Photocatalytic degradation composite particle as well as preparation method and application thereof

A technology of composite particles and photocatalysis, which is applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of inability to actively adsorb tail gas, weak adsorption, and no porosity, etc., to achieve effective Degradation, improve adhesion, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

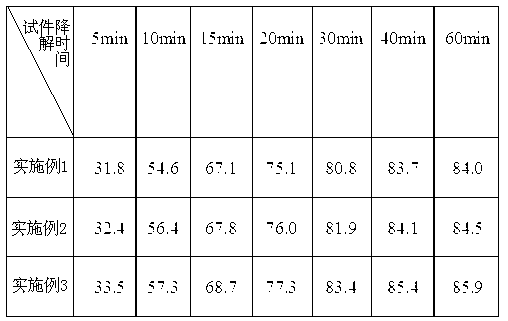

Embodiment 1

[0019] By mass, 20 parts of nanoscale anatase TiO 2 Put it in an oven at 110°C for 12 hours and seal it up. Wash the surface of 40 parts of diatomite, a micron-sized porous material, with water, bake it in a far-infrared drying oven at 110°C for 12 hours, and seal it up. The dried nanoscale anatase TiO 2 and micron-scale porous material diatomaceous earth in a mass ratio of 1:2 and dispersed in a mixer, the stirring speed is 2000rpm, and the stirring time is 40min; 2 parts of silane coupling agent γ-aminopropyltriethoxysilane and 40 parts of industrial Ethanol is configured as a dispersion solution, and the dispersed nano-scale anatase TiO 2 Diatomite, a micron-sized porous material, was added to a three-necked flask with a condenser, heated and stirred, recovered by distillation, and then heated to 80 °C for 12 hours to obtain photocatalytic degradation composite particles (TiO 2 / Diatomaceous earth degradable composite particles.

Embodiment 2

[0021] By mass, 20 parts of nanoscale anatase TiO 2 Put it in an oven at 110°C for 12 hours and then seal it up. Rinse the surface of 100 parts of diatomite, a micron-sized porous material, with water, bake it in a far-infrared drying oven at 110°C for 12 hours, and then seal it up. The dried nanoscale anatase TiO 2 and micron-scale porous material diatomaceous earth are put into the mixer according to the mass ratio of 1:2 to disperse, the stirring speed is 2000rpm, and the stirring time is 60min; 5 parts of silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane and 60 parts of industrial ethanol is configured into a dispersion solution, and the dispersed nano-scale anatase TiO 2 Diatomite, a micron-sized porous material, was added to a three-necked flask with a condenser, heated and stirred, recovered by distillation, and then heated to 80 °C for 12 hours to obtain photocatalytic degradation composite particles (TiO 2 / diatomite degradable composite particles). ...

Embodiment 3

[0023] By mass, 20 parts of nanoscale anatase TiO 2 Put it in an oven at 110°C for 12 hours and seal it up. Clean the surface of 60 parts of diatomite, a micron-sized porous material, with ultrasonic waves for 30 minutes, bake it in a far-infrared drying oven at 110°C for 12 hours, and seal it up. The dried nanoscale anatase TiO 2 and the micron-scale porous material diatomaceous earth are put into a mixer at a mass ratio of 1:3 to disperse, the stirring speed is 2000rpm, and the stirring time is 60min; 4 parts of titanate coupling agent 102 and 50 parts of industrial ethanol are prepared into a dispersion solution, and mixed with Dispersed nanoscale anatase TiO 2 Diatomite, a micron-sized porous material, was added to a three-necked flask with a condenser, heated and stirred, recovered by distillation, and then heated to 80 °C for 12 hours to obtain photocatalytic degradation composite particles (TiO 2 / diatomite degradable composite particles).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com