Patents

Literature

627 results about "Industrial alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methanol is the most common industrial alcohol, with about 12 million tons/y produced in 1980. The combined capacity of the other alcohols is about the same, distributed roughly equally. Toxicity. With respect to acute toxicity, simple alcohols have low acute toxicities. Doses of several milliliters are tolerated.

Alcohol zircon flour coating for heavy castings and its production method

The invention relates to a paint used in large casting element and relative production, wherein said paint is alcohol-base zircon powder casting paint, which contains zircon at 62-75%, lithium-base at alta-mud 1-3%, deionized water at 1-3%, modified almasilate at 1-3%, nanometer clay at 0.15-0.8%, alumind at 0.020-0.08%, soluble polyester resin at 0.2-1.2%, polyvinyl butyral (PVB) at 0.1-0.8%, abietyl at 0.6-3%, industrial alcohol at 15-25%, alcohol isopropylicum at 1-5%, and aromatic solvent oil at 150#1-5%. The inventive product has high fire resistance, etc.

Owner:德阳立达化工有限公司

Iron spar powder, guartz sand cement rock-soil similar material and preparation process thereof

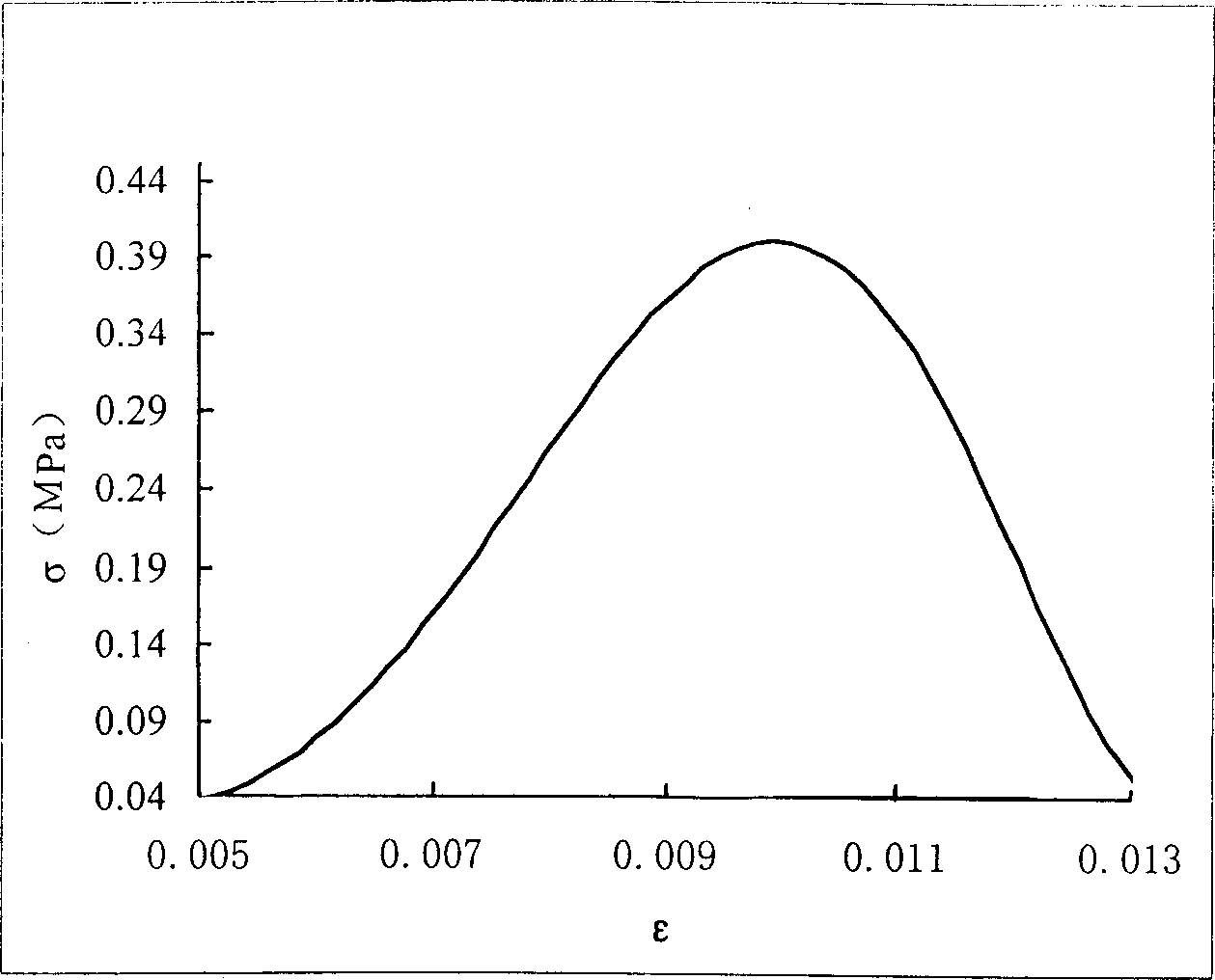

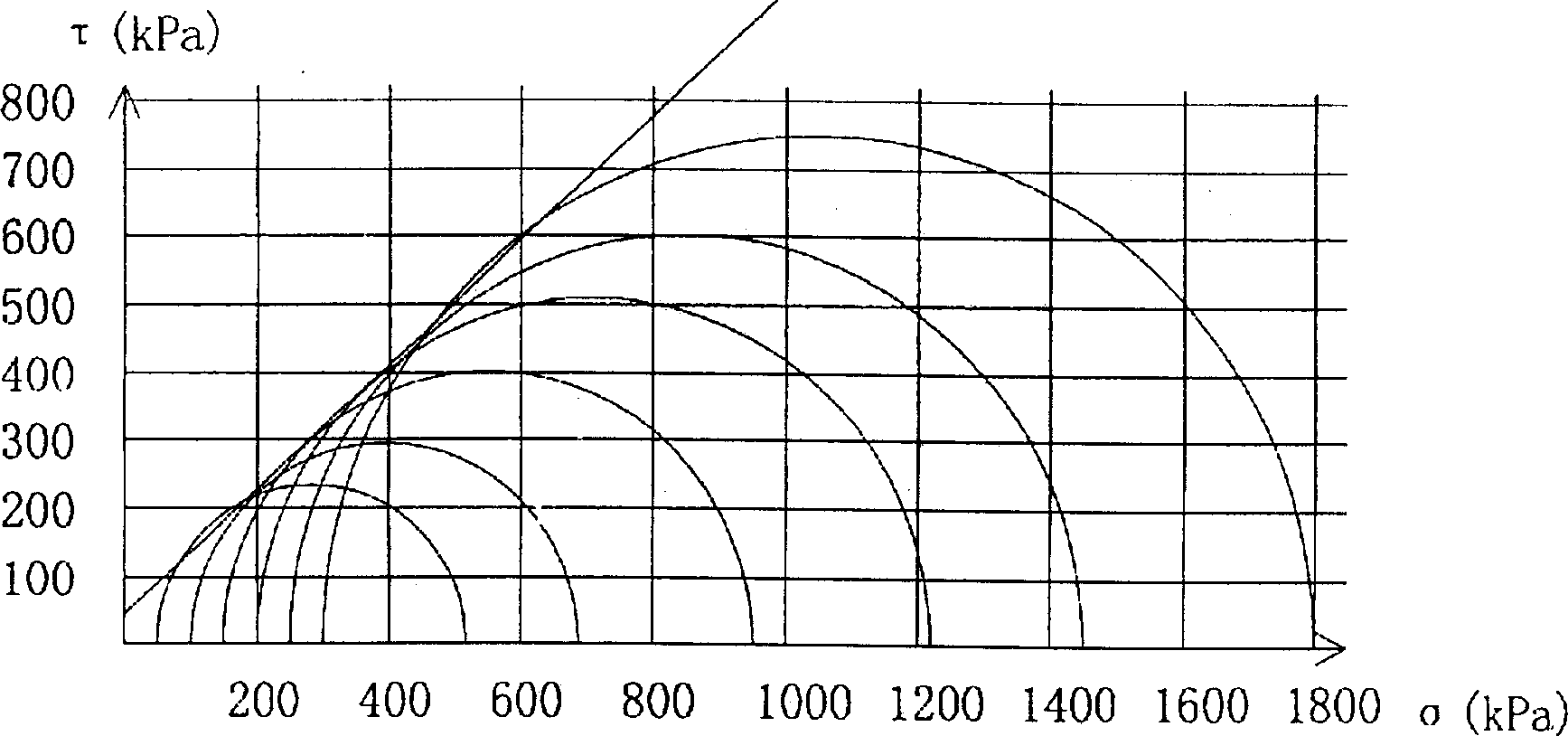

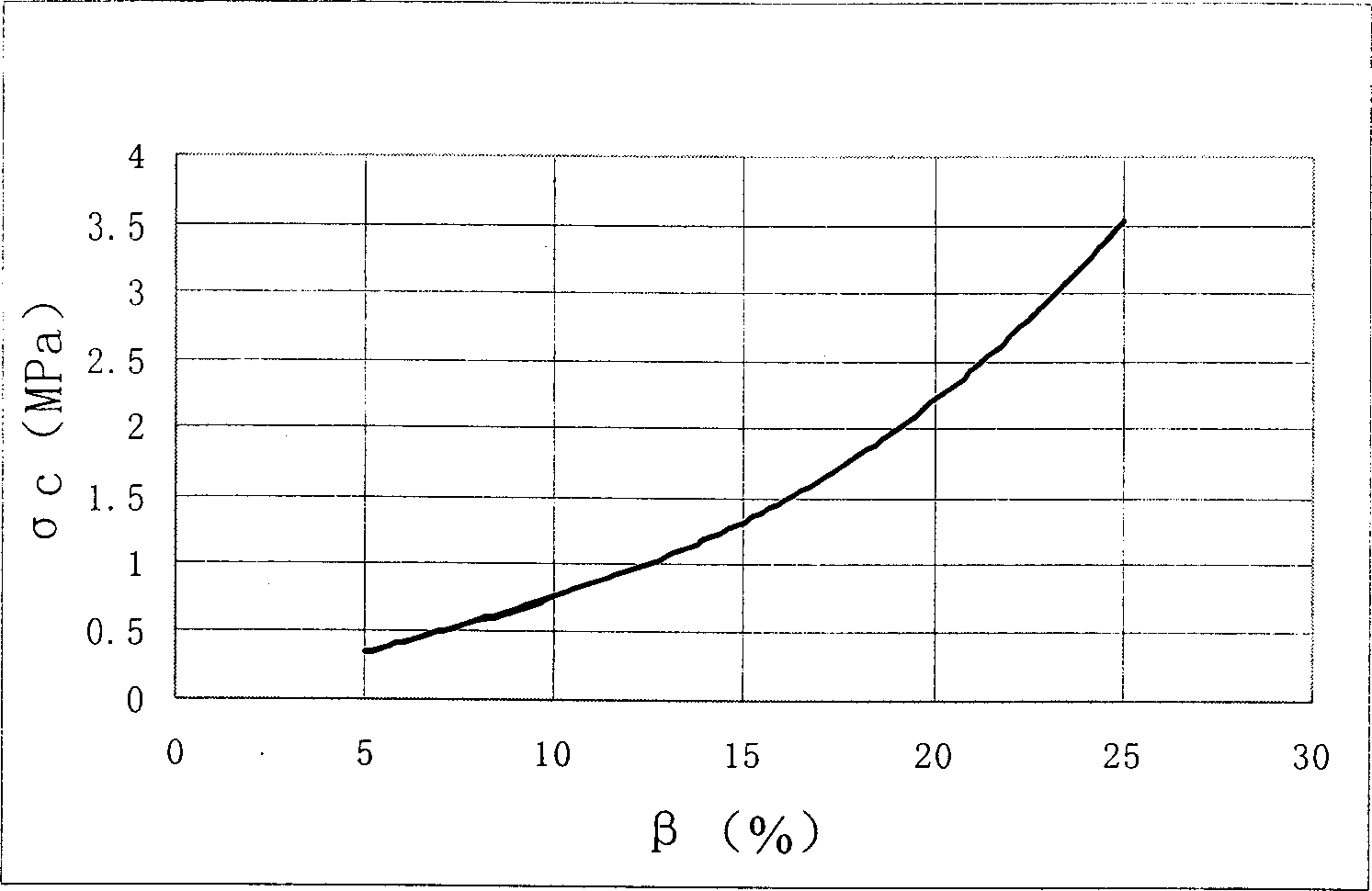

The invention relates to a method to produce equivalent material of iron crystal sand cemented rock soil that uses iron ore, barite powder and quartz sand as main aggregate, uses solution that is made up from rosin and alcohol as cementing agent, and uses gesso as regulator. Whisking the iron ore, barite powder and quartz sand, gesso, resin-alcohol solution to equal, pouring into steel mould, pressing the mixture, opening the mould, drying for 2-3 days, the invention could be gained. The invention has the advantages of high unit weight, large range of mechanics parameter, easy to process and low cost.

Owner:SHANDONG UNIV

Fe-Mo catalyst for preparing formaldehyde through methanol oxidation and preparation process thereof

ActiveCN1546232ASuitable structureSuitable grainOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHeat stabilityFour component

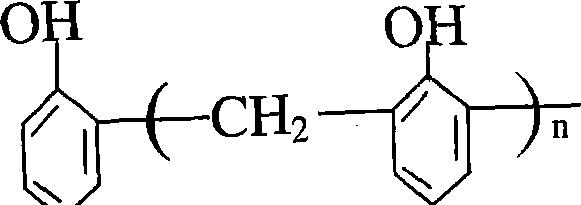

The invention refers to a kind of formaldehyde iron phase catalyst made up by oxidizing in industrial alcohol and the manufacturing method. Oxide of chromium and vanadium are added into the iron-molybdenum catalyst system, forms the four-component catalyst system; the shape of the catalyst is designed as a hollow cylinder ring structure, it has low catalyst bed resistance in using, the catalyst has a high alcohol converting rate and high yield of formaldehyde, the heat stability of catalyst is good and the lifespan is long.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Method for industrial production of ethyl alcohol by using straw or corn or Chinese sorghum straw

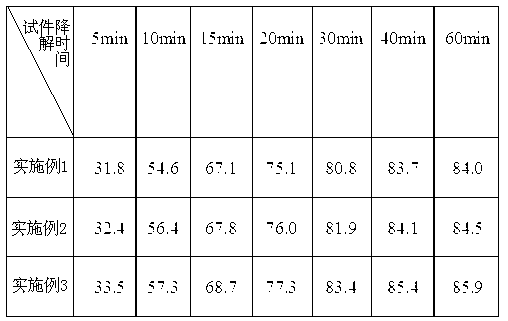

InactiveCN101041834AReduce pollutionIncreased degradation rateBiofuelsFermentationBiotechnologyAlcohol

The invention discloses a processing craft with rice straw or corn or sorghum straw to produce industrial alcohol, which comprises the following steps: pressing the rice straw and straw to brick; disposing with 60Co-gama ray of 0.5-2.0X106Gy or electron-beam accelerator; grinding with mechanical; screening through 200 order sieve; leaching with hot water; stripping lignin with alcohol; degrading enzyme; separating 1-2 mu m cord hole film; synchronous-saccharifying saccharomyces cerevisiae and pichia; dispersing and yeasting; dewatering and separating the alcohol; getting the product.

Owner:湖南省原子能农业应用研究所 +1

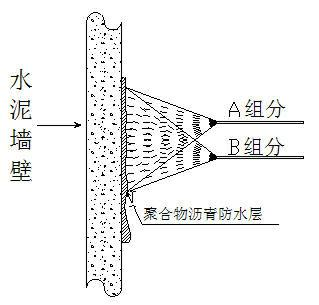

Polymer modified emulsified asphalt composition and preparation method thereof

ActiveCN102675889ARaw materials are cheap and easy to getImprove adhesionConjugated diene hydrocarbon coatingsChloropene polymer coatingsPolymer sciencePolymer modified

Owner:SHANXI MINGKESI TECH

Method for manufacturing electric brush used for industrial motor

InactiveCN102074875AGuaranteed uniformityImprove the lubrication effectBrushes manufactureEpoxyCopper

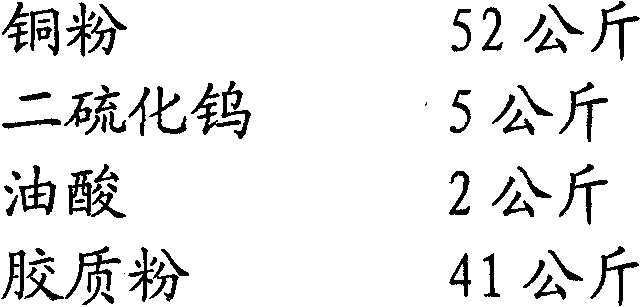

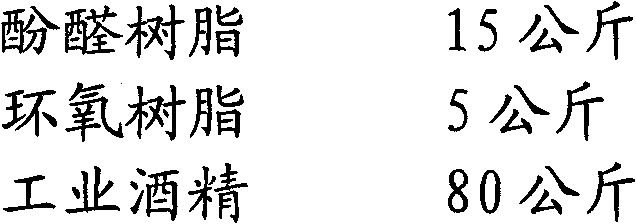

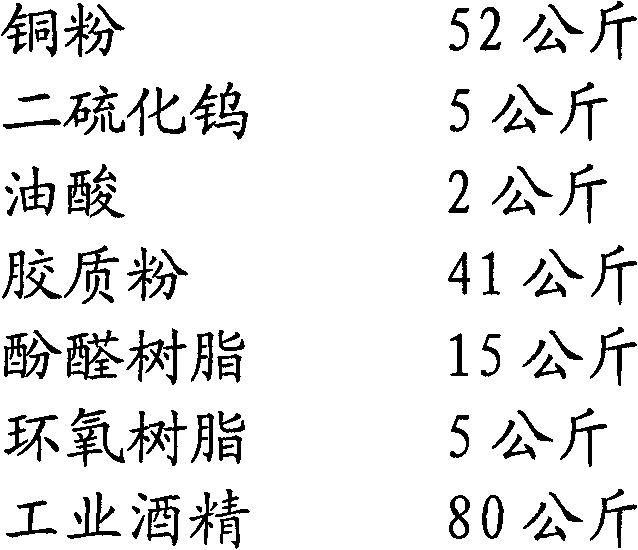

The invention discloses a method for manufacturing an electric brush used for an industrial motor. In the method, a main material is formed by proportioning 52 kilograms of copper powder, 5 kilograms of tungsten disulfide, 2 kilograms of surfactant oleic acid, 41 kilograms of rubber powder, 15 kilograms of phenolic resin, 5 kilograms of epoxy resin and 80 kilograms of industrial alcohol. The invention also discloses a preparation process for the electric brush used for the industrial motor. The method has the advantages of high abrasion resistance, prolonged service lives of the electric brush and a motor slip ring and the like.

Owner:杨长根

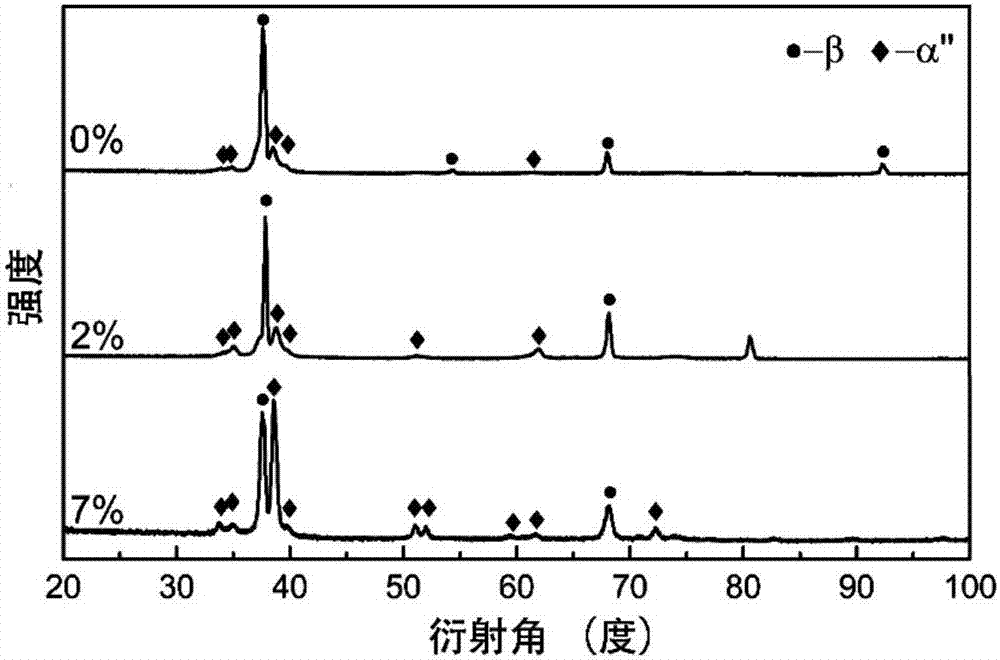

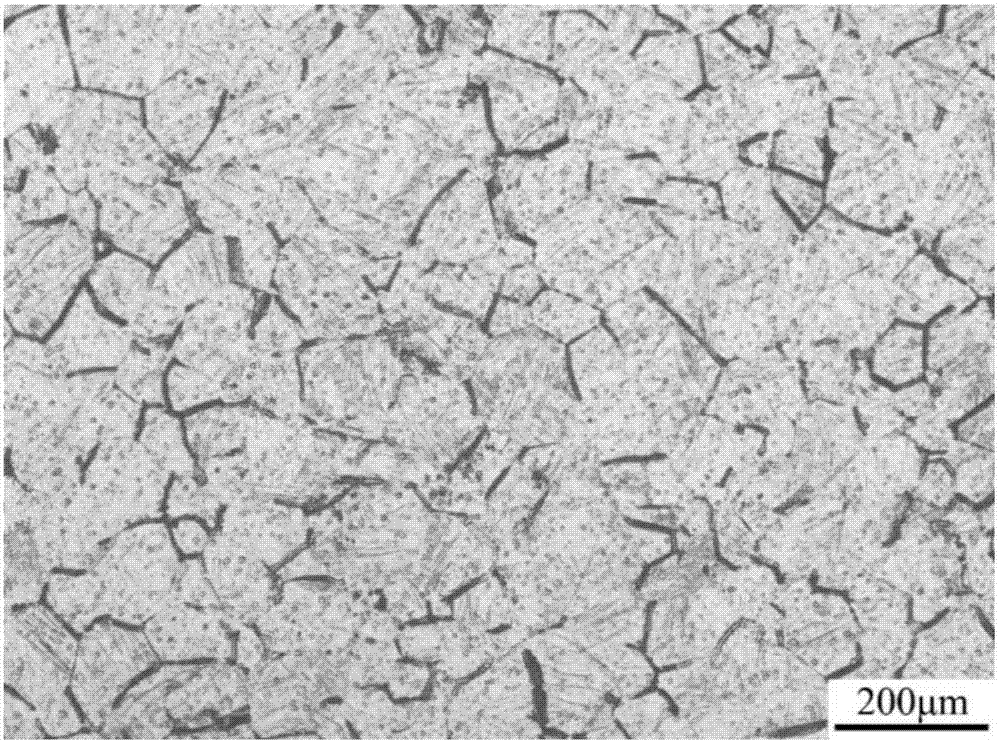

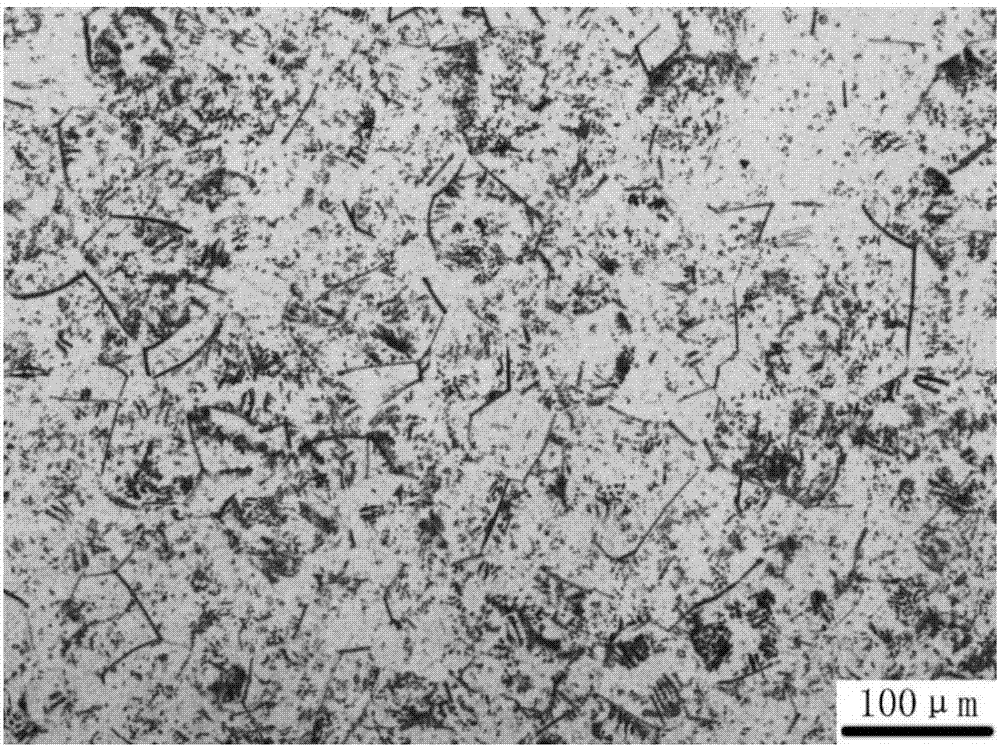

Hyperelastic TiZrHfNbAl high-entropy alloy and manufacturing methods thereof

The invention relates to a hyperelastic TiZrHfNbAl high-entropy alloy and manufacturing methods thereof, and belongs to the field of high-entropy alloy materials. The alloy ingredient expression is TiaZrbHfcNbdAle. The two manufacturing methods are included, according to one manufacturing method, a mechanical and chemical combined method is used for removing surface scale of raw material metal, and the raw material metal is washed through industrial alcohol ultrasonic vibration; a vacuum arc furnace is used for melting the alloy, and when the vacuum degree reaches 5*10<-2> Pa, industrial argon is inflated; and after a mother alloy is sufficiently melted evenly, a vacuum casting or suction-casting device is used, the alloy is injected into a water cooling copper die, a high-entropy alloy bar is obtained, cold rolling is carried out at the room temperature until the thickness is 30% to 80% of the original thickness, a surface layer is removed, washing through industrial alcohol ultrasonic vibration is carried out, and then the product is sealed into a quartz tube full of argon for heat treatment. According to the other manufacturing method, preparation according to the weight percentage is carried out, pressing is carried out after even mixing is achieved, an electrode is obtained, then vacuum melting is carried out in a vacuum consumable electrode electric arc furnace, an alloy bar is obtained through casting in a vacuum consumable electrode skull furnace, alloy remelting and casting are carried out, and the processes are repeatedly executed two to three times.

Owner:UNIV OF SCI & TECH BEIJING

Alcohol group mold wash used for low-pressure casting of aluminum alloy sand mold and coating process thereof

The invention relates to alcohol group mold wash used for the low-pressure casting of an aluminum alloy sand mold and a coating process thereof. The wash comprises the aggregates of talcum powder and titanium pigment, the adhesives of argil and water glass and a solvent of industrial alcohol and is formed by manual or mechanical stirring and mixing. The granularities of the talcum powder, the titanium pigment and the argil select different grain size grades. In the coating procedure of the mold wash of the sand mold, a mode combining rendering and spraying is adopted. After the preparation ofa cast of the sand mold is finished, the wash with coarse particles is firstly rendered at the surface of the cast, a coating is polished after solidification, then the wash with fine particles is sprayed, and the mold is combined and cast after baking. The invention has the advantages of low production cost, simple process, high quality of the surface of the cast and easy popularization.

Owner:NANTONG L S LIGHT METAL FORMING

Method for producing chitosan fiber with high hydroscopic property

ActiveCN101624778AAdequate hemostasis and anti-inflammationPromote healingAbsorbent padsAnimal fibresWater bathsFiber

The invention relates to a method for producing a chitosan fiber with high hydroscopic property, which comprises the following specific steps: 1, fully dissolving butanedioic anhydride into absolute ethyl alcohol or ethanol or industrial alcohol, adding hydrochloric acid and adjusting the pH value of the mixed solution to be 2-6; 2, soaking the chitosan fiber in the absolute ethyl alcohol or the ethanol or the industrial alcohol for 60 minutes and dewatering; 3, placing the dewatered chitosan fiber and the mixed solution of the step 1 into a thermostatic water bath for 5 to 120 minutes, dewatering the chitosan fiber, flushing the chitosan fiber with the absolute ethyl alcohol or the ethanol or the industrial alcohol and then dewatering; and 4, placing the chitosan fiber into mixed solution of Tween series surfactants and the absolute ethyl alcohol for soaking, dewatering and air-drying. The chitosan fiber produced by the method has the characteristic that gel is formed when encountering water, can absorb effluent liquid flowing from wound, ensures that the chitosan fiber is fully contacted with the wound surface to achieve the functions for quickly absorbing the blood on the wound surface, diminishing inflammation and promoting the wound to heal, and ensures that the periphery of the wound is maintained in the moisture environment in the healing process so that the wound easily heals.

Owner:QINGDAO JIFA GROUP

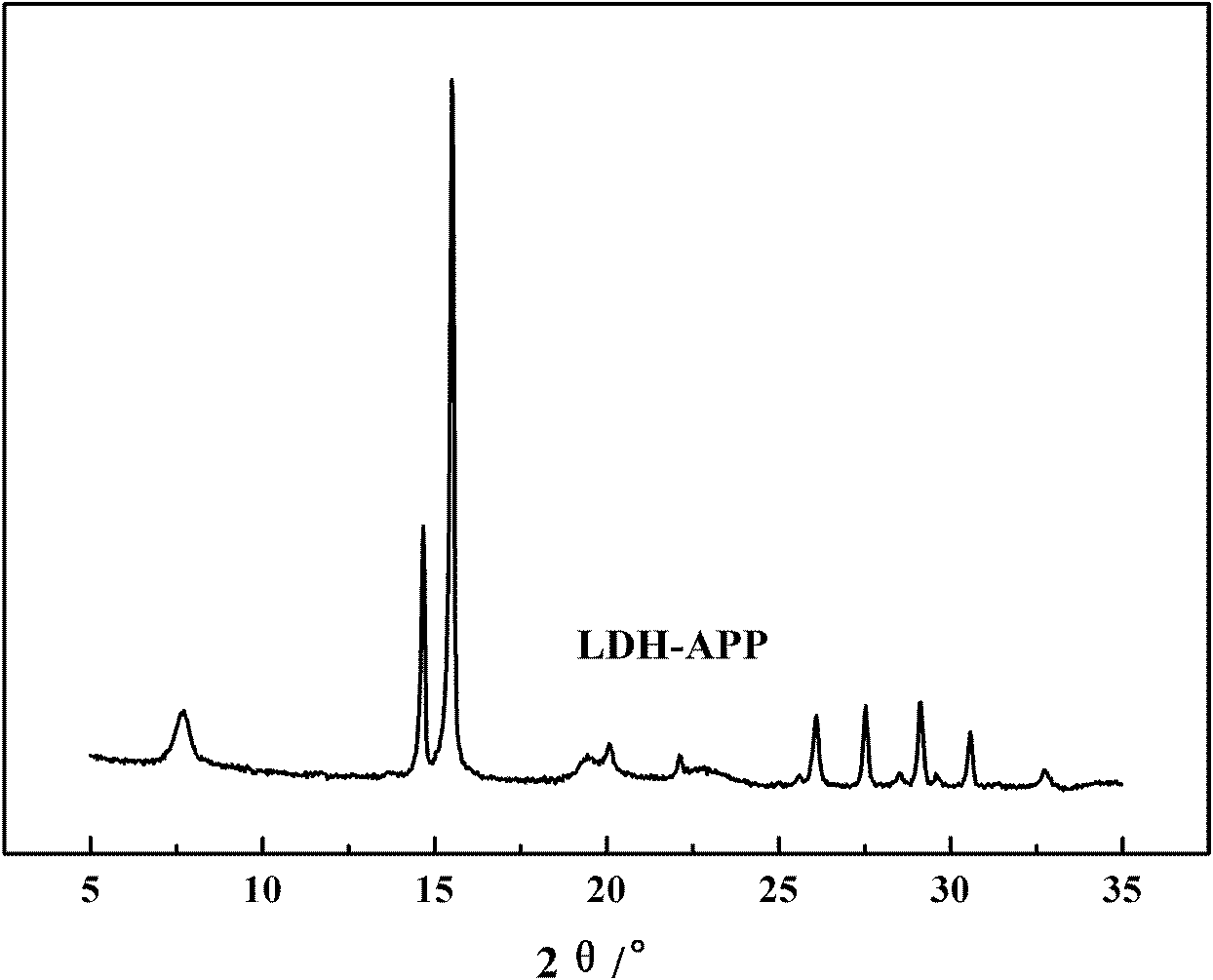

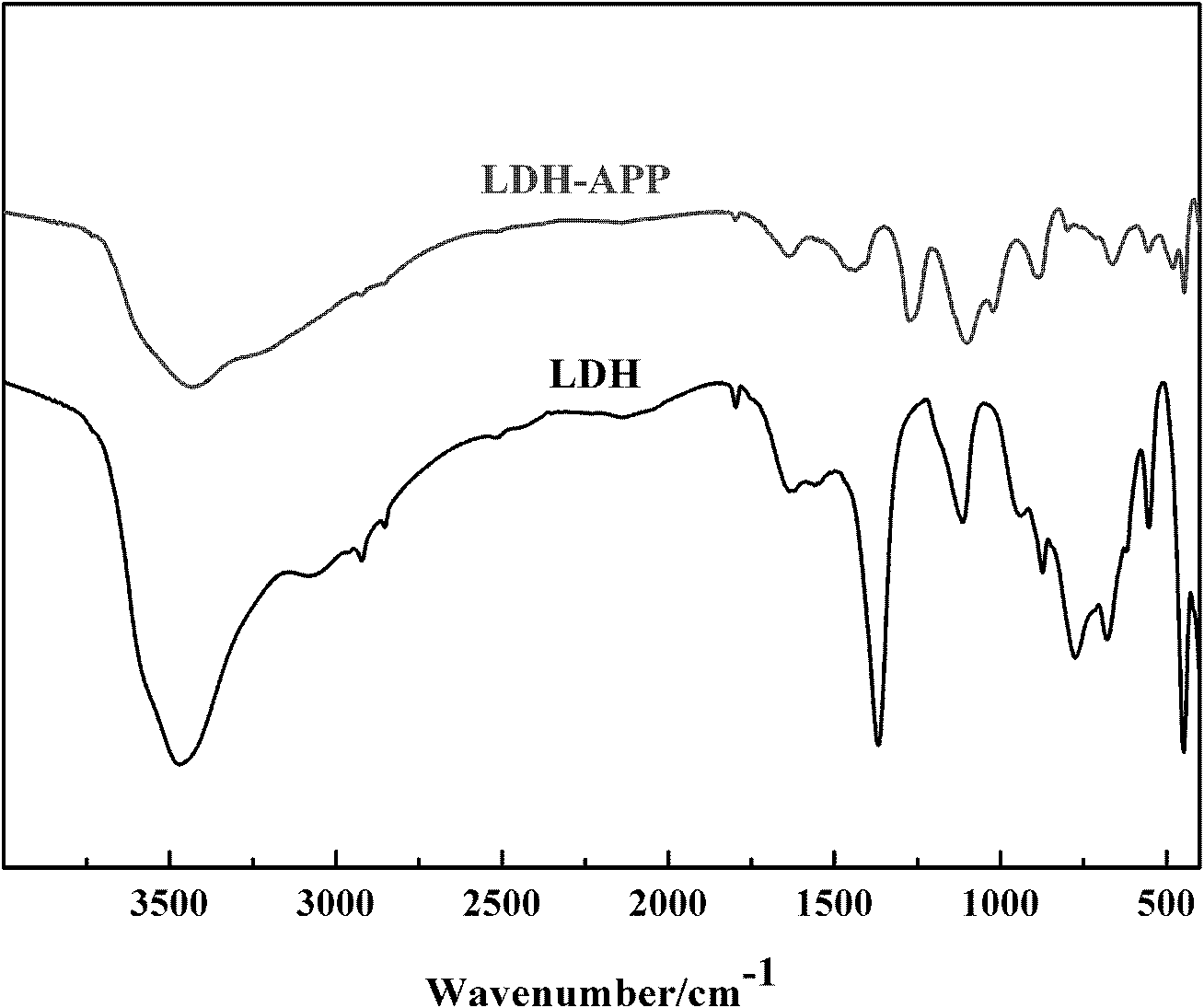

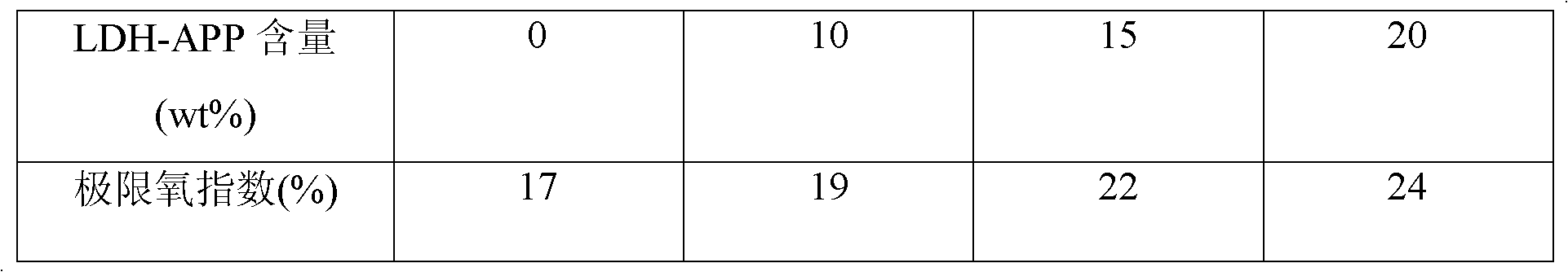

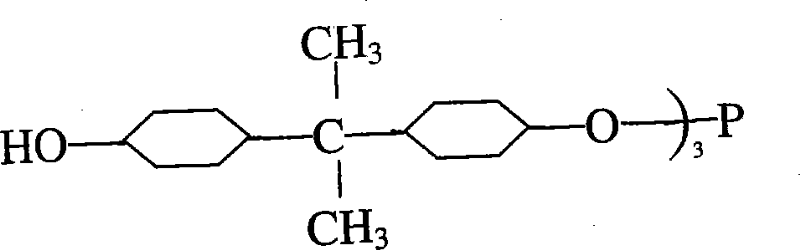

Hydrotalcite-ammonium polyphosphate halogen-free flame retardant and preparation method thereof

Owner:ZHEJIANG UNIV OF TECH

Method for preparing boron carbide ceramic composite material based on reaction sintering

The invention relates to a method for preparing boron carbide ceramic composite material based on reaction sintering. The method comprises the following steps: depositing a layer of metallic titanium on the surface of boron carbide powder, mixing the boron carbide powder with carbon black powder, phenolic resin powder and industrial alcohol, carrying out ball milling, drying, granulating to obtain a precursor mixed powder, placing the precursor mixed powder in a die to produce a precursor pressed compact, disposing powdery or blocky silicon on the precursor pressed compact, placing the obtained compact in a vacuum furnace, carrying out silicon infiltration reaction sintering, cooling in a furnace, and removing superfluous silicon on the surface to obtain the boron carbide ceramic composite material. Compared with the prior art, the method has the advantages of simple process steps, effective solving of the problem of high temperature and high pressure sintering needed by routine technologies, low production energy consumption and preparation cost, and very good application prospect.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

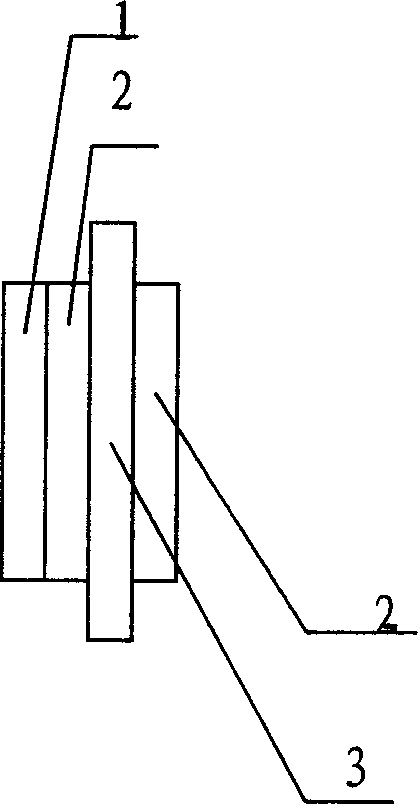

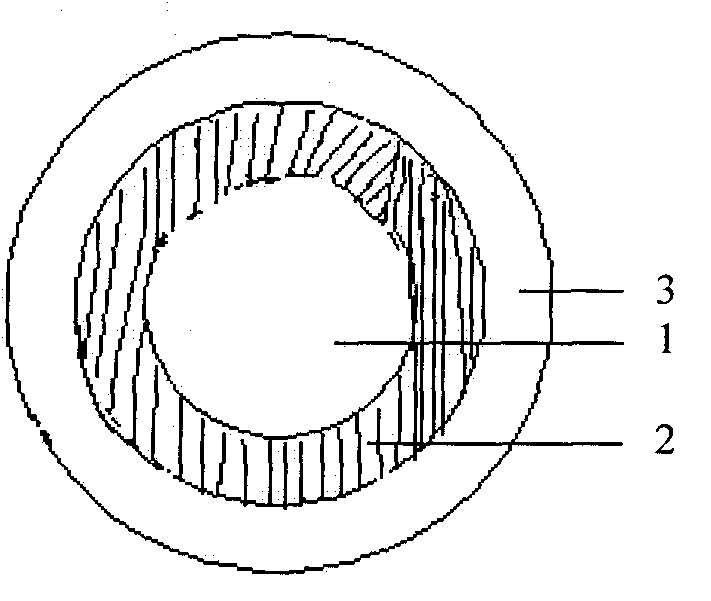

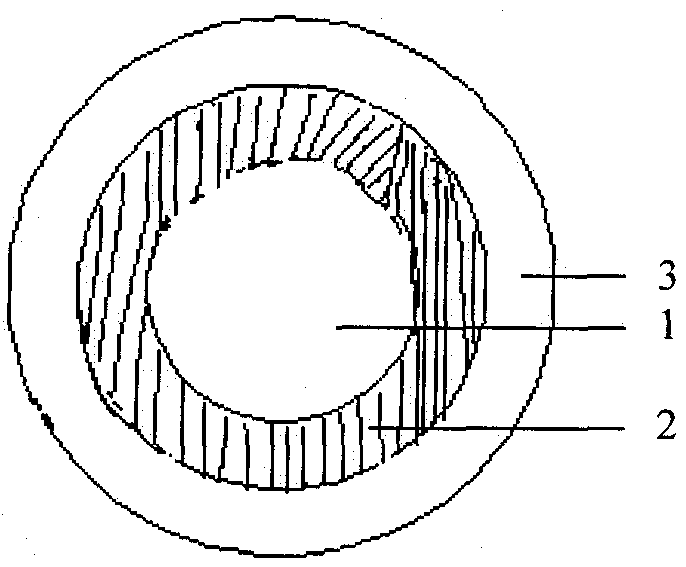

Positive electrode for zinc-air battery and its manufacturing method

InactiveCN1738085AChange structureChange granularityFuel and primary cellsCell electrodesElectrolysisEngineering

The invention relates to a positive electrode of zinc-air battery and its manufacturing method. Said positive electrode comprises a catalytic layer (2) mixed by polytetrafluoroethylene emulsion and the mixture which uses industrial alcohol to infiltrate carrier, conductor, and catalytic agent; a flow collector (3) and a waterproof layer (1), wherein, said catalytic agent is electrolytic manganese dioxide material. Since the conductor selects expansible graphite and the flow collector (3) selects nickel-plated iron net, the surface of material is increased more than 400 % to improve the ability of absorbing oxygen of electrode, and the conductivity of material is increased 40 % to improve the discharging current density and reduce the cost. The electrolytic manganese dioxide is processed into manganese dioxide powder, to change the crystal phase structure and its particle, so the manufacturing process is simplified.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Reproduced energy-saving material produced by using waste raw material and usage thereof

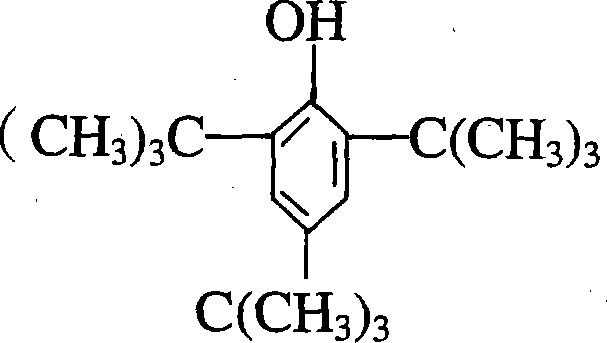

The invention discloses a regenerative energy saving material by using waste raw material, setting the mass percent at 42-52% regenerating particle mixed with waste polyvinyl chloride, waste polyethylene and waste propane polymer, 42-52% waste tailings ore, 0.5-0.8% silane cross linker, 0.2-0.5% antioxidant phosphorous acid bisphenol A or 2, 4, 6-tri- tertiary butyl phenol, 2-3% epoxide modified phenol resin or oil resin, 0.5-1% cadmium zinc heating stabilizer and 1-2% waste machine oil, the surplus is industrial alcohol. This material can be used to produce inspection cub, well cover, sewer well grate, curb, dustbin, railway sleeper or environmental material.

Owner:XIAN TIANJIU ENVIRONMENT PROTECTION REGENERATIVEMATERIAL

Preparation method of nano-copper powder

ActiveCN102586800AGood dispersionNo emissionsElectrolysis componentsElectrolytic organic productionChemical reactionHigh pressure

The invention discloses a preparation method of nano-copper powder, which comprises the following steps of: in a self-made special electrolytic cell, taking metal copper as an anode, taking conducting material as a cathode, taking electrolyte as organic alcohol, taking ammonium salt which is soluble in the electrolyte as electrolyte, forbidding the ammonium salt to participate chemical reaction, and combining the cathode copper with the organic alcohol, so that the precursor of the nano-copper can be generated; mixing the precursor of the nano-copper, the organic alcohol or the other saturated hydrocarbon with the unsaturated hydrocarbon liquid, and sealing the precursor of the mixed nano-copper in a high-pressure kettle to be subjected to reductive treatment, so that the nano-copper powder can be obtained; and separating the nano-copper powder from the mixture of the reduced nano-copper powder and the organic solvent by an industrial centrifugal machine device, and washing with industrial alcohol, so that wet nano-copper powder can be obtained, putting the nano-copper powder into a vacuum drying oven, and treating, so that the nano-copper powder which accords with the national standard can be obtained. The preparation method has the advantages of being free of pollution in reaction process, small in investment, low in cost, good in product dispersibility, even in distribution, and capable of realizing different-quantity production.

Owner:安徽纳洛米特新材料科技股份有限公司

Preparation method of alcohol soluble normal-temperature curing bi-component polyurethane-acrylate resin

InactiveCN101787170AGood alcohol solubilityImprove environmental adaptabilityPolyurea/polyurethane coatingsSolubilityEpoxy

The invention relates to a preparation method of alcohol soluble normal-temperature curing bi-component polyurethane-acrylate resin. The preparation method comprises the following steps of: preparing a substance A; preparing a substance B; and mixing the substance A and the substance B in the proportion of 3-6:1 to obtain the alcohol soluble normal-temperature curing bi-component polyurethane-acrylate resin, wherein the raw material substance A comprises acrylate, epoxy group monomer, vinylacetate or styrene, more than one type of active functional group monomer, initiating agent and industrial alcohol; and the raw material substance B comprises oligomer polyalcohol, polyisocyanate, chain extending agent, catalyst, polyamine, solvent and industrial alcohol. The alcohol is completely used as the solvent, and the alcohol solubility is favorable; compared with a bi-component polyurethane product, the components contain no toxic and dissociative isocyanate, and the obtained product has strong environmental adaptation, low requirements on moisture and interface cleaning degree, high drying speed after being coated, normal-temperature curing, good glossiness, large adjustable range of glass temperature and wide application range.

Owner:ANHUI UNIVERSITY

Coating for metal mold casting of aluminum alloy thin-walled piece and preparation method and coating method thereof

InactiveCN102145372AImprove filling abilityImprove feeding capacityFoundry mouldsFoundry coresAdhesivePhosphate

The invention provides a metal mold casting coating for an aluminum alloy thin-walled piece. The coating is prepared from refractory aggregate, adhesive and carrier liquid, wherein the refractory aggregate contains kieselguhr, corundum powder, titanium dioxide and asbestos powder; the adhesive is silica sol or anhydrous phosphate; the carrier liquid is industrial alcohol; and the coating comprises the following components in part by weight: 0.5 to 1 part of kieselguhr, 0.5 to 1 part of corundum powder, 1.5 to 3.5 parts of titanium dioxide, 3 to 7 parts of asbestos powder, 0.6 to 1 part of silica sol or anhydrous phosphate, and 20 to 60 parts of industrial alcohol. The invention also provides a preparation method for the coating; the method comprises the following steps of: putting the refractory aggregate and the adhesive into a container with proper size, stirring the refractory aggregate and the adhesive uniformly through manpower or a machine, pouring the industrial alcohol into the container, and stirring uniformly for later use. The invention finally relates to a coating method of the coating. When the coating is used, the temperature of a die is between 180 and 400 DEG C, and a coating with the thickness of 0.1 to 0.5 millimeter is coated on the surface of the die.

Owner:SHANGHAI AIERSI LIGHT ALLOY

Production method of PE weftless bullet-proof helmet

InactiveCN1515869AImprove bending performanceLong flex lifeSynthetic resin layered productsPersonal protection gearTO-18Aramid

The present invention relates to a method for producing high-performance PE fibre composite weftless fabric bullet-proof helmet. It includes the following steps: accoridng to the form and size of required helmet cutting aramid fibre fabric, previously brushing pre-prag material, spraying demoulding agent on the mould, tightly sticking a layer of aramid fibre pre-preg material on the male mould, then successively cross-laying 20-25 layers of high-performance PE weftless fabric, closing mould and applying 5MPA pressure, escaping air, heating to 125-130 deg.C and increasing pressure to 18-20 MPA, retaining constant temp. and constant pressure for 10 min, then cooling to below 80 deg.C and opening mould so as to obtain the invented product. The pre-preg material is made up by using PVB industrial alcohol colloidal solution whose concentration is about 10%.

Owner:NINGBO DACHENG ADVANCED MATERIAL

Glass fiber screen cloth immersing glue solution for grinding wheel reinforcement and initial rinsing method

InactiveCN101139172ASolve the problem that is easy to cause scrap rateReduce pollutionHydrometerFiberglass mesh

The present invention discloses a glass fiber mesh fabric dip solution for reinforcement of grinding wheel and the dipping method, which belongs to the field of composite materials; wherein the dip solution is formed by mixing the industrial alcohol with the liquid phenolic resin, the solid content of which is larger than or equal to 65 percent. The mixing ratio between the liquid phenolic resin against the industrial alcohol ranges from 1:0.15 to 0.20. The presoaking method is realized by utilizing the conventional dipping machine and the specific operating steps are that the glass fiber mesh fabrics are delivered into a dipping groove through a fabric transportation drum and a fabric storage roller so as to be dipped by the dip solution arranged in the dipping groove; then the dipped glass fiber mesh fabrics go into the rubber pressing by a dandy roll and then are fed into an oven to be pre-cured; the dipped glass fiber mesh fabrics are pulled out by a traction device and are trimmed and rolled up after passing through a buffering fabric storage roller and a deviation-correcting device. Two kinds of raw materials are selected as the raw materials of the present invention, thus simplifying the confection process of the present invention; the hydrometer is used to measure and adjust the proportion of the dip solution, thus resulting in that the gum chicle content is effectively controlled and the quality of products is stable; the volatile quantity is lowered from originally 5 percent to 1.5 percent. The glass fiber mesh fabric dip solution for reinforcement of grinding wheel causes few contaminations to the environment, has low cost and is easy to be popularized and put into use.

Owner:北京玻钢院复合材料有限公司

Fertilizer and pesticide combination reagent for preventing and killing bacterial canker of kivifruit and preparation method of fertilizer and pesticide combination

ActiveCN104628481AHigh affinityHigh activityNitrogenous fertilisersFertilizer mixturesLiquid productFermentation

The invention discloses a fertilizer and pesticide combination reagent for preventing and killing bacterial canker of kiwifruit and a preparation method of the fertilizer and pesticide combination reagent. The fertilizer and pesticide combination reagent is prepared from the following raw materials in parts by weight: 200 parts of agricultural amino acid water soluble powder, 40-50 parts of anhydrous zinc chloride, 45-65 parts of anhydrous manganese chloride, 40-80 parts of a ciprofloxacin active compound or a ciprofloxacin active compound, 100-200 parts of a 14% methyl chloride isothiazolinone water agent, 100-150 parts of oxine-copper active compound, 0.1 part of forchlorfenuron, 0.1 part of a 5-nitroguaiacol sodium salt active compound, 0.5 part of an alpha-pimacol active compound, 350-450 parts of molasses microbial fermentation concentrate solution, 0.2-0.25 part of sodium polyacrylate powder, 50-60 parts of No.YD-7 liquid fertilizer synergia solution, 0.1-0.2 part of industrial alcohol and the balance of deionized water to supplement the raw materials to 1200-1250 parts. The fertilizer and pesticide combination reagent disclosed by the invention is a high-density liquid product with fertilizer and pesticide effects, has good affinity for both water and plants, mainly contact and kill plant bacteria, and can also kill pathogenic fungus. A layer of compact organic pesticide and fertilizer film is formed outside a tree body when the fertilizer and pesticide combination reagent is applied in large concentration, and a sustained release function is exerted.

Owner:贵州三福生物科技有限公司 +1

Photocatalytic degradation composite particle as well as preparation method and application thereof

ActiveCN103252225ALarge specific surface areaHigh porosityPhysical/chemical process catalystsDispersed particle separationPhysical chemistryPhotocatalytic degradation

The invention relates to a photocatalytic degradation composite particle which is characterized by comprising the following components: nanometer anatase TiO2, a micrometer porous material kieselguhr and a dispersing solution, wherein the dispersing solution is a mixture of a coupling agent and industrial alcohol; and the mass ratio of the nanometer anatase TiO2 to the micrometer porous material kieselguhr to the coupling agent to the industrial alcohol is 1:(2-6):(0.1-0.3):(2-4). The invention also relates to a preparation method and an application of the photocatalytic degradation composite particle. The photocatalytic degradation composite particle disclosed by the invention has the advantages that the tail gas absorption can be increased; the light absorption area is improved; the photocatalytic efficiency is improved; the effective degradation of urban road tail gas can be realized; and the damage of the tail gas pollution to the environment is reduced.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

Leakage detecting agent for detecting leakage of weld joint in welding process and detection method

InactiveCN103558228AEasy to eraseSolve process problemsDetection of fluid at leakage pointOptically investigating flaws/contaminationTransformerFluorescence

The invention relates to a leakage detecting agent for detecting the leakage of a weld joint in the welding process and a detection method, and is suitable for leakage detection of the weld joint, with a sealing requirement, in a pipeline, a tank body and a transformer structural member. The technical scheme is as follows: the leakage detecting agent comprises a photographic developer and a penetrating agent, wherein the photographic developer refers to a turbid liquid prepared by stirring chalk powder and industrial alcohol; the penetrating agent comprises dimethylbenzene, butanol and red oil-soluble dye through mixing. The photographic developer is coated on one surface of the weld joint through welding, the penetrating agent is coated and brushed on an unwelded part of the back surface of the weld joint after being dried, and a red spot-shaped trace is observed from the surface of the photographic developer, namely, a leakage point exists in the position. According to the leakage detecting agent and the detection method, the problems of complicated operation process of postwelding pressure leakage testing, overlong fluorescent penetrating inspection leakage detection time and low efficiency are solved. The leakage detecting agent is applied to the practice, is convenient to configure, easy to operate and high in efficiency; the photographic developer is easily wiped, and the penetrating agent automatically volatilizes without residues, and thus no influences on subsequent welding, post-treatment operation and product quality are caused.

Owner:BAODING TIANWEI GRP CO LTD

Water-based marking paint and preparation method thereof

InactiveCN102702870AImprove wear resistanceGood weather resistancePolyurea/polyurethane coatingsWater basedEmulsion

The invention discloses a water-based marking paint which comprises the following components in parts by weight: 300-500 parts of water-based emulsion, 15-25 parts of industrial alcohol, 5-15 parts of titanium white, 200-350 parts of coarse whiting, 5-15 parts of glass bead, 5-15 parts of film-forming assistant, 1-2 parts of defoaming agent, 0.5-1.5 parts of wetting agent, 1.0-2.5 parts of dispersant, 0.5-1.0 part of pH regulator, 0.5-1.5 parts of thickening agent and 10-20 parts of water. The water-based marking paint disclosed by the invention uses water as the dispersion medium, thus, is safe and environment-friendly, and does not need heating in the construction process; and the water-based marking paint has the characteristics of favorable wear resistance, weather resistance, rain water resistance, acid resistance, alkali resistance and the like.

Owner:QINGDAO AIR NEW MATERIALS

Lubricating oil and preparation method thereof

The invention relates to a lubricating oil and a preparation method thereof and is characterized in that the lubricating oil is mixed by 0.1-1wt% of fatty acid ester and 99-99.9wt% of fatty group solvent, wherein the fatty acid ester is mixed by beeswax and paraffin, and fatty group solvent is a mixture of two or more solvents selected from a group of gasoline, industrial alcohol, 120# solvent, 200# solvent, cyclohexane, petroleum ether, absolute ethanol or xylene. The lubricating oil of the present invention has a premium lubricity and coating uniformity, a simple preparation method which is easy for operation, and a low price. In addition, coating the lubricating oil on an enamelled wire leaves no peculiar smell, so as to solve problem of ugly peculiar smell.

Owner:上海裕生特种线材有限公司

Anti-sticking coating for vacuum sintering of hard alloy and preparation method of anti-sticking coating

The invention discloses an anti-sticking coating for vacuum sintering of a hard alloy and a preparation method of the anti-sticking coating. The anti-sticking coating for the vacuum sintering of the hard alloy comprises the following materials: 900-1100 ml of industrial alcohol, 80-120 g of carbon black powder and 160-240 g of alumina powder. The anti-sticking coating for the vacuum sintering of the hard alloy, which is disclosed by the invention, can be used for completely isolating a hard alloy workpiece from the surface of a carbon boat during sintering through the combination of the materials, thereby avoiding the phenomenon of hard alloy workpiece scrapping caused due to adhesion. The preparation method of the anti-sticking coating for the vacuum sintering of the hard alloy comprises the steps: mixing and stirring the materials; statically standing; brushing; and naturally drying. The preparation method disclosed by the invention can be used for effectively generating the anti-sticking coating layer structure on the surface of the carbon boat through process step design. The anti-sticking coating layer structure can be used for completely isolating the hard alloy workpiece from the surface of the carbon boat during the sintering, thereby avoiding the phenomenon of hard alloy workpiece scrapping caused due to the adhesion.

Owner:DONGGUAN UNIV OF TECH +1

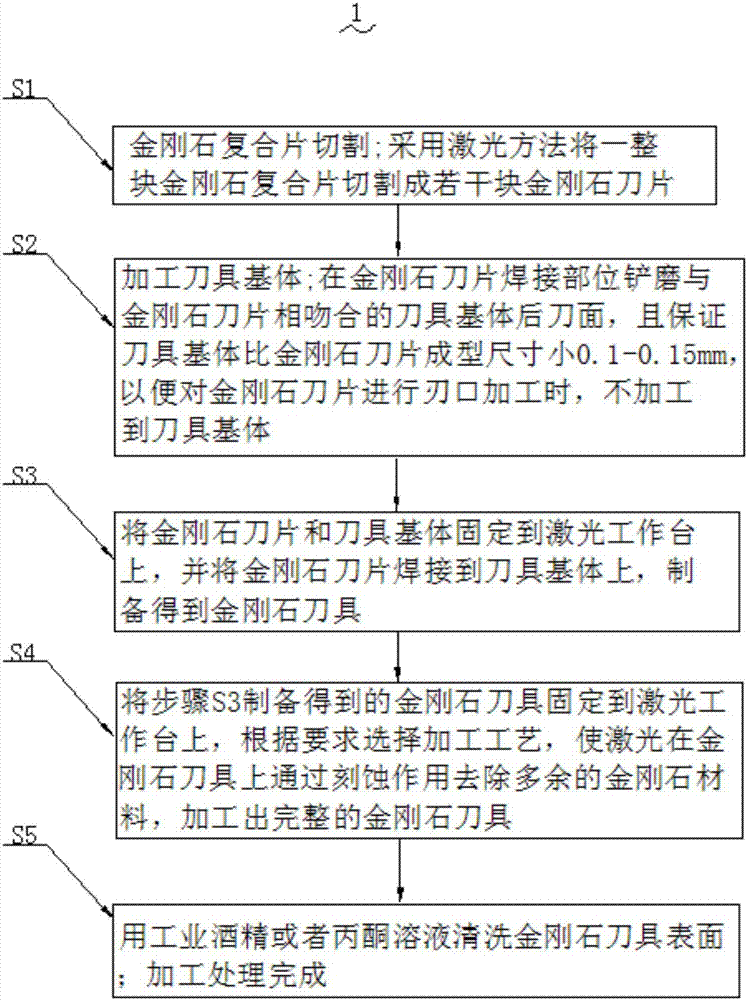

Full-laser manufacturing method of diamond cutter

ActiveCN106984913AIncrease profitImprove processing efficiencyLaser beam welding apparatusMaterials scienceLaser

The invention provides a full-laser manufacturing method of a diamond cutter. The full-laser manufacturing method of the diamond cutter comprises the following steps that S1 a diamond compact is cut, and the complete diamond compact is cut into a plurality of diamond blades in a laser manner; S2, cutter matrixes are machined, relief grinding is conducted on a cutter matrix flank face at the welding position of each diamond blade, and it is guaranteed that the forming dimension of each cutter matrix is 0.1-0.15 mm smaller than that of the corresponding diamond blade; S3, each diamond blade and the corresponding cutter matrix are fixed to a laser workbench, and each diamond blade is welded to the corresponding cutter matrix, and the diamond cutter is manufactured; S4, the diamond cutter manufactured in the step S3 is fixed to the laser workbench, a machining technology is selected according to requirements, redundant diamond materials on the diamond cutter are removed by means of the etching function of the laser, and a complete diamond cutter is machined; and S5, the surface of the diamond cutter is cleaned with industrial alcohol or an acetone solution, and then machining is completed. The full-laser manufacturing method of the diamond cutter is high in machining efficiency, not high in requirement for the manual technological level and suitable for large-scale industrial production.

Owner:深圳光韵达激光应用技术有限公司

High performance environmental protection processed adhesive powder and its preparing method

The adhesive powder for building is prepared with starch, modifier, alcohol, alkali solution, catalyst and tackifier. The preparation process includes adding mixed liquid of modifier and industrial alcohol into starch via stirring to obtain modified starch; adding alkali solution and tackifier into the modified starch via stirring and letting stand; drying the reaction product, crushing, sieving to obtain product. The adhesive powder exhibits high adhesion, excellent environment protecting performance and mildew-proof and antiseptic performance, and may be used widely in building inner wall putty, building paint, corrugated paper box adhesive, etc.

Owner:GUANGZHOU GLORYSTAR CHEM

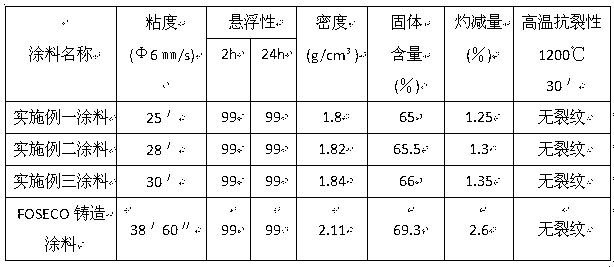

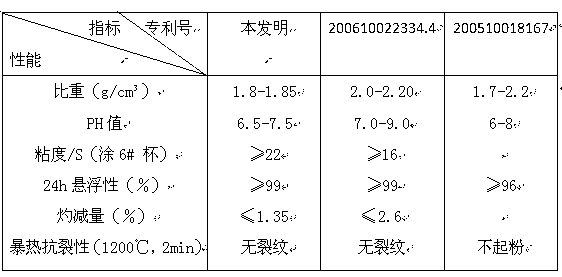

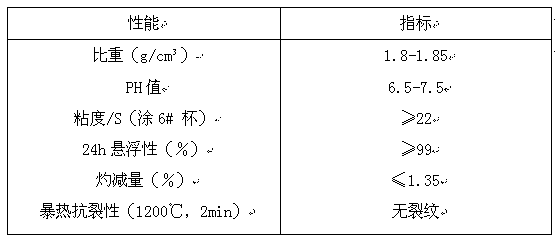

Simple alcohol-based casting coating and preparation method thereof

InactiveCN103008528AShorten production timeIncrease productivityFoundry mouldsFoundry coresAlcoholPolyvinyl alcohol

The invention discloses a simple alcohol-based casting coating and a preparation method thereof and belongs to the field of casting coatings. The coating comprises the following components in parts by weight: 65-75 parts of zircon power, 1.5-4 parts of lithium-based bentonite, 1-2.5 parts of clay, 0.8-3.5 parts of resin, 5-10 parts of silica sol, 0.1-0.3 part of polyvinyl butyral and 45-55 parts of industrial alcohol. The coating preparation method sequentially comprises the following steps of: 1, weighing and grinding the zircon power, adding and grinding lithium-based bentonite, adding and grinding clay and silica sol, adding and grinding resin, wherein the powder is uniformly ground; and adding an additive polyvinyl butyral into the powder, and fully grinding to prepare dry powder; and 2, slowly adding alcohol into the dry powder, stirring to a proper concentration, and preparation the coating. The defects in the prior art are overcome, the coating has good effects on aspects of suspension, brushing property, high-temperature cracking resistance and burnt-on sand resistance, and the produced casting piece is excellent in surface quality; and moreover, the coating is simple and rapid in process, short in production cycle, high in production efficiency, low in cost and good in market prospect.

Owner:LANZHOU LANSHI CASTING

Preparation method of mould release agent used for die casting

InactiveCN103878298AEasy to makeReduce manufacturing costFoundry mouldsFoundry coresDie castingGraphite

The invention discloses a preparation method of a mould release agent used for die casting, the mould release agent comprises the following raw materials by weight: 40-50 parts of graphite, 5-10 parts of powdered steatile, 1-2 parts of polyethylene wax, 2-4 parts of boric acid, 10-20 parts of industrial alcohol and 40-60 parts of deionized water; the method comprises the following steps: weighting the raw materials according to the weight fraction, purifying the graphite, crushing to graphite powder, then placing the crushed graphite powder and weighted raw materials in a clean container, uniformly stirring, and decomposing with high speed to prepare the mould release agent. While in use, the mould release agent can be used according to the casting condition, and is diluted with water and can be sprayed by using a spray gun. The mould release agent has the advantages of simple preparation, low production cost, good demoulding effect and no corrosion effect to casting; compactness and fineness on the surface of the die casting parts can be effectively increased, and the usage life of the mold can be prolonged.

Owner:温学敏

Thermoplastic elastomer grinding material for polishing and production method thereof

InactiveCN107674294AInhibit sheddingImprove adhesionOther chemical processesThermoplastic elastomerAntioxidant

The invention relates to a thermoplastic elastomer grinding material for polishing and a production method thereof and belongs to the technical field of production of grinding materials. The thermoplastic elastomer grinding material is prepared from the following raw materials in parts by weight: 60 to 97 parts of a grinding material, 2 to 35 parts of a thermoplastic elastomer, 0.05 to 1.5 parts of a dispersant, 0.05 to 1 part of a lubricant, 0.05 to 1.5 parts of an antioxidant, 0.6 to 3 parts of a coupling agent and 60 to 300 parts of industrial alcohol. The thermoplastic elastomer grinding material is prepared through an internal mixing-granulation technology. The material provided by the invention has a good cutting property, good wear resistance, high toughness and good elasticity; when the material is used for polishing, concave pits and scratches are not formed on a workpiece; the material is not fragmented and is easy to clean; the thermoplastic elastomer grinding material for polishing has the advantages of simple preparation technology, high production efficiency, short production period and greenness and environment friendliness and can be recycled and cyclically machinedand utilized for a plurality of times.

Owner:KUNSHAN NANO NEW MATERIAL TECH

Adhesive for rubber footwear lasting and preparation method of adhesive

ActiveCN104017516AGood initial adhesionImprove adhesionNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses an adhesive for rubber footwear lasting and a preparation method of the adhesive. The adhesive comprises the following raw materials in parts by weight: 1# standard rubber, zinc oxide, stearic acid, an accelerant M, an accelerant D, an anti-aging agent D, light calcium carbonate, rosin, 1# standard rubber threads, 120# gasoline, a terpene resin, industrial alcohol and sulfur. The adhesive has high initial adhesion and adhesive properties and is high in cohesive strength, and even if the adhesion is ineffective under temperature conditions of a drying oven, a phenomenon that the lasting is loosened is difficultly caused. Meanwhile, the adhesive has the characteristics of low price, low toxicity, quick dryness and simplicity in manufacture. In the preparation method, high molecular weight of natural rubber is kept, and the rubber footwear lasting is difficultly loosened under the drying conditions after being adhered. Moreover, the condition that the initial adhesion of the high molecular weight raw rubber threads does not meet the adhesion requirement is improved by directly adding a tackifier terpene resin into an adhesive cement pot, the industrial alcohol is added to reduce the viscosity, the brushing properties of the high molecular weight rubber threads are improved, and the raw foam rubber vulcanization speed is increased.

Owner:JIHUA 3539 SHOE MAKING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com