Pulp waste steam heat energy recycling and comprehensive utilization treatment method and device

A heat recovery and treatment method technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of polluting the environment and wasting a lot of energy, and achieve fast energy saving, high-efficiency heat recovery, and rapid vapor-liquid mass transfer hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

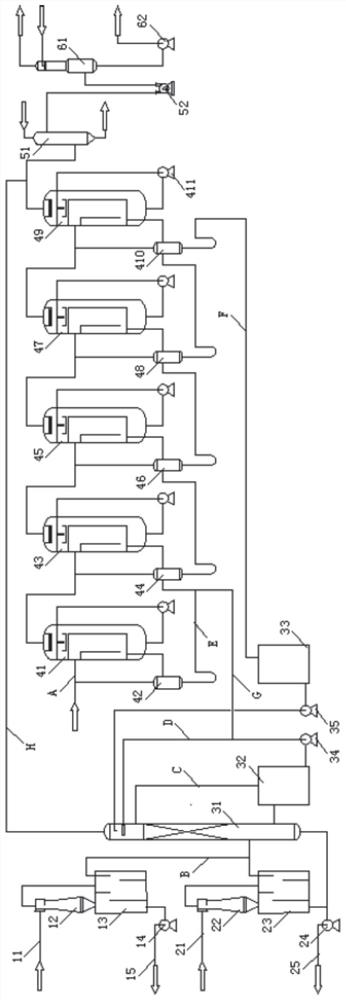

[0055] In this embodiment, the comprehensive utilization treatment device for pulp waste steam heat energy recovery, such as figure 1 As shown, it includes a pre-treatment system, an absorption energy storage unit, a black liquor evaporation system, a deodorization unit, and a condensation treatment unit. Specifically, the pre-treatment system includes large and small steam release treatment units arranged side by side with steam balls, wherein the steam The ball waste steam large release steam treatment unit includes a large steam release main pipe 11, a first cyclone separator 12, a first waste gas buffer tank 13, a pulp pump 14 and a pulp discharge pipe 15 arranged in series in sequence; The small steam release processing unit includes a small steam release main pipe 21, a second cyclone separator 22, a second waste gas buffer tank 23, a black liquor pump 24, and a black liquor discharge pipe 25 arranged in series in sequence; the absorption energy storage unit includes The...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, but the black liquor evaporation system in step 2) comprehensive utilization of heat energy adopts a six-effect evaporation system. In this way, the production capacity of steamed pulp is increased by 3%, and the heat energy of waste steam is recovered by 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com