Patents

Literature

38 results about "Pulp industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulp and paper industry is one of the key industries of forest complex, which combines different technologic processes of producing pulp, paper (also things like notebooks, newspapers, and napkins), paperboard, and other accompaniments. Due to some technologic specialties of pulp producing there are two main factors of manufacture placement.

System and process for the treatment of multiphase residues

ActiveUS20050218037A1Useful in treatmentProcess environmental protectionCatalytic crackingRetortsMining industryPhenol

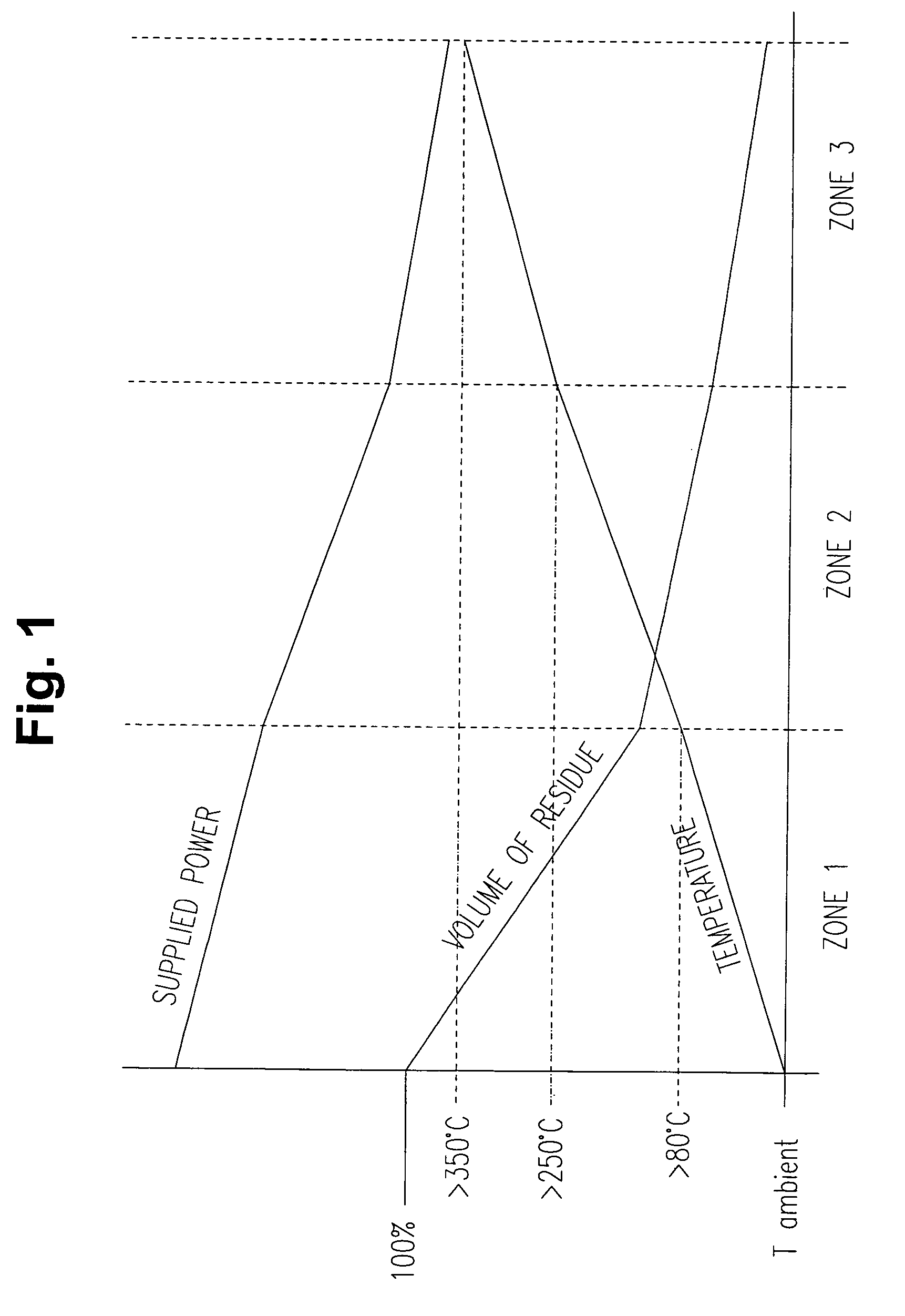

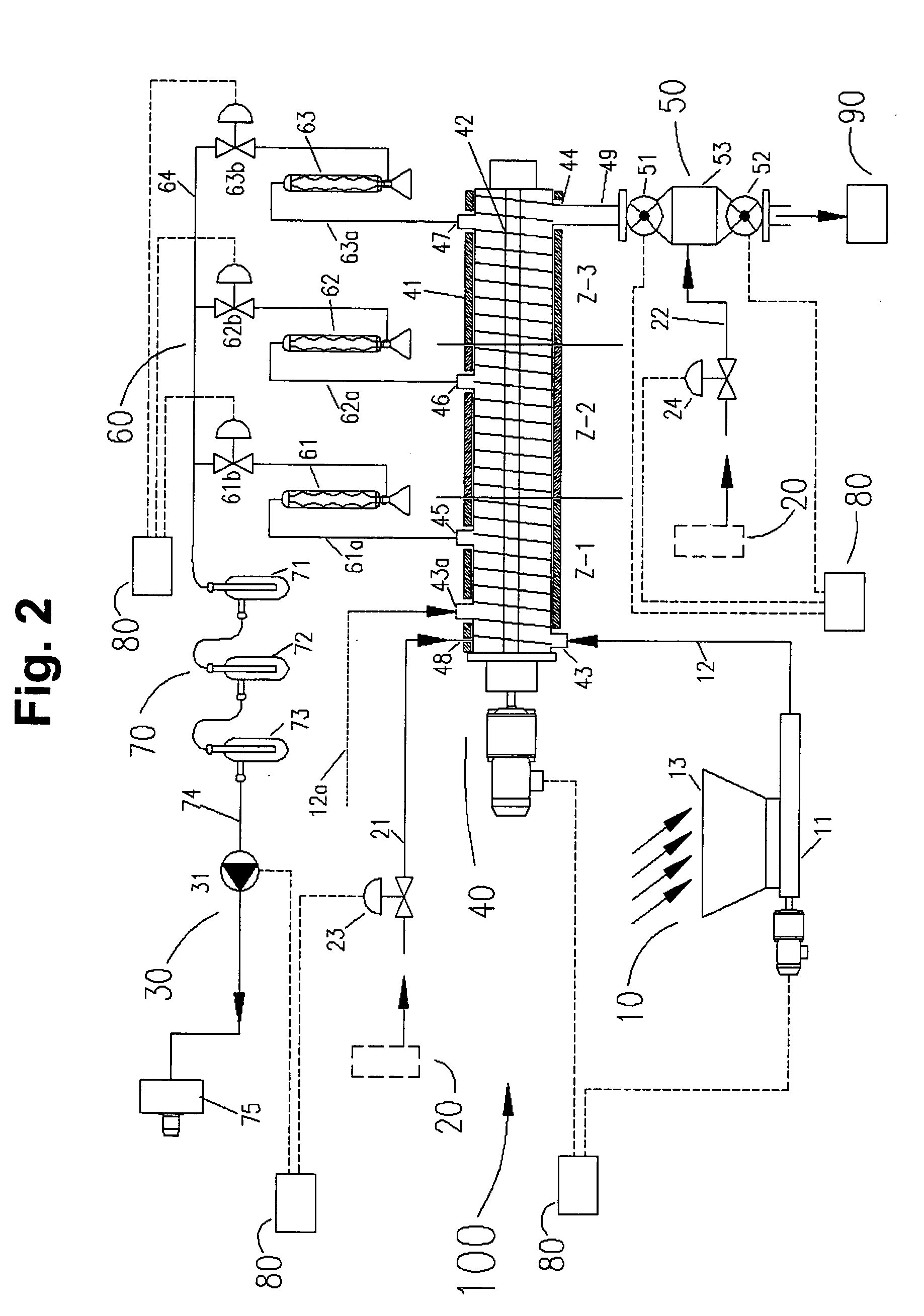

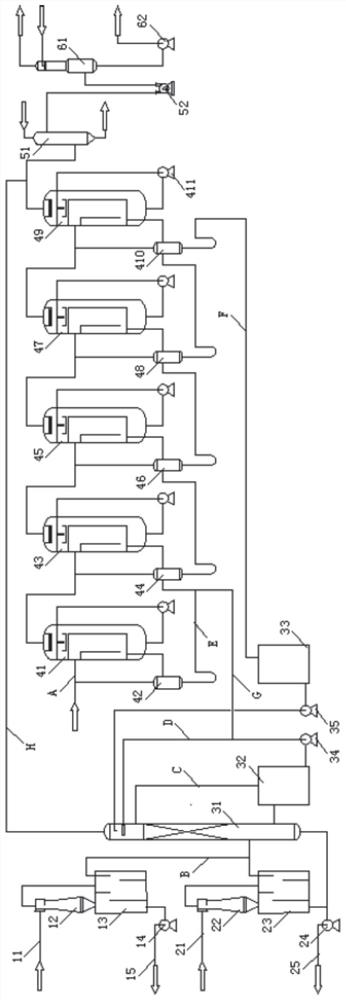

A system 100 is described for the treatment of multiphase residues having unlimited content of water, oil and solids to obtain hydrocarbons and other products, said system comprising multiphase residue feed system 10, inert gas system 20 and reduced pressure system 30, tubular reactor 40 provided with three heating zones Z-1, Z-2 and Z-3 with a temperature gradient and transportation helicoid 42 to displace the residue mass throughout the reaction zones, the hydrocarbon products and water being collected in a system 60 of condensers 61, 62 and 63 linked to a system 70 of bubbling vessels 71, 72 and 73, reactor 40 being operated in the sealed mode and being provided with a multiphase residue inlet 43 and exit 44 of solid product. The solid product is collected in a system 50 comprising upper valve 51 and lower valve 52, and intermediate silo 53 and then directed to post-treatment system 90 for activation aiming at industrial utilization. The process using the system 100 of the invention is also described. Multiphase organic residues, petroleum residues, pure or in admixture in any amount, from chemical and pharmaceutical industries, paper and pulp industry, and mining industries can be processed in the inventive system. Besides, it is possible to recover phenols from foundry sands in the system and process described.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS) +1

Method for producing xylose by using eucalyptus pulp pre-hydrolyzing liquid

InactiveCN102605108ARealize rational utilizationSolve processing problemsSaccharides productionPulp industryIon exchange

The invention discloses a method for producing xylose by using eucalyptus pulp pre-hydrolyzing liquid and belongs to the technical field of the production of functional sugars. The eucalyptus pulp pre-hydrolyzing liquid serves as a raw material and is prepared into the xylose through the procedures of pre-concentration, hydrolyzation, neutralization, decoloring, ion exchange, concentration, crystallization and drying processes. The reasonable utilization of eucalyptus pulp pre-hydrolyzing liquid is realized, the problem about treatment on the pre-hydrolyzing liquid in the eucalyptus pulp industry is solved, waste is changed into useful things, xylose products with multiple physiological functions are extracted from the pre-hydrolyzing liquid, the vacancy of producing the xylose by using the eucalyptus pulp pre-hydrolyzing liquid in China is filled, and a new raw material way for xylose production is made.

Owner:FUTASTE PHARM CO LTD

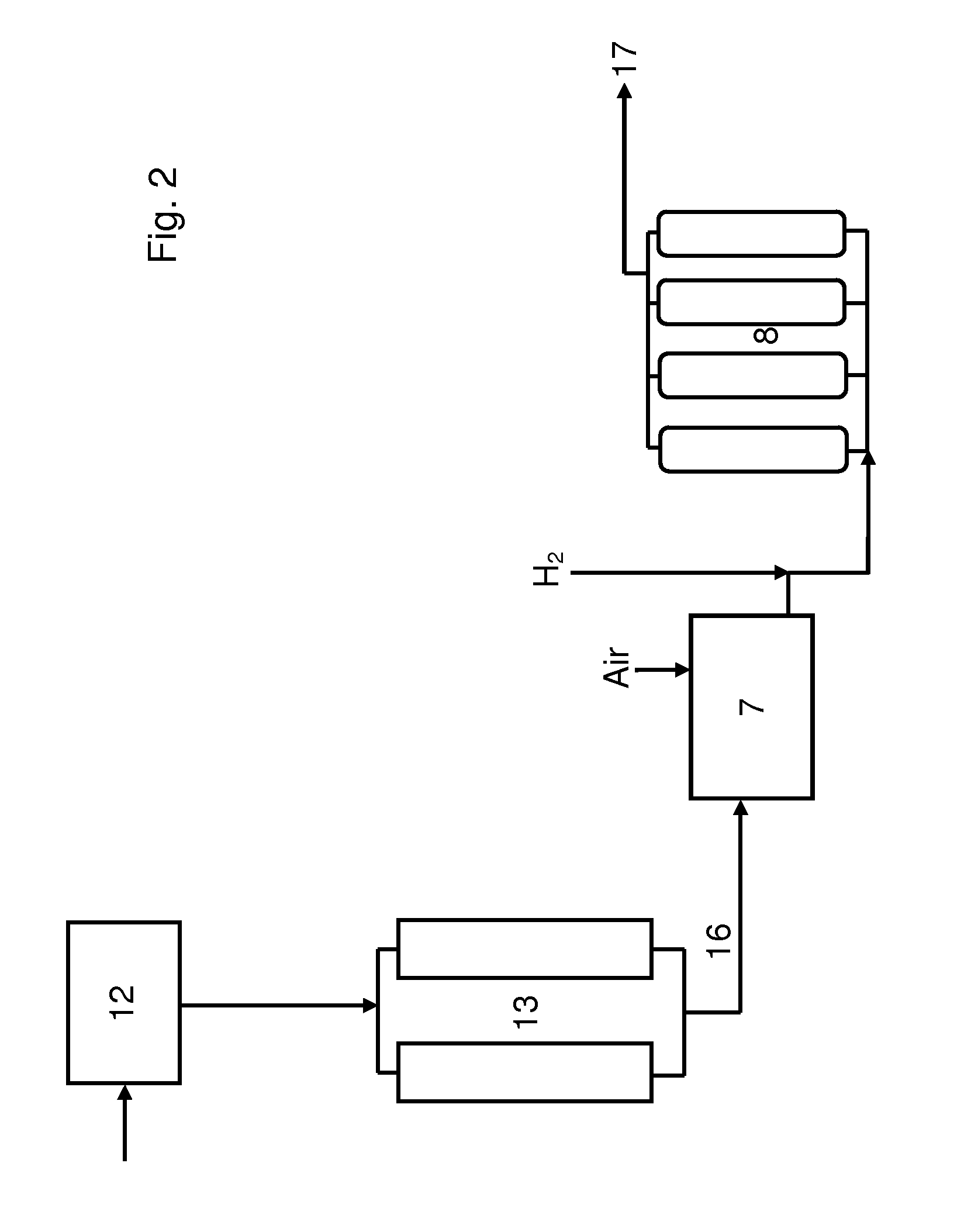

Use of Methanol in the Production of Hydrogen and Fuel, Processes and Plants for the Production of Hydrogen and Fuel

InactiveUS20100317905A1Removes malodorous sulphurRefining to change hydrocarbon structural skeletonCombustible gas catalytic treatmentHydrogenBlack liquor

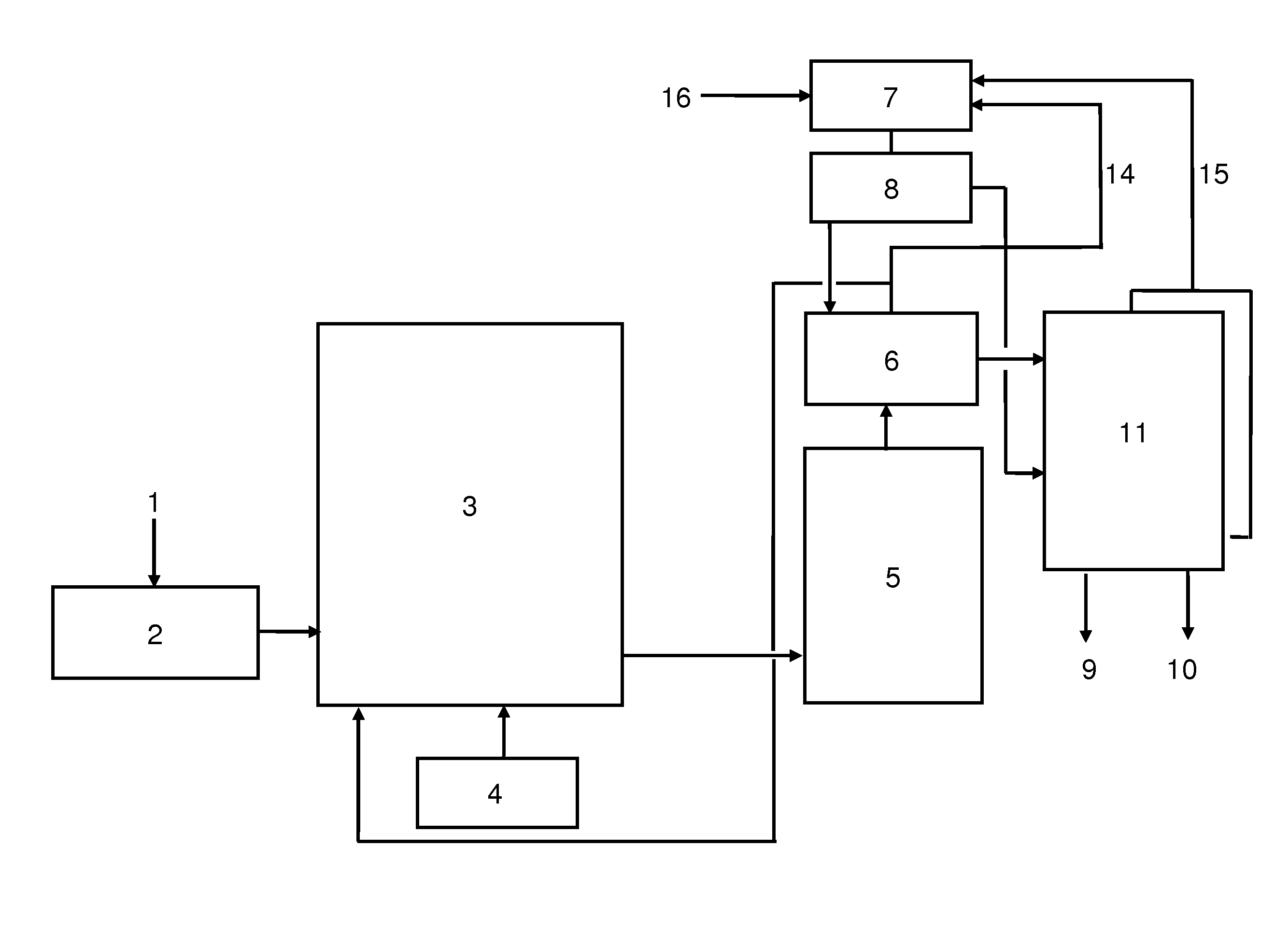

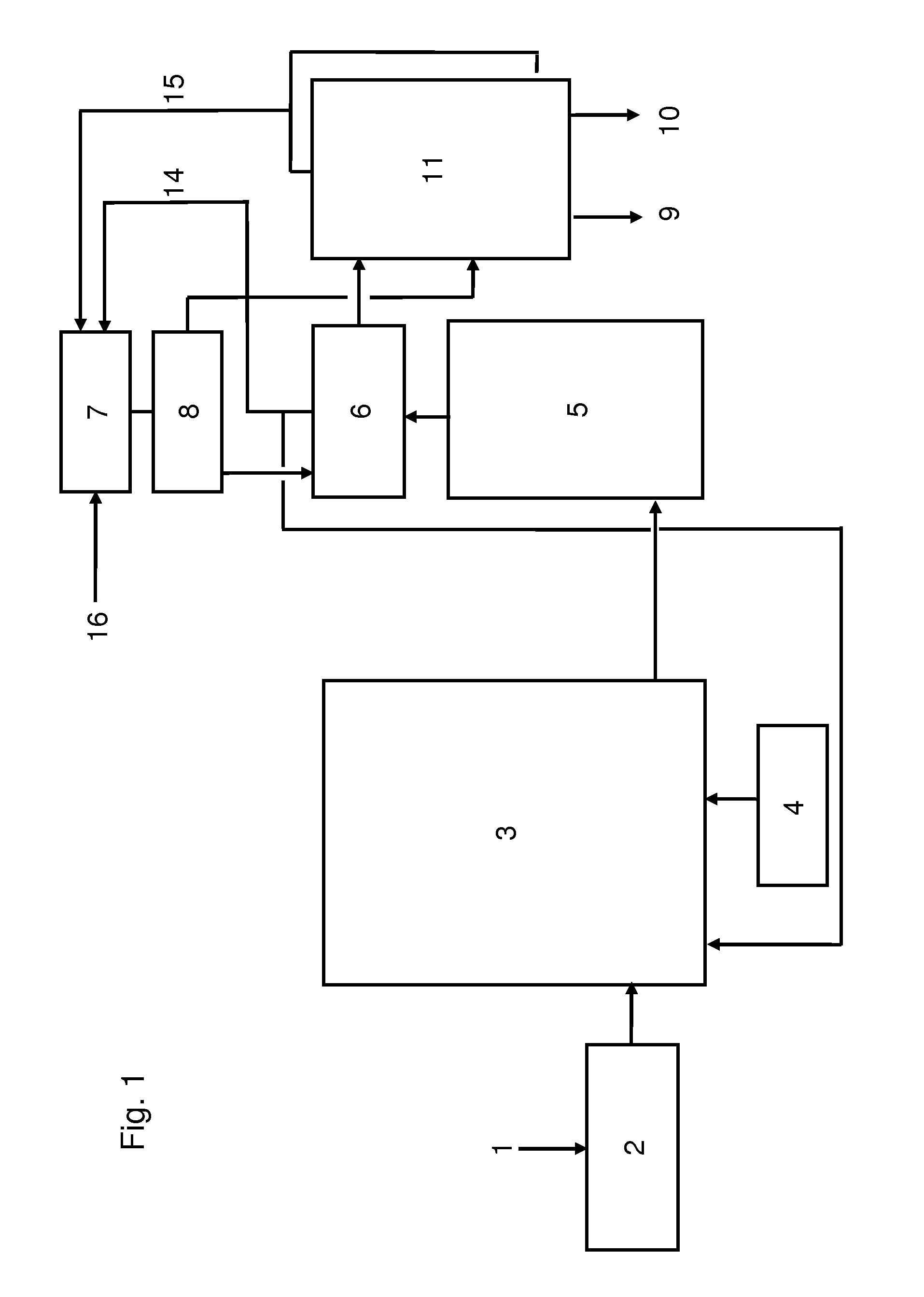

The invention relates to the use of biomethanol from the pulp industry in the production of biohydrogen. The preferred biomethanol comprises purified biomethanol derived from black liquor. The invention also relates to a process for the production of biohydrogen from crude biomethanol recovered from black liquor and to a process for producing hydrocarbon biofuel using such biohydrogen as a hydrogen source. The invention further relates to a biofuel production facility for producing fuel from biohydrogen and biohydrocarbon, and to biofuel so produced. The invention makes it possible to produce a biofuel, wherein 100% of the raw material stems from non-fossil sources.

Owner:UPM-KYMMENE OYJ

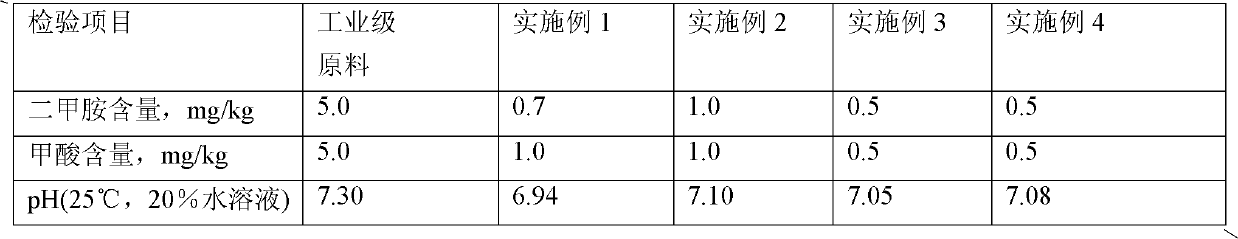

Method for preparing electronic-grade N, N-dimethylformamide by ion exchange resin method

InactiveCN101993386AReduce conductanceCarboxylic acid amide separation/purificationN dimethylformamideIon exchange

The invention discloses a method for preparing electronic-grade N, N-dimethylformamide by an ion exchange resin method, which comprises the steps of: pumping industrial-grade N, N-dimethylformamide into a heat exchanger; reducing the temperature of raw material to room temperature of 40 DEG C; entering an ion exchange unit; removing metal ions, formic acid, dimethylamine and salt impurities generated by the formic acid and the dimethylamine from the N, N-dimethylformamide by an ion exchange method; and filtering broken resin and granular impurities in the N, N-dimethylformamide by a filtering unit to obtain the electronic-grade N, N-dimethylformamide. In the prepared electronic-grade N, N-dimethylformamide DMF, the content of each metal ion is less than 10 ppb; the content of methylamine and the content of the formic acid are reduced to be less than 1 ppm; the pH value of DMF is 7.0 approximately; the conductance of pure DMF is less than 0.010 microsecond / cm; a purified DMF is used as a high-end product for electronics industry of manufacturing copper-clad plates and high-grade pulp industry of polyurethane synthetic leather.

Owner:TIANJIN UNIV

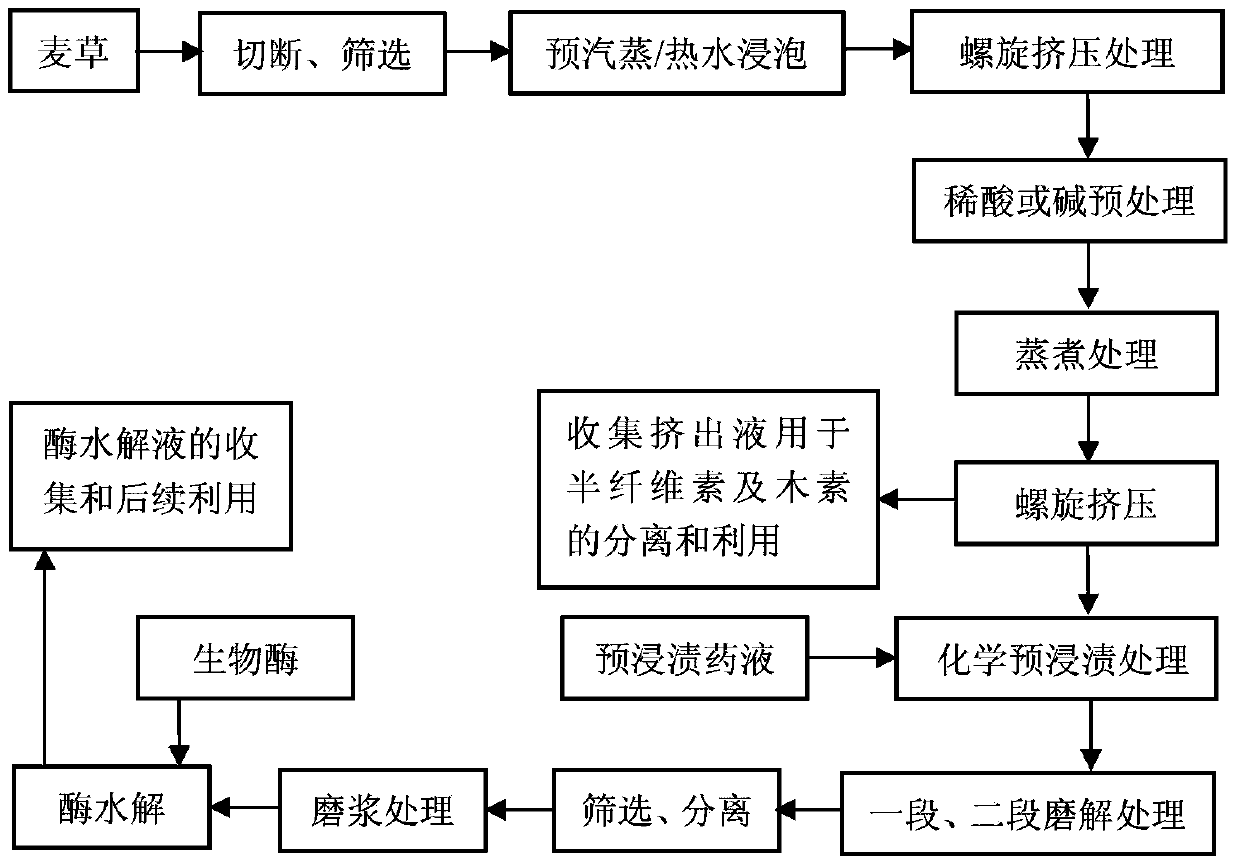

Pretreatment method assists in realizing wheat straw high-efficiency enzymatic hydrolysis conversion

ActiveCN103497982APromote sustainable developmentEfficient integrationFermentationWater bathsPretreatment method

The invention relates to a pretreatment method assists in realizing wheat straw high-efficiency enzymatic hydrolysis conversion. The method comprises the steps that: wheat straws are soaked and subjected to screw extrusion; H2SO4 or sodium hydroxide is added; distilled water is added; steaming is carried out, screw extruder extrusion is carried out, and constant-temperature water bath is carried out; two-stage grinding treatment, screening, and enzymatic hydrolysis are carried out; under a sterile condition, enzyme solution is added, and constant-temperature culturing and enzymatic hydrolysis are carried out; and the wheat straw hydrolysate is obtained after enzymatic hydrolysis. According to the invention, parts of existing devices in a pulping industry are sufficiently utilized, and the pretreatment process can be completed without additional investment, such that great economic cost is saved. Also, with the method, existing factories can be effectively fused with biomass refining industry, such that composite biomass refining industry can be developed, and sustainable development of pulping and papermaking industries is benefited.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

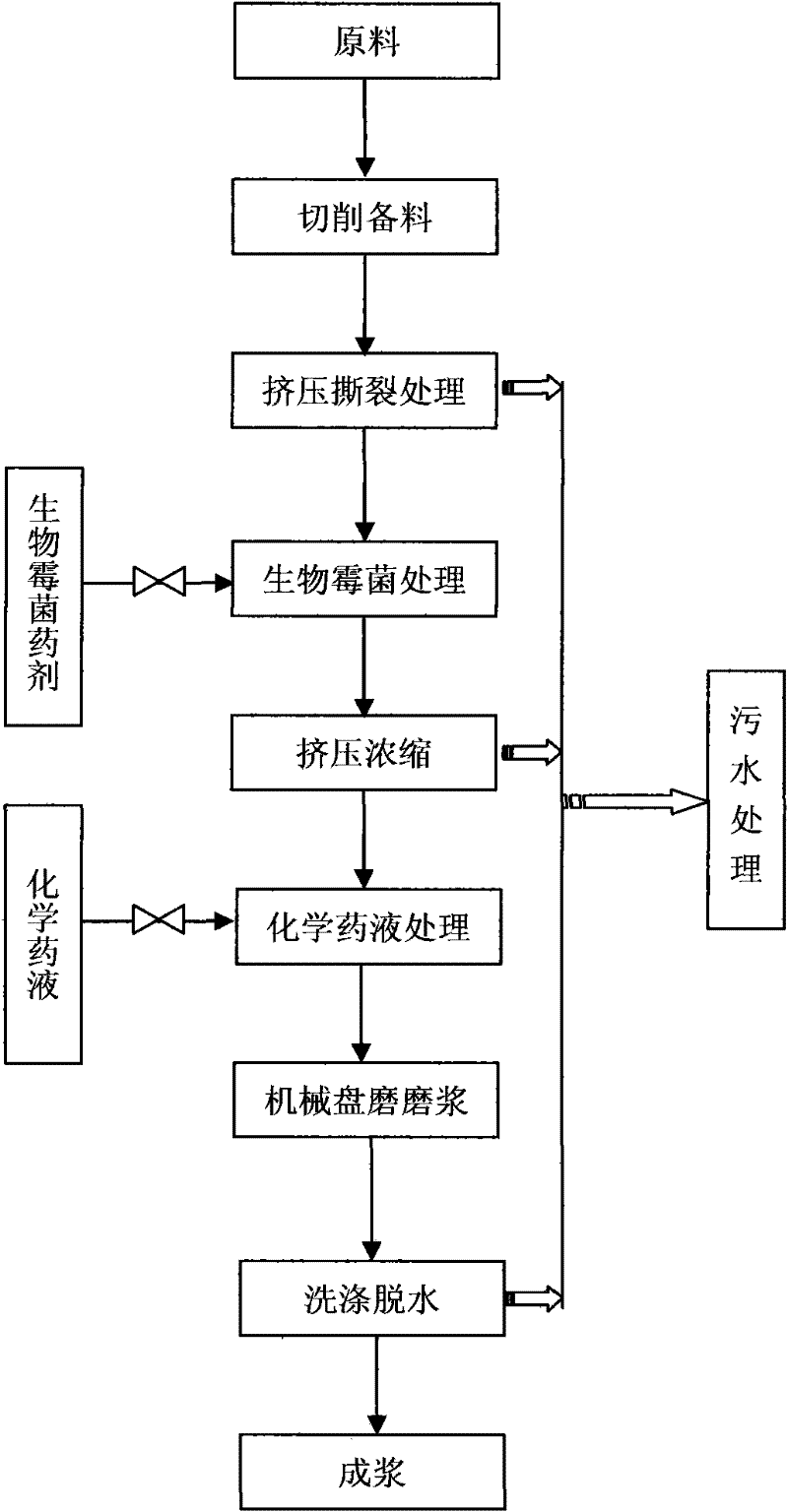

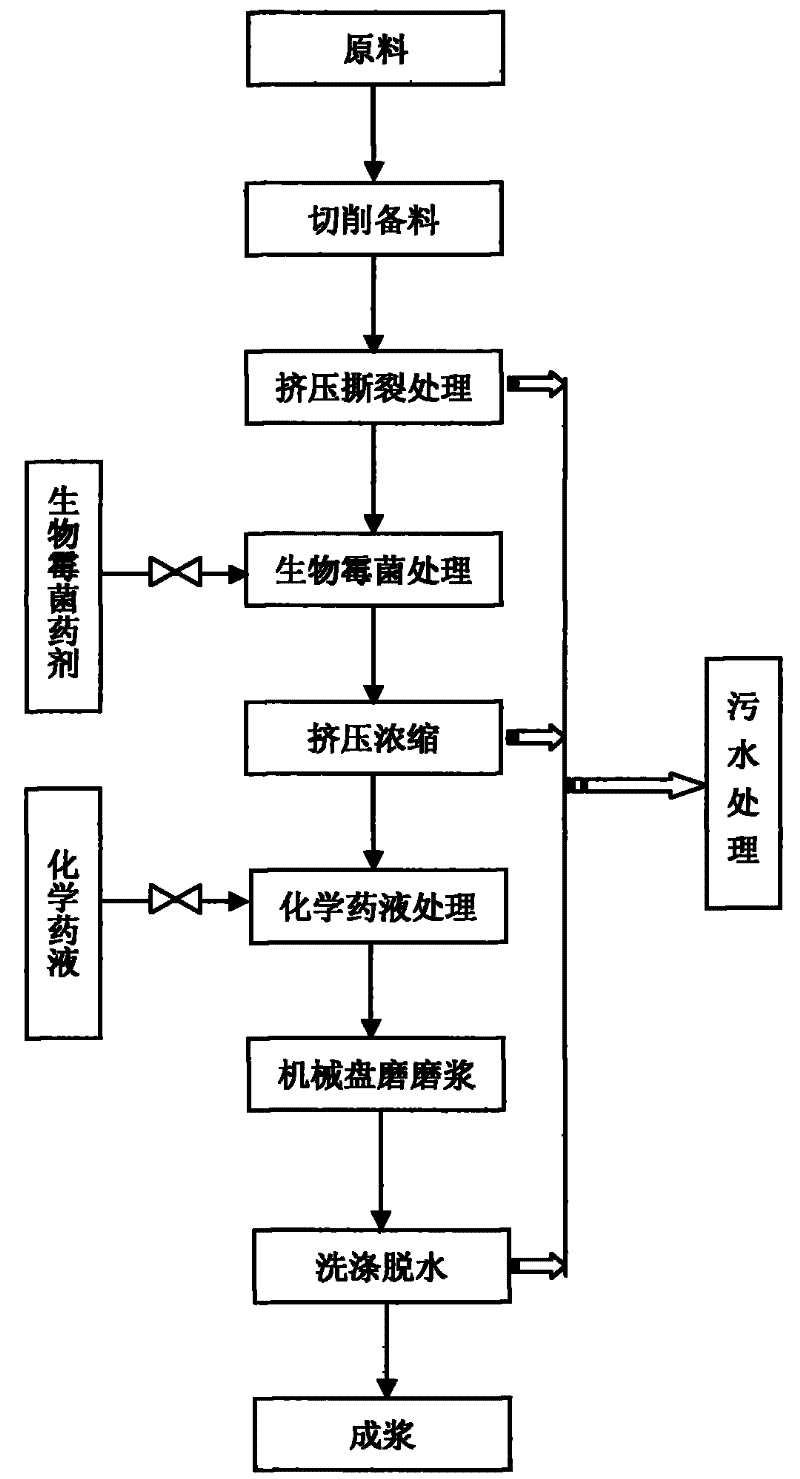

A combined pulping method

InactiveCN102268826AImprove efficiencyReduce pollutionPulping with inorganic basesPulp beating/refining methodsMature technologyPulp industry

A combined pulping method, using bamboo wood as raw material. The present invention relates to a combined pulping method, in particular to a biological, chemical and mechanical combined pulping method, which belongs to the technical field of pulping and papermaking, especially biochemical and mechanical Combined pulping technology. The present invention combines the current advanced biotechnology, mature chemical pulping technology and high-efficiency mechanical pulping technology through organic integration, comprehensively utilizes the advantages of the above technologies, conducts targeted combination, and develops a new pulping method. The method of the invention reduces the pollution of the pulping industry and improves the economic benefits of the pulping industry. The combined pulping method has strong raw material adaptability, good pulping performance, and good pulp is suitable for compounding various papers.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

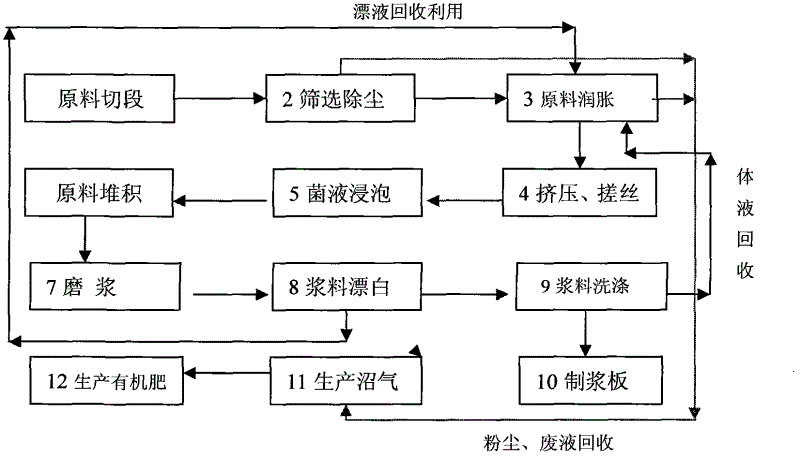

Biological accumulation pulping method

InactiveCN102619119ASimple processStable flowPaper material treatmentPulp industryPotassium hydroxide

The invention relates to a biological accumulation pulping method. The biological accumulation pulping method is characterized in that the biological accumulation pulping method comprises the following steps: cutting a pulping raw material into sections with the lengths of 4-5cm; carrying out screening and dust removal on the cut raw material; inputting the raw materials subjected to dust removal into a container; adding an aqueous solution of 0.5-0.6 potassium hydroxide according to the mass ratio of solid to liquid being 1:6; soaking the raw materials at the temperature of over 65DEG C and normal pressure for over 2 hours to enable the raw materials to quick absorb water and swell; inputting the swollen raw materials into an extrusion machine for removing water and rolling threads, wherein the thickness of the threads is 0.8-1.5mm; conveying the materials into a biological bacterial suspension pool, soaking the materials for over ten minutes, fishing and leaching; conveying the leached materials to a degradation pool for stacking fermentation; degrading lignin; sealing the upper end of the degradation pool with a plastic film and preserving moisture and temperature; controlling the temperature in the pool between 35 and 40DEG C and maintaining the temperature for 10-15 days; and pulping. The biological accumulation pulping method has the advantages of simple process, smooth flow, strong practicability, energy economization, water economization, and zero discharge and zero pollution in the pulping industry.

Owner:王福喜

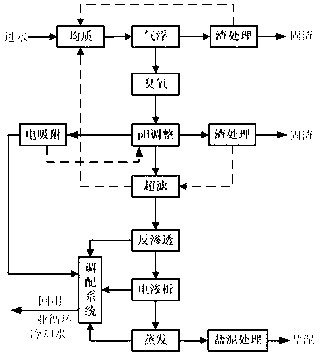

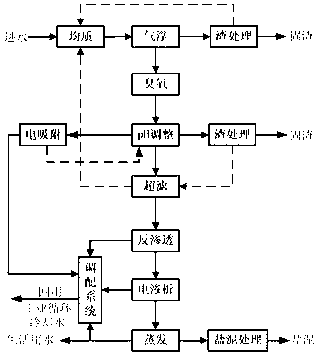

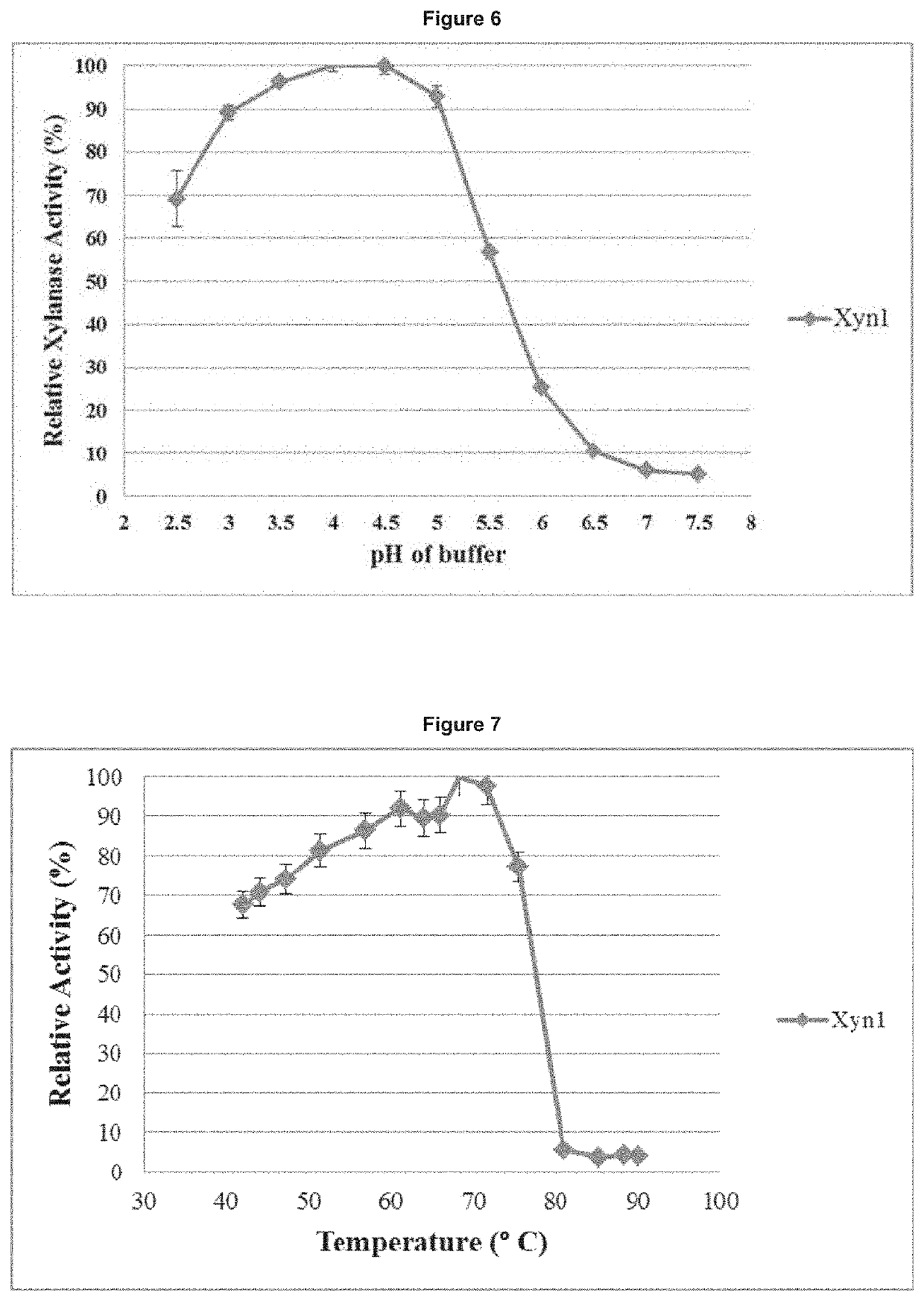

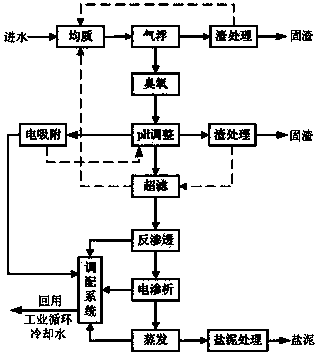

Process for reusing tail water in papermaking and pulping

ActiveCN103342431AAvoid large emissionsSolve water problemsDispersed particle separationWater/sewage treatment bu osmosis/dialysisWater useChemical oxygen demand

The invention relates to a process for reusing tail water in papermaking and pulping. The technology comprises the following specific steps of: (1) feeding wastewater into an equalization basin for premixing; (2) transferring the premixed wastewater into an air flotation system, and reducing COD (Chemical Oxygen Demand) and SS (Suspended Solids); (3) transferring the water treated by the air flotation system into an ozone system, and removing partial COD; (4) adjusting pH (Potential of Hydrogen) of the water treated by the ozone system, transferring partial water into an ultrafiltration system for pre-treating; transferring the other part of water into an electro-adsorption system, and directly feeding the water generated by the electro-adsorption system into an allocation system; (5) transferring the water subjected to ultrafiltration treatment into a reverse osmosis system; (6) transferring the fresh water subjected to reverse osmosis treatment into the allocation system for reusing, and transferring the concentrated water subjected to reverse osmosis treatment into an electroosmosis system for concentrating; and (7) feeding the fresh water subjected to electroosmosis into the allocation system for reusing, and feeding the concentrated water subjected to electroosmosis into an evaporating system for treating. The technology for reusing the tail water in papermaking and pulping realizes the recovery of water resources in the papermaking and pulping industry, and the treated water can be allocated according to the demand on water use of an enterprise, thus meeting the water supply under different requirements for water quality.

Owner:NANJING UNIV OF TECH +1

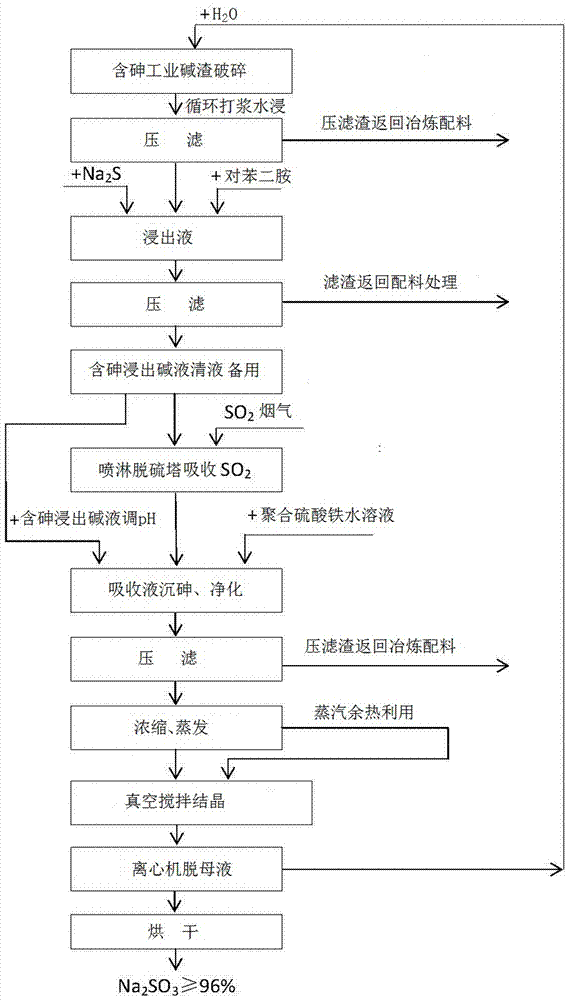

Technique for producing sodium sulfite products by absorption of SO2 flue gas through arsenic-containing industrial alkali residue water alkali liquor and arsenic removal purification

InactiveCN107963642AHigh product contentIncrease contentAlkali metal sulfite preparationSulfite saltFiltration

A kind of technological method of using arsenic-containing industrial alkali slag to absorb SO2 flue gas, remove arsenic and purify to produce sodium sulfite product. After treatment with p-phenylenediamine, press filter to obtain arsenic-containing leaching lye for later use, pump the clear liquid into the spray desulfurization tower to absorb SO2 flue gas, reduce the pH value of the absorption solution to 6.2-6.4, and then add arsenic-containing leaching lye After adjusting the pH value of the clear liquid to 10.5-11.5, adding polyferric sulfate aqueous solution for arsenic precipitation, pressure filtration for liquid-solid separation, clear liquid crystallization after concentration and evaporation, and drying after separating the mother liquor to obtain sodium sulfite products with a mass concentration ≥ 96% . This method starts with industrialized stable production, increases the content of sodium sulfite products as much as possible, optimizes the technical process and parameter selection, and has achieved obvious technological progress. Based on the annual output of 20,000 tons of alkali slag in the country, it can increase economic benefits by about 35 million The total amount of arsenic that can be removed and harmlessly treated is As 6%×20000=1200 tons / year, and the desulfurization is 4250 tons / year, resulting in huge environmental benefits.

Owner:YAN XIN ENVIRONMENTAL PROTECTION & TECH CO LTD

Novel energy conservation and environment protection process for realizing mutualistic symbiosis of straw pulping and papermaking industry and waste lead-acid cell recycling industry

ActiveCN104671497AAvoid burnsAvoid pollutionCombination devicesTreatment involving filtrationThermal energyProcessing cost

The invention discloses a novel energy conservation and environment protection process for realizing the mutualistic symbiosis of a straw pulping and papermaking industry and a waste lead-acid cell recycling industry. According to the alkaline characteristic of the straw pulping sewage, the acidic characteristic of the waste lead-acid cell recycling sewage, and the condition of the coupling utilization space of the after heat, the energy conservation and environment protection process for realizing the mutualistic symbiosis for comprehensive coupling processing the acid-alkali wastewater and complementarily using the heat energy is provided. By adopting the process, the pollution abatement cost and the difficulty of the two industries can be greatly reduced, the energy complementary utilization is realized and the mutualistic symbiosis of two industries is obtaind. By adopting the process, the complementary utilization of the energy sources of two distant related industries is realized, the alkaline black liquid generated by the straw pulping industry and the leaded acidic wastewater generated by the regenerated lead industry can be completely recycled and utilized, so that the problem of high processing cost of the sewages in two industries can be solved and the economic benefits of two industries can be effectively increased.

Owner:尚圣杰

Application of chitosan as viscosity protective agent for ozone bleaching section of paper pulp

InactiveCN111287010ASimple preparation processEasy to operateCellulosic pulp after-treatmentOXALIC ACID DIHYDRATEPulp industry

The invention belongs to the technical field of paper pulp bleaching, and particularly discloses an application of chitosan as a viscosity protective agent for an ozone bleaching section of paper pulp. Chitosan is used as a viscosity protective agent in paper pulp ozone bleaching, so that scaling, nondegradability of tert-butyl alcohol and the like formed by oxalic acid serving as the viscosity protective agent can be avoided, subsequent bleaching is not affected, and adverse effects on paper properties are avoided. Moreover, the chitosan is simple in preparation process, rich in raw materialsin nature, low in price, biodegradable and obvious in viscosity protection effect. Therefore, the application of the chitosan as the protective agent in ozone bleaching can promote the paper pulp industry to be further carried out on a full chlorine-free bleaching road, and has certain practical significance for industrial practical application of ozone.

Owner:SOUTH CHINA UNIV OF TECH

Water treating method in pulping industry

The water treating method in pulping process features the multiple washing, extruding and filtering of pulp, and the produced filtrate is returned completely to washing and digesting pulp liquid. Bycombining with chemical deposition method, all the organic pollutants are converted into the precipitant, so that the water pollution during pulping process is eliminated thoroughly.

Owner:梁植林

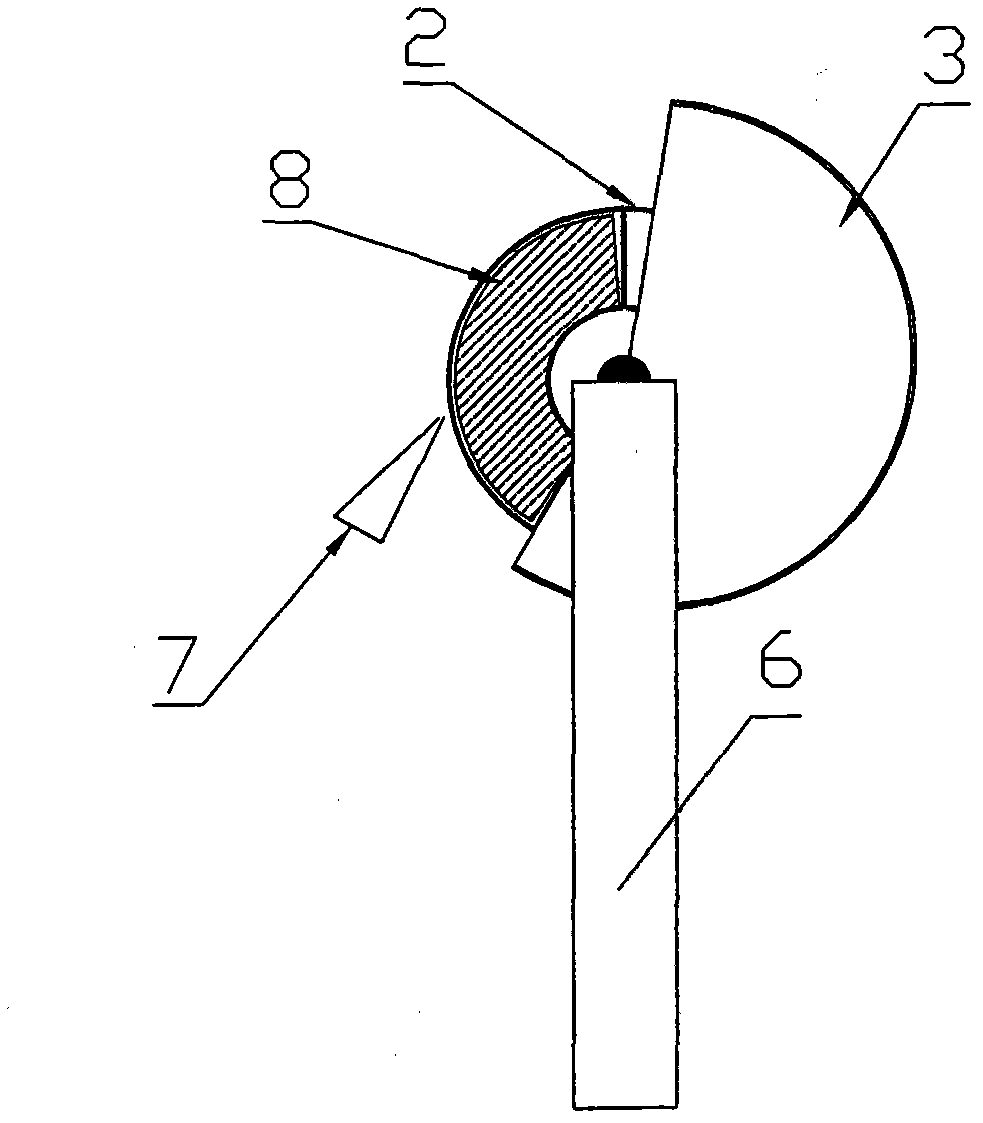

Method for separating bark from stalk and bark and stem separator

The invention discloses a method for separating bark from a stalk and a bark and stalk separator, mainly relates to a method and equipment for separating barks from stalks of crushed cotton stalk, mulberry trees, broussonetia papyrifera and other raw material for pulping and belongs to the technical field of standby materials in the pulping industry. In the invention, the bark and stalk separating equipment is used for separating and is provided with a rotary drum which can rotate and is provided with sieve holes on the surface; and the crushed materials are fed into the bark and stalk separating equipment, the crushed stalk materials are sucked into a cavity of the rotary drum and discharged by using vacuum sucking force and longer bark fibers are attached to the surface of the rotary drum and detached along with the rotation of the rotary drum. The invention has favorable separation effect and high separation efficiency when being used for separating bark from stalk and can be widely applied to the stand raw material in the pulping industry.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

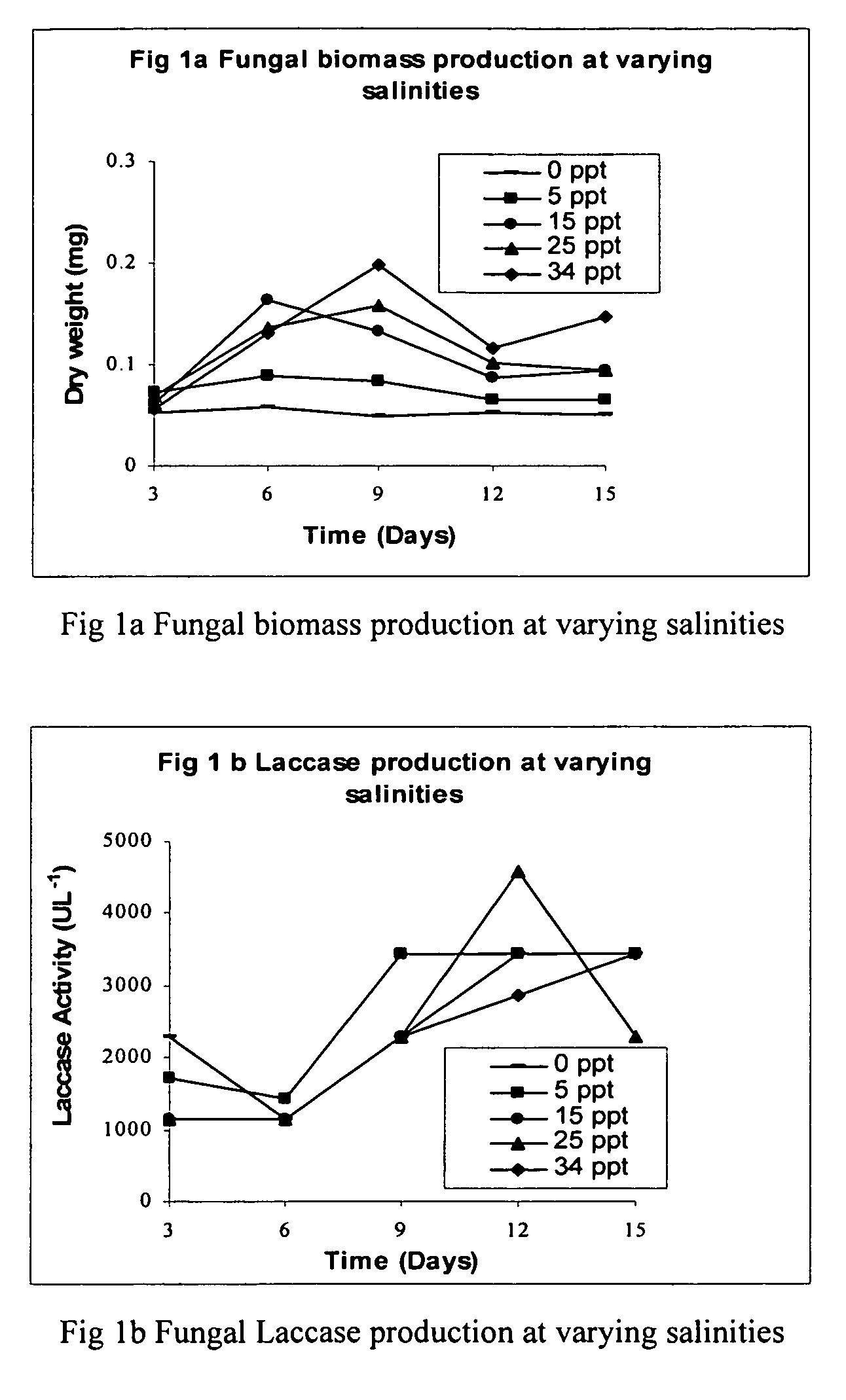

Processes for decolorization of colored effluents

InactiveUS8017374B2Efficient use ofGood curative effectMicroorganismsWater contaminantsMangroveCell free

Owner:COUNCIL OF SCI & IND RES

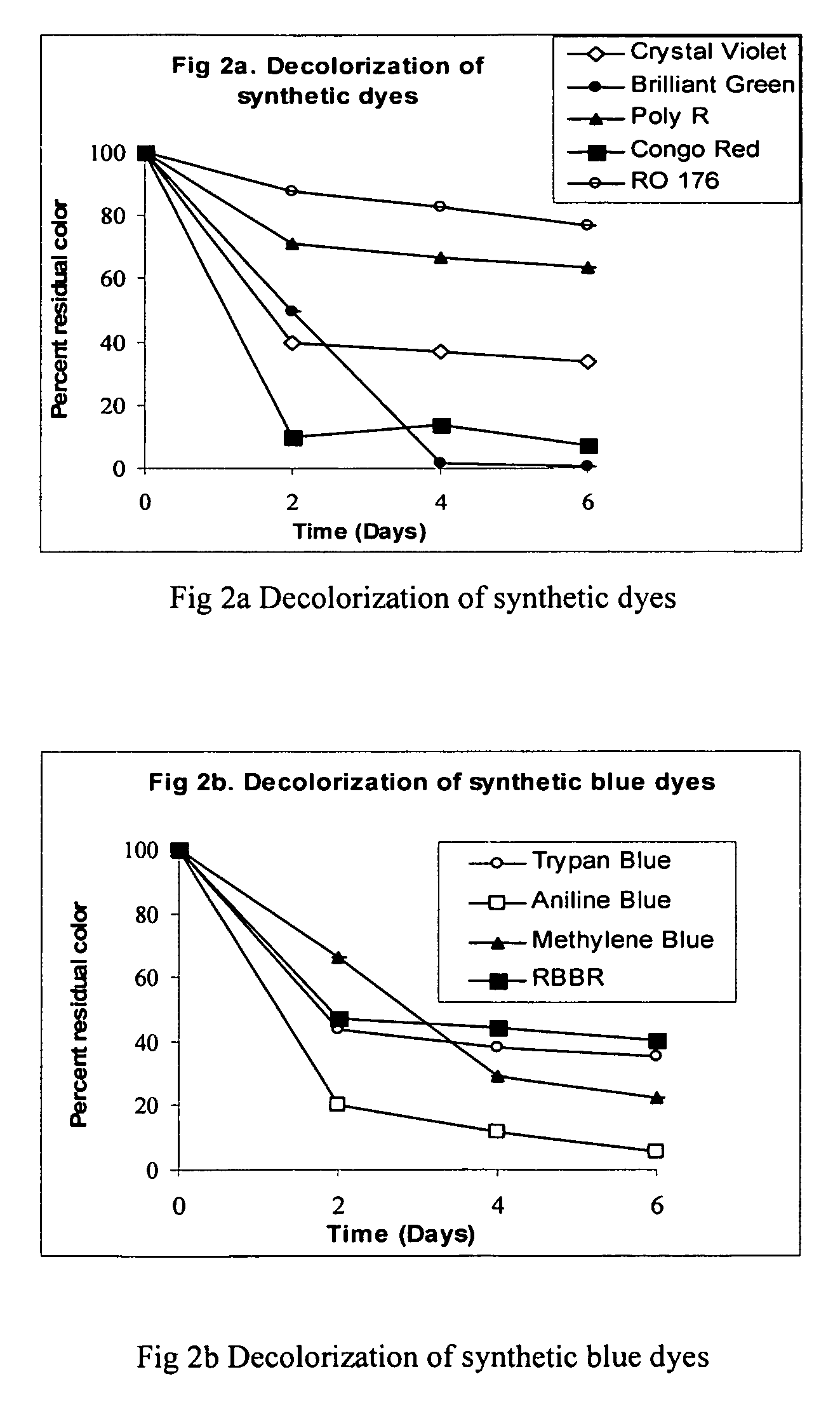

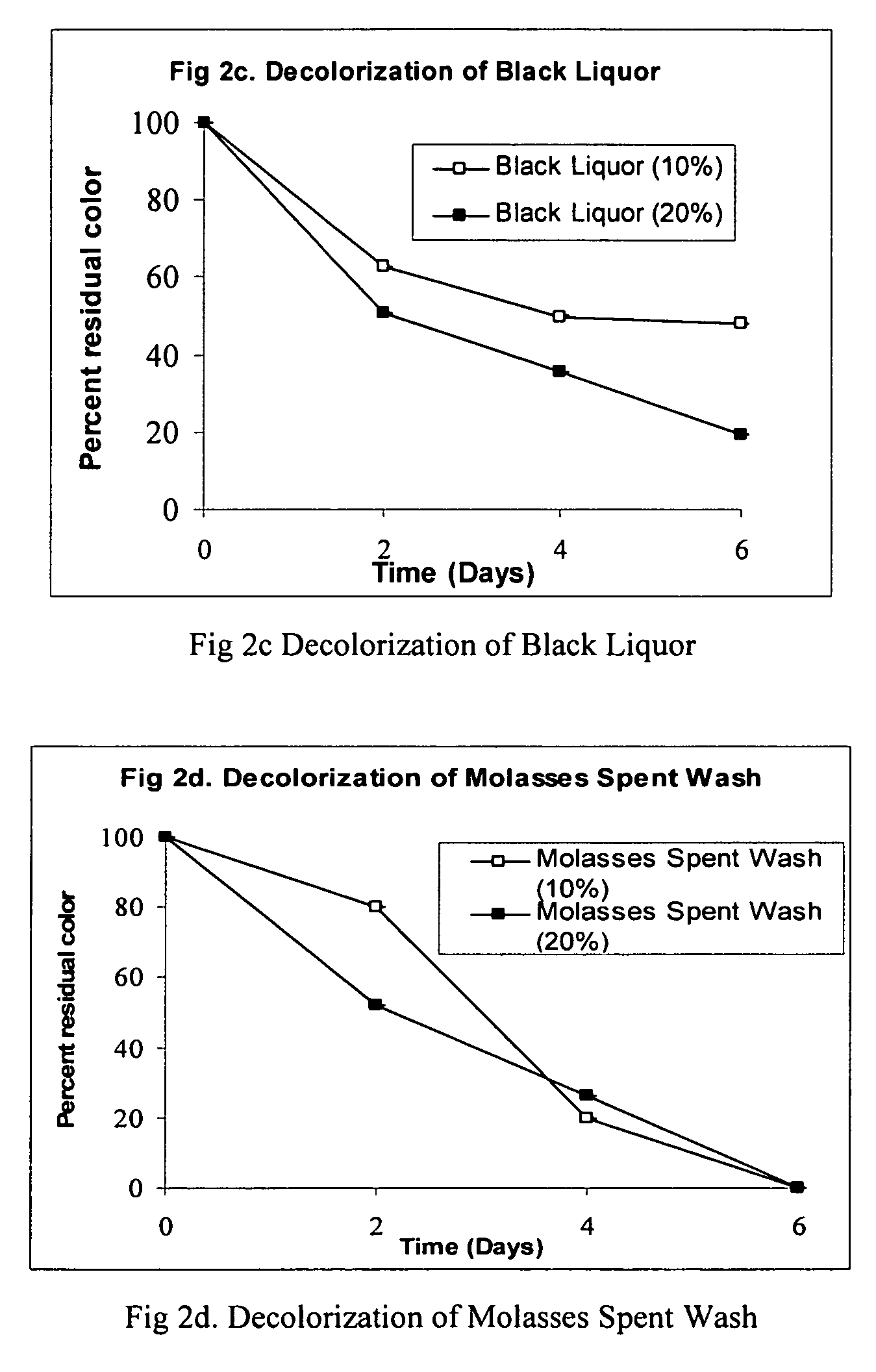

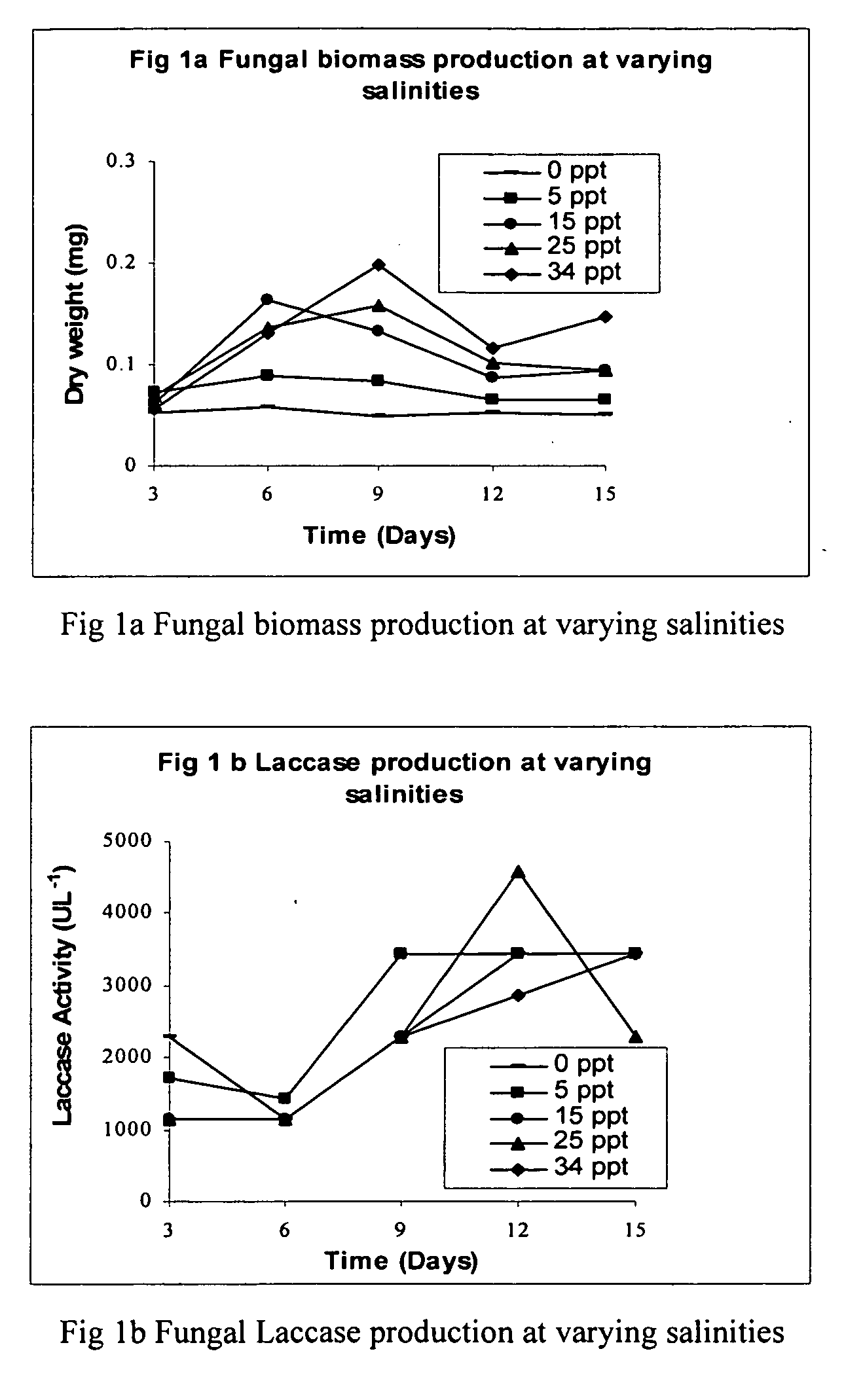

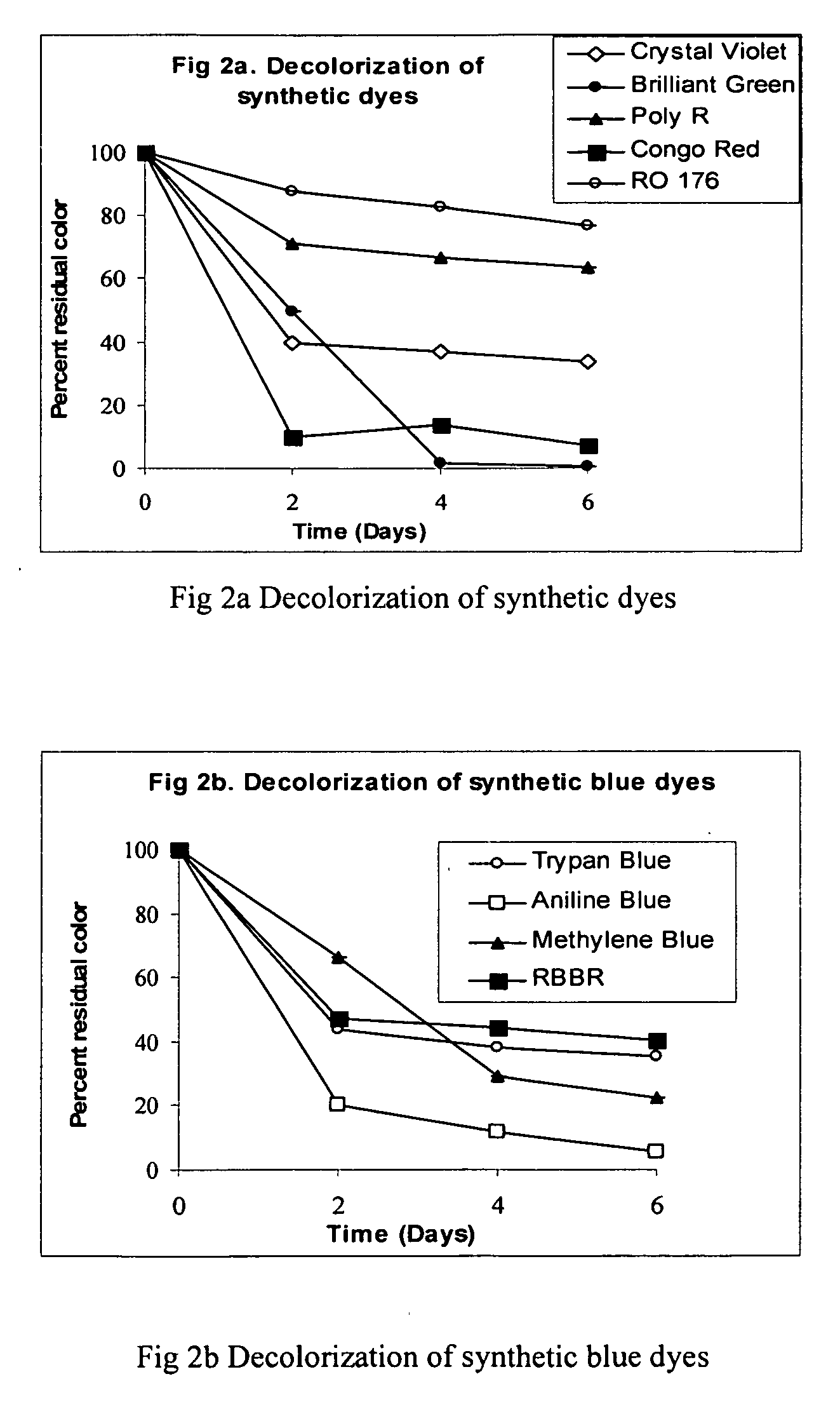

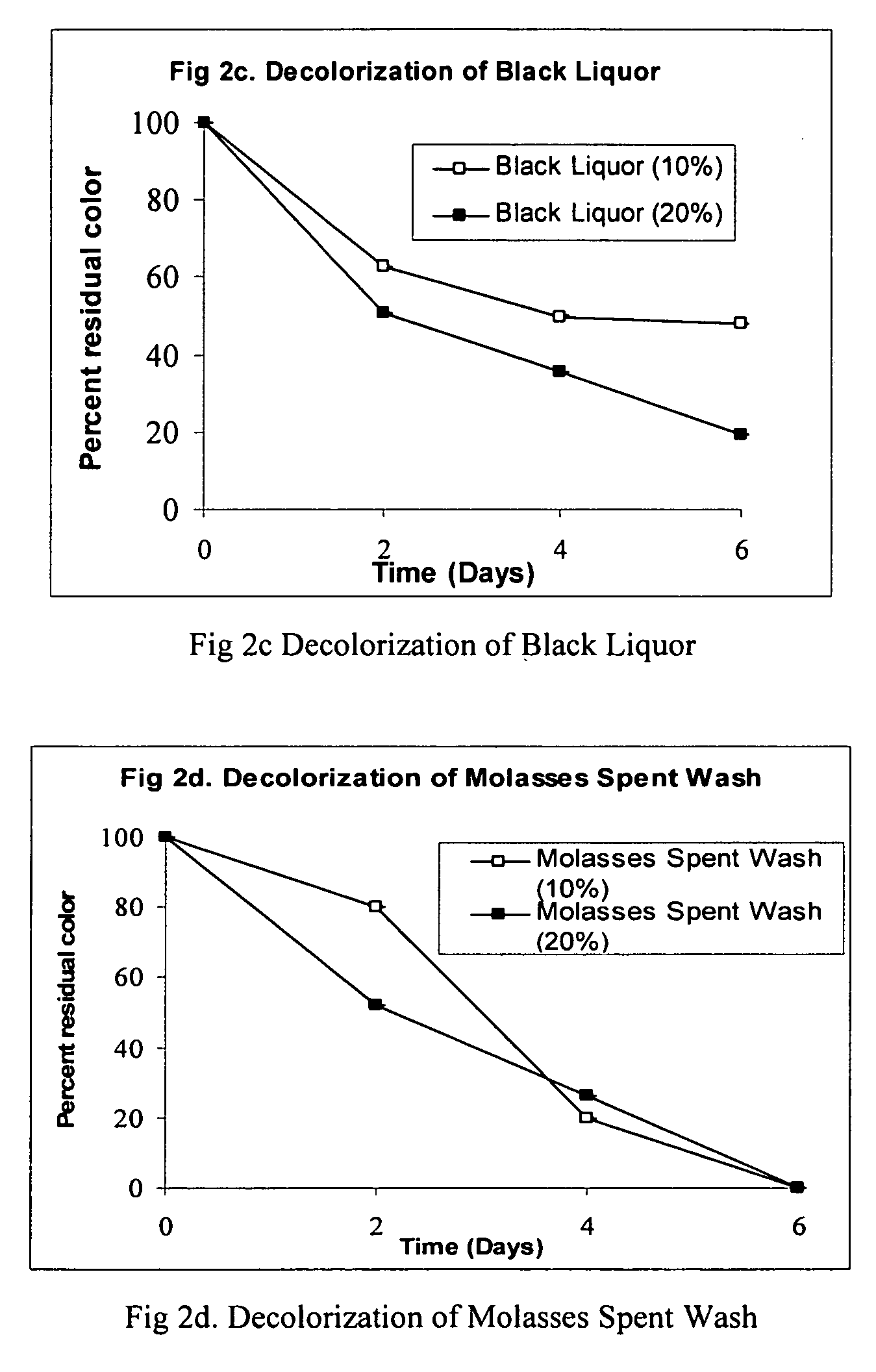

Novel Processes for Decolorization of Colored Effluents

InactiveUS20080057567A1Efficient use ofDrawback can be obviatedFungiWater contaminantsCell freeCulture fluid

The present invention relates to a novel process for decolorization of colored effluents. More particularly it relates to a process for decolorization of colored effluents of textile mills, dye-making industries, paper and pulp industries and molasses spent wash from alcohol distilleries using an unidentified marine fungus NIOCC #2a isolated from mangrove wood and deposited in the microbial type culture collection (MTCC) of the Institute of Microbial Technology, Chandigarh, India, under the accession number MTCC 5159. Further, this invention relates to decolorization of these effluents using the fungus directly, its cell-free culture supernatant or immobilized fungus or extracellular polymeric substances produced by the fungus. Furthermore, the decolorization of effluents can be carried out from 30° C. to 60° C. and at pH 3 to 6. The decolorization of various colored effluents occurs in the presence of sea water with 25 parts per thousand salinity. Besides, several synthetic dyes are also decolorized under similar conditions of temperature and pH by using free mycelia or immobilized fungus or extracellular culture fluids or extracellular polymeric substances.

Owner:COUNCIL OF SCI & IND RES

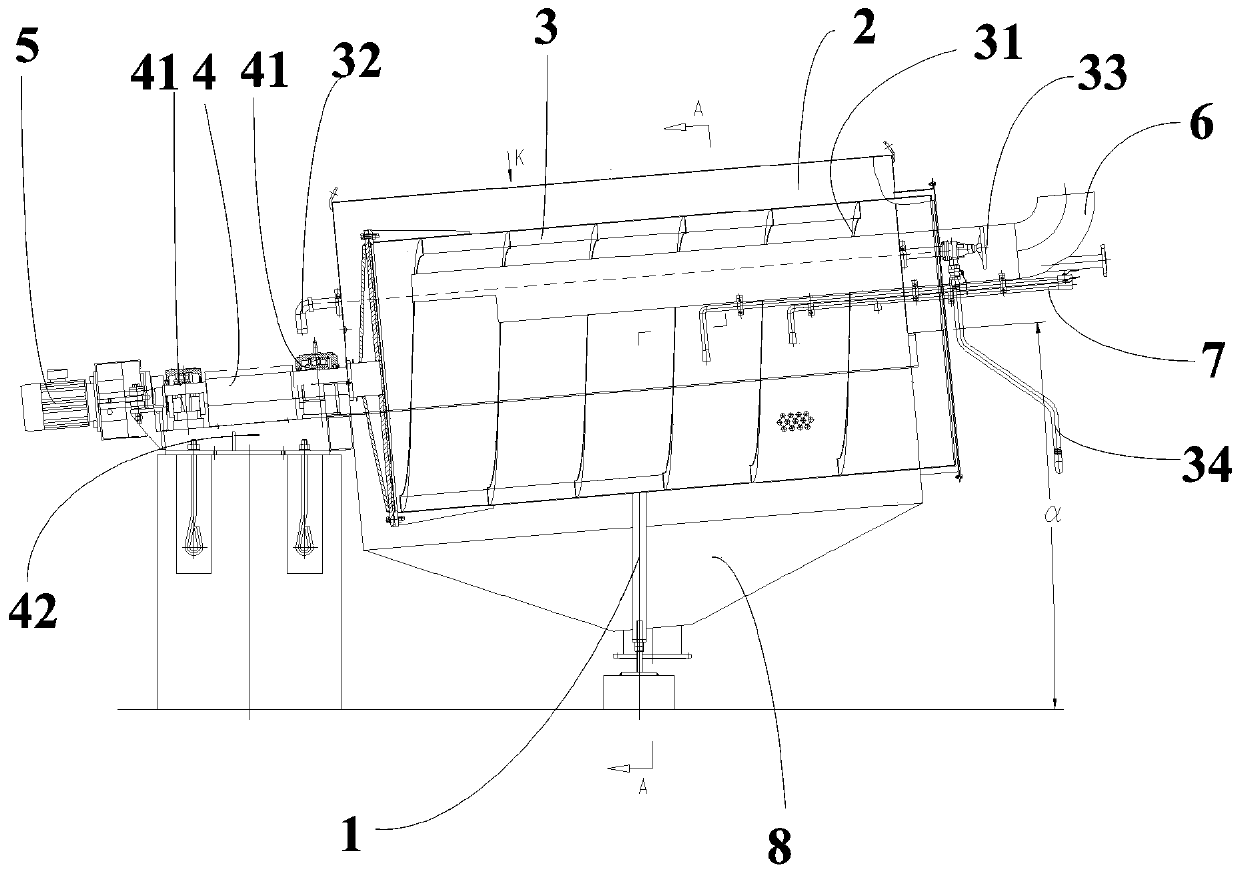

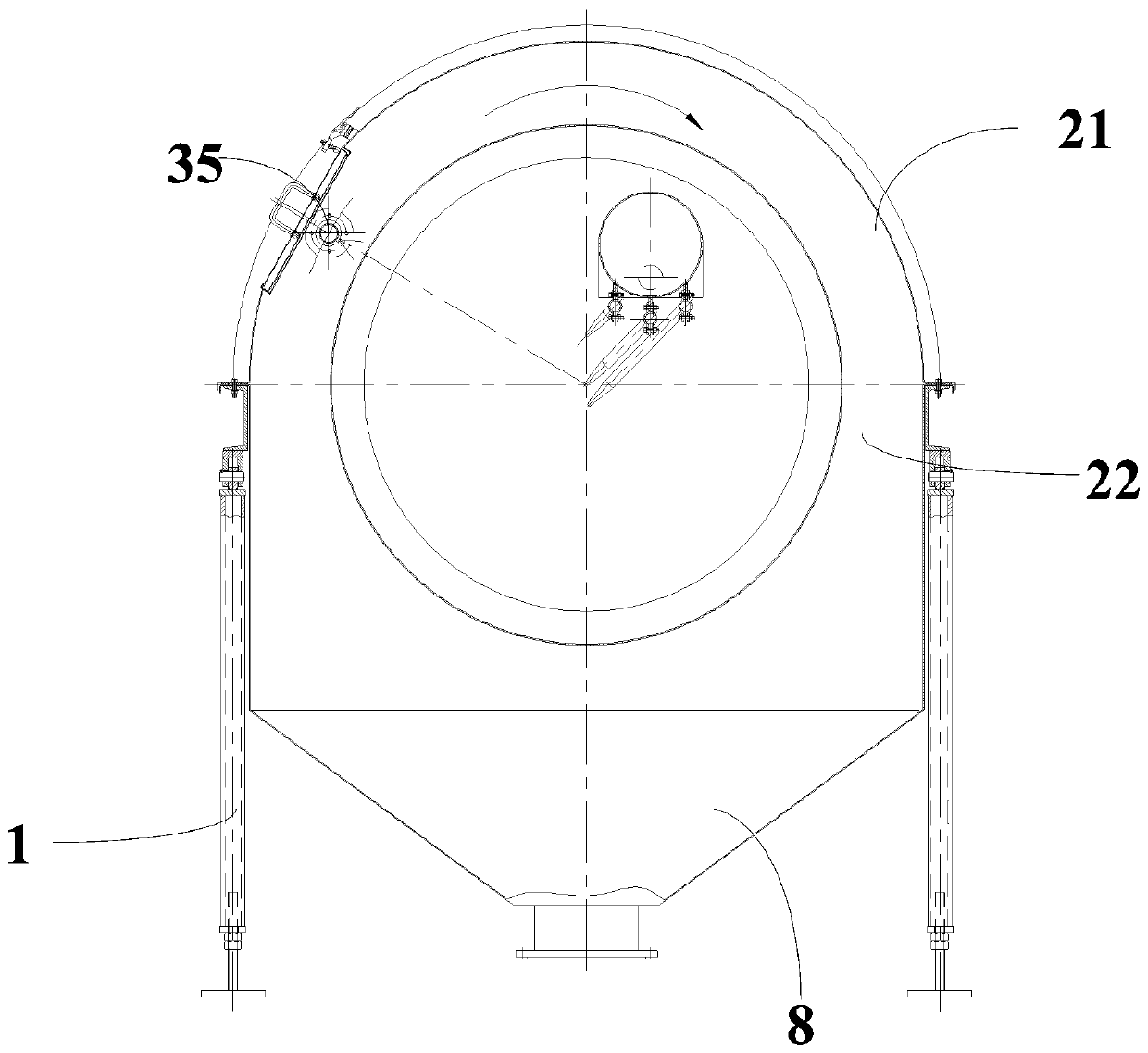

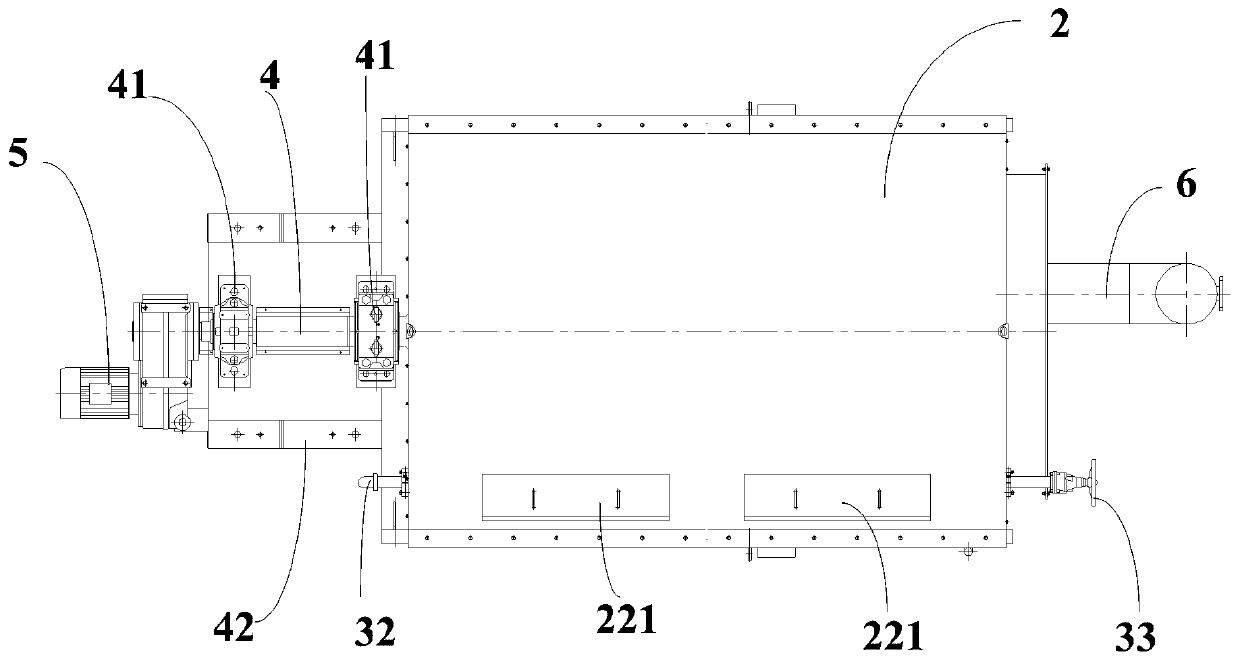

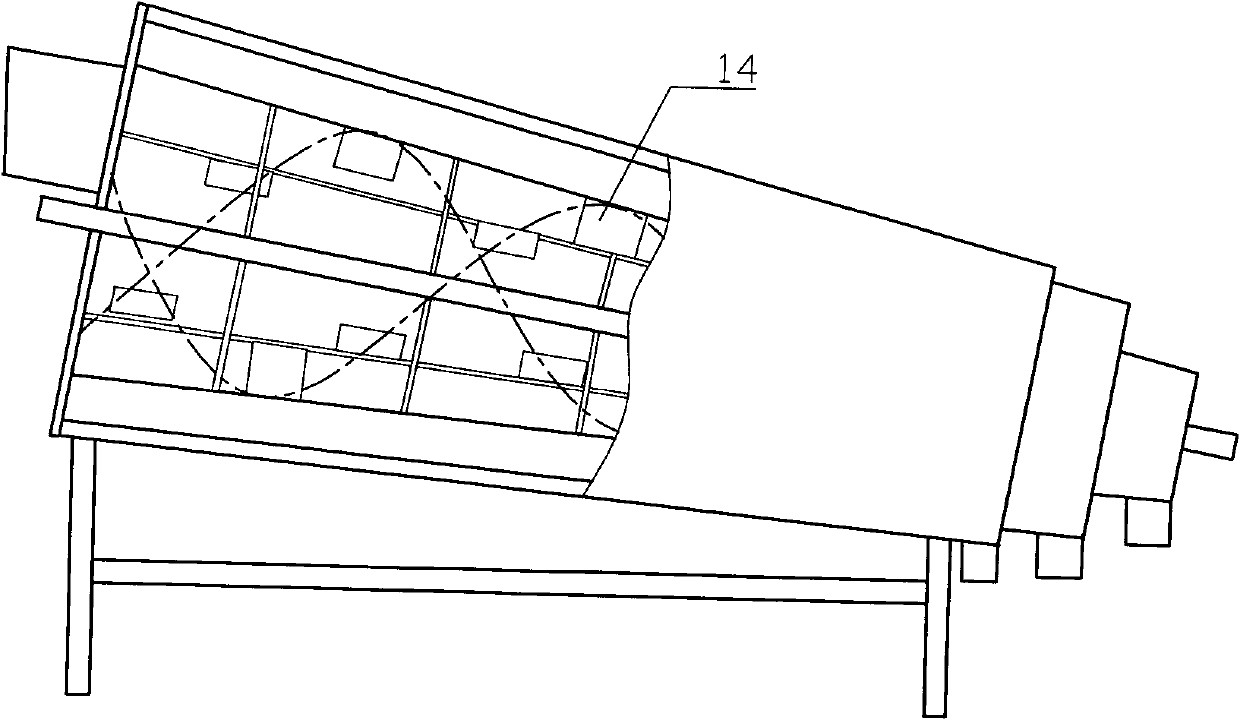

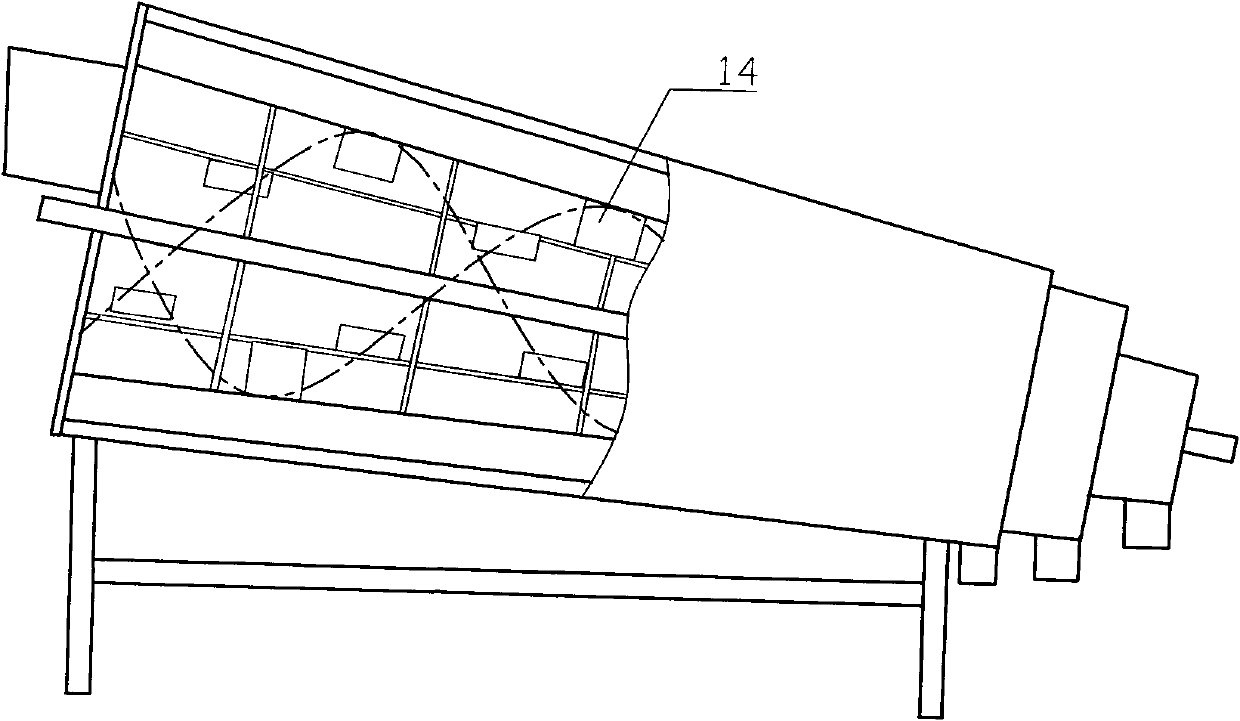

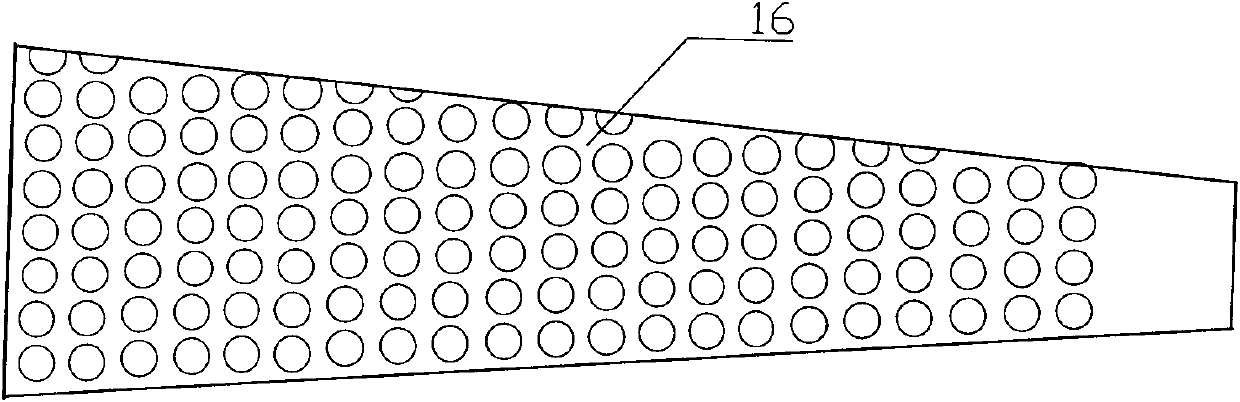

Inclined cylinder screening machine for pulping industry

PendingCN110387763AIncrease collection rateReduce manufacturing costPaper material treatmentFiberSpiral blade

The invention relates to an inclined cylinder screening machine for pulping industry. The inclined cylinder screening machine comprises a shell, a screen drum, a main shaft and a motor transmission set; the shell is of a cylindrical structure with an opening at one end; the axis is in an alpha angle with the horizontal plane; supporting legs support the bottom of the shell; the screen drum is of acylindrical screen drum structure, wherein the inner cavity of the screen drum is provided with a spiral blade, the screen drum is installed in the cylindrical structure through the opening end of the shell, and the axis of the screen drum coincides with the axis of the shell; one end of the main shaft is inserted into one side, far away from the opening end, of the shell and is fixed with one end of the screen drum through a flange; the other end of the main shaft is in power connection with the output end of the motor transmission set; the other end of the screen drum is a slag dischargingend, and a slurry inlet pipe and a dilution pipe are inserted into the inner cavity of the screen drum for feeding and diluting slurry through the slag discharging end; and the bottom of the shell communicates with a slurry outlet chamber, wherein the separated slurry flows out of the slurry outlet chamber. The manufacturing cost is reduced, the working noise is low, and the maintenance amount isreduced. The screen drum is in an alpha angle with the horizontal plane, namely, the screen drum is inclined to the horizontal plane by a certain angle, so that the collection rate of recyclable fibers can be improved.

Owner:SHANDONG CHENZHONG MACHINERY

Method for preparing corrugated paper pulp through sulfur trioxide micro-thermal explosion treatment of straw

PendingCN111778752AMild responseReduce consumptionPulp beating/refining methodsNon-woody plant/crop pulpPulp industryPapermaking

The invention discloses a method for preparing corrugated paper pulp through sulfur trioxide micro-thermal explosion treatment of straw, and relates to the field of wood biomass utilization. The method comprises the following steps: introducing sulfur trioxide gas into straws at normal temperature and normal pressure to carry out micro-thermal explosion reaction, leaching and neutralizing the acidic straws subjected to micro-thermal explosion treatment by using a dilute alkali liquor to obtain a neutral hemicellulose aqueous solution and a lignocellulose solid, adding water into an obtained filter-pressed and washed solid, and pulping to obtain corrugated paper pulp. The corrugated paper pulp preparation method provided by the invention has the advantages of resource saving, no emission of three wastes, energy conservation and environmental protection, and solves the problems of large investment, low efficiency, high energy consumption and large pollution in the traditional papermaking and pulping industry.

Owner:王剑

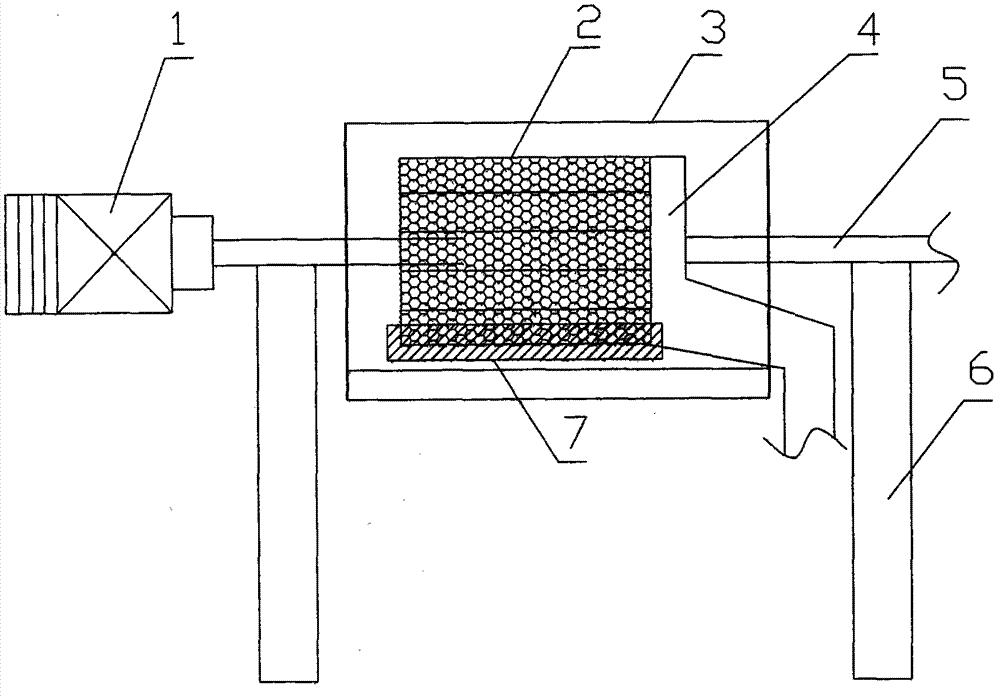

Classified dust collecting device of tablets

InactiveCN101949102AAchieve dust removalAchieve classificationFibrous raw materialsMaterials preparationPulp industry

The invention relates to material screening equipment in pulping industry, in particular relating to a classified dust collecting device of grass tablets. The device comprises a spindle and roller brackets, one end of the spindle is connected with a motor via a transmission mechanism, the spindle is encircled by at least two layers of roller brackets along the circumferential direction, the roller brackets at each layer are wrapped with sieve plates, the aperture of the sieve pore of each sieve plate is radially tapered along the roller bracket from inside to outside, the hollow structures at the middle of the sieve plate at the innermost layer and between each two sieve plates serve as material channels, and the tail end of the each material channel is provided with a material outlet. The invention can realize dust collection and classification of tablets at the same time, saves power consumption, improves classification effect, achieves optimal combination of material preparation efficiency and material preparation yield, and is suitable for classified screening of grass tablets in the pulping industry.

Owner:SHANDONG HAIYUN ECOLOGICAL PAPER +1

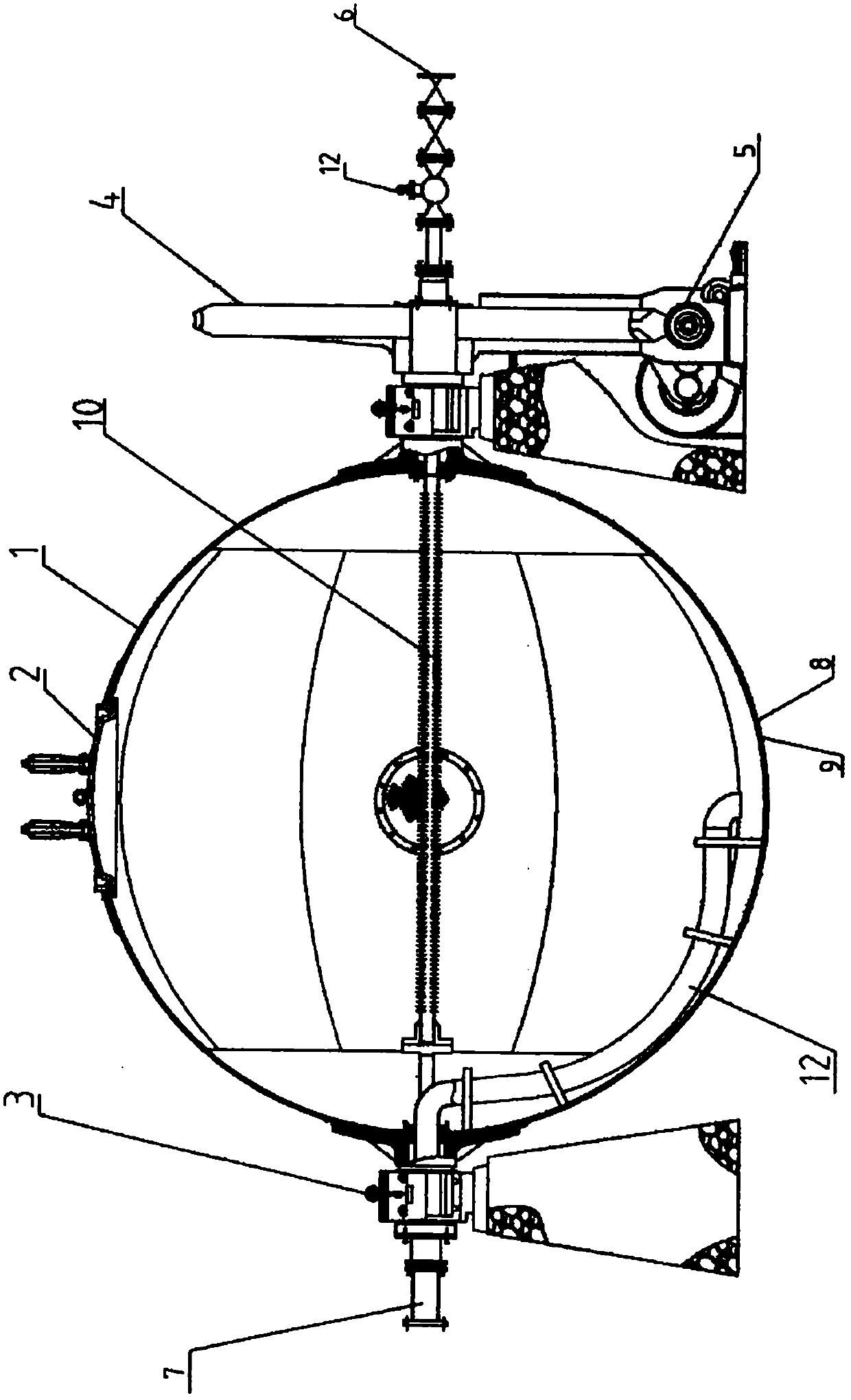

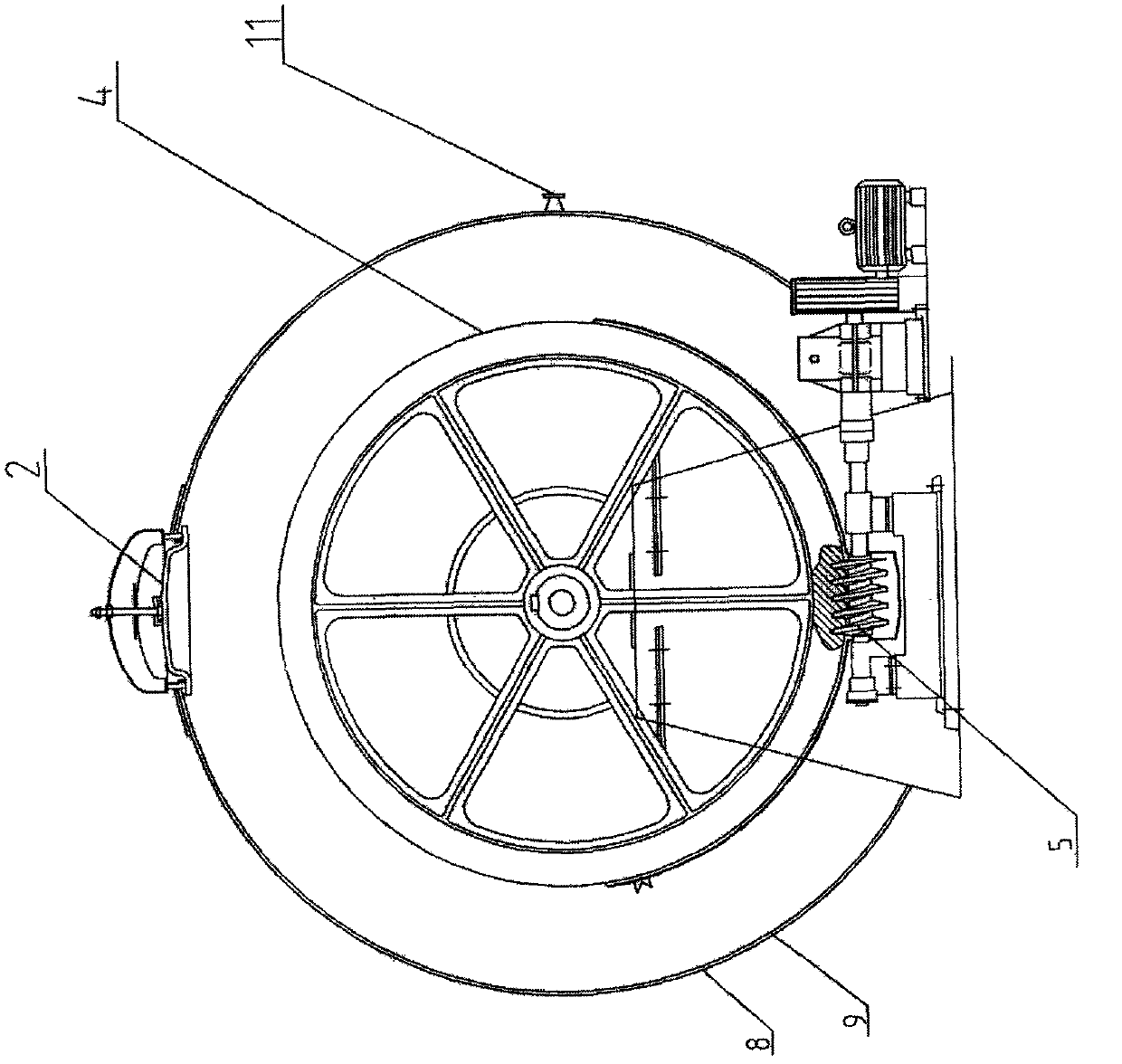

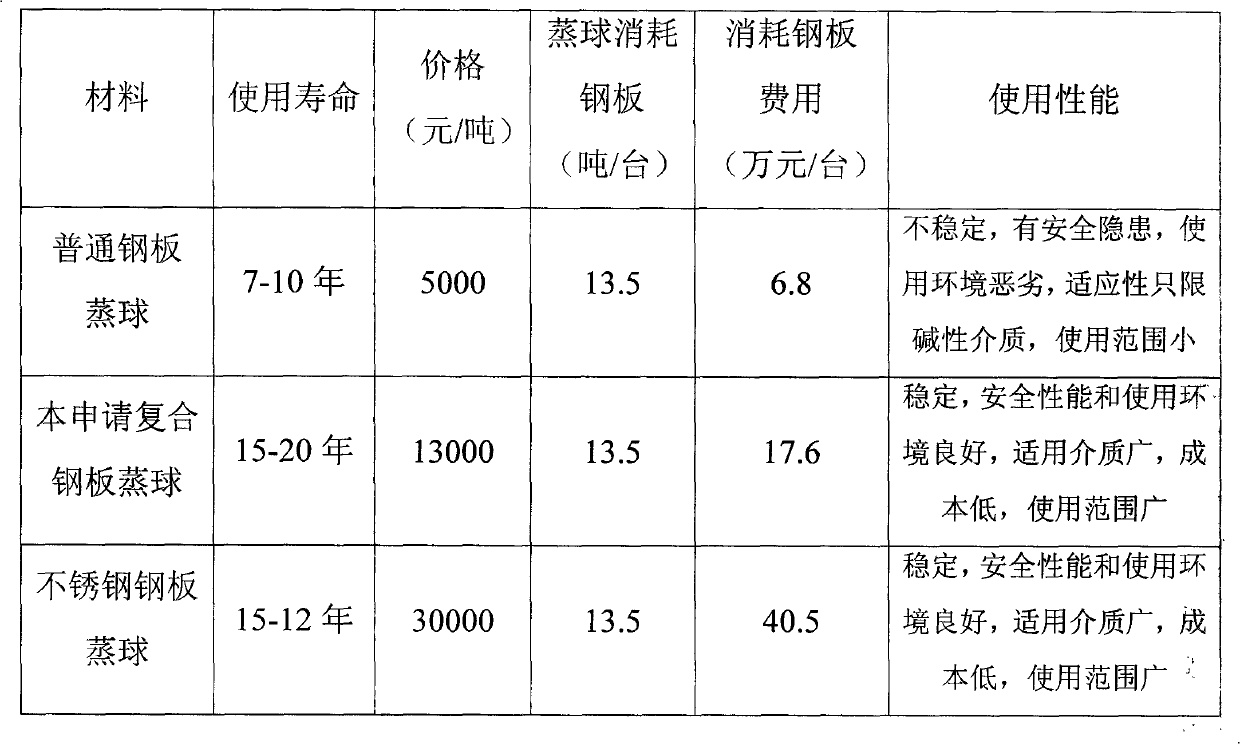

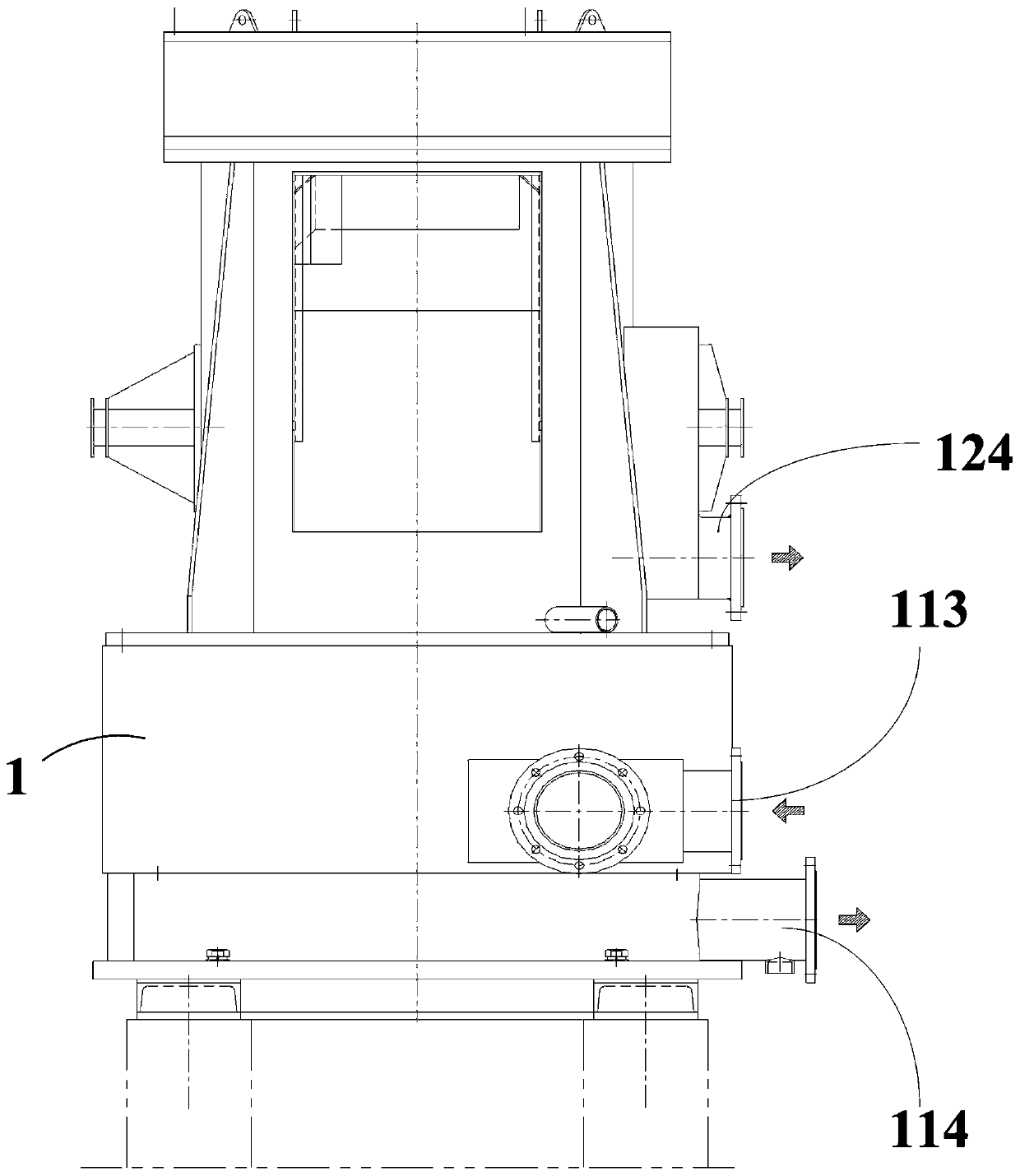

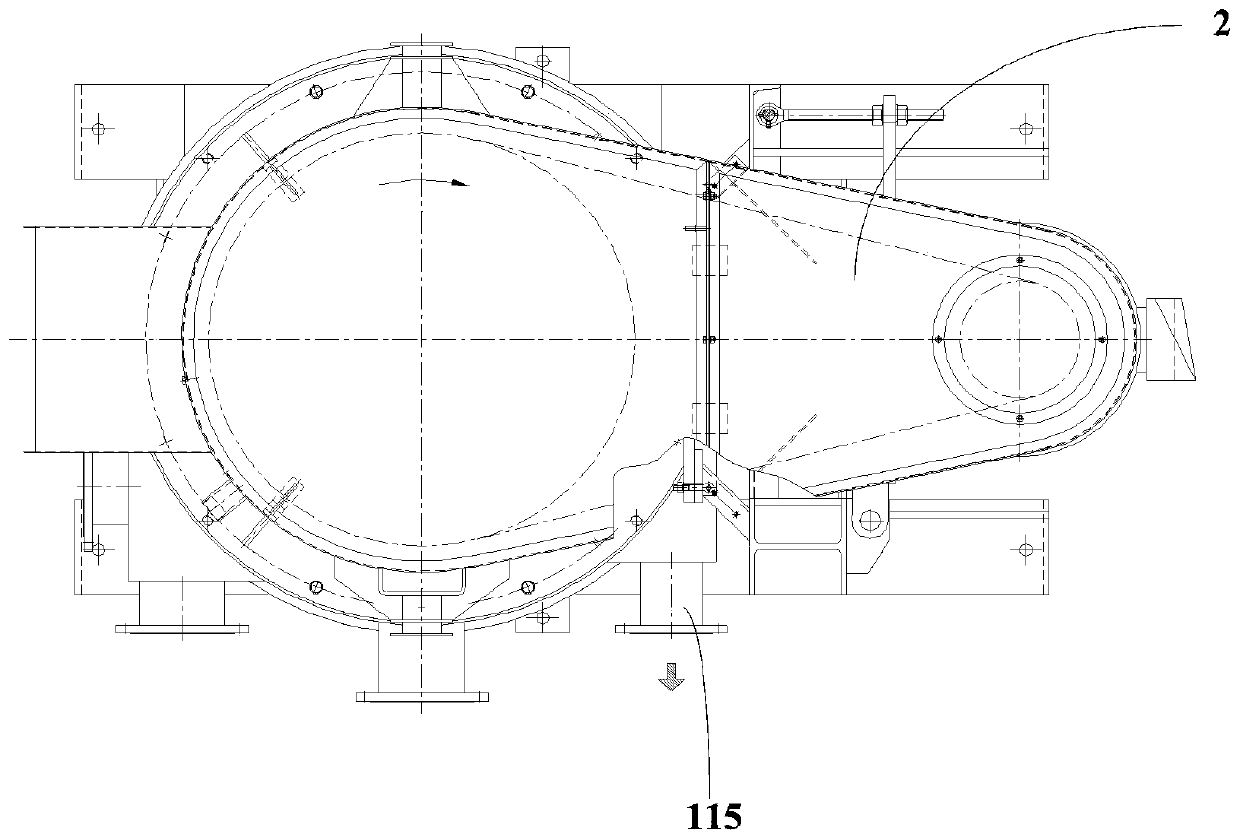

Composite stainless steel spherical digester

InactiveCN103374847ACorrosion resistanceWith wear resistanceDigestersPaper material treatmentFiberPulp industry

The invention discloses a composite stainless steel spherical digester which comprises a bracket, a spherical digester body, a transmission part, an air inlet, an air outlet, an air inlet pipe and a blowing pipe, wherein the spherical shell body is formed by compounding an outer carbon steel layer and an inner stainless steel layer. The stainless steel spherical digester is simple in structure, and the inner layer of the spherical shell is a stainless steel layer and has the advantages of high corrosion and wear resistance, so that the cost is reduced. According to the composite structure, the potential safety hazard of the spherical digester is eliminated, the service environment and the application range of the spherical digester are greatly improved, and the service life is prolonged. Compared with a carbon steel spherical digester, the composite stainless steel spherical digester has high corrosion resistance, a wide application range and an excellent performance; compared with a pure stainless steel spherical digester, the composite stainless steel spherical digester has the advantages that the cost is reduced by 50 percent, and the service effect and the service life are equal, so that the market application range is increasingly widened, the application prospect is wide, and the application is extended from the traditional papermaking and pulping industry to multiple fields of pharmacy, chemical fiber, biochemical engineering, environment friendliness and sanitary food.

Owner:QINYANG JUNENG PRESSURE VESSEL

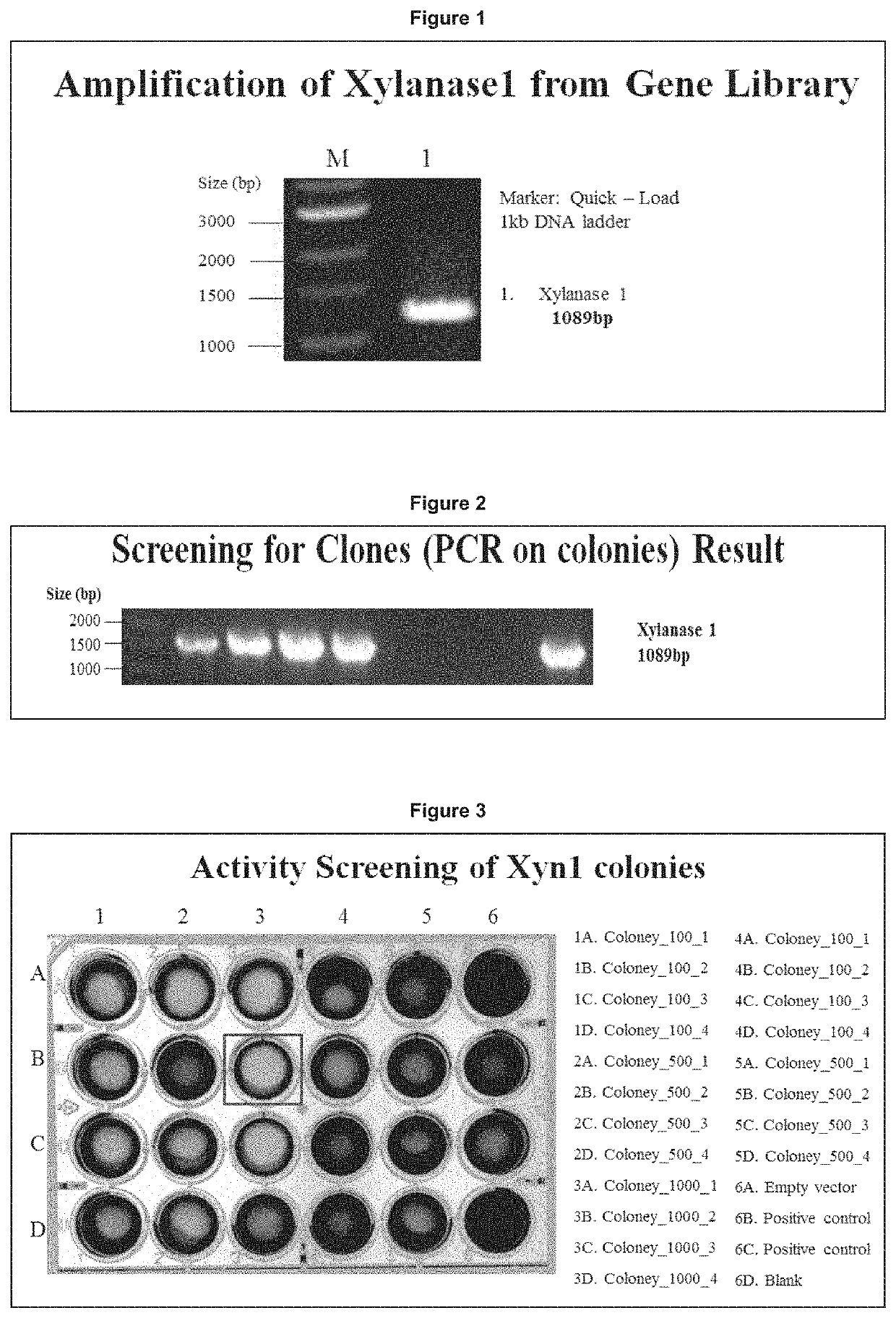

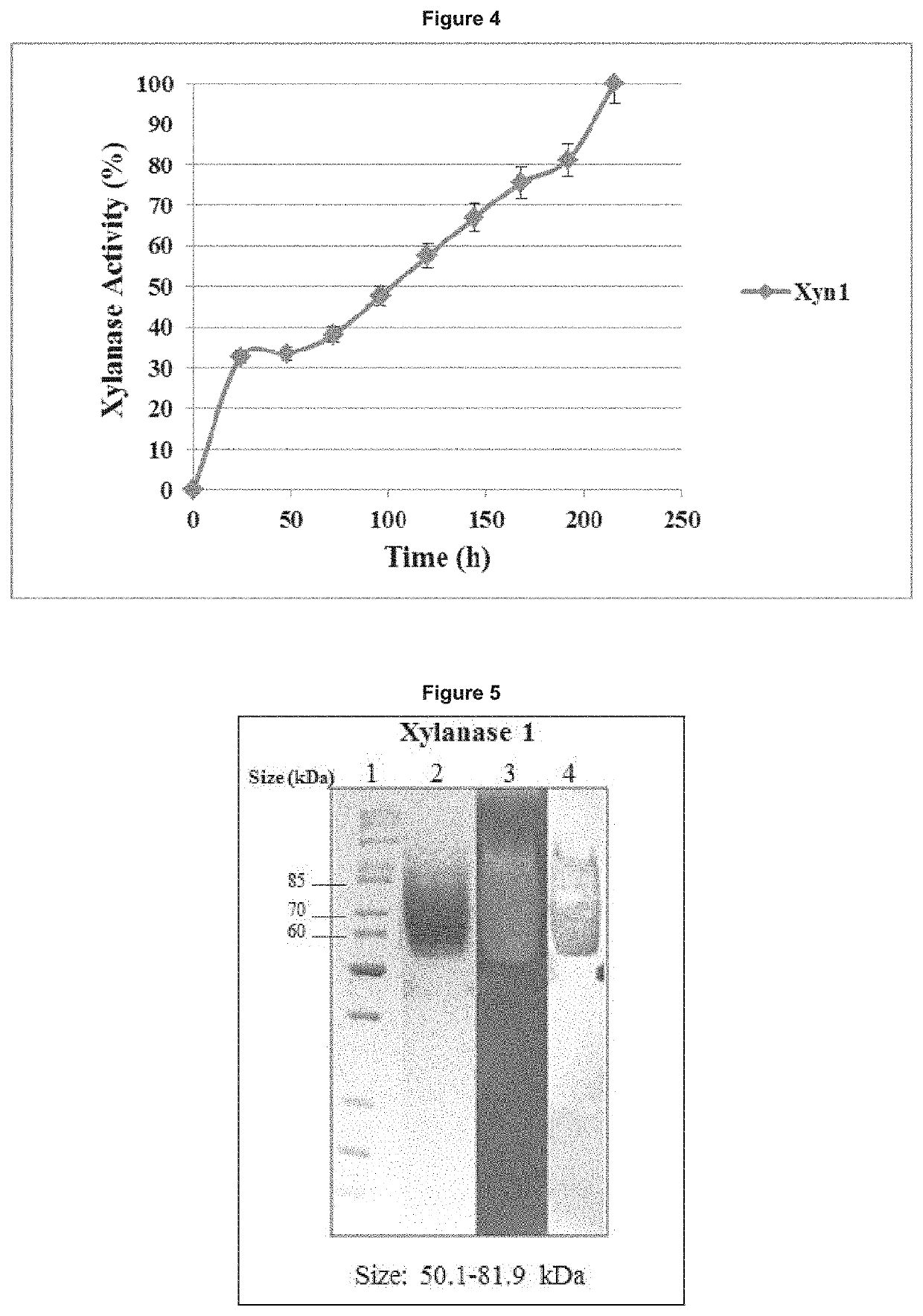

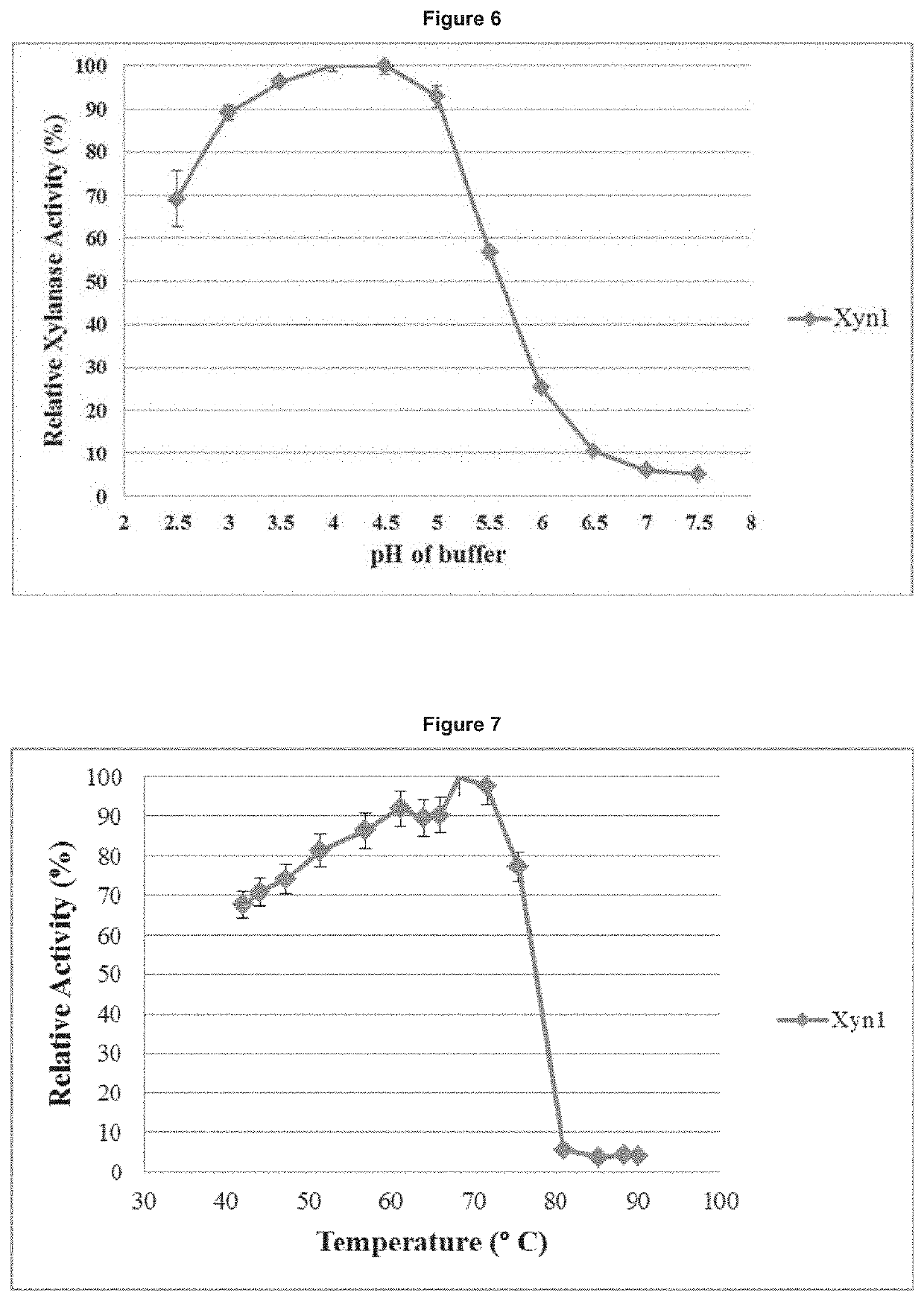

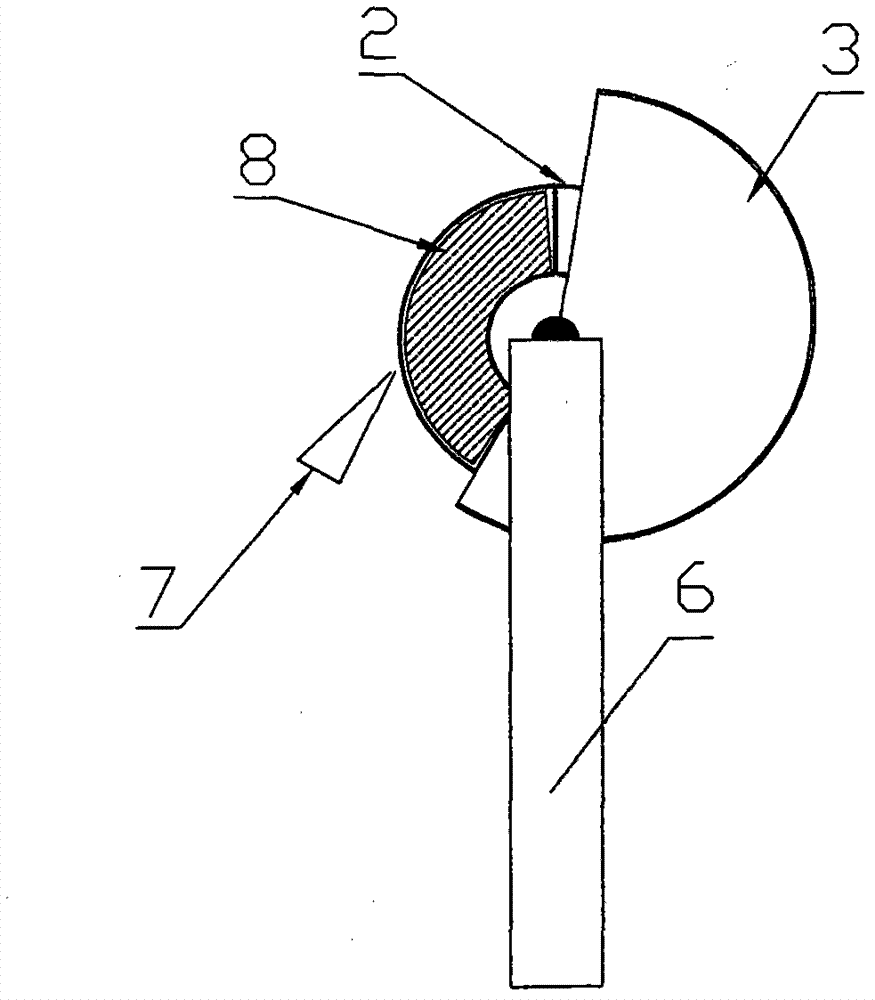

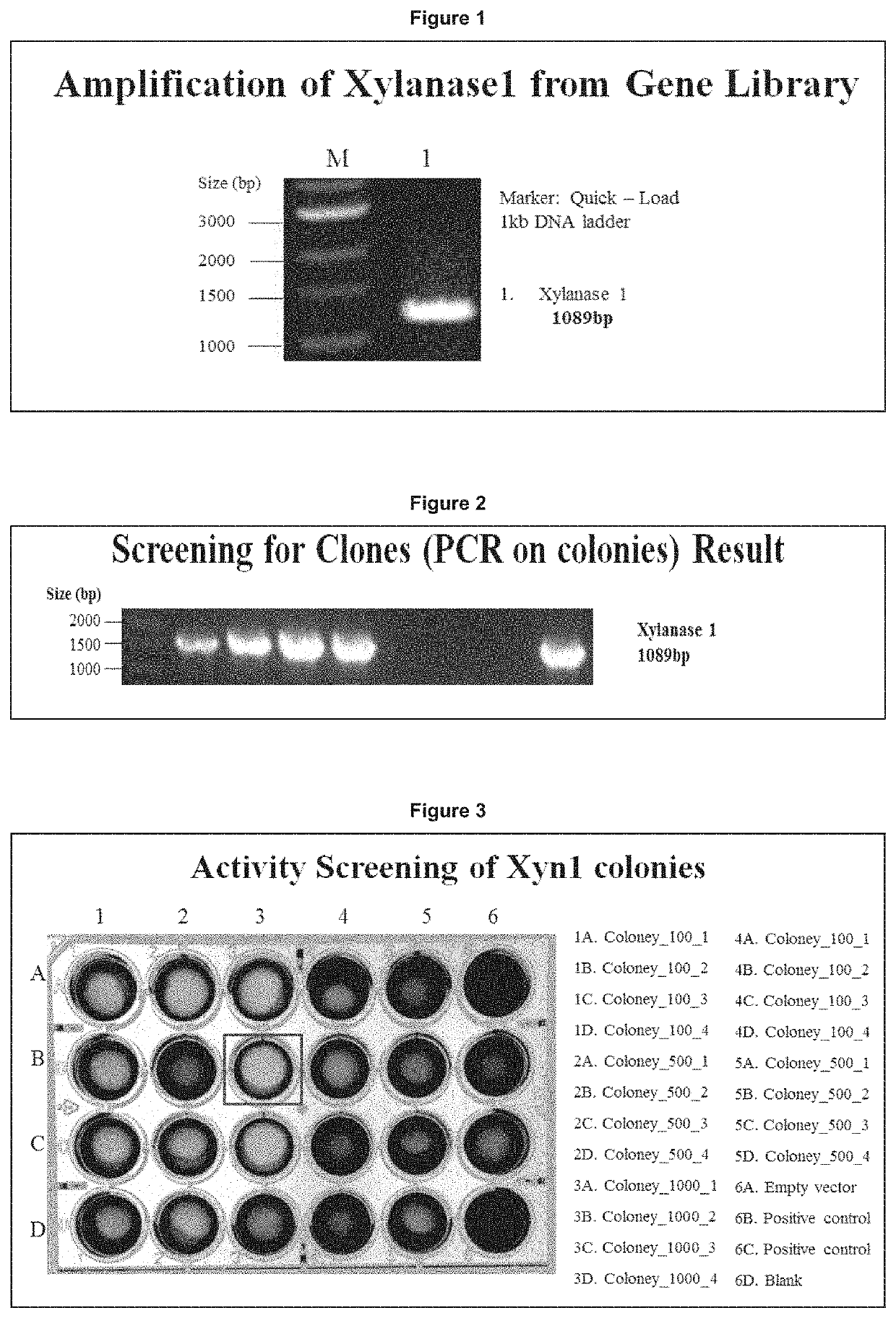

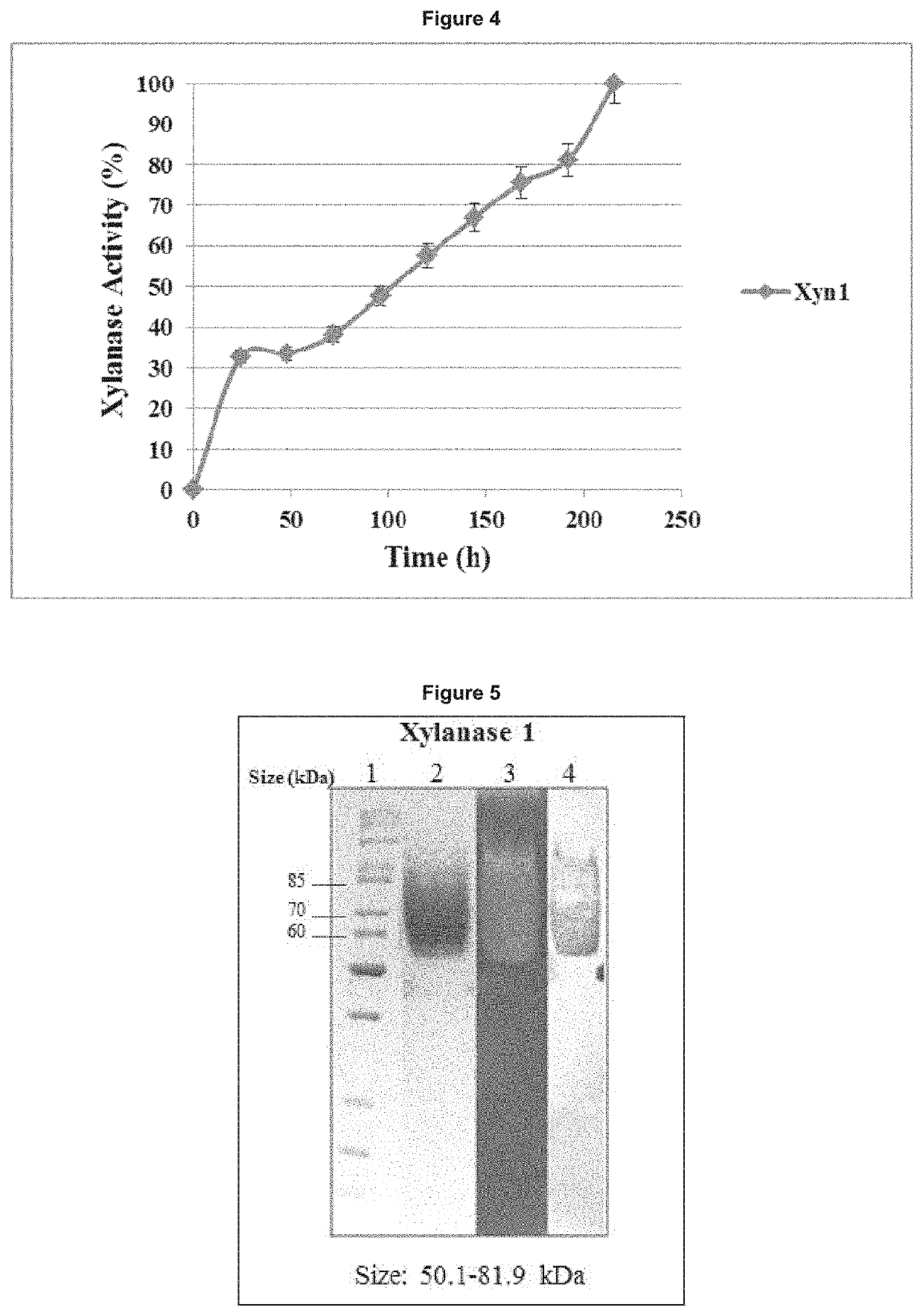

A polypeptide having xylanase activity

The present invention relates to an isolated polypeptide having xylanase activity. Also disclosed are isolated polynucleotides encoding the polypeptide, recombinant host cells expressing the polypeptide, and methods for degrading lignocellulosic biomass using the polypeptide. He invention finds utility in the production of biofuels, in the paper and pulp industry, in clothing or leather softening, in the food industry such as baking, etc.

Owner:MONAGHAN MUSHROOMS IRELAND +1

Water treating method in pulping industry

The water treating method in pulping process features the multiple washing, extruding and filtering of pulp, and the produced filtrate is returned completely to washing and digesting pulp liquid. By combining with chemical deposition method, all the organic pollutants are converted into the precipitant, so that the water pollution during pulping process is eliminated thoroughly.

Owner:梁植林

Method for separating bark from stalk and bark and stem separator

Owner:CHAMBROAD CHEM IND RES INST CO LTD

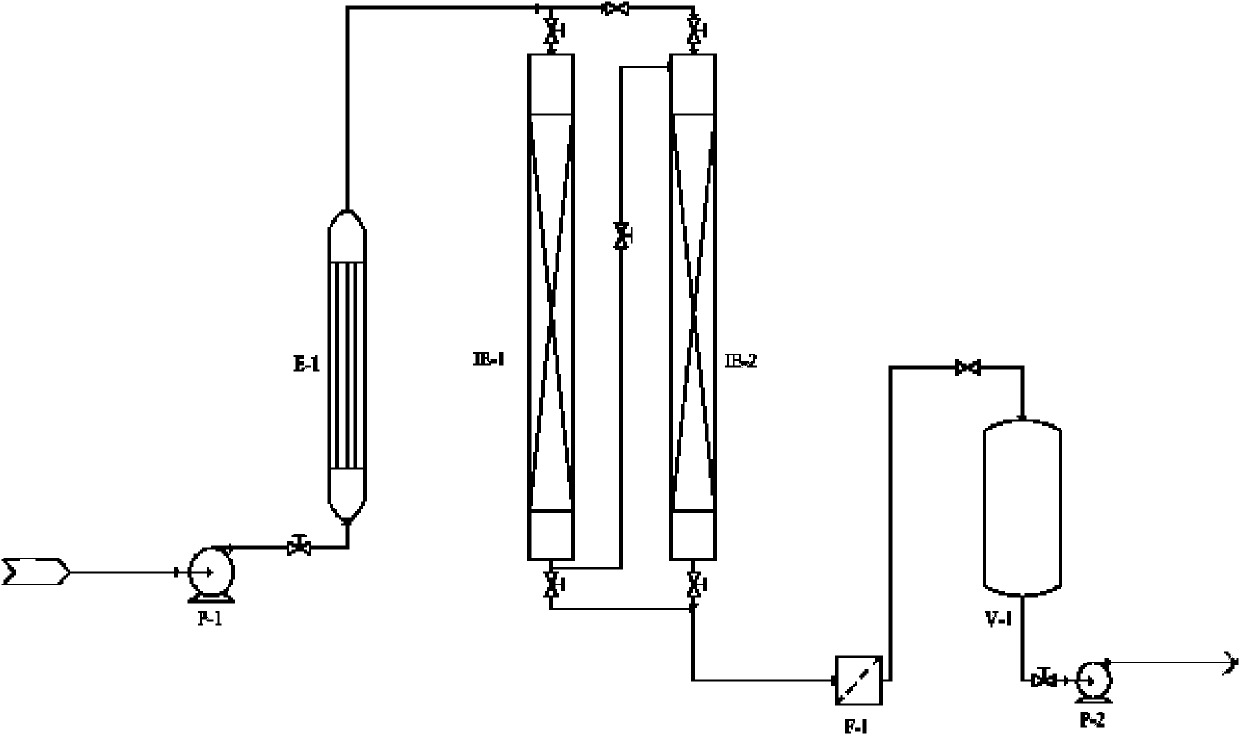

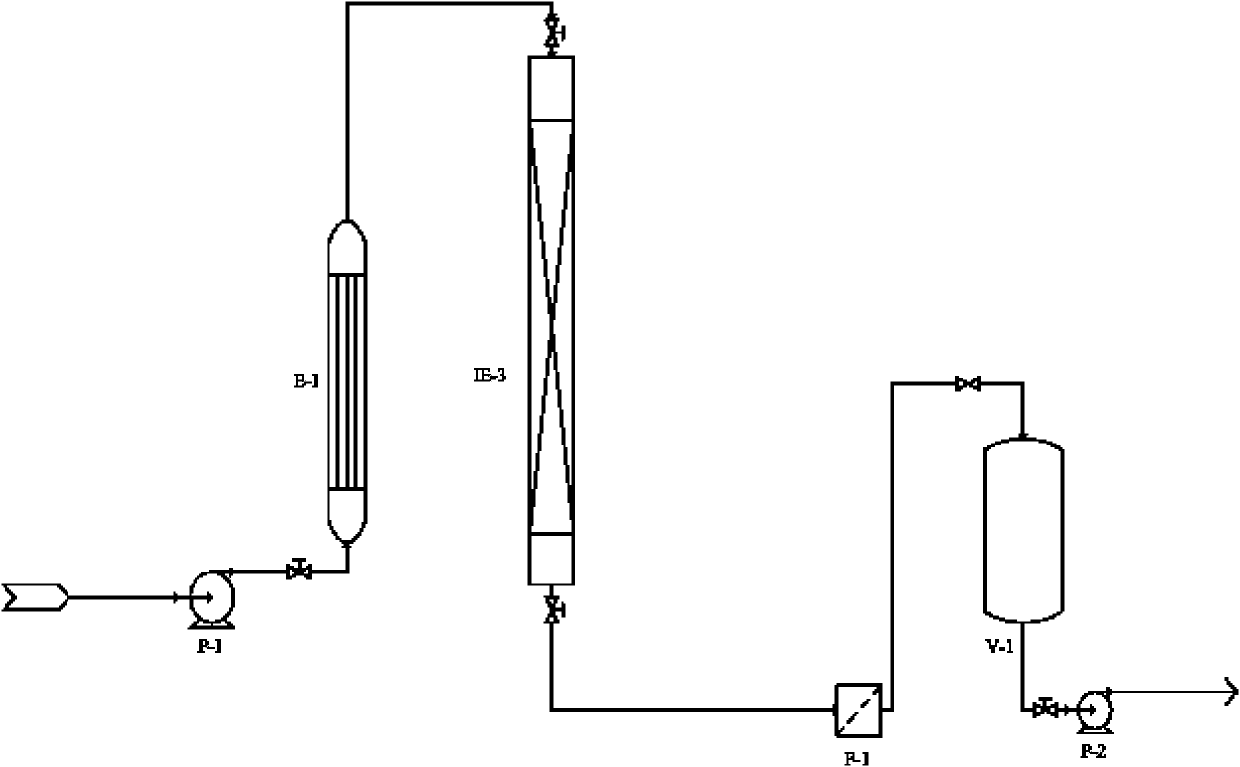

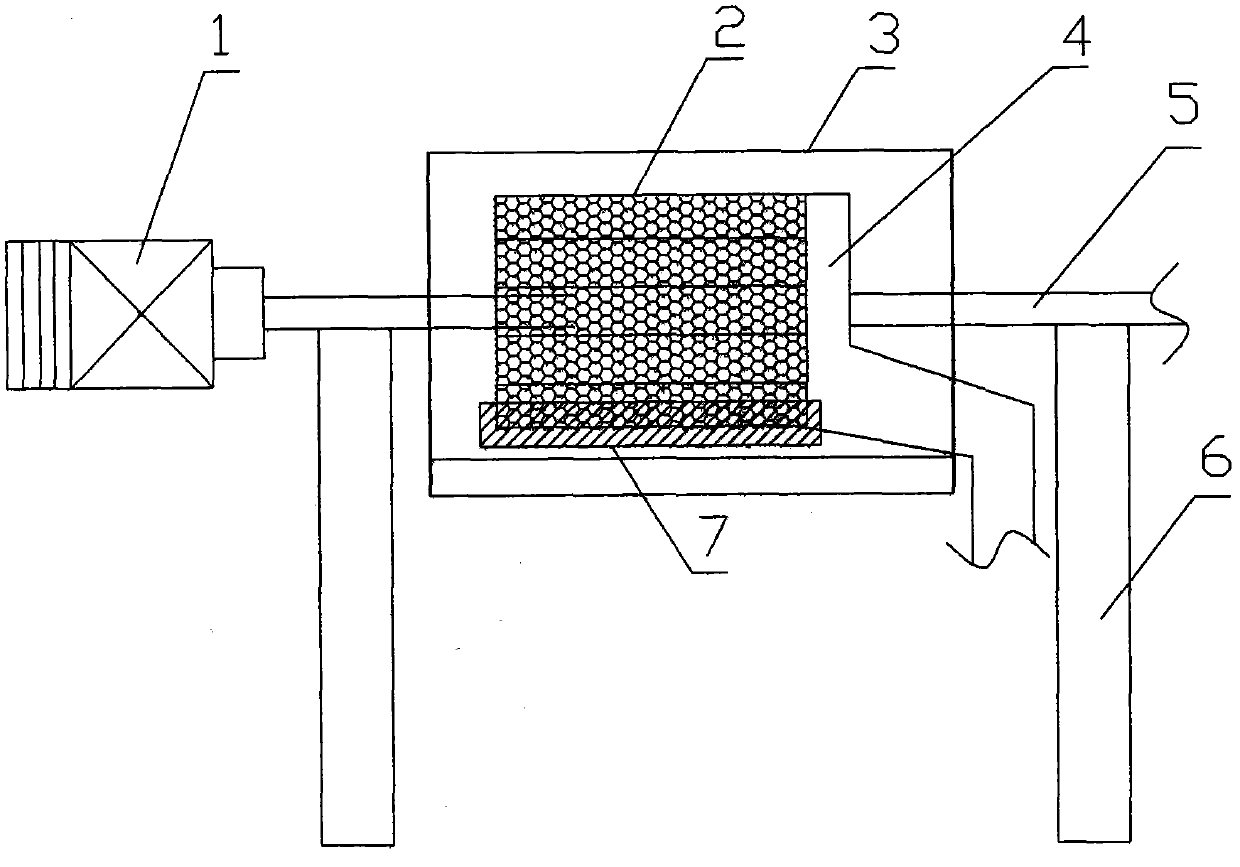

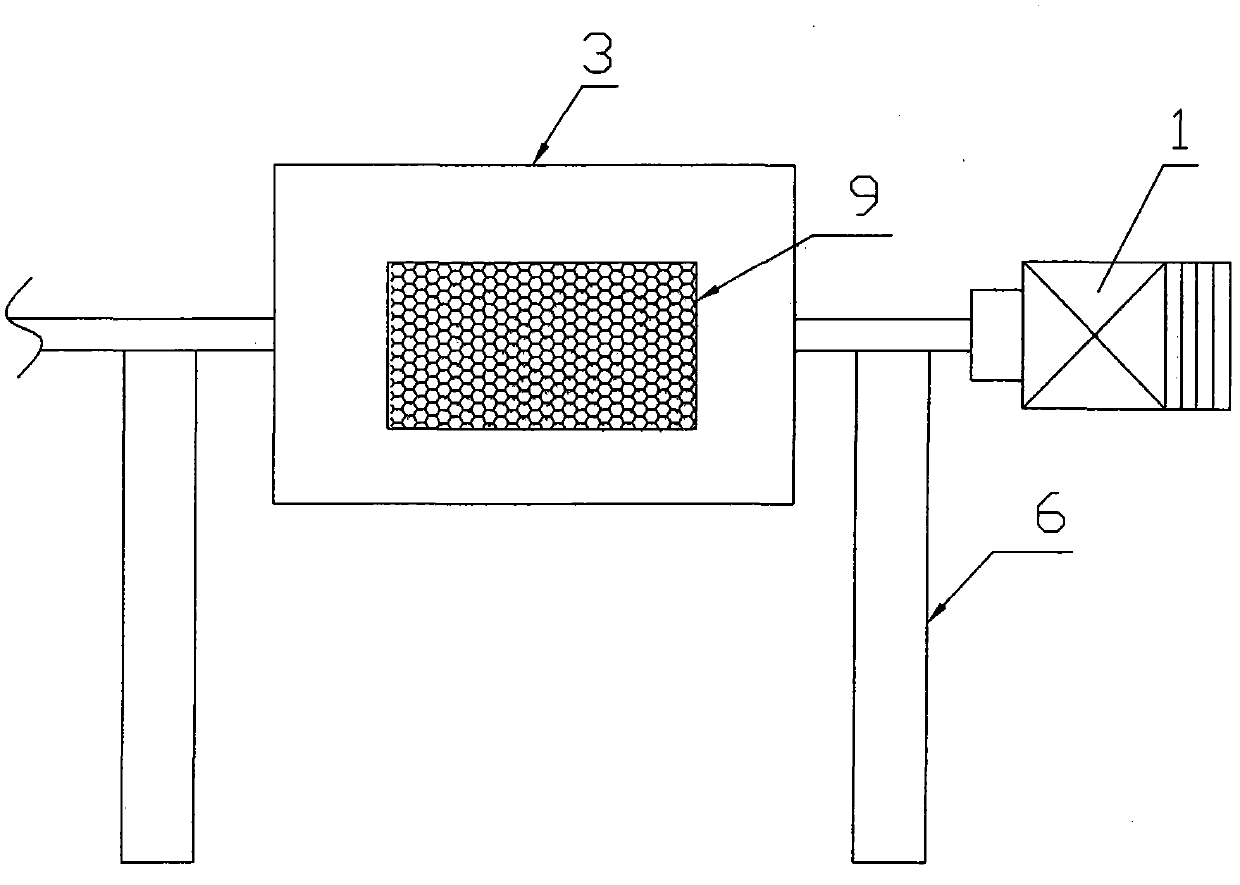

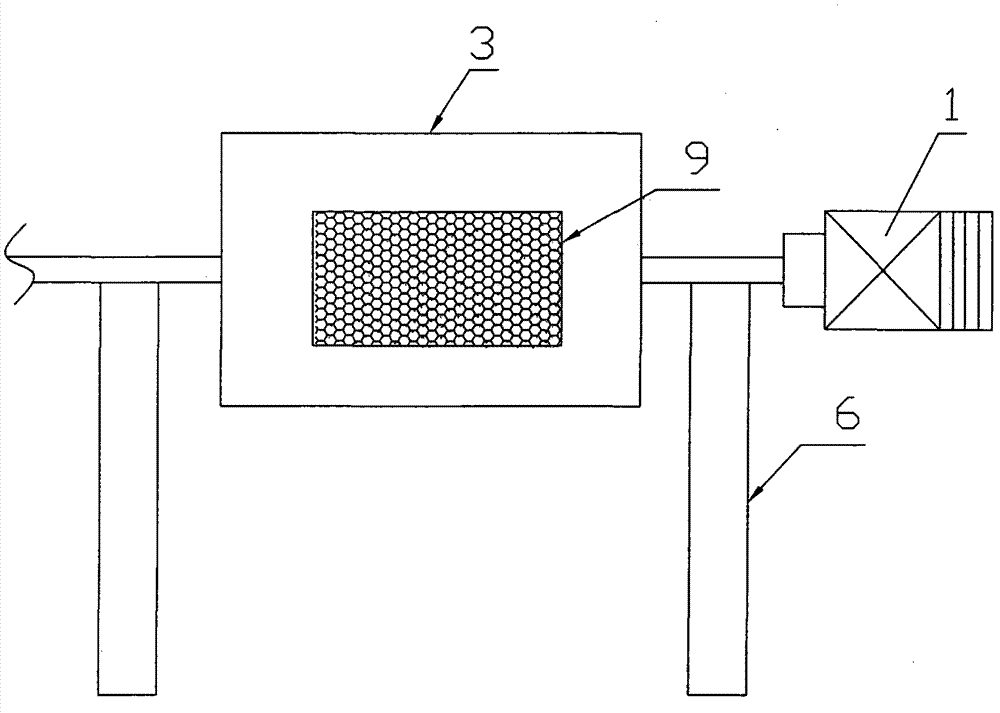

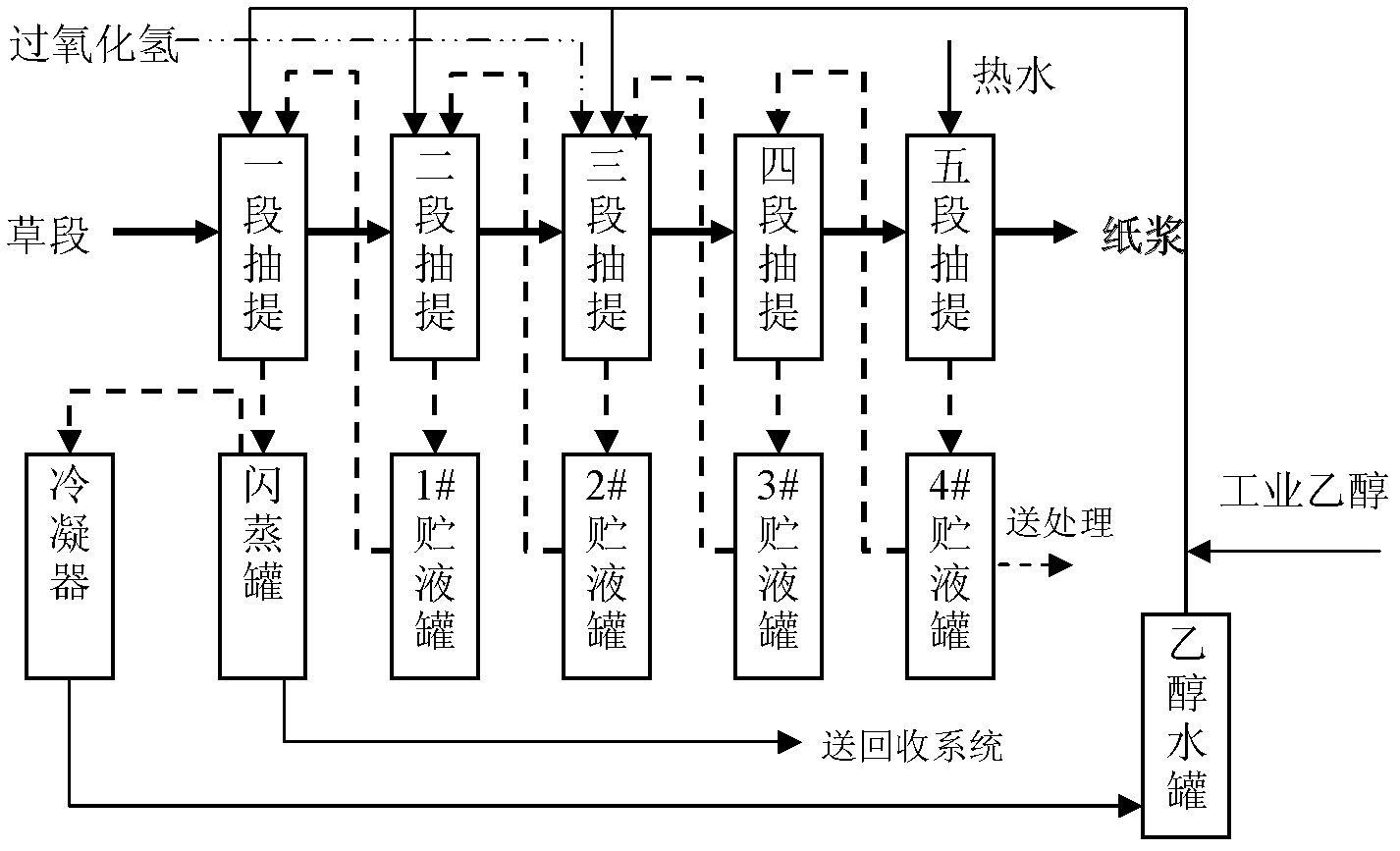

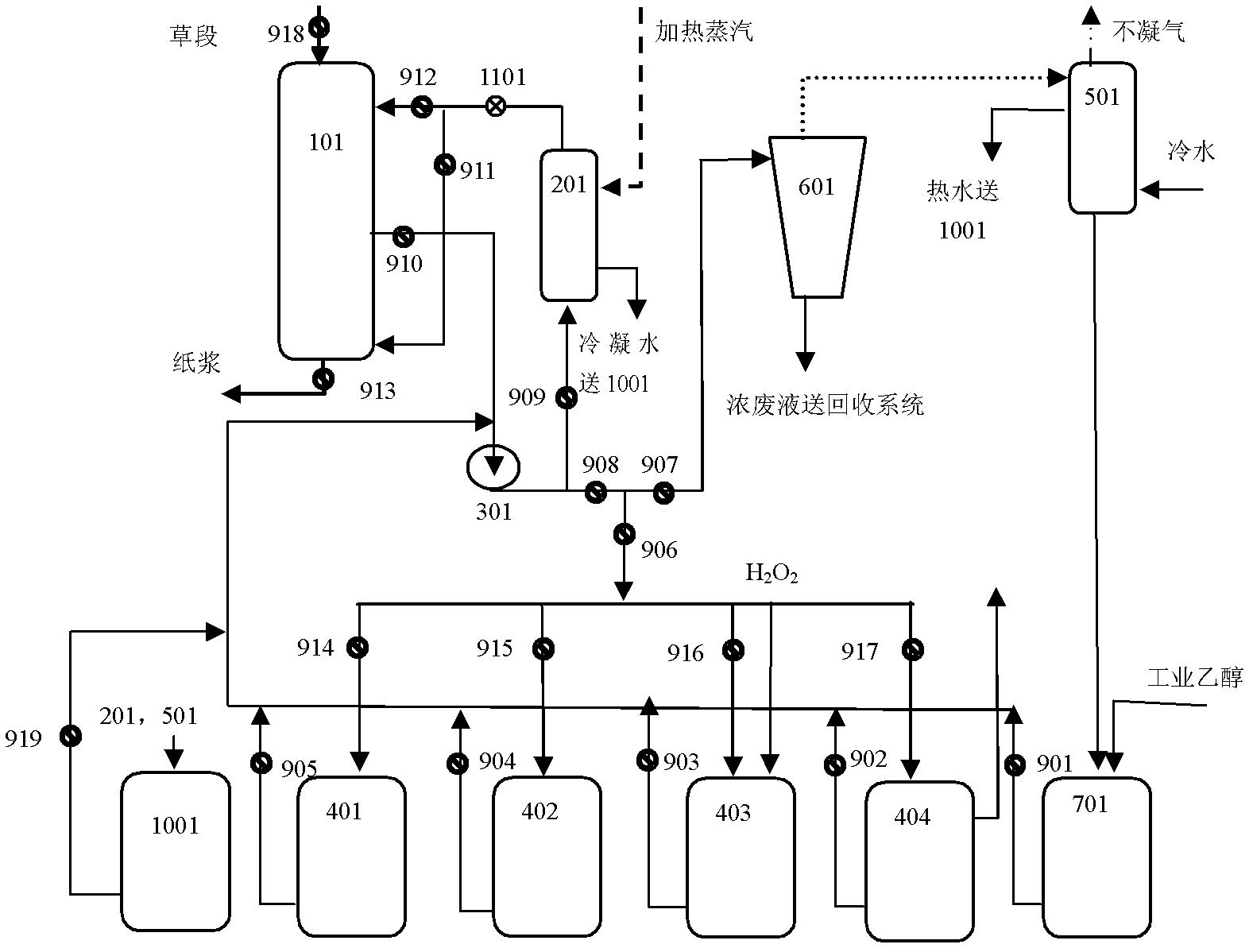

Process and device for pulping by reversely extracting grass raw materials

ActiveCN102704298BEliminate the pulp washing processEasy to recyclePulping with organic solventsNon-woody plant/crop pulpPeroxideDihydrogen Peroxide

The invention discloses a process and a device for pulping by reversely extracting grass raw materials. The process for pulping by reversely extracting grass raw materials utilizes an ethanol-water-superoxide multistage mode. In a boiling stage, the volume concentration of ethanol in an extract is controlled to be from 40% to 65%, the temperature of different segments is controlled to be 90-190 DEG C, the extracting time is controlled to be 40-180 minutes, the liquid ratio is controlled to be 1:4-1:10, and 0.5-5% of superoxide by weight is added to a tail segment of the boiling stage and serves as an assistant. In a pulp washing stage, the temperature of different segments is controlled to be 70-100 DEG C, the extracting time is controlled to be 30-60 minutes, and the liquid ratio is controlled to be 1:3-1:6. The device for pulping by reversely extracting grass raw materials mainly comprises an extractor, a heat exchanger, a liquid storage tank, a flash bucket, a condenser, an ethanol liquid tank, a circulation pump and the like. The process is suitable for the pulping industry, has the advantages of wide adaptability to grass raw materials, low boiling temperature, good pulping quality, easiness in pulp bleaching, low investment, easiness in recovery of high-additional-value byproduct from waste liquid and the like, and can realize pulping cleanly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Pulp waste steam heat energy recycling and comprehensive utilization treatment method and device

PendingCN111721156AAchieve separationIncrease production capacityGas treatmentRecuperative heat exchangersThermodynamicsBlack liquor

The invention discloses a pulp waste steam heat energy recycling and comprehensive utilization treatment method and device. The method comprises the steps that (1), the heat energy in pulp waste steamis absorbed and stored through an absorption and energy storage unit, and the recycling of the heat energy of the waste steam is achieved; (2), hot water generated after the absorption and energy storage unit absorbs the heat energy is inputted into a black liquor evaporation system provided with an evaporation unit and a steam balance unit, steam of each grade for hot water flash evaporation isstably conveyed and distributed to the black liquor evaporation system through the steam balance unit, and the cooled hot water is returned to the absorption and energy storage unit; and (3), the waste gas generated by the absorption and energy storage unit and the black liquor evaporation system is condensed in a condenser, the condensed waste gas is conveyed to a deodorization unit through a vacuum pump, and the deodorized waste gas is discharged into the atmosphere. According to the pulp waste steam heat energy recycling and comprehensive utilization treatment method and device, comprehensive utilization of waste steam heat energy in the pulp industry can be achieved, meanwhile, waste gas is discharged up to the standard, environmental friendliness is achieved, and the production cost of enterprises can be effectively saved.

Owner:阿拉尔市中泰纺织科技有限公司 +1

An energy-saving and environmentally-friendly process that realizes the symbiosis and win-win of the two industries of straw pulping and papermaking and waste lead-acid battery regeneration

ActiveCN104671497BReduce deforestationSave woodCombination devicesTreatment involving filtrationThermal energyProcessing cost

The invention discloses a novel energy conservation and environment protection process for realizing the mutualistic symbiosis of a straw pulping and papermaking industry and a waste lead-acid cell recycling industry. According to the alkaline characteristic of the straw pulping sewage, the acidic characteristic of the waste lead-acid cell recycling sewage, and the condition of the coupling utilization space of the after heat, the energy conservation and environment protection process for realizing the mutualistic symbiosis for comprehensive coupling processing the acid-alkali wastewater and complementarily using the heat energy is provided. By adopting the process, the pollution abatement cost and the difficulty of the two industries can be greatly reduced, the energy complementary utilization is realized and the mutualistic symbiosis of two industries is obtaind. By adopting the process, the complementary utilization of the energy sources of two distant related industries is realized, the alkaline black liquid generated by the straw pulping industry and the leaded acidic wastewater generated by the regenerated lead industry can be completely recycled and utilized, so that the problem of high processing cost of the sewages in two industries can be solved and the economic benefits of two industries can be effectively increased.

Owner:尚圣杰

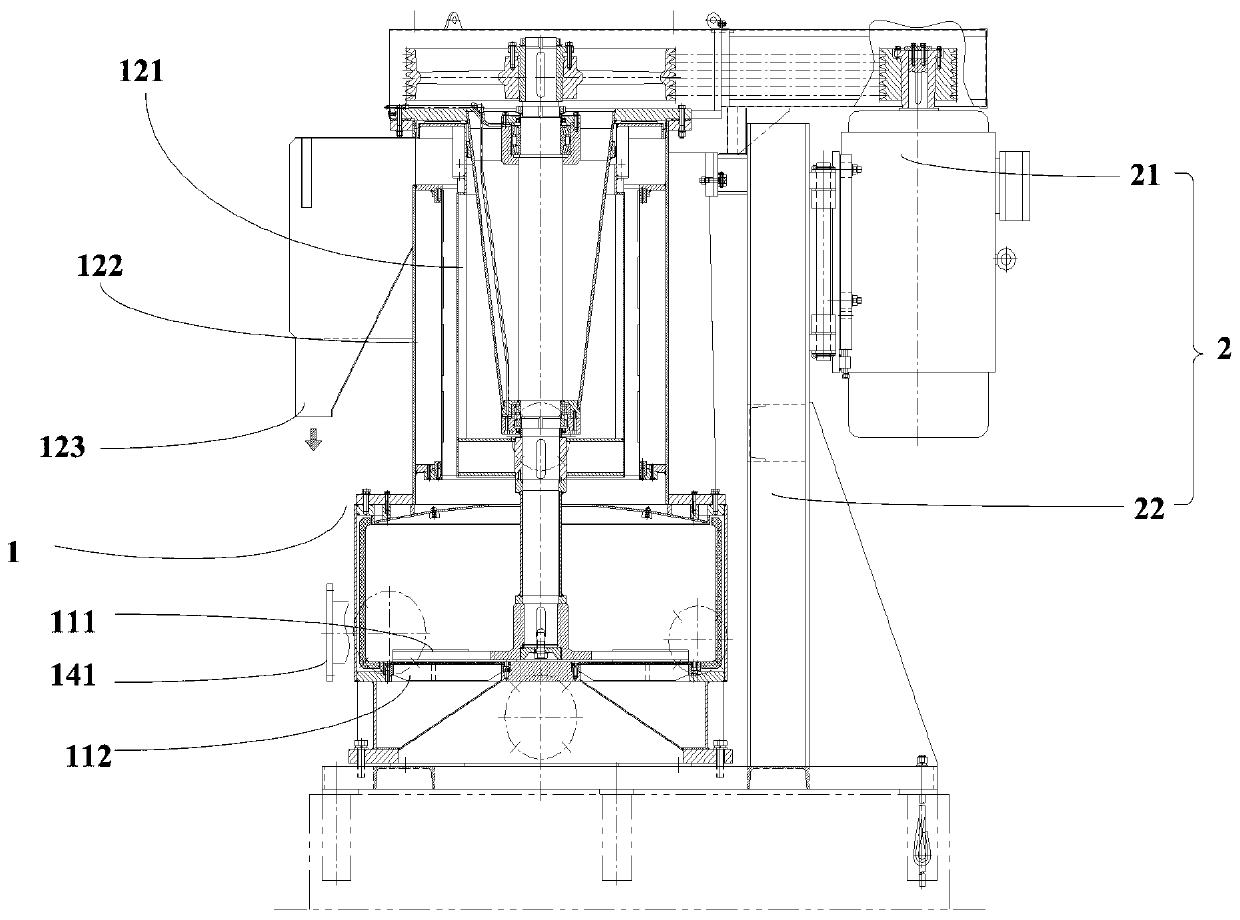

Pressure composite sieve for pulping industry

The invention relates to a pressure composite sieve for the pulping industry. The pressure composite sieve comprises a housing and a power device. The housing is internally provided with a pulp feeding and crushing zone and a washing and dewatering zone from bottom to top in sequence, wherein the pulp feeding and crushing zone is communicated with the washing and dewatering zone; the pulp feedingand crushing zone is provided with a crushing structure formed by an impeller and a sieve plate; the washing and dewatering area is internally provided with a washing and dewatering structure formed by a rotor and a sieve drum, and the rotor and the impeller are coaxially arranged in a vertical direction; the portion, corresponding to the pulp feeding and crushing zone, of the housing is providedwith a pulp inlet, a first good pulp outlet and a heavy slag outlet; the portion, corresponding to the washing and dewatering zone, of the housing is sequentially provided with a light slag outlet anda second good pulp outlet from top to bottom. The power device is fixed to one side of the top of the housing, an output end of the power device is provided with a first belt pulley, and transmissionthrough a belt and power transmission through a second belt pulley which is arranged on the top of a main shaft are realized; the pulp facing surface of each blade of the impeller is in a circular arc shape, and the length of the upper end surface of the end, away from an impeller core, of each blade is greater than that of the lower end surface of the end, away from the impeller core, of the blade, so that an included angle alpha is formed between the upper end surface and lower end surface of each blade.

Owner:SHANDONG CHENZHONG MACHINERY

Preparation method of enteromorpha protease

InactiveCN106434608AReduce energy consumptionEfficient use ofHydrolasesSodium bicarbonateLeather industry

The invention discloses a preparation method of enteromorpha protease. The preparation method comprises the following steps: selecting raw materials; cleaning under high pressure; shearing water leaking; adding protease inhibitor juice; adding leaching liquor and a buffer solution in a triturator and preparing coarse extraction liquid; centrifuging solid ammonium sulfate; dialyzing and desalting an acetic acid solution; adding a Roche protease inhibitor and cooling by ice bath; adding chloroprene rubber cr322 and stirring and centrifuging; purifying with sodium bicarbonate; crystallizing n-acetyl-l-a cysteine solution; freezing, centrifuging and collecting crystals; and storing finished products. Activity and purity of the enteromorpha protease are guaranteed effectively. The enteromorpha protease can be widely used in the industries of washing industry, food industry, textile industry, leather industry, pulp industry, feedstuff, petroleum and gas drilling, clinic medicines, agriculture, forestry, animal husbandry and the like, and has excellent effects of reduction of energy consumption, reduction of chemicals, speediness and environmental protection in application.

Owner:威海红印食品有限公司

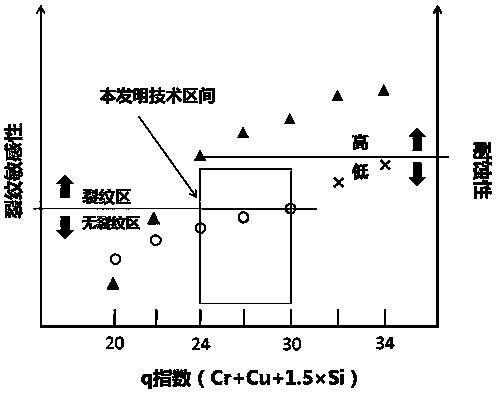

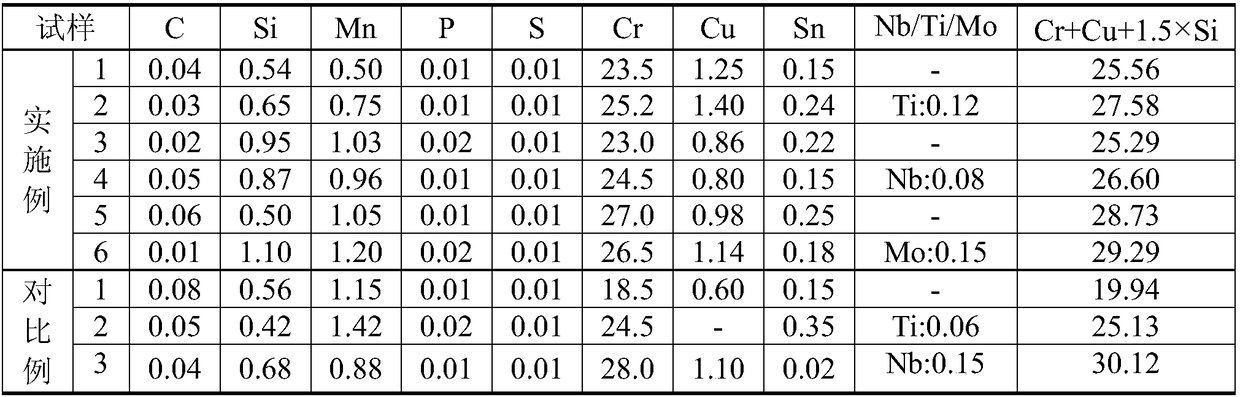

High corrosion resistant surfacing electrode

InactiveCN108422123AImprove corrosion resistanceImprove high temperature strengthWelding/cutting media/materialsSoldering mediaChemical industryChemical composition

The invention discloses a high corrosion resistant surfacing electrode. Chemical components of deposited metal in a surfacing layer are as follows, by weight: 0.01-0.08 of C, 0.3-1.5 of Si, 0.2-1.5 ofMn, no more than 0.02 of P, no more than 0.01 of S, 20-30 of Cr, 0.1-2.0 of Cu, and 0.05-0.5 of Sn, with the balance being iron and unavoidable impurities, wherein 24<=Cr+Cu+1.5*Si<=30. Welding wiresof the invention has excellent corrosion resistance performance and processing performance and is suitable for surfacing protection of a recovery system bearing high temperature and high pressure inpaper pulp industry, chemical industry and the like.

Owner:张宇

Polypeptide having xylanase activity

The present invention relates to an isolated polypeptide having xylanase activity. Also disclosed are isolated polynucleotides encoding the polypeptide, recombinant host cells expressing the polypeptide, and methods for degrading lignocellulosic biomass using the polypeptide. He invention finds utility in the production of biofuels, in the paper and pulp industry, in clothing or leather softening, in the food industry such as baking, etc.

Owner:MONAGHAN MUSHROOMS IRELAND +1

Process for reusing tail water in papermaking and pulping

ActiveCN103342431BAvoid large emissionsSolve water problemsDispersed particle separationWater/sewage treatment bu osmosis/dialysisWater useChemical oxygen demand

The invention relates to a process for reusing tail water in papermaking and pulping. The technology comprises the following specific steps of: (1) feeding wastewater into an equalization basin for premixing; (2) transferring the premixed wastewater into an air flotation system, and reducing COD (Chemical Oxygen Demand) and SS (Suspended Solids); (3) transferring the water treated by the air flotation system into an ozone system, and removing partial COD; (4) adjusting pH (Potential of Hydrogen) of the water treated by the ozone system, transferring partial water into an ultrafiltration system for pre-treating; transferring the other part of water into an electro-adsorption system, and directly feeding the water generated by the electro-adsorption system into an allocation system; (5) transferring the water subjected to ultrafiltration treatment into a reverse osmosis system; (6) transferring the fresh water subjected to reverse osmosis treatment into the allocation system for reusing, and transferring the concentrated water subjected to reverse osmosis treatment into an electroosmosis system for concentrating; and (7) feeding the fresh water subjected to electroosmosis into the allocation system for reusing, and feeding the concentrated water subjected to electroosmosis into an evaporating system for treating. The technology for reusing the tail water in papermaking and pulping realizes the recovery of water resources in the papermaking and pulping industry, and the treated water can be allocated according to the demand on water use of an enterprise, thus meeting the water supply under different requirements for water quality.

Owner:NANJING TECH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com