Patents

Literature

466 results about "Alcohol production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol is produced during a natural process called fermentation, which occurs when yeast, a microscopic plant that floats freely in the. air, reacts with the sugar in fruit or vegetable juice, creating alcohol. and releasing carbon dioxide.

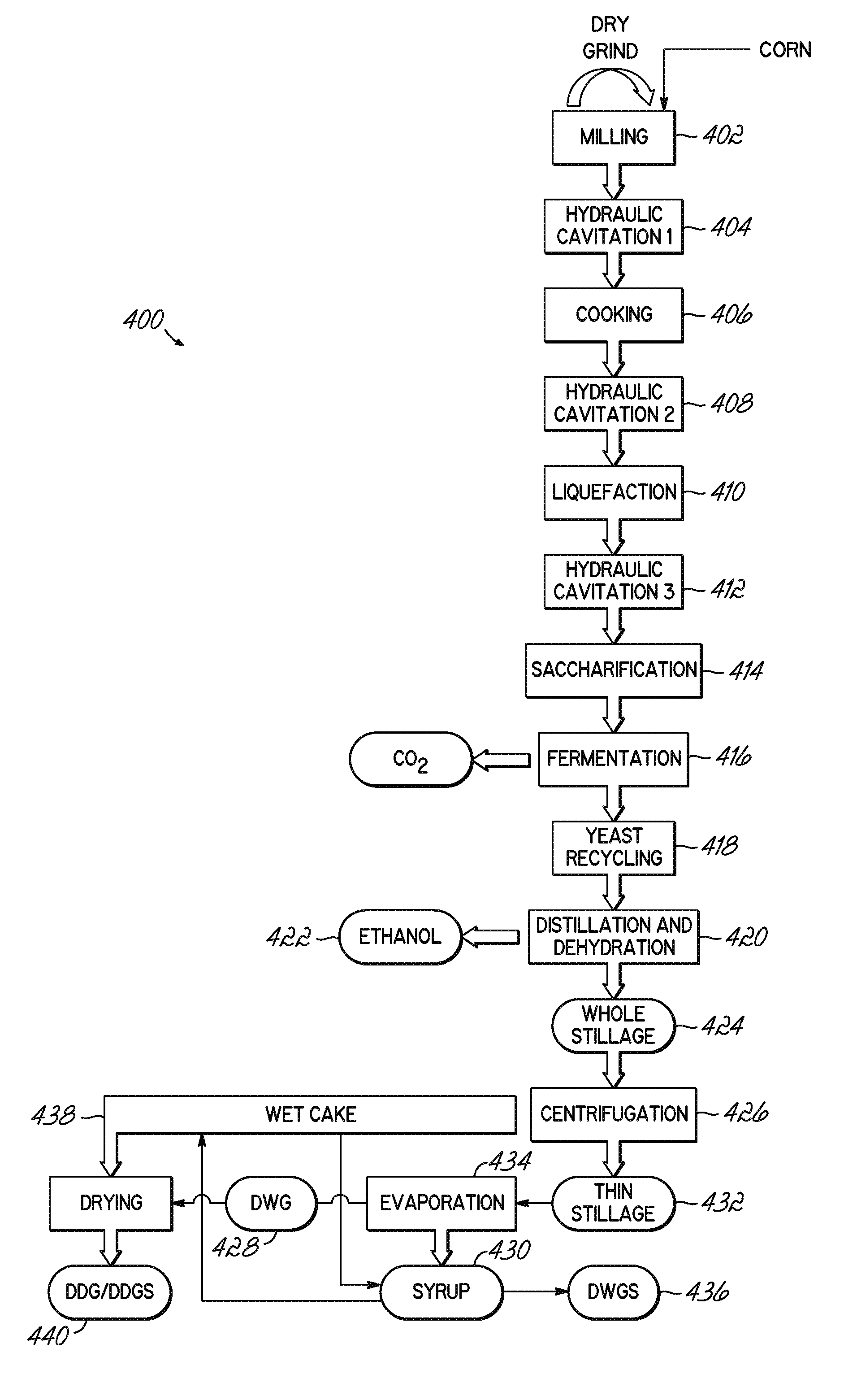

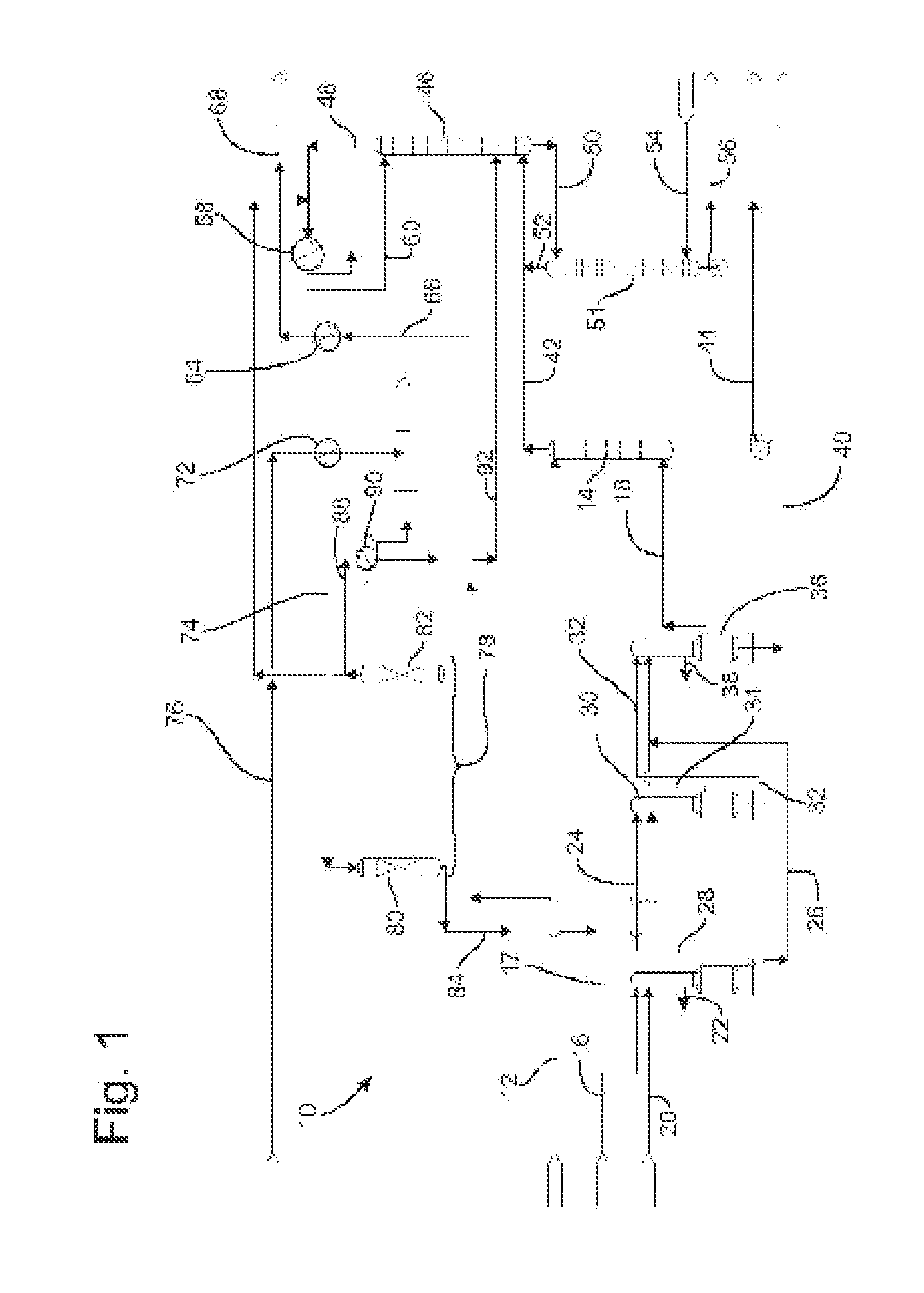

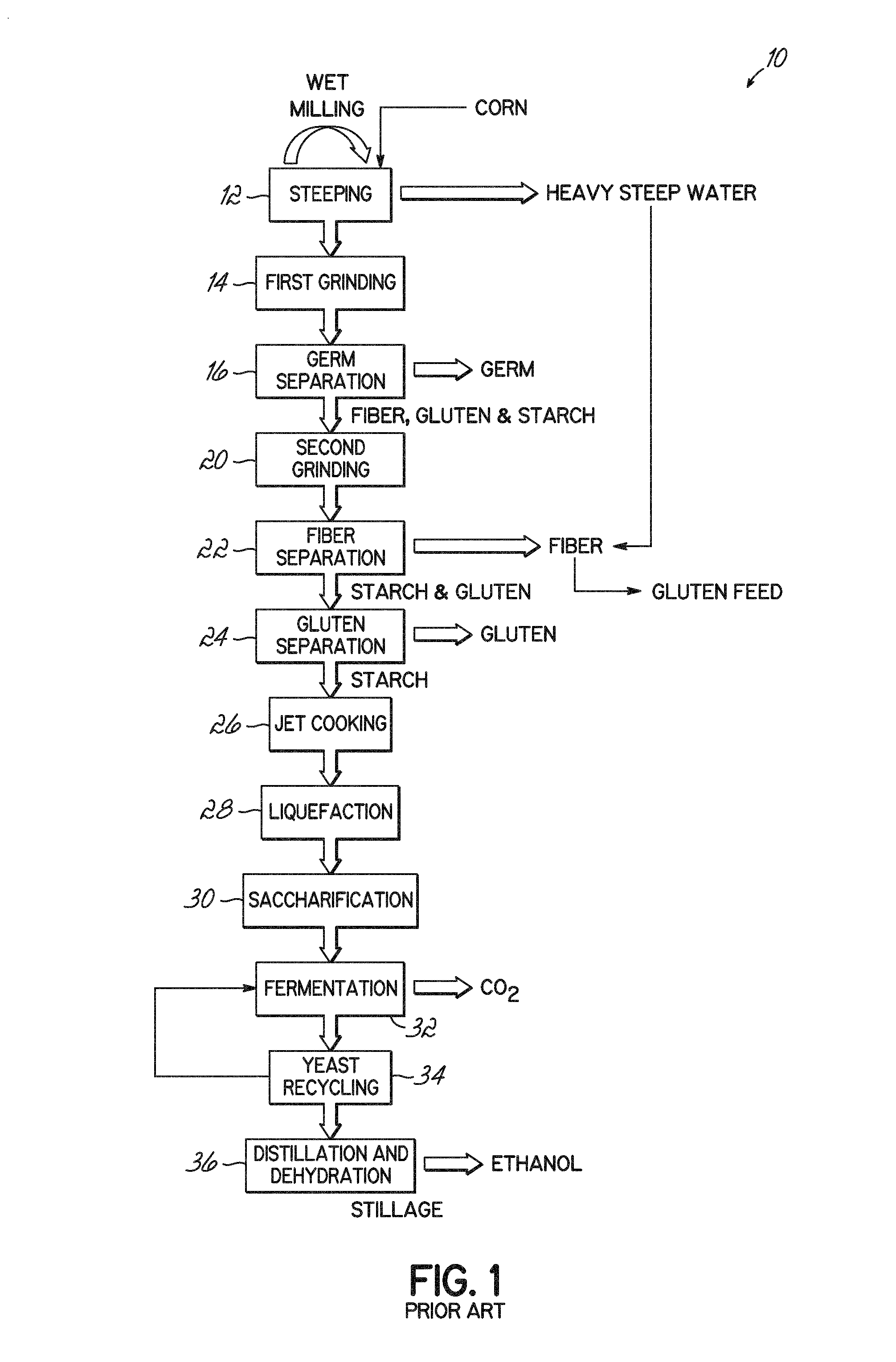

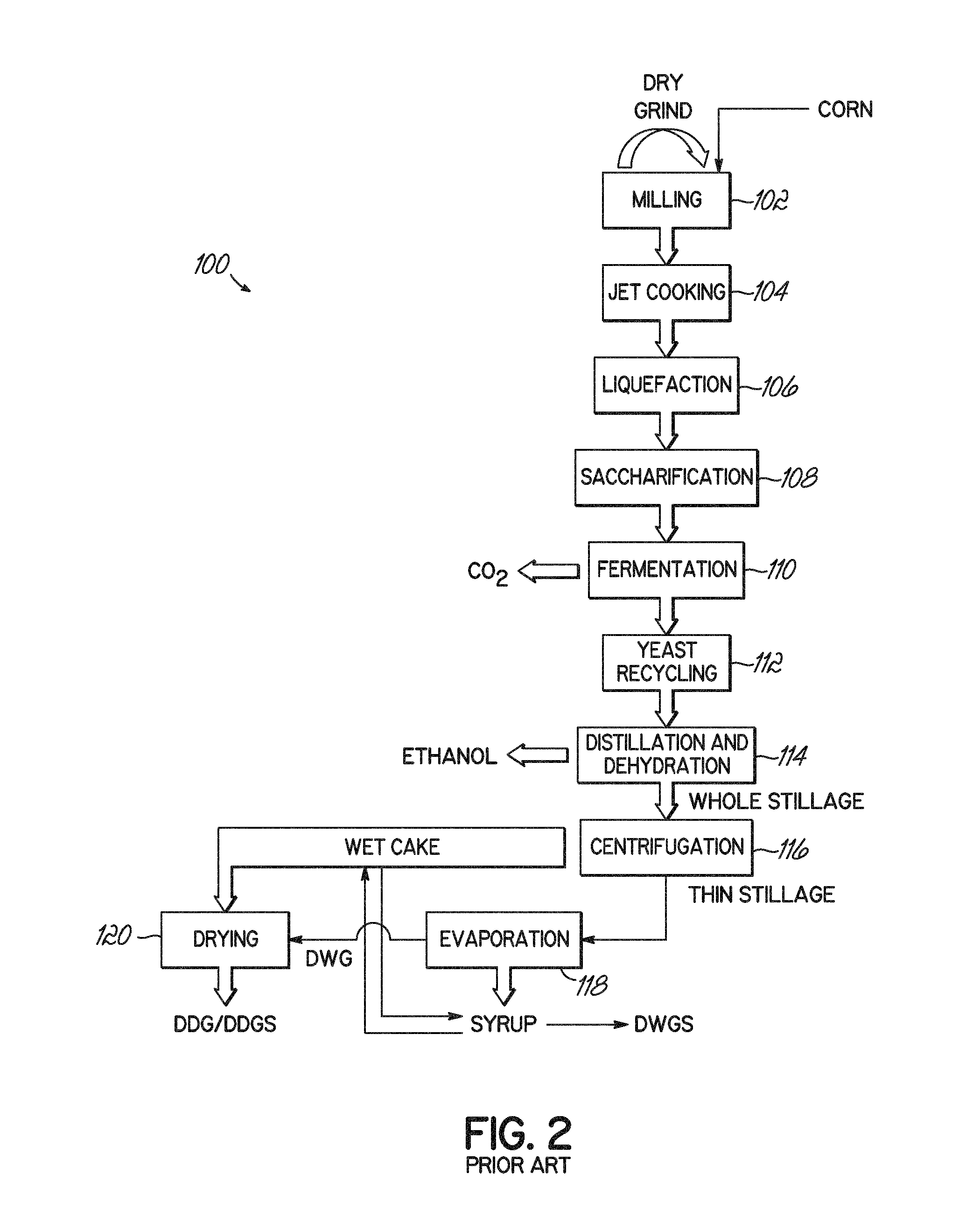

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

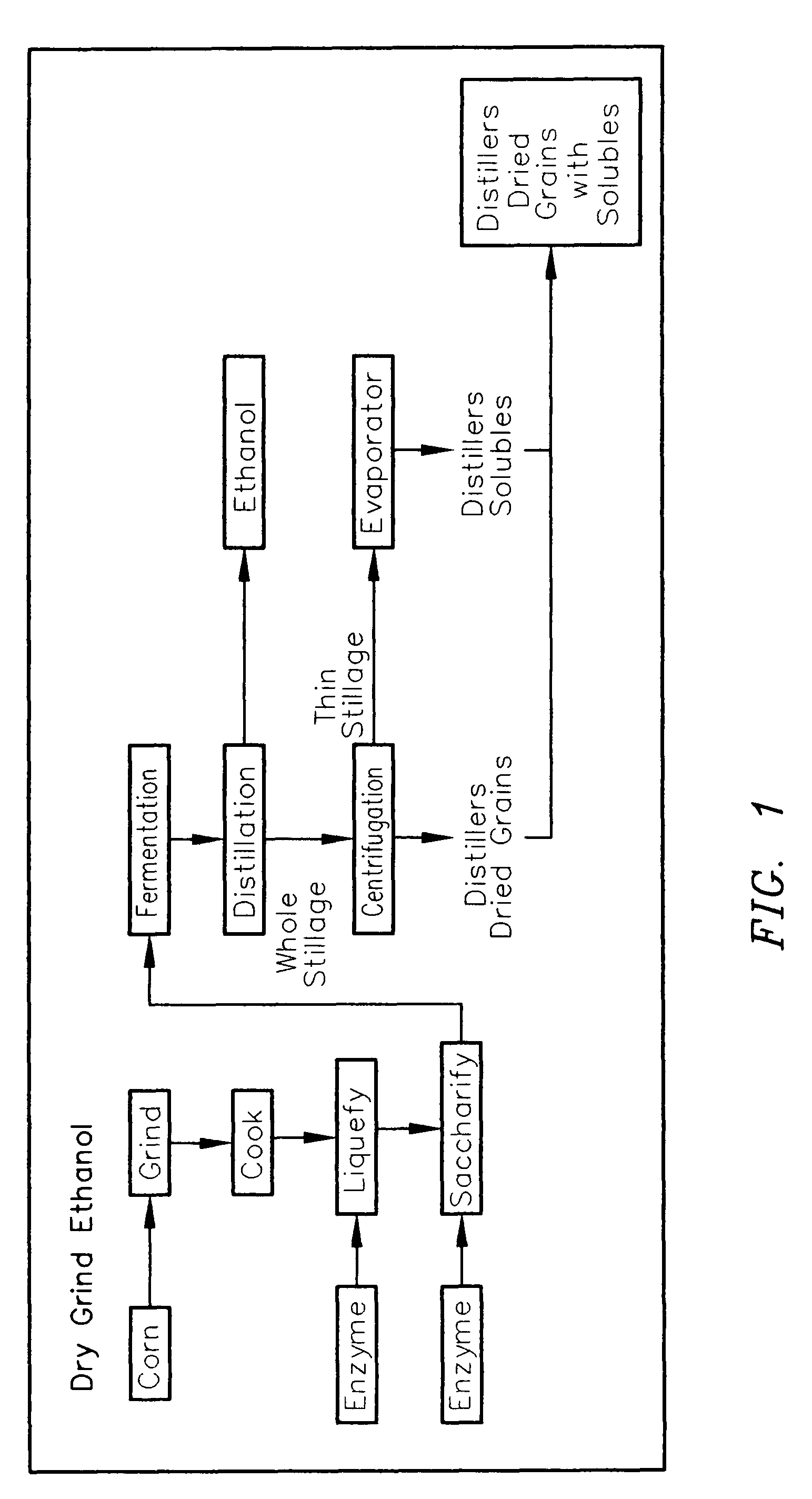

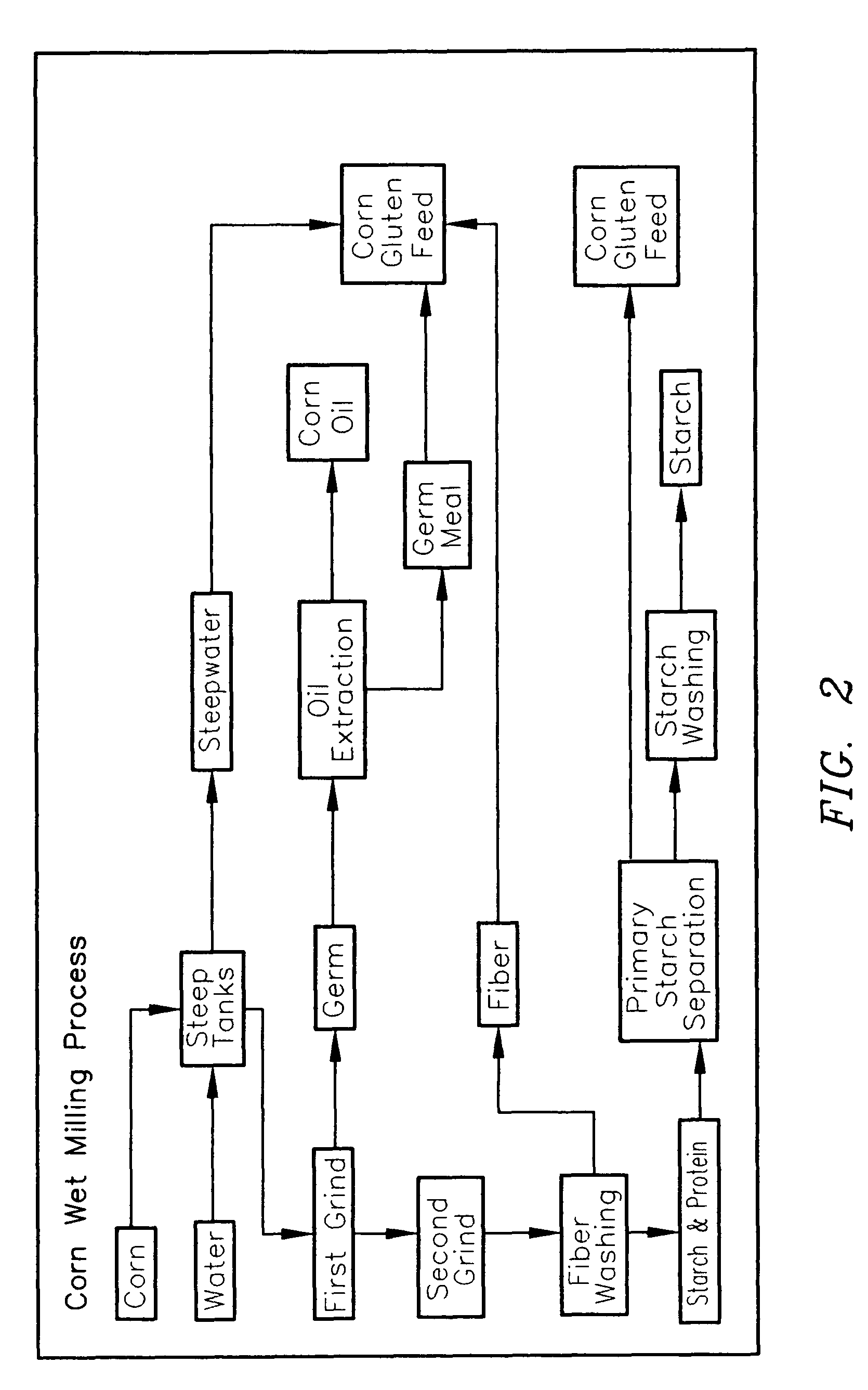

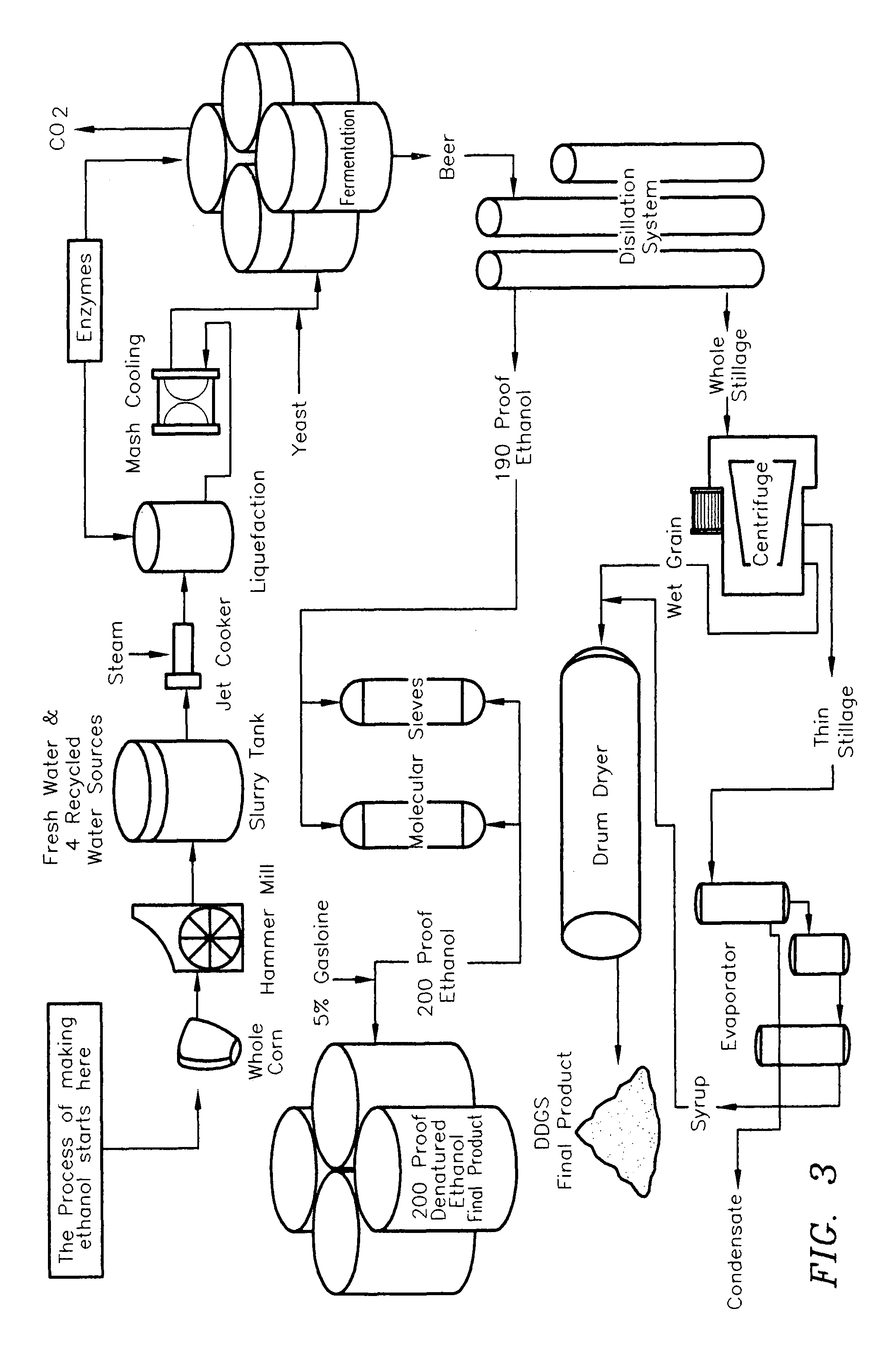

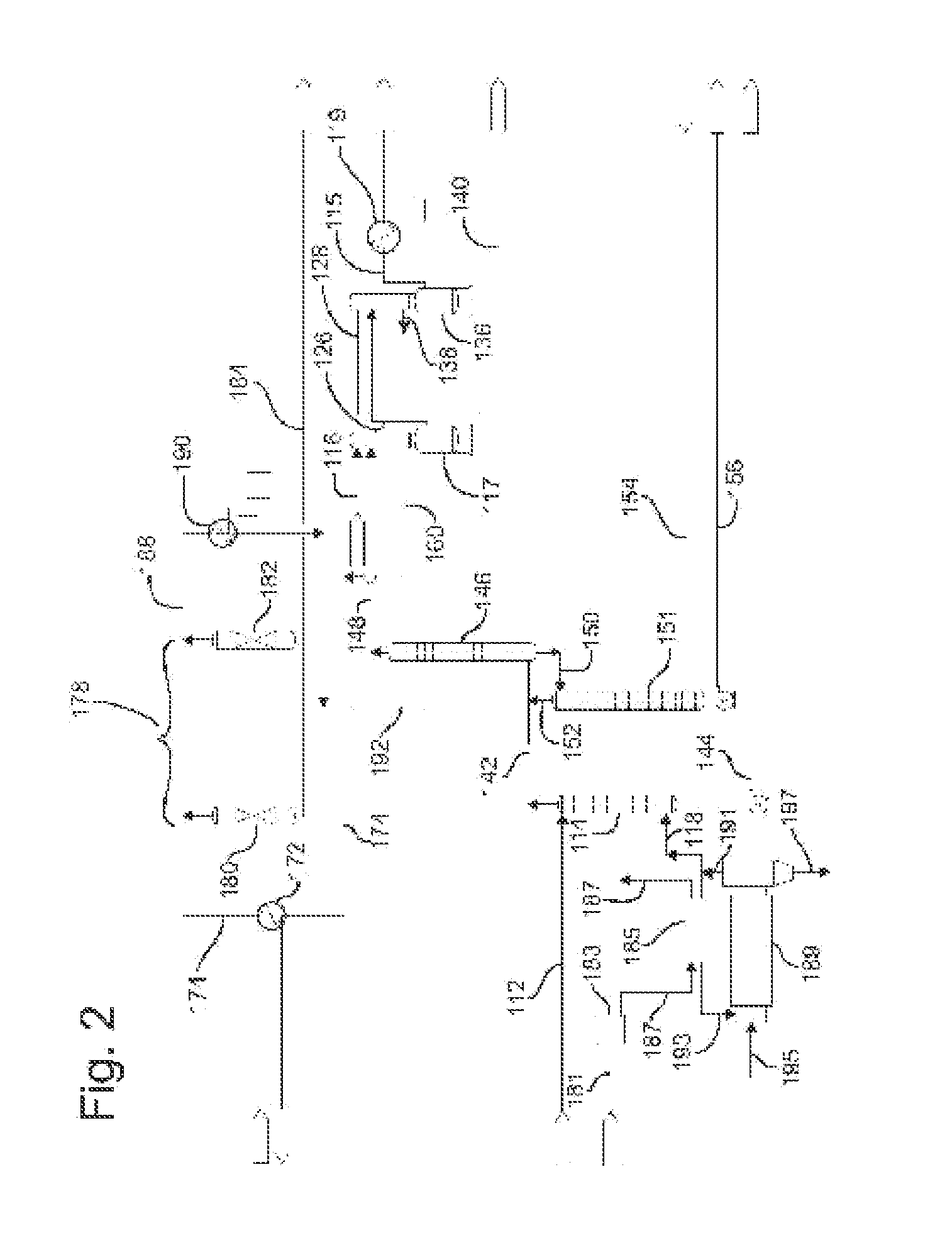

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

Alcohol production process

ActiveUS20100105115A1Bioreactor/fermenter combinationsBiological substance pretreatmentsButanolChemistry

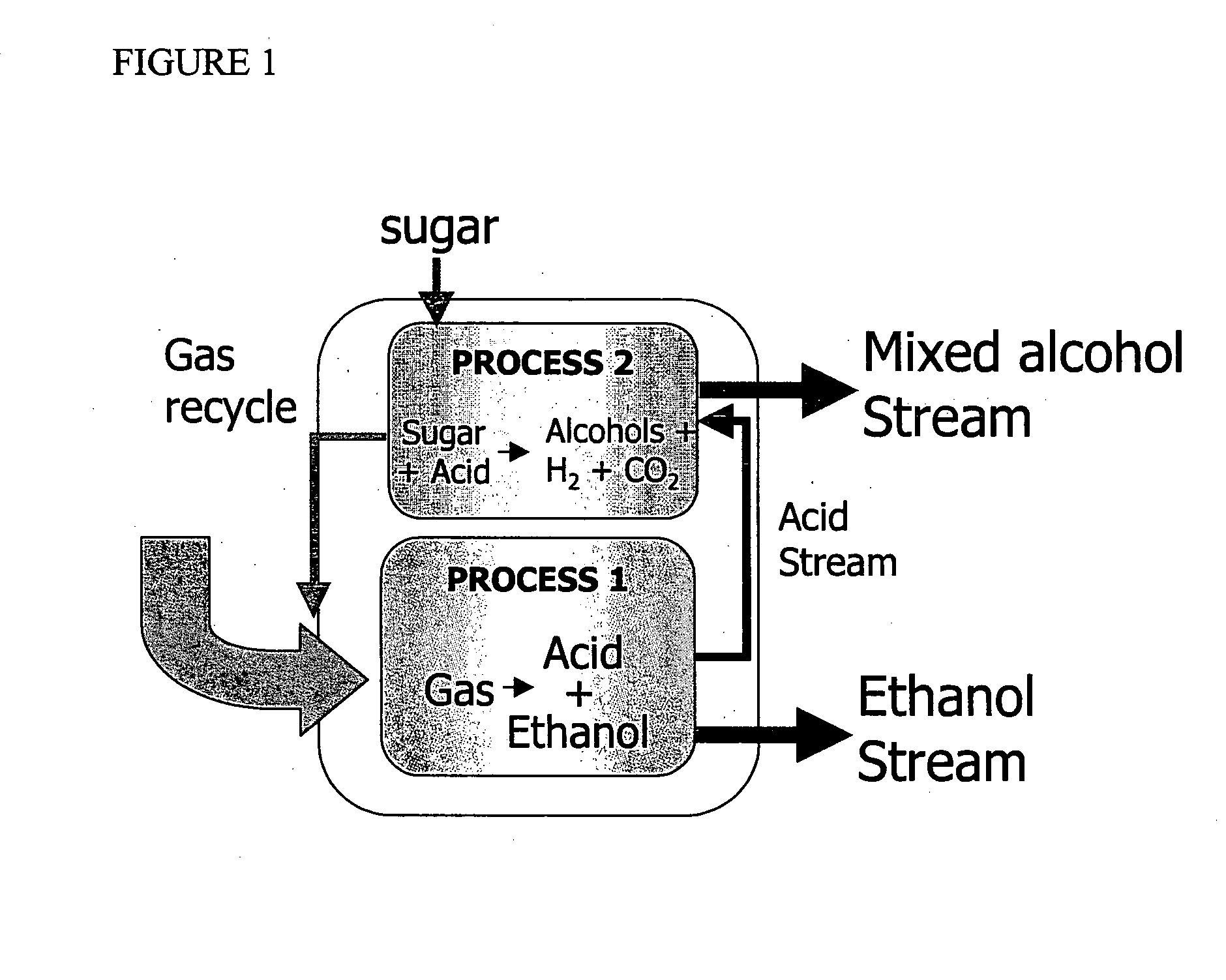

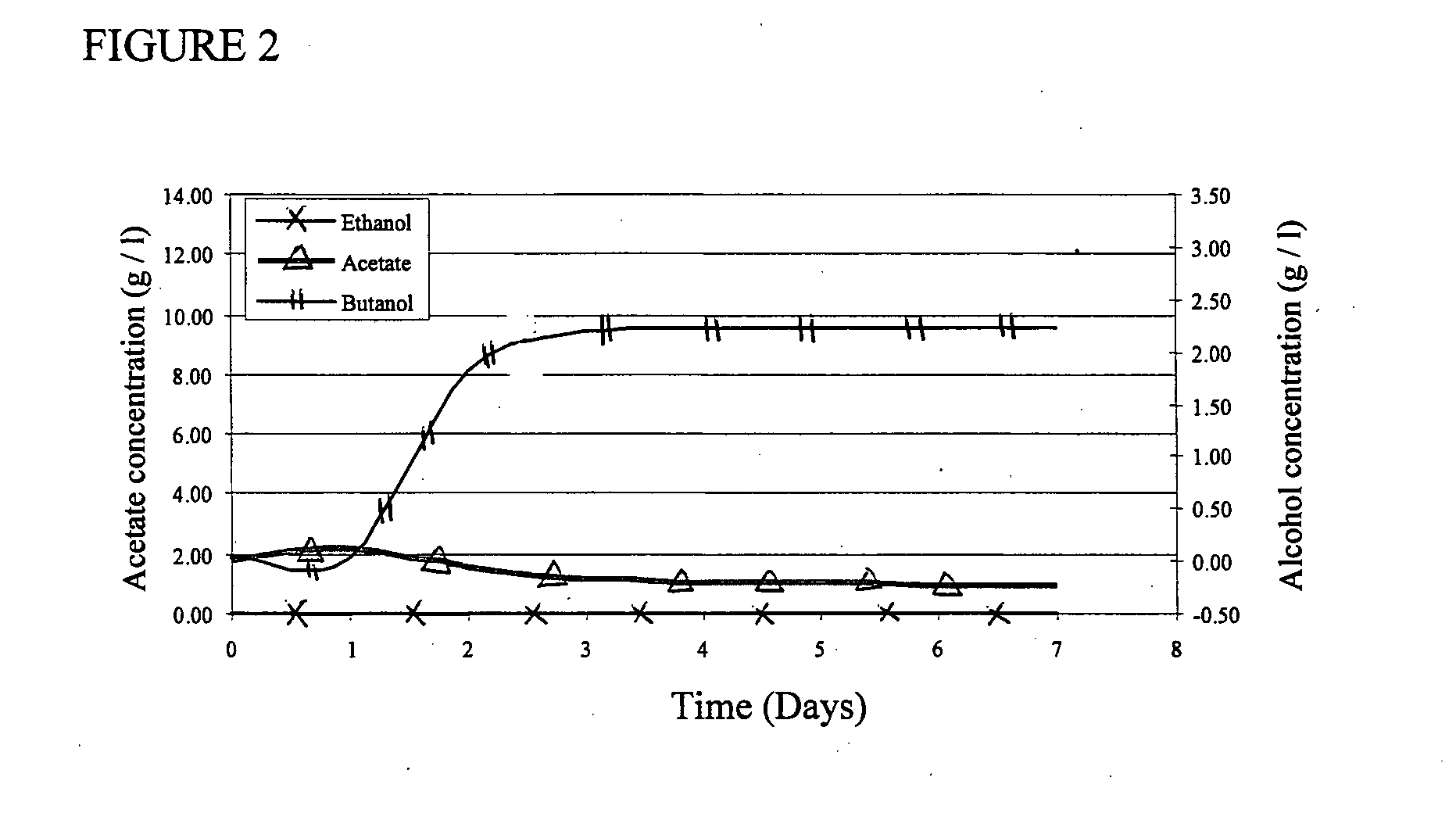

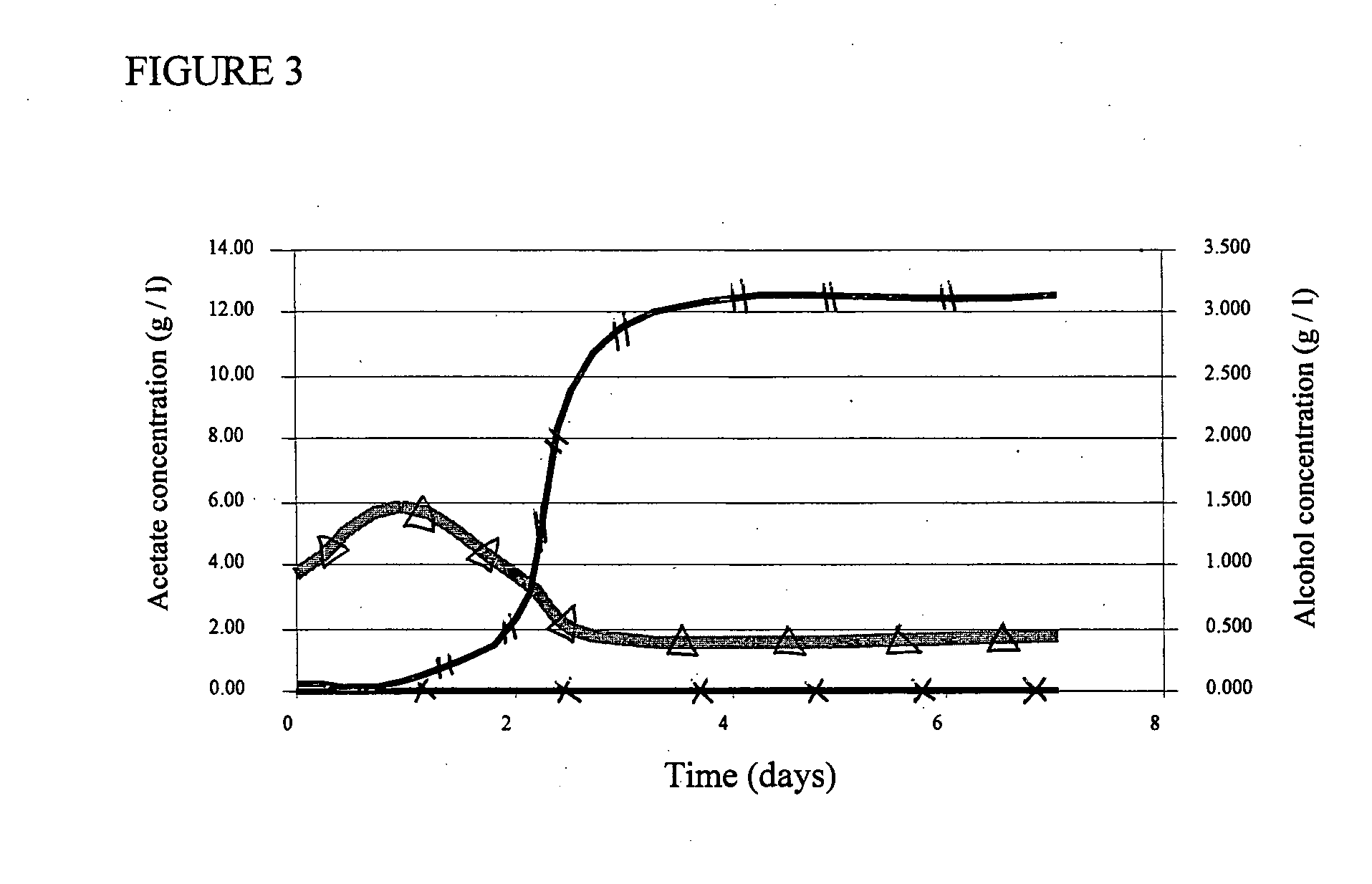

The invention relates to biological processes for producing one or more desired products, including alcohols such as ethanol and butanol. The processes comprise carrying out first and second fermentations of substrates in first and second bioreactors, wherein each fermentation produces one or more desired products and / or one or more by-products that can be utilised in the other fermentation. A product and / or by-product of the first fermentation is introduced to the second bioreactor during the fermentation, and a product and / or by-product of the second fermentation is introduced to the first bioreactor during the fermentation.

Owner:LANZATECH NZ INC

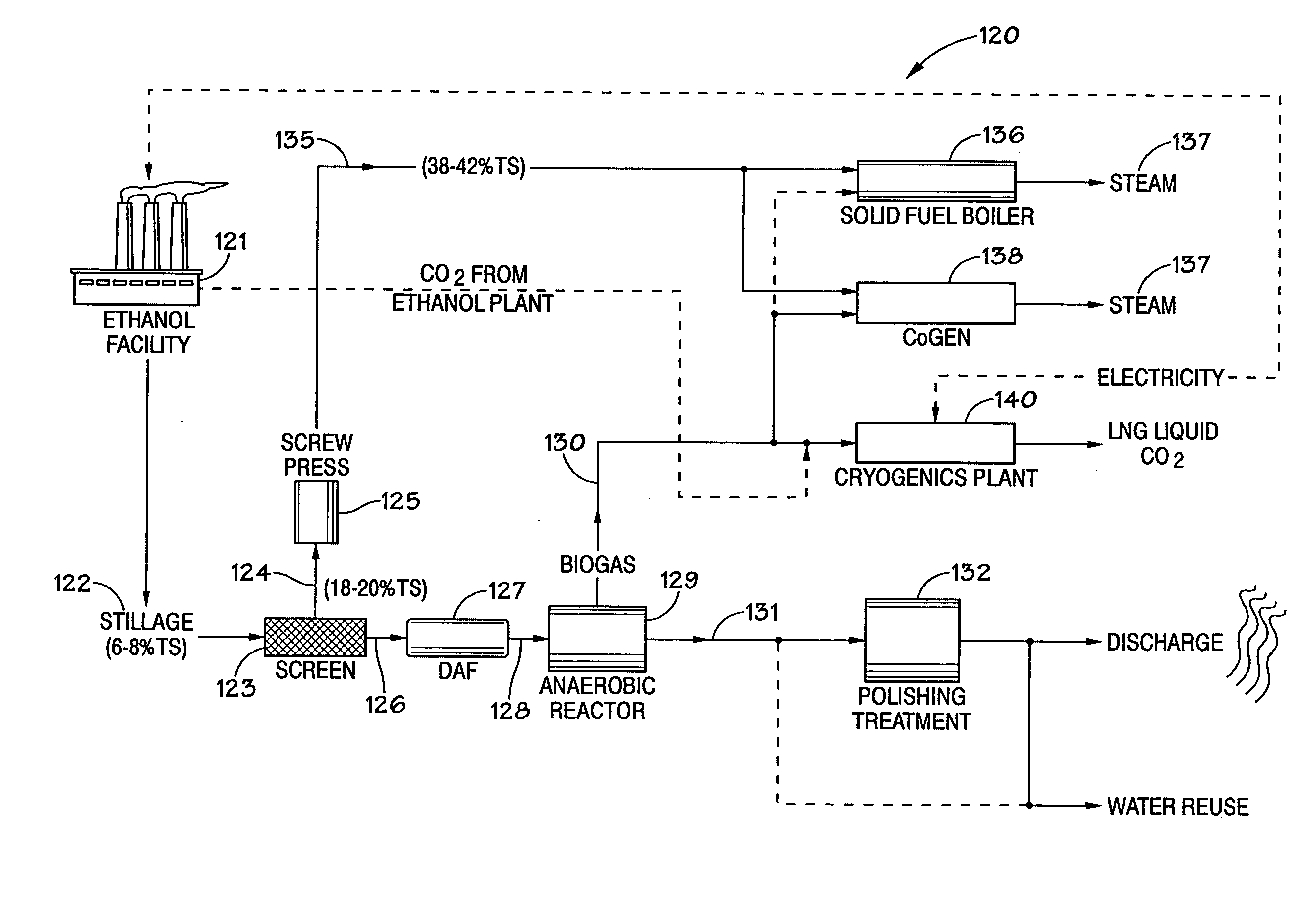

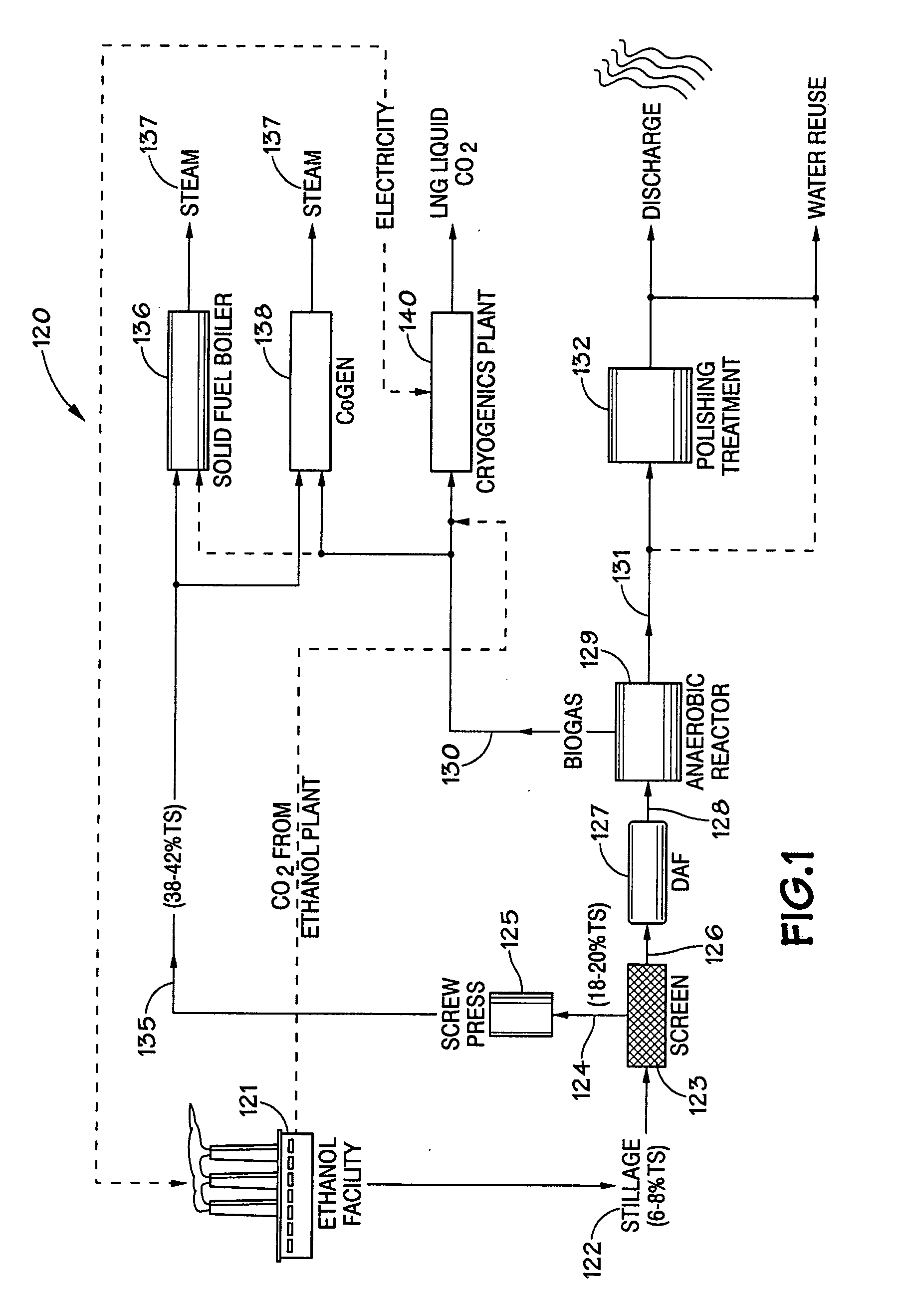

Method and apparatus for the treatment of byproducts from ethanol and spirits production

A method and system for the treatment of byproducts from the production of ethanol or alcohol spirits may include: a screw press to dewater the byproducts to produce a wet cake product and a filtrate product; and an anaerobic reactor to treat to filtrate product.

Owner:ECOVATION

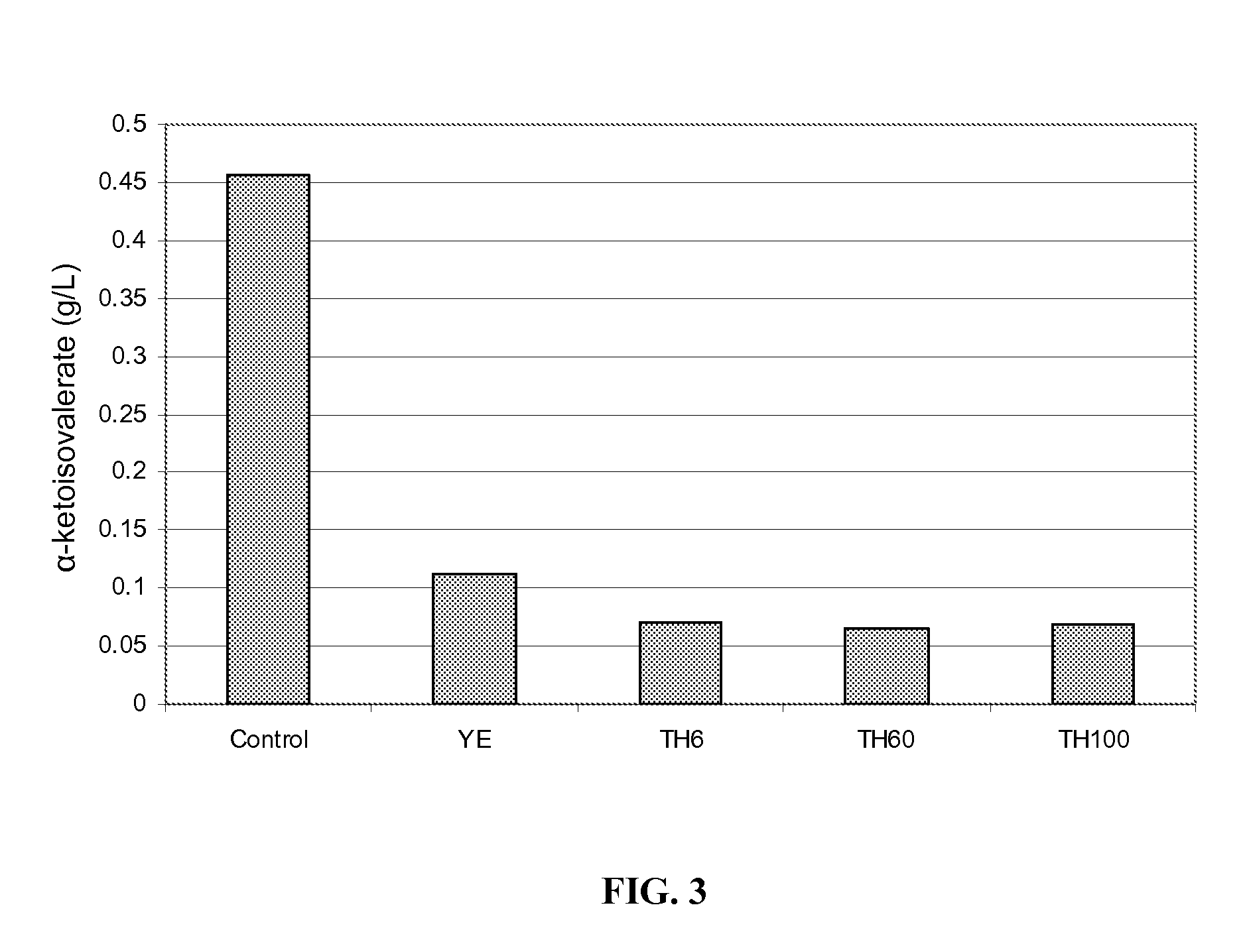

Acetate supplemention of medium for butanologens

The invention relates to the fields of industrial microbiology and alcohol production. More specifically, the invention relates to improved production of butanol isomers by recombinant microorganisms containing an engineered butanol pathway and disrupted activity of the genes in pathways for the production of by-products during the fermentation when the microorganisms are grown in a fermentation medium containing acetate. In embodiments, recombinant microorganisms have an increased growth rate in a fermentation medium containing acetate as a C2 supplement.

Owner:GEVO INC

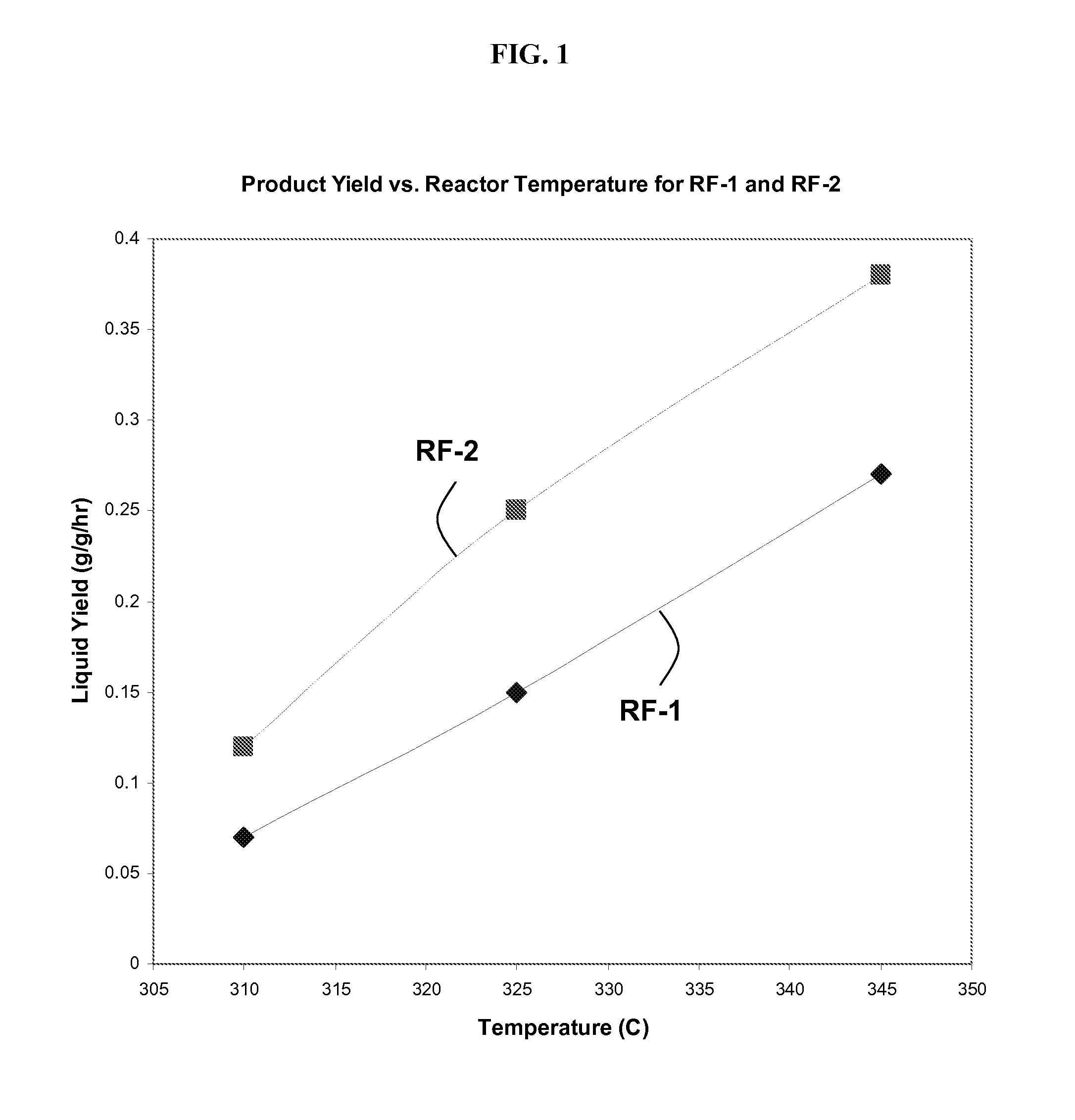

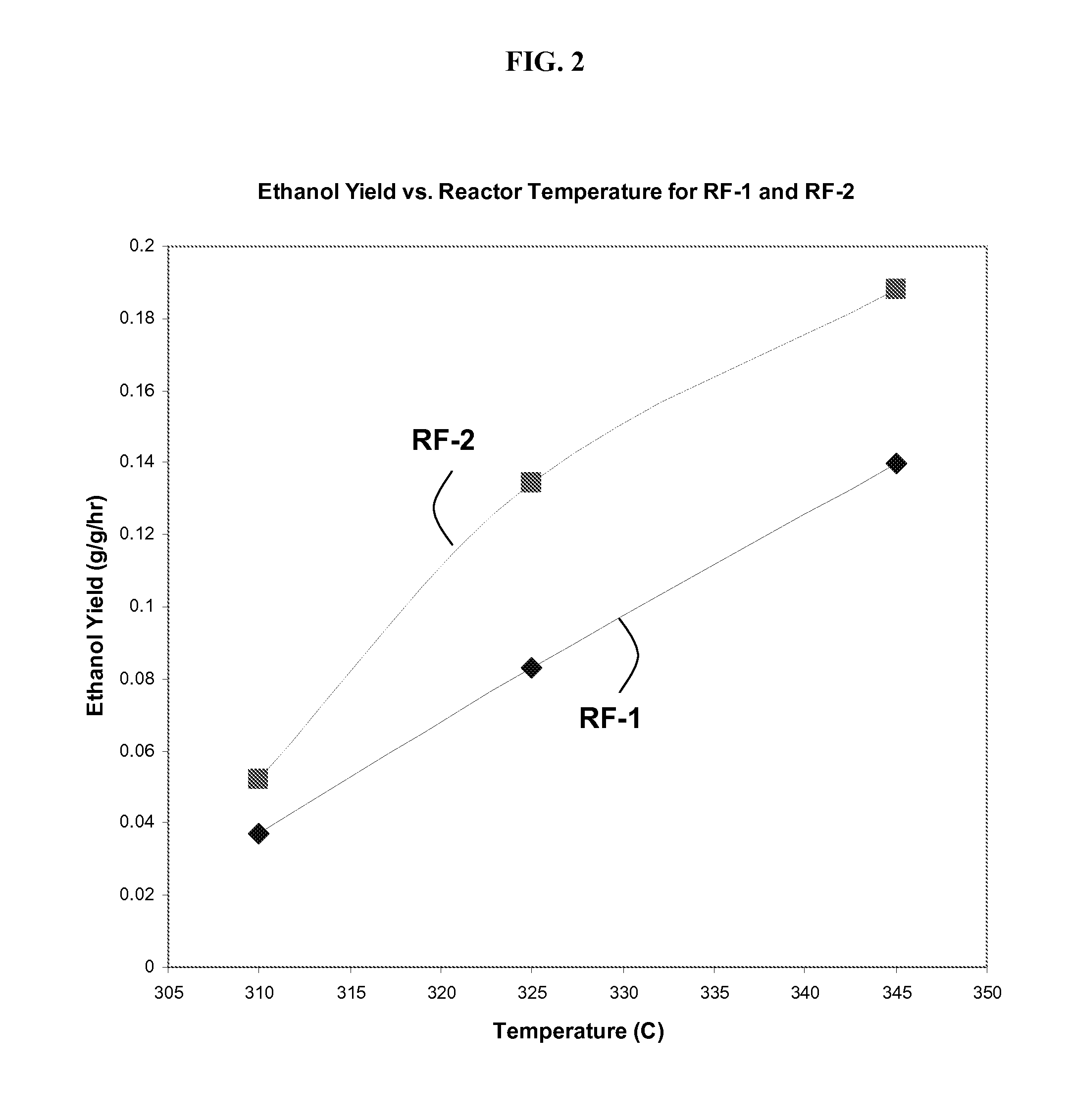

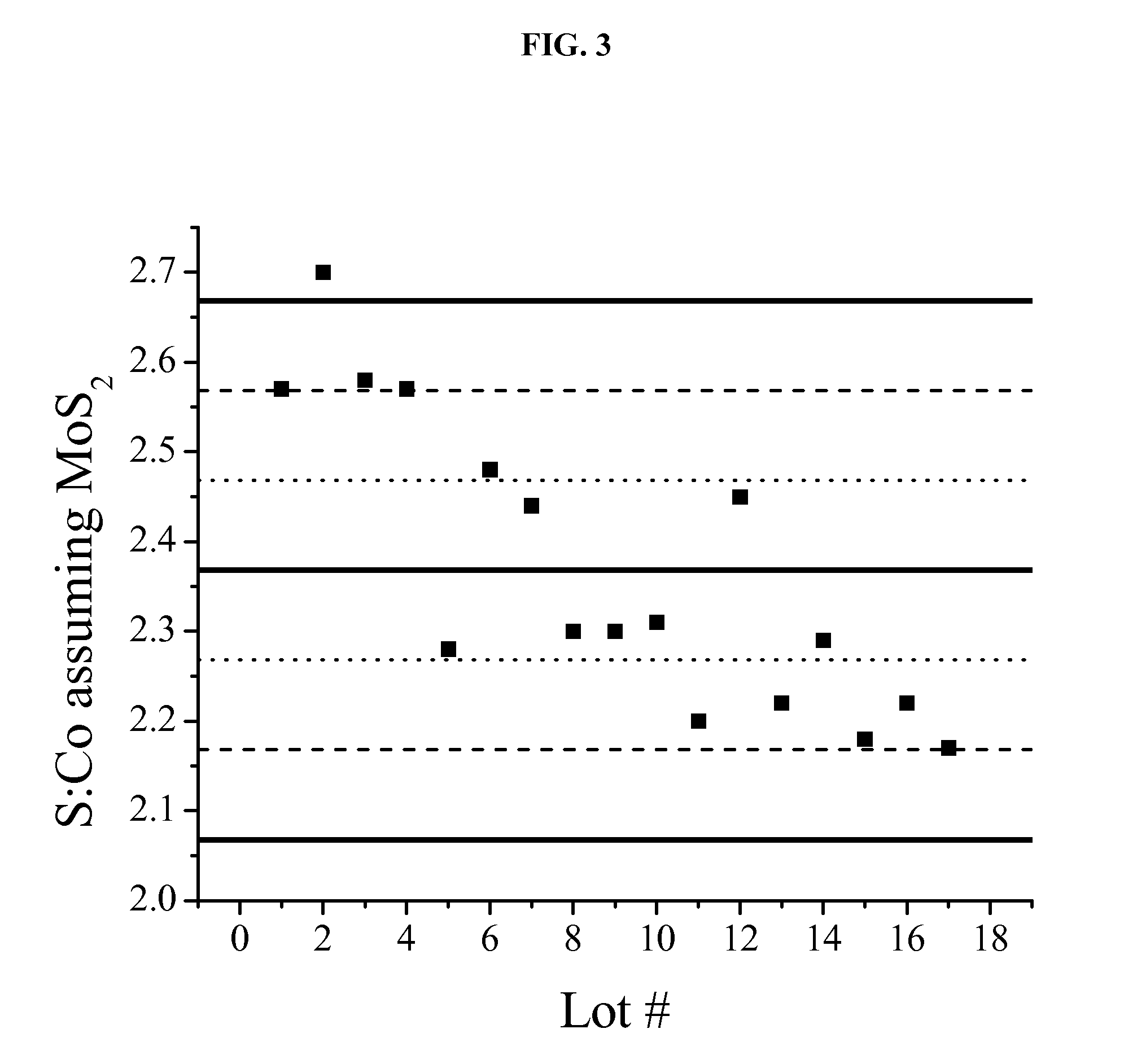

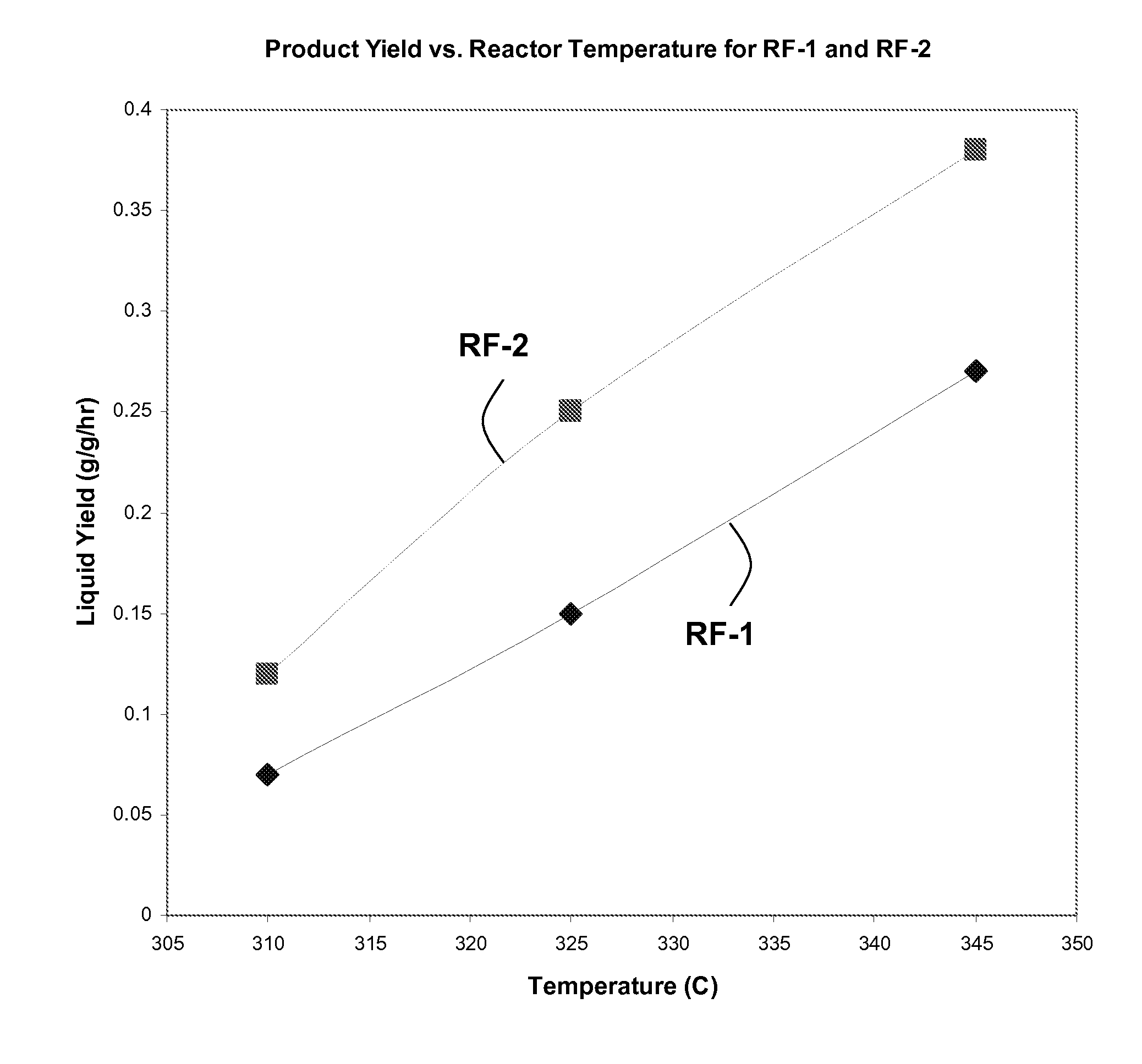

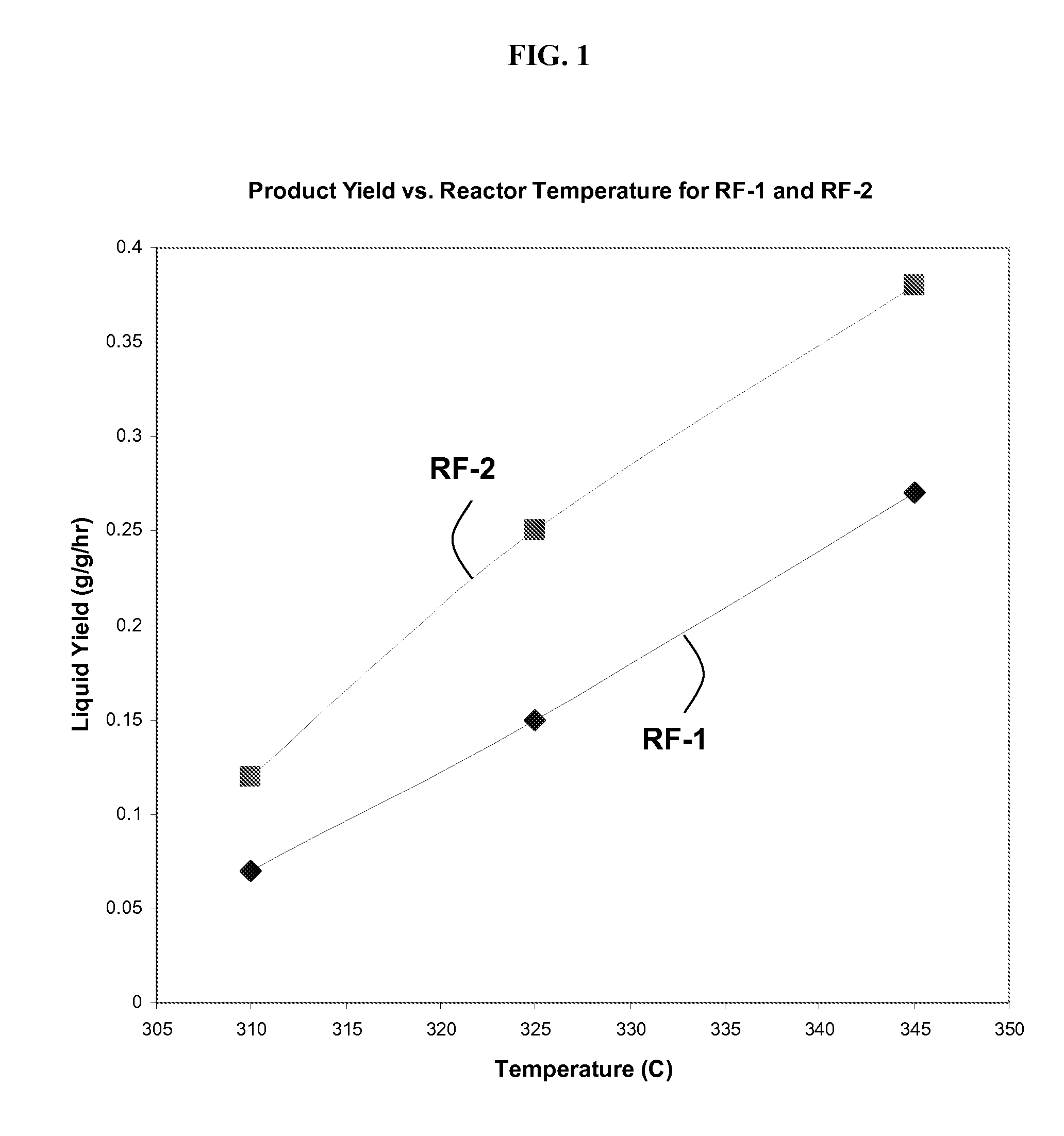

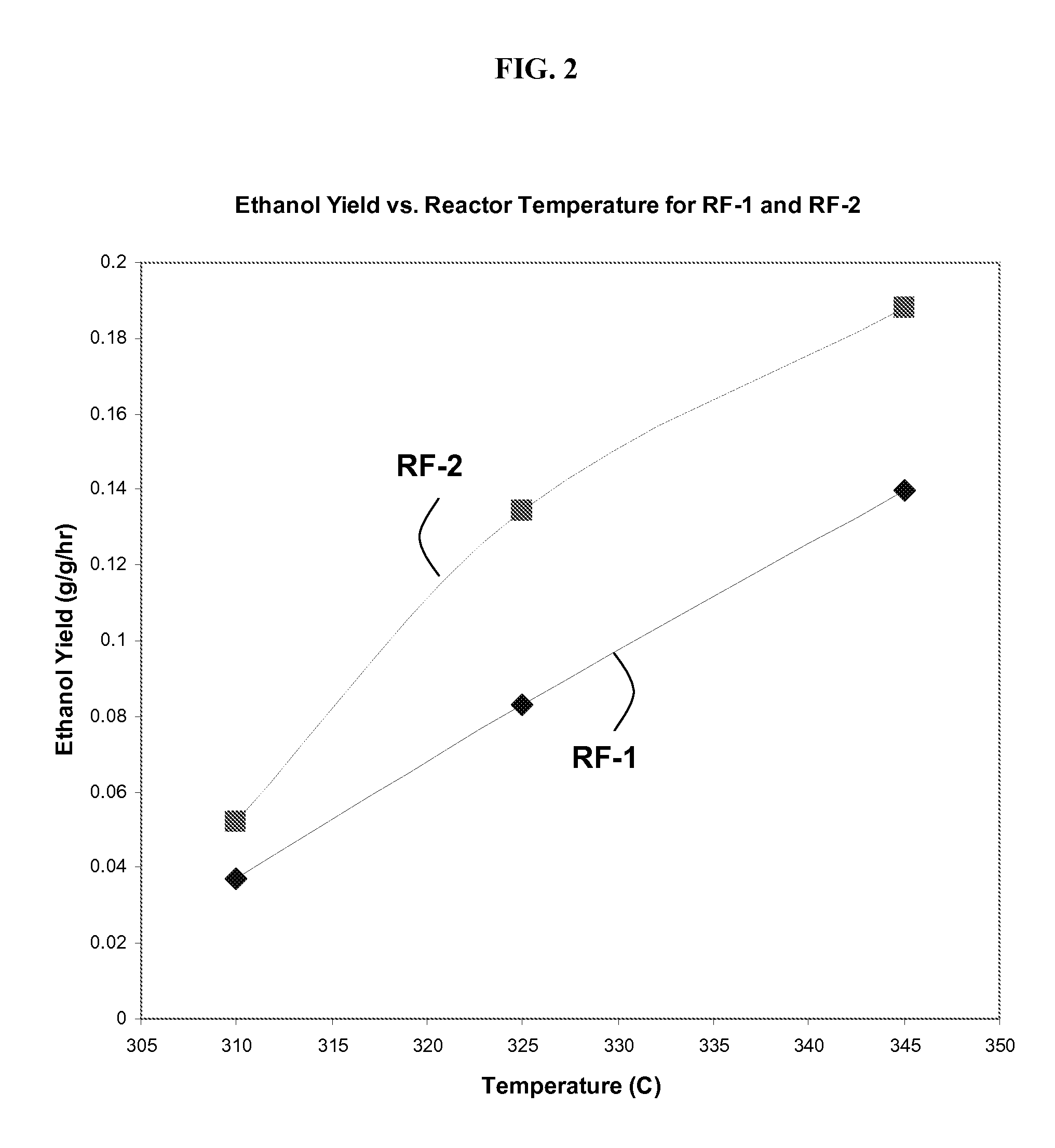

Cobalt-molybdenum sulfide catalyst materials and methods for stable alcohol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalysts, and methods of using the catalysts including techniques to maintain catalyst stability. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur, and avoid metal carbides both initially and during reactor operation.

Owner:ALBEMARLE CORP

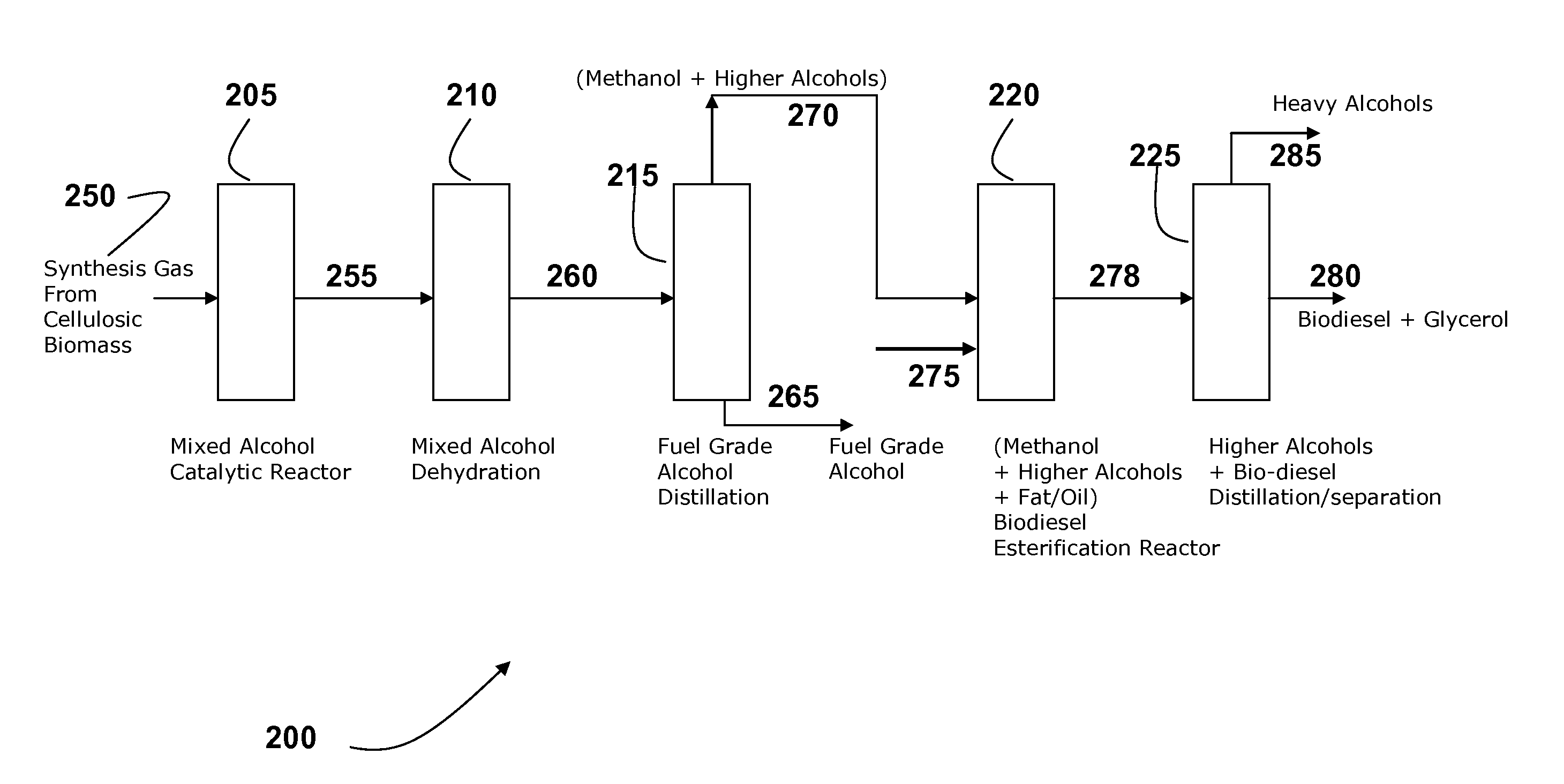

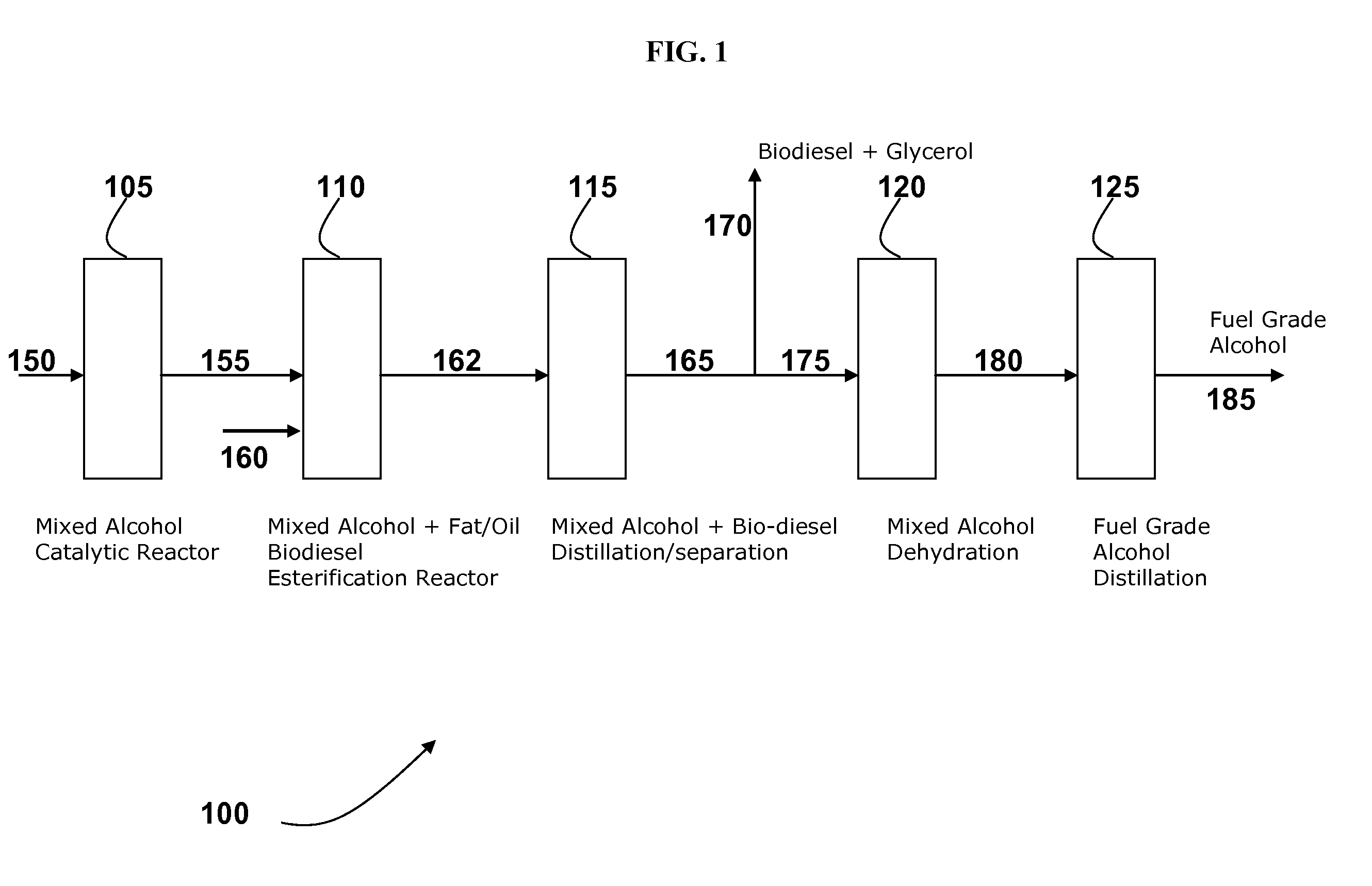

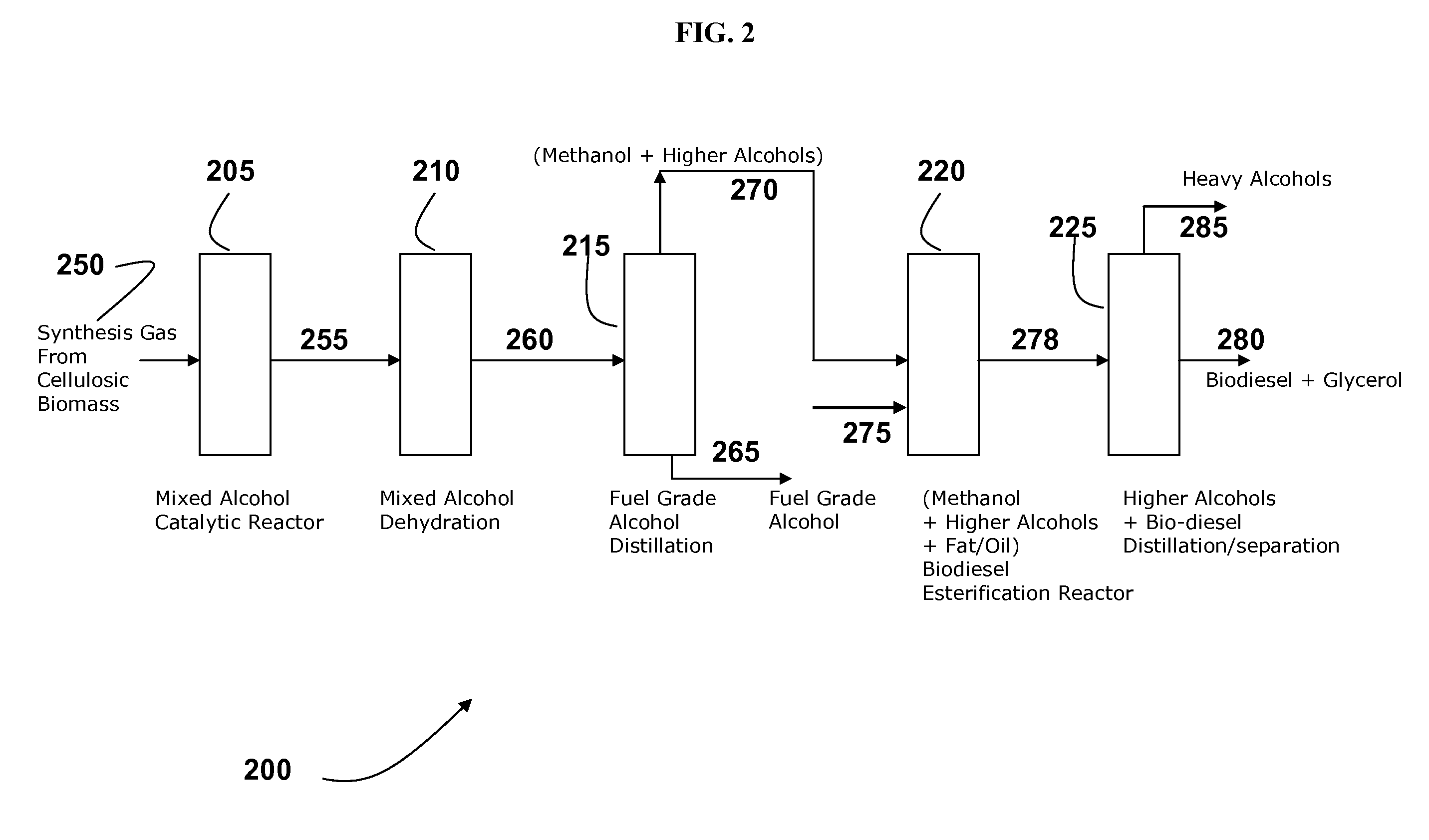

Process for combined biodiesel and alcohol production, and fuel compositions produced therefrom

InactiveUS20100212220A1Fatty acid esterificationFatty acids production/refiningBiodieselAlcohol production

Improvements to biodiesel compositions, and methods for making those compositions more efficiently, are provided. Some variations of this invention provide processes for producing biodiesel and at least one C1-C4 alcohol, such as ethanol. Other variations provide certain biodiesel compositions containing C2+ alkyl esters. In some embodiments, biodiesel compositions are produced entirely from renewable resources.

Owner:ALBEMARLE CORP

Cobalt-molybdenum sulfide catalyst materials and methods for stable alcohol production from syngas

ActiveUS20100210741A1Inhibition formationReduce conversionChemical analysis using catalysisOrganic compound preparationSyngasSulfur

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalysts, and methods of using the catalysts including techniques to maintain catalyst stability. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur, and avoid metal carbides both initially and during reactor operation.

Owner:ALBEMARLE CORP

System and method for isolation of gluten as a co-product of ethanol production

The present invention is a method for protein isolation as a co-product of alcohol production. The method includes receiving grain product at a holding receptacle, the grain product being at least one of whole stillage, dried distillers grain, and wet distillers grain. The method further includes directing the grain product from the holding receptacle over a plurality of screens, thereby allowing a fiber-containing portion of the grain product to be collected on the plurality of screens and further allowing a protein-containing portion of the grain product and an oil-containing portion of the grain product to pass through the plurality of screens. The method further includes directing the protein-containing portion and the oil-containing portion over a finishing screen, thereby allowing remaining fiber fractions from the protein-containing portion and the oil-containing portion to be collected on the finishing screen and further allowing the protein-containing portion and the oil-containing portion to pass through the finishing screen. Further, the method includes centrifuging the protein-containing portion and the oil-containing portion for isolating a protein fraction, an oil fraction, and a water and minerals fraction.

Owner:VALICOR SEPARATION TECH

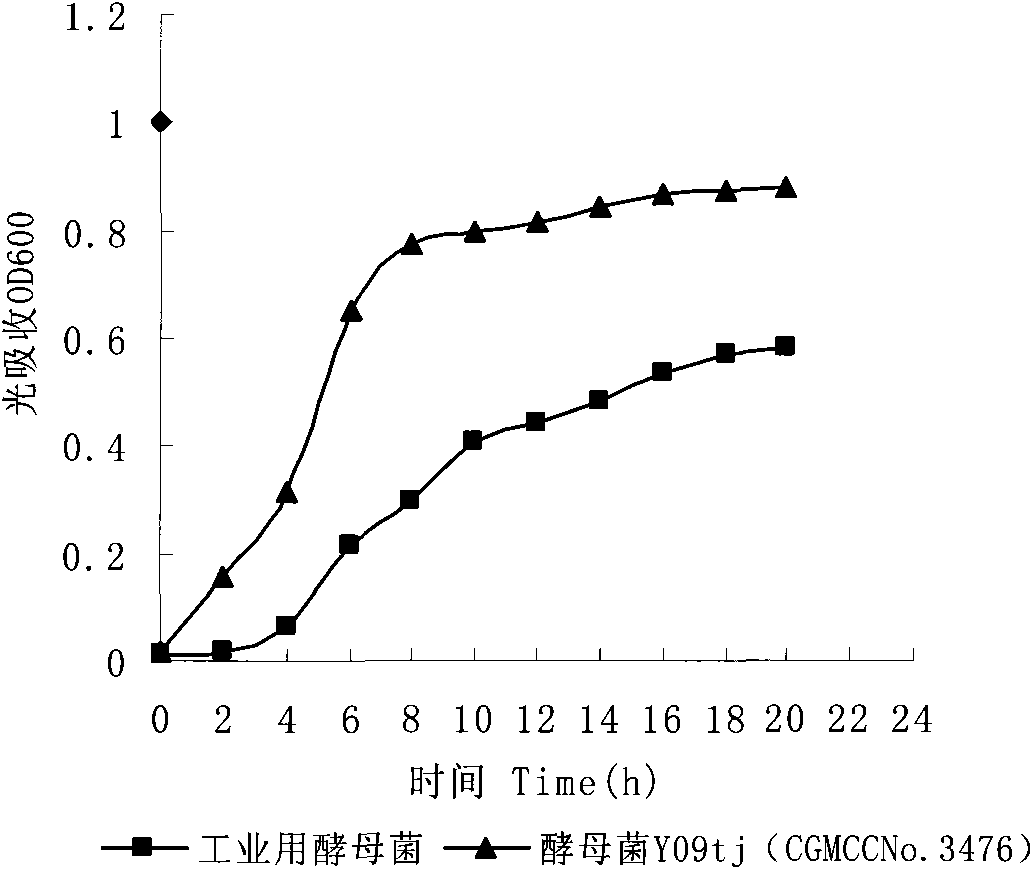

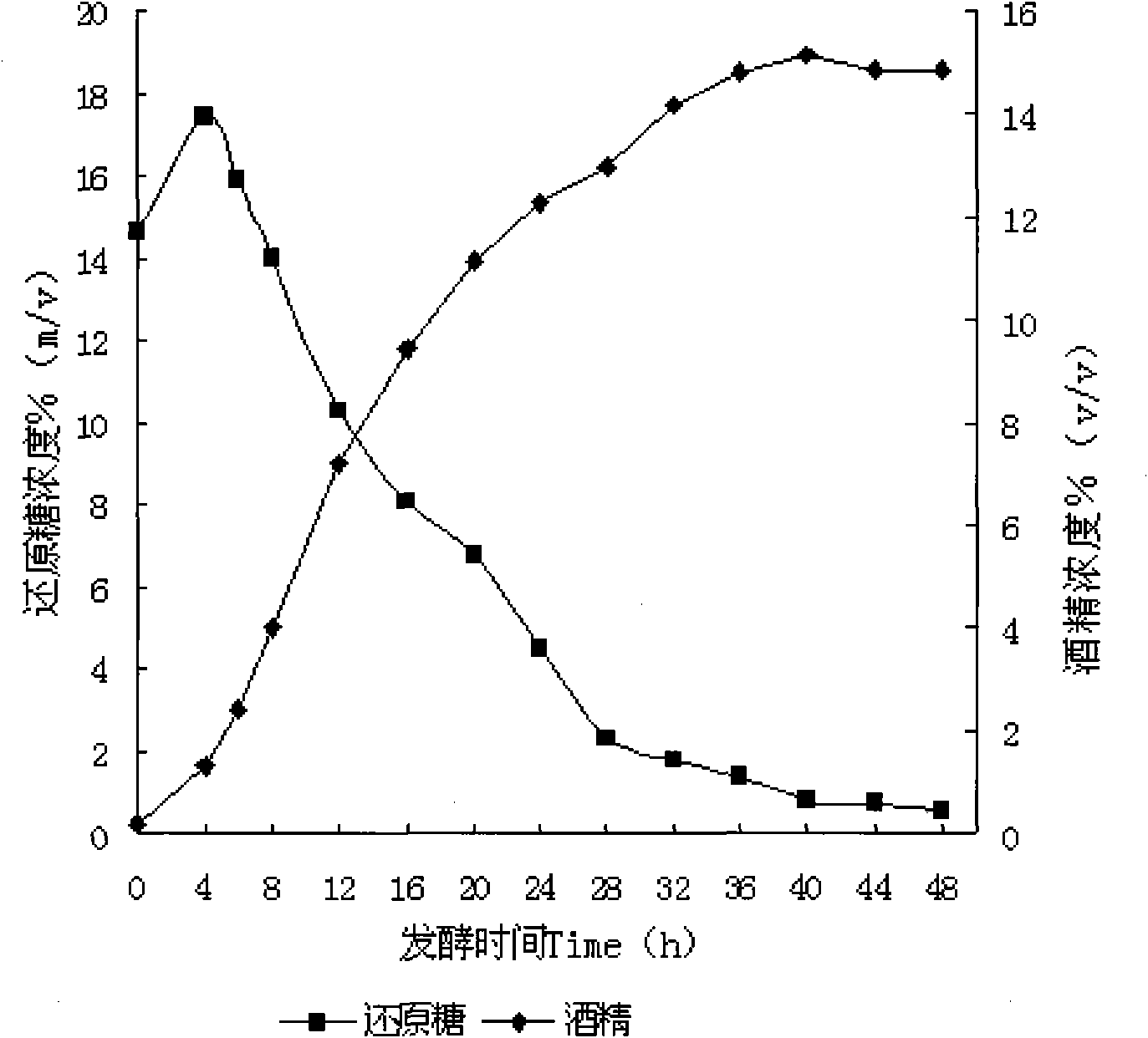

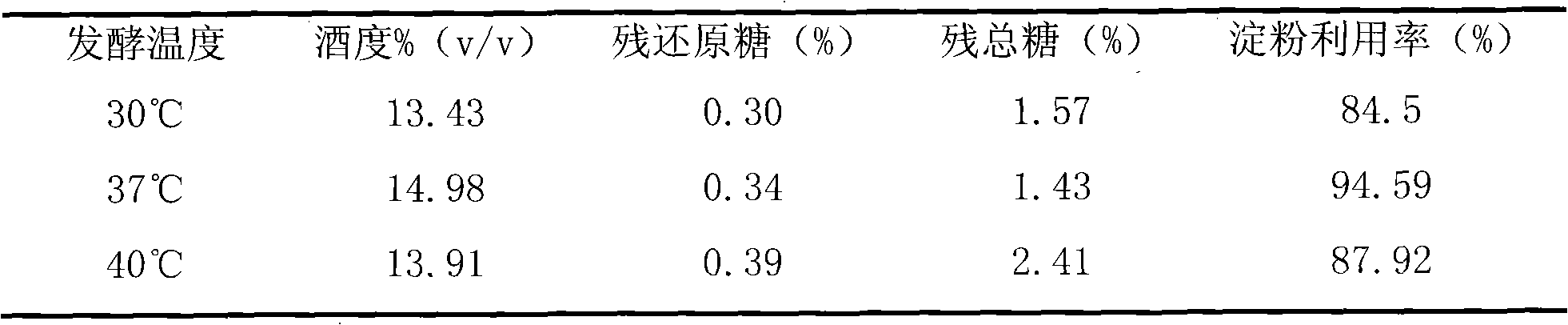

Brewing yeast strain, breeding method thereof, and application of the strain in alcohol production

InactiveCN101845404AWide growth temperature rangeGuaranteed normal fermentationFungiMutant preparationConcentrations glucoseAlcohol production

The invention discloses a brewing yeast strain, which has the classified name Saccharomyces cerevisiae Y09tj, and is preserved in Common Microorganism Center of China General Microbiological Culture Collection Center with the preservation number of CGMCC No.3476. The invention also provides a breeding method for the strain and a method for producing ethanol by quick high-temperature thick mash fermentation of starch. The strain is obtained by the following steps of: separating from common self-brewed sweet wine of peasant families; and performing ultraviolet mutagenesis for breeding. The brewing yeast strain CGMCC NO.3476 has the advantages of quick growth, strong fermentation capacity, high ethanol toxin resistance, and high-glucose concentration resistance of 62 percent (m / v) to the maximum. The average wine yield by the method is improved by 1.2 percent than that of other producing strains, and the wine yield can reach 16.0 percent (v / v); the fermentation period is short, and only 46 hours; the equipment utilization rate can be greatly improved; and the fermentation cost is greatly reduced.

Owner:GUANGXI ACAD OF SCI

Production of alcohol from mixed bacterial population degradable fermented bastose substance

InactiveCN1896254AReduce degradationShorten the fermentation cycleBiofuelsMicroorganism based processesAlcohol productionCellulose degradation

Production of alcohol from mixed microbial pool degradable and fermented lignocellulose substance is carried out by crushing lignocellulose substance, soaking with H2SO4, bursting by steam, solid-liquid separating, adding nutritive liquid into solid-phase substance, sterilizing, adding distiller's yeast and cellulose degrading microbe into saccharifying fermentative substrate, degradation saccharifying-fermenting synchronously, distilling and rectifying to obtain final product. It is simple, has short saccharifying and fermenting period, higher raw material utilization rate and more alcohol yield and no feedback inhibition function.

Owner:HARBIN INST OF TECH

Use of superheated steam dryers in an alcohol distillation plant

InactiveUS20110108409A1Efficient use of energyLow costFermented solutions distillation/rectificationUsing liquid separation agentAlcohol productionFractionating column

The present invention is for the production of fuel grade alcohol, specifically ethanol. A steam dryer is used to dry the solid byproduct into usable animal feed. The steam dryer typically contains less than 6% air in its exhaust stream is directed to the bottoms of one or more distillation columns to heat the distillation column and scrub the exhaust stream simultaneously. The elimination of a thermal oxidizer and the efficient use of the energy in the exhaust stream provide considerable cost savings for an alcohol production plant.

Owner:BROWN CHRISTOPHER J

High-purity isomaltose hypgather and alcohol co-production preparation method

ActiveCN101805767AImprove qualityIncrease valueBiofuelsMicroorganism based processesGlucose highFood industry

The invention belongs to the field of food industries and discloses a high-purity isomaltose hypgather and alcohol co-production preparation method. The method comprises the following steps of: preparing high-purity glucose higher than 95 percent by compounding diastatic enzymes; through diastatic enzyme conversion, fermenting by using dry activity yeast to prepare superhigh-purity isomaltose hypgather (the total content of isomaltose, panose and isomaltotriose are not less than 70 percent, and the total content of isomaltose hypgather is not less than 90 percent); and meanwhile, co-producingalcohol of 18 percent (the recovery rate is not less than 90 percent). The method can realize the organic combination of the superhigh-purity isomaltose hypgather production and the alcohol production and has novel process, excellent product quality, reduced cost, economy and practicability.

Owner:BAOLINGBAO BIOLOGY

Novel technique for producing manioc waste ethanol

InactiveCN101195836ASolve the use problemImprove stabilityBiofuelsFermentationAlcohol productionSlurry

The invention discloses a new cassava dreg alcohol production technology. The new production technology is characterized in that cassava dregs are separated from raw cassava or cassava dry plates to be separately performed steam boiling and saccharification, the dregs and water separation is performed to the cassava dregs after being saccharified, solid dregs are directly pulled out to be used as forage or fertilizer, and the filtrate of the cassava dregs saccharifing is used as the slurry-adjusting liquid of the raw cassava or the cassava dry plates. The production cycle of the method is short, the energy consumption is low, the operation is simple, and the product stability is high. The problem that the energy consumption of producing the cassava dregs alcohol is high and the pollution is serious are effectively solved, the economic efficiency of the cassava dregs is enhanced, the problem of the utilizing of the present cassava dreg wastes is solved, and the economic efficiency of cassava grain distilleries is enhanced.

Owner:广西农垦明阳生化有限公司

Methods of making improved cobalt-molybdenum-sulfide catalyst compositions for higher alcohol synthesis

InactiveUS20100331581A1Organic compound preparationHeterogenous catalyst chemical elementsAlcohol productionAlcohol synthesis

This invention improves prior methods of making cobalt-molybdenum-sulfide catalysts for alcohol production from syngas. In one aspect, improved methods are provided for making preferred cobalt-molybdenum-sulfide compositions. In another aspect, processes utilizing these catalysts for producing at least one C1-C4 alcohol, such as ethanol, from syngas are described.

Owner:ALBEMARLE CORP

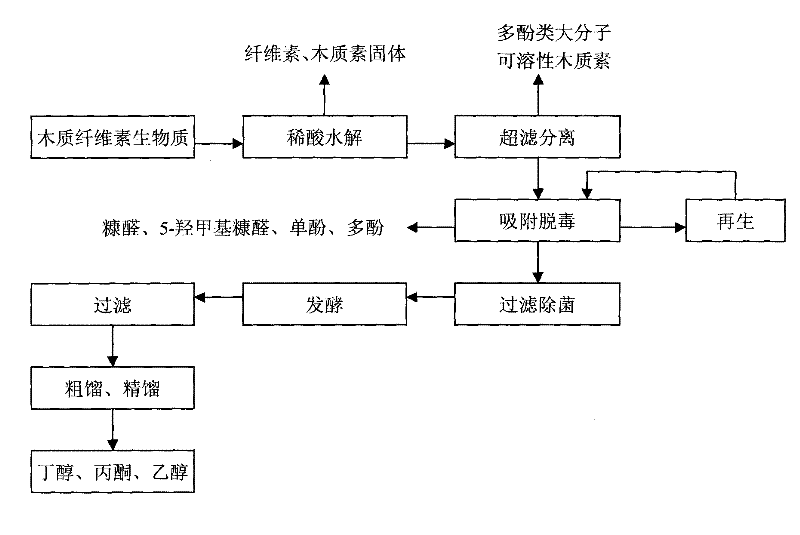

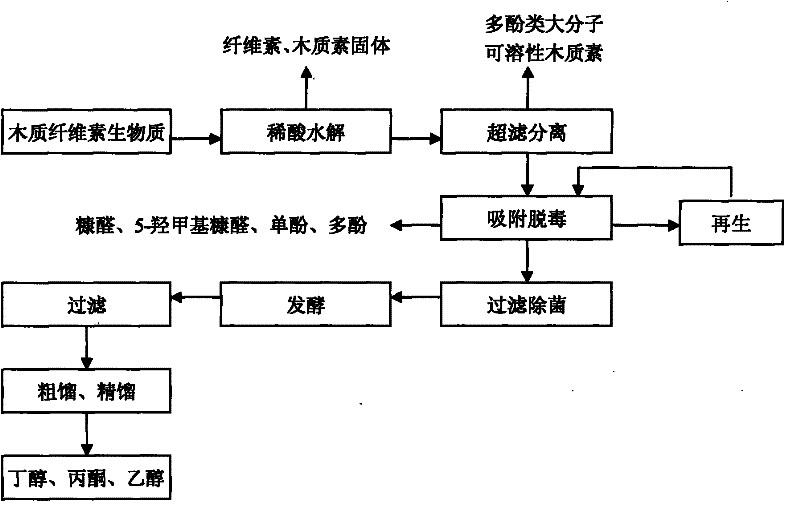

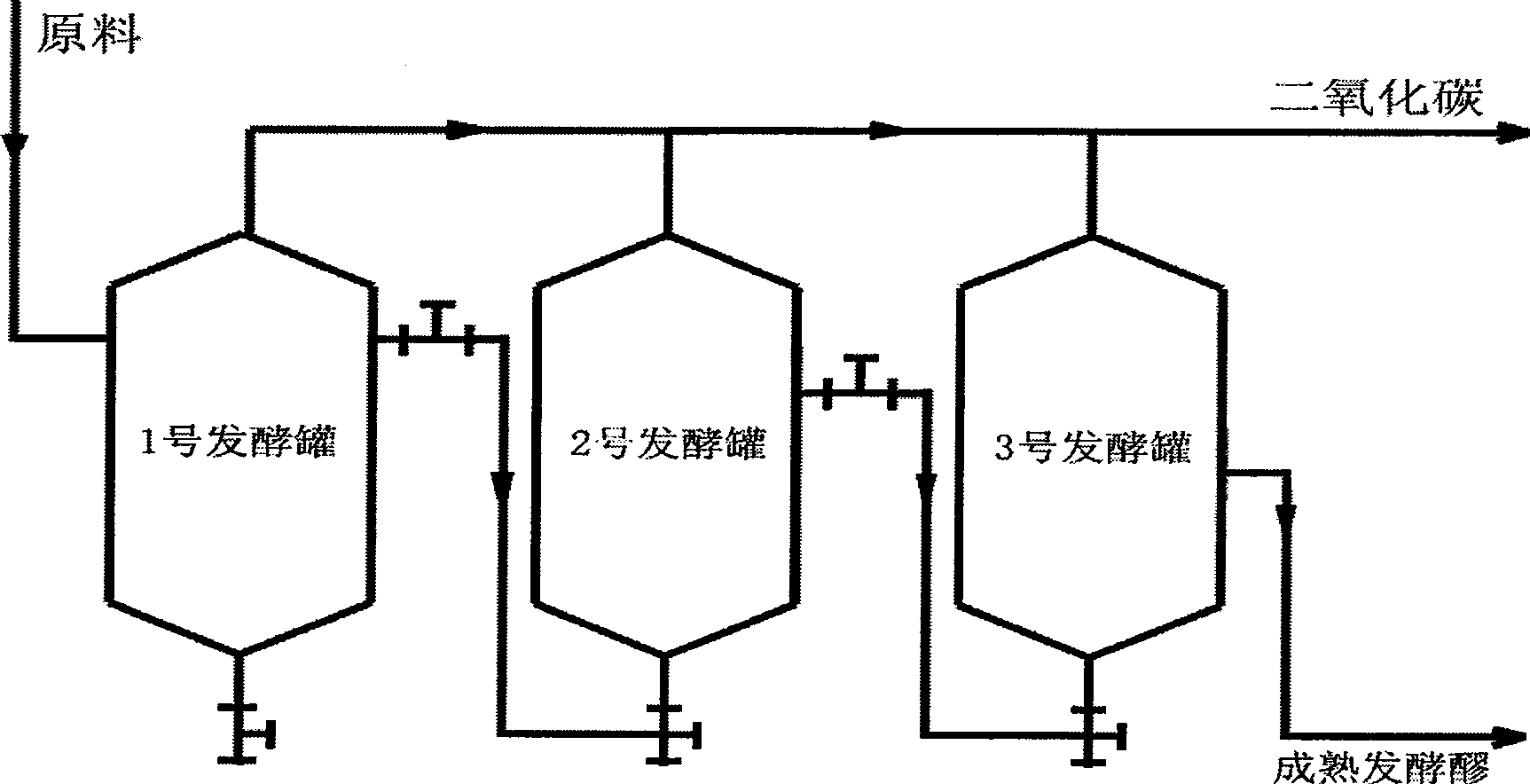

Method for fermenting and preparing biological butyl alcohol by using lignocellulose biomass as raw material

InactiveCN101748158AAvoid it happening againAvoid pollutionBiofuelsMicroorganism based processesAlcohol productionAdsorption separation

The invention discloses a method for fermenting and preparing biological butyl alcohol by using lignocellulose biomass as raw material. Dilute acid is used to hydrolyze lignocellulose biomass to prepare multi-component sugar solution; detoxication treatment and sterilization treatment are conducted to the multi-component sugar solution through membrane separation method and adsorption separation method, sterilization treatment is conducted to the multi-component sugar solution through the membrane separation method, then sterilization treatment is conducted to fermentation culture medium containing no carbon source under high temperature, and finally the sterilized multi-component sugar solution and the sterilized fermentation culture medium containing no carbon source are combined together to prepare fermentation culture medium; butyl alcohol production strains are inoculated in the fermentation culture medium and biological butyl alcohol is prepared through fermentation; and solid-liquid separation treatment is conducted to the fermented liquid and the liquid is distilled to obtain butyl alcohol, acetone and ethyl alcohol. The invention solves the problems of 'striving for grains with people and striving for land with grains' and high raw material cost existing in the traditional butyl alcohol fermentation and production method, and realizes the multiple utilization of lignocellulose biomass.

Owner:NANJING UNIV OF TECH

Wine brewing yeast strain and method for producing ethanol by efficient sugarcane juice fermentation

InactiveCN101434911AHighlight substantiveSignificant progressFungiBiofuelsFreeze-dryingContinuous flow

The invention relates to an excellent Saccharomyces cerevisiae gxas02 and a method for carrying out scale production of ethanol by utilizing the Saccharomyces cerevisiae gxas02 as a production strain and adopting sugar cane juice as a raw material. The strain is vacuum freeze-dried and collected in China Center for Type Culture Collection with the collection No. of CCTCC NO: M208110, the collection date is July 19, 2008, the strain is the Saccharomyces cerevisiae by identification, the strain is applicable to fermenting the ethanol by using the sugar cane juice, with fast speed, low residual sugar content, high temperature resistance and alcohol resistance. A production technology adopts a single concentration continuous flow processing technology, the sugar cane juice which is pressed but not concentrated or diluted is directly fermented under the conditions without using yeast reuse and fixed yeast technology, the continuous operation is carried out on a production line with daily production capacity of 10 tons of the ethanol, the effect is good, the fermentation time is 12-16h, alcohol degree reaches 8.6-9.4(V / V) and the residual sugar is 0.2-0.3g / 100ml. The invention is characterized by convenient implementation, high equipment utilization rate, high ethanol concentration of fermented mash, high sugar utilization rate which is close to the theoretical value, and the like, thereby reducing the costs for producing the ethanol.

Owner:GUANGXI ACAD OF SCI

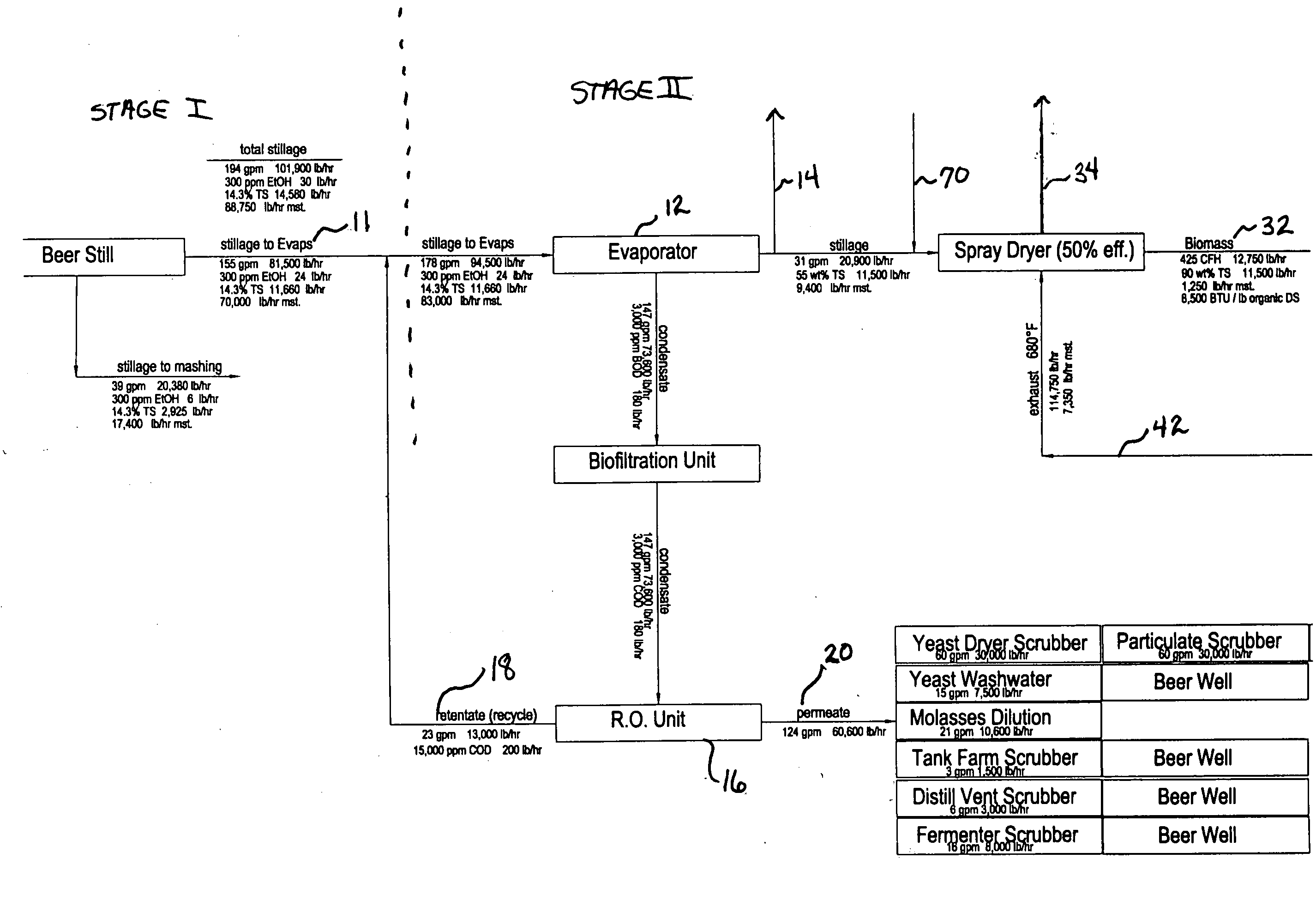

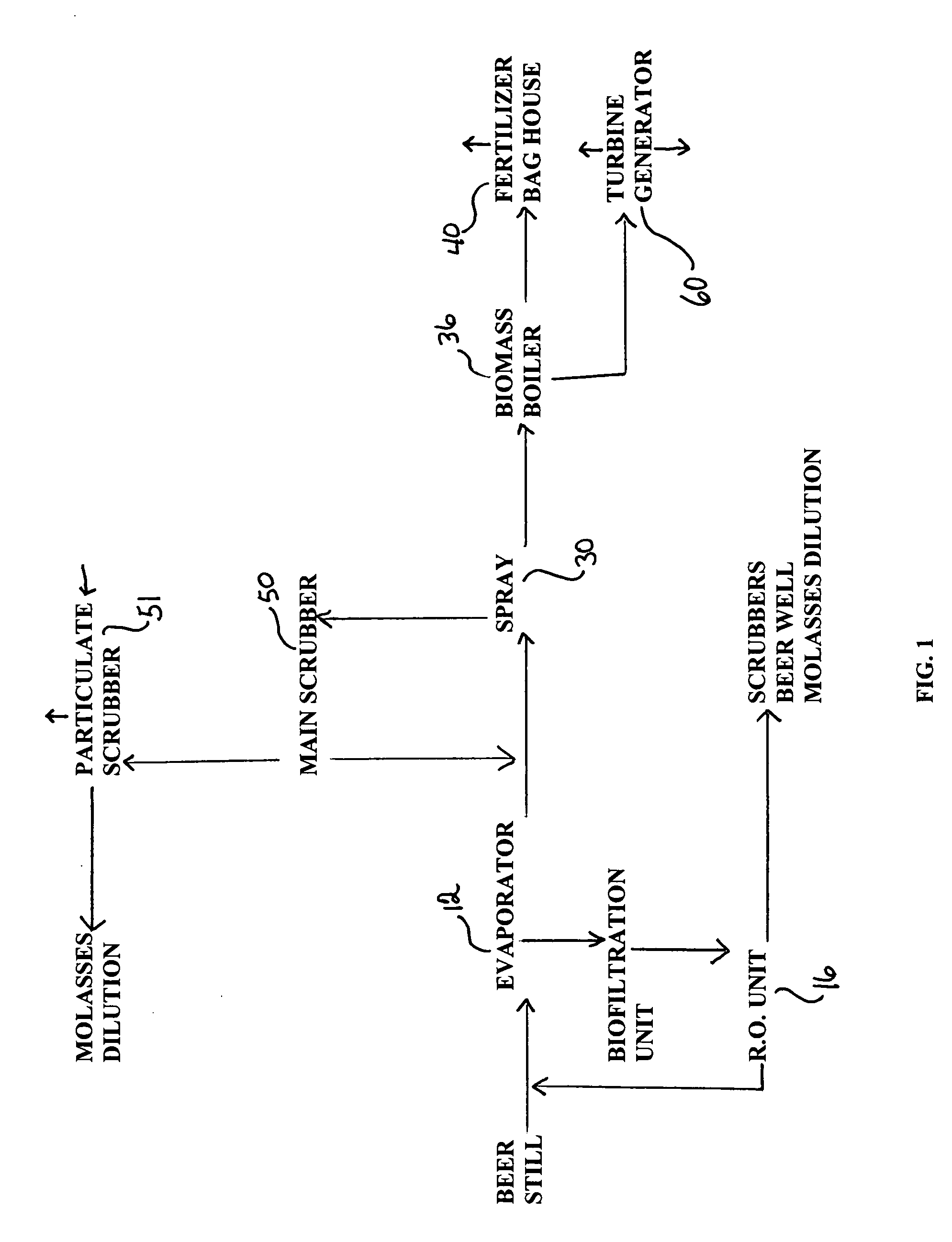

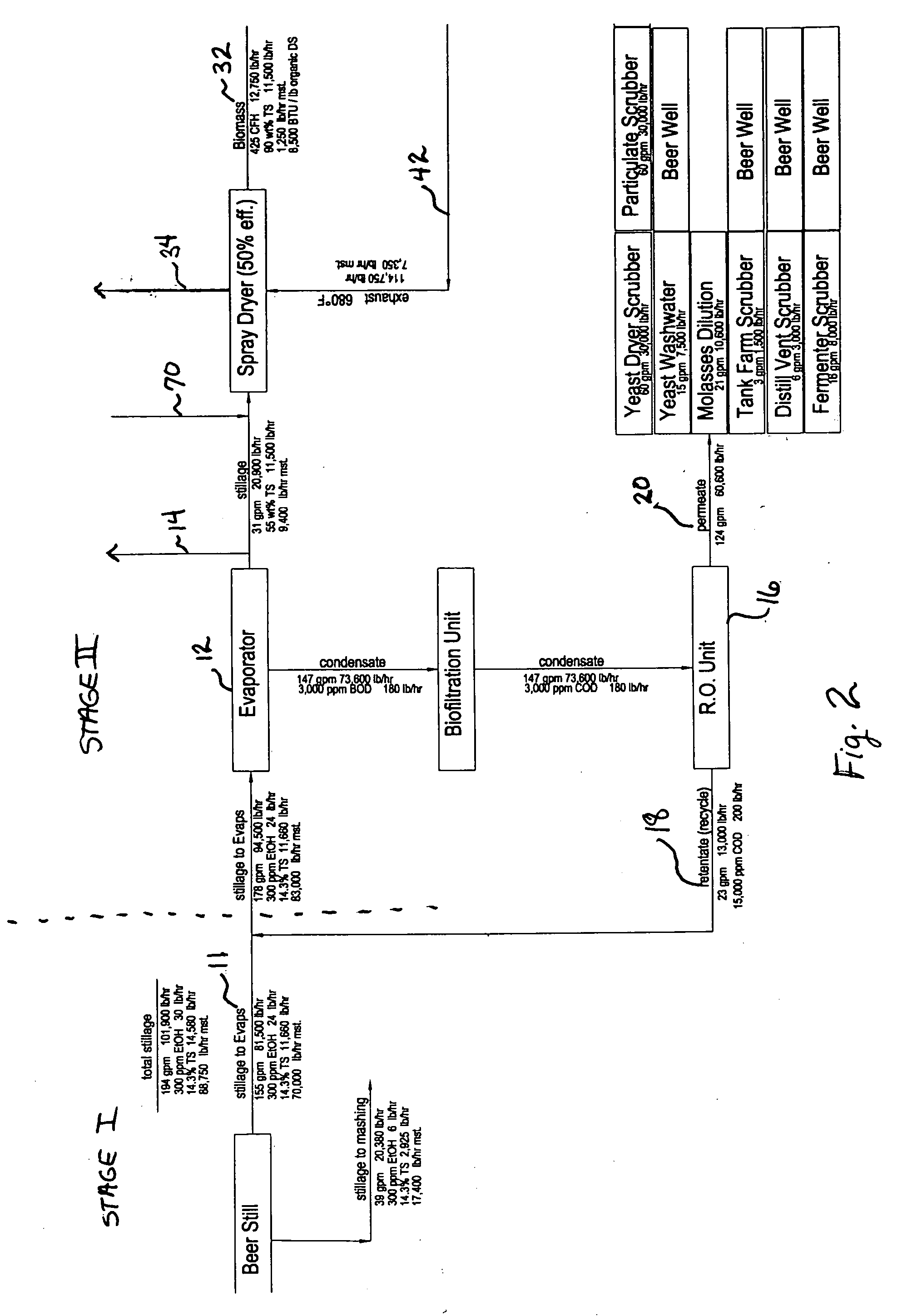

Process and apparatus for reusing energy recovered in alcohol production

A process for producing ethanol wherein stillage is recycled into the process as a source of heat and power. Specifically, stillage is spray dried and then combusted in a biomass boiler. Spray drier exhaust is exported to the main scrubber and employed to extract particulates. Flue gas from the boiler is used to produce high pressure steam and the cooled gas is recycled back to the spray dryer as a heat source. The high pressure steam is used by a turbine generator which in turn produces electric power and low pressure steam both of which are returned to the process. Ash remaining after combustion may be used as a fertilizer.

Owner:HEARTLAND RENEWABLE ENERGY

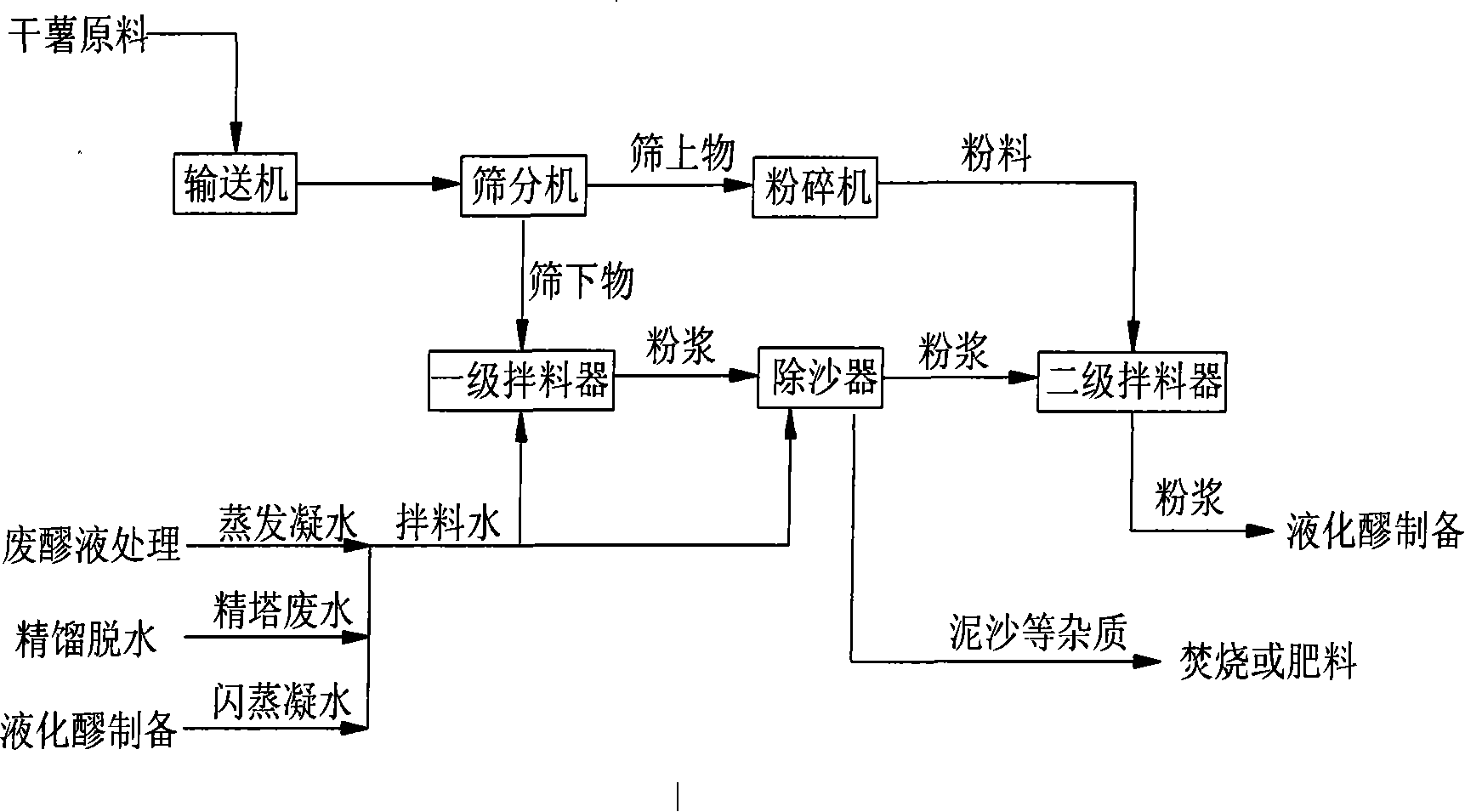

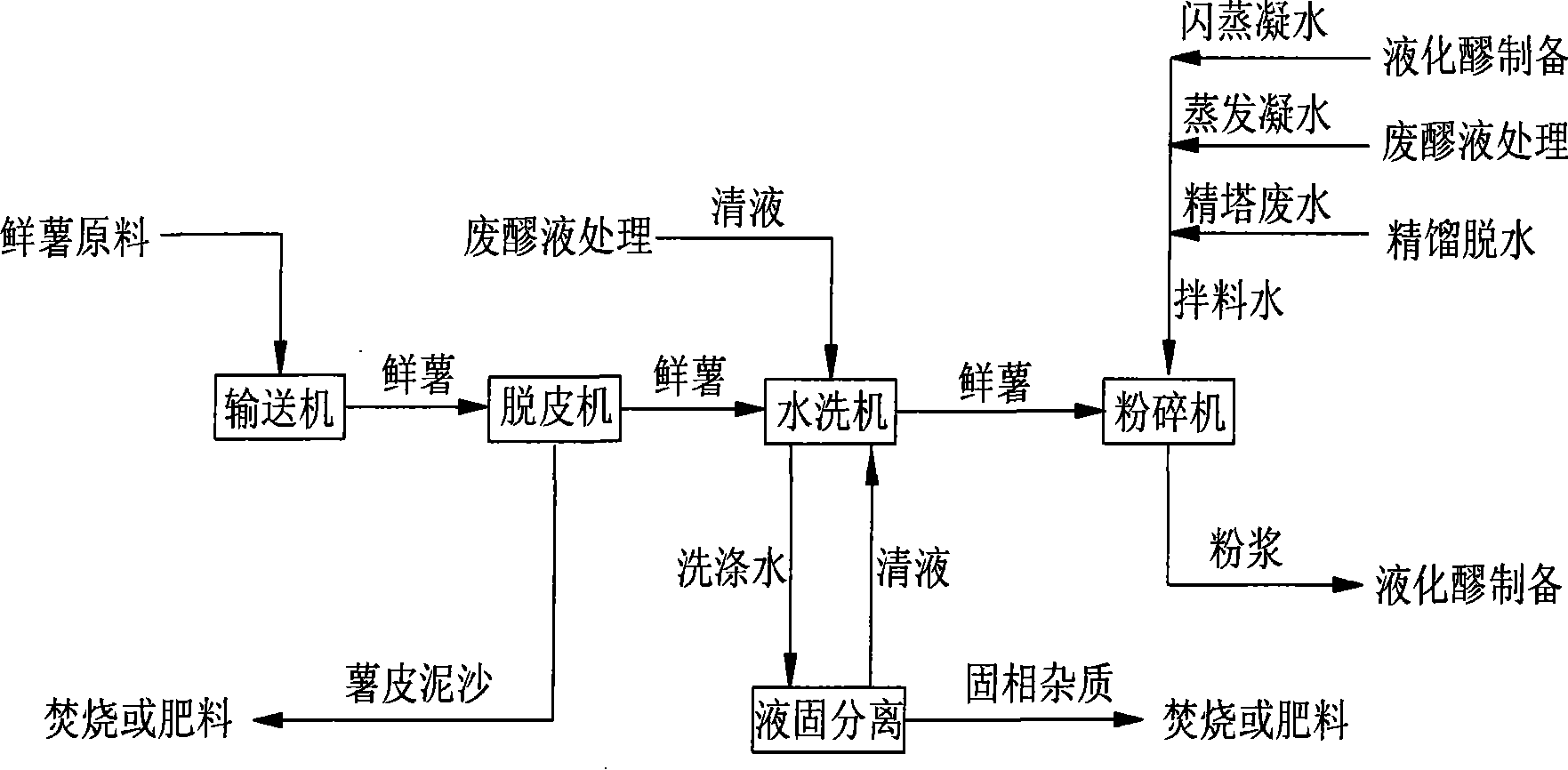

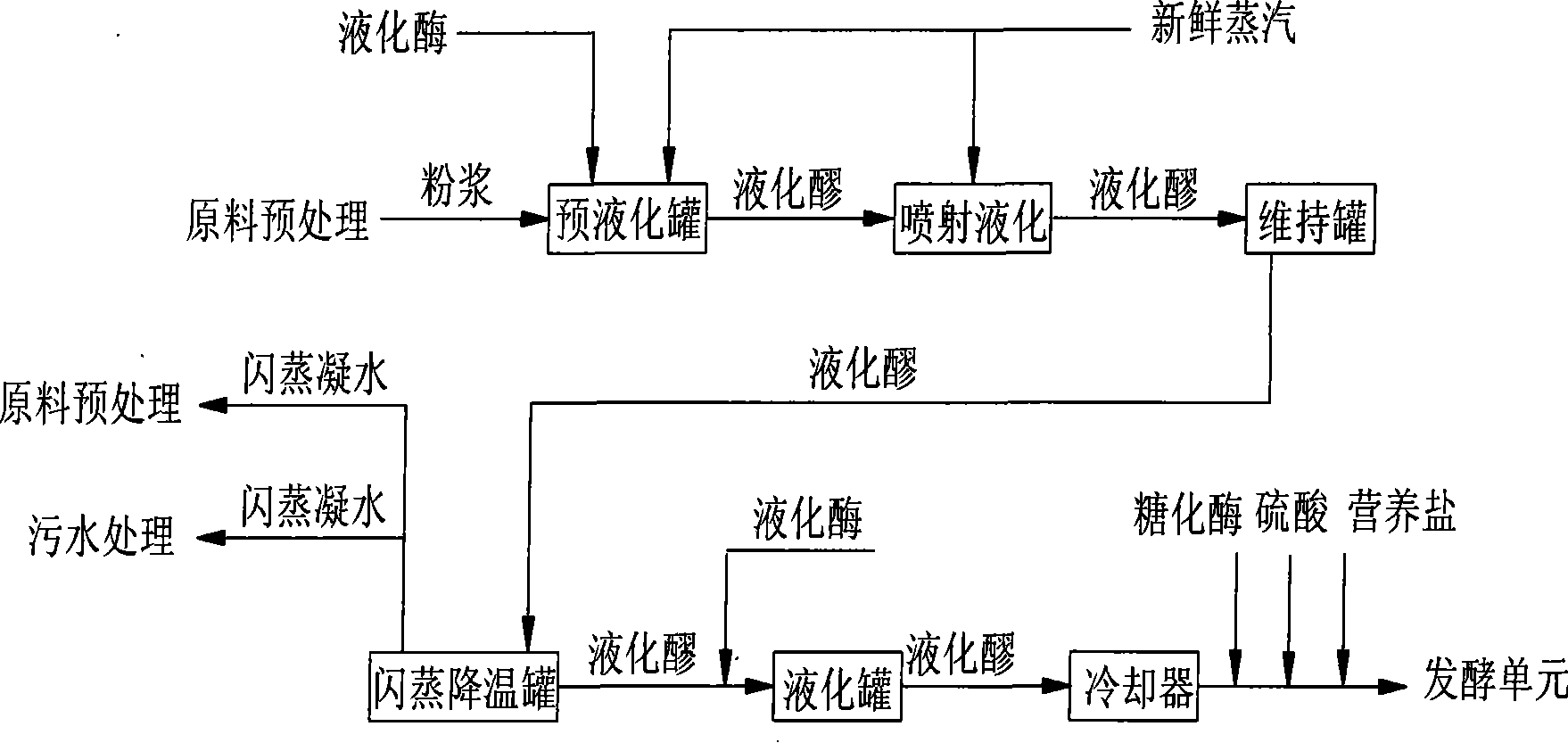

Novel method for producing ethanol with potato raw material

InactiveCN101245354AEfficient removalAchieve fermentationBiofuelsFermentationAlcohol productionEvaporation

The invention relates to a new method for producing alcohol by using potato raw material, which is mainly characterized in that: the pretreatment process of the raw materials of the dry potato chips adopts the two-level pulp-making production technique, thin pulp with a relatively low viscosity obtained by the level one material stirring and pulp making undergoes sand removing operation process, the thin pulp is subject to the secondary material stirring and pulp making to obtain a thicker powder pulp; a washing water mixture containing potato skins and sands which is drained from a fresh potato raw material water washing machine is separated by a liquid-solid separation device, the obtained clean liquid is returned to the water washing machine for continuous circulating usage; the washing water with the alcohol degree of 5 to 12 percent which is drained from a tower kettle of a CO2 washing tower is arranged to a rectification dehydration unit together with fermented mash after adding base solution, so as to ensure the acid value and the oxidation time of the produced alcohol to be qualified; a part of the clean liquid which is drained when the waste mash of the crude tower passes through the solid-liquid separation device is directly sent to a fresh potato pretreatment unit as the supplementary water of the washing water of the water washing machine for washing the cassava, thus reducing the production load of the evaporation and the concentration of the clean liquid, and the supplementary water of the cleaning water of the water washing machine does not consume other water.

Owner:TIANJIN UNIV

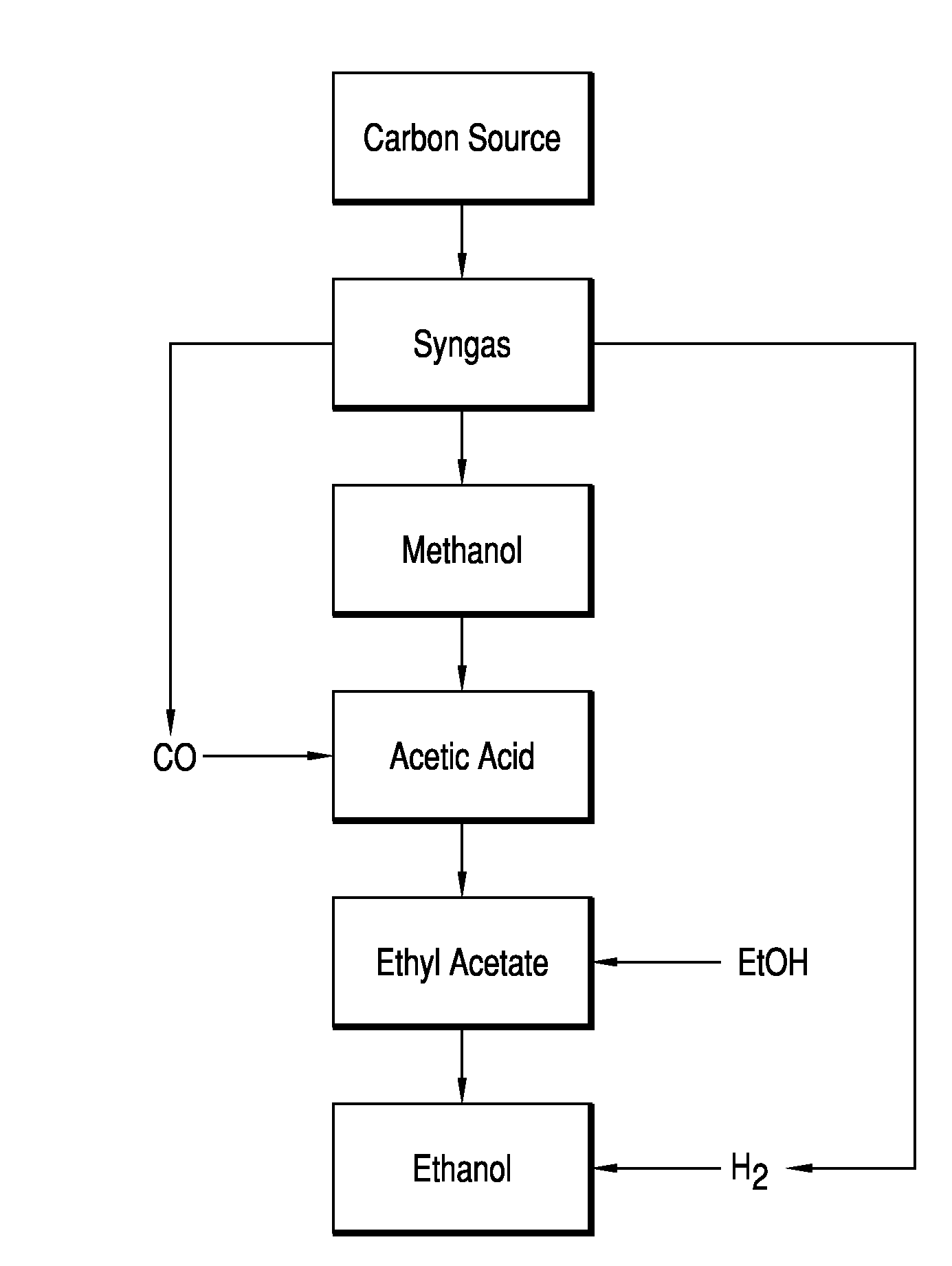

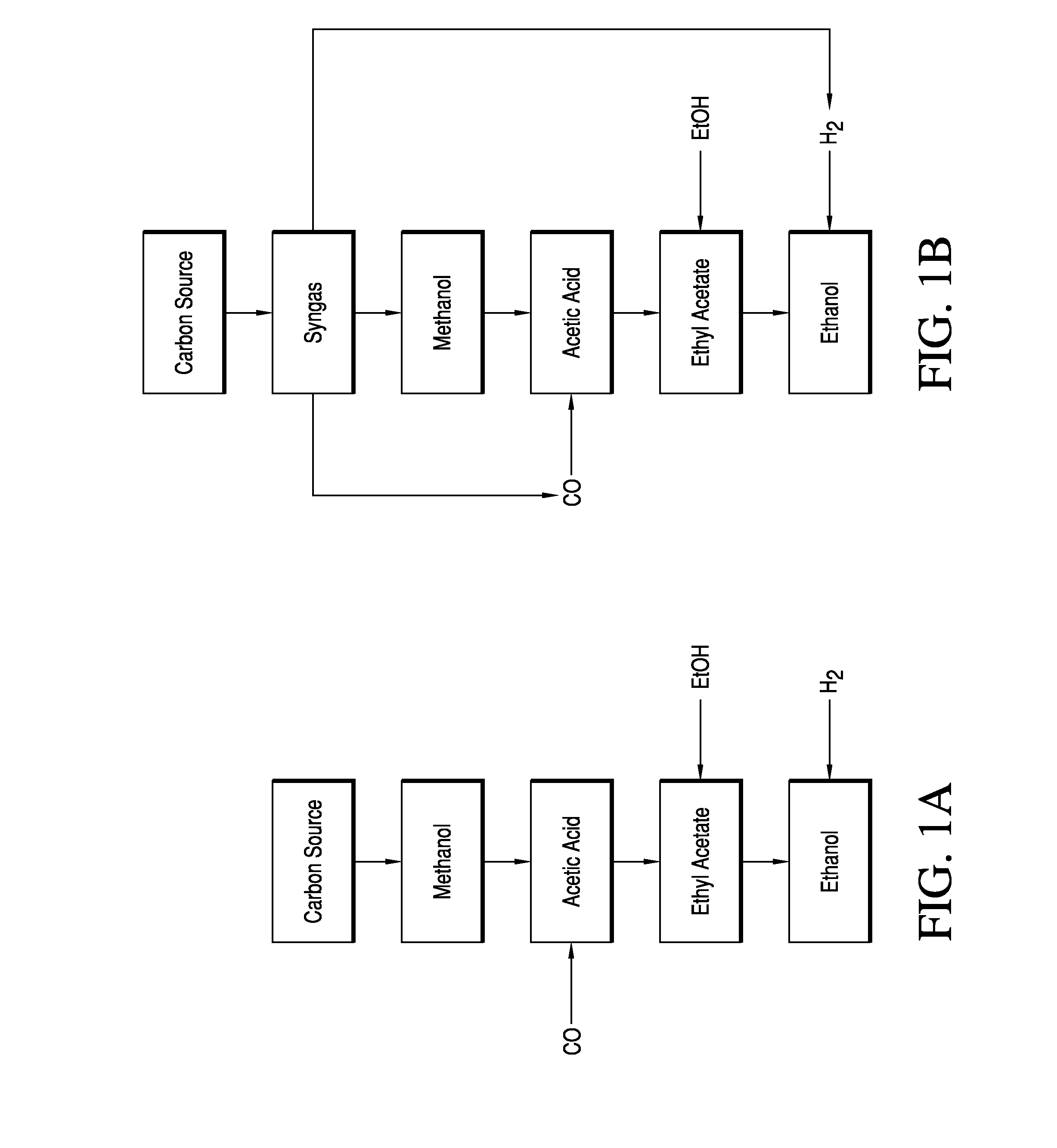

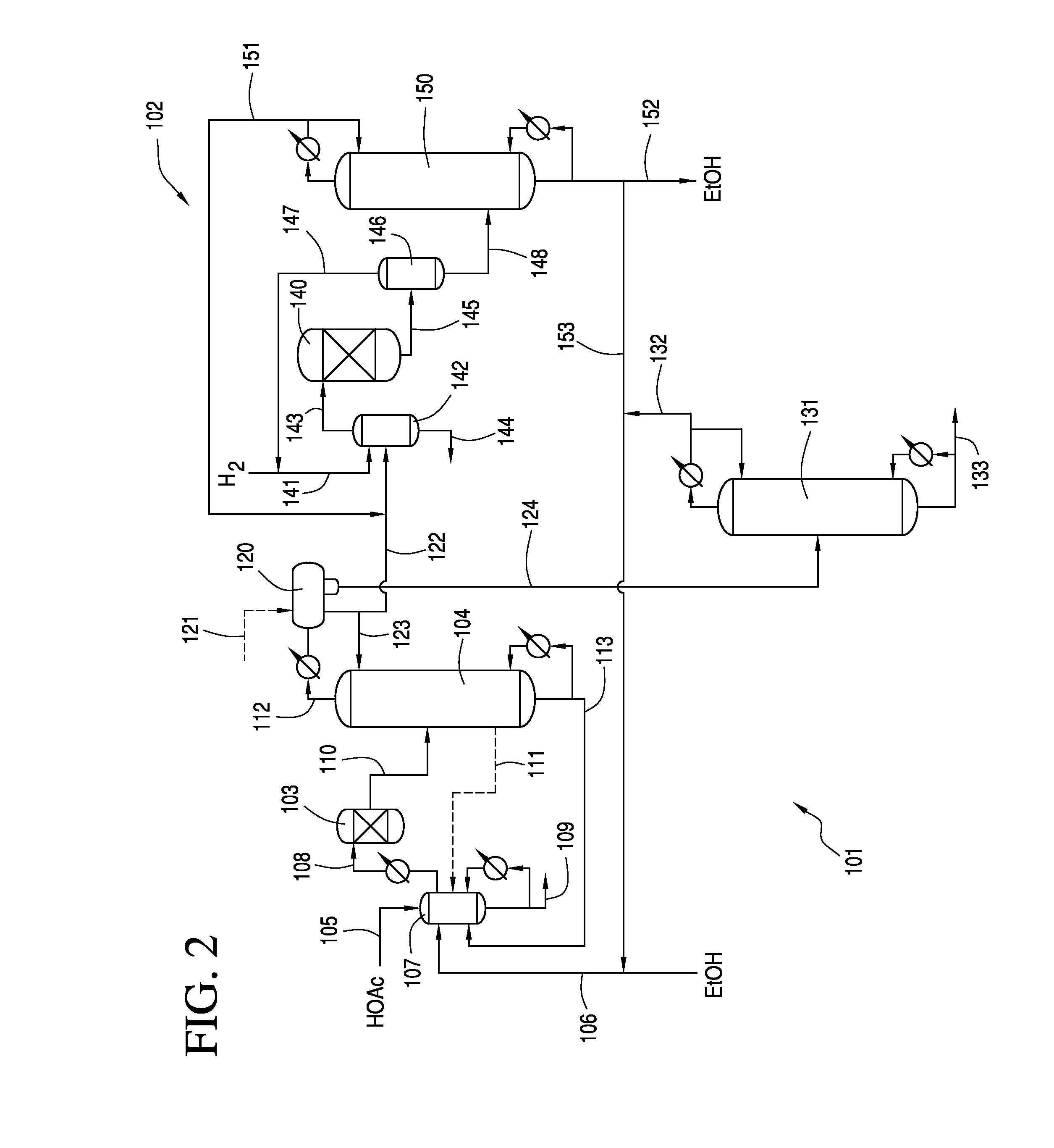

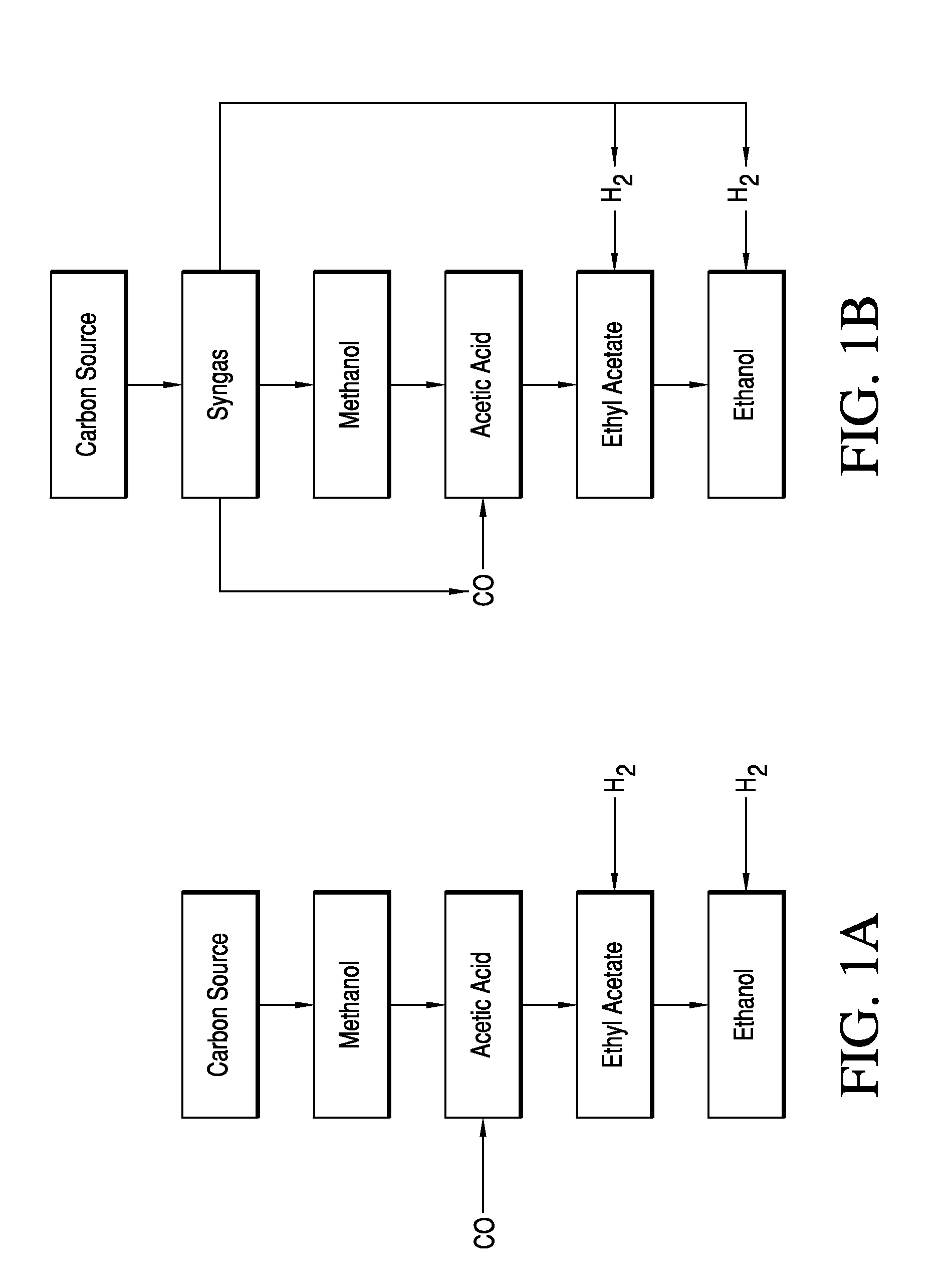

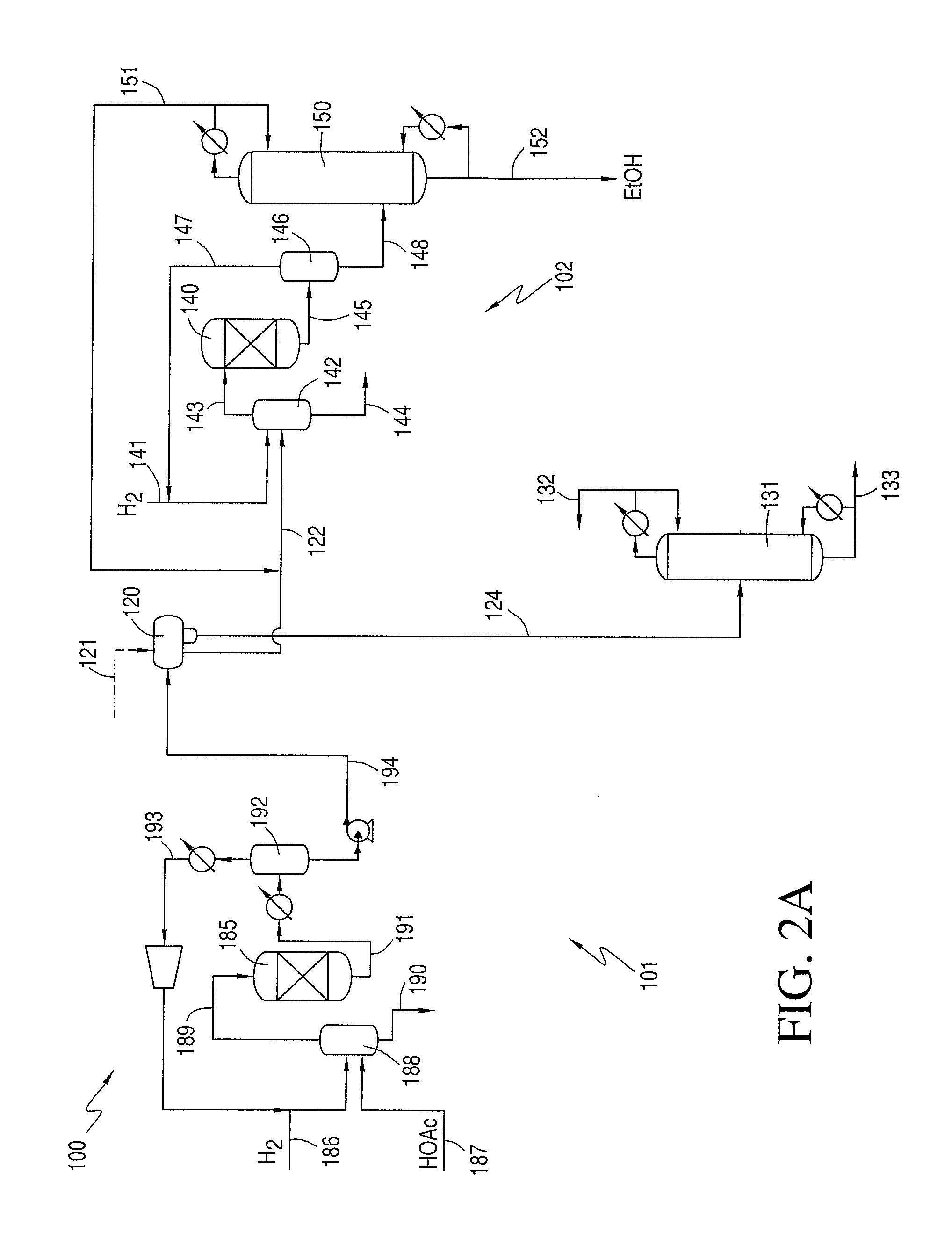

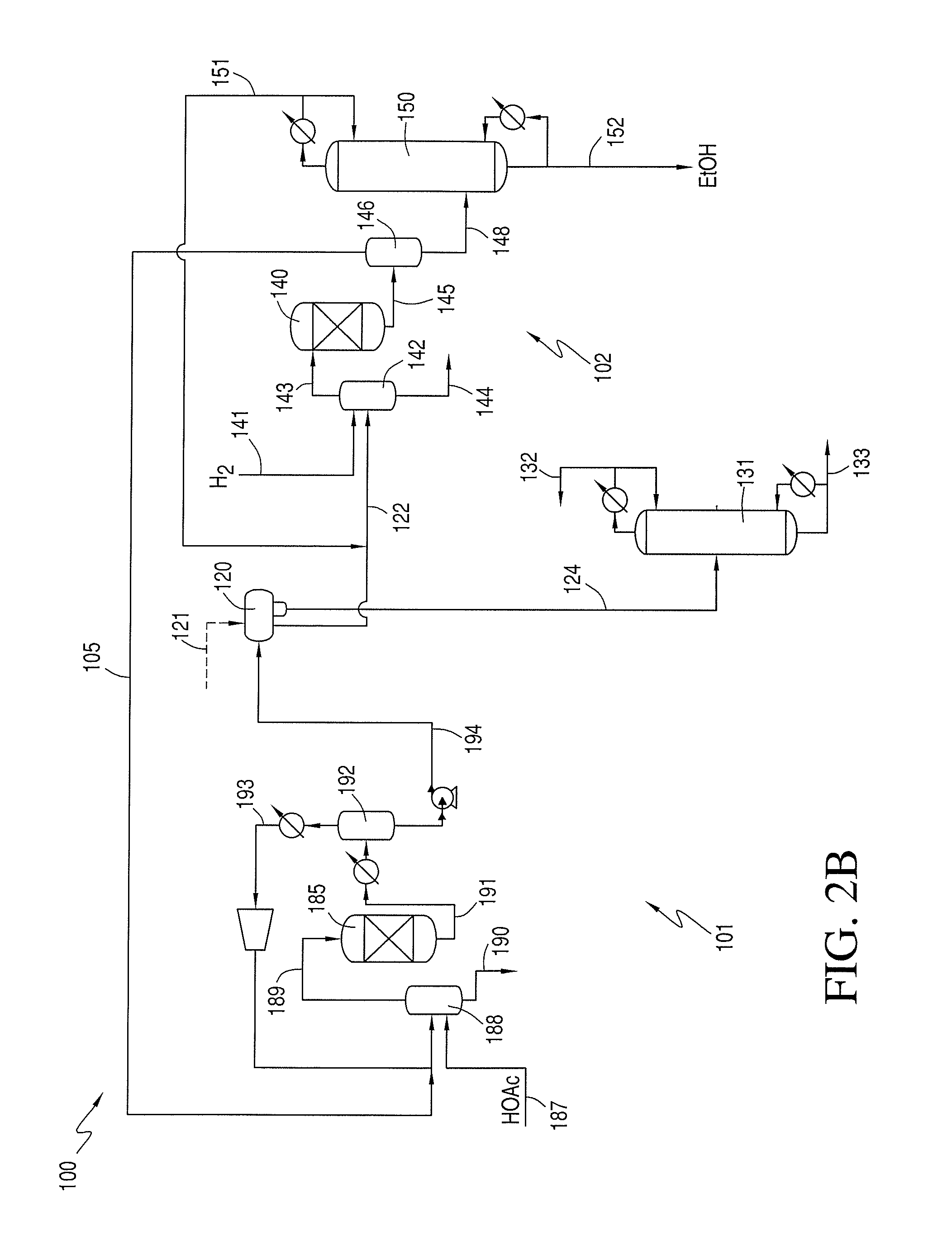

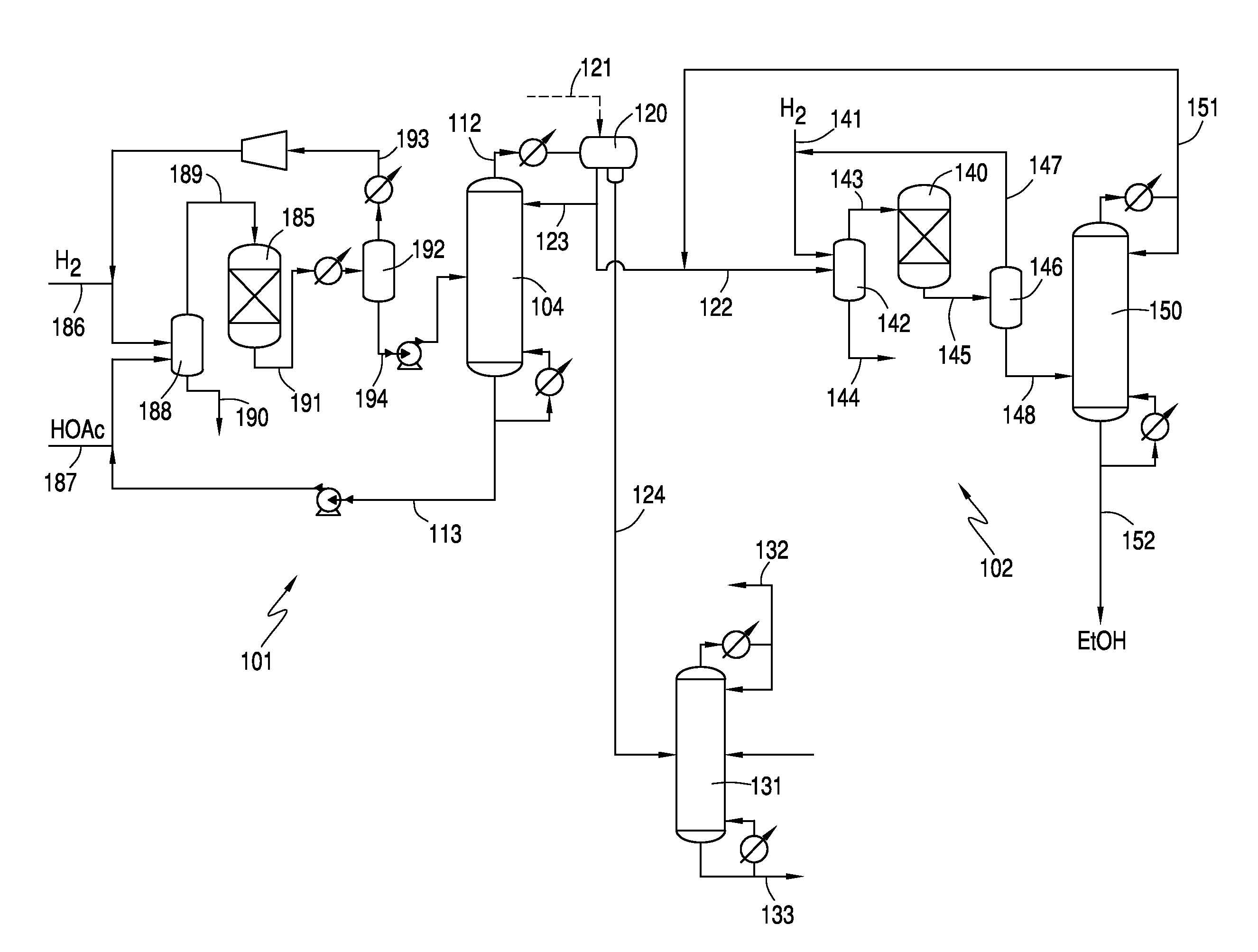

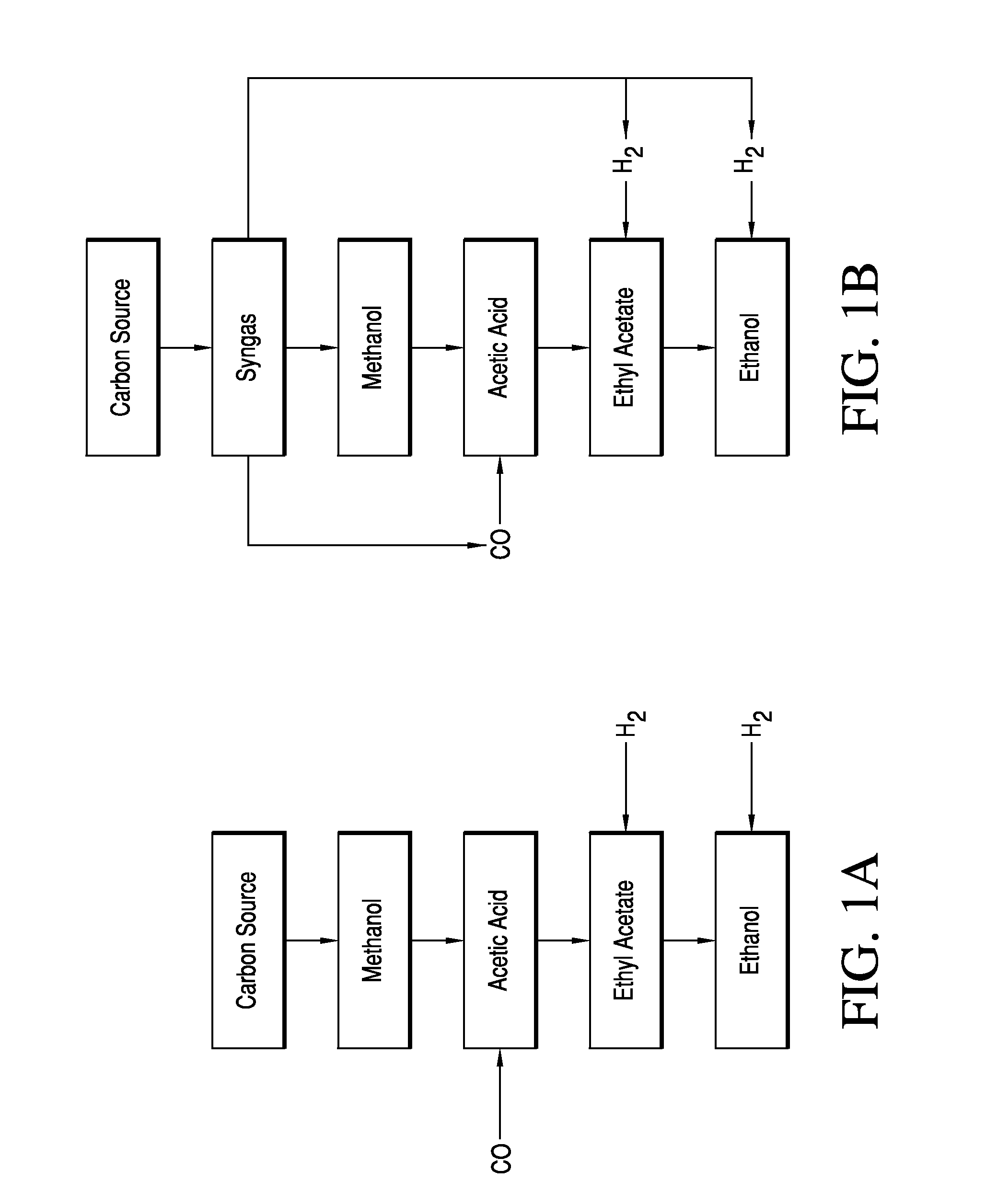

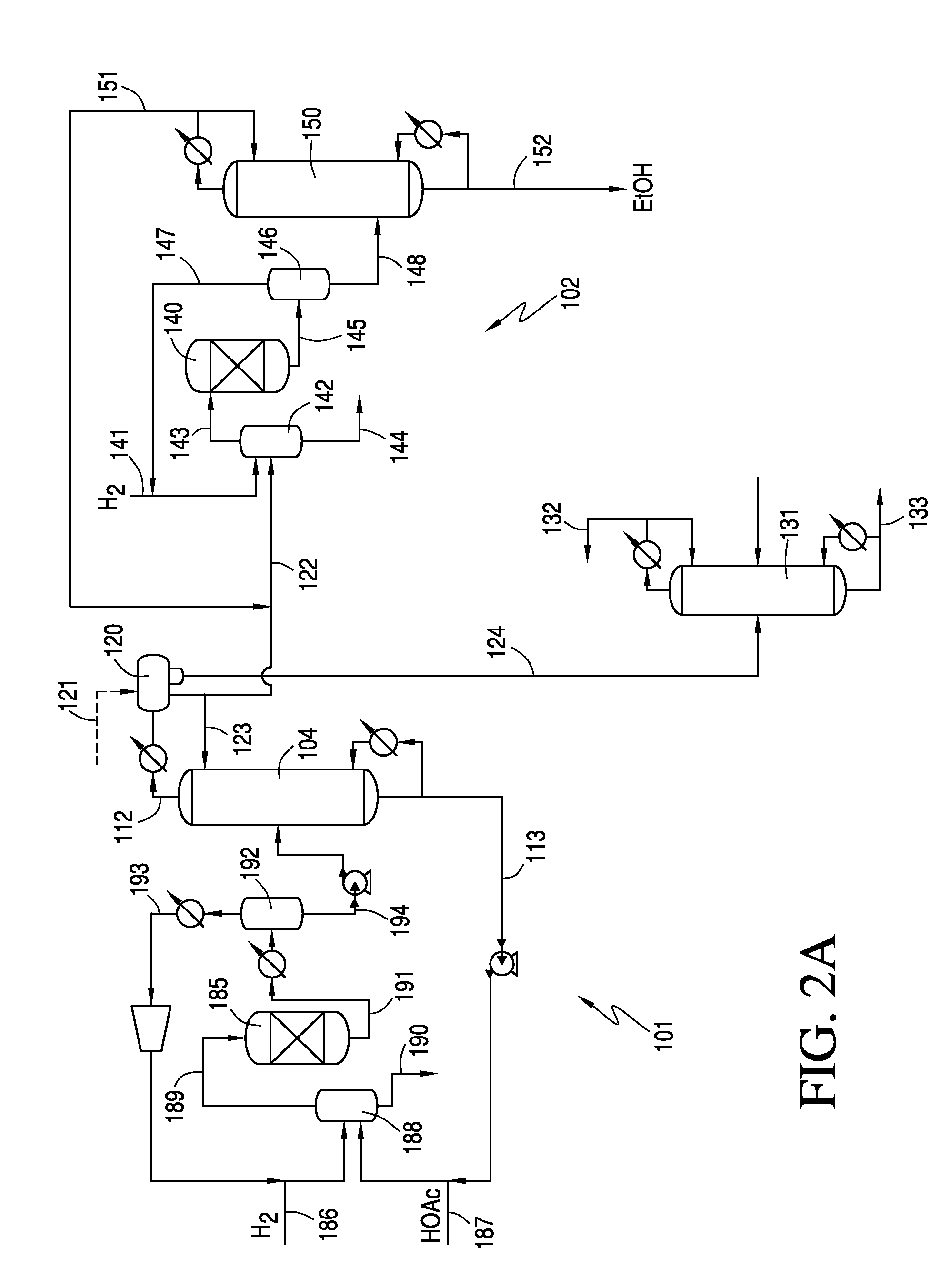

Process of Recovery of Ethanol From Hydrogenolysis Process

InactiveUS20130131398A1Reduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogen

Disclosed herein are processes for alcohol production by reducing an esterification product, such as ethyl acetate. The processes comprise esterifying acetic acid and an alcohol such as ethanol to produce an esterification product. The esterification product is reduced with hydrogen in the presence of a catalyst to obtain a crude reaction mixture comprising ethyl acetate, ethanol, and at least one alcohol having at least 4 carbon atoms. The ethanol is recovered with a reduced amount of the alcohol having at least 4 carbon atoms.

Owner:CELANESE INT CORP

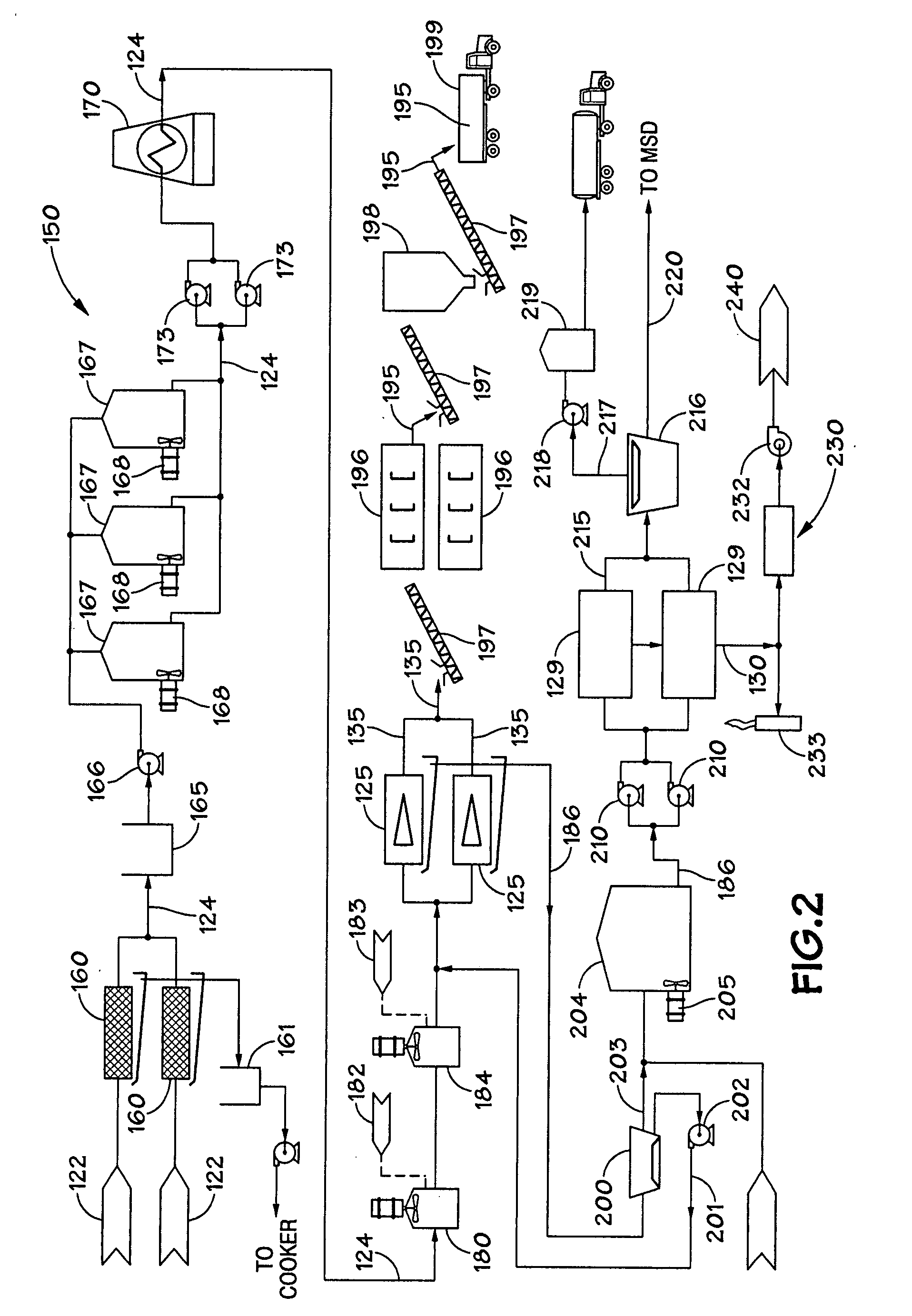

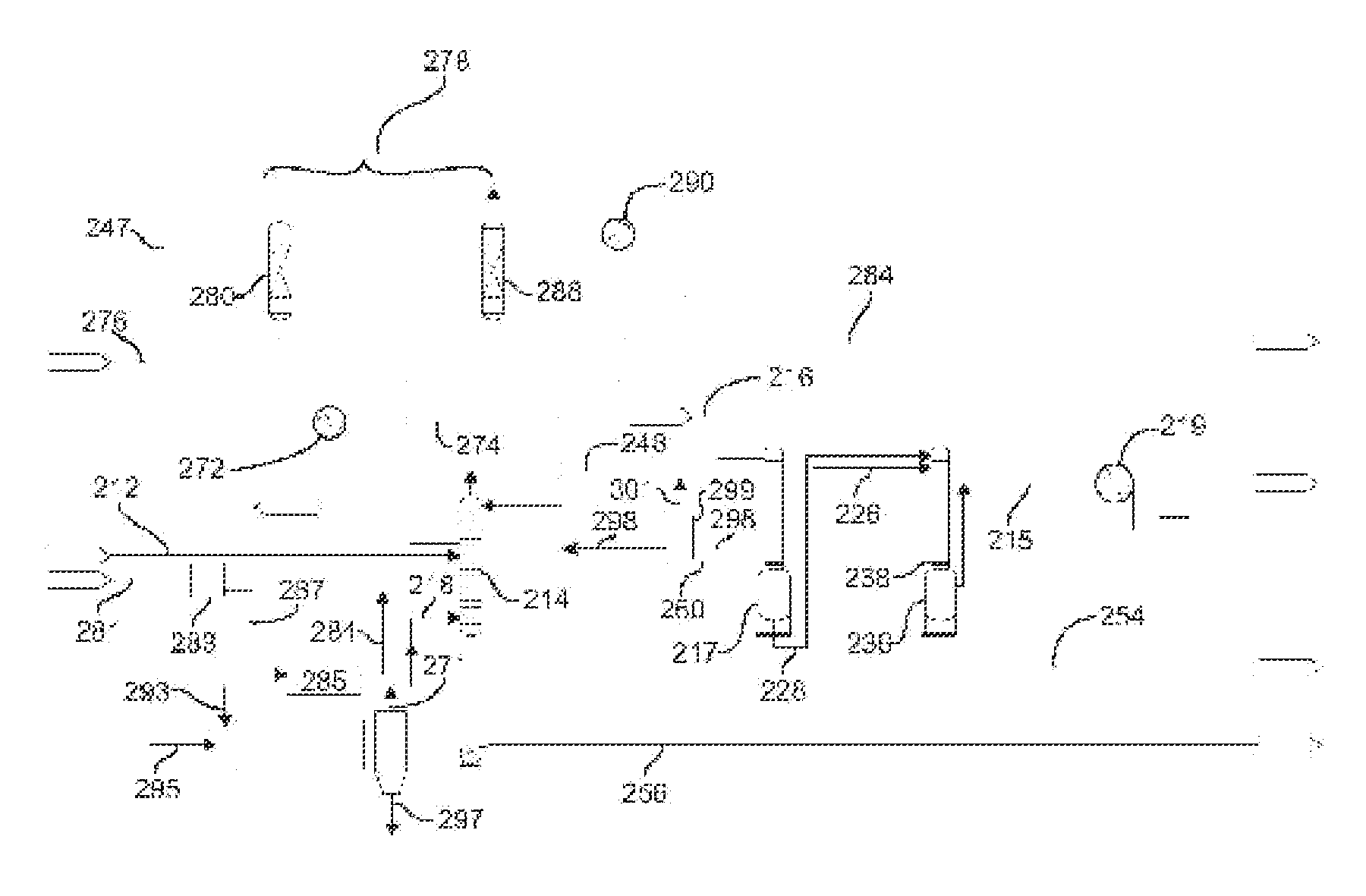

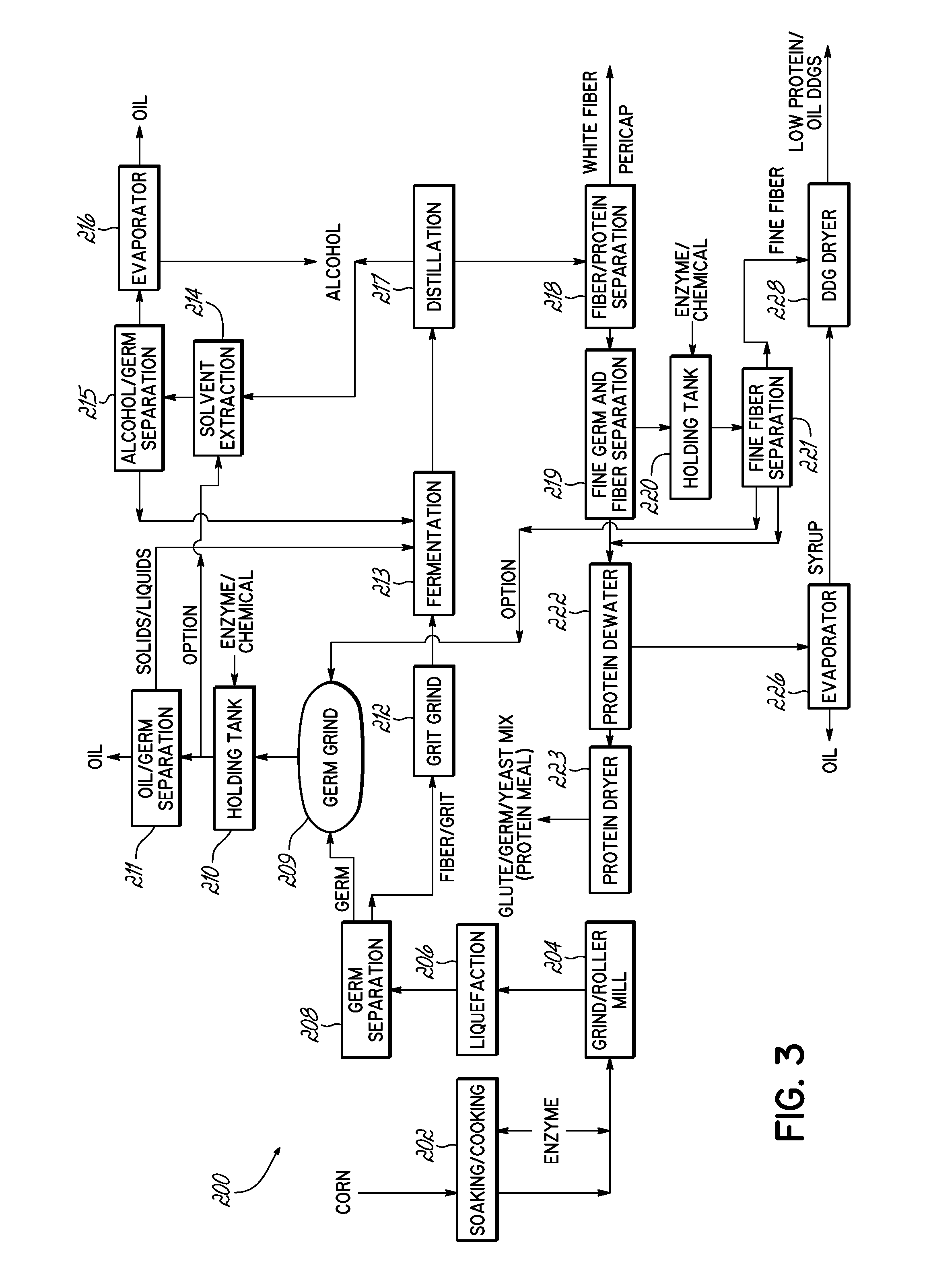

A system and method for separating high value by-products from grains used for alcohol production

ActiveUS20130236936A1Increase valueDesirable yieldBioreactor/fermenter combinationsBiological substance pretreatmentsFiberAlcohol production

Systems and methods are provided for separating high value by-products, such as oil and / or germ, from grains used for alcohol production. In one embodiment, a method for separating by-products from grains used for alcohol production includes, subjecting milled grains to liquefaction to provide a liquefied starch solution including fiber, protein, and germ. The germ is separated from the liquefied starch solution. The separated germ is ground, e.g., to a particle size less than 50 microns, to release oil to provide a germ / oil mixture. Then, prior to fermentation, the oil is separated from the germ / oil mixture to yield an oil by-product. The pH of the germ / oil mixture can be adjusted to about 8 to about 10.5 and / or cell wall breaking enzymes or chemicals may be added to help release oil from the germ. In one example, the oil yield is greater than 1.0 lb / Bu.

Owner:LEE CHIE YING

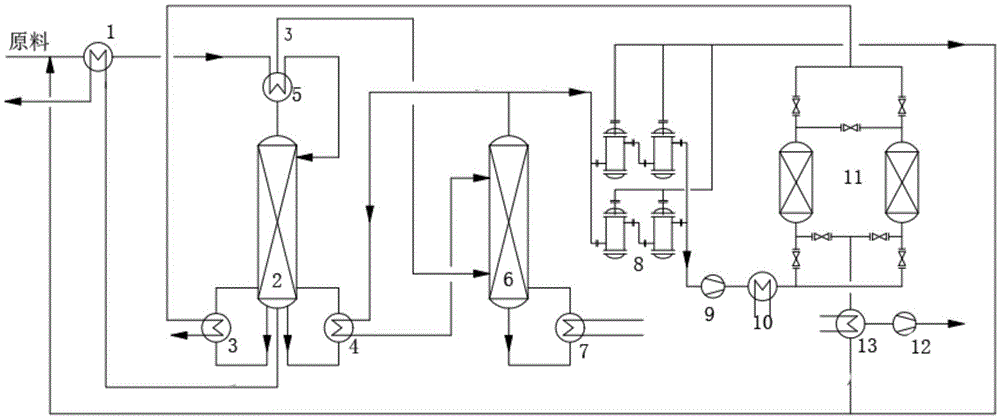

Technology and device for producing high-purity ethyl alcohol

ActiveCN105418368AEfficient and environmentally friendly separation technologyHydroxy compound separation/purificationMolecular sieveCoupling

The invention relates to a technological method for preparing high-purity ethyl alcohol through two-tower differential pressure rectification-film equipment-molecular sieve adsorption tower coupling. The technological method is mainly used for solving the problem that an existing high-purity ethyl alcohol production technology is high in energy consumption and not high in purity. Two rectification towers, a film and two molecular sieve adsorption towers are included, and the technological method mainly comprises the steps that 1, low-concentration ethyl alcohol raw materials are used as decompression rectification tower feed after being preheated through decompression rectification tower bottoms and tower top alcohol logistics steam in sequence, the tower top alcohol logistics steam enters the pressurization rectification tower after raw material condensation is carried out, ethyl alcohol positive pressure steam is obtained on the top of the pressurization rectification tower, and bottom residual liquid is obtained on the tower bottom; 2, the ethyl alcohol positive pressure steam enters film equipment and is separated through a film assembly, ethyl alcohol steam is located on a film outlet, and penetrating fluid containing a small amount of ethyl alcohol is located on the negative pressure side; 3, the ethyl alcohol steam on the film outlet enters the molecular sieve adsorption towers, and the high-purity ethyl alcohol is obtained. The penetrating fluid on the negative pressure side of the film equipment and a dilute solution reproduced through the molecular sieve adsorption towers can be returned back to the decompression rectification tower.

Owner:JIANGSU NINE HEAVEN HIGH TECH

Phasing Reactor Product from Hydrogenating Acetic Acid Into Ethyl Acetate Feed to Produce Ethanol

InactiveUS20130158302A1Reduce the amount requiredProduced cost-effectivelyOrganic compound preparationCarboxylic acid esters preparationAcetic acidProduction rate

Disclosed herein are processes for alcohol production by reducing ethyl acetate produced by hydrogenating acetic acid in the presence of a suitable catalyst. The product of the acetic acid hydrogenation is fed directly to a decanter to separate the hydrogenation product into an aqueous phase comprising water and ethanol and an organic phase comprising ethyl acetate. The organic phase is reduced with hydrogen in the presence of a catalyst to obtain a crude reaction mixture comprising the alcohol, in particular ethanol, which may be separated from the crude reaction mixture. Thus, ethanol may be produced from acetic acid through an ethyl acetate intermediate without an esterification step. This may reduce the recycle of ethanol in the hydrogenolysis process and improve ethanol productivity.

Owner:CELANESE INT CORP

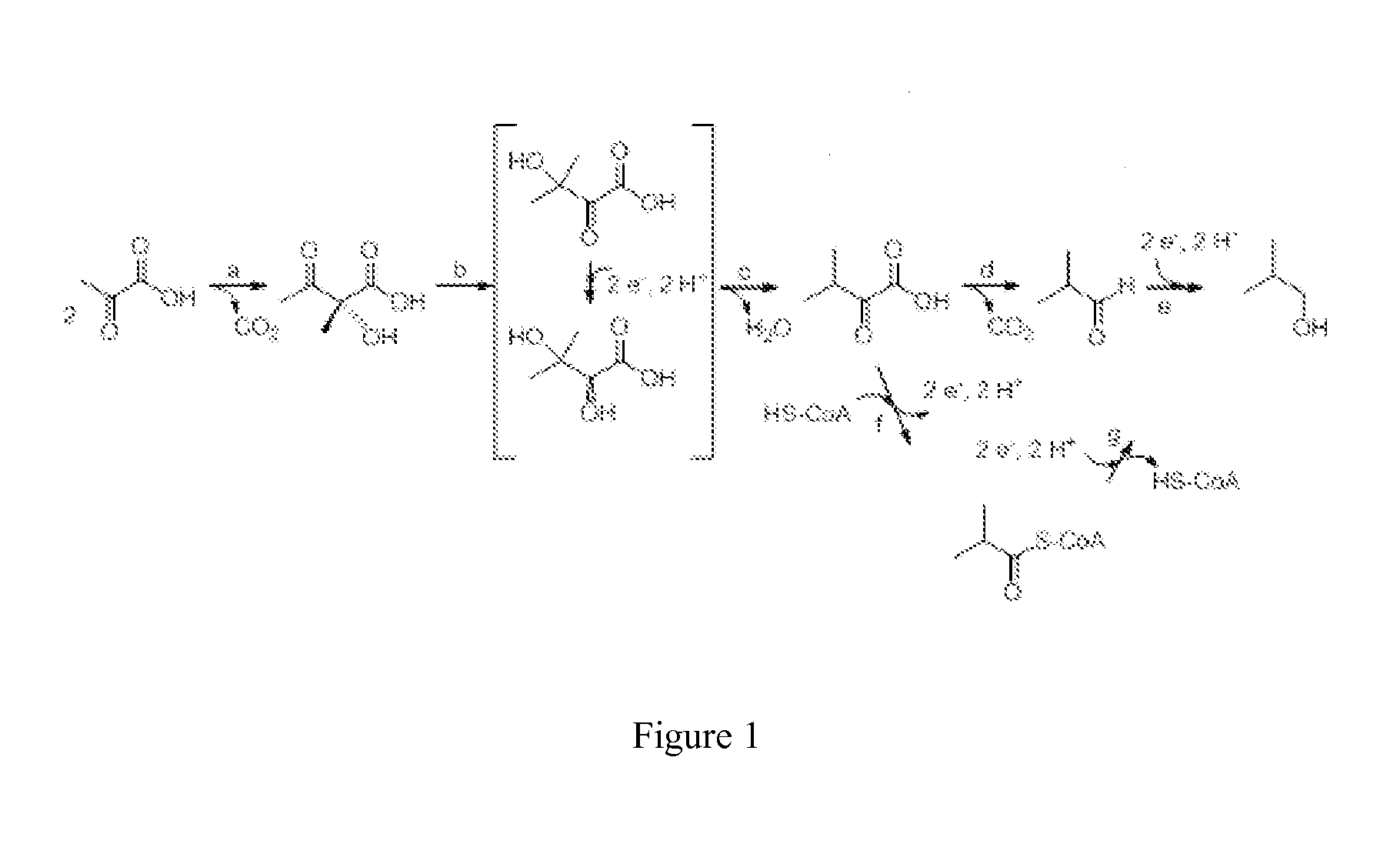

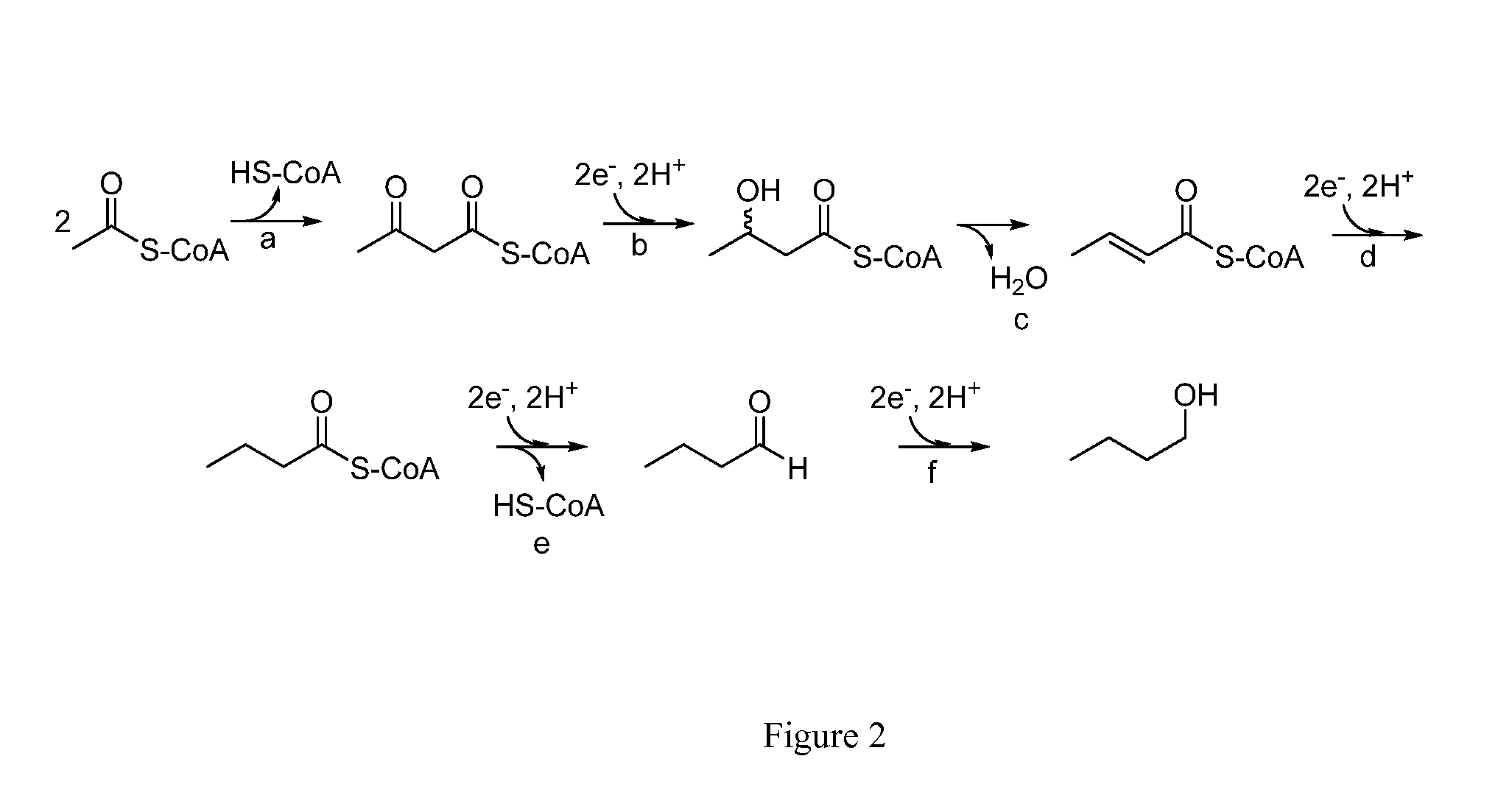

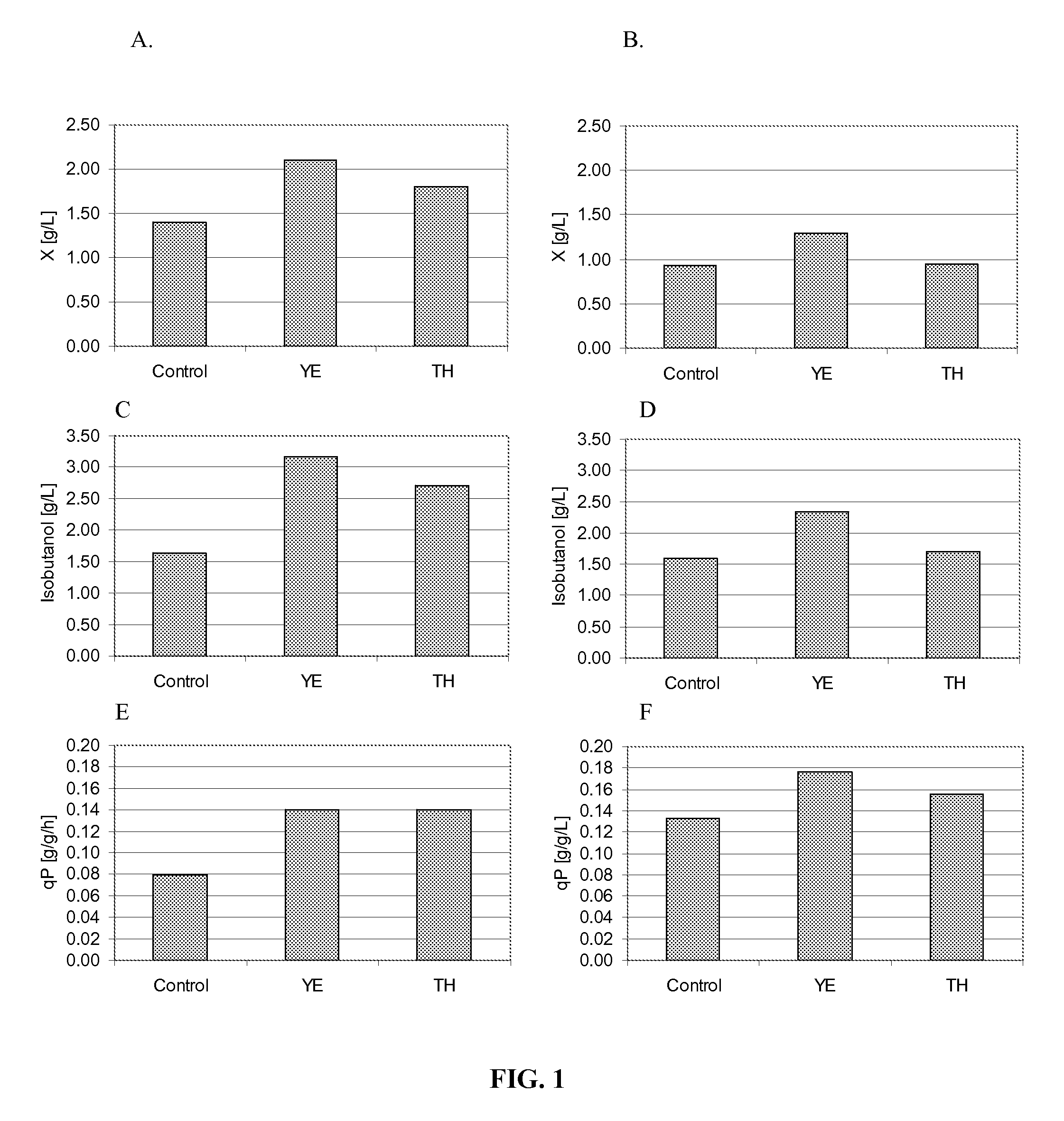

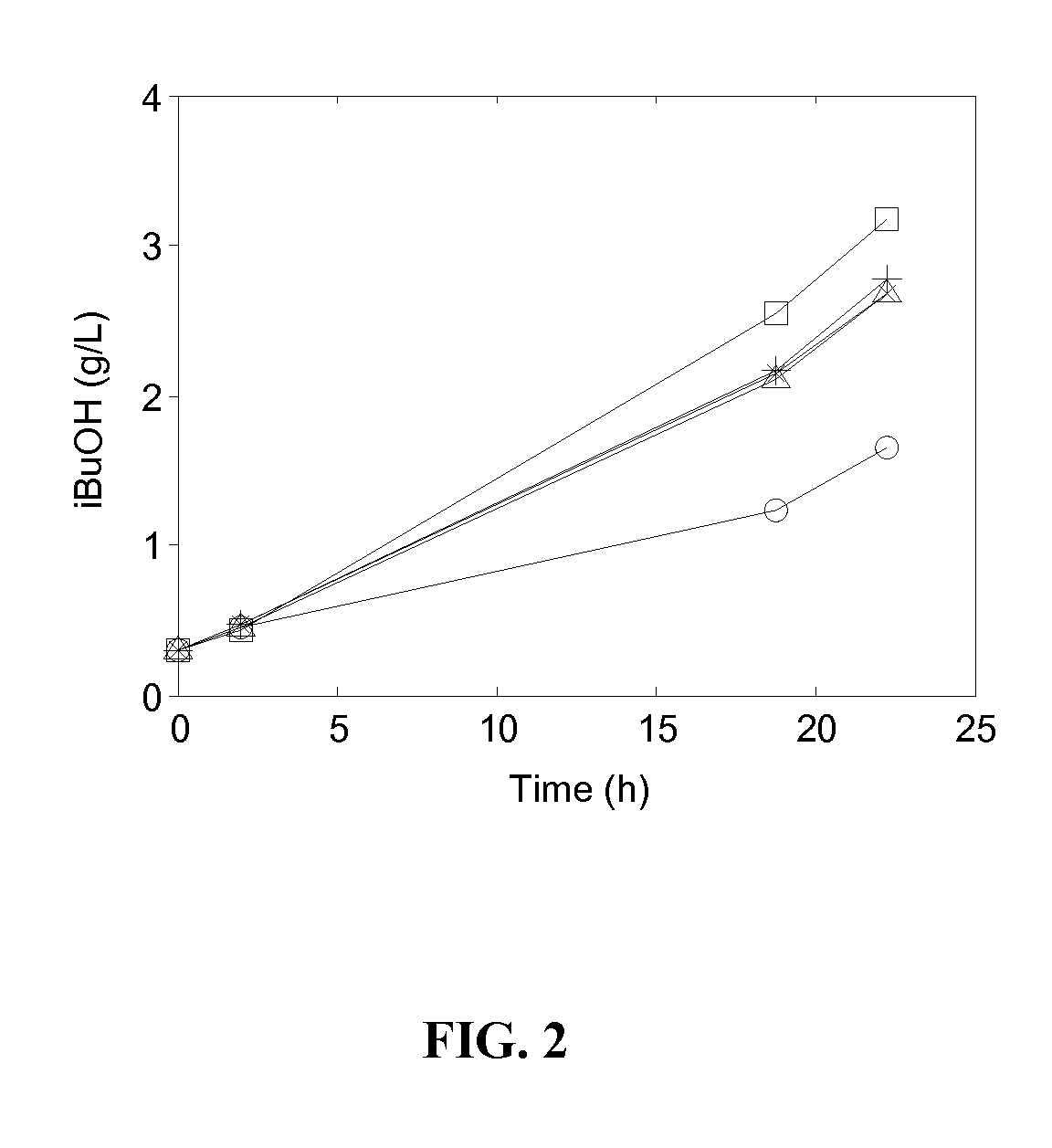

Use of thiamine and nicotine adenine dinucleotide for butanol production

The invention relates generally to the field of industrial microbiology and alcohol production. More specifically, the invention relates to the use of thiamine, biosynthetic precursors of thiamine, nicotinic acid, nicotinamid, nicotinic acid riboside, nicotinamid riboside, or other biosynthetic precursors of nicotine adenine dinucleotide (NAD) to improve butanol production. Butanol production can be improved by providing sufficient amounts of thiamine, biosynthetic precursors of thiamine, nicotinic acid, nicotinamid, nicotinic acid riboside, nicotinamid riboside, or other biosynthetic precursors of nicotine adenine dinucleotide (NAD) in the production media.

Owner:GEVO INC

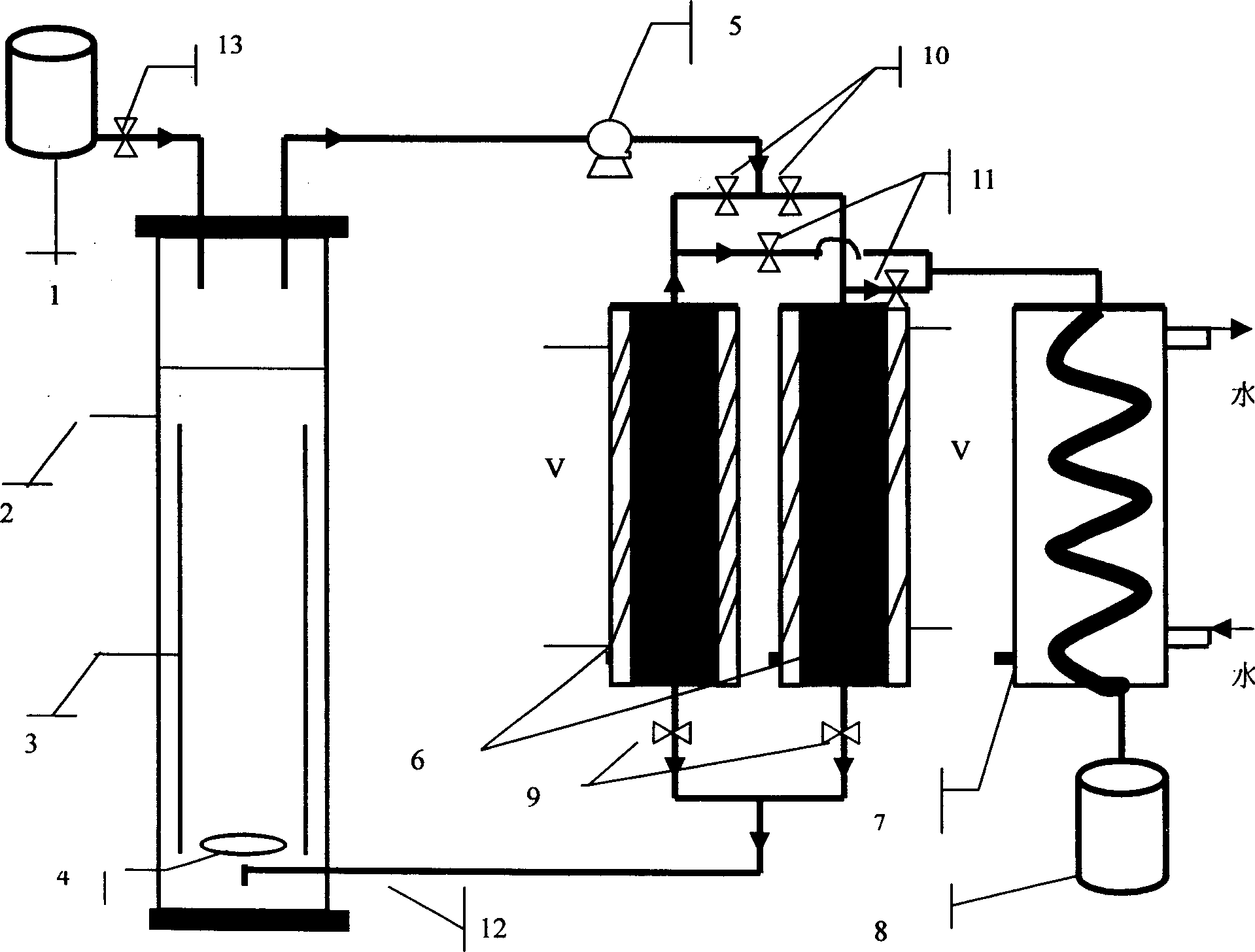

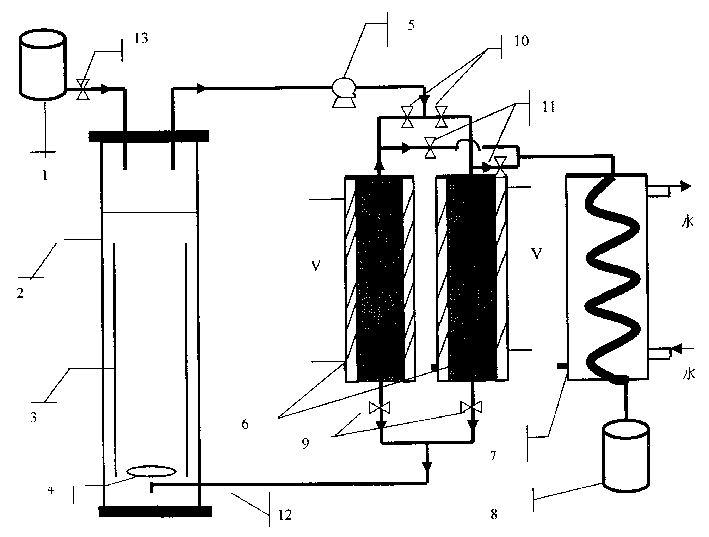

Production of fatty poly-ester carbonate polyhydric alcohol

Production of fatty polycarbonate polyol is carried out by taking carbon dioxide / epoxide as raw materials, putting catalyst, epoxide and molecular-weight regulator into cyclic reactor and copolymerization reacting under action of the catalyst in cyclic reactor at 0.1-8MPa and 40-150degree for 0.5-48hrs. The main apparatus consists of cyclic reactor, condenser, vapor / liquid separator, high-pressure carbon dioxide buffer tank, carbon dioxide compressor and liquid cyclic pump, the said cyclic reactor is arranged with single draft tube and multiple draft tubes. It costs low and is efficient.

Owner:JIANGSU ZHONGKE JINLONG CHEM

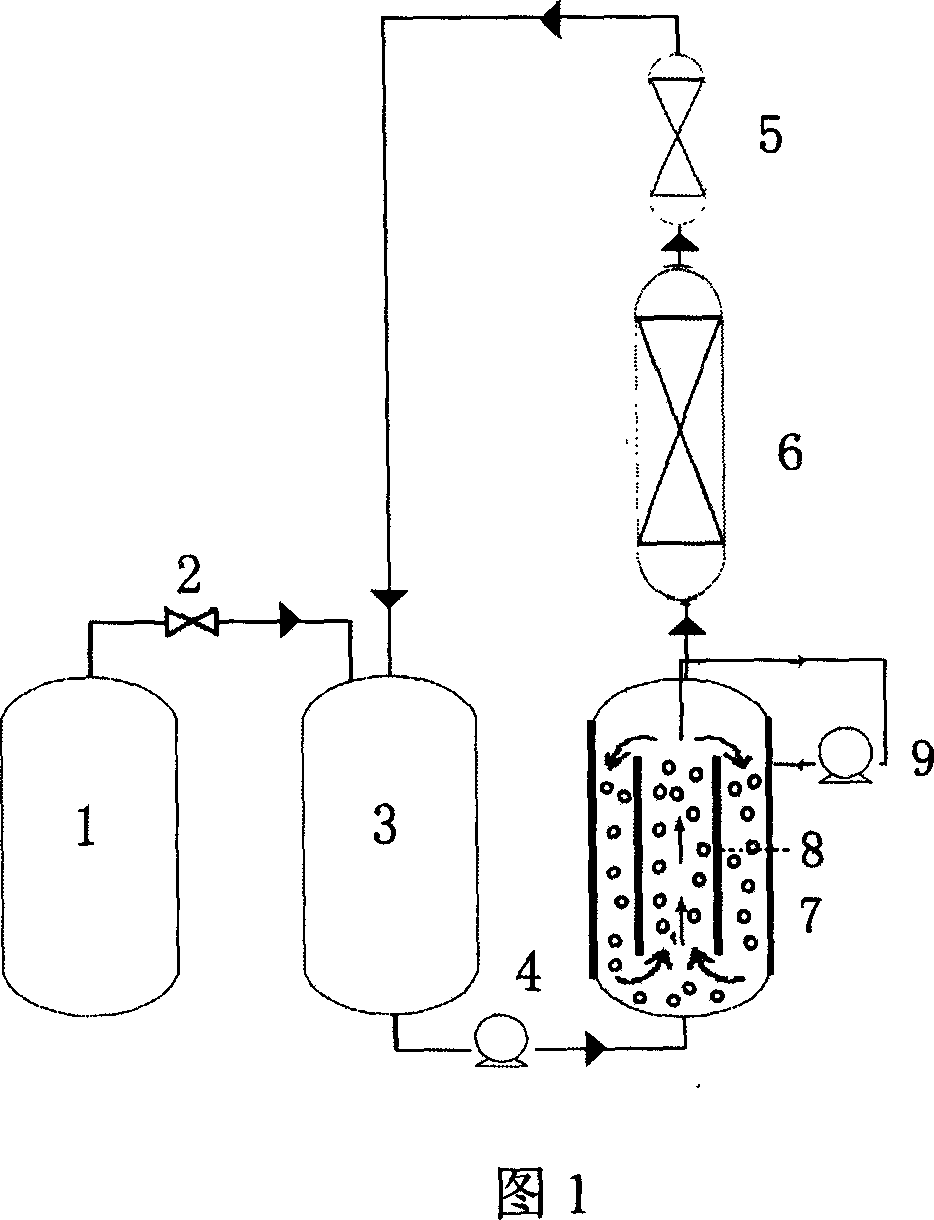

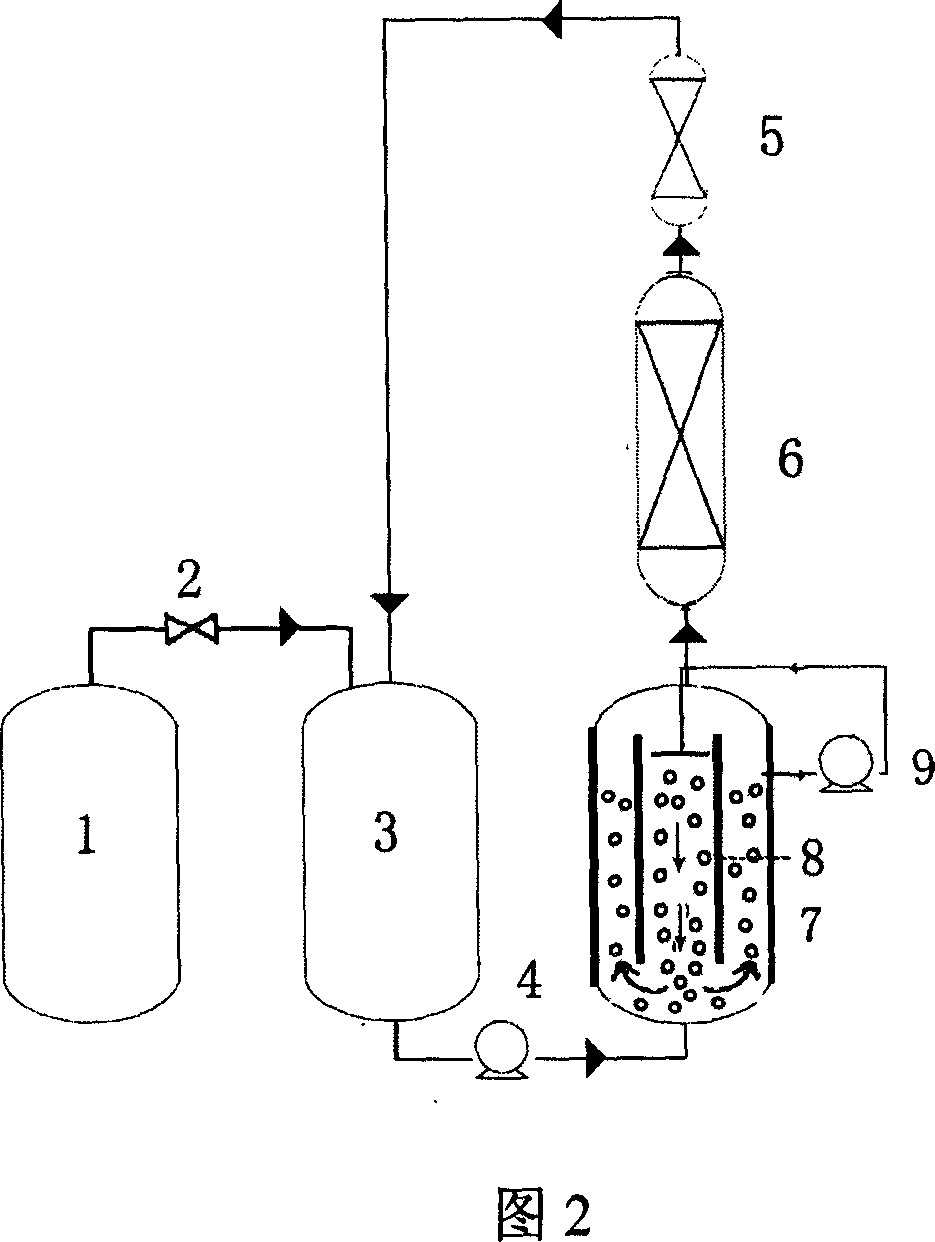

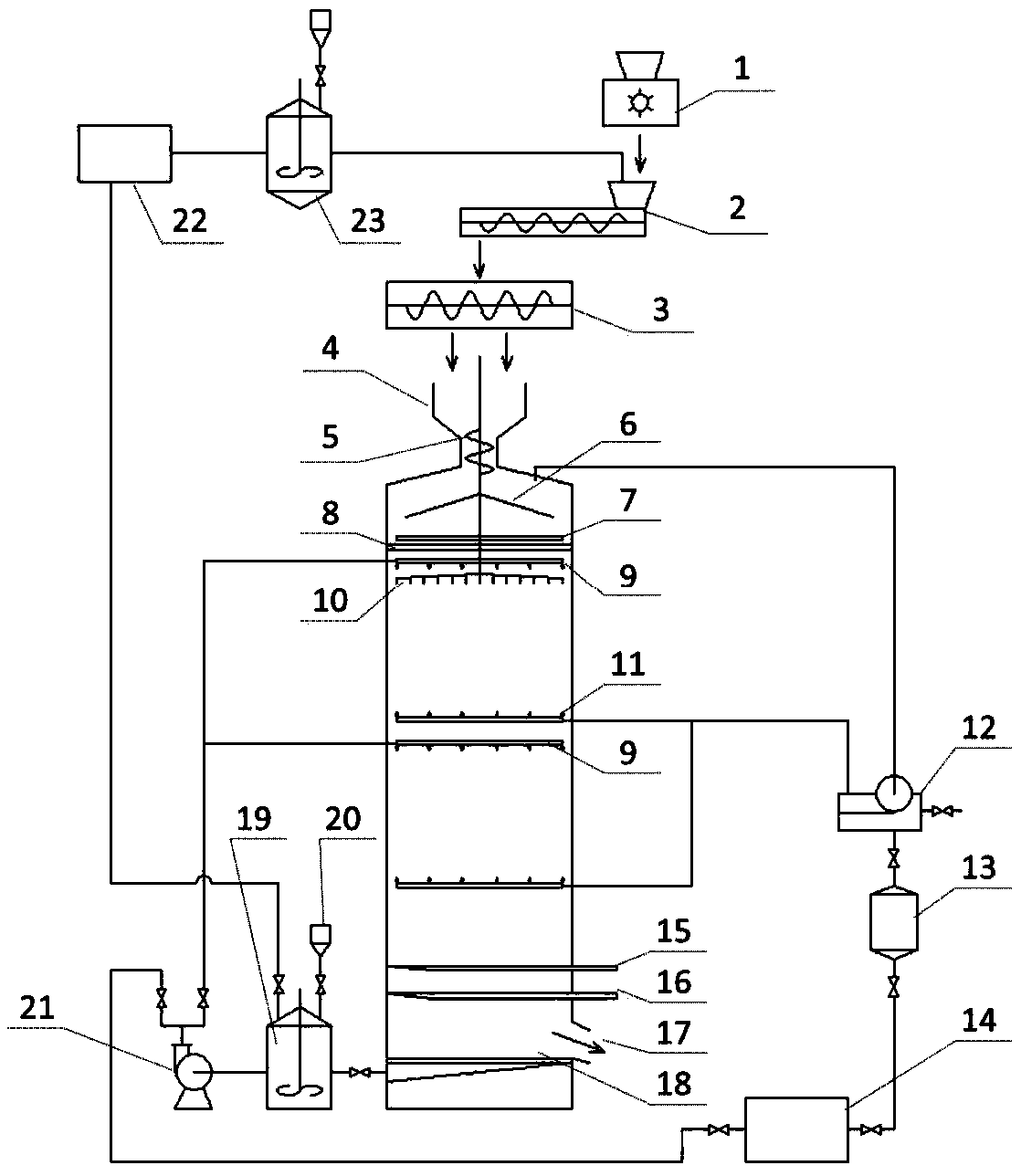

Alcohol preparing airlift fermentation and separation coupling technological process and special equipment

InactiveCN1403579ASave cycle compressorHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionProduct gas

The present invention belongs to the technology of fermenting alcohol production, and is especially alcohol preparing airlift fermentation and separation coupling technological process and special equipment. The equipment is one airlift alcohol fermenting reactor, which includes one tank, one inner circulating guide tube concentrically set inside the tank, one gas distributor below the guide tube, and one active carbon adsorbing and desorbing unit comprising condensator and two parallelly connected adsorbing active carbon towers. The airlift alcohol bioreactor is maintained in a 4000-8000 Pa vacuum with a water ring pump; the two parallelly connected adsorbing active carbon towers are used to adsorb and desorb the pumped mixed gas alternately; and the condensator is used to collect the desorbed alcohol.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for treating molasses alcohol waste water

InactiveCN102537982AAchieve emissionsWater/sewage treatment by heatingIncinerator apparatusAlcohol productionClosed loop

The invention discloses a method for treating molasses alcohol waste water. The method is characterized by comprising the following steps: (1) concentrating molasses alcohol waste water in an evaporator, thereby obtaining the concentrated slurry; (2) discharging waster water in the evaporator in a form of vapor condensed water, wherein the condensed water is recycled for alcohol production; (3) preparing dry powder after the concentrated slurry is incinerated in an incinerator; or (4) combusting the concentrated slurry with combustibility in a boiler to generate vapor; and (5) recycling the vapor for alcohol production and heating in waste water concentration. The method is main used for recycling water and solids and heat in the waster water and is a method for comprehensive treatment and utilization. The molasses alcohol waste water is concentrated in the evaporator, then is prepared into the dry powder, or the concentrated slurry with combustibility is combusted to generate vapor, and then the vapor is recycled for alcohol production and waste water concentration. The waste water in the evaporator is recycled for alcohol production in the form of vapor condensed water, thus an alcohol production closed-loop water system without waste emission is realized.

Owner:广西皎龙能源科技有限公司

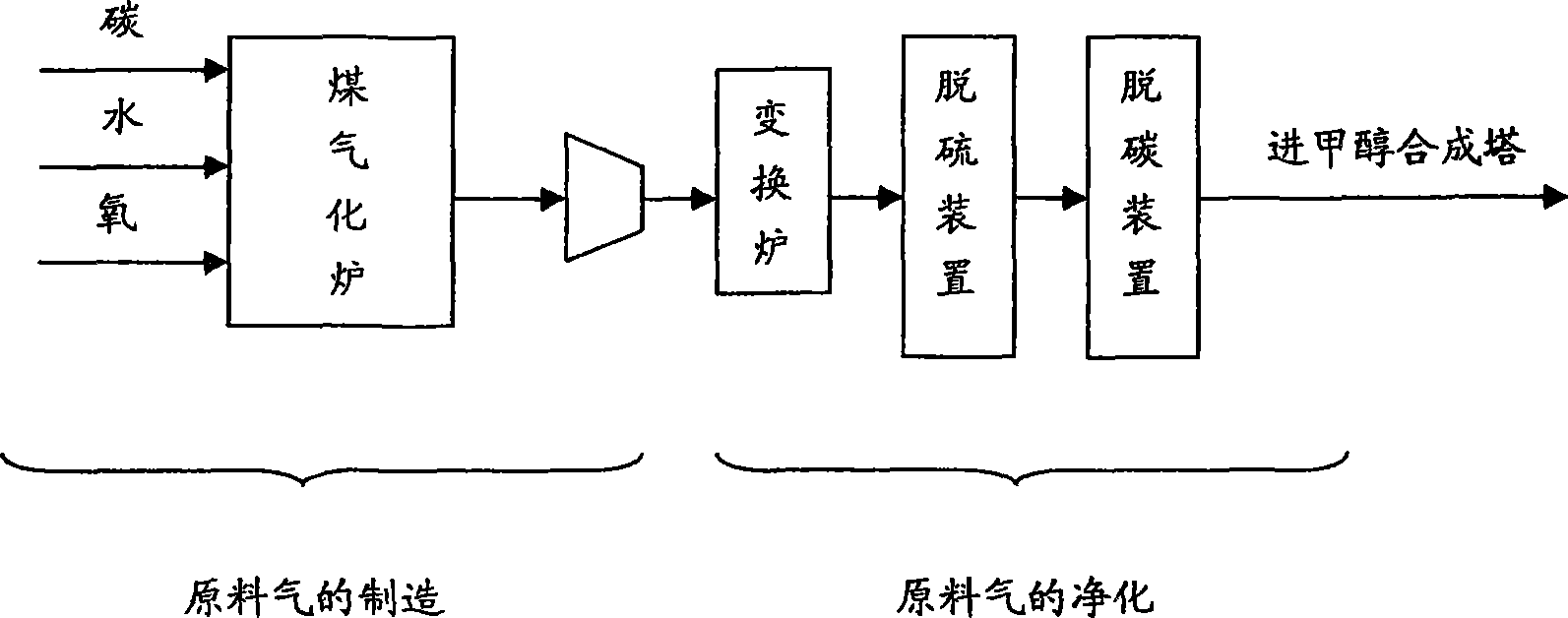

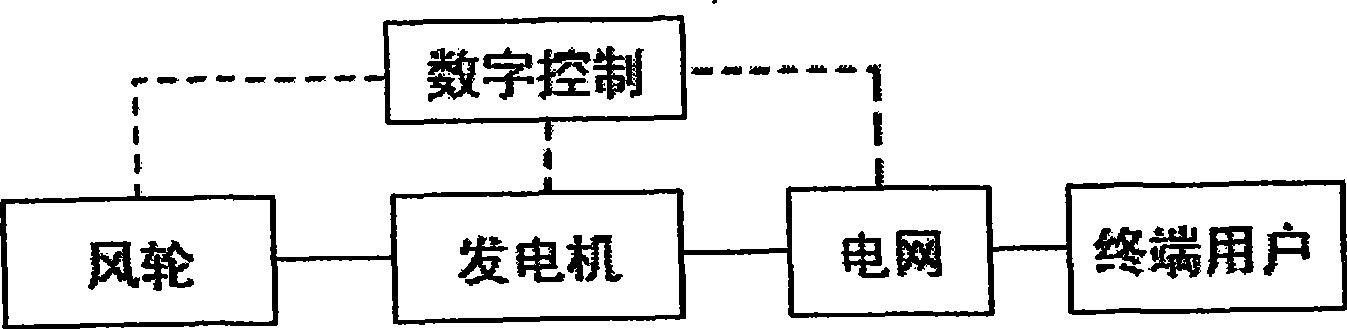

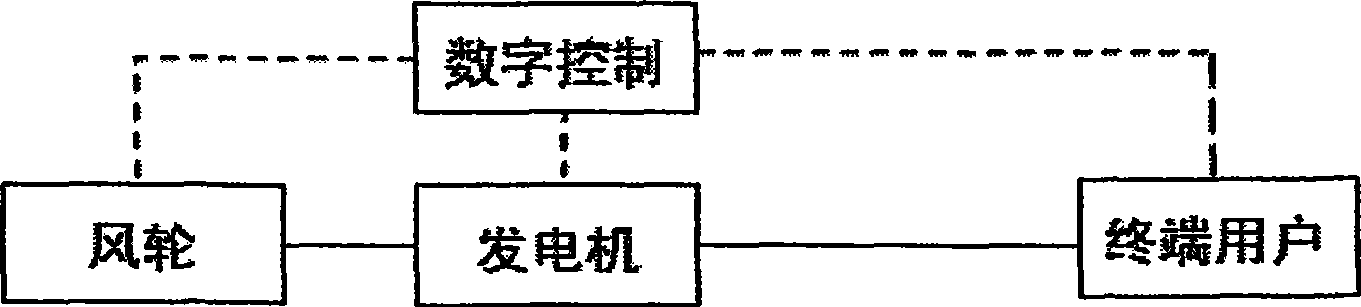

Method for directly applying large scale non-grid connected wind power to methyl alcohol production

ActiveCN101440019ALow investment costLow operating costElectrolysis componentsOrganic compound preparationElectrolysisAlcohol production

The invention relates to a method of directly applying large-scale non-grid-connected wind power to producing methanol. The method mainly uses the large-scale non-grid-connected wind power as a working power supply for electrolyzing equipment, uses oxygen electrolyzed by water as gasifying agent, uses hydrogen electrolyzed by the water to adjust carbon-hydrogen ratio in desulfurized water gas, and uses the water gas with the obtained optimal carbon-hydrogen ratio to prepare the methanol. The method has the advantages of: 1, improving the yield of the methanol greatly, wherein the yield of the methanol in coal unit is doubled; 2, reducing the equipment investment and operating cost of the methanol processing technology greatly, saving energy and reducing consumption; 3, reducing carbon dioxide discharge greatly by more than 92 percent compared with the prior method for producing the methanol; 4, reducing water consumption for producing each ton of the methanol by nearly 40 percent; and 5, accumulating and converting wind energy with instant variability into stable complementing energy or an important chemical raw material, making full use of regenerated wind resources, having little interference to environment and ecology. The method is a full good method for producing the methanol.

Owner:JIANGSU INFORMATION RES CENT

Vertical light wine solid-state continuous fermentation equipment and process

InactiveCN104357315ARealize continuous fermentationControl and improve fermentation qualityBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationAlcohol production

The invention relates to vertical light wine solid-state continuous fermentation equipment and a vertical light wine solid-state continuous fermentation process, and belongs to the technical field of alcohol production. The vertical light wine solid-state continuous fermentation equipment comprises a vertical fermentation tank, wherein a material distribution device is arranged at the upper part of the vertical fermentation tank, and a discharge port is formed in the lower part of the vertical fermentation tank; an upper discharge plug board and a lower discharge plug board are arranged at the discharge port, and are connected with and controlled by a gear mechanism to be alternately unplugged from or plugged into the vertical fermentation tank to control the continuous sinking discharge of fermented grains respectively. Materials are continuously fed into the fermentation tank and uniformly distributed at a feed port, are fermented into the fermented grains, continuously descend under the action of gravity at the same time, and are controlled by the upper and lower discharge plug boards to be continuously discharged, and the discharge speed is matched with the feeding speed to realize continuous fermentation. The equipment and the process are used for vertical continuous fermentation, and are favorable for improving the quality of a product, and the equipment and production running costs are lowered.

Owner:姜蓉生 +1

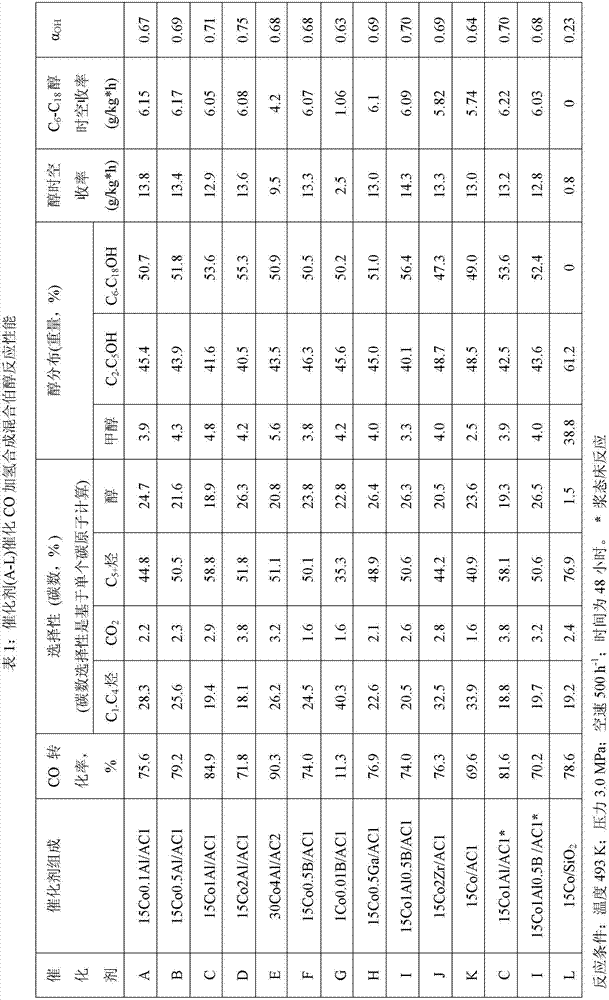

Catalyst used for increasing selectivity of higher carbon alcohol production via Fischer-Tropsch synthesis, and preparation method and applications thereof

ActiveCN103586060AHigh selectivityHigh conversion rate of COPhysical/chemical process catalystsLiquid hydrocarbon mixture productionPlasticizerActive component

The invention provides a catalyst used for increasing selectivity of higher carbon alcohol production via Fischer-Tropsch synthesis, and a preparation method and applications thereof, and specifically relates to a catalyst used for increasing selectivity of high carbon primary alcohols (more than 6 carbon atoms) in mixed primary alcohols prepared via hydrogenation of CO, and a preparation method and applications of the catalyst. According to the catalyst, active carbon is taken as a carrier, Co element is taken as an active component, one or more elements selected from Al, B or Ga are taken as auxiliary agents. The catalyst comprises 1 to 30wt% of the active component (based on the content of Co), and 0.01 to 5wt% of the auxiliary agents. The catalyst is capable of increasing selectivity of the high carbon primary alcohols (more than 6 carbon atoms) in the mixed primary alcohols prepared via hydrogenation of CO. The high carbon primary alcohols can be used as main raw materials of washing agents, plasticizers, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenating Acetic Acid to Produce Ethyl Acetate and Reducing Ethyl Acetate to Ethanol

InactiveUS20130131400A1Reduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogen

Disclosed herein are processes for alcohol production by reducing an ethyl acetate produced by hydrogenating acetic acid in the presence of a suitable catalyst. The ethyl acetate is reduced with hydrogen in the presence of a catalyst to obtain a crude reaction mixture comprising the alcohol, in particular ethanol, which may be separated from the crude reaction mixture. Thus, ethanol may be produced from acetic acid through an ethyl acetate intermediate without an esterification step. This may reduce the recycle of ethanol in the hydrogenolysis process and improve ethanol productivity.

Owner:CELANESE INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com