Simple alcohol-based casting coating and preparation method thereof

A technology of casting coatings and manufacturing methods, applied in the direction of manufacturing tools, casting molding equipment, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

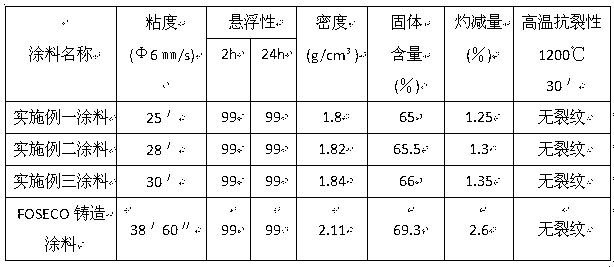

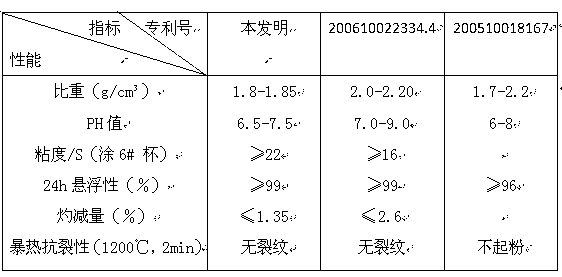

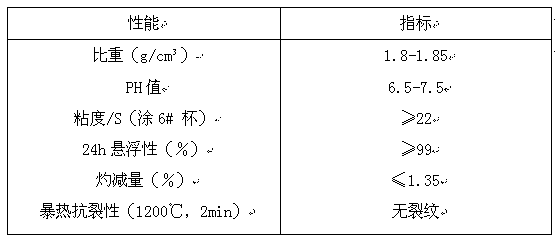

Examples

Embodiment 1

[0042] 1. The coating is composed of the following components: 66 parts of zircon powder, 1.8 parts of lithium bentonite, 0.8 parts of clay, 7 parts of silica sol, 2.5 parts of resin, 0.3 parts of polyvinyl butyral (PVB), 45 parts of industrial alcohol .

[0043] 2. Coating preparation method:

[0044] (1) Preparation of dry powder:

[0045] ① Weigh 66 parts of refractory filler zircon powder and roll it in the container for 10 minutes;

[0046] ②Add 1.8 parts of lithium soil as suspending agent and roll for 5 minutes;

[0047] ③ Add 0.8 parts of high-temperature binder clay and 7 parts of silica sol and roll for 6 minutes;

[0048] ④ Add 2.5 parts of normal temperature binder resin and roll for 5 minutes to ensure that the powder is rolled evenly;

[0049] ⑤Add 0.3 parts of additive polyvinyl butyral PVB to the powder, and fully roll it for 5 minutes to prepare dry powder;

[0050] (2) Preparation of alcohol-based casting coatings:

[0051] Slowly add 45 parts alcohol t...

Embodiment 2

[0054] 1. The coating is composed of the following components: 70 parts of zircon powder, 2 parts of lithium bentonite, 1.5 parts of clay, 8 parts of silica sol, 2.8 parts of resin, 0.2 parts of polyvinyl butyral (PVB), 50 parts of industrial alcohol .

[0055] 2. Coating preparation method:

[0056] (1) Preparation of dry powder:

[0057] ① Weigh 70 parts of refractory filler zircon powder and pour it into a container for rolling for 12 minutes;

[0058] ② Add 2 parts of lithium soil as suspending agent and roll for 5 minutes;

[0059] ③ Add 1.5 parts of high-temperature binder clay and 8 parts of silica sol and roll for 8 minutes;

[0060] ④ Add 2.8 parts of normal temperature binder resin and roll for 5 minutes to ensure that the powder is rolled evenly in the container;

[0061] ⑤ Add 0.2 parts of additive polyvinyl butyral PVB to the powder, and fully roll it for 5 minutes to prepare a dry powder;

[0062] (2) Preparation of alcohol-based casting coatings:

[0063] ...

Embodiment 3

[0066]1. The coating is composed of the following components: 75 parts of zircon powder, 3.5 parts of lithium bentonite, 2.5 parts of clay, 10 parts of silica sol, 3.5 parts of resin, 0.25 parts of polyvinyl butyral (PVB), 55 parts of industrial alcohol .

[0067] 2. Coating preparation method:

[0068] (1) Preparation of dry powder:

[0069] ① Weigh 75 parts of refractory filler zircon powder and roll it in the container for 15 minutes;

[0070] ② Add 3.5 parts of lithium soil as suspending agent and roll for 7 minutes;

[0071] ③ Add 2.5 parts of high-temperature binder clay, 10 parts of silica sol and roll for 10 minutes;

[0072] ④ Add 3.5 parts of normal temperature binder resin and roll for 6 minutes to ensure that the powder is rolled evenly;

[0073] ⑤ Add 0.25 parts of additive polyvinyl butyral PVB to the powder, and fully roll it for 5 minutes to prepare a dry powder;

[0074] (2) Preparation of alcohol-based casting coatings:

[0075] Slowly add 55 parts of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com