Novel method for producing ethanol with potato raw material

A new method and raw material technology, applied in the new field of potato raw material alcohol production, can solve the problems of unstable quality of alcohol products, equipment abrasion, unstable production, etc., to ensure long-term stable operation, reduce material consumption and energy consumption, and improve production efficiency. The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

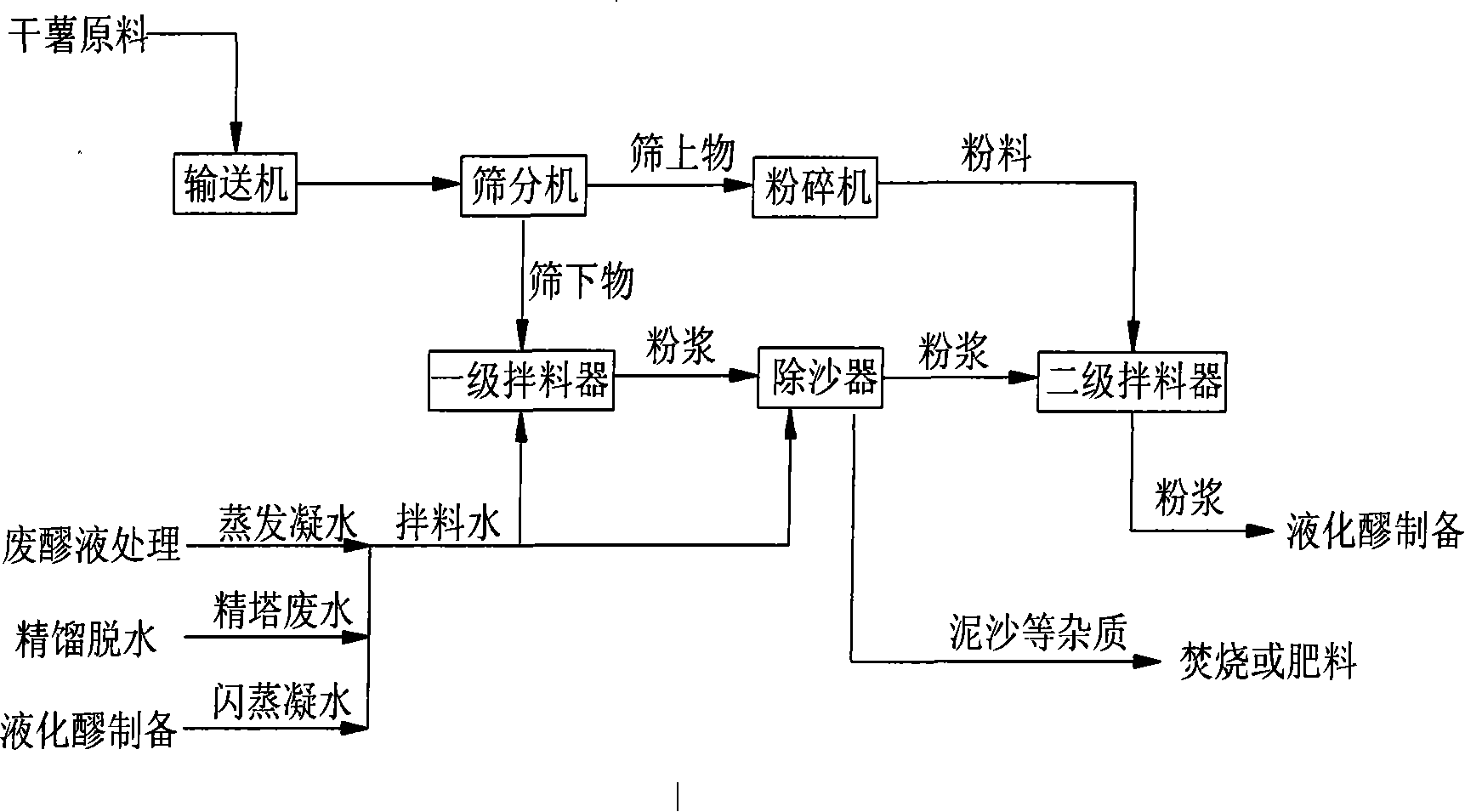

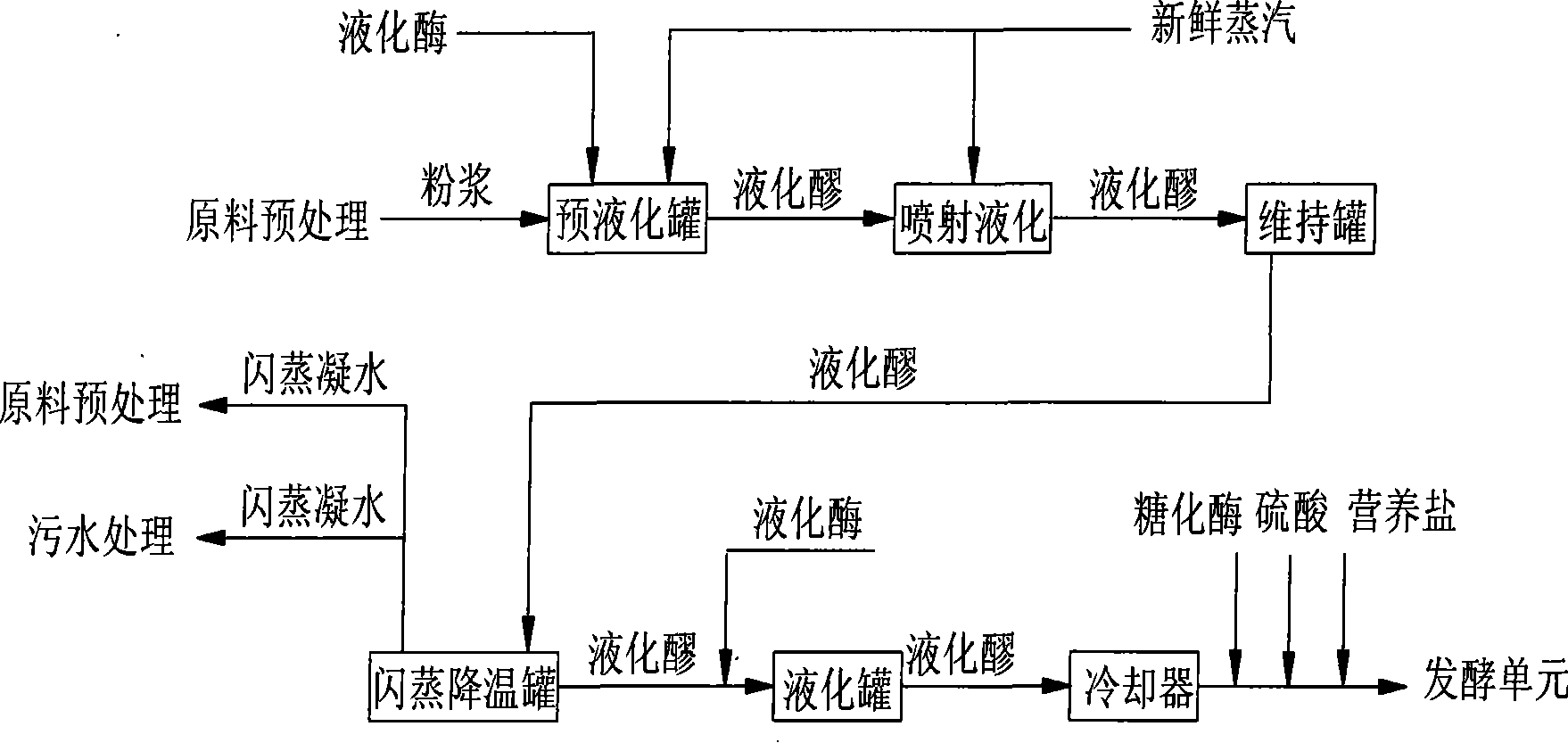

[0052] Using dried sweet potato as raw material, using figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The potato raw material alcohol production method shown is for the production of fuel ethanol.

[0053] The sweet potato dry raw material with a starch content of 65% is transported to a sieving machine by a conveyor with a sieve hole of 3.5 mm. The dried sweet potato on the sieve is sent to a pulverizer through a belt, and is pulverized into powder by the pulverizer in two stages. Sent to the secondary mixer for pulping. The undersize of the sieving machine is sweet potato dry powder rich in sand, accounting for 15% of the total raw material. The undersize is collected and sent to the primary mixer, mixed with mixing water to make a slurry to the desander The sand is washed and desanded by mixing water in the sand tank, and the sand and other impurities removed from the sand remover are collected and sent to the boiler for incineration. The slurr...

Embodiment 2

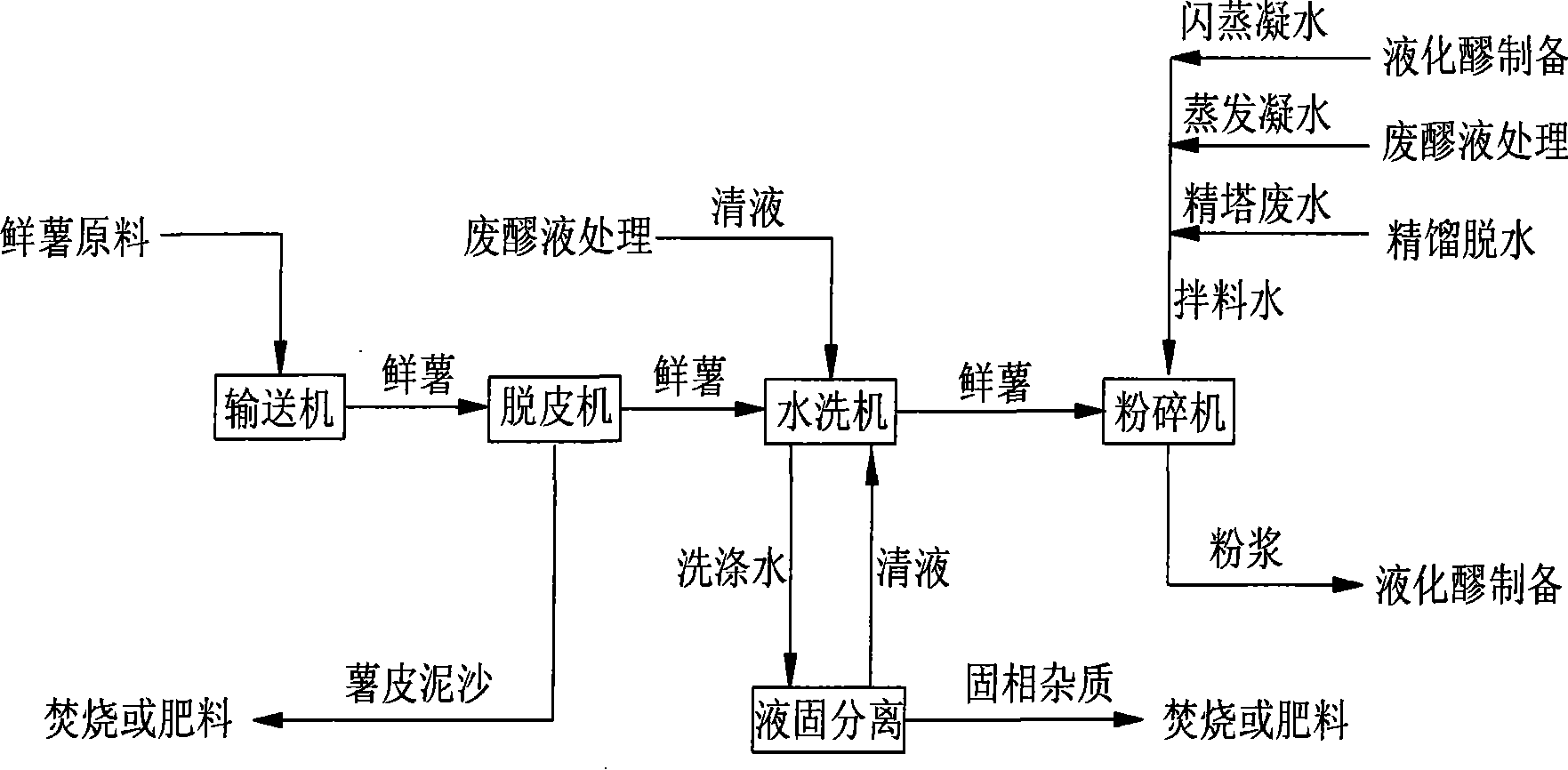

[0060] Using fresh cassava as raw material, using figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 The potato raw material alcohol production method shown carries out the production of edible alcohol, and concurrently produces industrial alcohol.

[0061] Fresh cassava raw materials with a starch content of 25% are sent to the peeling machine through a conveyor to remove most of the impurities such as potato skins and silt, which are collected and retting to be sold as fertilizer. The peeled raw materials are sent to the washing machine for cleaning, and the fresh potato raw materials after washing are sent to the pulverizer for pulverization and pulping. No mixing water is added, and the sieve hole of the pulverizer is 3.5×12mm. The washing water mixture containing potato skins and sediment is separated from liquid and solid through a centrifuge. The separated solid impurities are collected and sent to the boiler for incineration, and the separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com