Process for reusing tail water in papermaking and pulping

A technology of tail water and process, which is applied in the process of wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of solving the problem of large discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

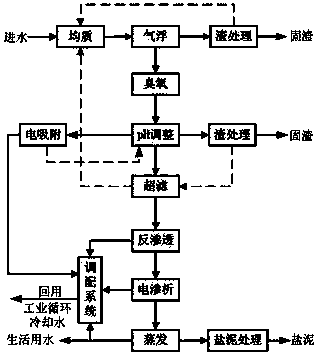

[0027] The sewage of a papermaking enterprise is used for industrial circulating cooling water after treatment. The process flow chart is as follows figure 1 shown. After using a complete mixing homogeneous pool to mix mechanically, the COD Cr is 112mg / L, TDS is 1840mg / L, SS is 45mg / L, after being treated by aeration flotation machine, COD Cr Reduced to 68mg / L, SS reduced to 5mg / L, COD after ozone system treatment Cr Reduced to 56mg / L, the wastewater enters the pH adjustment tank, and the pH is adjusted to 6.5. After the wastewater with a volume fraction of 45% enters the electrosorption system, the TDS of fresh water decreases to 731mg / L, and the conductivity removal rate is 40%. The other water enters the ultrafiltration System treatment, in which ultrafiltration adopts hollow fiber membrane with an average pore size of 10nm, after treatment COD Cr The reverse osmosis system uses 4 stages of reverse osmosis, of which 1~3 stages use low-pressure reverse osmosis membranes, ...

Embodiment 2

[0030] A large pulp and paper company conducts advanced treatment of biochemical tail water and reuses it as industrial circulating cooling water. The process flow is as follows figure 1 . The quality of biochemical tail water is 150mg / L for COD, 1184mg / L for TDS, and 56mg / L for SS. Cr Reduced to 87mg / L, SS reduced to 5mg / L, COD after ozone system treatment Cr Reduced to 66mg / L, the wastewater enters the pH adjustment tank, and the pH is adjusted to 8. After the wastewater with a volume fraction of 75% enters the electrosorption system, the TDS of fresh water decreases to 568mg / L, and the conductivity removal rate is 70%. The other wastewater enters the ultrafiltration Systematic treatment, the ultrafiltration system uses a tubular ceramic membrane with an average pore size of 50nm, and the treated wastewater COD Cr Reduced to 61mg / L, the reverse osmosis system uses 6 stages of reverse osmosis, of which 1 to 5 stages use low-pressure reverse osmosis membranes, and the sixth ...

Embodiment 3

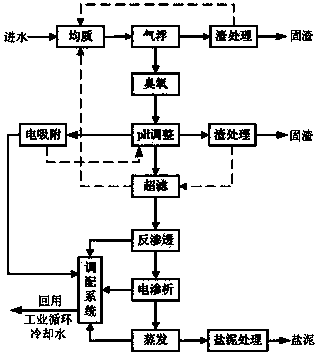

[0033] The process flow of advanced treatment of sewage in a pulping enterprise is as follows figure 2 shown. After mechanically stirring and mixing in a homogeneous tank with uniform distribution, the COD Cr is 130mg / L, TDS is 3210mg / L, SS is 48mg / L, after being treated by air flotation machine, COD Cr Reduced to 81mg / L, SS reduced to 5mg / L, COD after ozone system treatment Cr Reduced to 63mg / L, the wastewater enters the pH adjustment tank, and adjusts the pH to 10. After the wastewater with a volume fraction of 12% enters the electrosorption system, the TDS of fresh water decreases to 1898mg / L, and the conductivity removal rate is 50%. The other water enters the ultrafiltration System treatment, the ultrafiltration system uses a hollow fiber organic membrane with an average pore size of 100nm, and the COD after treatment Cr Reduced to 59mg / L, the reverse osmosis system uses 2 stages of reverse osmosis, of which the first stage uses a low-pressure reverse osmosis membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com