Intelligent dust-removal and ventilating system

A ventilation system, intelligent technology, applied in ventilation system, space heating and ventilation, space heating and ventilation details, etc., can solve the problem of poor exhaust effect of ventilation devices, inability to effectively adjust ventilation volume, and large demand for ventilation volume and other problems, to achieve the effect of improving dust removal efficiency, reducing labor costs, and increasing ventilation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

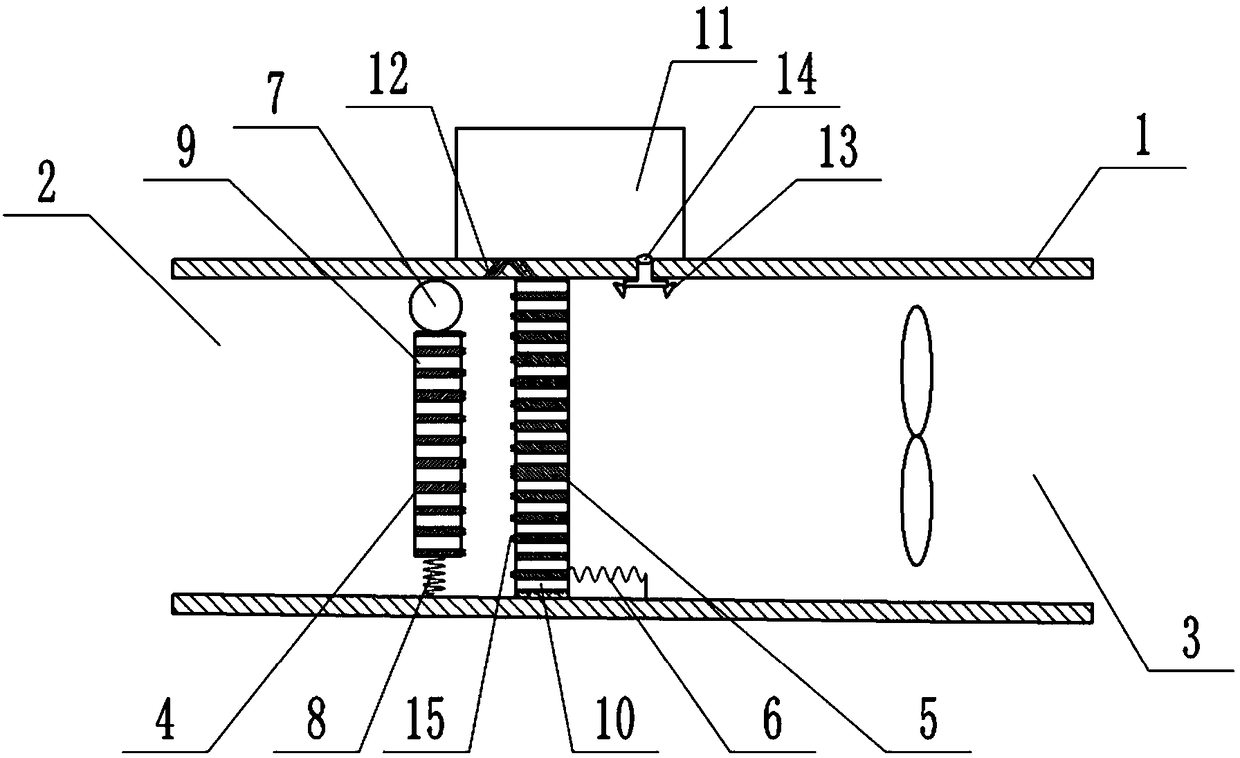

[0029] The reference signs in the drawings of the description include: channel 1, air inlet 2, air outlet 3, first filter plate 4, second filter plate 5, reset member 6, air bag 7, elastic member 8, through hole 9, fine hole 10. Water tank 11, nozzle hole 12, nozzle 13, solenoid valve 14, soft brush 15.

[0030] like figure 1 As shown, the intelligent dust removal and ventilation system of the present invention includes a channel 1 with an air inlet 2 and an air outlet 3, the channel 1 is arranged along the horizontal direction, and a negative pressure fan located at the air outlet 3 in the channel 1, the channel in this embodiment The shape can be a hollow cuboid, and the bottom wall of the channel 1 is slightly inclined downward along the direction of the air outlet 3;

[0031] A first filter plate 4 and a second filter plate 5 that can be attached are arranged in parallel in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com