Classified dust collecting device of tablets

A technology of dust removal device and tablet, which is applied in the direction of fiber raw material, fiber raw material treatment, textile and paper making, etc. It can solve the problems of low raw material utilization rate, raw material loss, and inability to classify blanks, so as to save power consumption and low power consumption , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

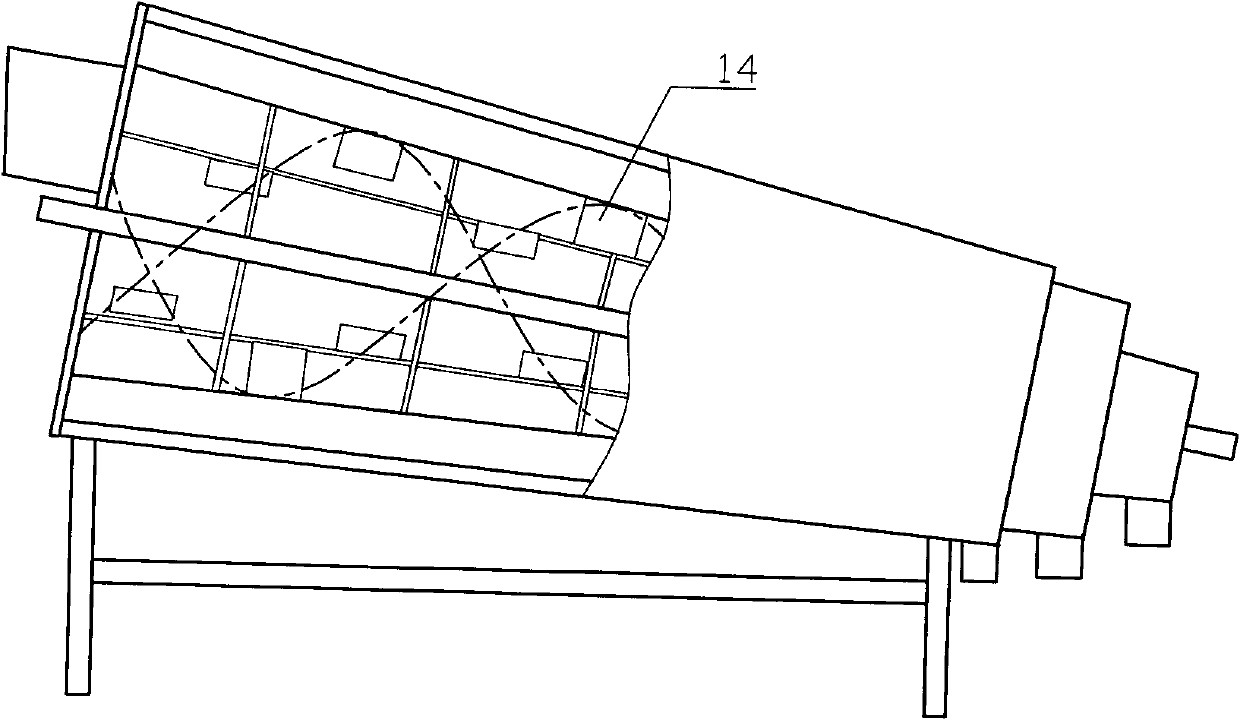

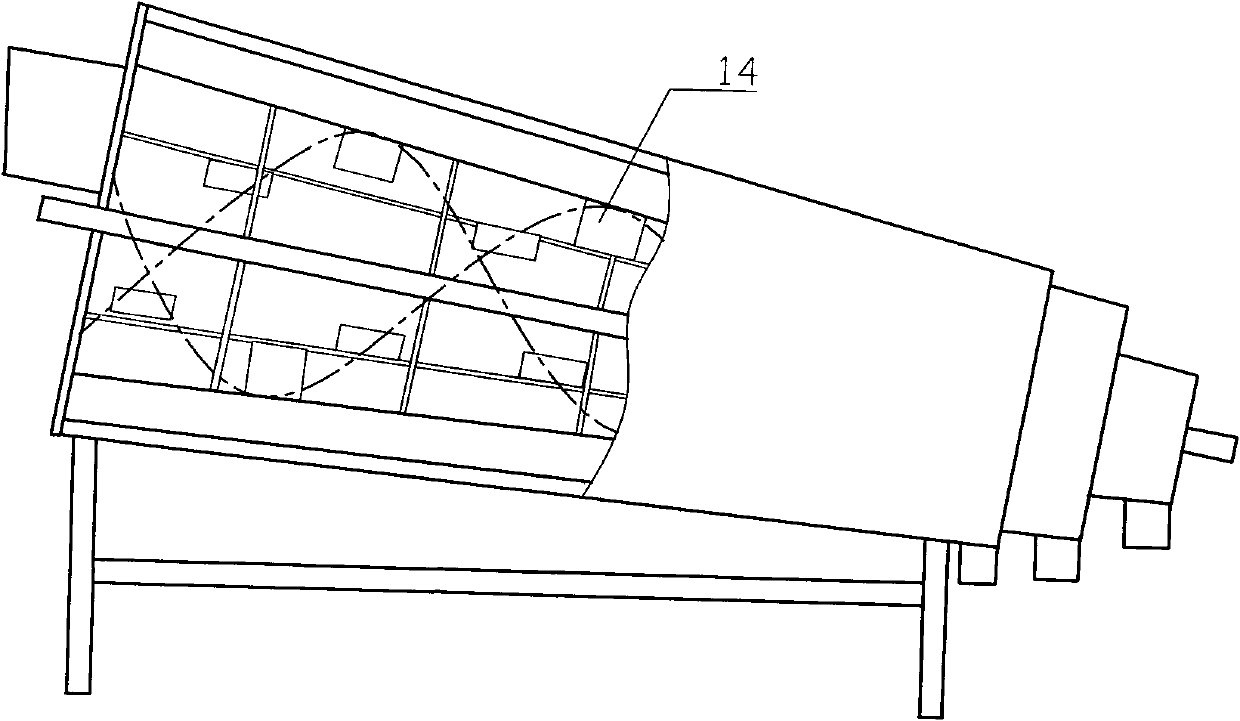

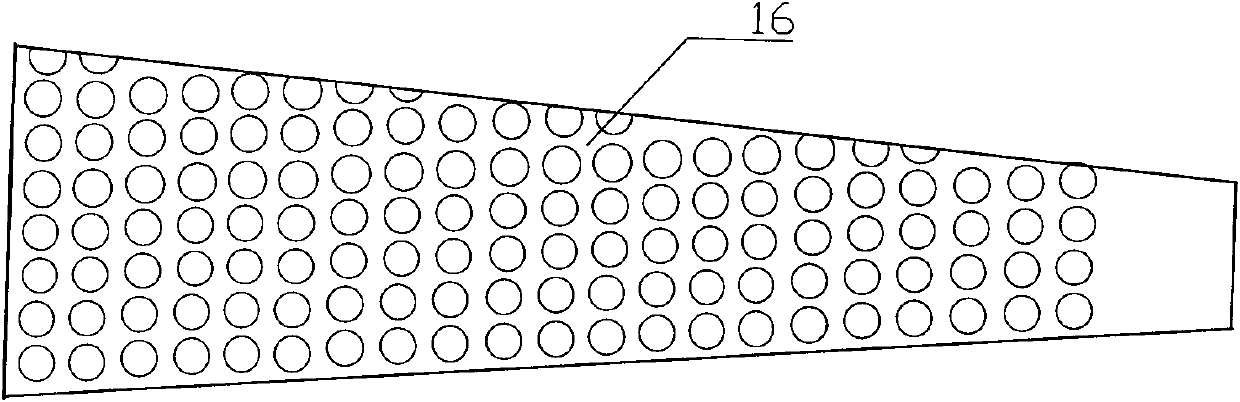

[0019] Embodiments of the present invention are as follows: a device for classifying and dedusting materials, as shown in the figure, includes a machine base 1, a casing 3, a main shaft 4, and a roller frame. On seat 1, standard, the angle between the bottom surface of the roller frame and the installation surface is 5°, the angle between the main shaft 4 and the installation surface depends on the cone angle of the roller frame and the angle between the bottom surface of the roller frame and the installation surface, specifically, when When the cone angle is 10°, the angle between the main shaft and the mounting surface is 10°. The large hole end of the roller frame is the head end, the small hole end is the tail end, and the head end is higher than the tail end. One end of the main shaft 4 is connected to the motor (not shown in the figure) through a pulley and a belt, and the main shaft 4 is connected to two layers of roller frames in the circumferential direction through r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com