Alcohol type fermentation wastewater purification treatment and circulation method

A technology for fermentation wastewater, purification and treatment, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of discharge wastewater pollution, long fermentation cycle, low treatment efficiency, etc., to reduce costs, sugar The effect of small loss of similar substances and avoiding large emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

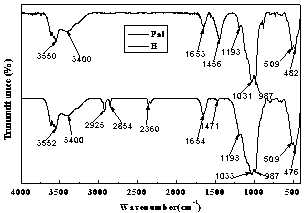

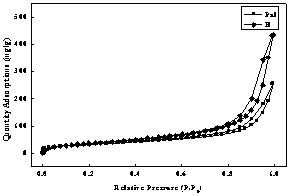

[0016] Embodiment 1: Preparation of organically modified attapulgite clay

[0017] ①Crush the attapulgite clay raw ore through a 100-mesh sieve, take 200g and pour it into 2000g of tap water, add 8g of sodium hexametaphosphate, high-shear for 30min, remove impurities by centrifugation, and dry in an oven at 85°C to obtain purified soil; pulverize the purified soil Pass through a 200-mesh sieve, pour 100 g into 500 g of dilute sulfuric acid solution (mass fraction 12%), stir and react in a water bath at 85°C for 2 hours, wash with tap water until neutral, and dry in an oven at 85°C to obtain acidified soil; crush the acidified soil 200 mesh sieve, pour 80g into 400g tap water, stir well in 85°C water bath, add 8g of organic modifier γ-propyltrimethoxysilane, stir in 85°C water bath for 3h, wash with tap water, bake in 85°C oven Dry to obtain organic modified soil A;

[0018] ②The method is the same as ①, except that the organic modifier is octadecyltrimethylammonium chloride, ...

Embodiment 2

[0027] Example 2: First use a centrifuge to remove the solid impurities in the alcohol fermentation wastewater, then use quicklime to adjust the pH value of the alcohol fermentation wastewater after impurity removal to 4.5, and filter for solid-liquid separation after settling; Add 50g of fermentation wastewater into a 150ml Erlenmeyer flask, add 1.0g of organic modified soil A to purify it, absorb it in a shaking table at normal temperature and pressure for 4.0h, and separate solid and liquid after adsorption.

[0028] The absorbance was measured with a 752 ultraviolet-visible spectrophotometer (test wavelength 540nm), and the decolorization rate was converted to 29.03%. The content of sugar and organic acid was detected by high performance liquid chromatography. The loss rate of total sugar was 7.17%, and the removal rate of total acid was 14.31%, of which the removal rate of butyric acid was 5.31%.

Embodiment 3

[0029] Example 3: First use a centrifuge to remove the solid impurities in the alcohol fermentation wastewater, then use quicklime to adjust the pH value of the alcohol fermentation wastewater after impurity removal to 5.5, and filter for solid-liquid separation after settling; Add 50g of fermentation waste water into a 150ml Erlenmeyer flask, add 1.75g of organic modified soil C to purify it, absorb it in a shaking table at normal temperature and pressure for 2.0h, and separate solid and liquid after adsorption is completed.

[0030] The absorbance was measured with a 752 ultraviolet-visible spectrophotometer (test wavelength 540nm), and the decolorization rate was converted to 60.21%. The content of sugar and organic acid was detected by high performance liquid chromatography. The loss rate of total sugar was 7.19%, and the removal rate of total acid was 7.19%. 15.77%, of which the removal rate of butyric acid was 6.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com