Biological accumulation pulping method

A pulping and biological technology, which is applied in the field of papermaking and pulping, can solve the problems of increasing production costs, unable to eliminate pollution, and polluting the environment with waste liquid, and achieves the effects of saving coal, being conducive to popularization and application, and improving pulp yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

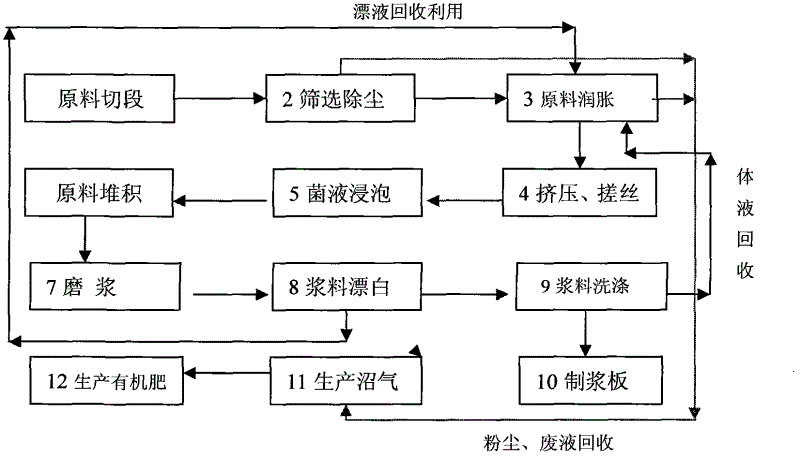

[0025] The technological process of degrading lignin by bioaccumulation of raw materials such as straw, wheat straw, and reed is uniform; the same is true for broad-leaved wood such as bamboo willow and salix, but the accumulation time is longer.

[0026] The bioaccumulation pulping method of wheat straw, straw, reed, bamboo willow and salix is carried out according to the following steps:

[0027] The first step: cut wheat straw, straw, reed, bamboo willow, salix and other raw materials with a grass cutter to a length of 5 cm, and slice woody plants to a length of 4 cm.

[0028] Step 2: Screening and dedusting the above-mentioned cut raw materials to remove impurities in the raw materials. First use air separator to remove soil, powder, plastic cloth and other sundries in raw materials. Then use a jumping sieve to remove iron wires, stones and other sundries, and finally wash with water to remove silicon-containing substances and some pigments.

[0029] Step 3: Put the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com