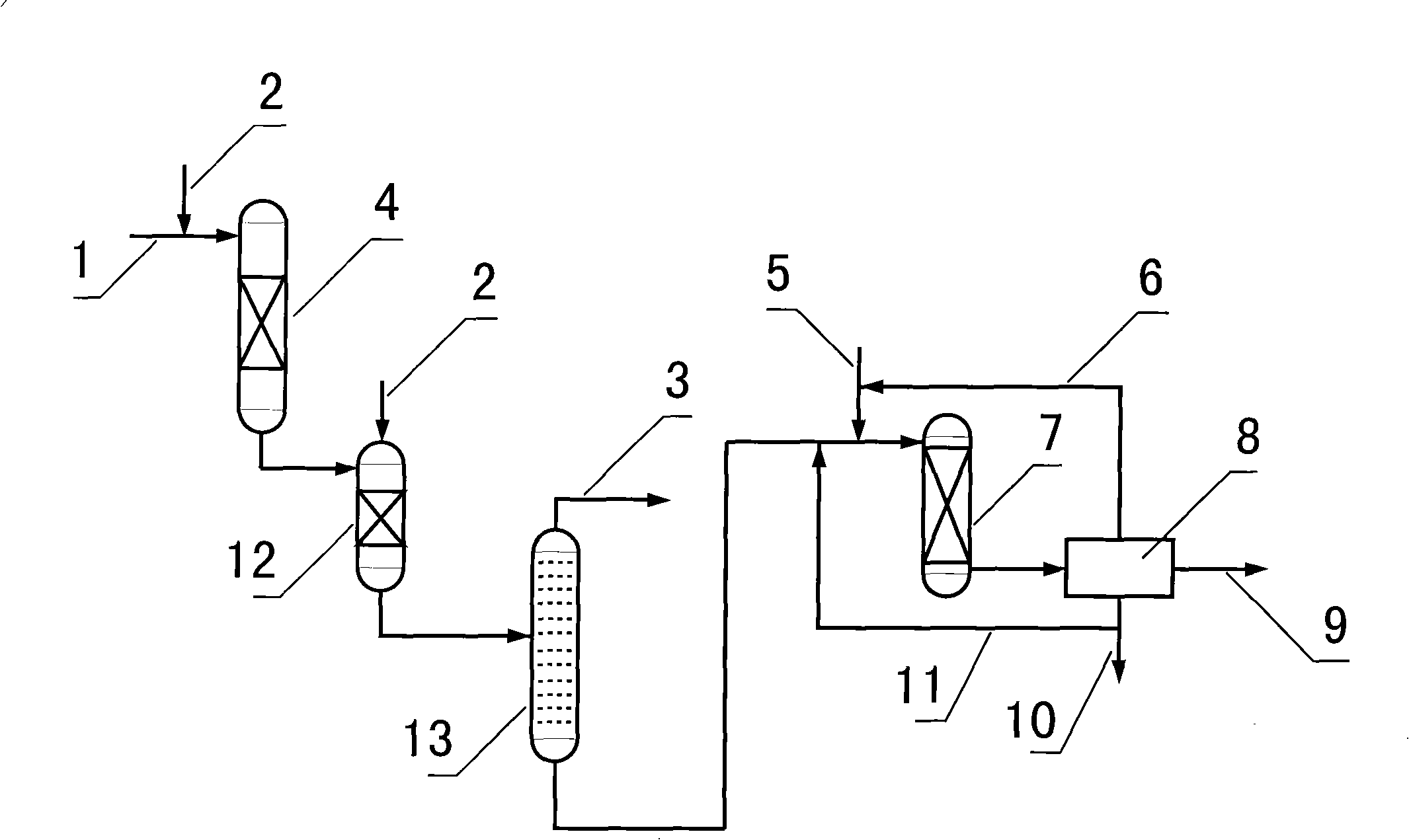

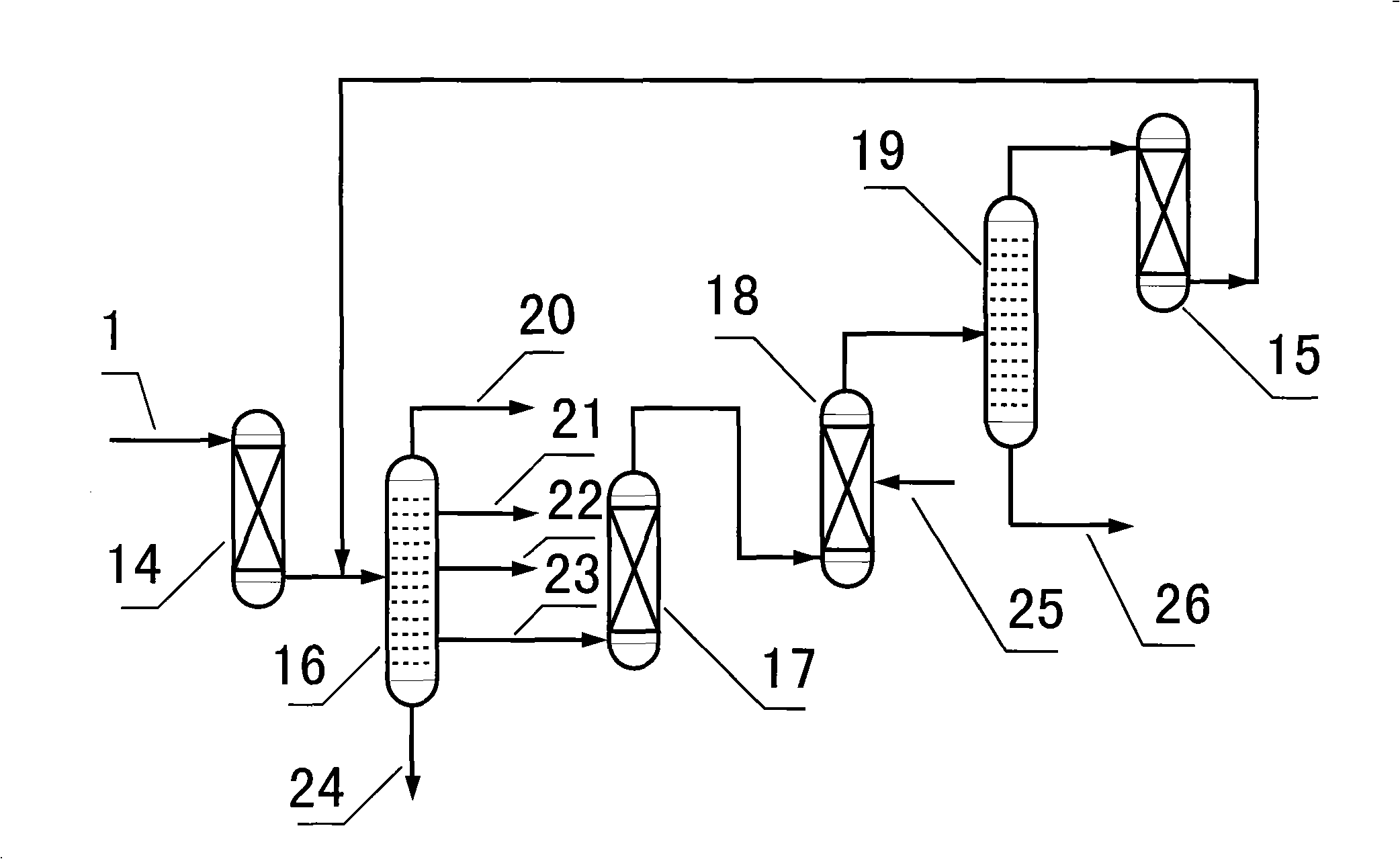

The invention relates to a method for improving the chemical industrial utilization value of mixed C4. The method mainly solves the problem that the chemical industrial utilization value and the comprehensive utilization rate of a byproduct of the mixed C4 of a steam cracking device and the byproduct of the mixed C4 of an FCC device in the prior art are low. The invention solves the problem well by the technical proposal which comprises the steps as follows: 1) a selective hydrogenation technology is adopted to ensure that butadiene and acetylene in the mixed C4 are hydrogenated into monoolefine; 2) a hydroisomerization technology is adopted to ensure that butylene-1which is a product in step 1 is isomerized into butylene-2; 3) the product of step 2 is separated by rectifying technology to obtain a product of isobutene; 4) olefin disproportionation technology is used for disproportionating the butylene-2 in the rest of the mixed C4 in step 3 and ethane to produce propylene; and 5) the remained mixed C4 in step 4 is recycled as a cracking raw material. The invention can be used in the industrial production for increasing the production of the propylene and improving the chemical industrial utilization value of the mixed C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

Curable resin composition

The object of the present invention is to provide a novel acrylic-modified silyl-terminated polyether resin composition which is advantageous not only in terms of the availability of raw materials and the ease of synthetic reaction, but also in fast-curing, good storage stability, good weatherability, high adhesiveness, thus promising high potentials of industrial utilization. Further, the object of the present invention is also to develop an environment-friendly curable composition which is a major social consideration. A curable composition comprising an oxyalkylene polymer (A) containing silyl functional group capable of crosslinking by forming a siloxane bond and a copolymer (B) having a molecular chain comprising alkyl acrylate and / or alkyl methacrylate monomer units and containing silyl functional group capable of crosslinking by forming a siloxane bond, said copolymer (B) having both dialkoxysilyl and trialkoxysilyl groups as said silyl functional group.

Owner:KANEKA CORP

Resourceful treatment method for inorganic salts in industrial waste water

ActiveCN103708572AHigh purityReduce wasteWater/sewage treatment by heatingAlkali metal chloridesInorganic saltsIndustrial waste water

The invention discloses a resourceful treatment method for inorganic salts in industrial waste water. The method comprises the following steps: evaporating and concentrating waste water to obtain solid salts; carrying out thermal cracking on organic substances in the solid salts into organic gas; introducing the organic gas obtained by thermal cracking into a burning device for full burning, quickly cooling produced tail gas, and exhausting the cooled tail gas; further purifying the thermally-cracked solid salts via high-temperature carbonization to obtain high-purity solid salts, and introducing gas produced by carbonization into the burning device for full burning. According to the method, the flow is simple, the process is mature, industrial utilization is facilitated, and the methd can be applied to treatment of pesticides and even other industrial high-salt waste water. By adopting the method, the purity of the inorganic salts is increased, so that the inorganic salts can be reused. Secondary wastes which are difficult to treat are not produced in a production process, so that waste of resources is reduced, environmental pollution caused by the waste water is lowered, and very good economical and social benefits are achieved.

Owner:SHANDONG WEIFANG RAINBOW CHEM

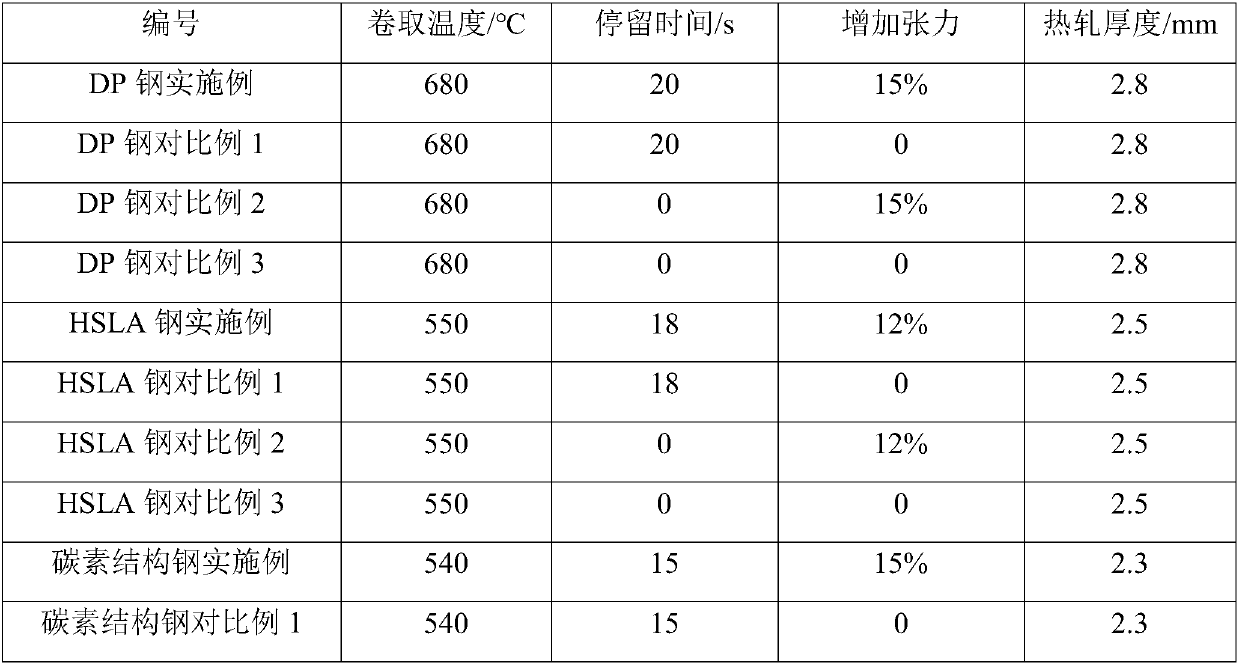

Method for preventing hot rolled reel from being flattened

ActiveCN107812789AReduced flat rollEasy to operateMetal rolling arrangementsLaminar coolingStrip steel

The invention belongs to the technical field of high-strength steel and particularly relates to a method for preventing a hot rolled reel from being flattened. The problems that as for an existing method for preventing a hot rolled reel from being flattened, either operation is complex and the production efficiency is low, or the cost is increased and industrial utilization is difficult are solved. The method for preventing the hot rolled reel from being flattened comprises the following steps that hot-rolled strip steel is subjected to laminar cooling and rapidly cooled to be 650-700 DEG C or500-550 DEG C to be reeled, and the reeled hot-rolled steel reel is stopped on a reeling machine for 5-20 s; and reeling tension is increased by 5-10% than regular reeling tension. According to the method for preventing the hot rolled reel from being flattened, the problem that the hot-rolled strip steel is flattened and subsides after being reeled can be effectively solved, normal implementationof subsequent unreeling technique is ensured, and the method for preventing the hot rolled reel from being flattened is easy to implement and obvious in cost advantage and has removable economic andsocial benefits.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

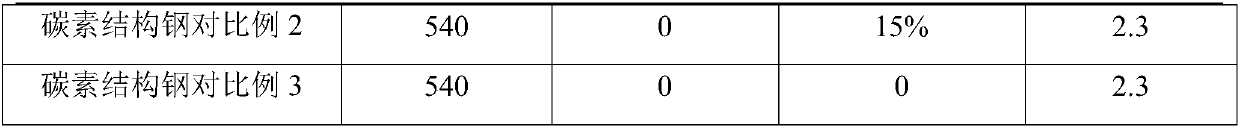

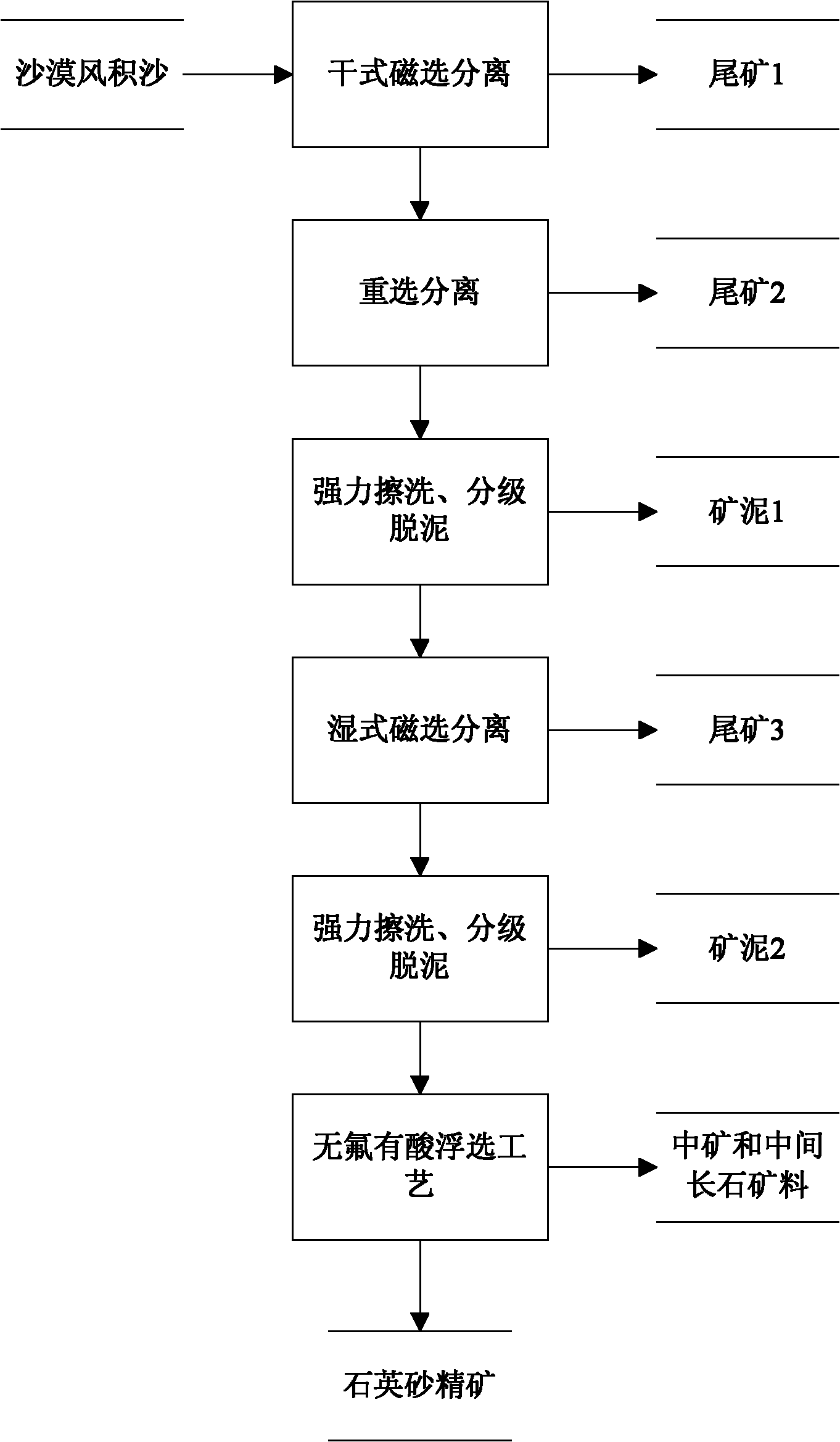

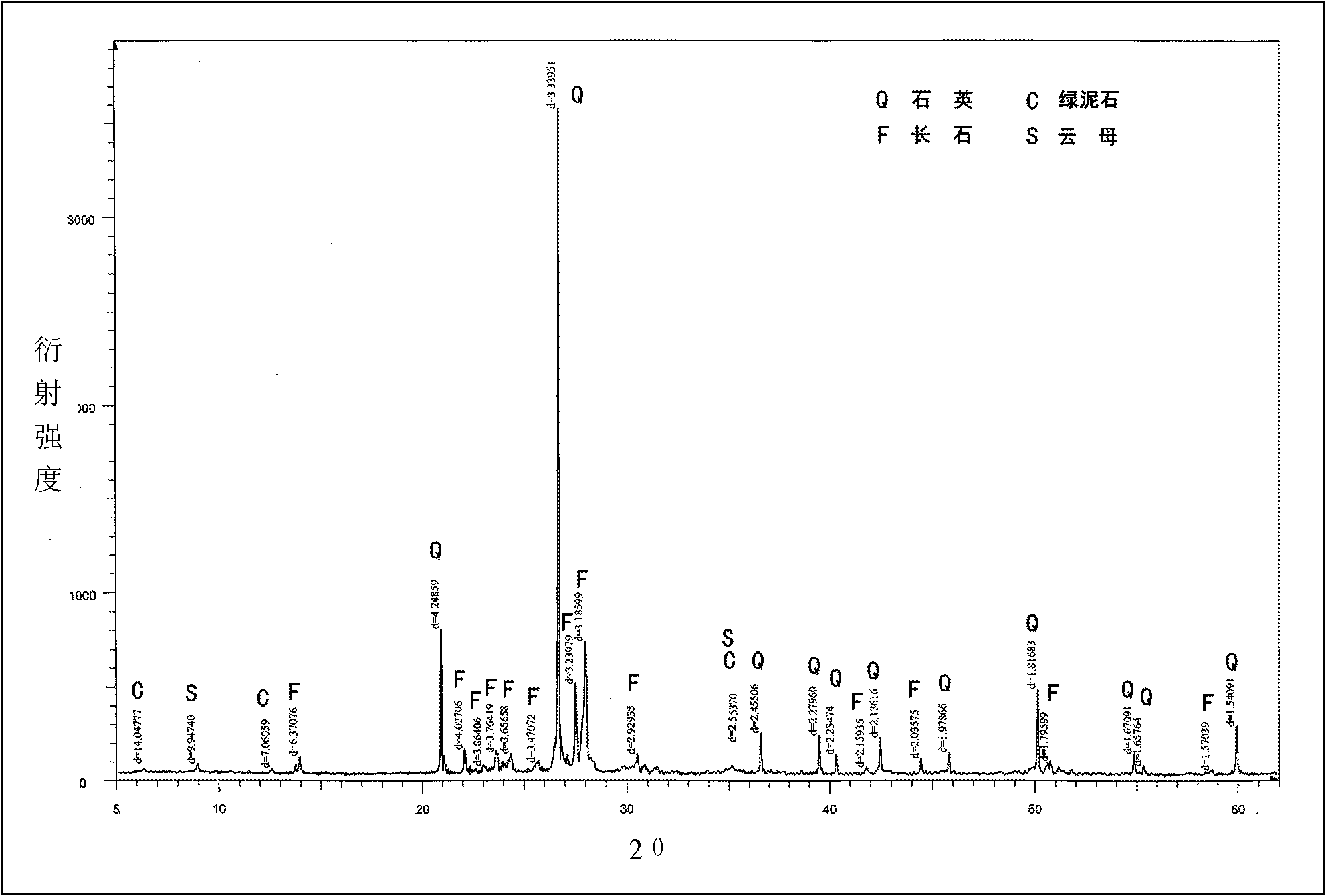

Method for separating and preparing quartz sand concentrate from wind-laid sand in desert

ActiveCN101870474AReduce production water consumptionReduce contentSilicaWet separationQuartzGravity separation

The invention belongs to an industrial utilization method for wind-laid sand in desert, and discloses a method for separating and preparing quartz sand concentrate from the wind-laid sand in desert. The method comprises an early-stage deironing process and a later-stage quartz separation process, wherein the early-stage deironing process comprises the following steps of: performing dry magnetic separation on the wind-laid sand in desert; performing gravity separation on the concentration after the dry magnetic separation; performing strong scrubbing and classification and desliming on the concentrate after the gravity separation; and performing wet magnetic separation; and the concentrate after the deironing is subjected to the later-stage quartz separation process to form the quartz sand concentrate product. The process saves water, reduces consumption, reduces cost, and can produce high-quality quartz sand concentrate by fully utilizing the wind-laid sand resources.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

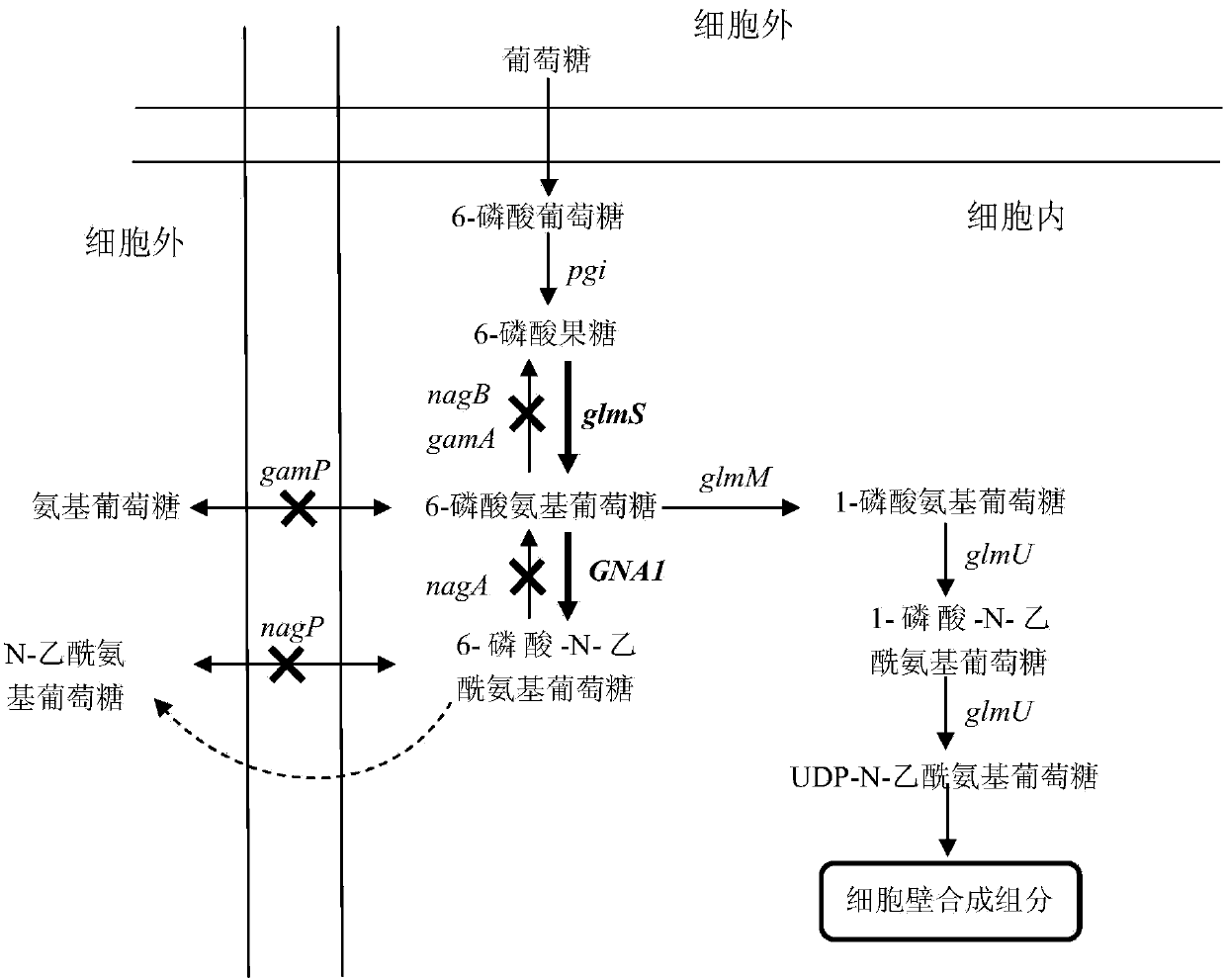

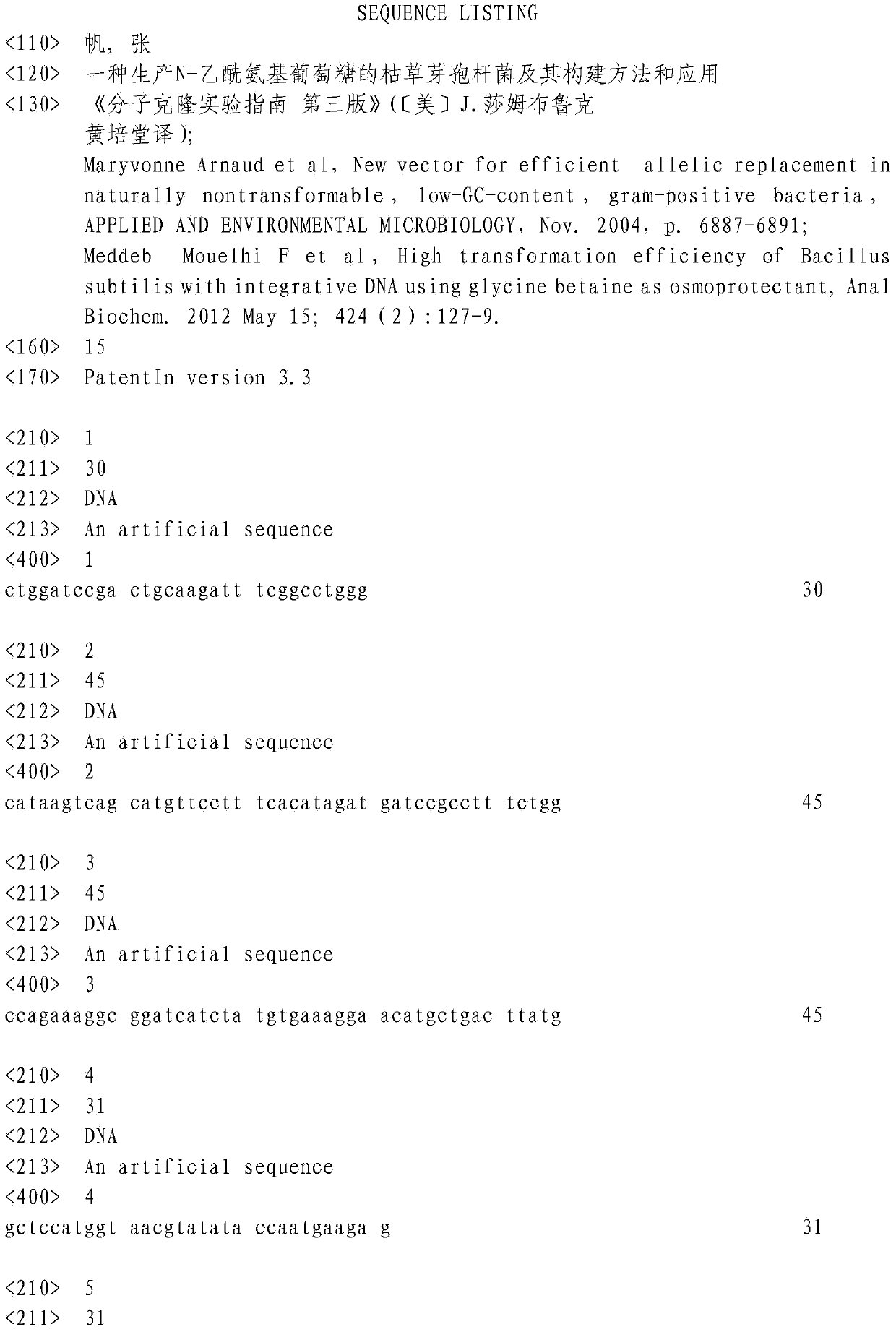

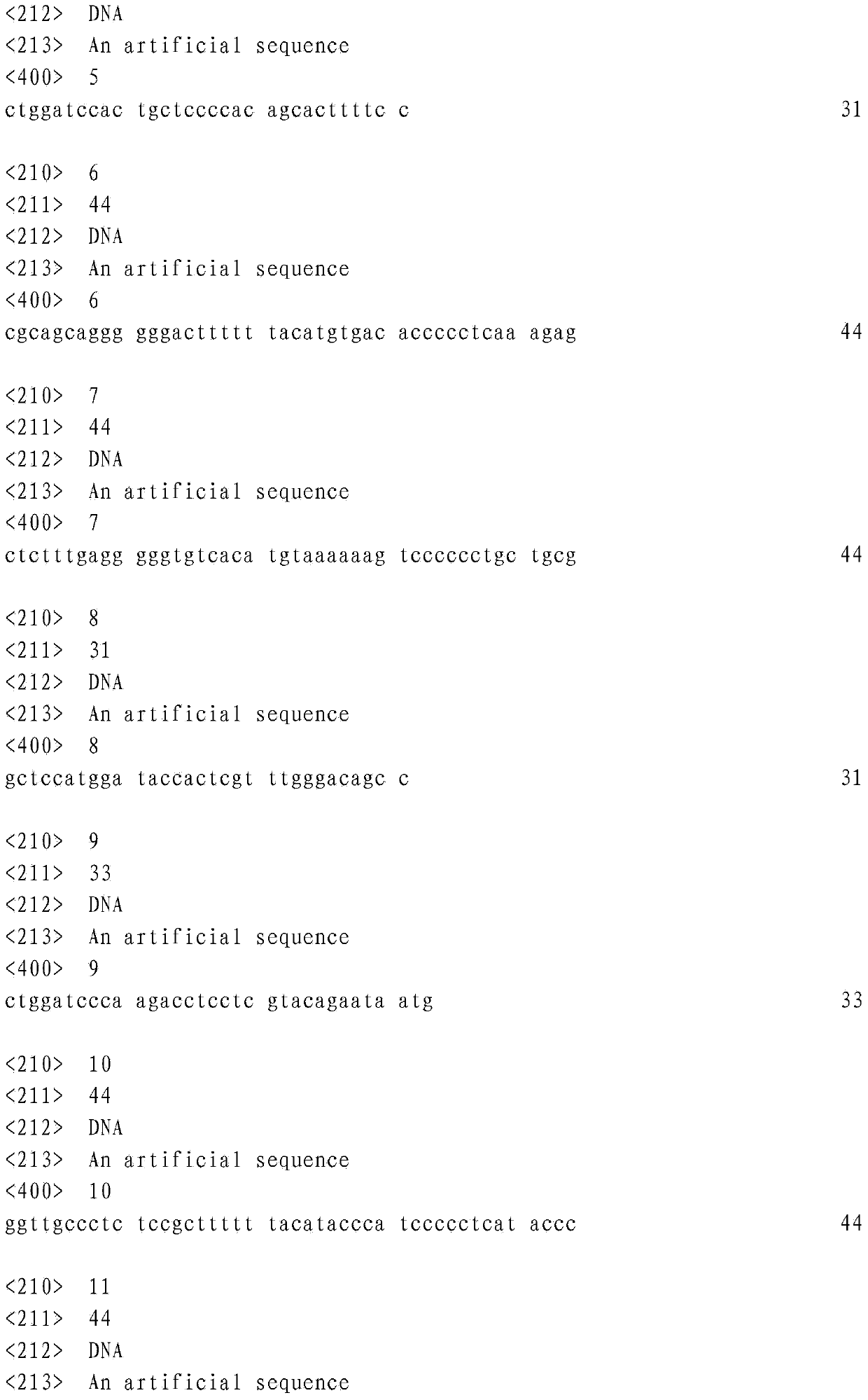

Bacillus subtilis for producing N-acetylglucosamine as well as construction method and application of bacillus subtilis

InactiveCN104195094APrevent backflowAvoid consumptionBacteriaMicroorganism based processesHigh concentrationPhosphate

The invention belongs to the construction and the application of genetically engineered bacterium and particularly relates to bacillus subtilis for producing N-acetylglucosamine as well as a construction method and application of bacillus subtilis. The construction method for the genetically engineered bacterium (bacillus subtilis) comprises the following steps: expressing and coding 6-glucosamine phosphate synthetase gene and 6-glucosamine phosphate acetylase gene in bacillus subtilis to form a complete metabolic pathway from glucose to N-acetylglucosamine; knocking out or inactivating glucosamine 6-phosphate deaminase genes nagB and gamA, an N-acetylglucosamine 6-phosphate deacetylase gene nagA, a glucosamine transport protein gene gamP and an N-acetylglucosamine transport protein gene nagP in an N-acetylglucosamine catabolism pathway in bacillus subtilis. The construction method can be used for solving the problem that N-acetylglucosamine produced in the prior art is poor in safety, low in yield and high in cost. The constructed genetically engineered bacterium has the advantage that N-acetylglucosamine with relatively high concentration can be accumulated, and the industrial utilization value is relatively high.

Owner:张帆

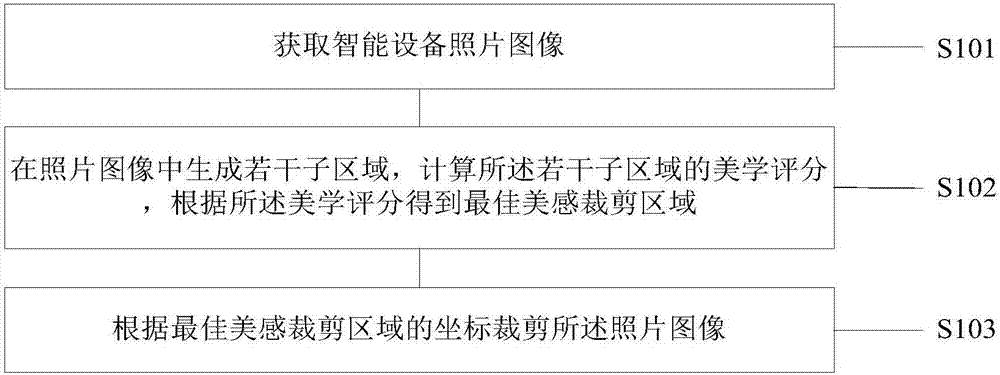

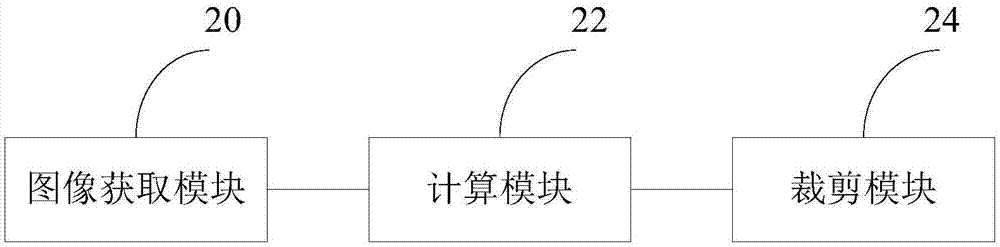

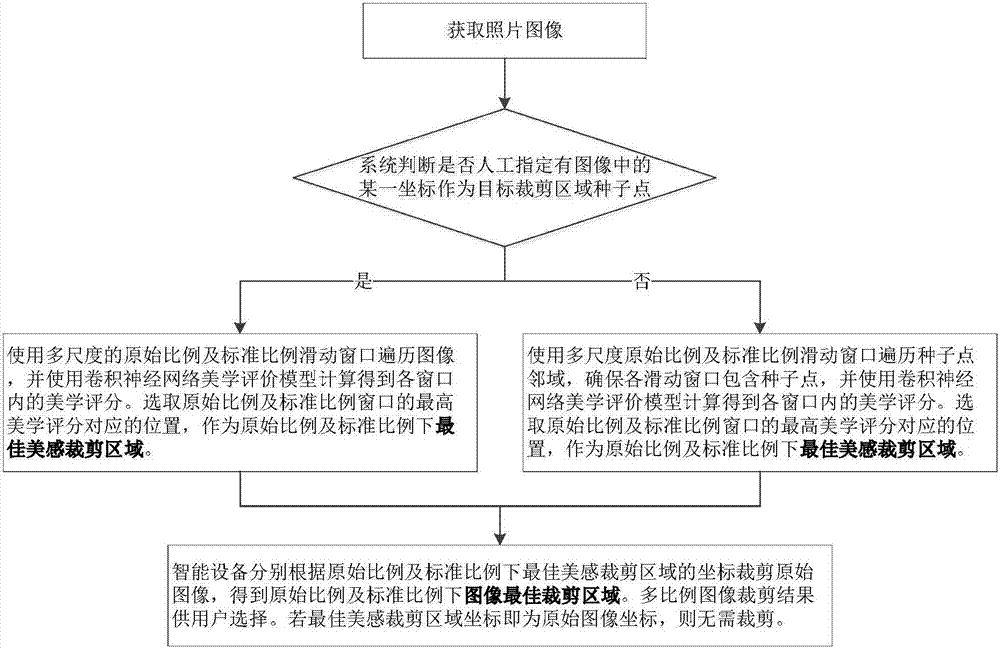

Intelligent photo clipping method and device

ActiveCN107146198ACommon photo typeEasy to operateGeometric image transformationPhoto imageSmart device

The present invention discloses an intelligent photo clipping method and device. The method comprises the following steps: a photo image of an intelligent device is obtained; a plurality of sub-regions are generated in the photo image, the aesthetic scores of the sub-regions are calculated, and an optimal aesthetic clipping area is obtained according to the aesthetics scores; and the photo image is clipped according to the coordinates of the optimal aesthetic clipping area. According to the intelligent photo clipping method and device provided by the embodiments of the invention, the intelligent clipping of a photo is realized through picture aesthetic evaluation technology, so that a clipped photo can better accord with an application scene from the perspective of aesthetics. The types of photos to which the intelligent photo clipping method and device can be applied are more universal. The intelligent photo clipping method and device of the invention have the advantages of convenient operation, high efficiency and high industrial utilization value. With the intelligent photo clipping method and device of the invention adopted, defects in the prior art can be eliminated.

Owner:CHINA ACADEMY OF ELECTRONICS & INFORMATION TECH OF CETC

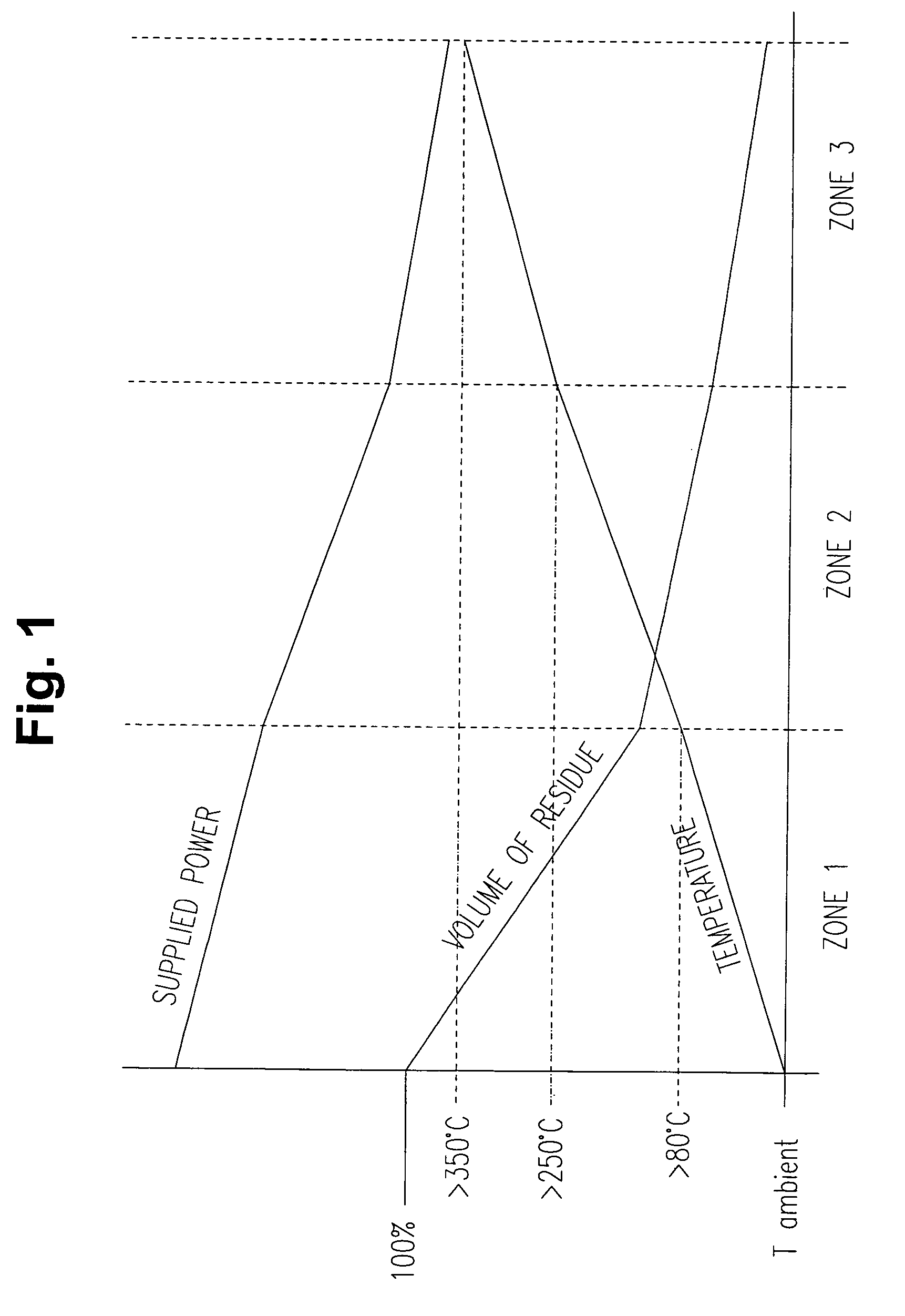

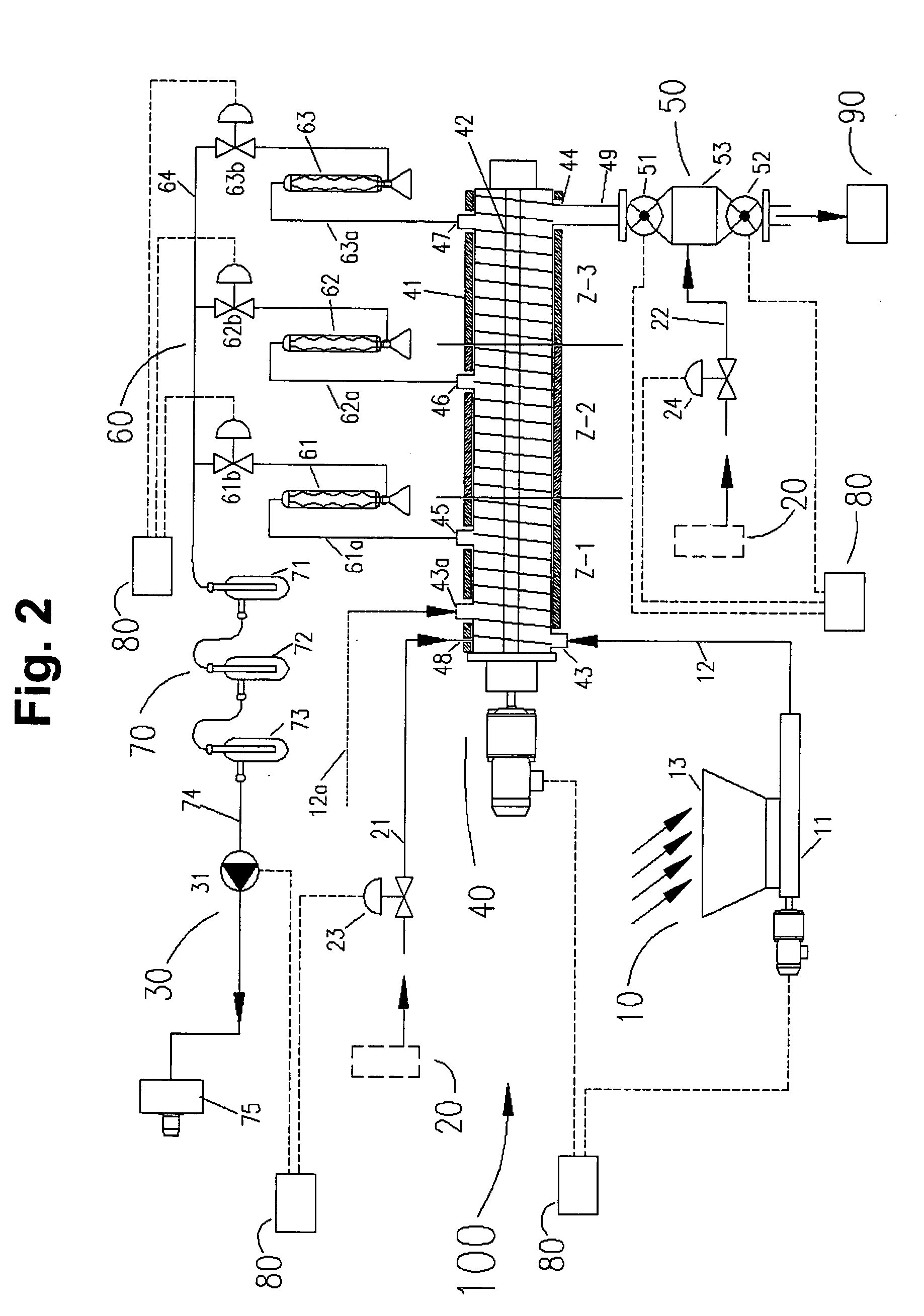

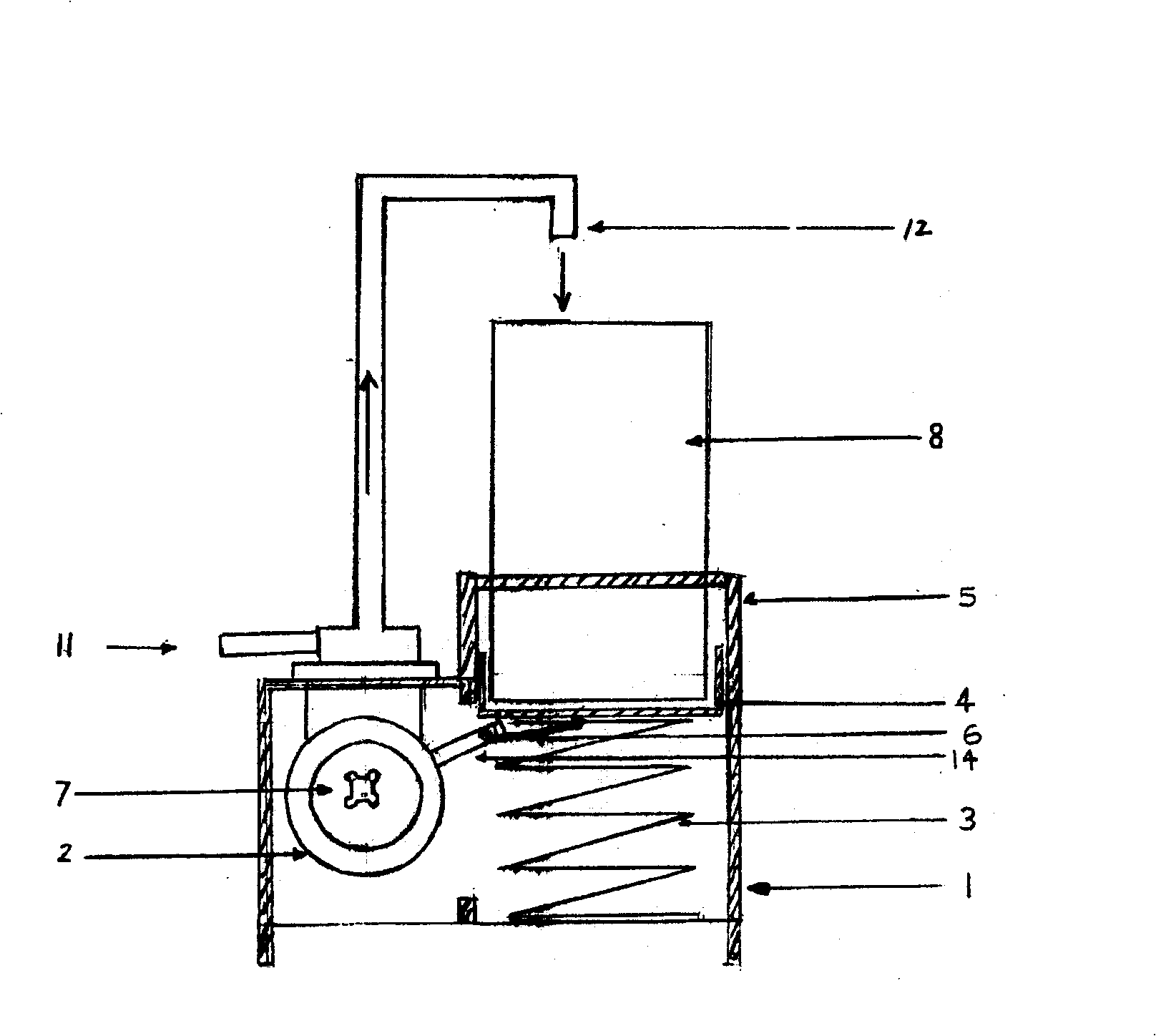

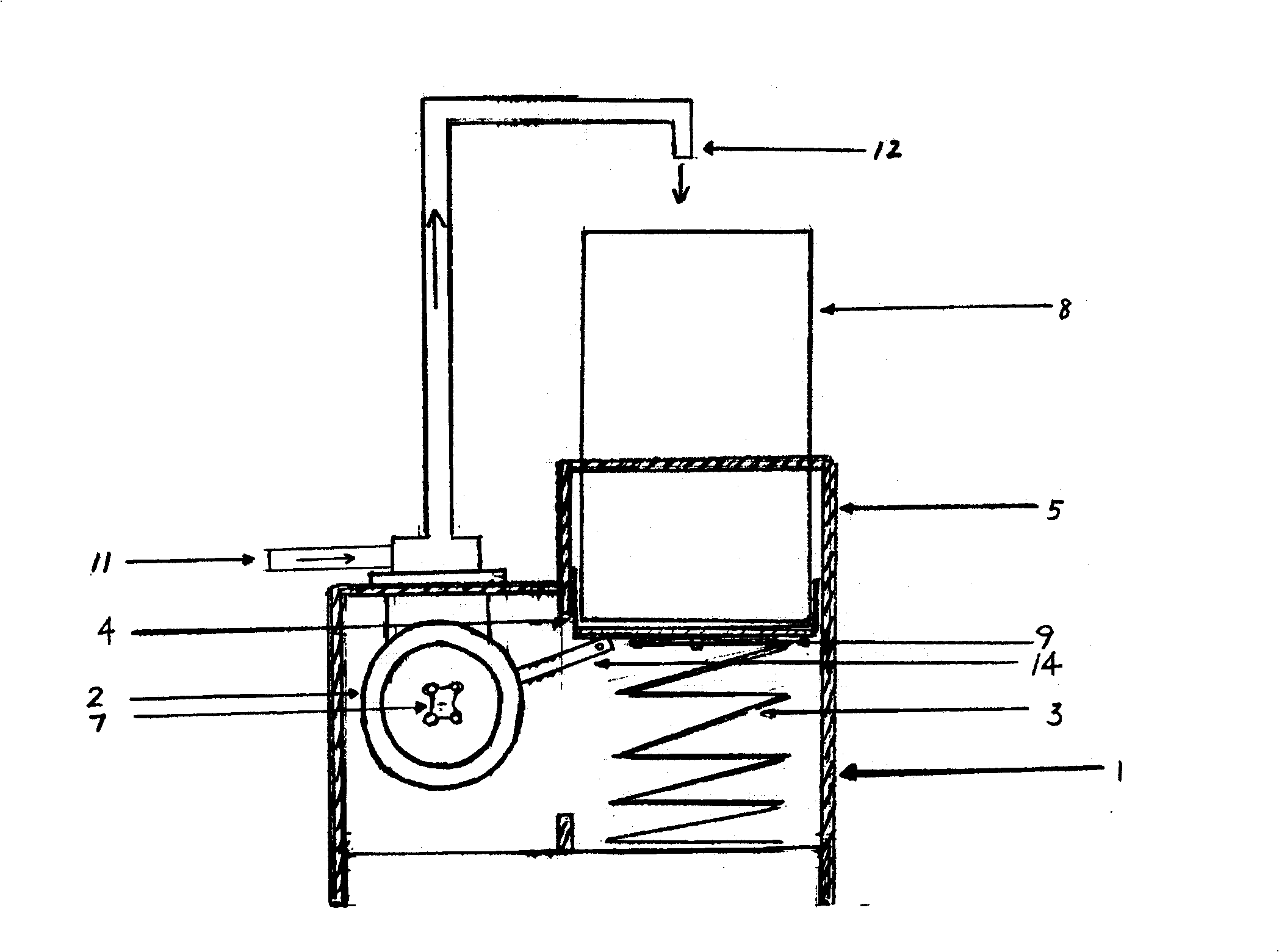

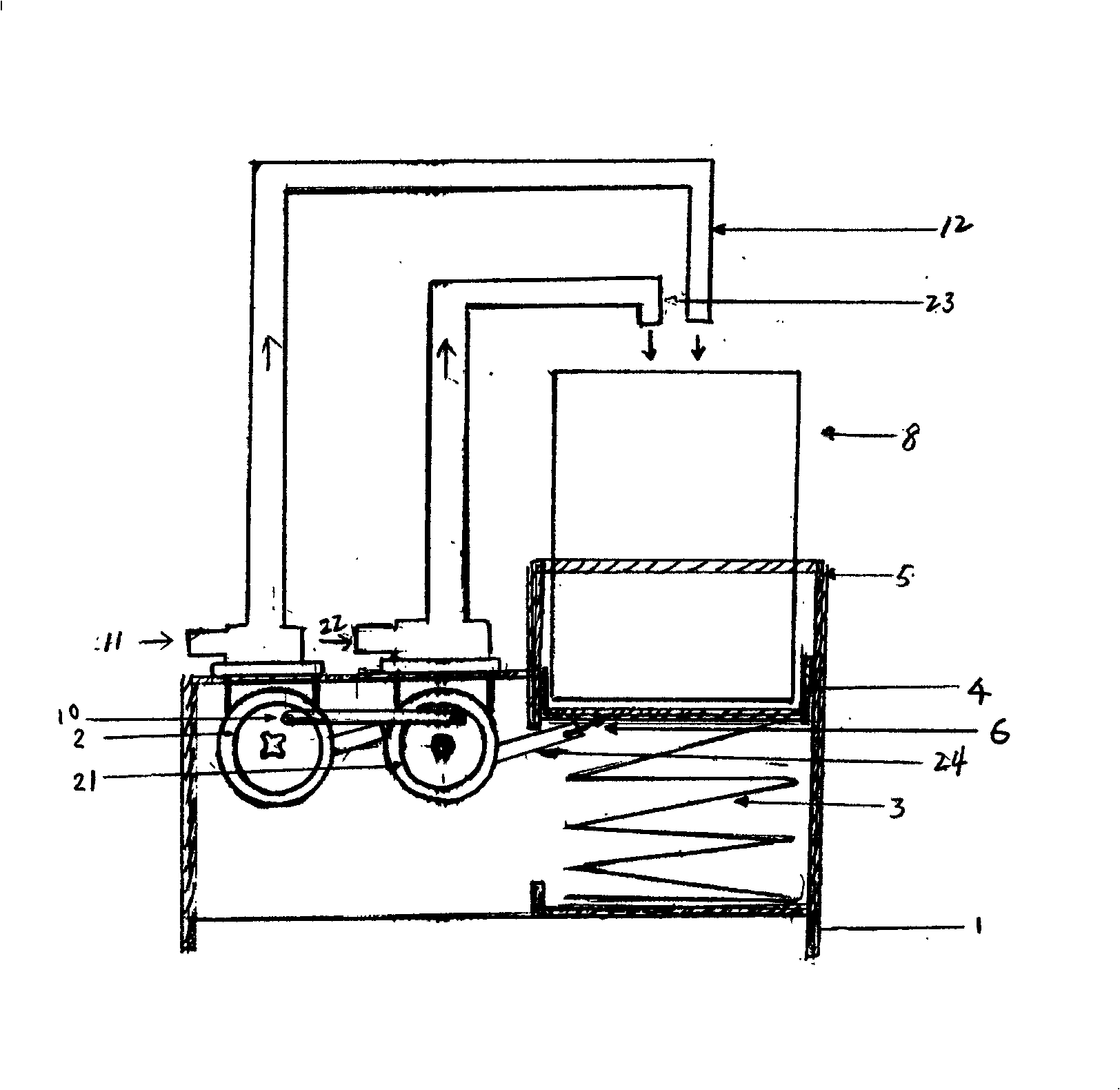

System and process for the treatment of multiphase residues

ActiveUS20050218037A1Useful in treatmentProcess environmental protectionCatalytic crackingRetortsMining industryPhenol

A system 100 is described for the treatment of multiphase residues having unlimited content of water, oil and solids to obtain hydrocarbons and other products, said system comprising multiphase residue feed system 10, inert gas system 20 and reduced pressure system 30, tubular reactor 40 provided with three heating zones Z-1, Z-2 and Z-3 with a temperature gradient and transportation helicoid 42 to displace the residue mass throughout the reaction zones, the hydrocarbon products and water being collected in a system 60 of condensers 61, 62 and 63 linked to a system 70 of bubbling vessels 71, 72 and 73, reactor 40 being operated in the sealed mode and being provided with a multiphase residue inlet 43 and exit 44 of solid product. The solid product is collected in a system 50 comprising upper valve 51 and lower valve 52, and intermediate silo 53 and then directed to post-treatment system 90 for activation aiming at industrial utilization. The process using the system 100 of the invention is also described. Multiphase organic residues, petroleum residues, pure or in admixture in any amount, from chemical and pharmaceutical industries, paper and pulp industry, and mining industries can be processed in the inventive system. Besides, it is possible to recover phenols from foundry sands in the system and process described.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS) +1

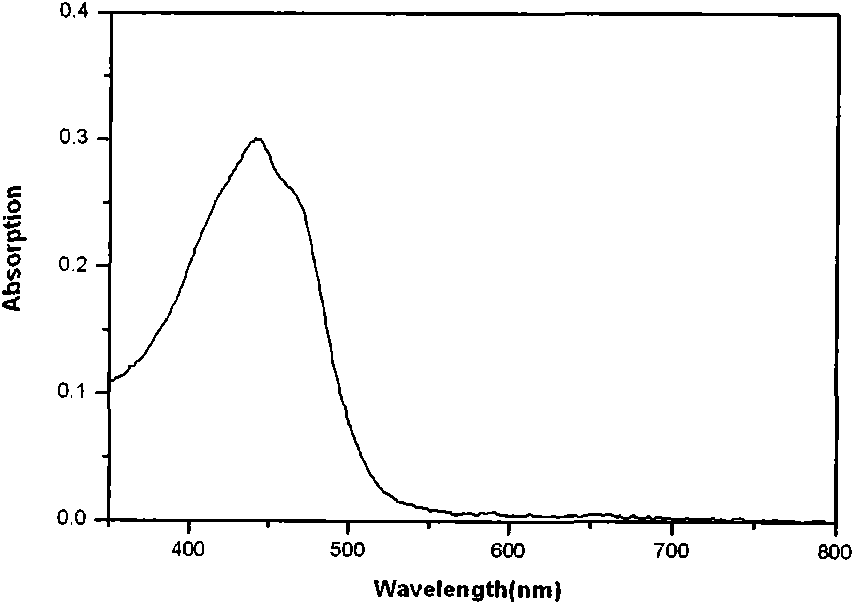

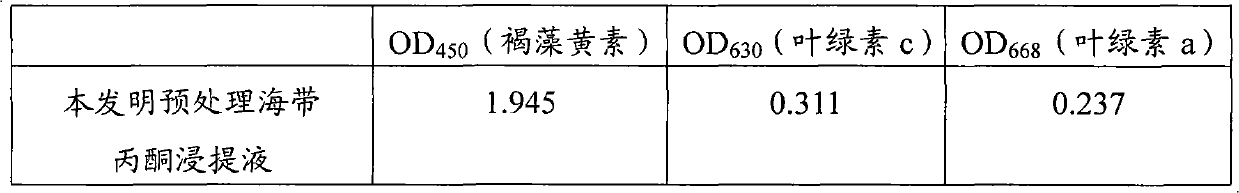

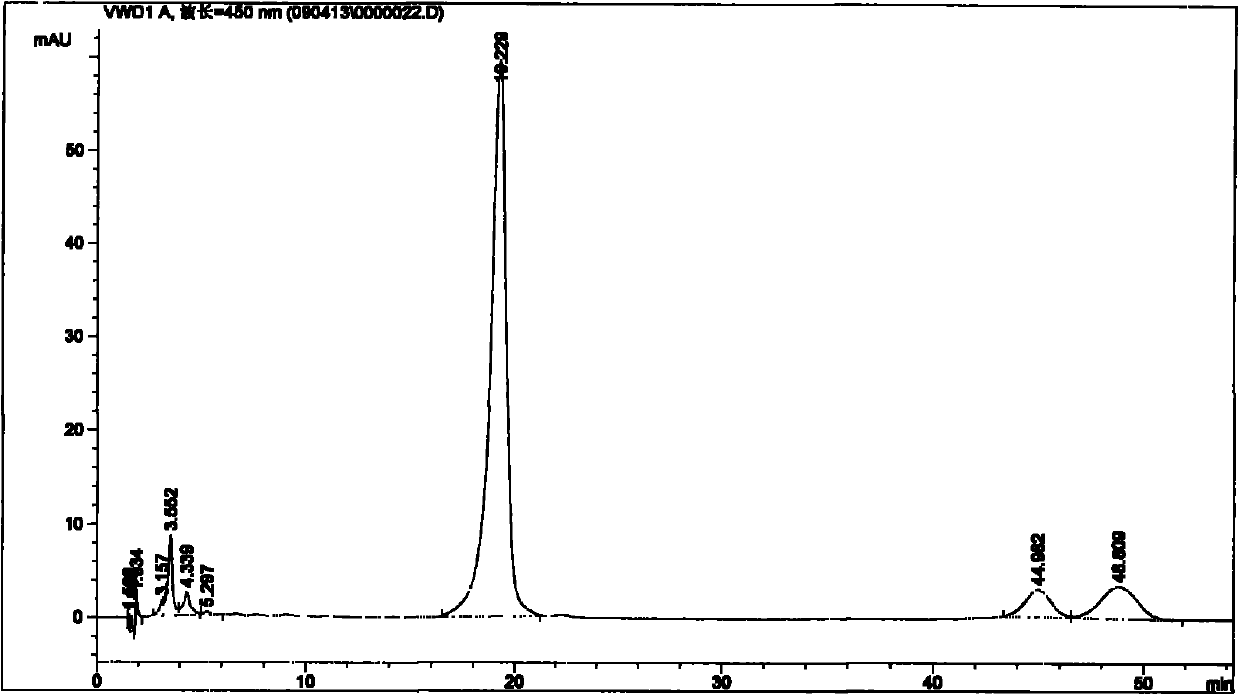

Method for extracting fucoxanthin from brown algae

The invention relates to a method for extracting fucoxanthin from brown algae. The method comprises the following steps of: performing water swelling pretreatment on the crushed brown algae, and leaching the brown algae by using a water-soluble organic solvent; purifying fucoxanthin in leaching solution by adopting an extraction method and twice column chromatography in turn; and finally, further purifying to obtain a fucoxanthin standard substance with the purity of over 90 percent or over 99 percent through preparative thin-layer chromatography or preparative high performance liquid chromatography. The method for extracting the fucoxanthin has the advantages of simple, economic and efficient technology, and capacity of providing an experimental basis for industrial production of the fucoxanthin and improvement of industrial utilization rate of the algae.

Owner:秦皇岛惠恩生物技术有限公司

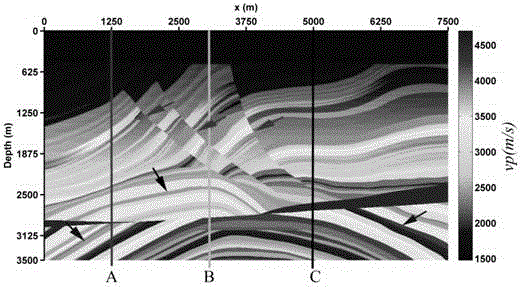

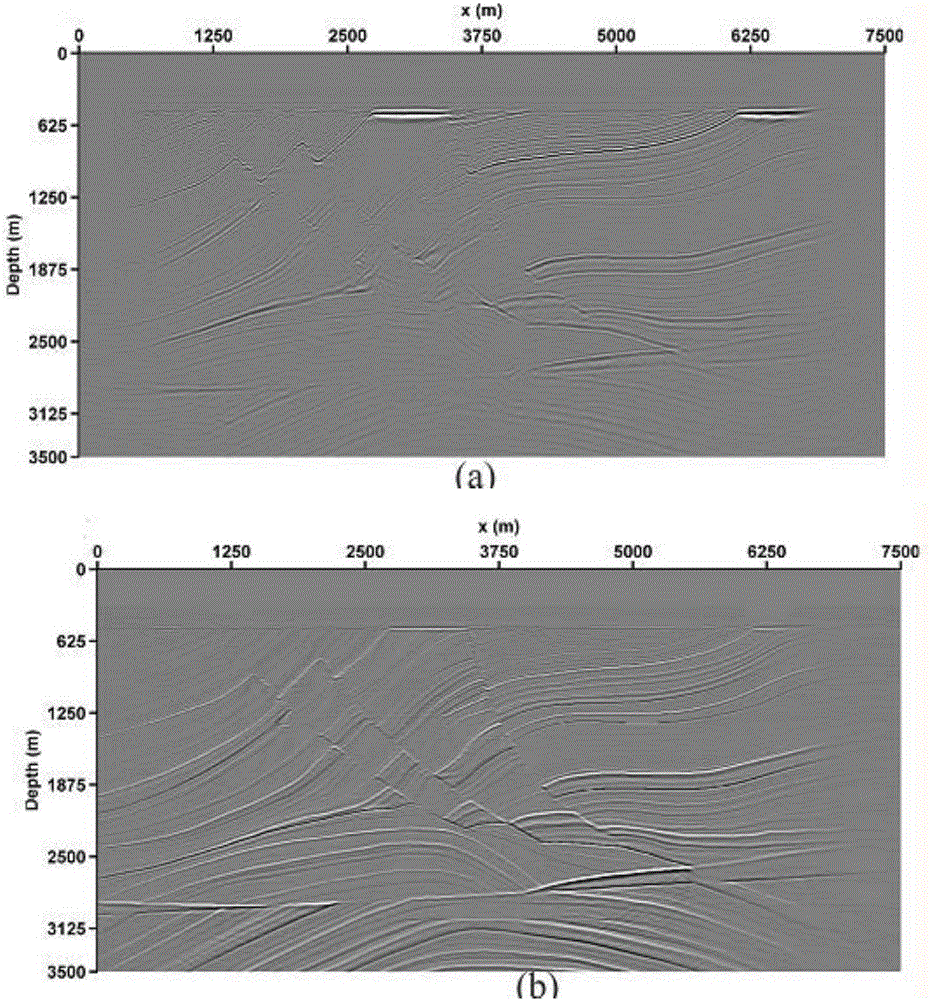

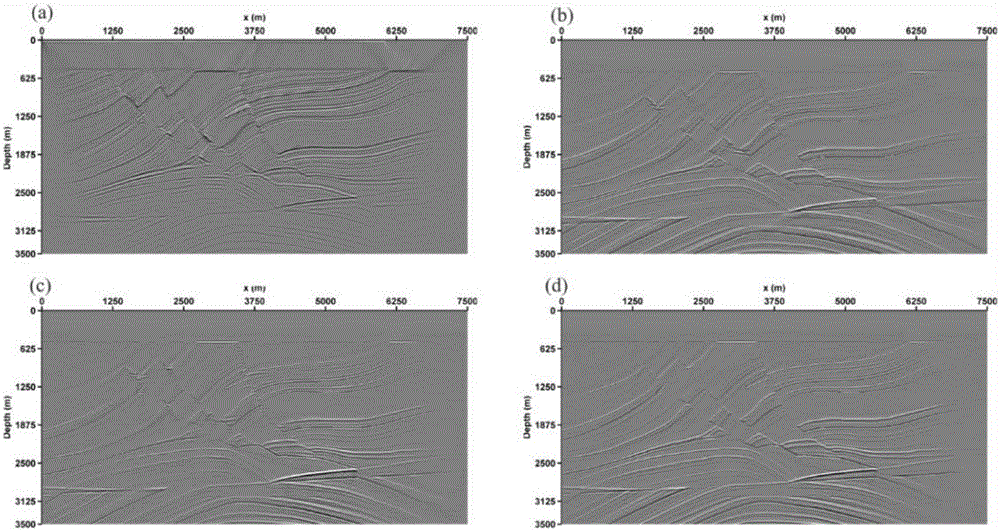

Two-way wave pre-stack depth migration method through one-way wave operator

ActiveCN105911587AHigh industrial production application valueIncrease credibilitySeismic signal processingMaximum depthFull wave

The invention relates to a two-way wave pre-stack depth migration method through a one-way wave operator. The two-way wave pre-stack depth migration method comprises the following steps that 1. an upper and lower dual detector seismic data acquisition system is adopted so that a detector wave field is formed; 2. seismic wavelet information is extracted so that a seismic source wave field is formed; 3. single-shot seismic data, a speed model and the seismic source wave field are read; 4. Fourier transform is performed on the seismic source wave field and the detector wave field in a time domain so that frequency-space domain wave field data are obtained; 5. depth continuation calculation is performed on the frequency-space domain wave field data; 6. migration imaging is performed by utilizing the principle of cross-correlation imaging or the principle of reflection coefficient imaging; 7. continuation calculation of the steps 4-6 is repeated to the maximum depth, the migration result is saved and the next shot of seismic data are calculated; and 8. the steps 3-7 are repeated to the last shot and a migration profile is outputted. According to the two-way wave pre-stack depth migration method through the one-way wave operator, full wave equation depth migration is performed by utilizing the one-way wave operator so that the rapid and accurate two-way wave depth migration algorithm is realized, and the method has more industrial utilization value.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

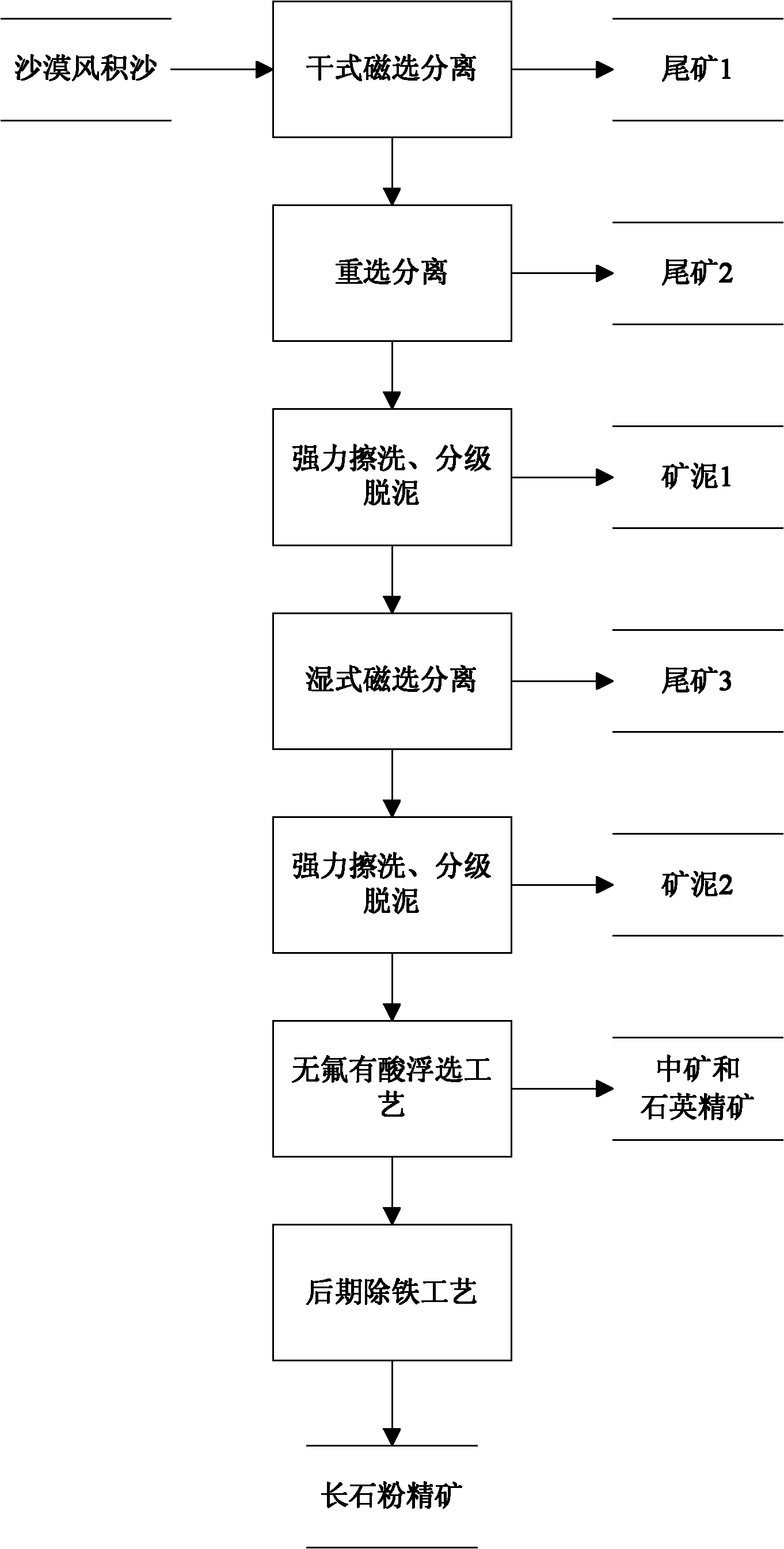

Method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert

ActiveCN101885489AReduce production water consumptionReduce manufacturing costSilicon compoundsIntermediate stageEnergy consumption

The invention belongs to an industrial utilization method of aeolian sand in desert, in particular to a method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert. The method comprises an early-stage ferrum-removal process, a middle-stage feldspar flotation separation process and a later-stage ferrum-removal process. The early-stage ferrum-removal process comprises the following specific steps: firstly, carrying out dry magnetic separation on the aeolian sand in the desert; carrying out reselection and separation on the concentrate obtained after dry magnetic separation; carrying out powerful scrubbing and sizing-desliming on the concentrate obtained after reselection and separation; and carrying out wet magnetic separation to obtain the ferrum-removal concentrate for the middle-stage feldspar flotation separation process, and carrying out the later-stage ferrum-removal process on the feldspar mineral aggregate obtained in the middle-stage feldspar flotation separation process to finally obtain the feldspar powder concentrate. The processes of the invention have the advantages of water conservation, reduced energy consumption and low cost, and can fully utilize the existing aeolian sand resources to produce the high-quality feldspar powder concentrate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

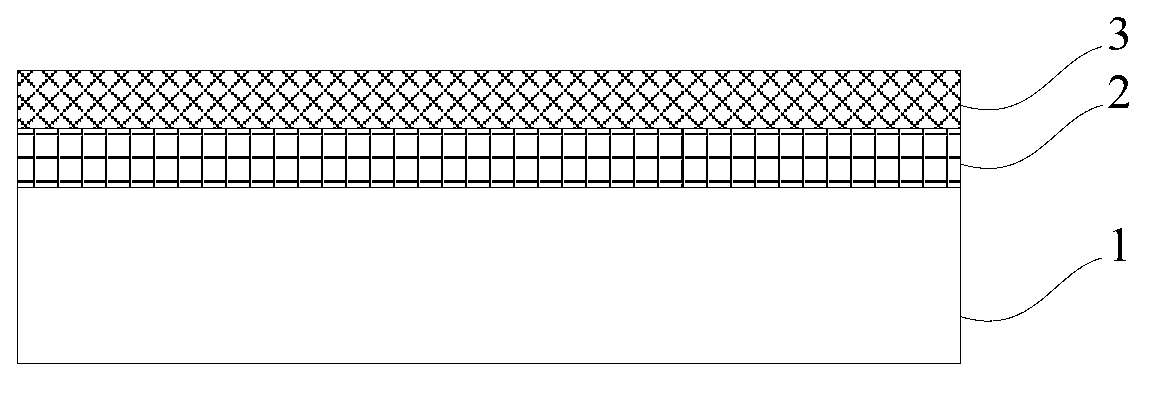

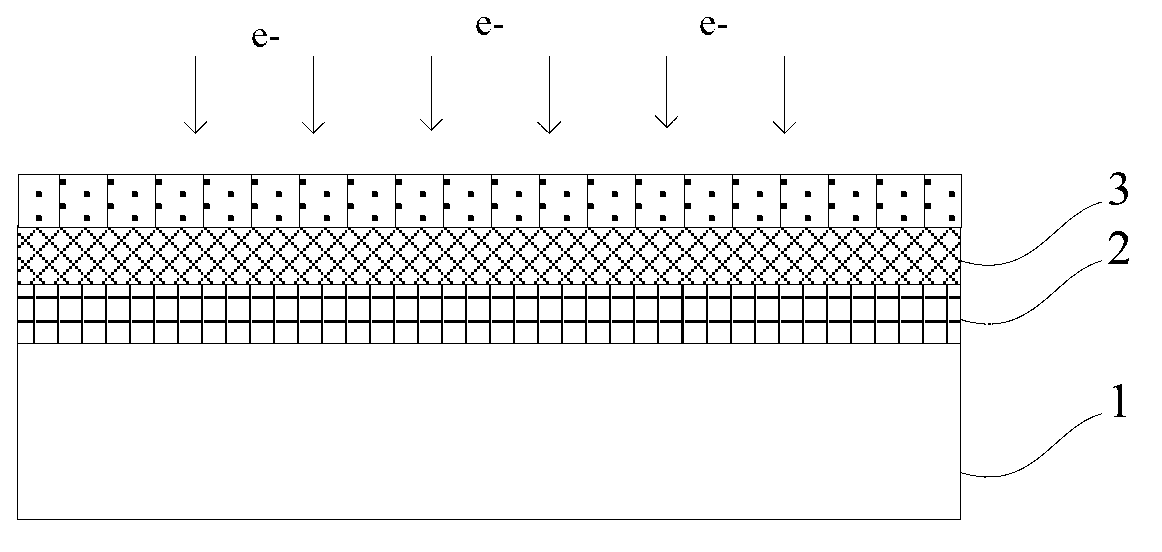

Electron beam exposure patterning method on insulating substrate

InactiveCN103176354ASolve the problem of charge accumulationPhotomechanical coating apparatusPhotomechanical exposure apparatusElectron-beam lithographyMetal electrodes

The invention provides an electron beam exposure patterning method on an insulating substrate. The electron beam exposure patterning method comprises the following steps of: 1) providing the insulating substrate; 2) coating electron beam photoresist on the insulating substrate in a rotating way; 3) forming a metal film on the upper surface of the electron beam photoresist; 4) carrying out electron beam exposure to obtain a required photoetching pattern; 5) depositing to form a metal layer on the obtained photoetching pattern, so as to form a metal electrode; and 6) stripping, and removing the photoresist and redundant metal, so as to obtain a required metal pattern. According to the electron beam exposure patterning method on the insulating substrate, the double-layer electron beam photoresist is adopted for the exposure, an undercut structure beneficial to a follow-up metal stripping technology can be obtained by developing, discontinuous metal films are formed on the double-layer electron beam photoresist in an evaporating manner, then the electron beam exposure is carried out, and therefore, the electric charge on the surface of the insulating substrate can be effectively taken away, and as a result, a precise exposure pattern is formed. The patterning technology provided by the invention is applicable to the processing technology of micro-nanometer components on various insulating substrates, overcomes the shortcomings in the prior art, and has a high industrial utilization value.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for producing saponin and organic acid by using turmeric

InactiveCN101812499AFully clean productionHigh extraction rateUltrafiltrationSteroidsSlagBio engineering

The invention discloses a method for producing saponin and organic acid by using turmeric, which belongs to the field of biological engineering and solves the problem that the conventional method for extracting turmeric saponin by using a turmeric raw material has large discharge amounts of waste water and waste slag and cannot effectively use turmeric starch. The method comprises the steps of turmeric saponin release, turmeric starch saccharification, fermentation medium preparation, organic acid fermentation, saponin enrichment and saponin preparation. By pretreating the turmeric raw material by using fermentation and membrane separation coupling, the method has the advantages of pollution-free production of the saponin and the organic acid, high turmeric saponin extracting rate, full utilization of the turmeric starch, little waste water amount and little production during turmeric saponin production, pollution-free process and great industrial utilization value in the turmeric industry.

Owner:HUAZHONG UNIV OF SCI & TECH

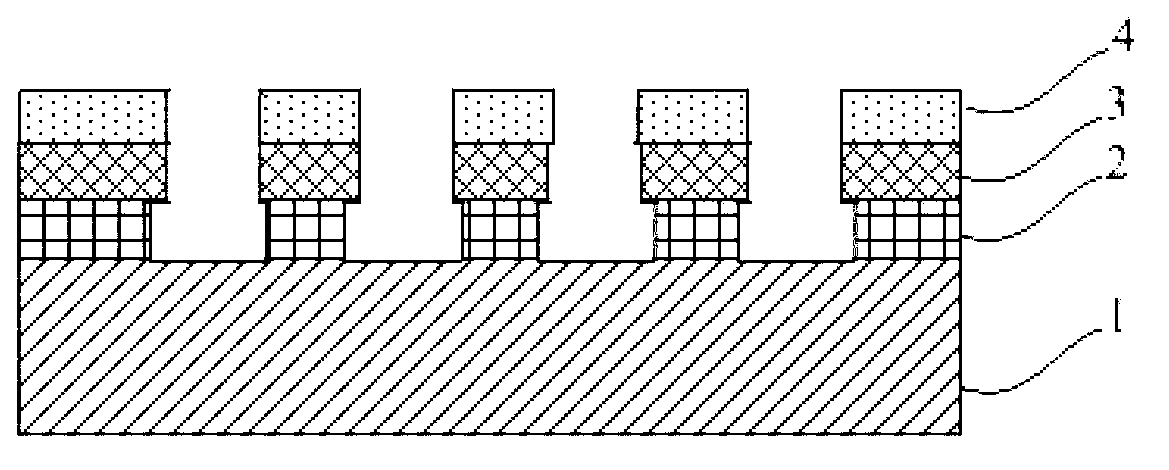

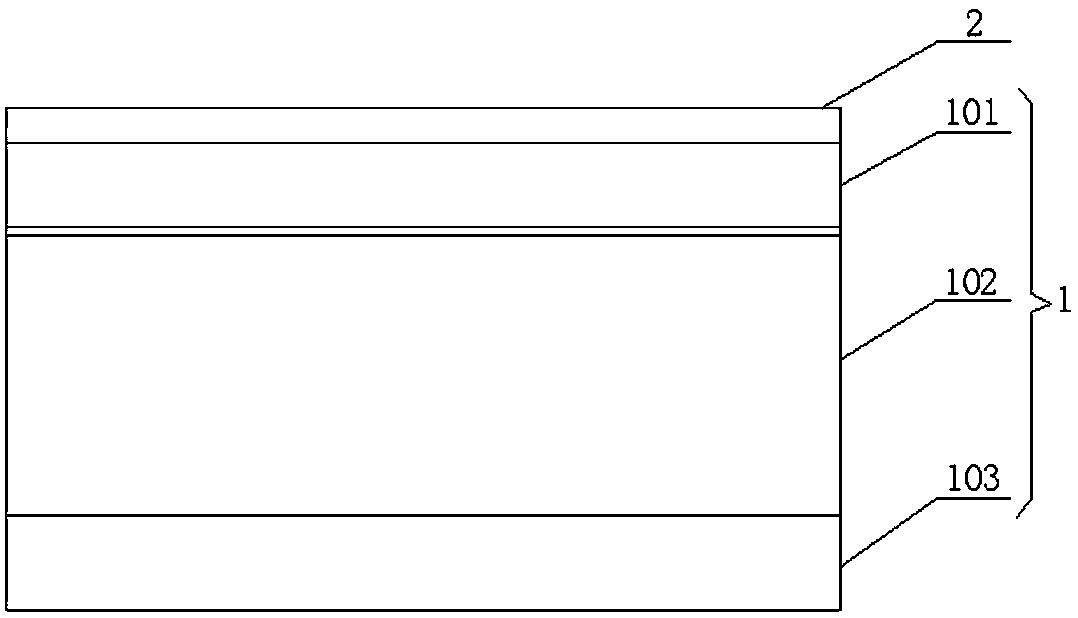

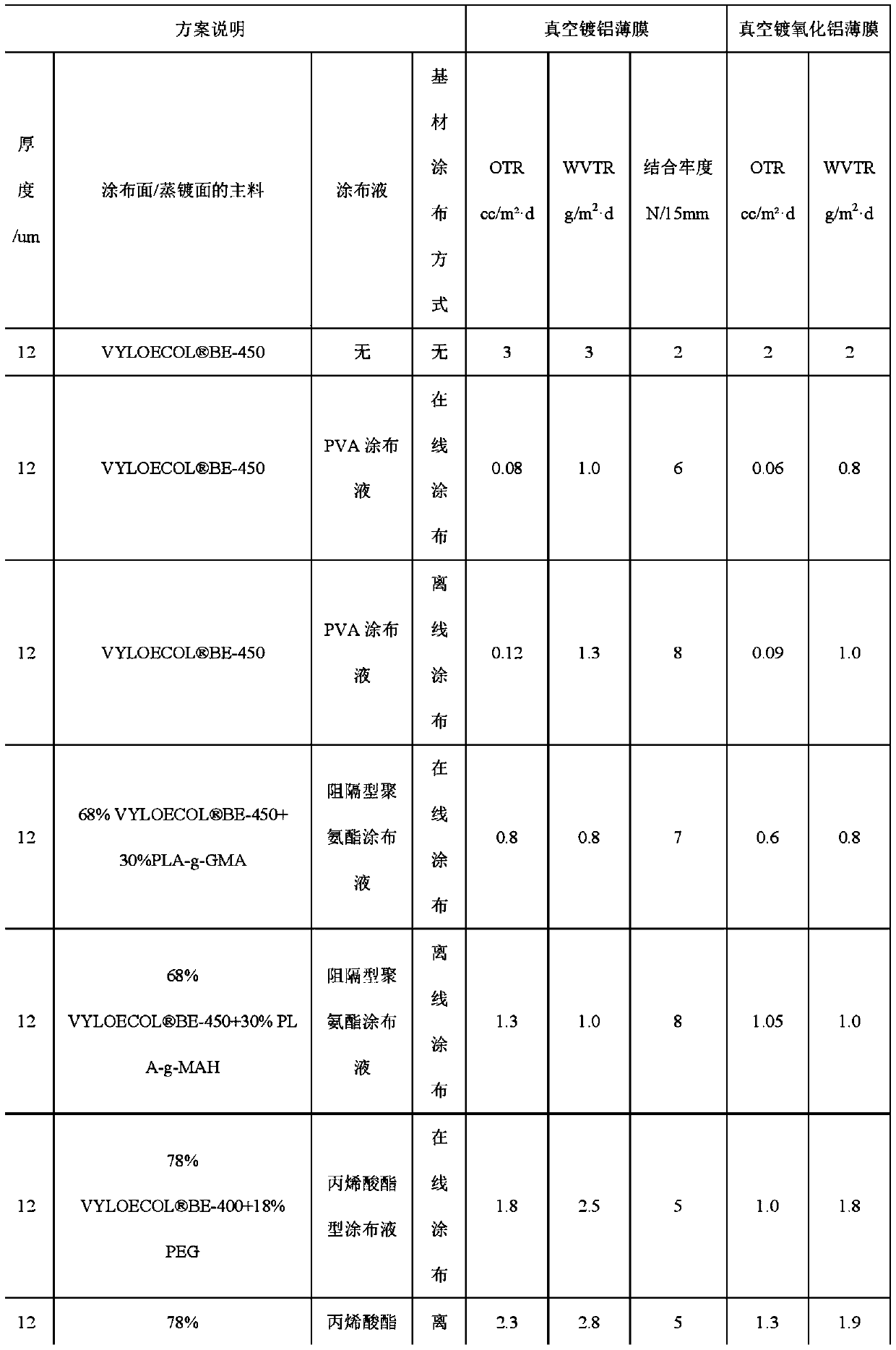

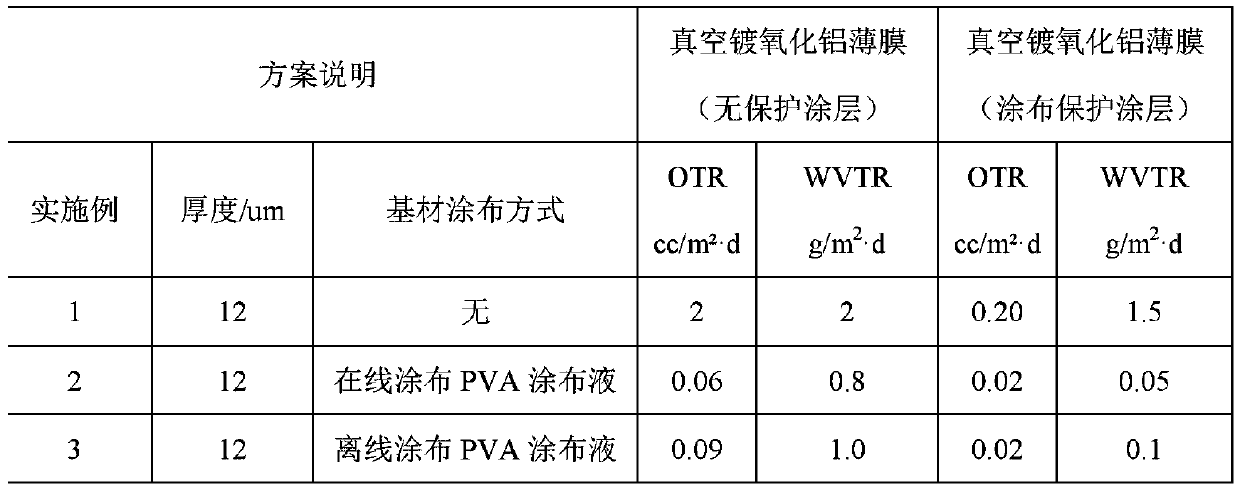

Full-biodegradable high-barrier vacuum evaporation film and preparation method thereof

InactiveCN110435277AImprove barrier propertiesImprove use valueSynthetic resin layered productsCoatingsSurface layerWater vapor

The invention discloses a biodegradable high-barrier vacuum evaporation film base material and a preparation method thereof. A film is sequentially composed of a high-barrier coating layer and a biaxially-oriented polylactic acid (BOPLA) film base material layer from top to bottom, wherein the base material layer consists of an upper surface layer, a core layer and a lower surface layer. The preparation method comprises the following two steps: firstly, preparing a polylactic acid film (BOPLA) base material meeting the coating requirement by using a horizontal drawing method, and then formingthe high-barrier coating layer on the surface of the film base material by using an online coating process or an offline coating process. According to an aluminum-plated film and an aluminum oxide-plated film which are produced by utilizing the high-barrier vacuum evaporation film base material prepared by the invention, the optimal oxygen permeability can be less than 0.02 cc / m<2>.24h, and the optimal water vapor permeability reaches 0.05 g / m<2>.24h; and the high-barrier vacuum evaporation film base material not only has an excellent barrier effect, but also is biodegradable, can effectivelysolve the environmental problem caused by waste packaging films, and is high in industrial utilization value.

Owner:广东华通新材料科技有限公司 +1

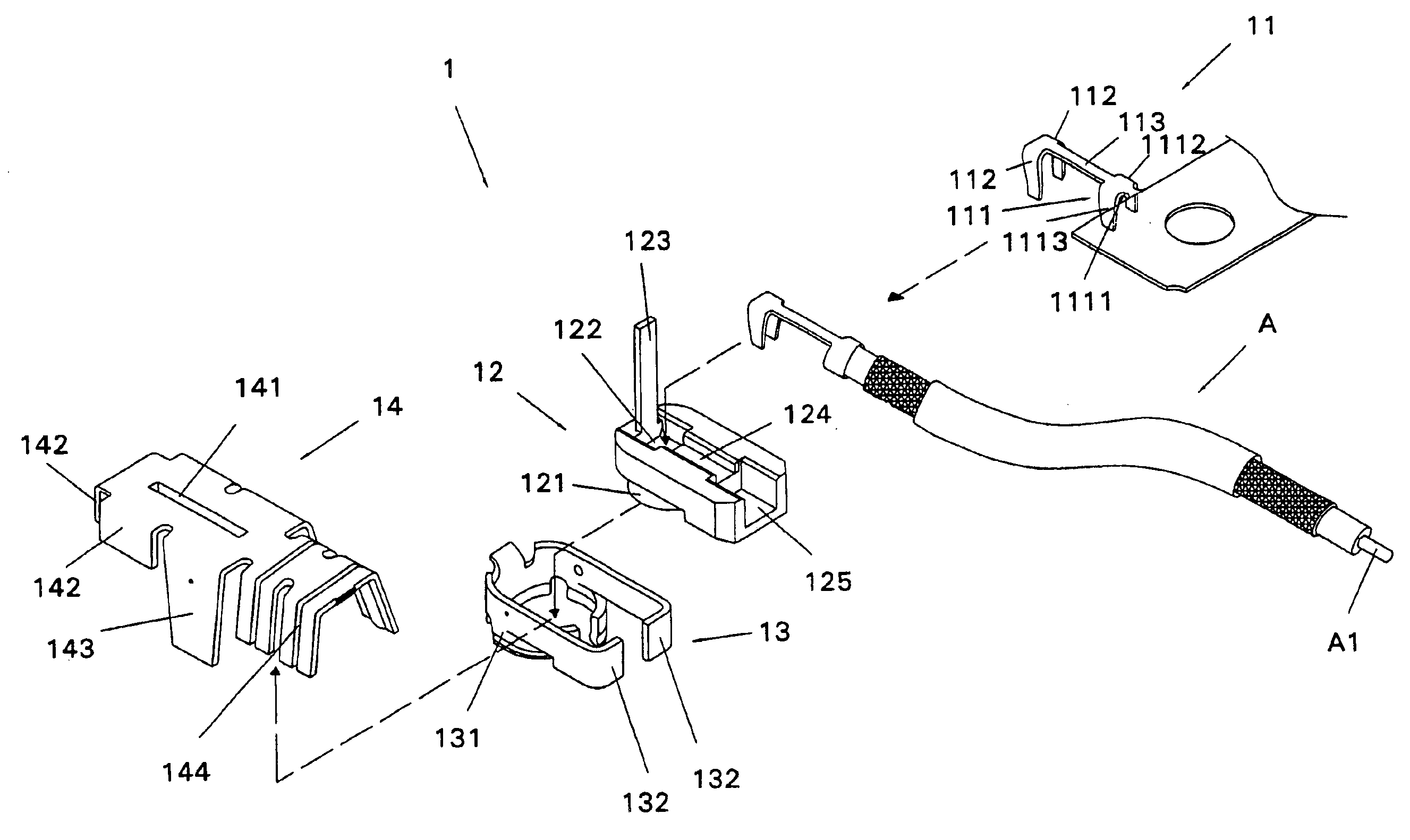

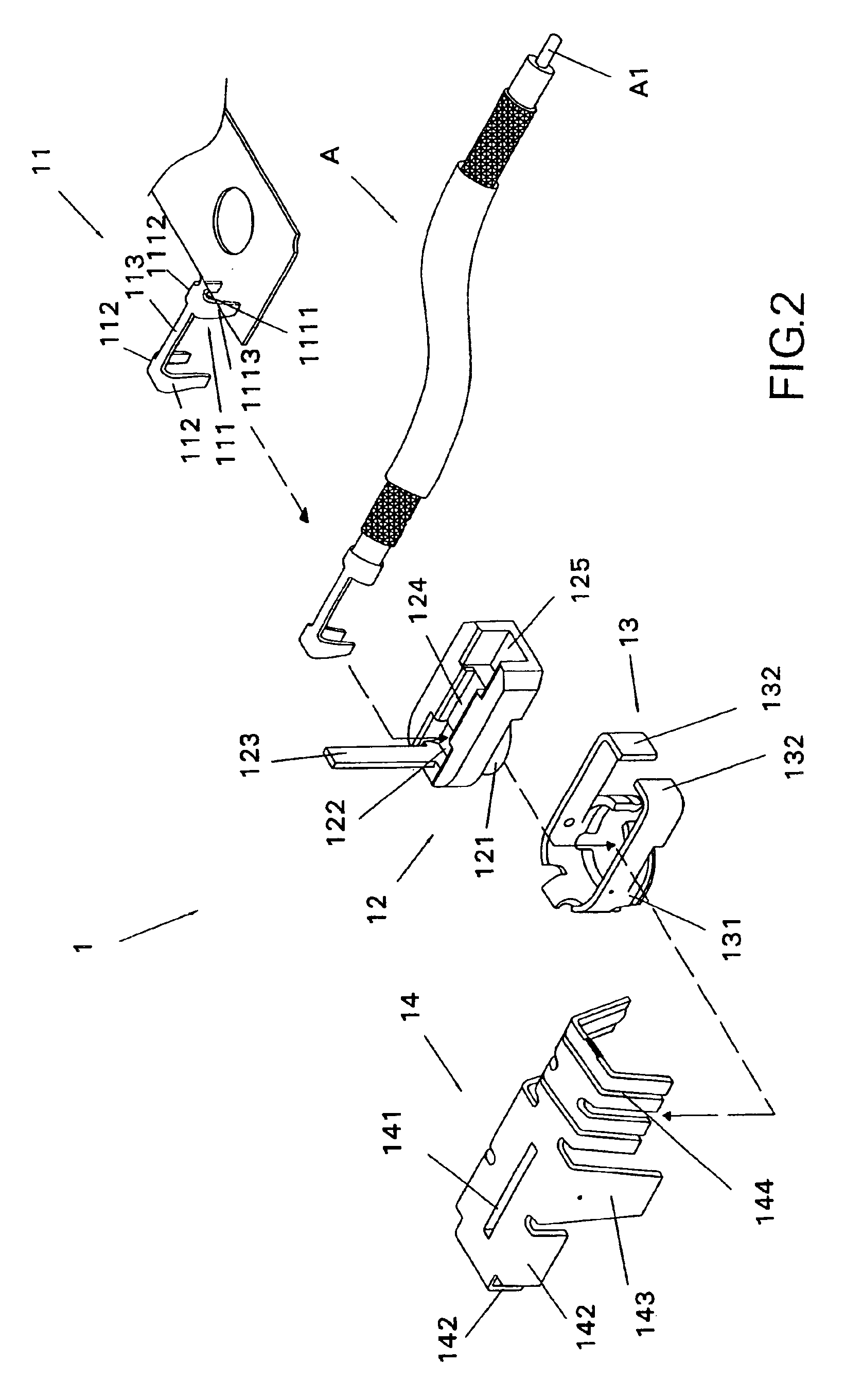

Micro coaxial cable connecting device

InactiveUS6916201B1Low production costImprove productivityElectrically conductive connectionsTwo pole connectionsCoaxial cableElectrical conductor

A micro coaxial cable connecting device, with application to cable to cable inter-connecting of micro coaxial cables, whereby the connecting device is separately configured as a female terminal connector and a male terminal connector, wherein the female terminal connector is assembled to include a signal terminal, an insulator, a conductor and a cover; and the male terminal connector is assembled to include a socket terminal, an insulator base and a casing. Structural design of the male terminal connector and the female terminal connector allows utilizing a lap joint method to connect said two connectors, and thereby enables reduction in production costs of connecting devices, provides enhancement in productivity, and answers to industrial utilization of such.

Owner:SPEED TECH

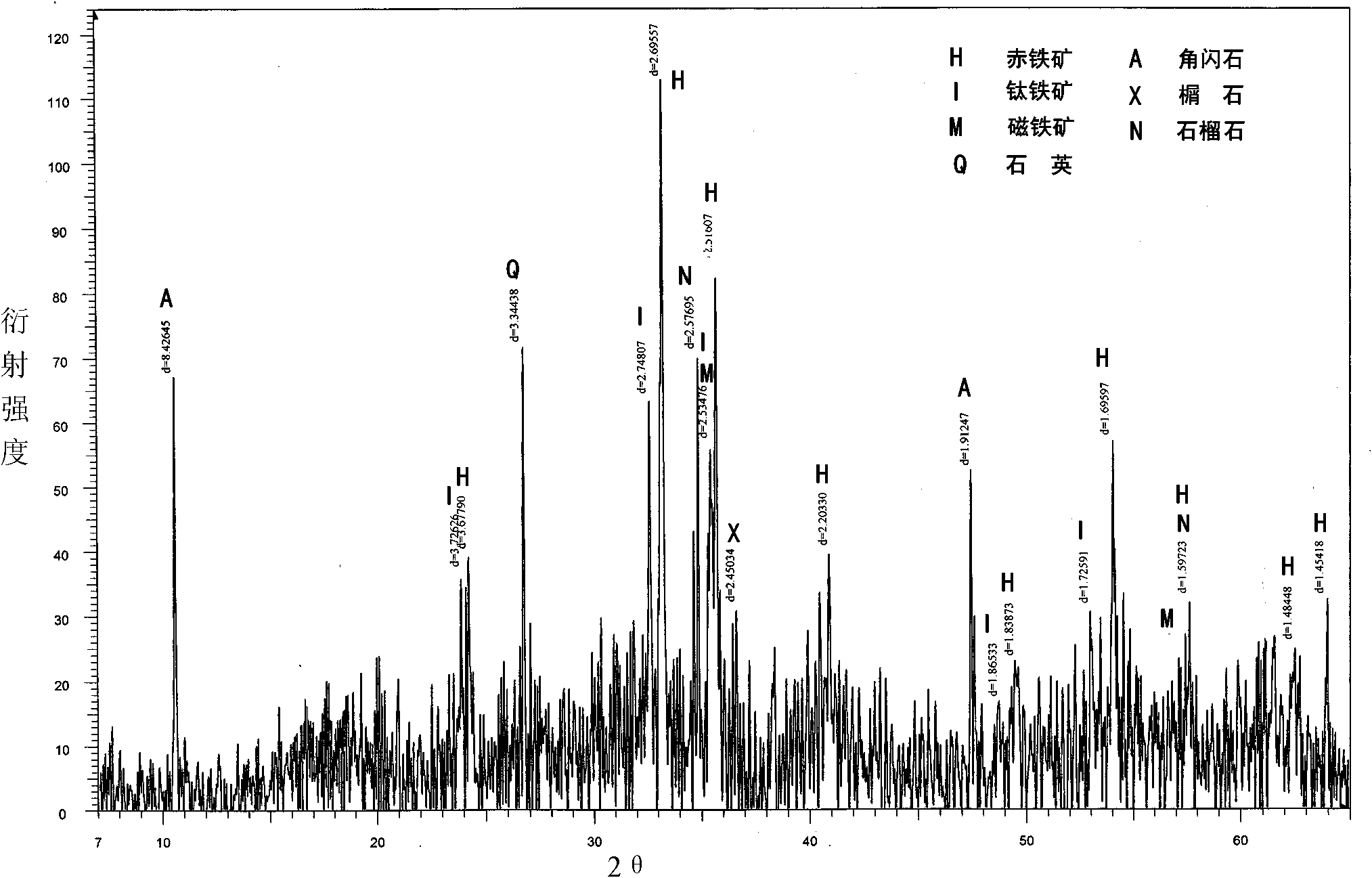

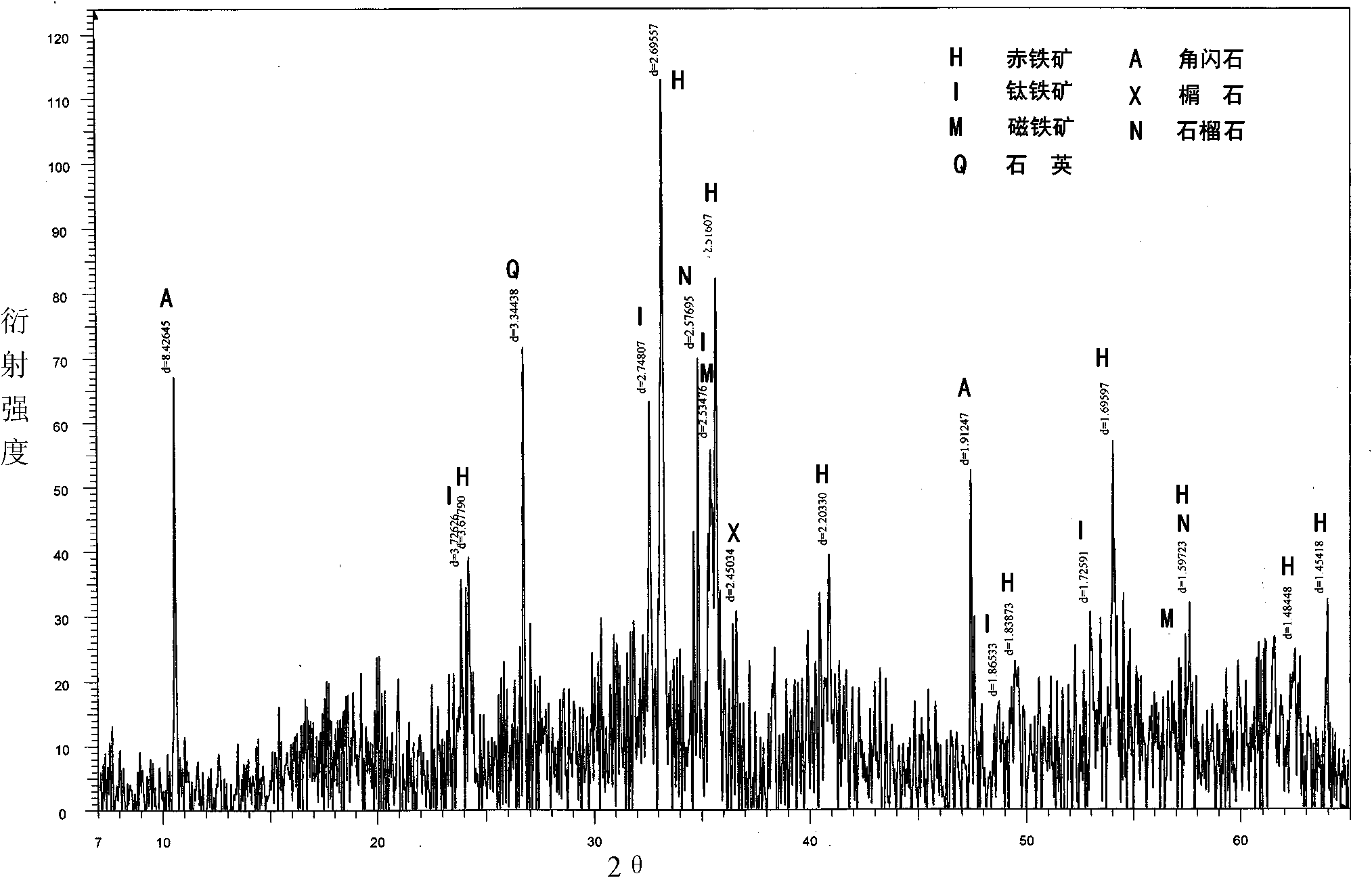

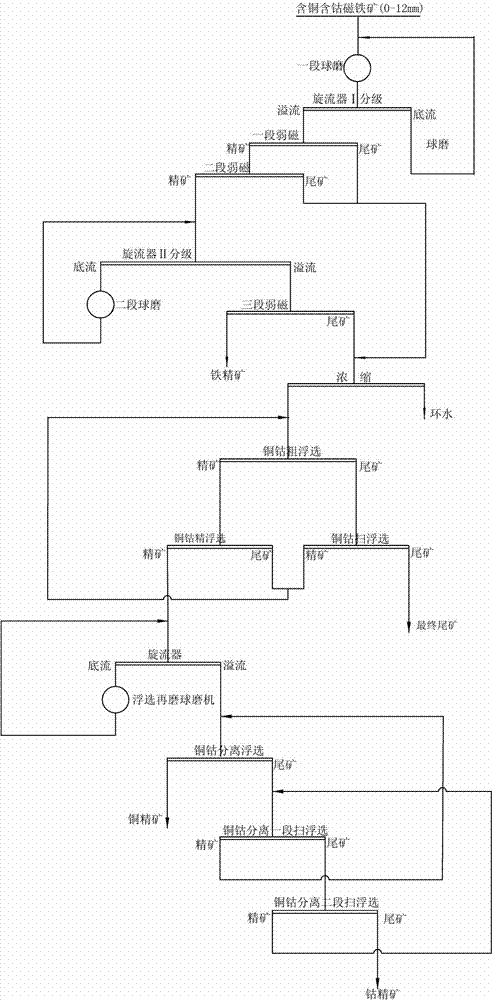

Sorting technology for iron ore containing copper, cobalt and magnetite

ActiveCN104258963AAchieve efficient recyclingReduce ore handlingFlotationMagnetic separationSeparation technologyEconomic benefits

The invention belongs to the technical field of ore dressing and in particular relates to a sorting technology for iron core containing copper, cobalt and magnetite. An ore grinding-grading-magnetic separation magnetite dressing technology is adopted for sorting magnetite, and a copper-cobalt bulk flotation and separation technology is adopted for sorting copper and cobalt. The sorting technology for the iron core containing copper, cobalt and magnetite has the advantages that three valuable minerals are respectively separated out by firstly adopting magnetic separation to obtain qualified iron ore concentrate and then adopting flotation for successively sorting qualified copper concentrate and cobalt concentrate, treatment ore quantity of the next sorting system is gradually reduced, energy consumption is effectively reduced, and production cost is reduced; meanwhile, three concentrates respectively reach an industrial utilization level, effective and comprehensive recycling of three elements is realized, and the economic benefit is increased.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

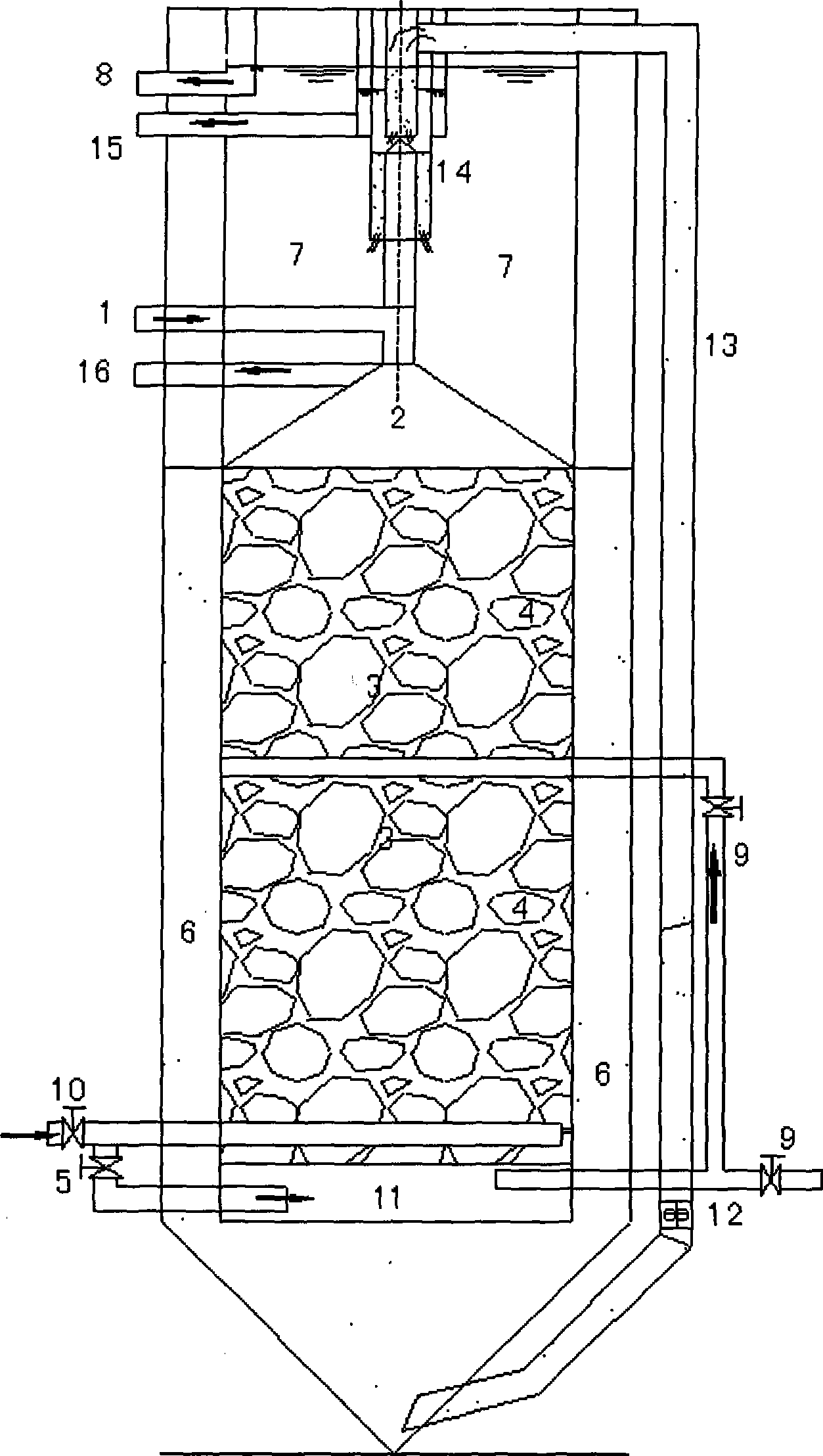

Apparatus for and method for filtering, treating and recycling seprobia

InactiveCN101367595ALow investment costLow running costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualityAeration system

The invention relates to a sewage biofiltration treatment, reusing equipment and a method thereof, comprising a biochemical treatment unit and a depth filtering treatment unit. The biological treatment area in the biochemical treatment unit is located on the internal layer or the external layer of the equipment, and is filled with filling materials. The filtering area is located on the internal layer or the external layer of the equipment. The top surface of the biological treatment area is provided with a water intake and distribution area which is connected with a sewage intake pipe and the undersurface is provided with a distribution system. The interior of the biological area is divided into at least one treatment area which comprises an aerobic zone through an aeration system and an entire biochemical treatment unit is formed. The upper part of the intake and distribution areas is provided with a clear water area. A sand washer which is connected with the water intake area is arranged in the clear water area. The sewage biofiltration treatment has the advantages of integrity and flexibility, low investment, operation expenditure and cost, high automation level and so on. The processing effect can reach the reused water quality standard of the relevant sewage treatment. The reused water can be used for road sprinkling, greening and irrigating, car washing, floor cleaning, industrial utilization and so on.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

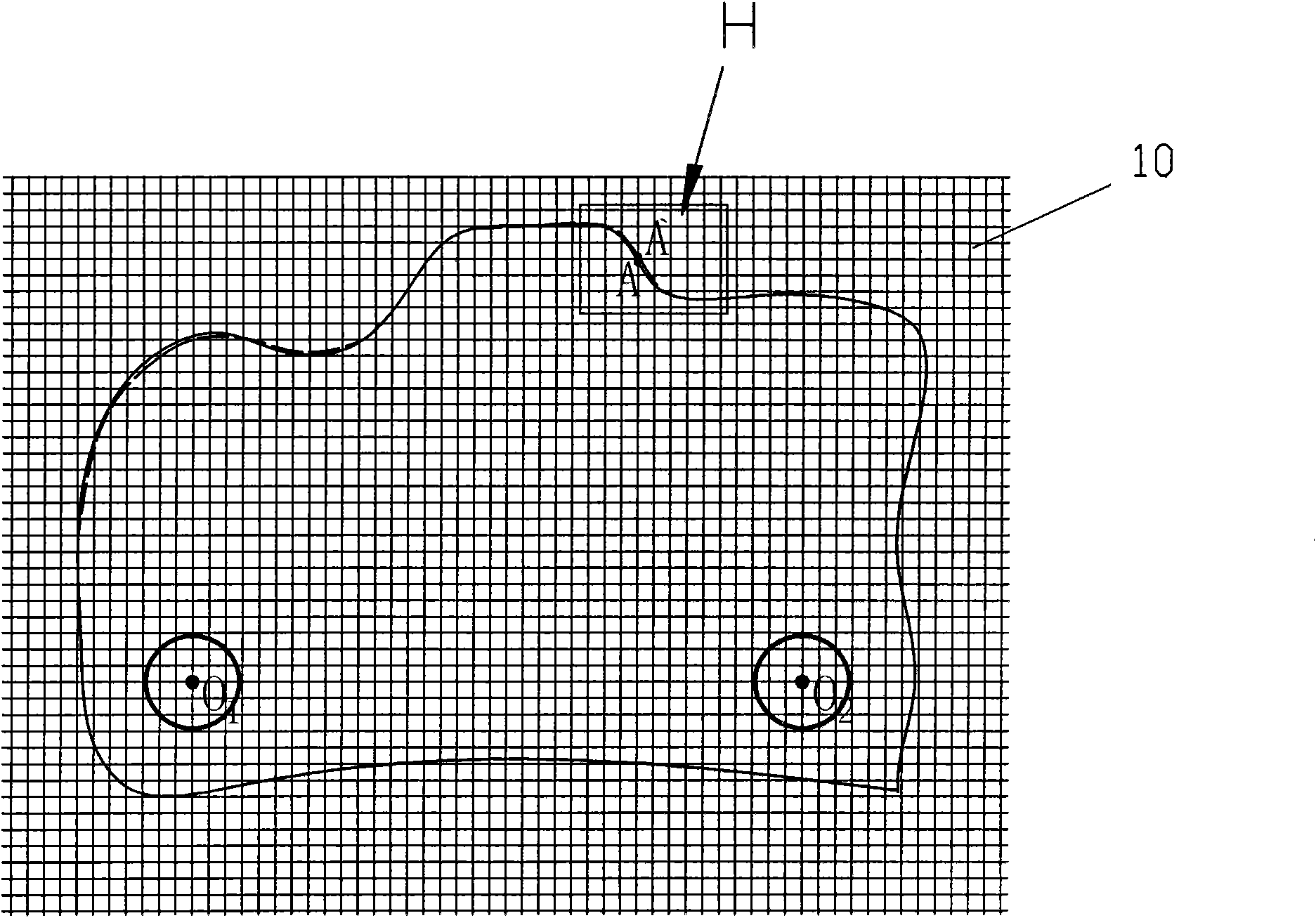

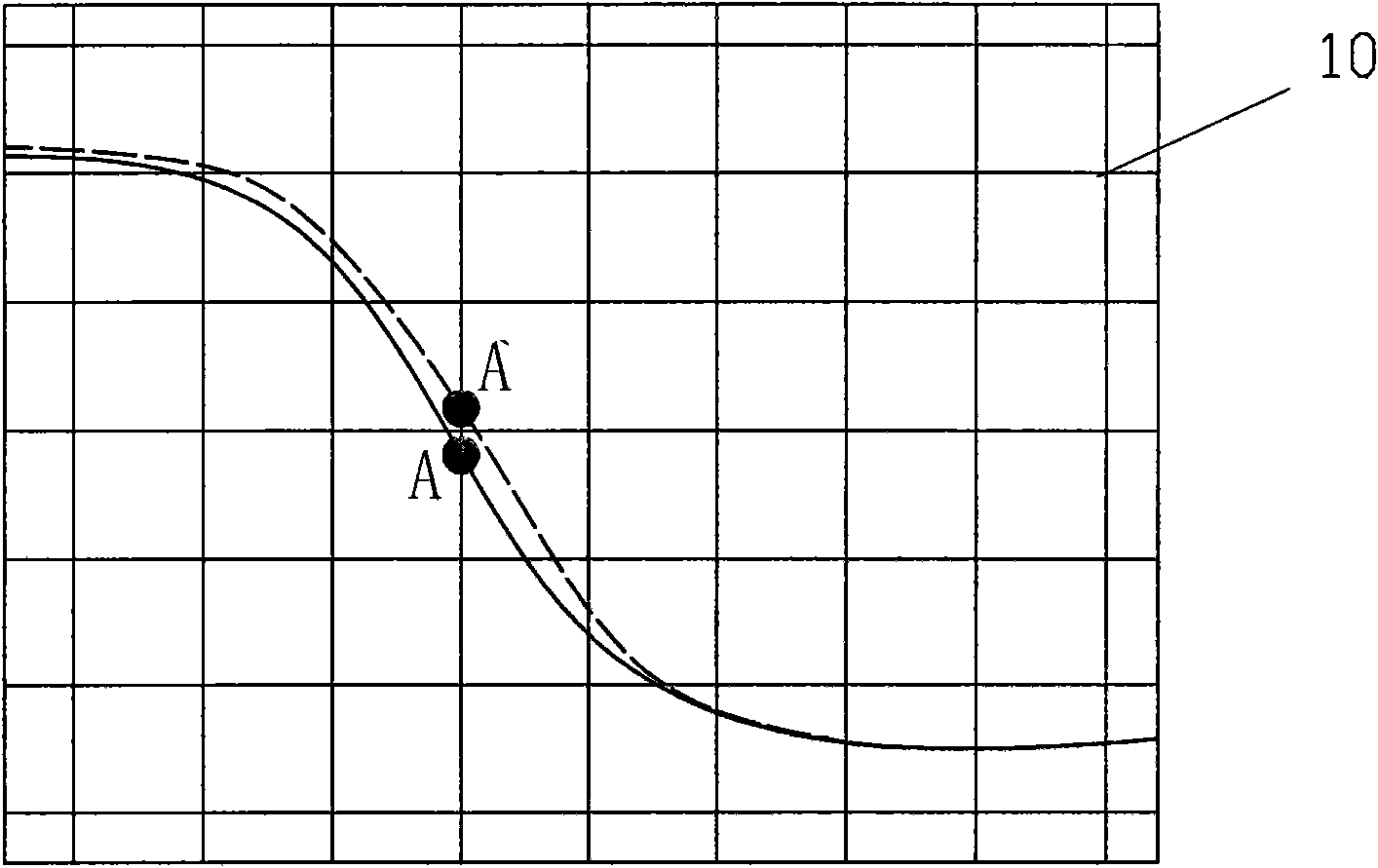

Contour line quality detection method

InactiveCN101614527AImprove accuracyReduce false positivesUsing optical meansGraphicsMeasuring instrument

The invention relates to the measurement technical field, in particular to a detection method for measuring product contour line combining a photoelectric instrument. The method includes the following steps: inputting a standard graph into a computer, reading corresponding point or line of the standard graph in the world coordinate system of the computer as the basis standard, and then constructing a virtual network in the computer and recording the coordinate of the intersecting point of the contour line of the standard graph and the virtual network; inputting the image of a product to be detected into the computer by a measurement instrument, leading the image to fall into a virtual grid and reading the coordinate of the intersecting point of the contour line of the image and the virtual grid; and comparing the coordinate value of the intersecting point of the contour line of the standard graph and the virtual grid with that of the intersecting point of the corresponding part of the contour line of the image and the virtual grid and judging the product contour line quality by coordinate deviation value. The invention has high detection precision and easy operation and accords with industrial utilization.

Owner:HEXAGON METROLOGY SPA

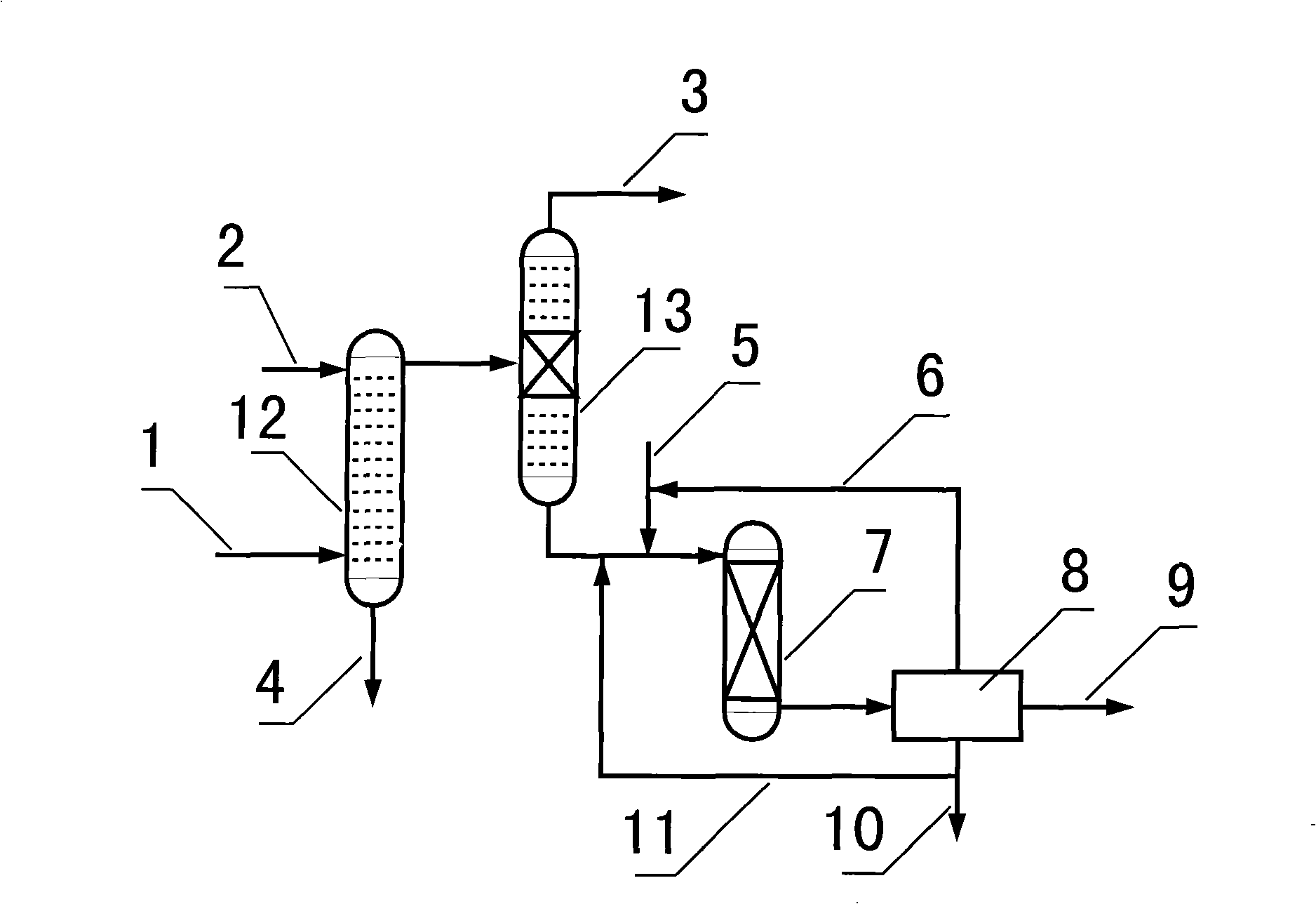

Combination method for comprehensive utilization of mix C4

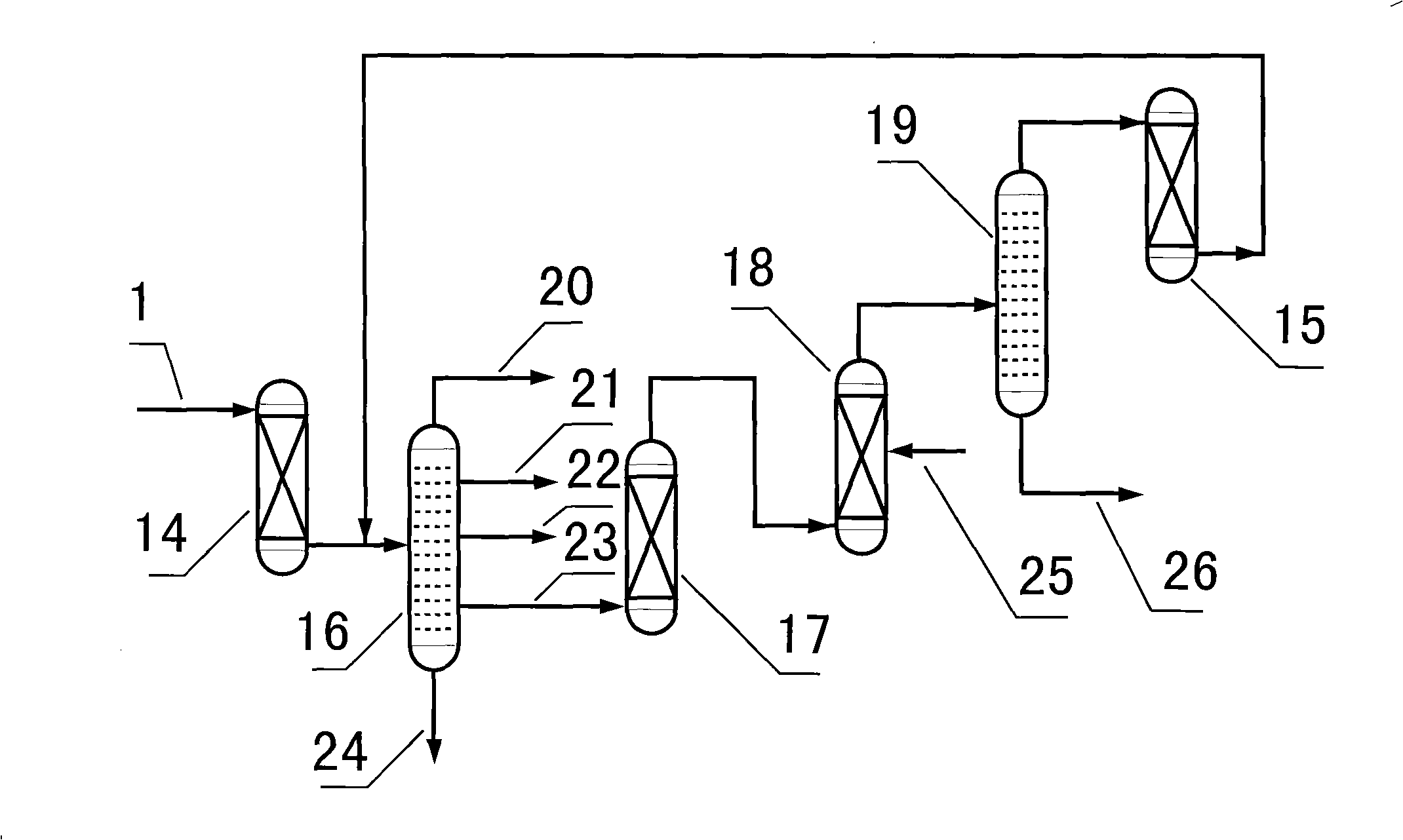

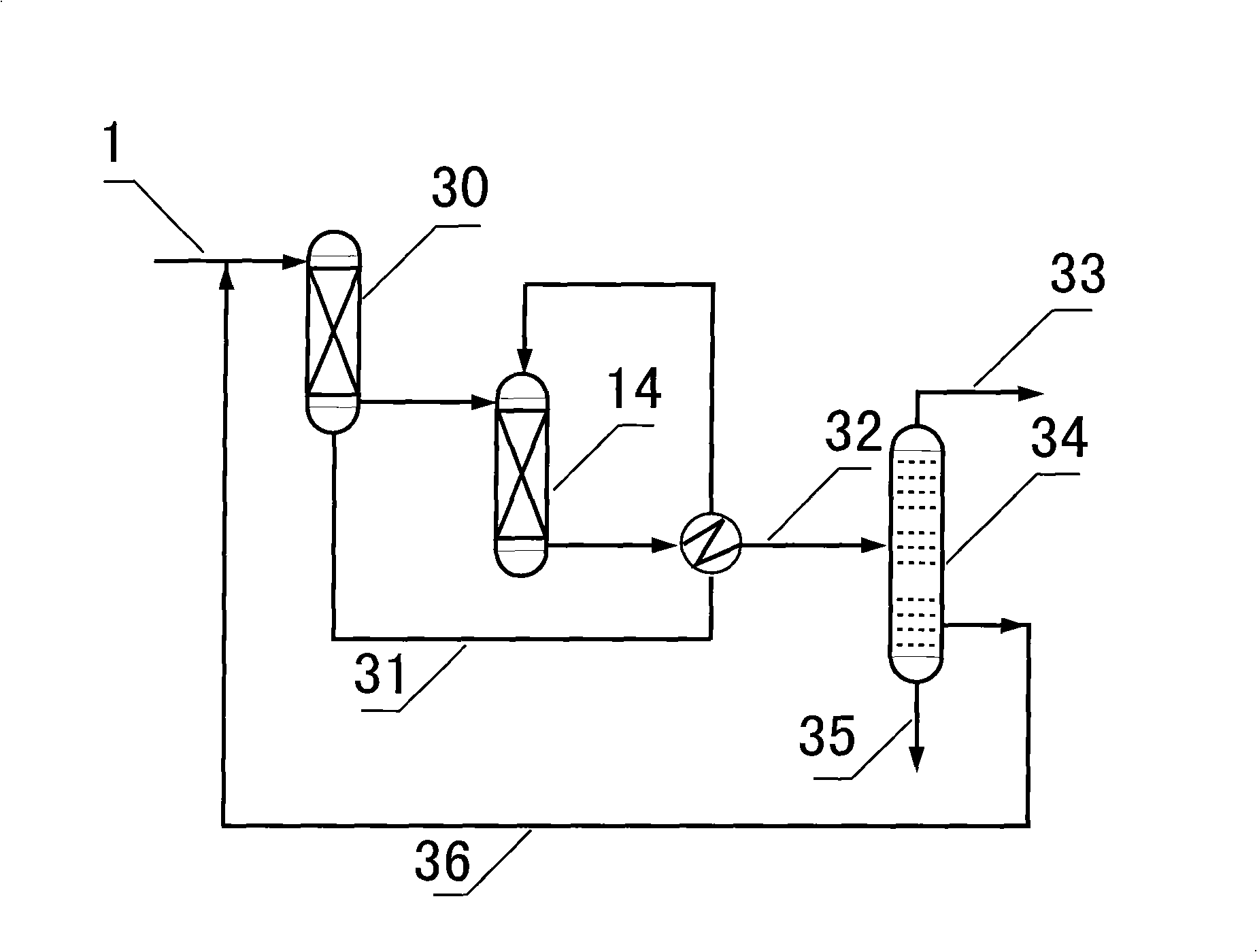

ActiveCN101492335AIncrease valueHigh chemical added valueHydrocarbon by isomerisationChemical industryBiochemical engineeringCatalytic distillation

The invention relates to a combination method for using mixed C4 comprehensively. The method mainly solves the problem that the chemical industrial utilization added value and the comprehensive utilization rate of a byproduct of the mixed C4 of a steam cracking device and the byproduct of the mixed C4 of an FCC device in the prior art are low. The method solves the problem well by the technical proposal which comprises the steps as follows: 1) extraction technology is adopted to obtain butadiene separating; 2) catalytic distillation technology is used for ensuring that butylene-1 in C4 which is remained after being extracted in step 1 is isomerized into butylene-2 and is also separated to obtain isobutene; 3) olefin disproportionation technology is used for disproportionating the butylene-2 in the rest of the mixed C4 in step 2 and ethene to produce propylene; and 4) the remained mixed C4 in step 3 is recycled as a cracking raw material. The invention can be used in the industrial production for increasing the production of the propylene and improving the comprehensive utilization value of the mixed C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

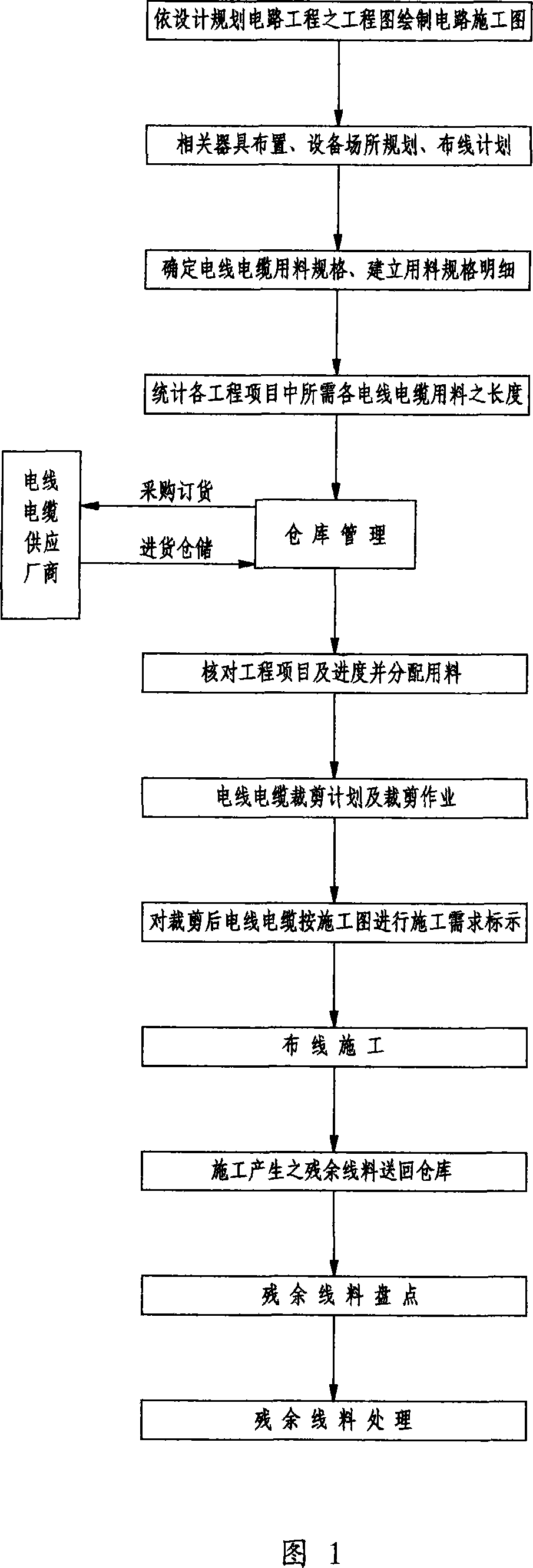

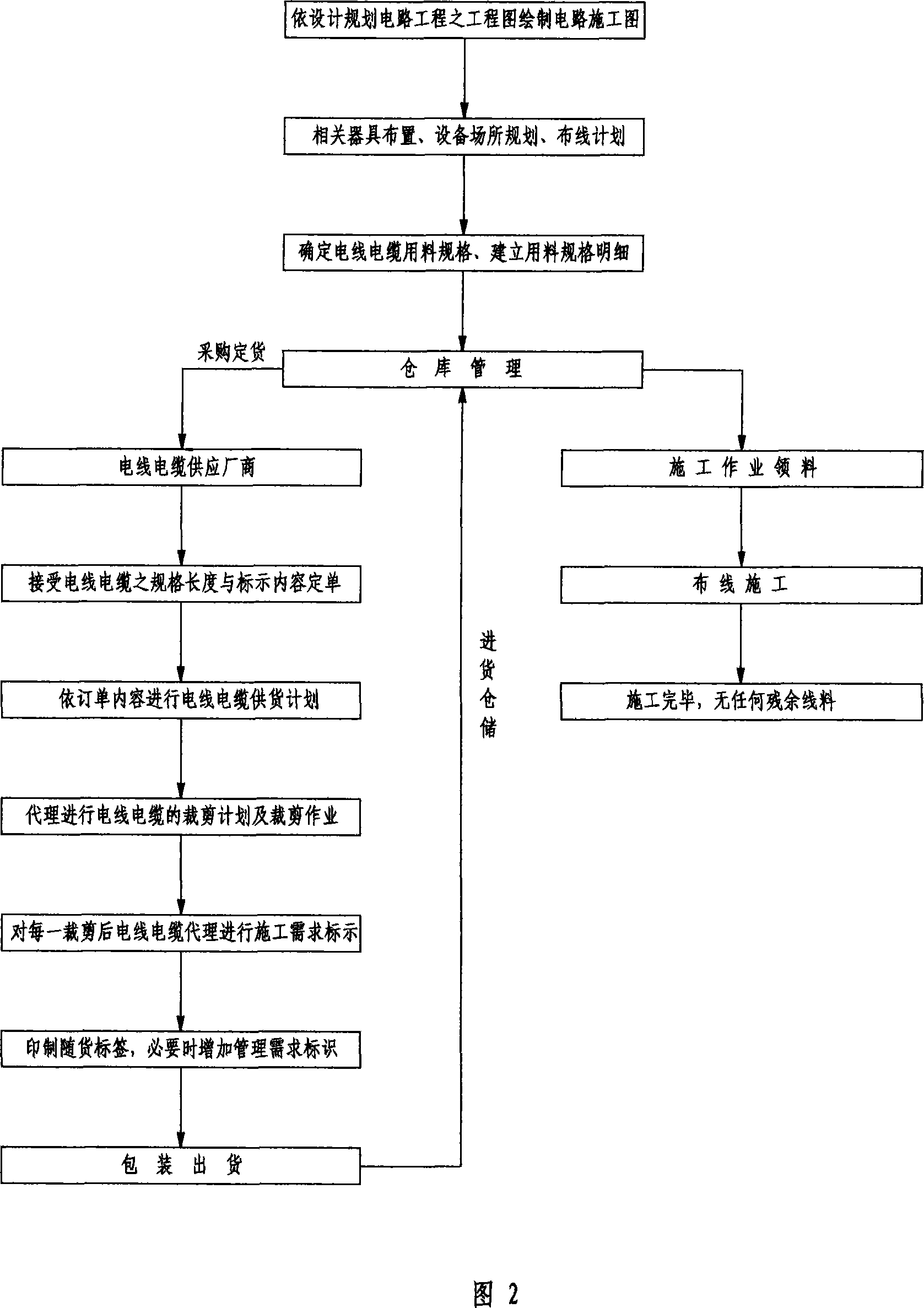

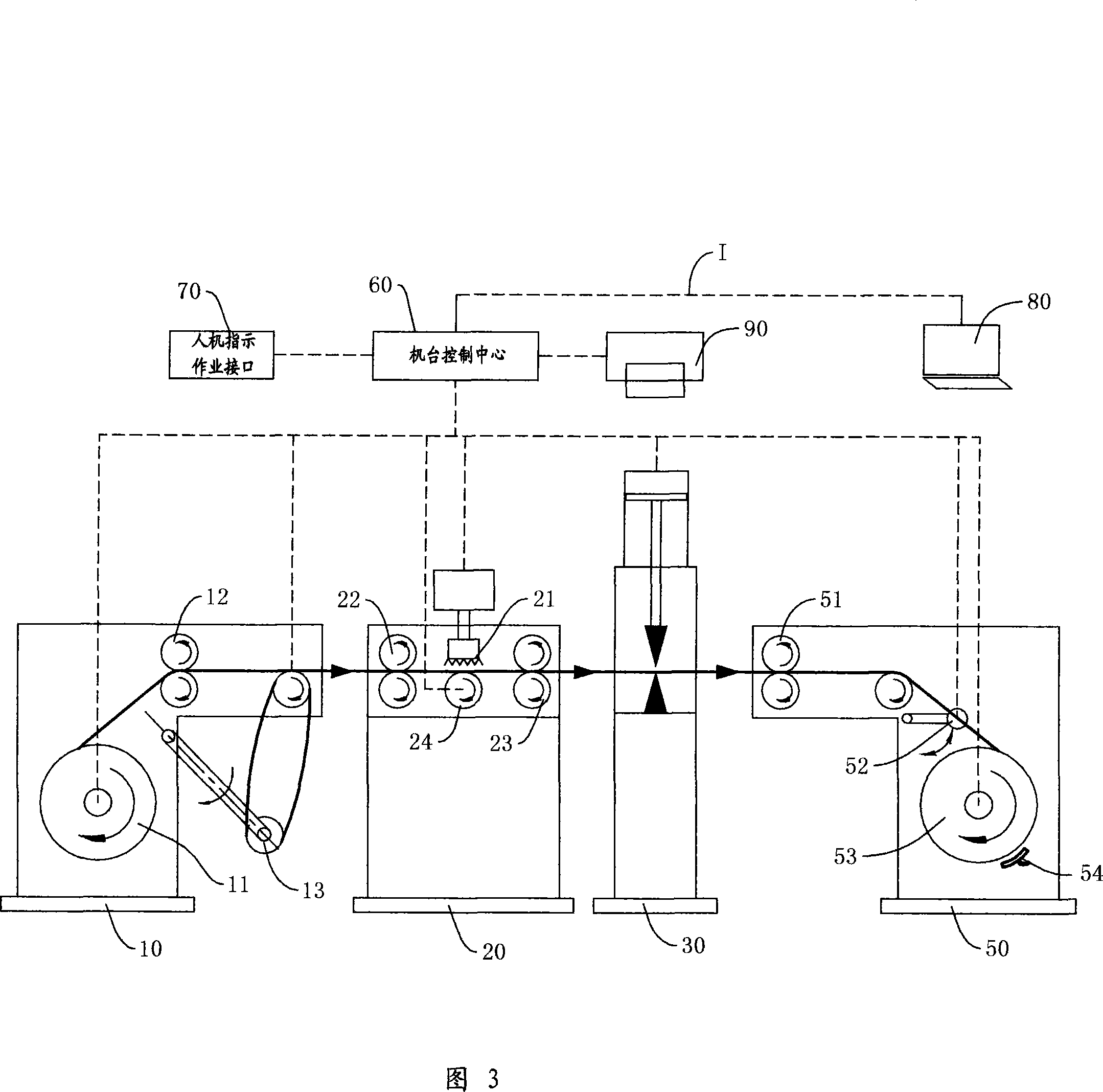

Method and special-purpose equipment for electric wire and cable increasing operation of clipping and signal

ActiveCN101178956ASimplify inventory managementEliminate wear and tearInsulated cablesCable/conductor manufactureProgram planningMultiple function

The invention discloses an operation method and special equipment for adding cutting and labeling of electric wires and cables. The wire and cable suppliers supply the wires and cables according to the wire and cable specifications, length and labeling content provided by consumers. Then use the multifunctional cutting and labeling device to go through the procedures of pre-cutting and marking the construction requirements on the surface of the wire and cable, and use the accompanying label to increase the management requirement label, and then package the packaging method and equipment for the implementation of the operation. In order to effectively reduce the inventory management of wire and cable materials for consumers, thereby eliminating the phenomenon of residual material loss after the construction of wire and cable, and by pre-marking the content on the wire and cable, it is more convenient to guide the construction, effectively improve the construction efficiency, and greatly The construction cost is saved, and the utility model has great industrial utilization value.

Owner:巫协森

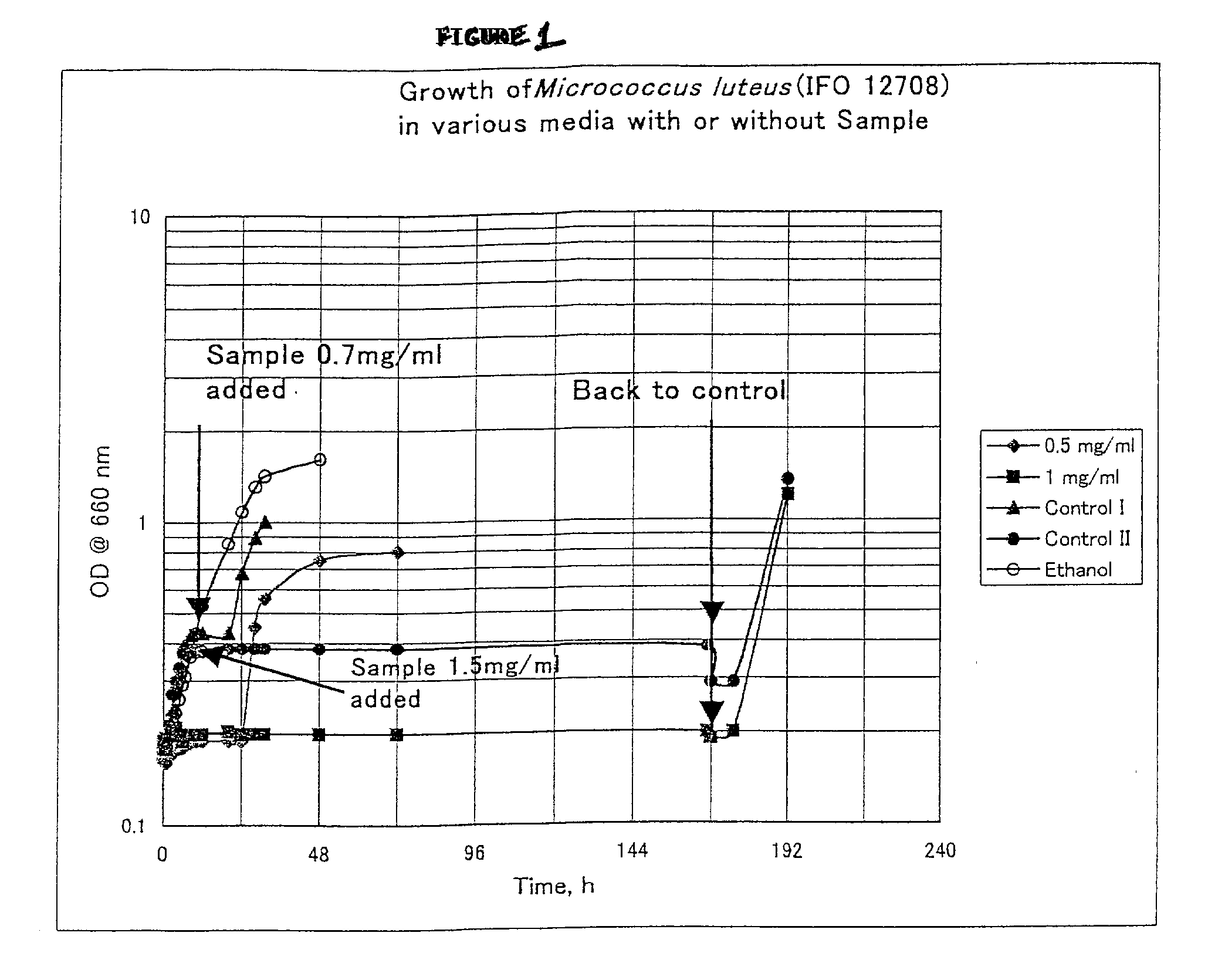

Method of utilization of zygosaccharomyces rouxii

The present invention provides commercial utilization of a novel yeast strain Zygosaccharomyces rouxii and its fermented metabolites as probiotic, as an antioxidant and as an antimicrobial agent in foods and cosmetics. The fermented broth and metabolite substance (s) produced by this invention have a wide spectrum antibacterial activity, strong antioxidant activity, cytochalasin-like activity that inhibits cell cleavage, and is expected to be effective in the treatment of allergy, atopic dermatitis, psoriasis and various skin diseases, second degree burns, high blood pressure, diabetes, cancer, AIDS and as an anti-aging agent. Moreover, this invention is expected to lead to industrial utilization of Z.rouxii for manufacturing succinic acid and malic acid from a yeast.

Owner:OK TAING

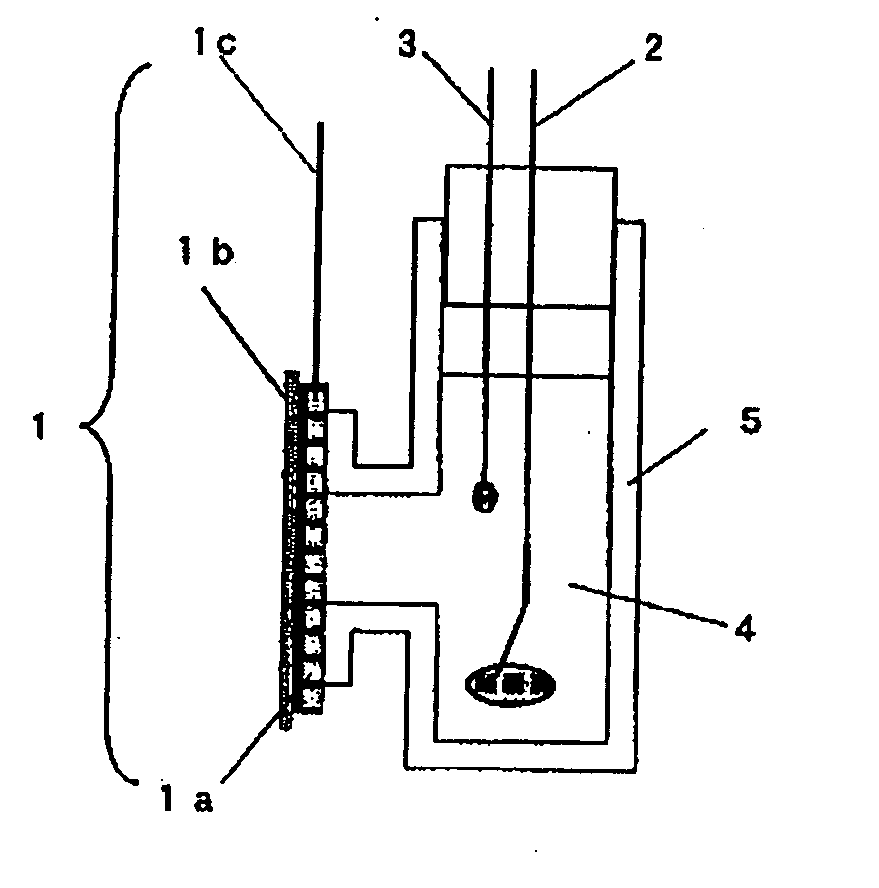

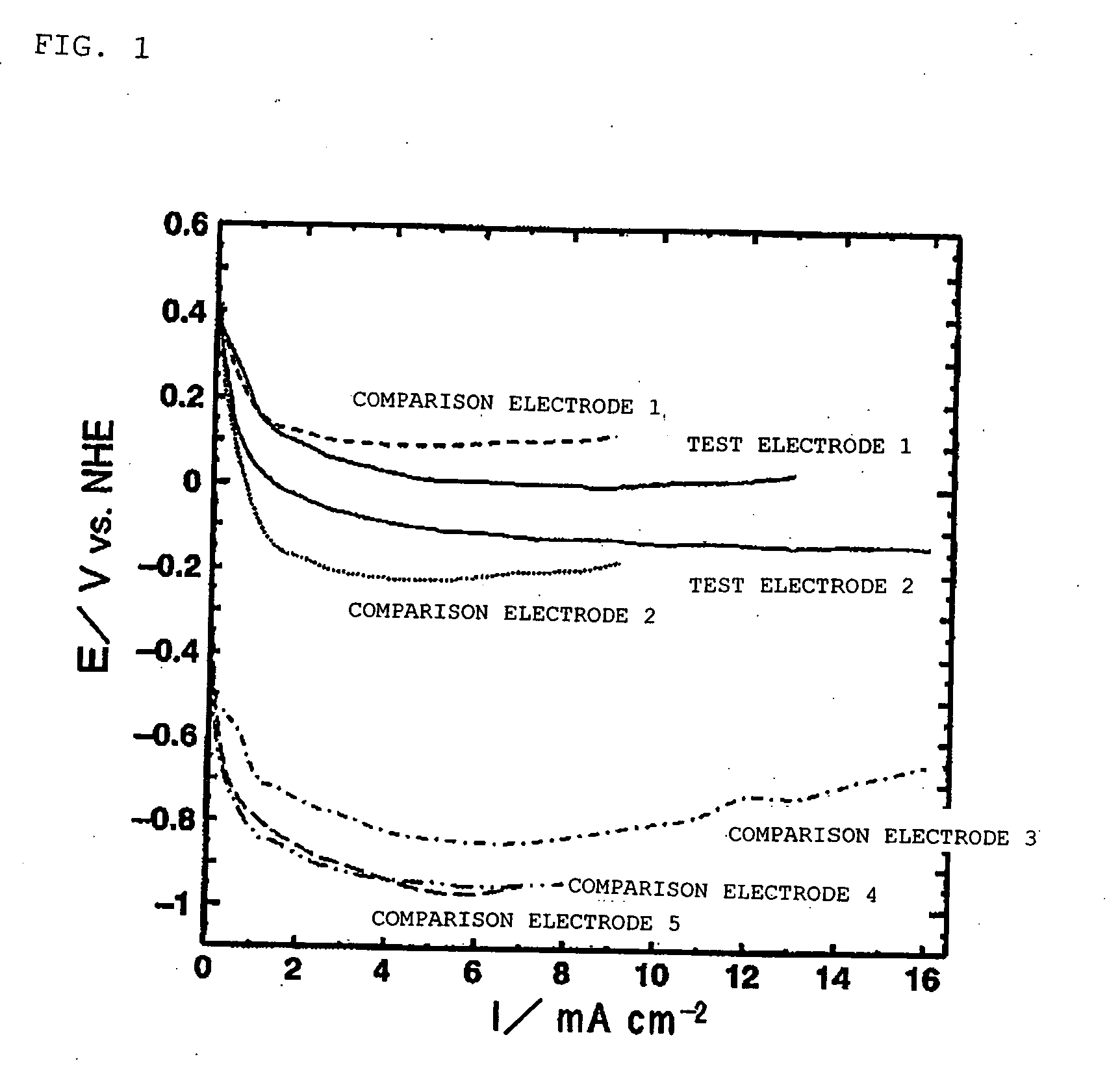

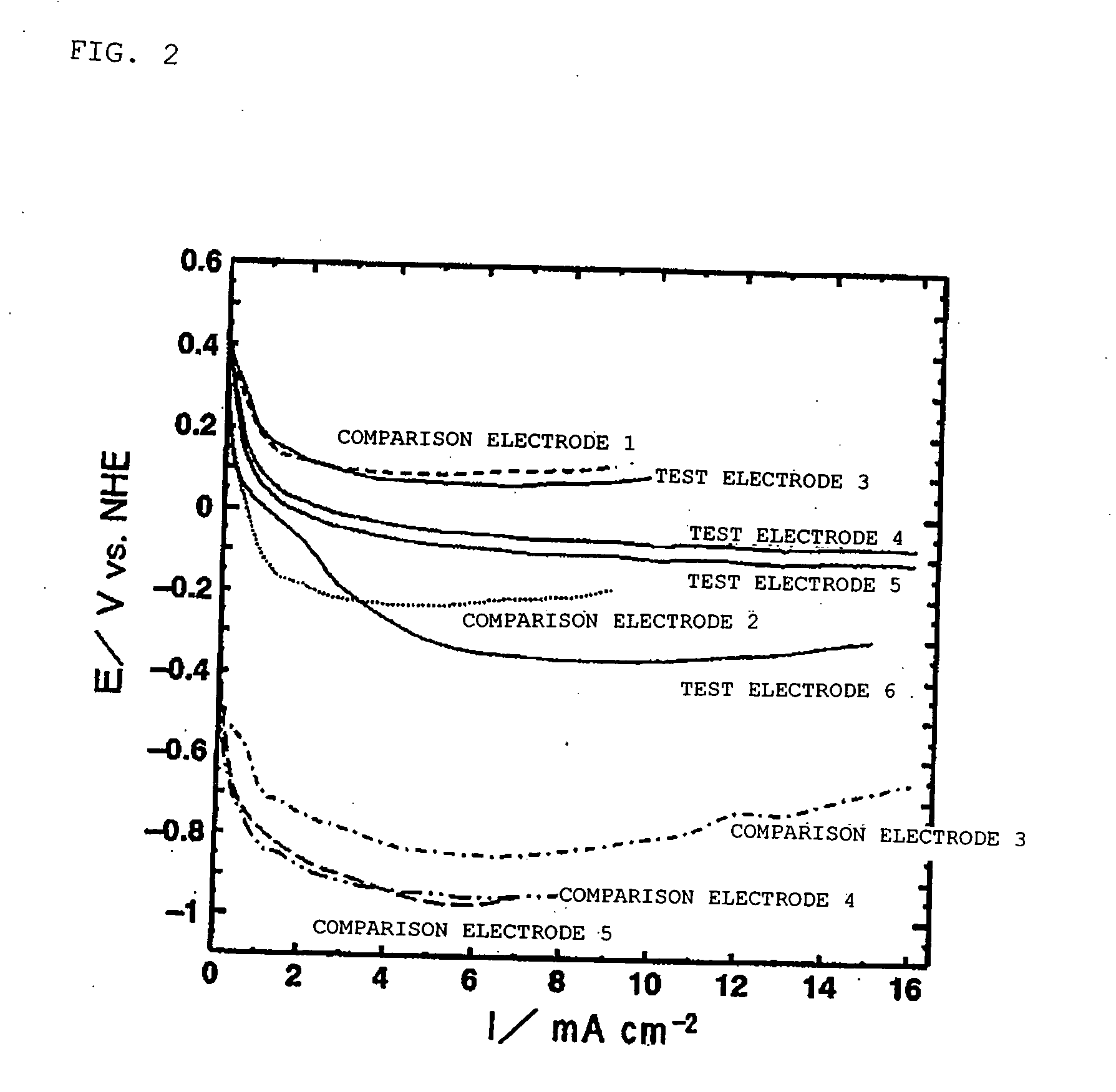

Oxygen reduction electrode and electrochemical element using same

InactiveUS20050153198A1Efficient electrochemical reductionLarge electromotive forceCell electrodesElectrodesPtru catalystCarbonization

Methods of effectively utilizing yeast-containing waste products generated after yeast use can be applied to absorbing agents, drying agents, soil conditioners, catalysts, and other common applications in the same manner as to charcoal-based materials of other materials by carbonizing the waste product, but a new search was needed in order to broaden the industrial utilization of these products. By supporting a particulate or powdered charcoal-based material obtained by carbonizing a yeast-containing material on an electrically conductive gas-permeable base, an electrode can be obtained that is capable of the electrochemical reduction of oxygen. The present charcoal-based material can provide new applications that have not been hitherto proposed, in the sense that oxygen can be electrochemically reduced smoothly and at a small overvoltage (resistance), and a large electromotive force can be obtained, by placing the charcoal-based material at the intersection of the ion path and the oxygen path.

Owner:PANASONIC CORP

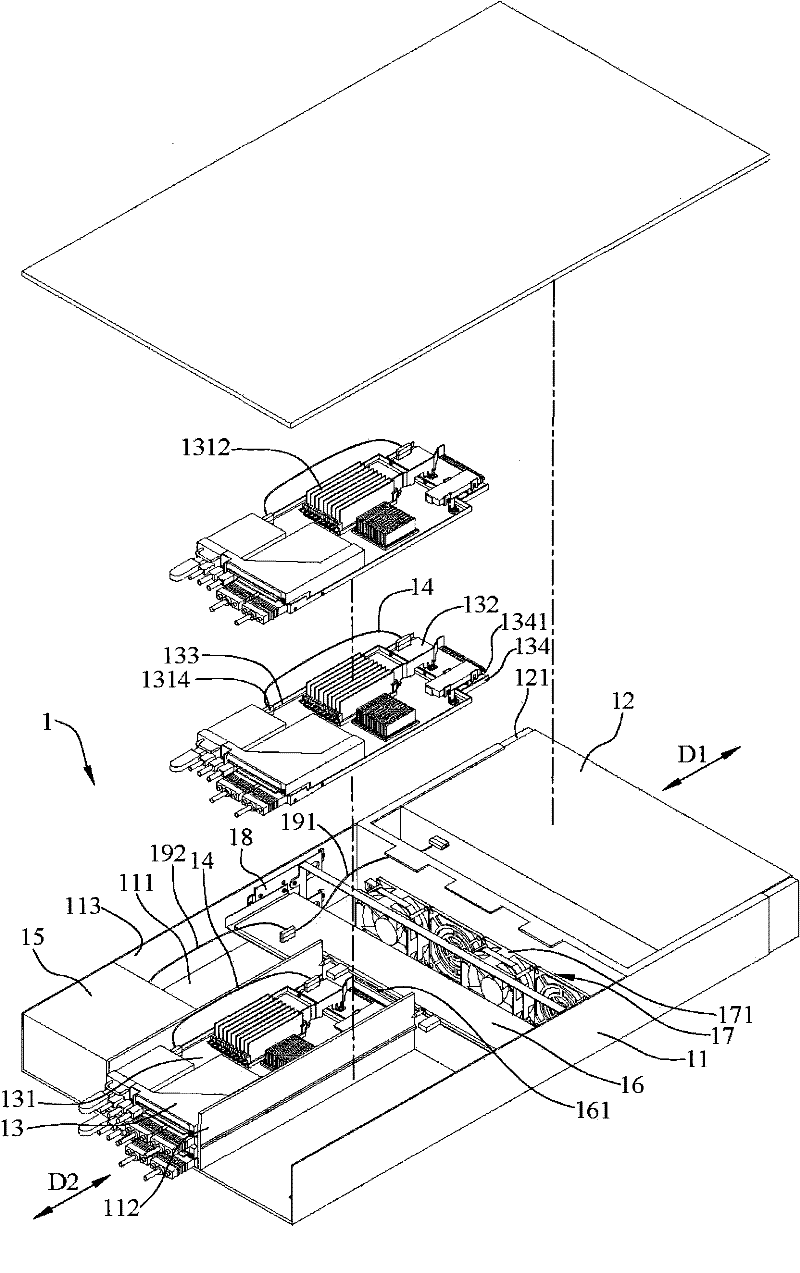

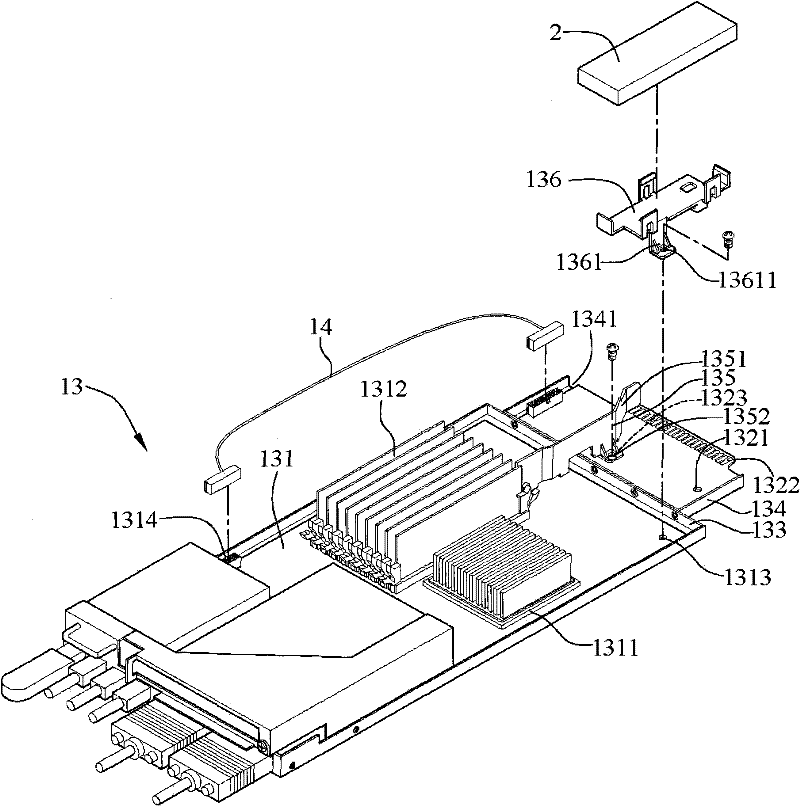

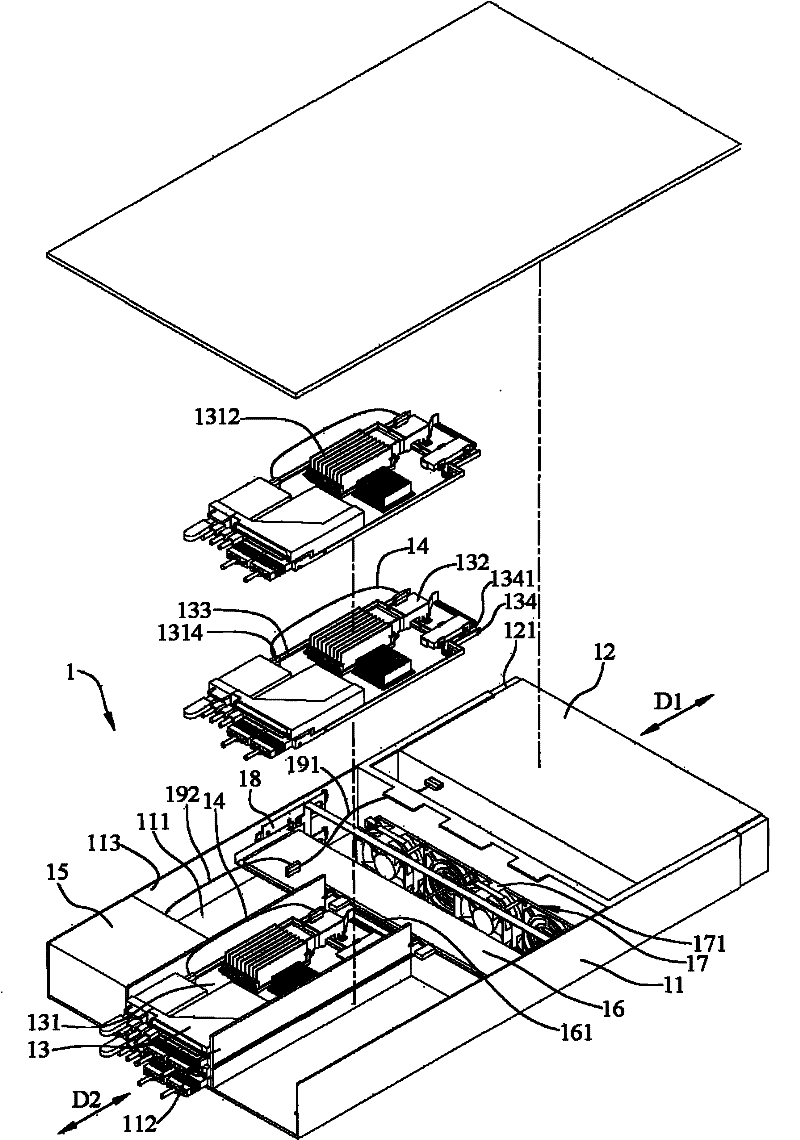

Server

InactiveCN102346504AReduce design costReduce manufacturing costDigital processing power distributionExpansion cardComputer module

The invention discloses a server which is provided with a hard disk array and a main board module which are respectively arranged at the front end and rear end of a case in a removable mode so that hot plug is realized in the server. The main board module is provided with a bearing plate for bearing a main board, an expansion rack for bearing an expansion card with a golden finger, and a cable for electrically connecting the main board and the expansion card; and the cable can prevent the signal of the main board from being distorted by the influence of the length of a transmission path. The main board can be in contact with the server for plugging the main board through the golden finger of the expansion card, so that the design and manufacturing costs of the server are reduced, i.e., the server can be used for effectively overcoming various defects in the prior art and has high industrial utilization value.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Gravity type liquid quantitative water supply automatic closing apparatus

InactiveCN101408259ASave time and effort to collectImprove reliabilityOperating means/releasing devices for valvesMultiple way valvesEngineeringGravitation

The invention discloses a gravity-typed liquid quantitative water supply automatic closing device, comprising a frame, a water outlet tap, a positioning seat with a container positioning ring wall, a water closing valve with a side linked rod, a water taking container, a pressure spring, a container positioning platform with circumferential balance side walls and an independent connection hook which can hook the linked rod of the water closing valve. The working principle of the device is that liquid is injected into the water taking container on the positioning seat by the tap of the water inlet and the water outlet; when the accumulated gravity of the liquid flowed in the water taking container gradually presses the pressure spring to move downwards and synchronously drive the linked rod beside the water closing valve to move downwards, the water is injected continuously and the gravity presses down the pressure spring till the water inlet is closed when the quantitative water supply operation is completed as the quantitative liquid is injected into the water taking container. The gravity-typed liquid quantitative water supply automatic closing device can improve the collection work on the liquid with extremely low flowing speed, consumes no electric energy, and has no pollution, extremely low cost and high industrial utilization value.

Owner:李静娴

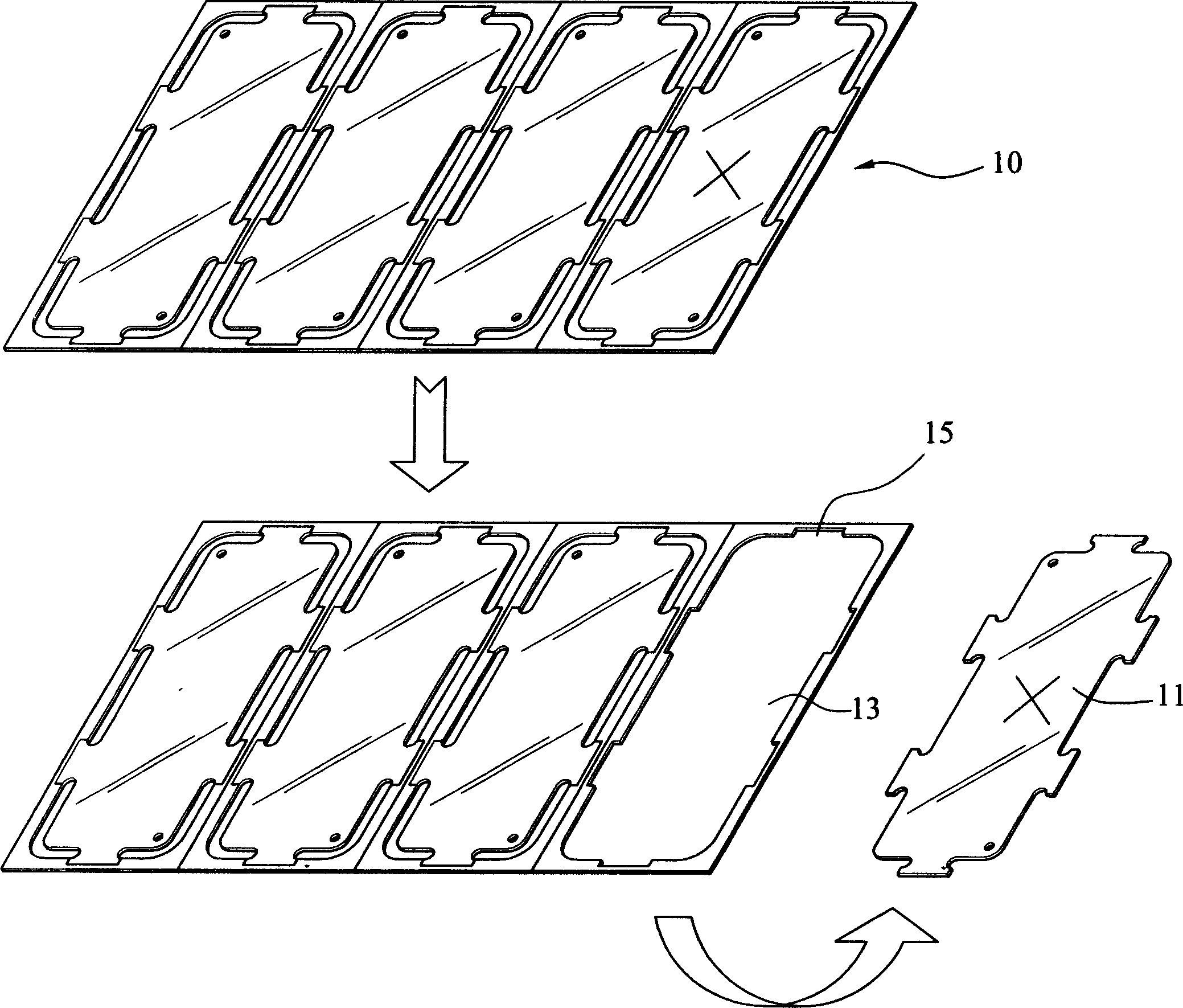

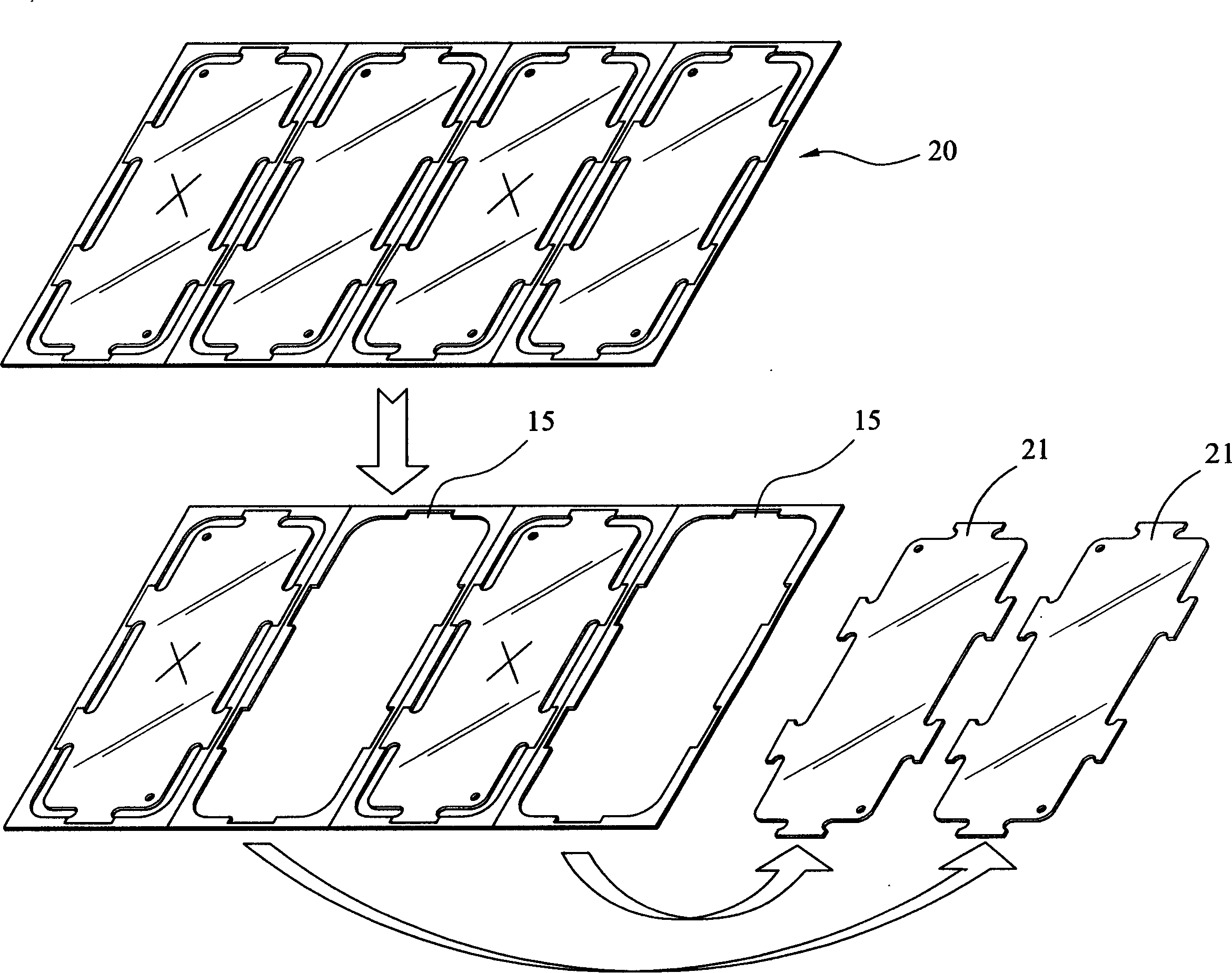

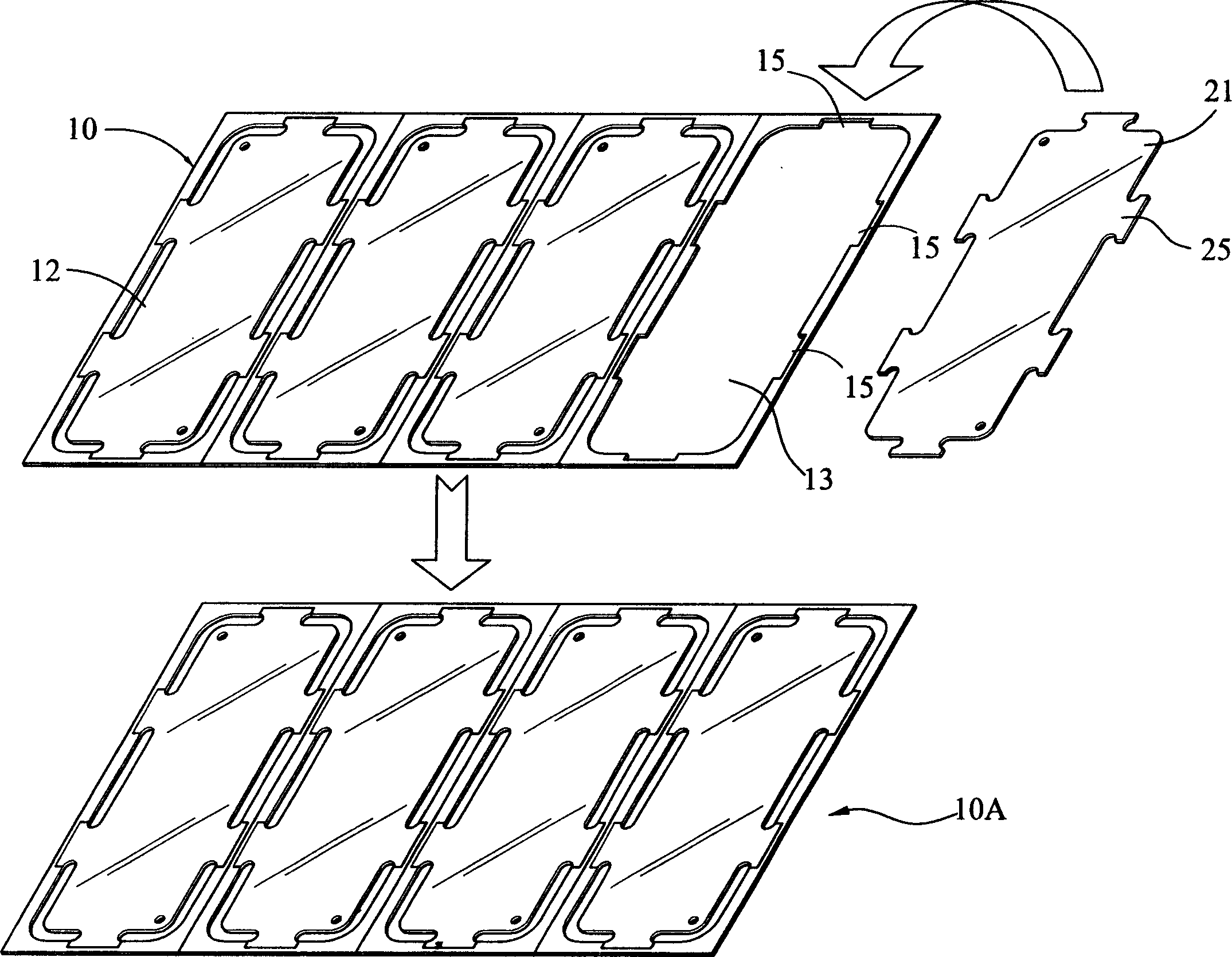

Method for replacing and resetting imperfect multi-piece printed circuit board

InactiveCN1642386AReduce processingReduce manufacturing costPrinted circuit manufactureAdhesiveSingle plate

The invention is a method for displacing and rearranging bad cascaded-plate printed circuit board (PCB), firstly cutting the bad single-plate PCB off a bad cascaded plate PCB and similarly cutting the good single-plate PCB off another bad cascaded PCB, where the cutting-off is carried out by precision cutters such as laser, CNC, etc; an incomplete part is formed in the bad cascaded-plate PCB whose bad single-plate PCB is cut off, and successively the cut-off good single-plate PCB is filled in the incomplete part, and by module locating, optical locating, computer locating, or other precision locating, in a mode of glue injecting, printed, automatic, manual, etc, special adhesive is injected to glue the bad cascaded-plate PCB and the good single-plate PCB together, and then processed by curing procedure, they form a bad cascaded-plate PCB with the same strength and precision as those of the original PCB; by this, its industrial utilization can be achieved and then the production cost is reduced and the problem of processing wastes is reduced as well as the market competitive power is strengthened.

Owner:赖金泉

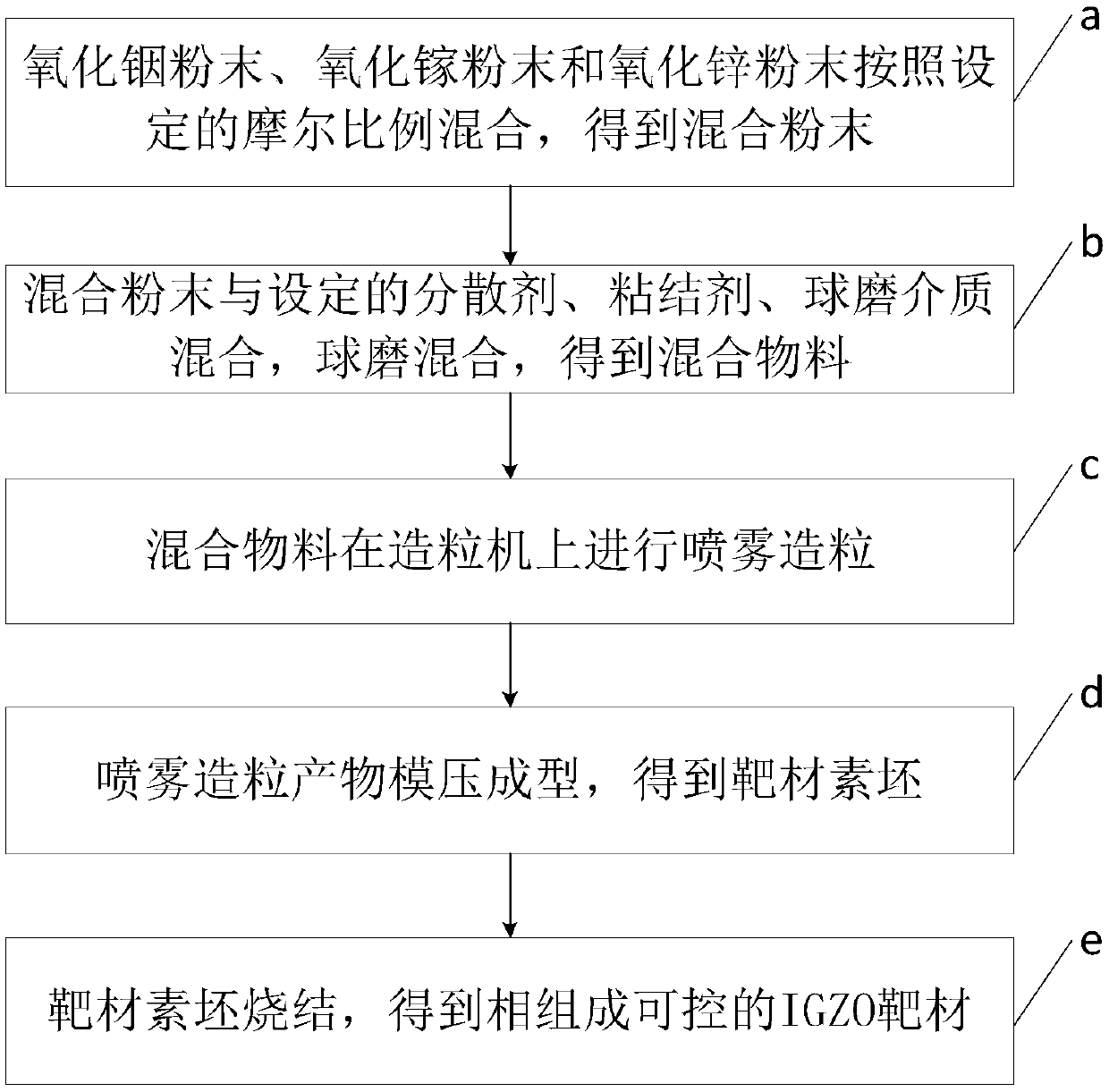

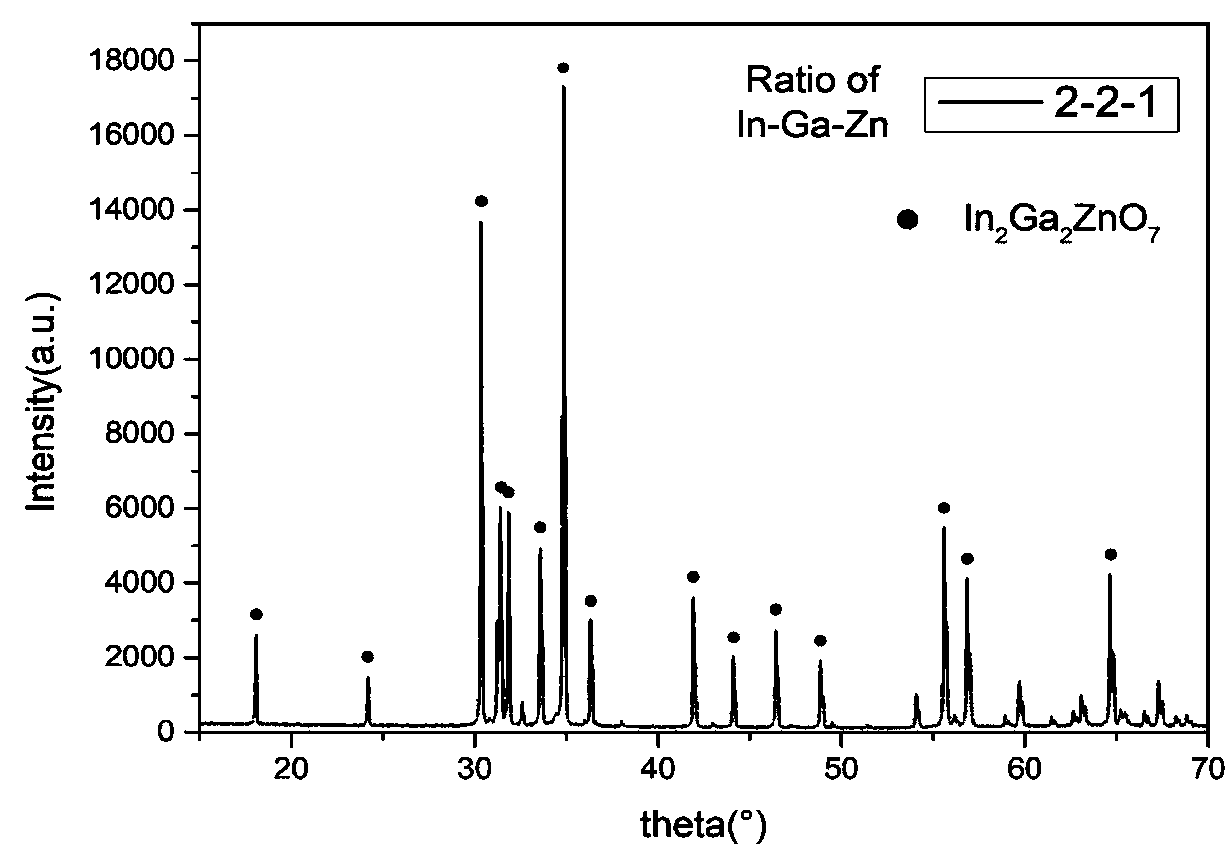

Phase composition controllable indium gallium zinc oxide target material and preparation method thereof

The invention discloses a phase composition controllable indium gallium zinc oxide target material and a preparation method thereof. The preparation method includes that indium oxide powder, gallium oxide powder and zinc oxide powder are mixed according to the set molar ratio to obtain a mixed powder; the mixed powder is mixed with the set amount of dispersant, binder and ball milling medium; a ball milling device is applied to control the ball milling parameters, and the ball milling mixing is carried out to obtain a mixed material; the mixed material is sprayed and granulated on a granulator, the product obtained by spray granulation is molded and a target blank is obtained; and the target blank is sintered to obtain the IGZO target material with controllable phase composition. A high quality IGZO target material with single phase and controllable phase is obtained by controlling the process parameters effectively in the preparation process according to the molar ratio of the raw materials. Other mixed phase composition is not contained in the target material, no secondary phase structure is existed between grains and inside, the bonding between grains is compact, and the targetmaterial has high density and has high industrial utilization value.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com