Patents

Literature

44results about How to "Change granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

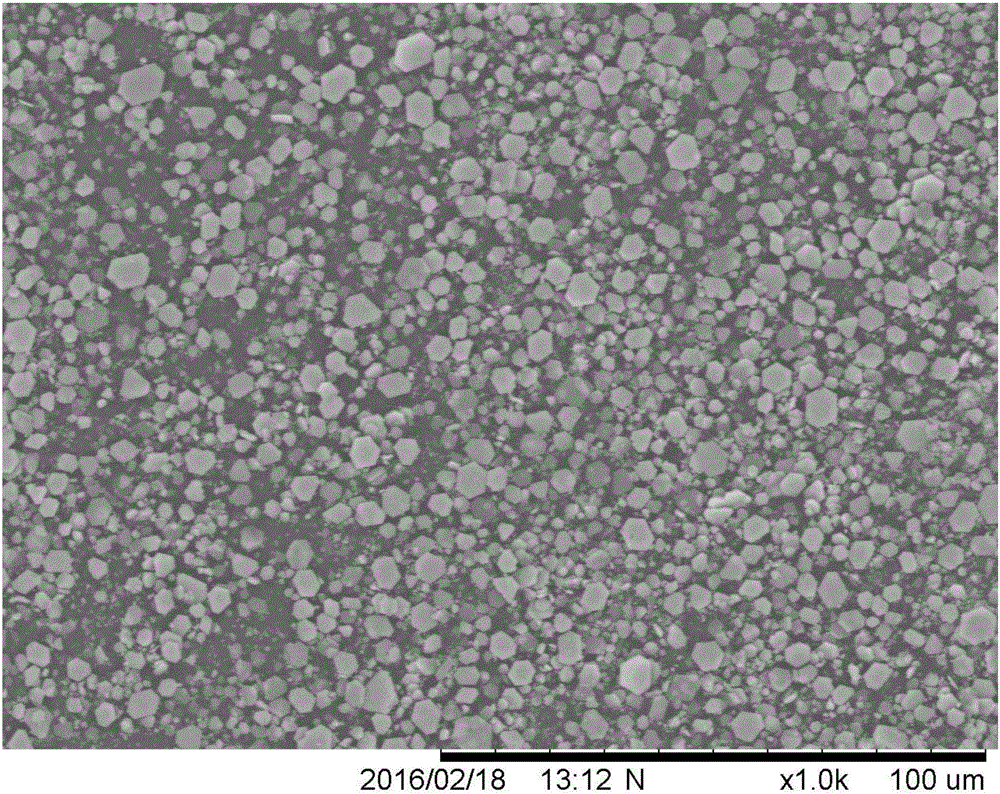

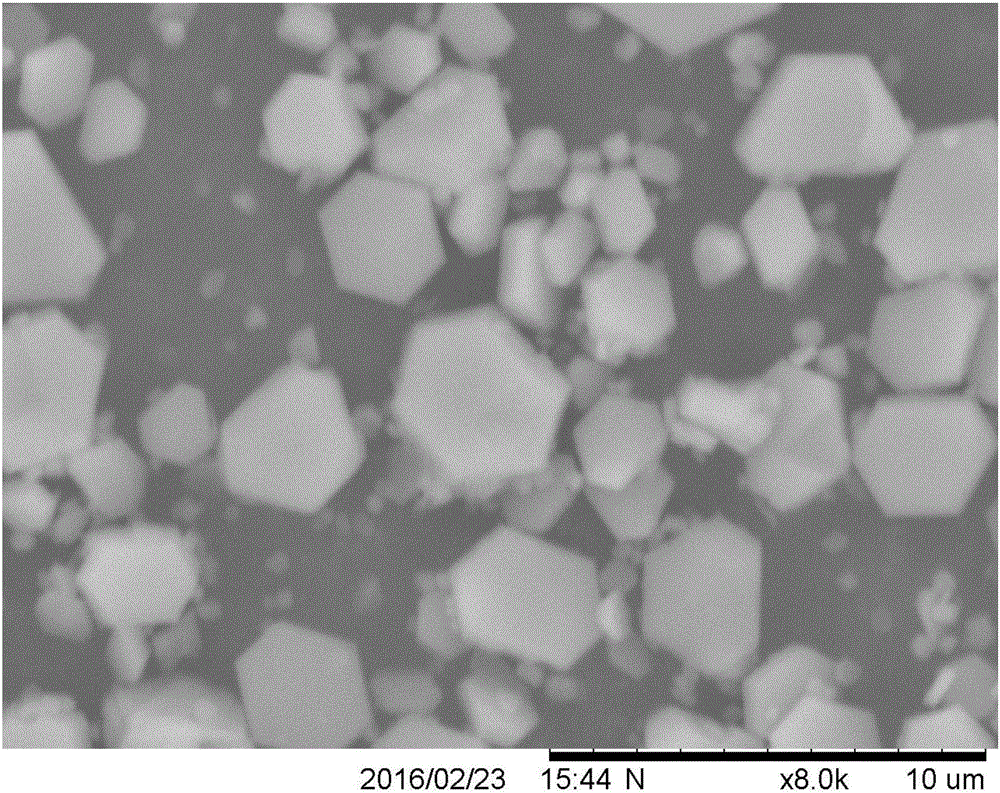

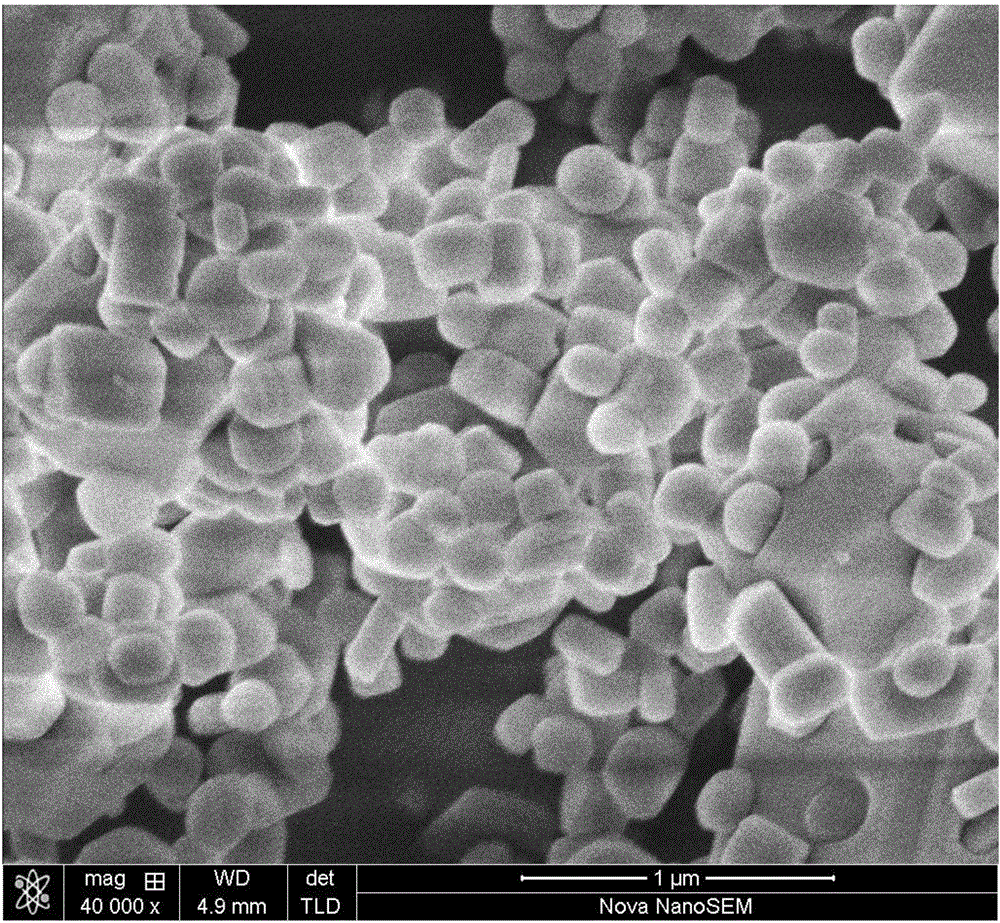

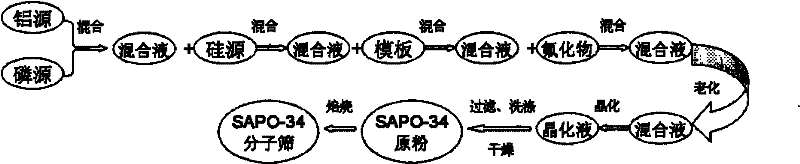

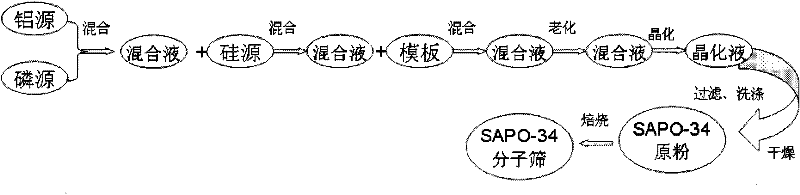

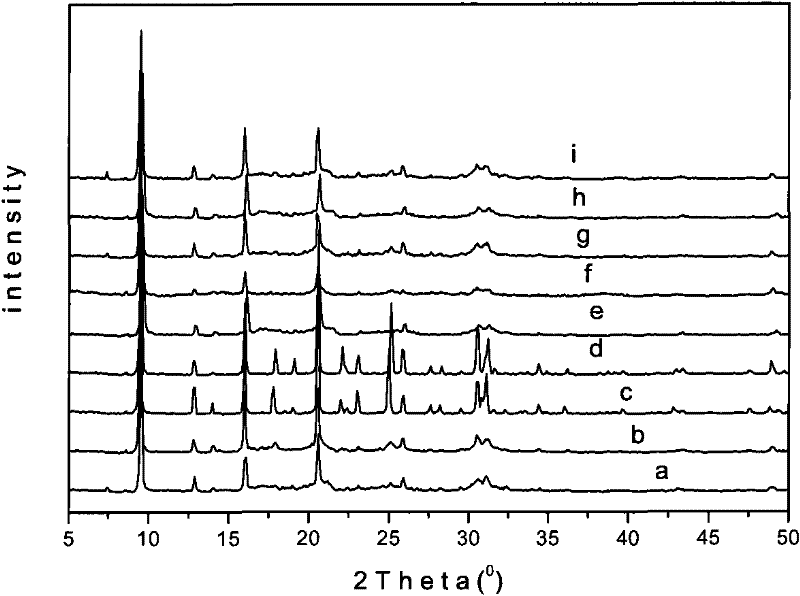

Method for preparing SAPO-34 molecular sieve

ActiveCN101767800AIncrease profitChange shapeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCrystallization temperature

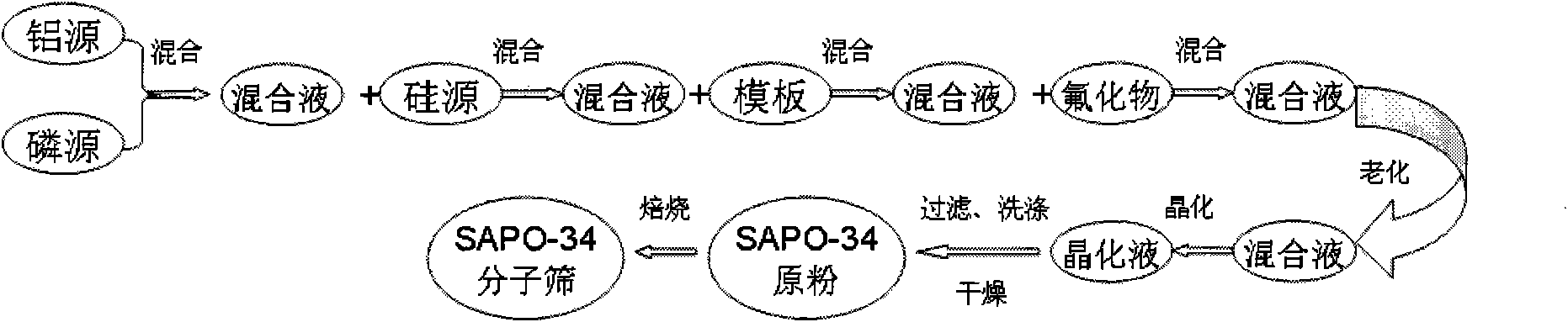

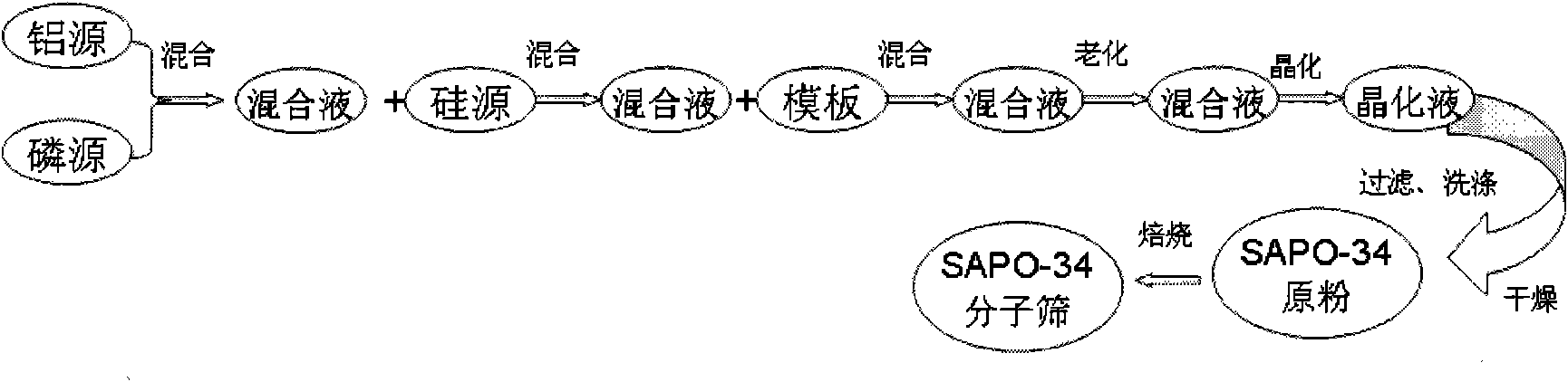

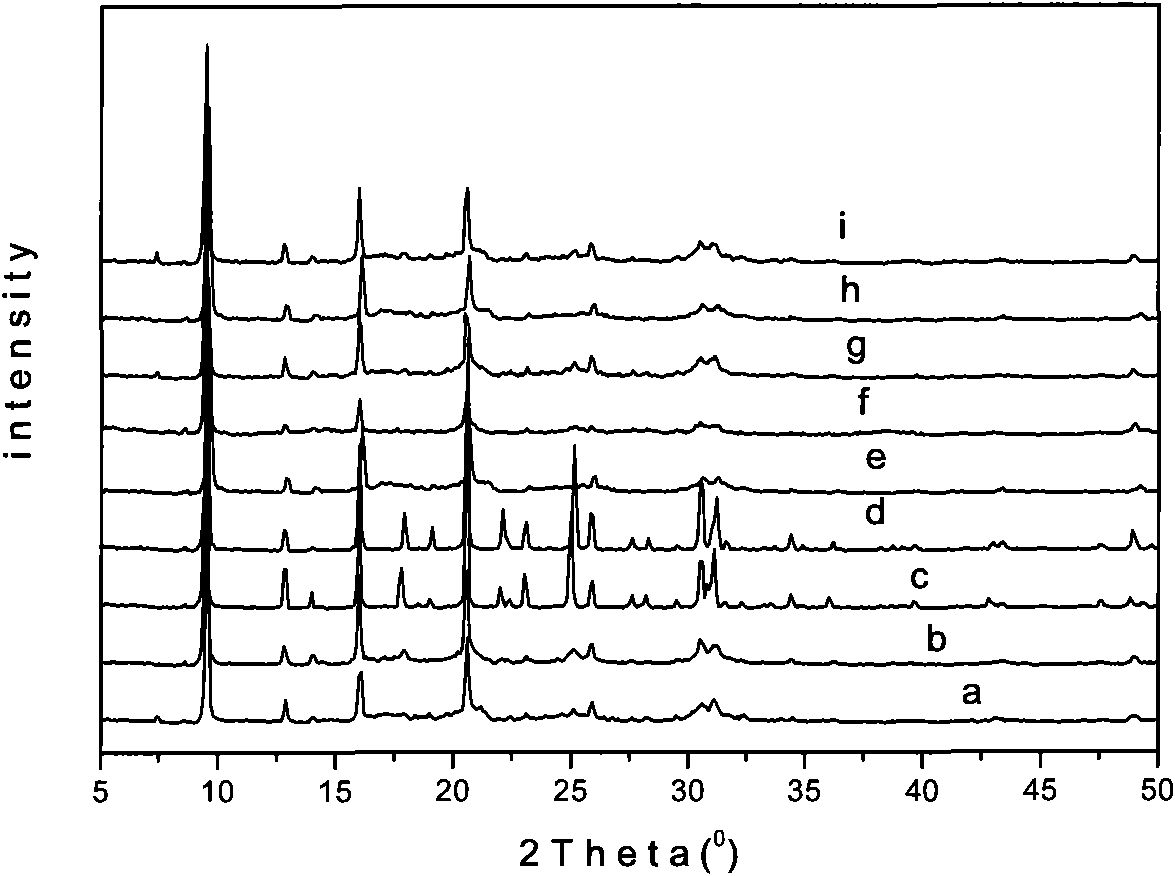

The invention provides a method for preparing a SAPO-34 molecular sieve. The method comprises the following steps of: 1, uniformly mixing a proper amount of phosphorus source, aluminum source, silicon source, template, auxiliary template and water at a proper temperature and under a stirring condition to obtain mixed solution, of which a molar ratio of all components, namely, the molar ratio of R to F- to SiO2 to Al2O3 to P2O5 to H2O, is a:b:c:1:d:e, wherein R represents the template, a is 0.2 to 5.0, b is 0 to 1.0, c is 0.2 to 1.5, d is 0.2 to 2.0 and e is 20 to 200; 2, ageing the mixed solution; and putting the aged mixed solution in a crystallization kettle, sealing the crystallization kettle, heating the mixed solution to a crystallization temperature, and crystallizing the mixed solution at the constant crystallization temperature; 3, performing centrifugal separation of the crystallized mixed solution, filtering, washing the mixed solution until a pH value of the mixed solution is 7 to 8, and drying a solid sample to obtain the SAPO-34 raw powder; and 4, baking the SAPO-34 raw powder at the temperature of between 450 and 650 DEG C for 4 to 8 hours to obtain the SAPO-34 molecular sieve. The SAPO-34 molecular sieve prepared by the method is characterized by high crystallinity and can show better low carbon olefin selectivity in an MTO reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Positive electrode for zinc-air battery and its manufacturing method

InactiveCN1738085AChange structureChange granularityFuel and primary cellsCell electrodesElectrolysisEngineering

The invention relates to a positive electrode of zinc-air battery and its manufacturing method. Said positive electrode comprises a catalytic layer (2) mixed by polytetrafluoroethylene emulsion and the mixture which uses industrial alcohol to infiltrate carrier, conductor, and catalytic agent; a flow collector (3) and a waterproof layer (1), wherein, said catalytic agent is electrolytic manganese dioxide material. Since the conductor selects expansible graphite and the flow collector (3) selects nickel-plated iron net, the surface of material is increased more than 400 % to improve the ability of absorbing oxygen of electrode, and the conductivity of material is increased 40 % to improve the discharging current density and reduce the cost. The electrolytic manganese dioxide is processed into manganese dioxide powder, to change the crystal phase structure and its particle, so the manufacturing process is simplified.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

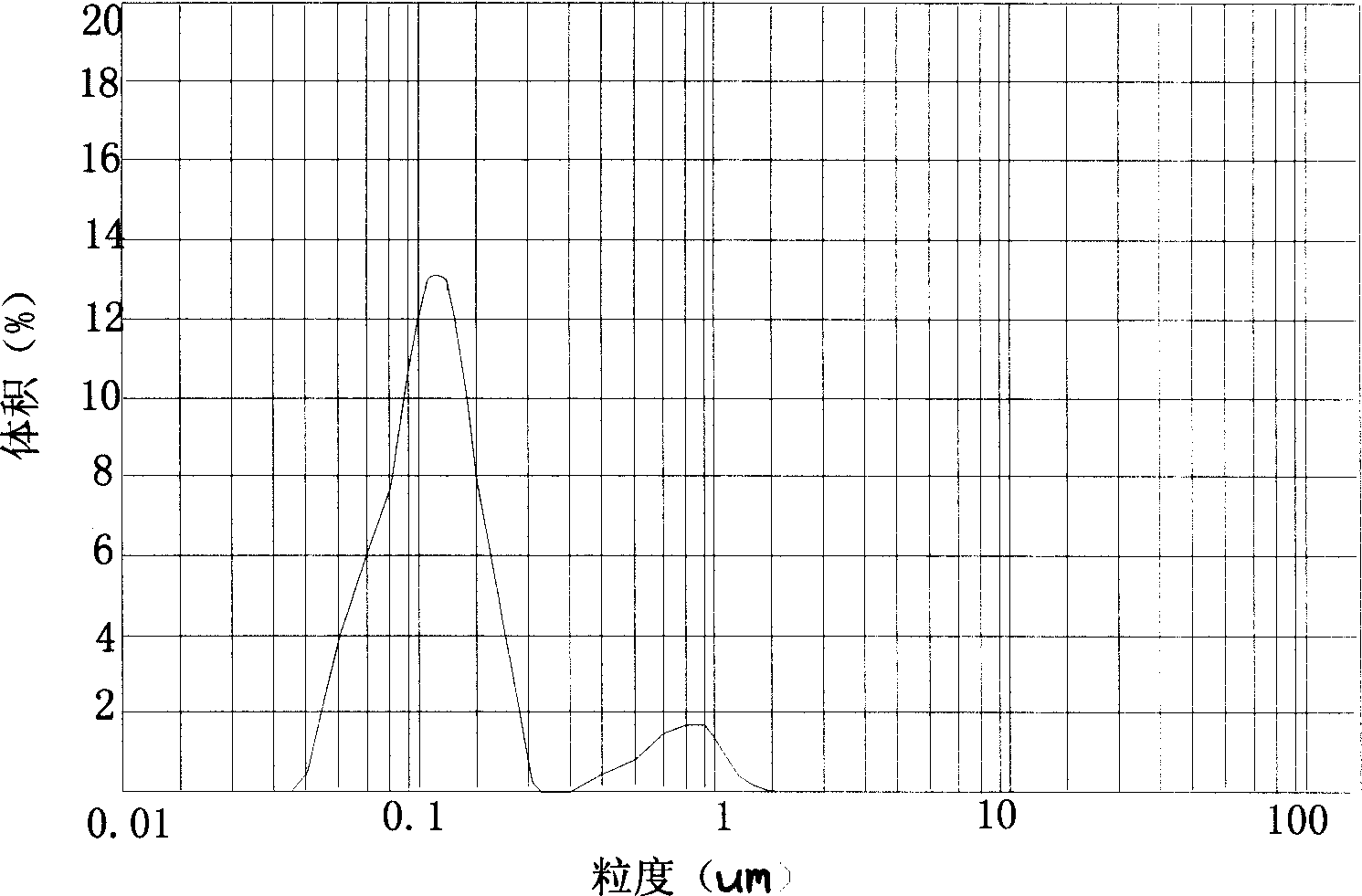

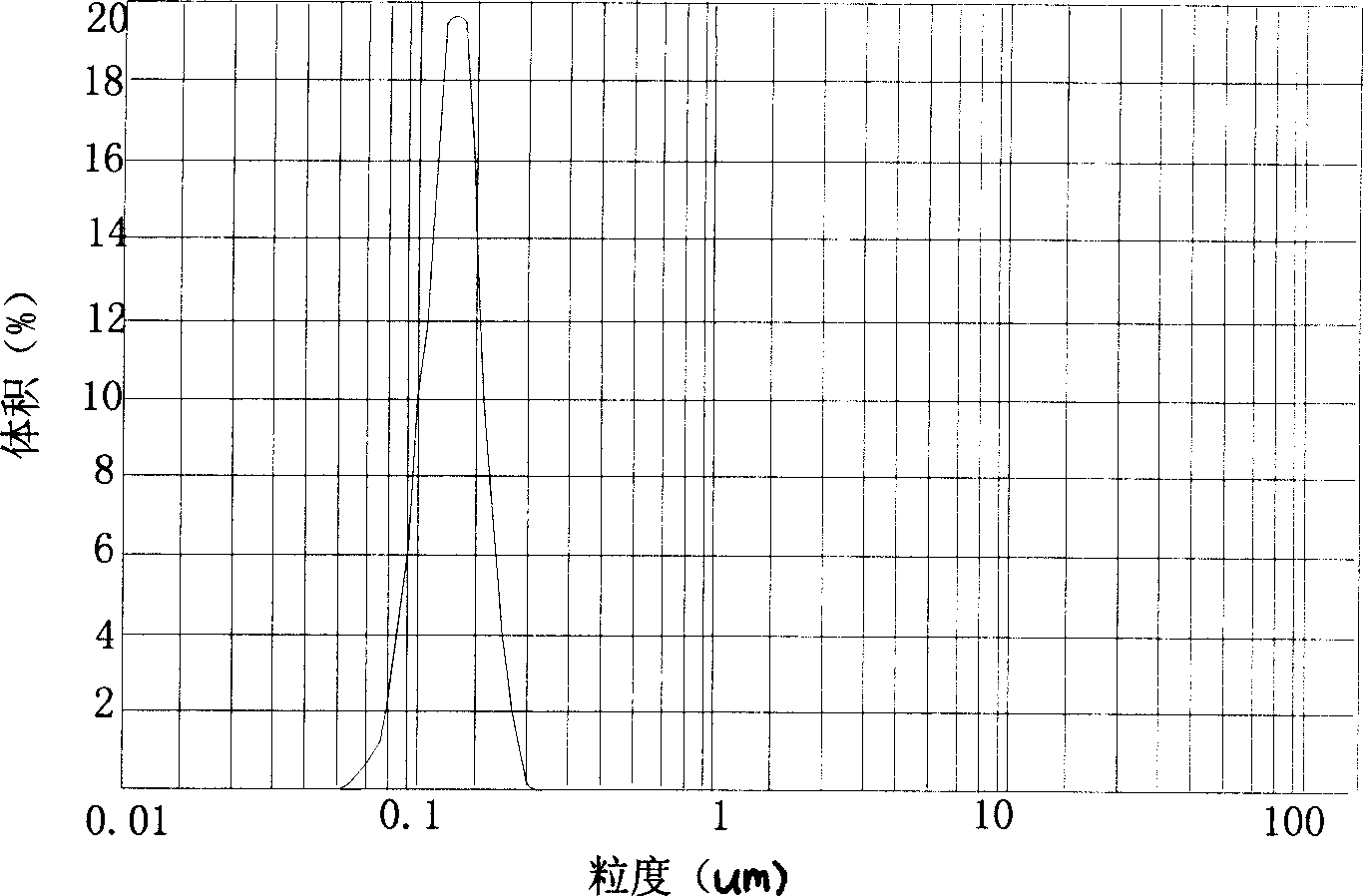

Preparation method for high-strength and high-hardness nanocrystalline tungstate-cobalt hard alloy

InactiveCN102994792ASlow down irregular growthPrevents oxidation and spontaneous combustionCemented carbideDoping

The invention discloses a preparation method for a high-strength and high-hardness nanocrystalline tungstate-cobalt hard alloy, which is finished by adopting eight process flows of reinforced grinding machining, proportioning, wet-grinding, drying, forming agent doping, granulating, press-forming and pressure-sintering for the conventional raw material, namely, sub-fine WC (tungstate-cobalt) powder; in the method, common sub-fine-grain WC powder having a Fsss (furnace safeguard supervisory system) granularity of 0.6-0.8 mum, and metal Co powder having a granularity of 0.2-0.4 mum; and the granularity and the granularity distribution of the sub-fine WC are changed by the added working procedure of reinforced grinding treatment, so that the advantage granularity of WC in the obtained super-coarse-grain hard alloy achieves 0.2-0.4 mum, and the hard alloy is high in toughness, complete in crystallization, few in defects, small in microstrain, uniform in sub-fine grains, high in microhardness, and greatly improves the wear resistance and impact toughness.

Owner:HUNAN CENTURY SPECIAL ALLOY

Preparation and synthesis method of hexagonal flaky magnesium hydroxide fire retardant

InactiveCN106673027AImproved shape stabilityGood compatibilityMagnesium hydroxideAlcoholMagnesium salt

The invention provides a preparation and synthesis method of hexagonal flaky magnesium hydroxide fire retardant, and relates to the field of material chemistry. The preparation and synthesis method comprises the following steps of adding a magnesium salt solution and a crystal-directing agent in a reaction vessel; uniformly stirring under the condition that the temperature is 30 to 50 DEG C, and dropwise adding an inorganic base solution in the reaction vessel at a constant rate under the condition that the temperature is 30 to 50 DEG C; carrying out ultrasonic oscillation on reaction slurry for 20 to 30 minutes after reacting completely, and transferring the reaction slurry to a high-pressure reaction kettle; adding absolute ethyl alcohol; carrying out hydrothermal reaction, wherein the reaction temperature is 180 to 200 DEG C, and the reaction time is 24 to 48 hours; finally carrying out filter pressing, water washing, alcohol washing and drying, thus obtaining a magnesium hydroxideproduct. According to the preparation and synthesis method of the hexagonal flaky magnesium hydroxide fire retardant, provided by the invention, the hexagonal flaky magnesium hydroxide fire retardantis in a hexagonal flaky and monodispersed state due to the addition of the crystal-directing agent; compared with literatures and other patents, the hexagonal flaky magnesium hydroxide fire retardanthas the characteristics that the morphology is more stable, the particle size is more uniform, and the like.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

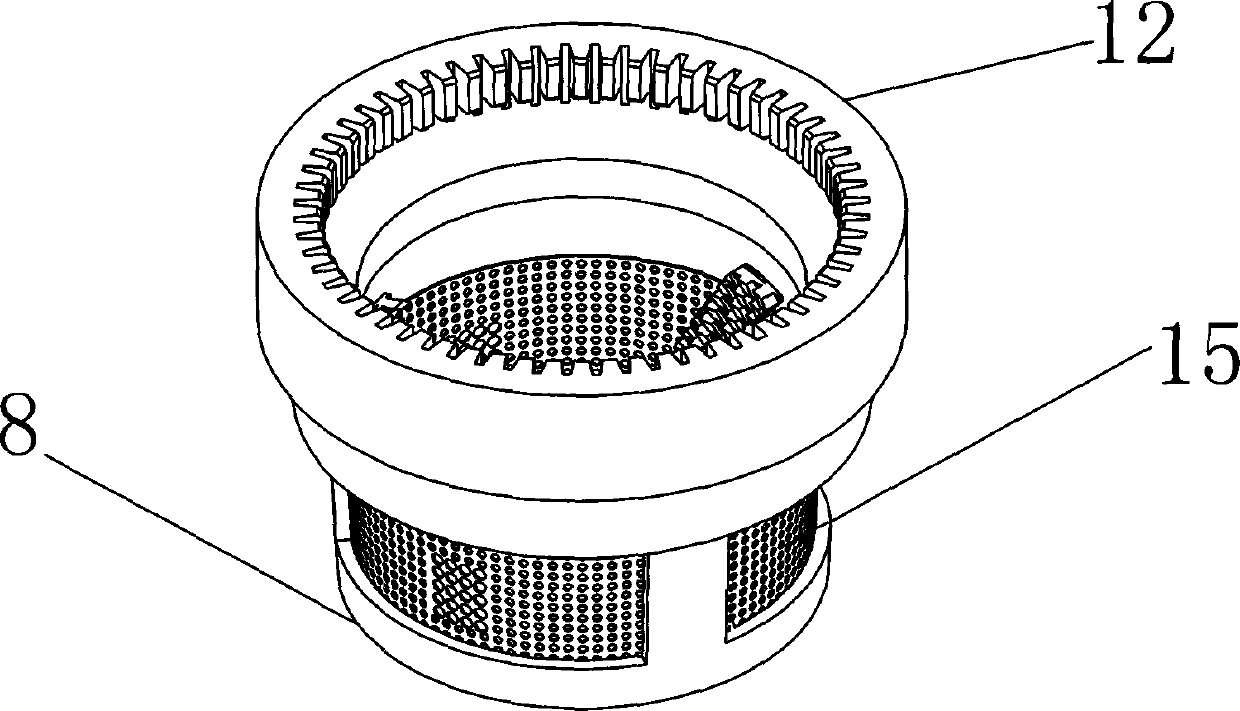

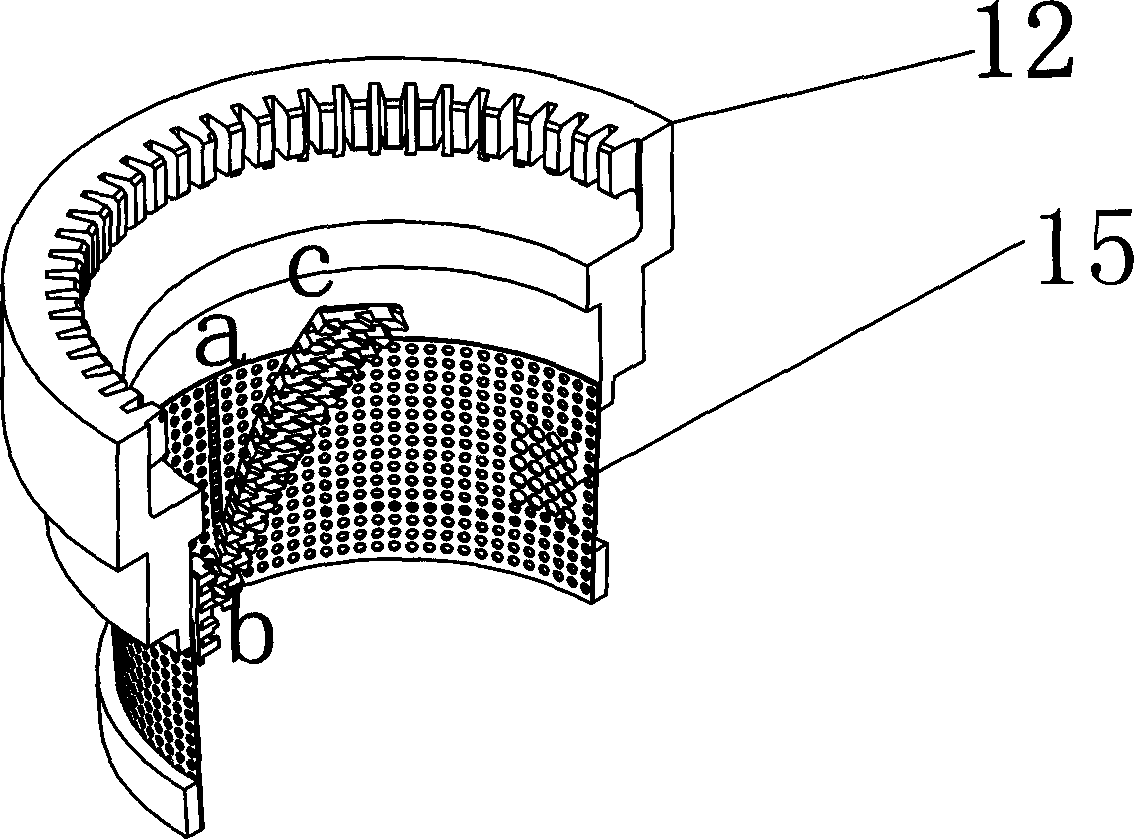

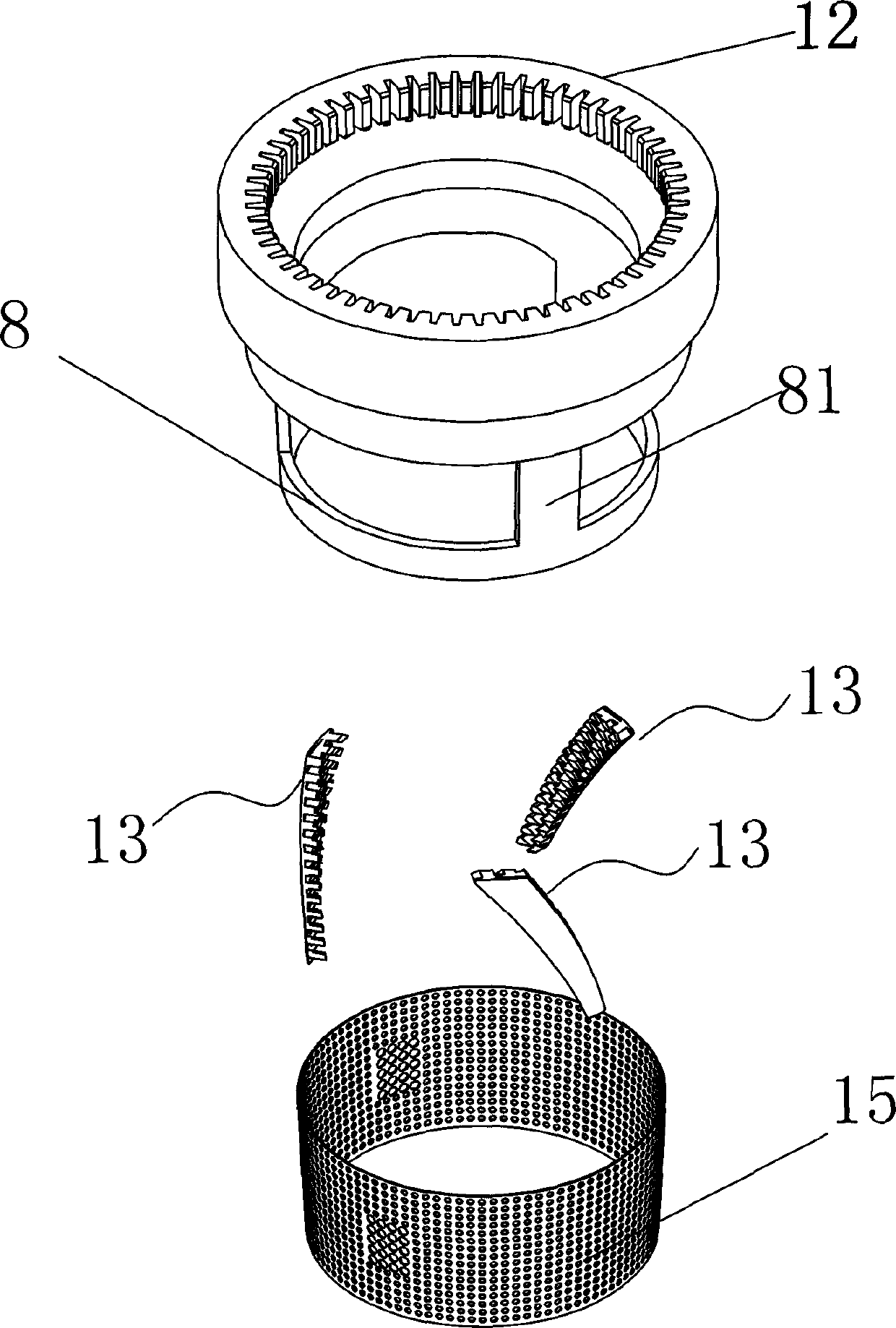

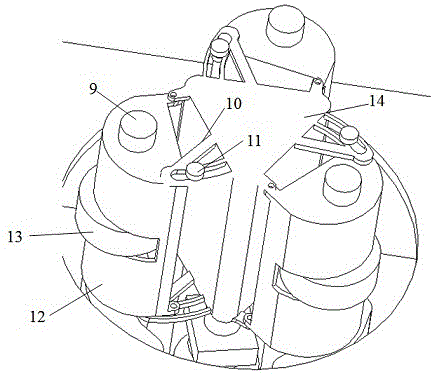

Filter screen mechanism and fruit and vegetable squeezing and grinding machine using same

The invention belongs to the field of a fruit and vegetable machine and particularly discloses a filter screen mechanism for a fruit and vegetable squeezing and grinding machine. The filter screen mechanism comprises an upper filter screen and a lower filter screen; a middle ring screen is also arranged between the upper filter screen and the lower filter screen; the middle ring screen is fixedly provided with a shielding ring; the shielding ring is provided with a plurality of notches; the notches are positioned in a mesh region of the middle ring screen; and the aperture of each mesh of the middle ring screen is respectively greater than those of each mesh of the upper filter screen and each mesh of the lower filter screen. The invention also discloses the fruit and vegetable squeezing and grinding machine utilizing the filter screen mechanism, which comprises the filter screen mechanism and a screw drive mechanism. The screw drive mechanism comprises a screw and a center shaft; the center shaft is connected with the screw; the screw is connected with a motor shaft; the screw is a spinning-cone-shaped sphere with a small upper part and a big lower part; the outer surface of the sphere is provided with a helix-shaped convex strip; the center shaft of the screw is coincided with a center shaft of the upper filter screen; gaps are formed between the edge of the screw and the inner walls of the upper filter screen, the middle ring screen and the lower filter screen; and fruits rotate along with the screw in the gaps to be processed. The filter screen mechanism and the fruit and vegetable squeezing and grinding machine have the advantage of multiple functions.

Owner:杭州富阳正易工贸有限公司

Process for preparing spherical high purity alumina

InactiveCN1631788AUniform particle size distributionHigh product purityAluminium oxide/hydroxide preparationEnergy efficient lightingChemistrySapphire

A method for preparing a spherical alumina of high purity, relates to the preparation of alumina of high purity which is especially suitable to the used in the fields such as compact fluorescent lamp, illuminating material for PDP and LED and transparent ceramics, monocrystal of sapphire, monocrystal of ruby and polishing of paint of car. Its characteristics are that aluminum ammonium sulfate and ammonium hydrogen carbonate are used as the raw material to react into nanometer structure spherical aluminum ammonium carbonate AACH in the container with agitation, and the nanometer structure spherical ª†-Al2O3 and ª‡- Al2O3 are obtained by filtration, washing and roasting. The spherical alumina of high purity has remarkable liquidity, high mechanic strength, infragile and keeping its shape in the course. The invention has high purity, remarkable quality, few requirements for technical condition, without pollution and has low cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Spherical nickel-rhenium alloy powder and preparation method and application thereof

InactiveCN107008916AGood composition uniformitySpeed up evaporationTransportation and packagingMetal-working apparatusRheniumSpray Granulation

The invention discloses a preparation method of spherical nickel-rhenium alloy powder. The preparation method comprises the following steps that dissolving and mixing are carried out; reducing is carried out after atomizing or dynamic drying is carried out, and precursor powder is obtained; and reducing, slurry preparation, spray granulation and balling forming are carried out. According to the aim, the preparation method of the spherical nickel-rhenium alloy powder is provided, the problems that an existing low-rhenium alloy is uneven in ingredient, rhenium-containing elements can hardly be introduced into a base material, multicomponent ingredient controllability is poor, and the preparation process is complex are solved, a balling process is creatively used two times, and the spherical powder is obtained well and fast in a saving manner. The powder obtained through the method can be directly applied to wear-resisting anti-corrosive coatings, thermal spraying, 3D printing and powder metallurgy parts, and powder raw materials do not need to be additionally matched.

Owner:湖南元极新材料有限公司

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Mold releasing agent and preparation method thereof

InactiveCN104174812ADoes not affect normal useImprove stabilityFoundry mouldsFoundry coresPolyvinyl alcoholAdhesive

The invention discloses a mold releasing agent and a preparation method thereof. The mold releasing agent comprises the following raw materials by weight: 500 g of pure water, 6-9 g of adhesive, 1-3 g of stabilizing agent, and 15-35 g of cork powder, wherein the adhesive is bone glue; the stabilizing agent is polyvinyl alcohol; and the cork powder is mixed powder of cork powder of 200 mesh and cork powder of 600 mesh. The preparation method of preparing the mold releasing agent comprises the following steps: (1) pouring of a backing material: the pure water is poured in an aluminum pot; (2) adding of the adhesive and the stabilizing agent, heating and stirring: the adhesive and the stabilizing agent are added in the aluminum pot; the aluminum pot is heated to a boiling point; and the mixing is performed during heating; (3) adding of the cork powder: the cork powder is added in the aluminum pot, and the mixture is cooled to the room temperature; and (4) storage. The process is simple and the cost is low; the mold releasing agent has the advantages of easy coating, good adhesiveness, high-temperature resistance, high-pressure resistance and smooth exhaust; the number of mold spraying times in unit time is decreased; the production efficiency and the product quality are improved; and the economic benefit of enterprises is enhanced.

Owner:TIANNENG BATTERY WUHU

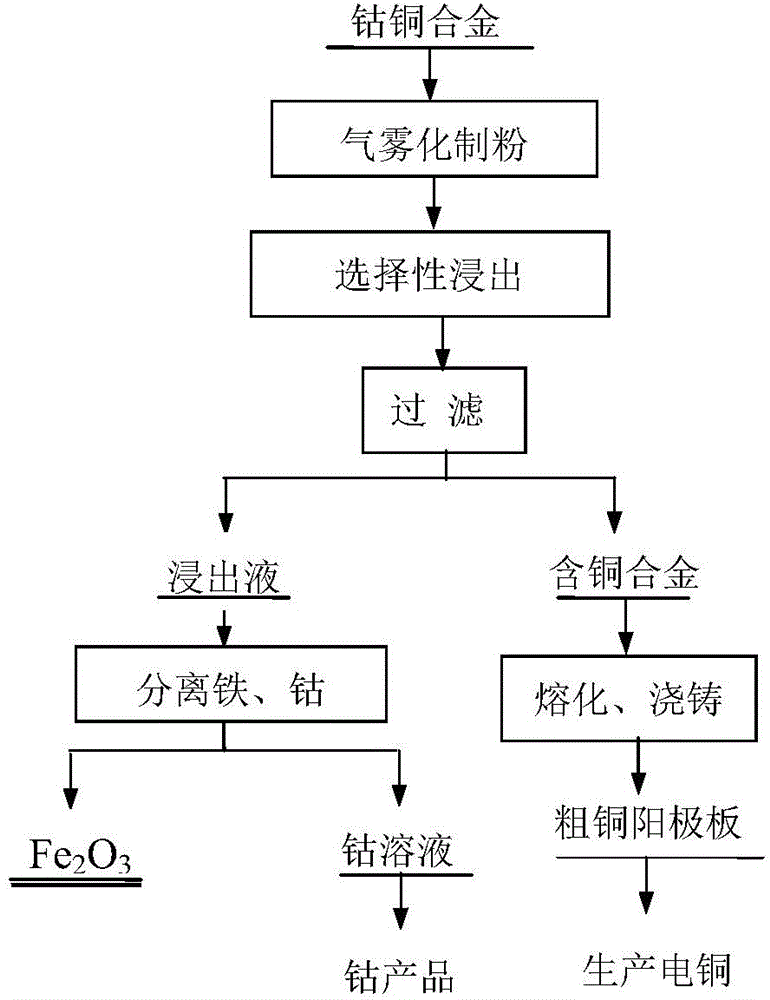

Method for extracting valuable metals in cobalt-copper alloy by virtue of full hydrometallurgy

ActiveCN104087758AUniform particle sizeReduce energy consumptionPhotography auxillary processesFerric oxidesElectrode potentialSlag

The invention discloses a method for extracting valuable metals in a cobalt-copper alloy by virtue of full hydrometallurgy. The method comprises the following steps: melting the cobalt-copper alloy in gas atomization powder manufacturing equipment, performing atomization and powder manufacturing on the molten cobalt-copper alloy by adopting high-pressure inert gas, and sieving to obtain cobalt-copper alloy powder; adding a leaching agent and the cobalt-copper alloy powder into a normal-pressure reactor, controlling the electrode potential of a reaction system in the normal-pressure reactor, heating to reach the leaching temperature, and introducing an oxidizing agent to perform selective leaching; enabling iron and cobalt in the cobalt-copper alloy powder to enter a leaching liquid; and ensuring that copper in the cobalt-copper alloy powder is inhibited in leaching slags and can not enter the leaching liquid; respectively performing metallurgical purification treatment on the leaching liquid and / or the leaching slags to obtain the corresponding valuable metals. The method disclosed by the invention has the advantages of cleanness, high efficiency, short process, simple operation, low energy consumption, high metal recovery rate and low production cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing yttria of different sizes and different appearances

The invention discloses a method for preparing yttria of different sizes and different appearances. According to the method, an yttria solution and an oxalic acid solution undergo settling reaction and then are heated and distilled by water bath till the mother solution is totally evaporated to dryness to generate yttrium oxalate, and yttria is obtained by filtering, washing, burning, thermally insulating and cooling to the room temperature. The production process of the method is easily controlled, and the requirements of production performance are met.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

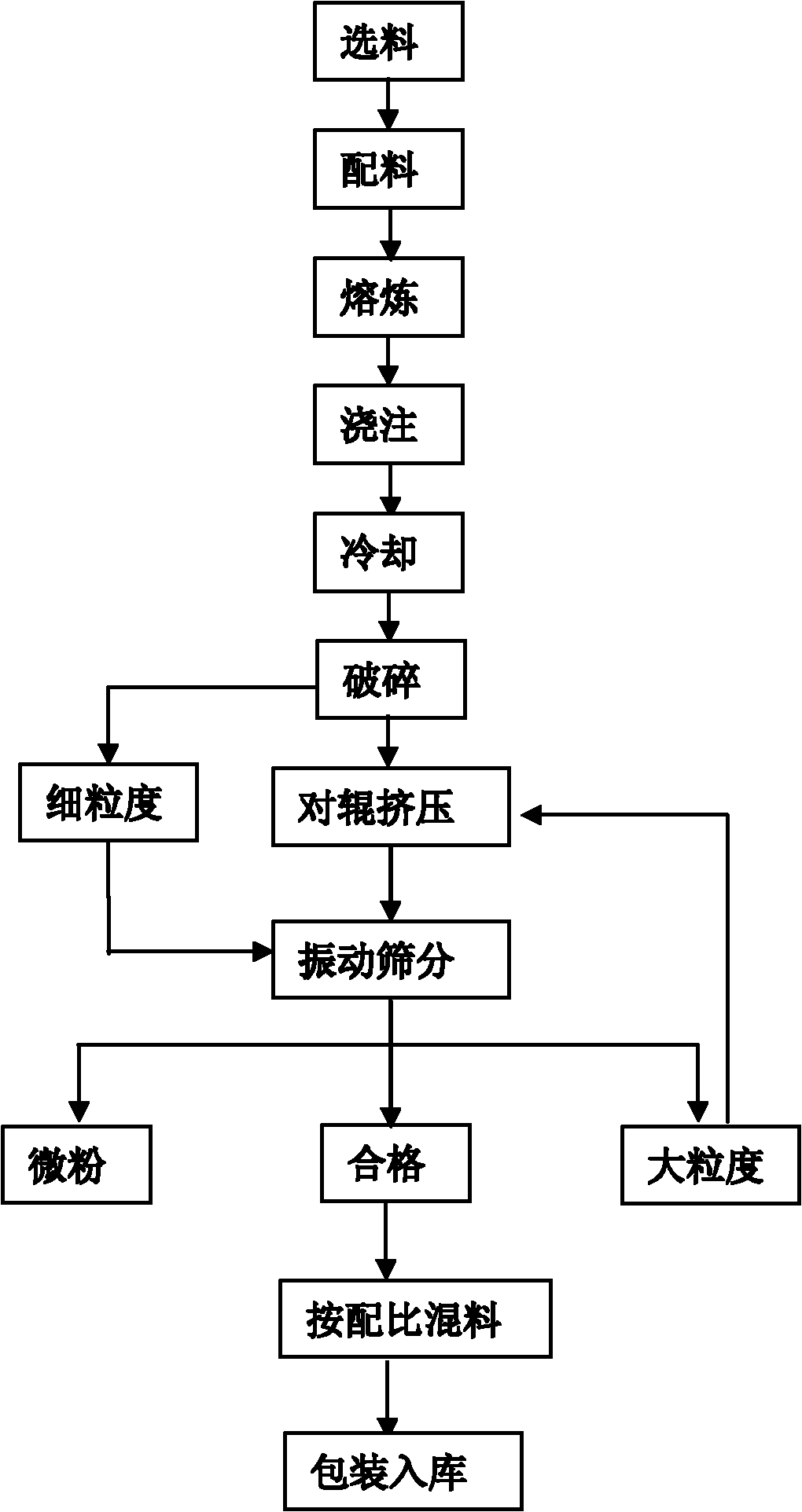

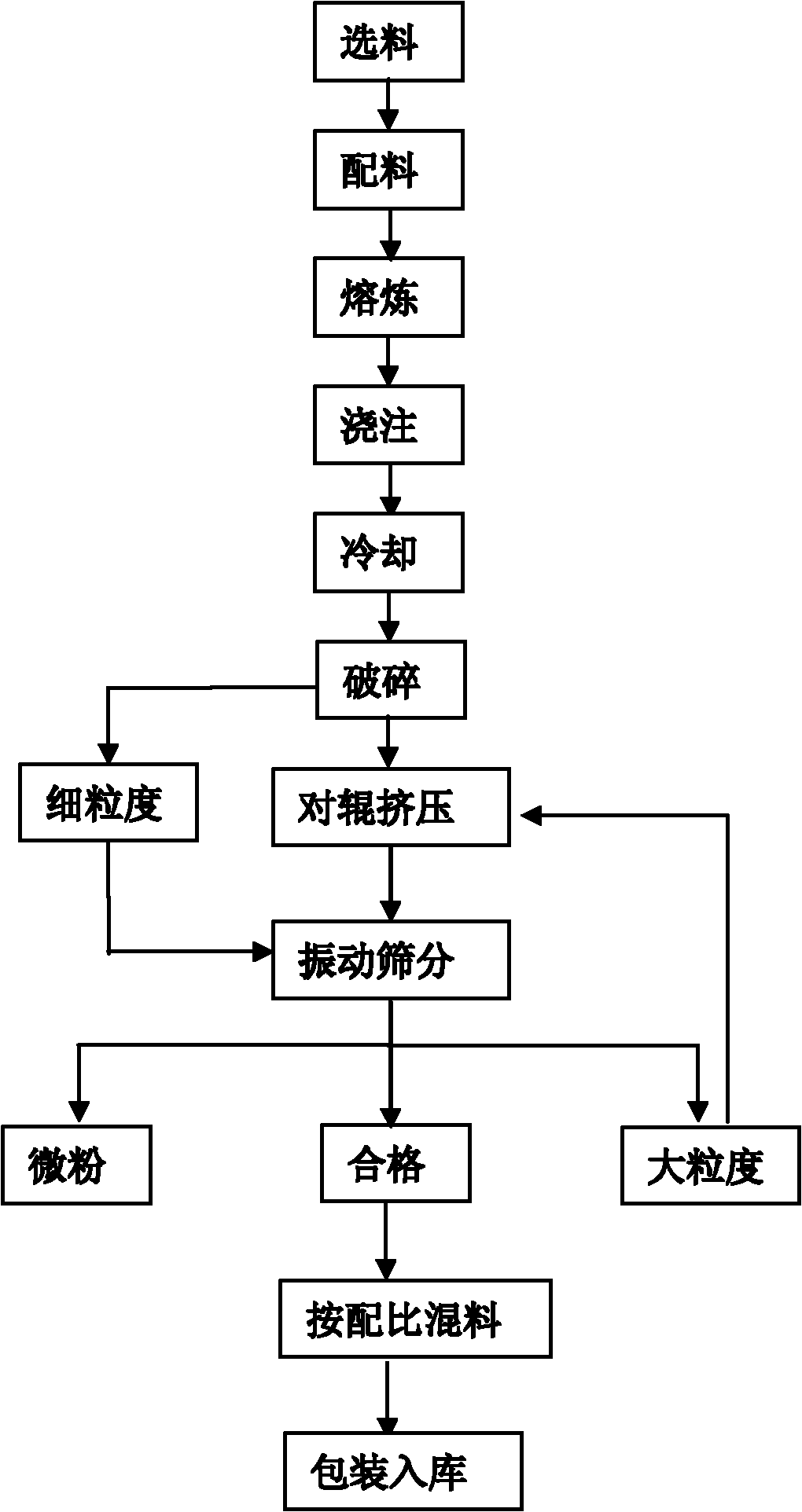

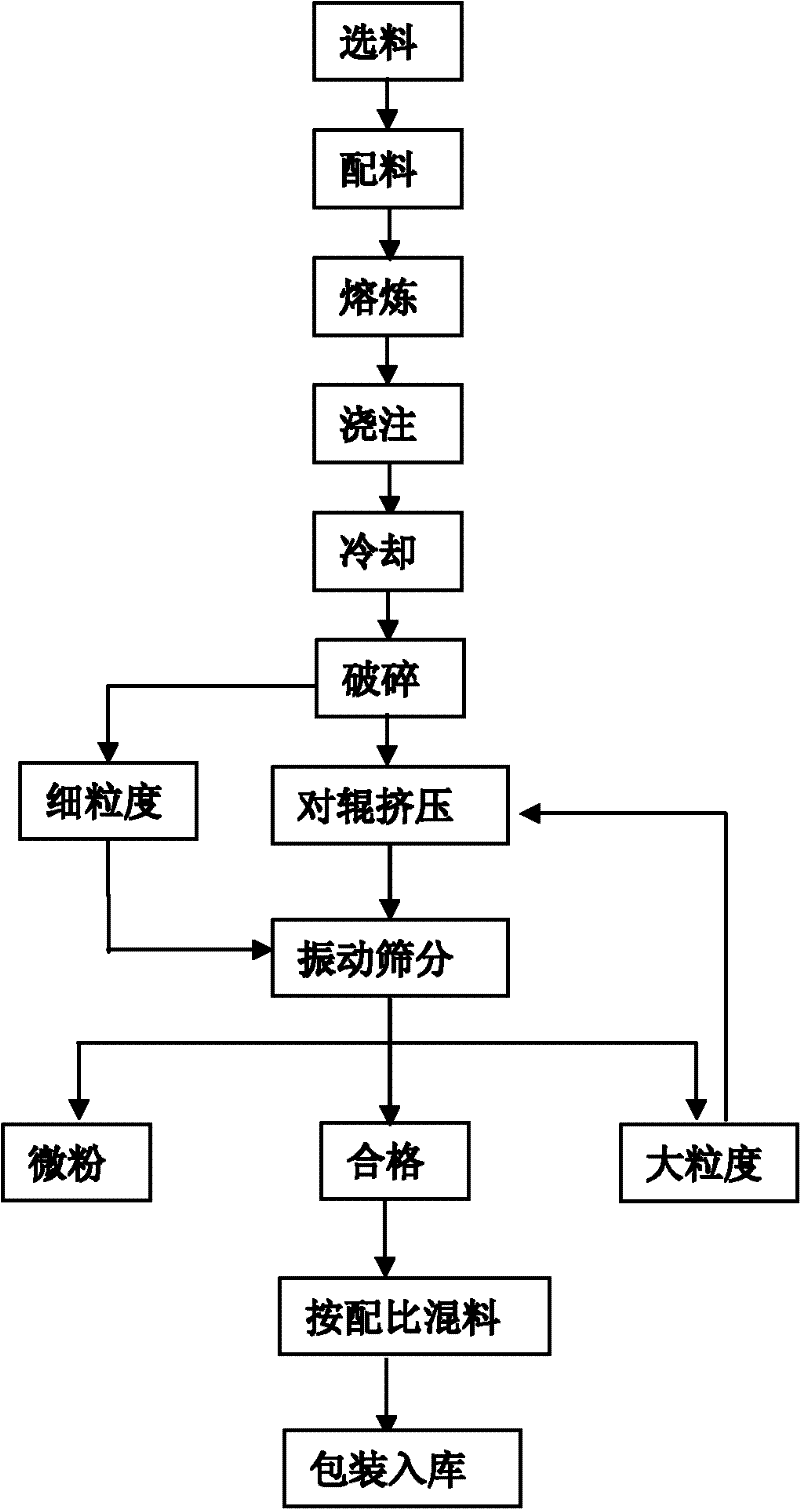

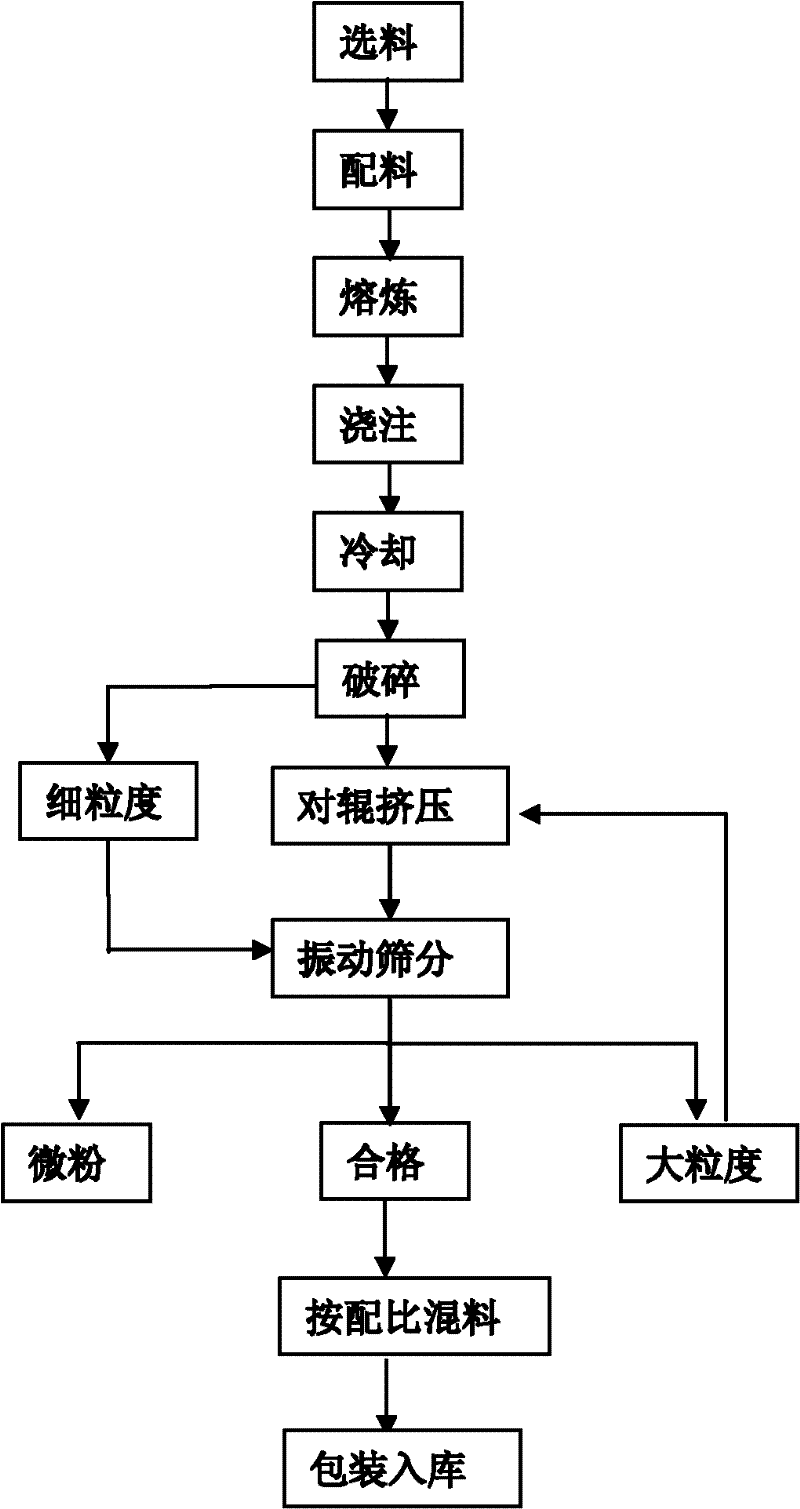

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

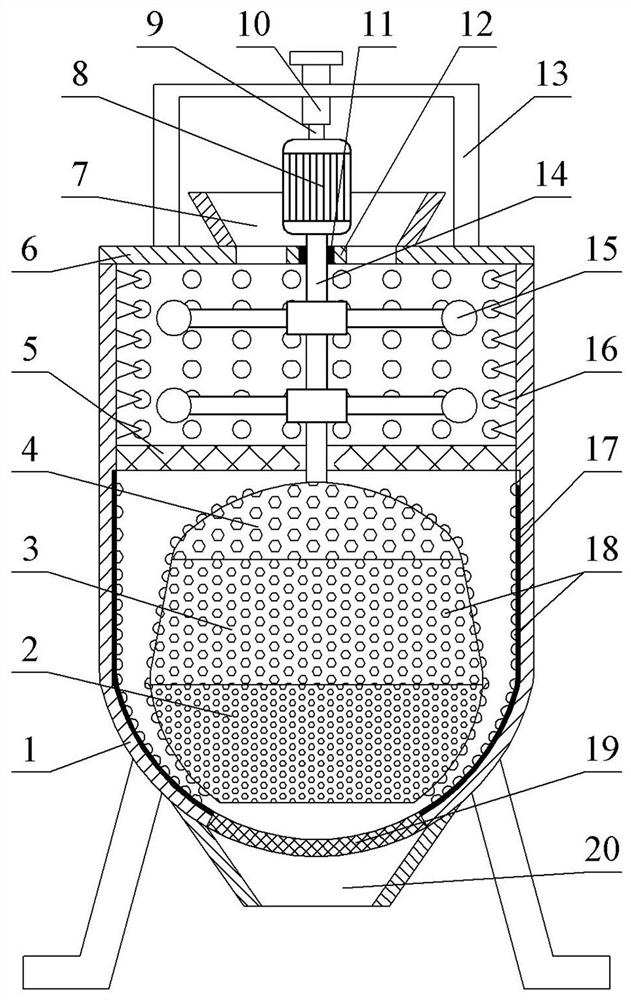

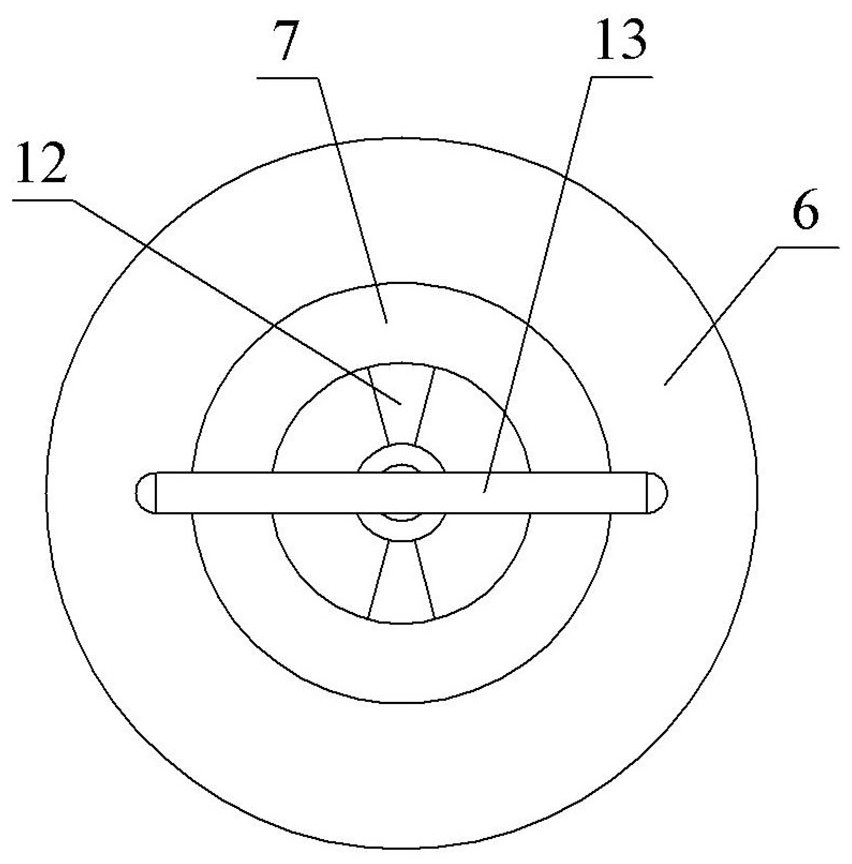

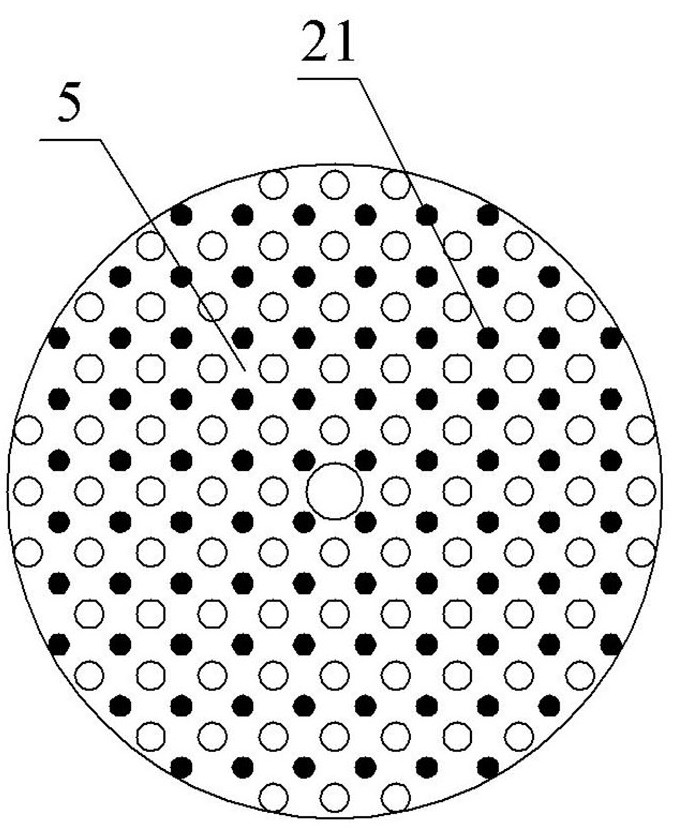

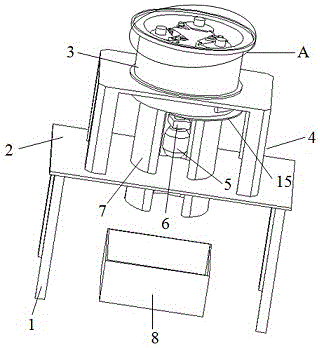

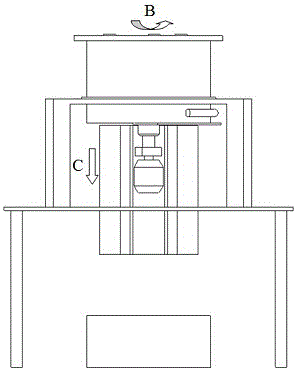

Sand making device for building engineering

InactiveCN111604153ASmall granularityImprove grinding uniformityGrain treatmentsArchitectural engineeringElectric machinery

The invention relates to a sand making device for building engineering. The device includes a barrel, an end cap is arranged at an opening in the top end of the barrel, the center of the end cap is provided with a feed inlet, the feed inlet is internally provided with a mounting frame, a vertical shaft is rotationally connected to the mounting frame, the portion, in the barrel, of the vertical shaft is connected with smashing hammers, a filter plate is arranged on the inner side face of the barrel and located below the smashing hammers, a grinding block is connected to the vertical shaft and located below the filter plate, the position, corresponding to the grinding block, on the inner side face of the barrel is provided with a grinding base, the surfaces of the grinding block and the grinding base are provided with grinding protrusions, a screening net is arranged on the bottom end face of the barrel and located below the grinding block, a discharge hopper is arranged on the outer side face of the barrel and located below the screening net, the top end of the vertical shaft is connected with a motor, and the top end of the motor is connected to a fixing frame on the upper surfaceof the end cap through an adjusting mechanism. In general, the device has the advantages of reasonable structural design, uniform sand grain grinding size and long service life.

Owner:河南航天建筑工程有限公司

Preparation method of pipe mold powder for nodular cast iron and application thereof

Owner:成都宏源铸造材料有限公司

Method for preparing SAPO-34 molecular sieve

ActiveCN101767800BIncrease profitChange shapeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCrystallization temperature

The invention provides a method for preparing a SAPO-34 molecular sieve. The method comprises the following steps of: 1, uniformly mixing a proper amount of phosphorus source, aluminum source, silicon source, template, auxiliary template and water at a proper temperature and under a stirring condition to obtain mixed solution, of which a molar ratio of all components, namely, the molar ratio of Rto F- to SiO2 to Al2O3 to P2O5 to H2O, is a:b:c:1:d:e, wherein R represents the template, a is 0.2 to 5.0, b is 0 to 1.0, c is 0.2 to 1.5, d is 0.2 to 2.0 and e is 20 to 200; 2, ageing the mixed solution; and putting the aged mixed solution in a crystallization kettle, sealing the crystallization kettle, heating the mixed solution to a crystallization temperature, and crystallizing the mixed solution at the constant crystallization temperature; 3, performing centrifugal separation of the crystallized mixed solution, filtering, washing the mixed solution until a pH value of the mixed solution is 7 to 8, and drying a solid sample to obtain the SAPO-34 raw powder; and 4, baking the SAPO-34 raw powder at the temperature of between 450 and 650 DEG C for 4 to 8 hours to obtain the SAPO-34 molecular sieve. The SAPO-34 molecular sieve prepared by the method is characterized by high crystallinity and can show better low carbon olefin selectivity in an MTO reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

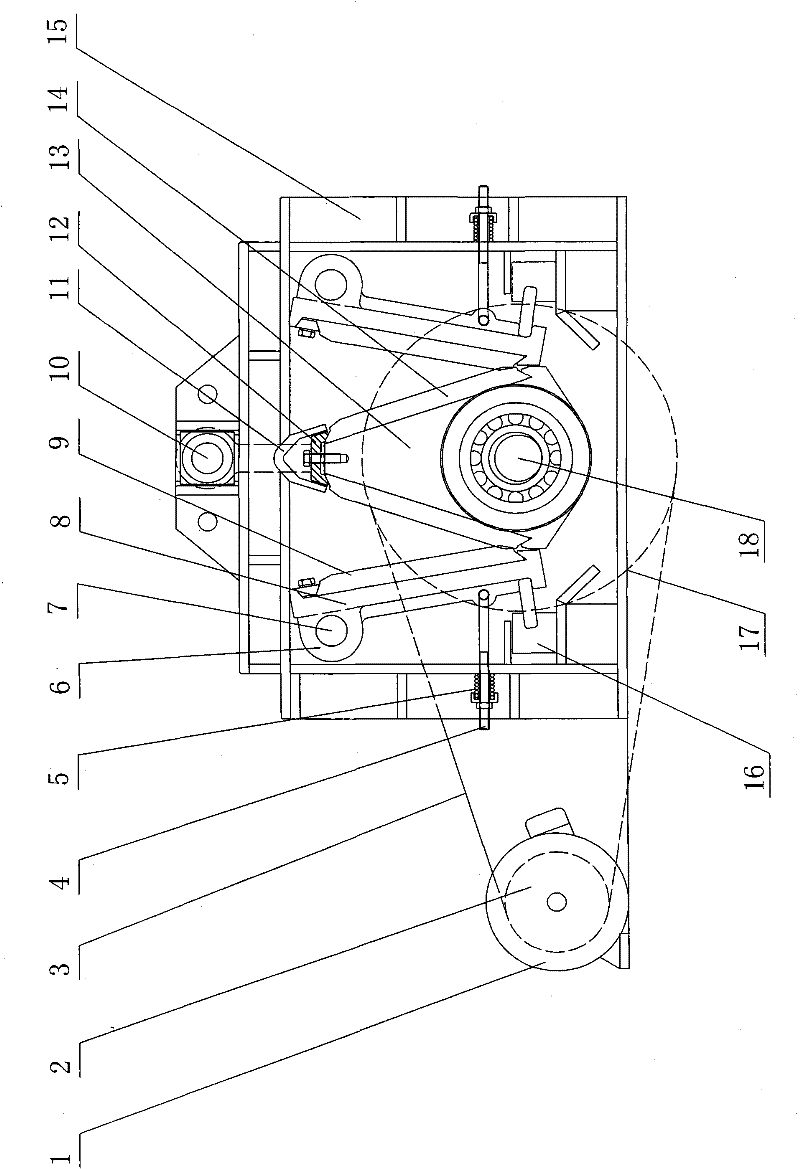

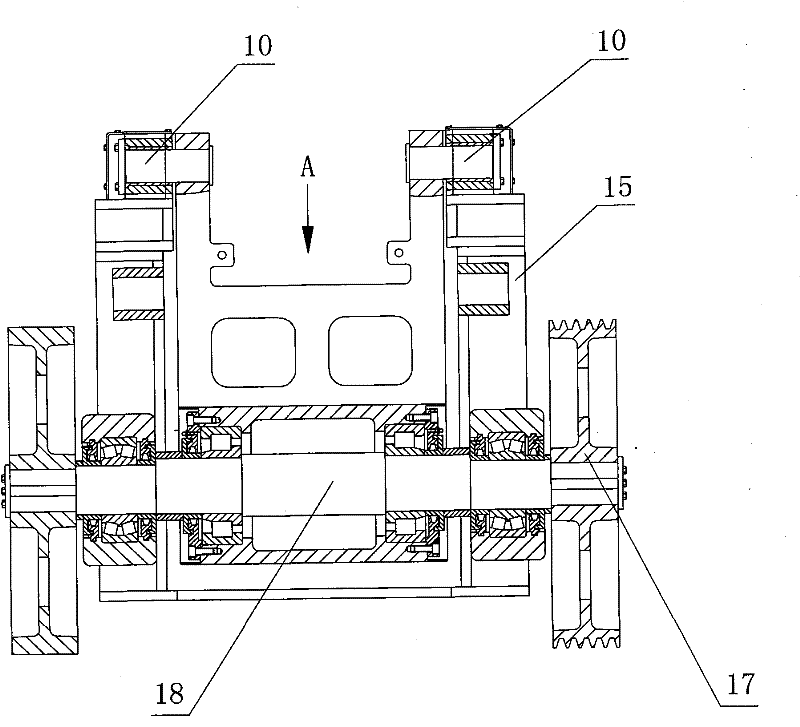

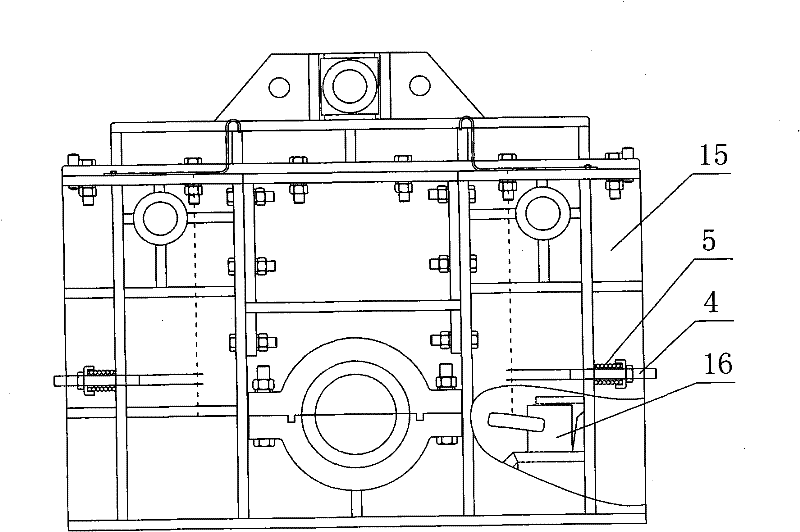

Compound pendulum double-cavity jaw crusher

InactiveCN102451783AImprove crushing efficiencyReduce power consumptionGrain treatmentsFixed frameMotor drive

The invention relates to a compound pendulum double-cavity jaw crusher. The compound pendulum double-cavity jaw crusher is characterized in that an upper end of a compound pendulum double-cavity jaw crusher body is provided with a slide block unit; the slide block unit is connected to a double-face movable jaw body located in the compound pendulum double-cavity jaw crusher body; two movable jaw plates are respectively fixed on two faces of the double-face movable jaw body by a movable jaw pressing plate; an upper end of the movable jaw pressing plate is provided with a material distribution plate; a lower end of the double-face movable jaw body is connected to an eccentric shaft; a motor drives the eccentric shaft to rotate; two inner sides of the compound pendulum double-cavity jaw crusher body are respectively provided with two jaw fixing frames; one end of each one of the jaw fixing frames is fixed on the compound pendulum double-cavity jaw crusher body by a long pin and the other end is fixed on the compound pendulum double-cavity jaw crusher body by a stay bolt and a compression spring; fixed jaw plates are fixed on the two jaw fixing frames by fixed jaw pressing plates; a low end of the interior of the compound pendulum double-cavity jaw crusher body is provided with bracket grooves; the bracket grooves are connected to the jaw fixing frames; and an upper part of the compound pendulum double-cavity jaw crusher body is provided with a feed inlet. The compound pendulum double-cavity jaw crusher is suitable for crushing processing of a material having high hardness and / or strong brittleness, and has high crushing production efficiency, good crushing effects and low energy consumption.

Owner:左中凯

Preparation method of pipe powder for nodular cast iron and application of pipe powder

The invention discloses pipe powder for nodular cast iron. The formula of the pipe powder comprises the following components in percentage by weight: 62-70% of Si, 3-10% of Ba, 1-2% of Ca, 0.8-1.8% of Al, 0.5-1.5% of Fe3O4, the balance of Fe and inevitable microelements. According to the pipe powder for the nodular cast iron disclosed by the invention, the overall performance of the nodular cast iron can be improved, and the inoculation efficiency is improved.

Owner:成都宏源铸造材料有限公司

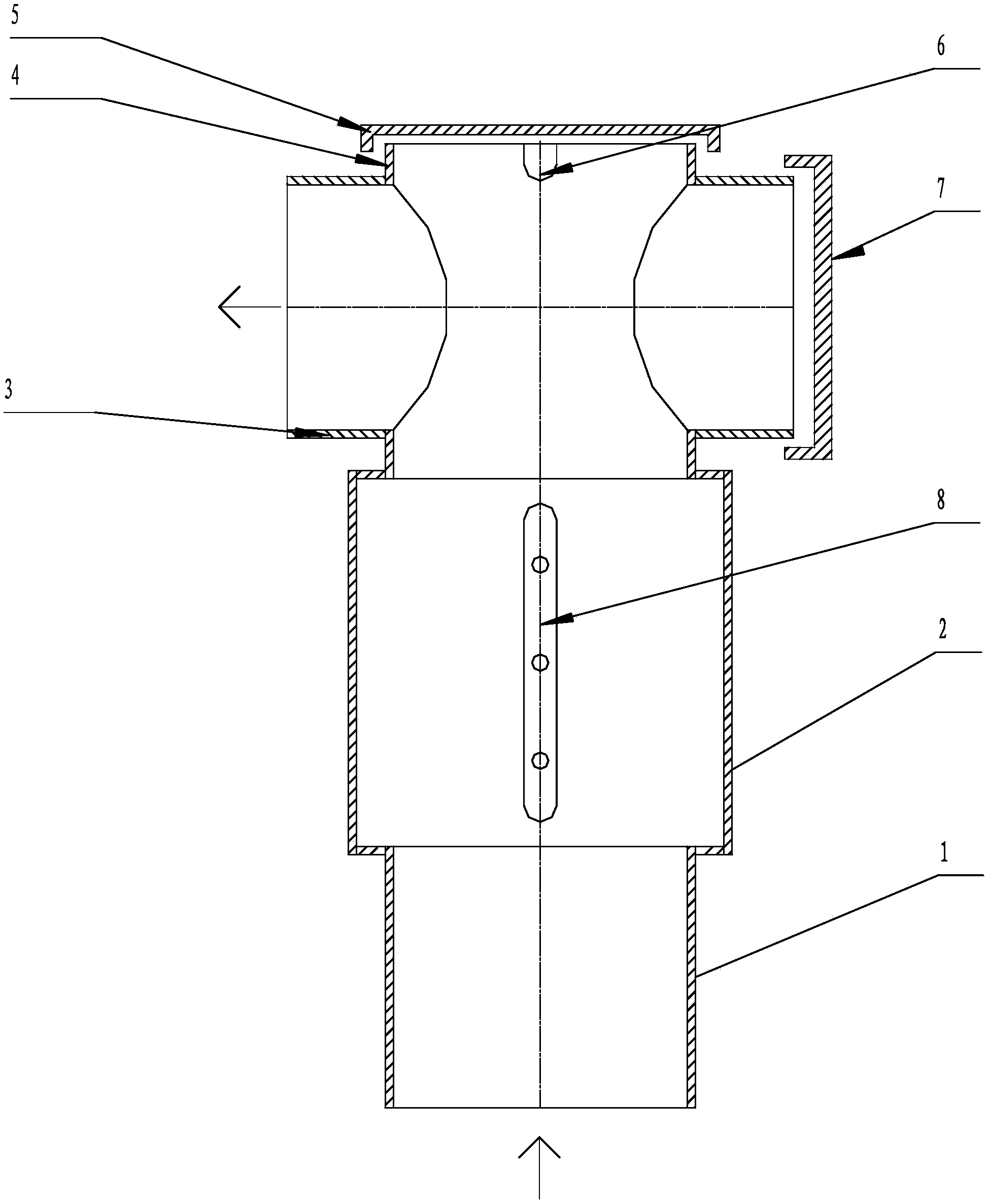

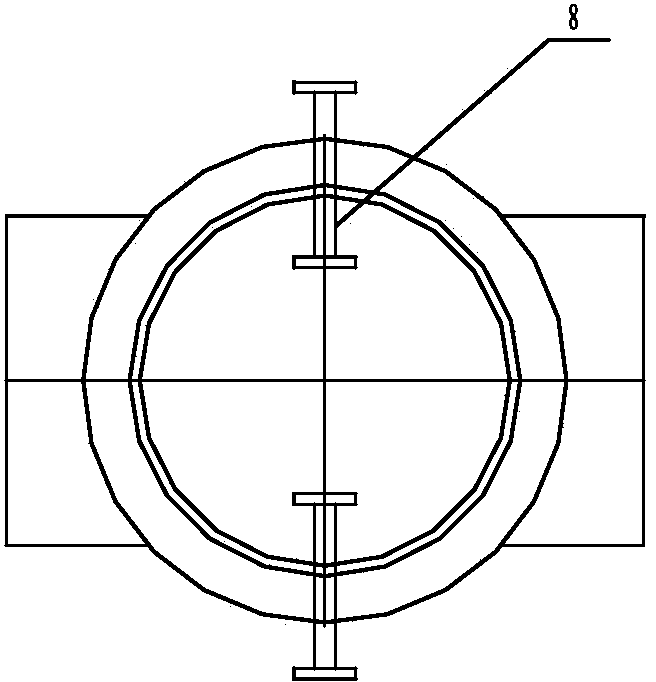

Multi-functional upper expanding device for producing antimony trioxide

ActiveCN103508490APromote aggregationWon't cause cloggingAntimony compoundsEngineeringAntimony trioxide

A multi-functional upper expanding device for producing antimony trioxide comprises an inlet pipe, an abdomen pipe, and an air exhausting pipe, wherein the inlet pipe, the abdomen pipe and the air exhausting pipe are orderly connected and communicate with each other; the inner diameter of the abdomen pipe is larger than those of the inlet pipe and the air exhausting pipe; the inlet end of the inlet pipe is arranged on the outlet end of the antimony trioxide reaction chamber, and the outlet end of the air exhausting pipe is connected to the inlet end of the antimony trioxide crystallization device. The multi-functional upper expanding device can adjust the particle size of antimony trioxide product at will, effectively controls the antimony trioxide product quality, timely recycles the agglomerated oxides generated during the antimony trioxide production process, and improves economic and technical indexes such as product yield, and the like.

Owner:湖南黄金股份有限公司 +1

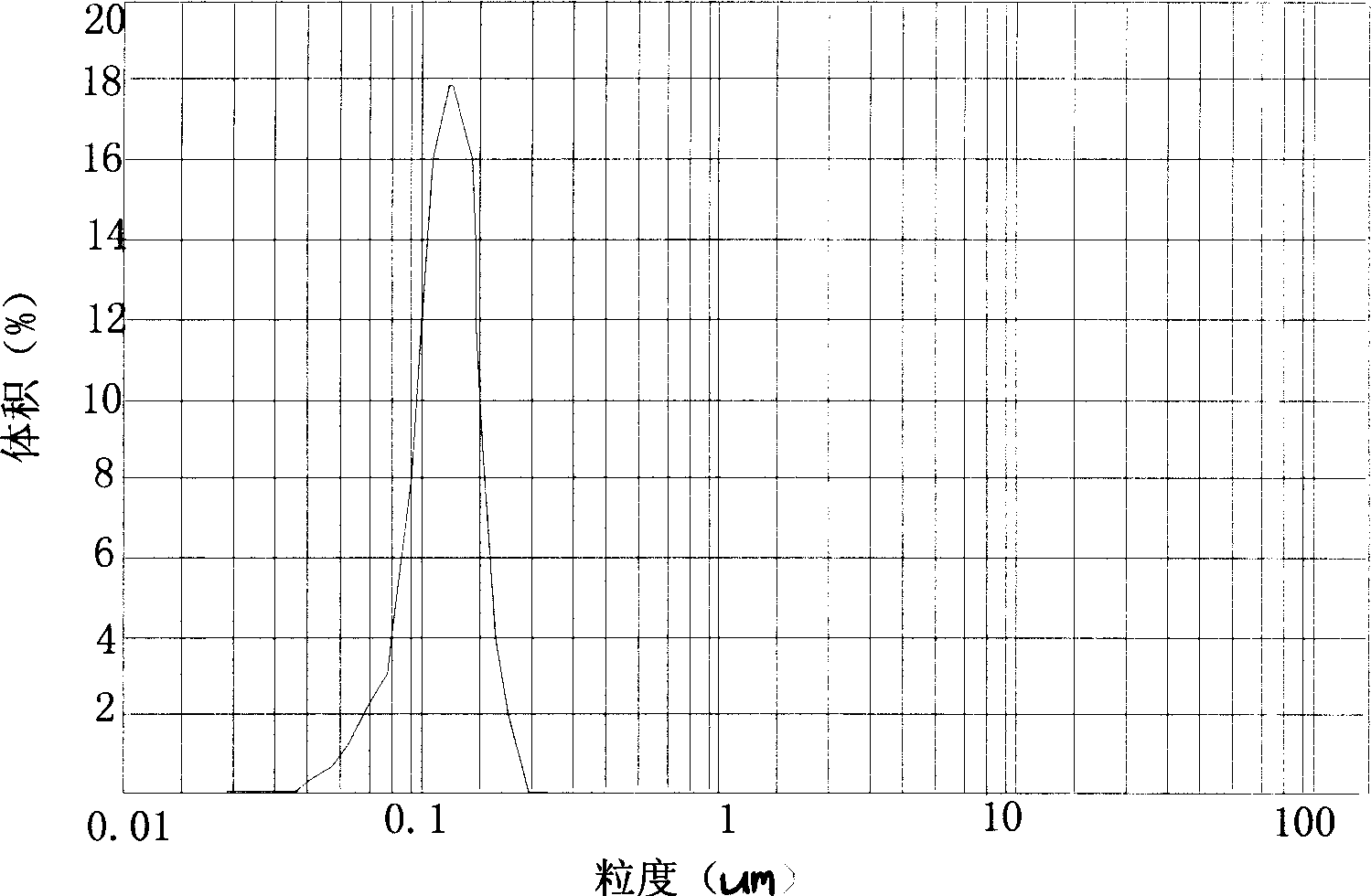

Method for preparing superfine natrium bentonite grout

InactiveCN1843910AChange granularityImprove anti-settling effectSilicon compoundsSodium BentoniteBentonite suspension

Disclosed is a method for preparing superfine natrium bentonite grout, which mainly comprises the following steps: (1) charging 1-50 parts by alta-mud weight of water into sodium bentonite or calcium bentonite containing montmorillonite higher than 92%, fully stirring and moistening, obtaining suspending liquid, (2) charging 0-0.1 part of sodium agent into the suspending liquid, stirring 10-60 minutes, (3) ball grinding the suspending liquid.

Owner:浙江安吉县宇宏粘土有限公司 +1

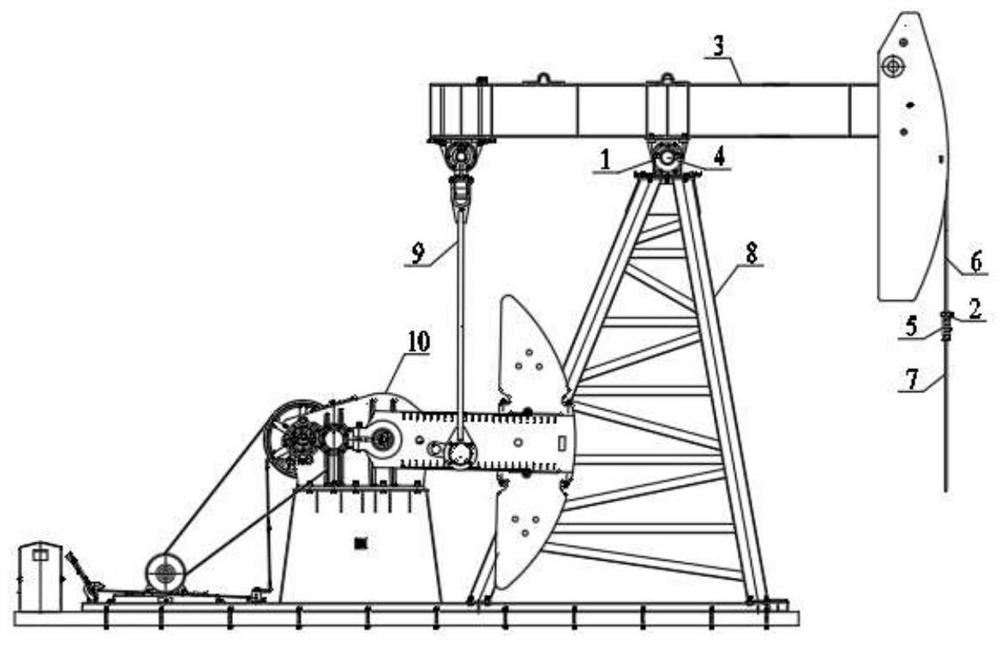

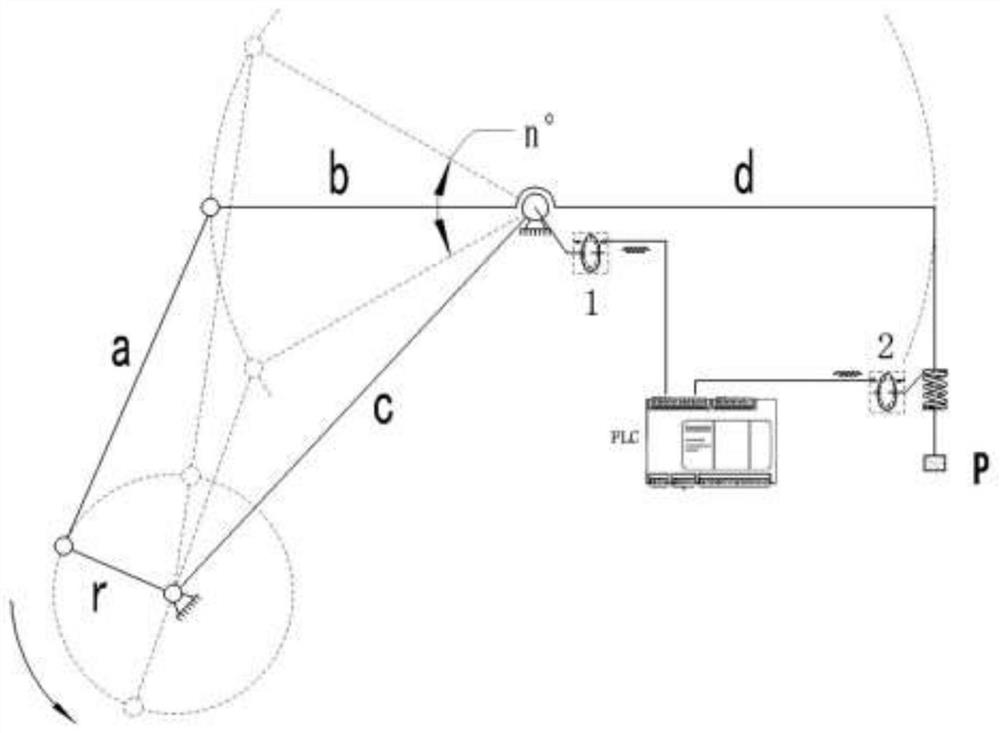

Digital high-precision indicator diagram data acquisition device

PendingCN111946327AOvercoming field temperature difference interference and impact interferenceExtended service lifeMeasurement devicesConstructionsRelative displacementOil production

The invention discloses a digital high-precision indicator diagram data acquisition device, and belongs to an electronic indicator diagram technology of an oil field pumping unit in the field of oil production engineering. The device utilizes an angle sensor to obtain a rotation angle of a walking beam, and then utilizes a displacement sensor to obtain relative displacement of a polish rod and a beam hanger; and a processor carries out calculation by using the rotation angle and the pulse number of the relative displacement and completes acquisition of pumping unit indicator diagram data, andan indicator diagram is displayed by a man-machine screen or remotely transmitted to a network to draw the indicator diagram. According to the digital high-precision indicator diagram data acquisitiondevice, a novel indicator diagram data acquisition mode is adopted, aiming at the mechanical structure and the working principle of the beam-pumping unit, the angle sensor is used for acquiring the swing angle of the walking beam and calculating the stroke, the displacement sensor is used for acquiring the displacement data of the polish rod and calculating the load, and the stroke and the load are both direct digital values, outdoor temperature difference interference and impact interference which cannot be overcome by an existing sensor are solved, and the device has the advantages of beinglong in service life, low in cost, high in anti-interference performance and the like.

Owner:SHAANXI KEWO ELECTRIC CO LTD

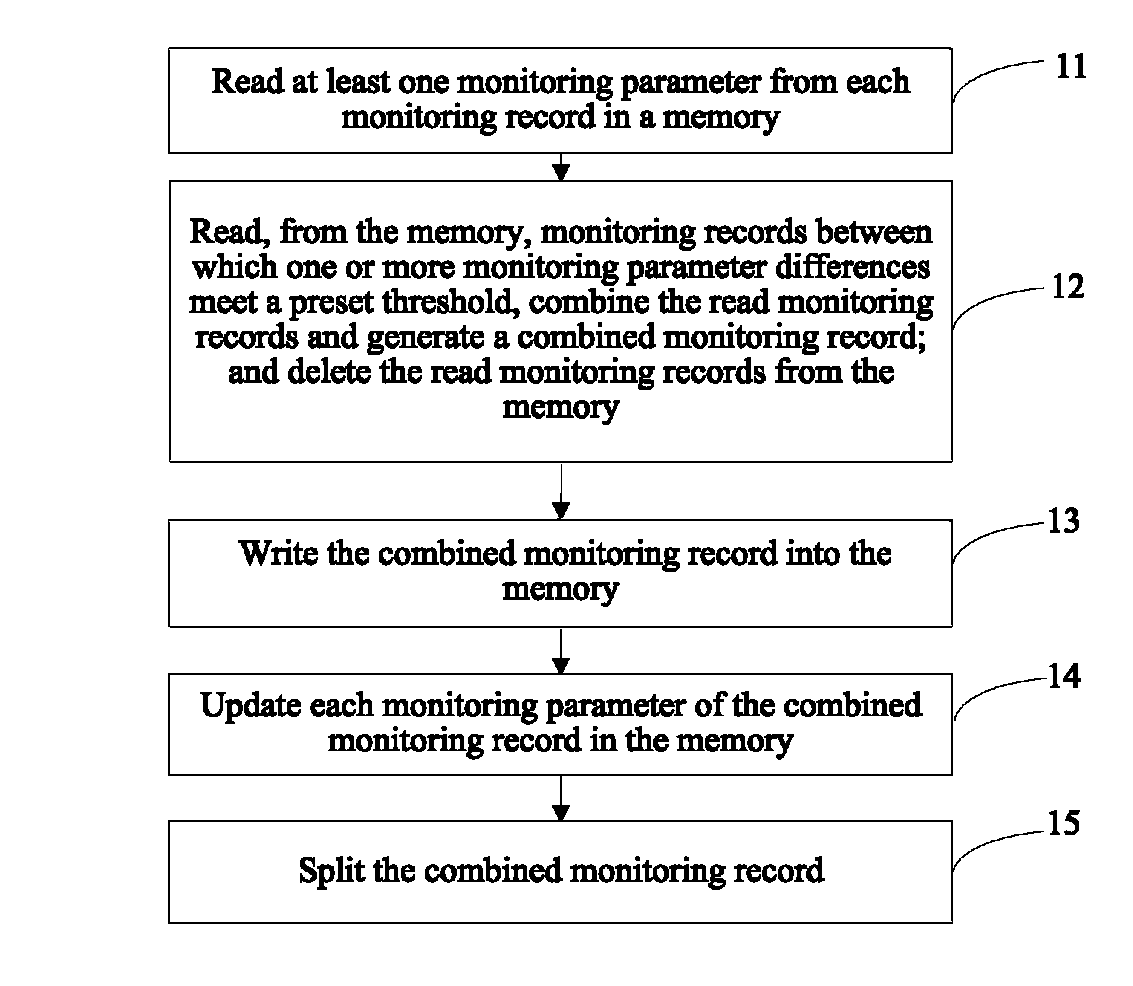

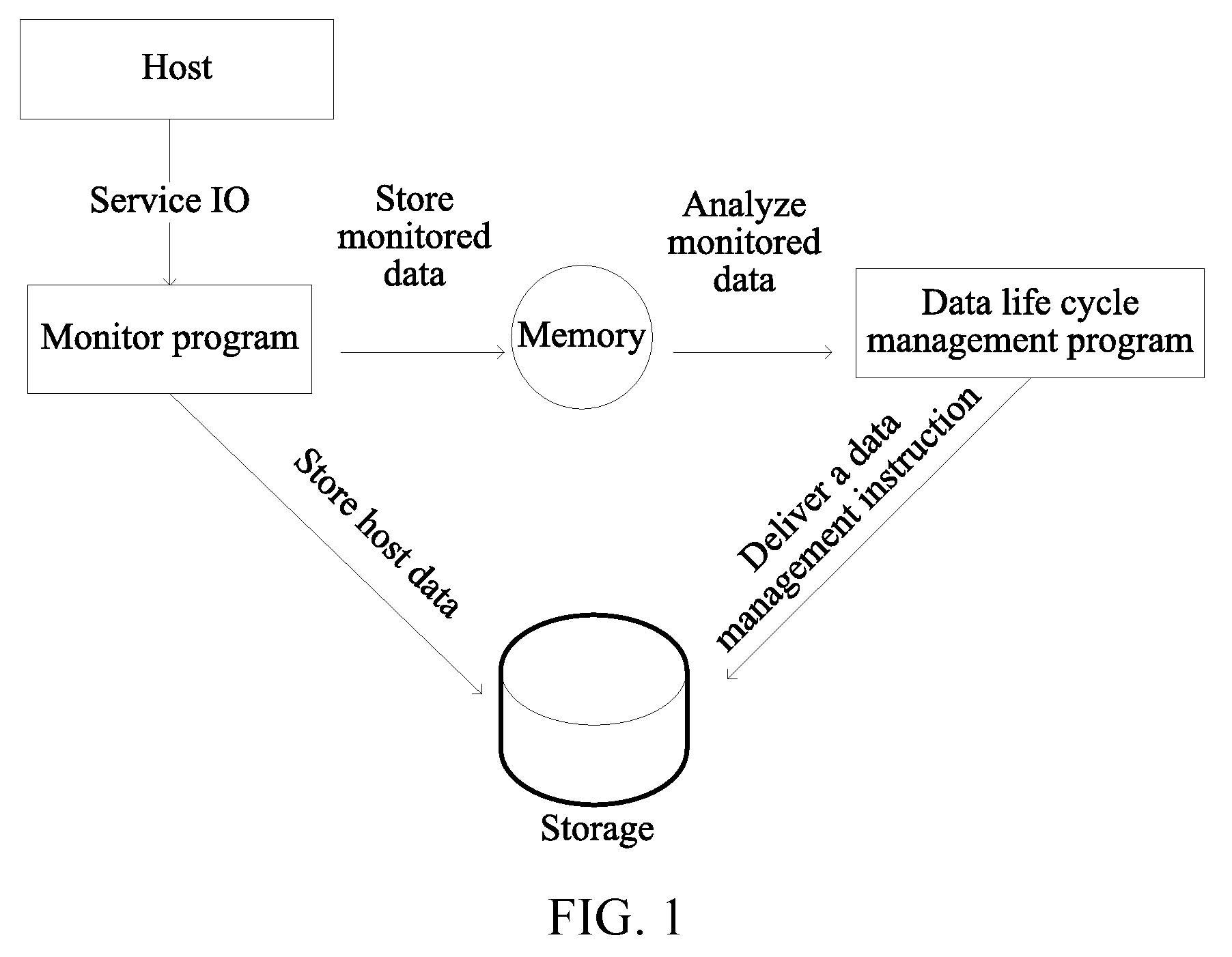

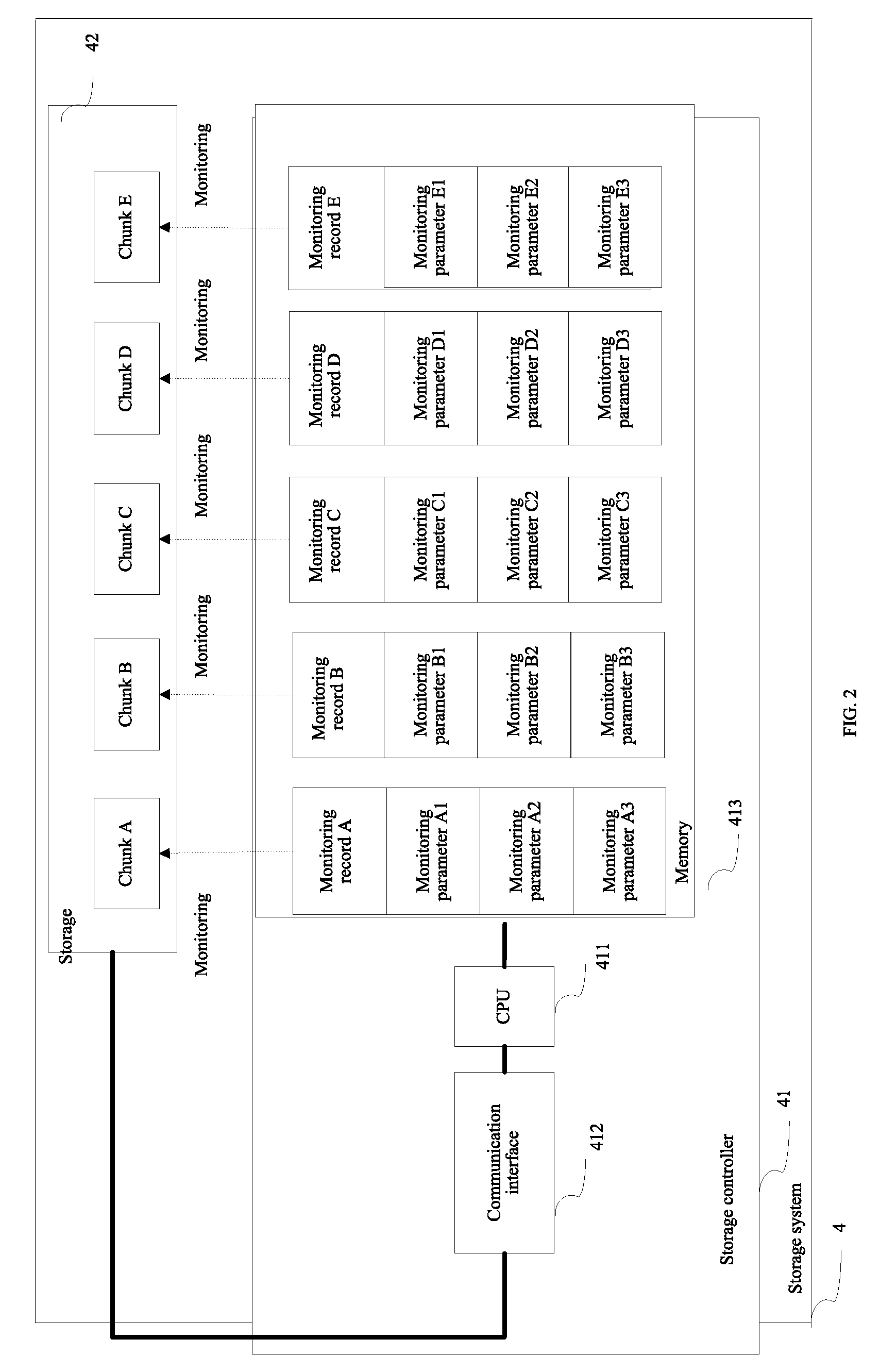

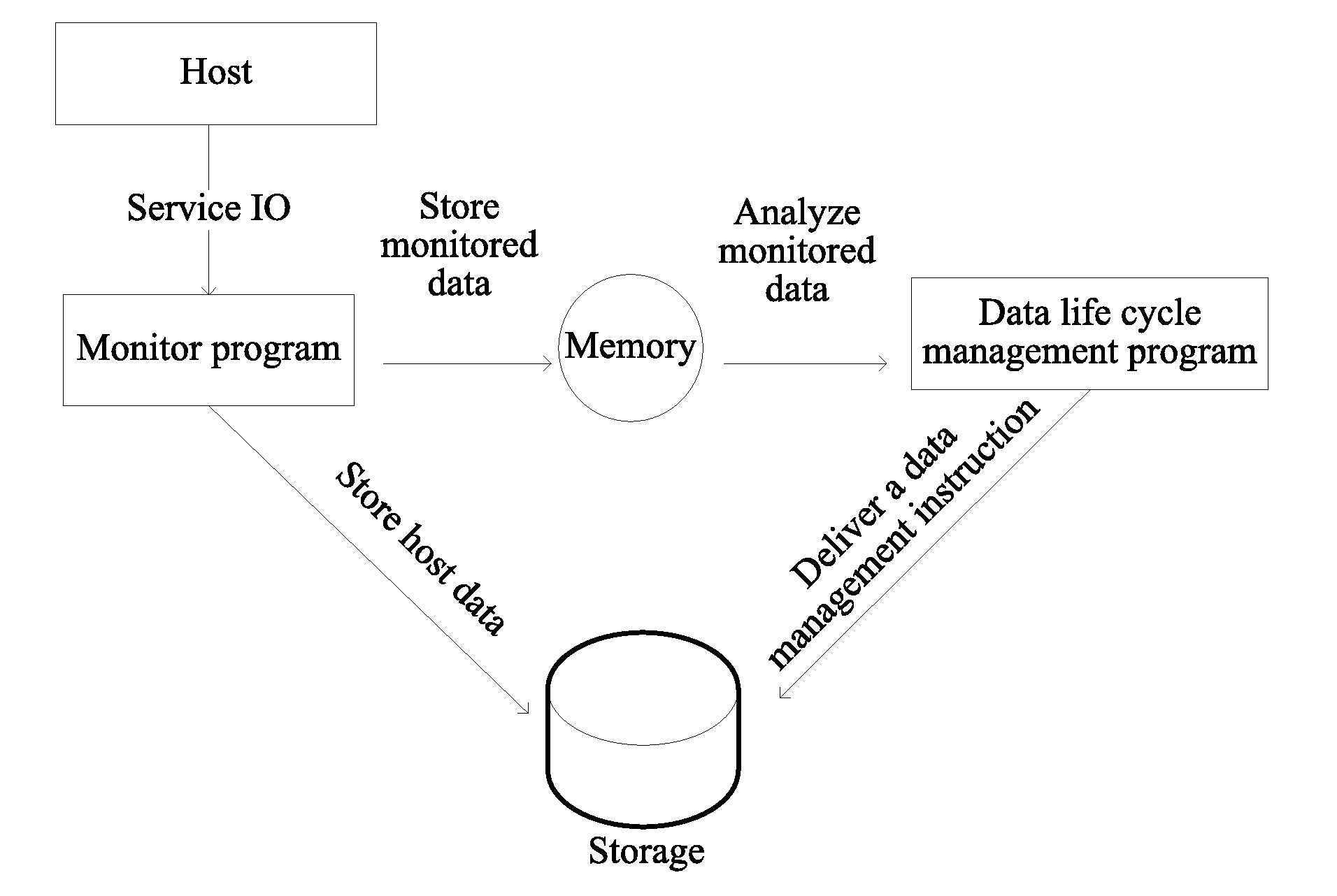

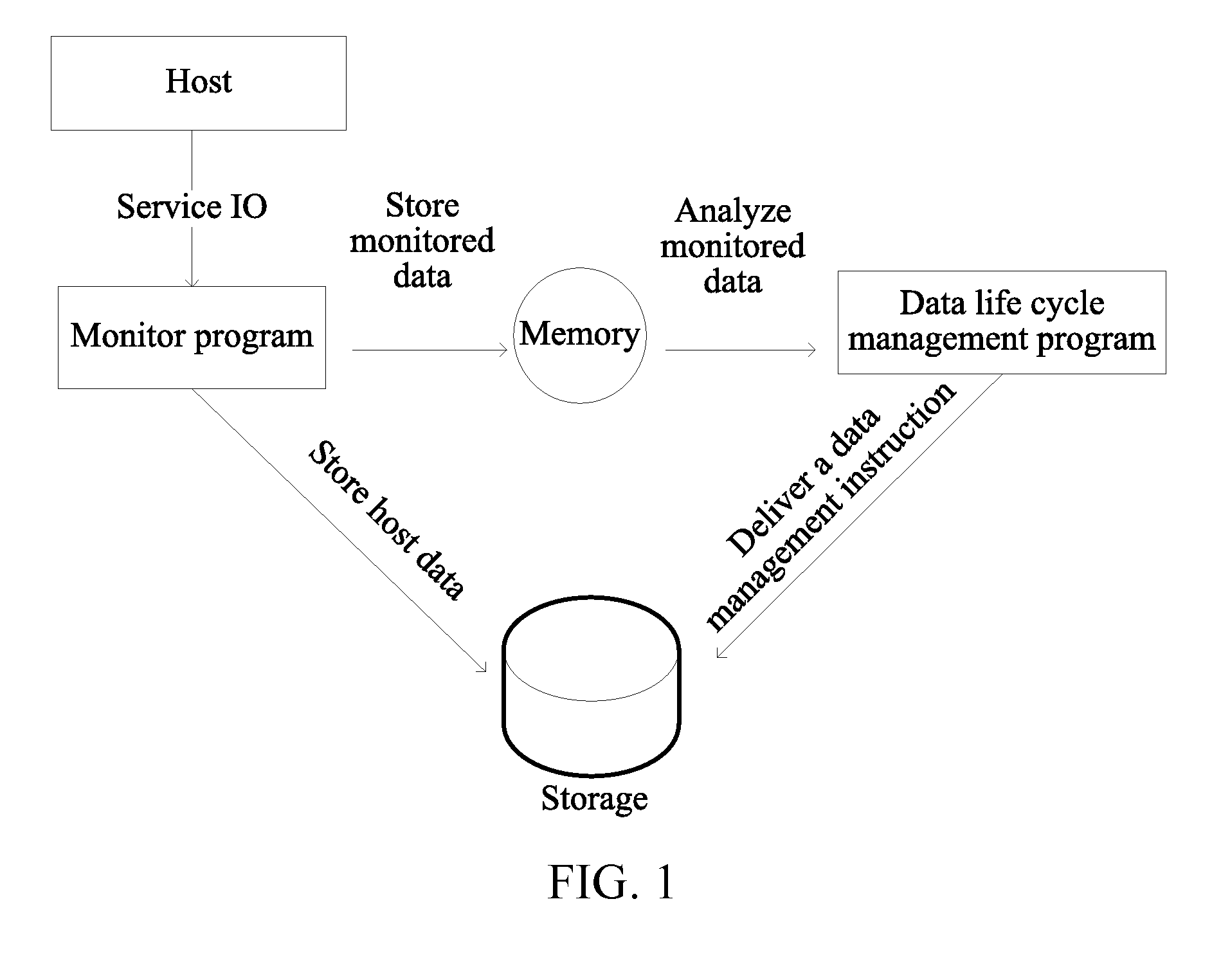

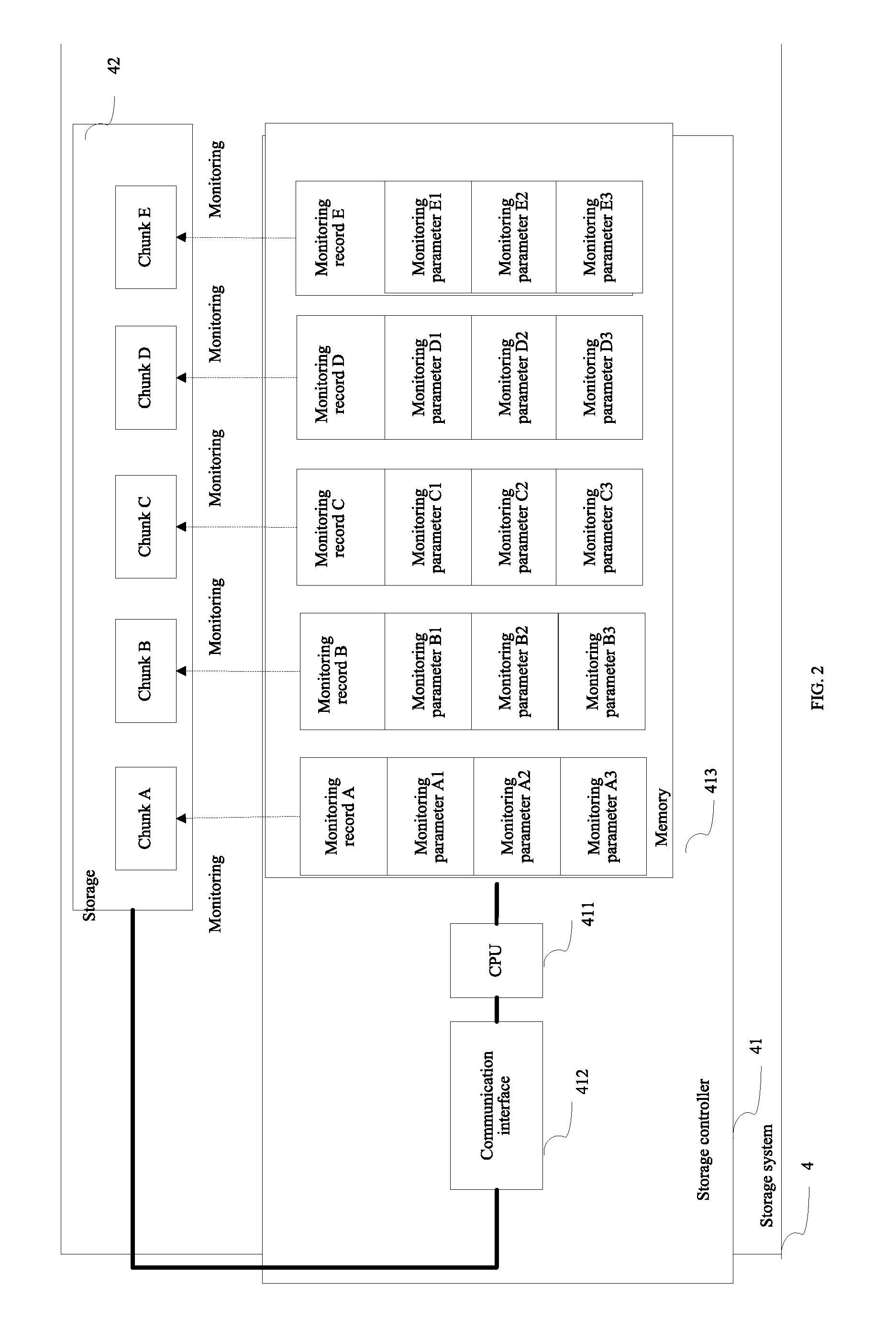

Monitoring record management method and device

The present invention provides a monitoring record management technology, which is used to manage a monitoring record stored in a memory, where the monitoring record is used to monitor a chunk in a storage, and by reading at least one monitoring parameter from each monitoring record in the memory, monitoring records between which a monitoring parameter meets a threshold are combined or split. After the monitoring record management technology provided in the present invention is applied, the occupancy of the memory can be reduced or the accuracy of the monitoring record can be improved.

Owner:XFUSION DIGITAL TECH CO LTD

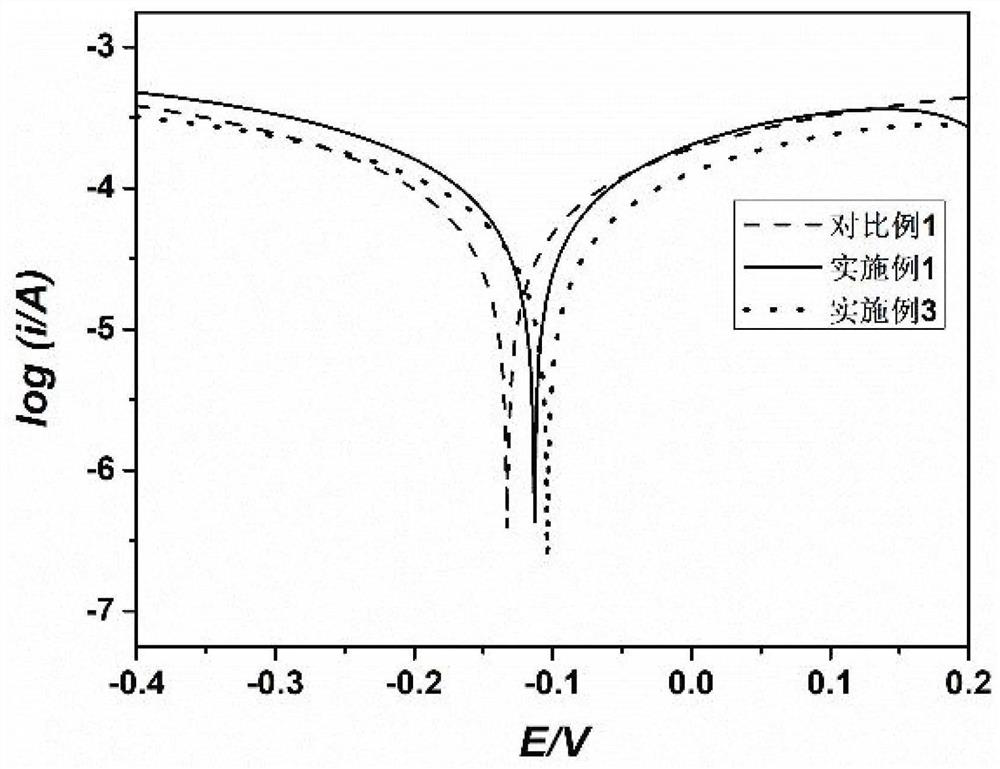

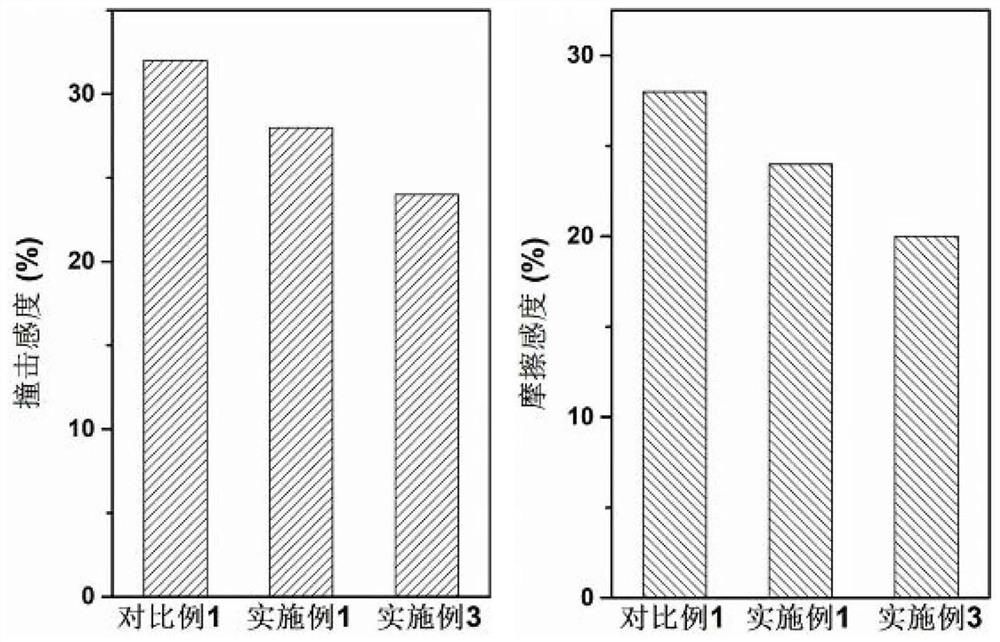

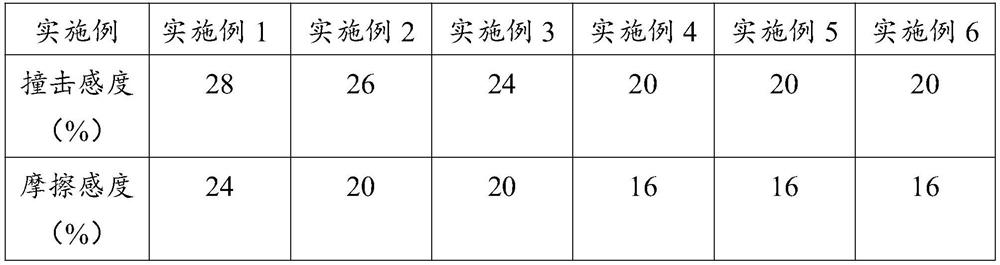

Metal corrosion resistant insensitive ammunition and preparation method thereof

ActiveCN113916066AImprove conductivityImproves metal corrosion resistanceVibration crystallizationAmmunitionNitrotriazoloneInsensitive munition

The invention relates to the technical field of energetic materials, and particularly discloses a metal corrosion resistant insensitive ammunition and a preparation method thereof. The metal corrosion resistant insensitive ammunition is prepared from, by weight, 0-10% of layered MXene and 90-100% of 3-nitro-1, 2, 4-triazole-5-ketone. The preparation method comprises the following steps of firstly, etching an aluminum layer in an MAX phase with hydrofluoric acid to obtain layered MXene, dissolving the layered MXene and NTO raw materials in absolute ethyl alcohol in proportion, and finally, carrying out evaporative crystallization to obtain the metal corrosion resistant insensitive ammunition. According to the metal corrosion resistant insensitive ammunition, the metal corrosion resistance of NTO is enhanced, and the impact sensitivity and friction sensitivity of NTO are further reduced; and the preparation method is simple, the MAX phase is etched by hydrofluoric acid to obtain conductive MXenes, then the MXenes and NTO are prepared by a recrystallization method, and the preparation method has practical application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Monitoring Record Management Method and Device

The present invention provides a monitoring record management technology, which is used to manage a monitoring record stored in a memory, where the monitoring record is used to monitor a chunk in a storage, and by reading at least one monitoring parameter from each monitoring record in the memory, monitoring records between which a monitoring parameter meets a threshold are combined or split. After the monitoring record management technology provided in the present invention is applied, the occupancy of the memory can be reduced or the accuracy of the monitoring record can be improved.

Owner:XFUSION DIGITAL TECH CO LTD

Crushing device used in pretreatment stage of sodium sulphide raw materials

InactiveCN106076504ASimple structureImprove reliabilityAlkali metal sulfides/polysulfidesGrain treatmentsWorking environmentReducer

The invention discloses a crushing device used in the pretreatment stage of sodium sulphide raw materials. Before the device works, a worker places a finished product box below a discharging pipe. Then, a crushing motor is started, a triangular block is driven to rotate through a speed reducer, and the triangular block drives an extrusion crushing mechanism to act. At the same time, a roller driving motor is started, a crushing wheel rotates, the worker fills a crushing barrel with sodium sulphide producing raw materials including mirabilite and raw coal, the mirabilite and the raw coal are crushed and mixed under the action of the extrusion crushing mechanism, then flow across the discharging pipe and fall into the finished product box, and so far, the device finishes the functional action. The device can safely and reliably crush and mix the raw coal and the mirabilite, simultaneously carries out the two procedures, has low requirement on operation space, is favorable to keeping a clean working environment, and reduces the labor intensity of an operator.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

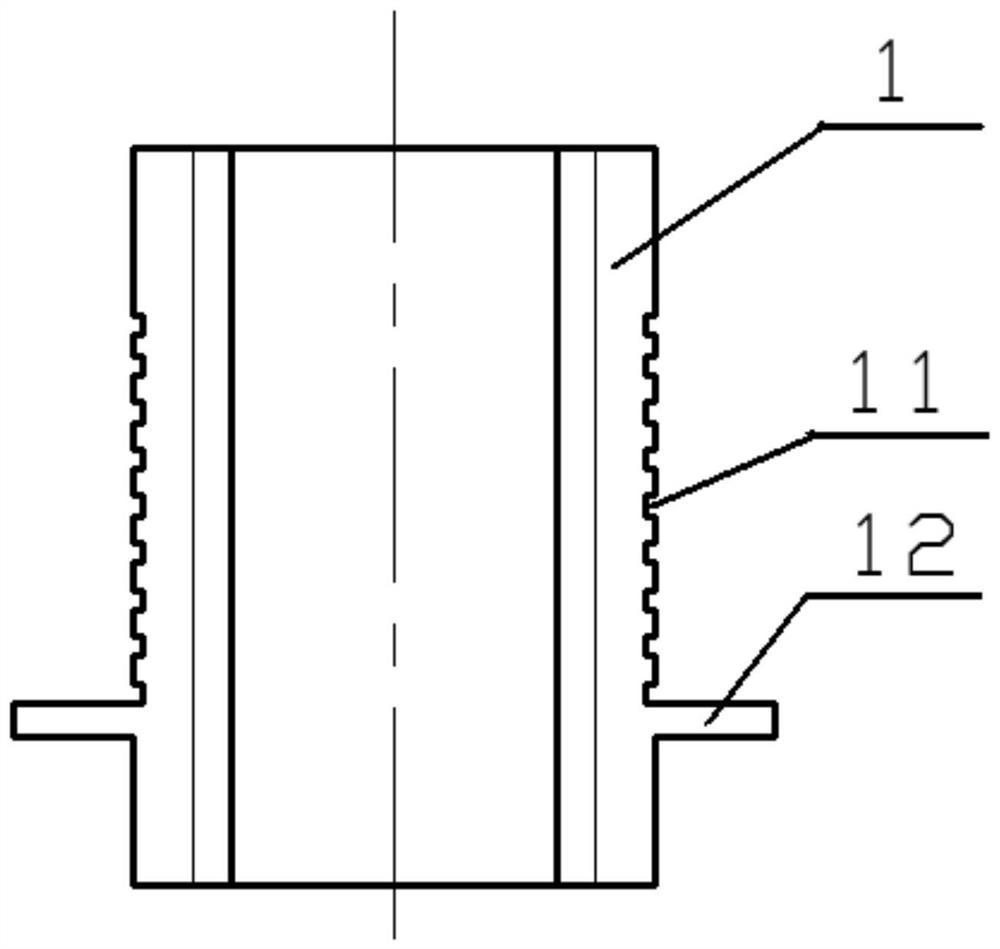

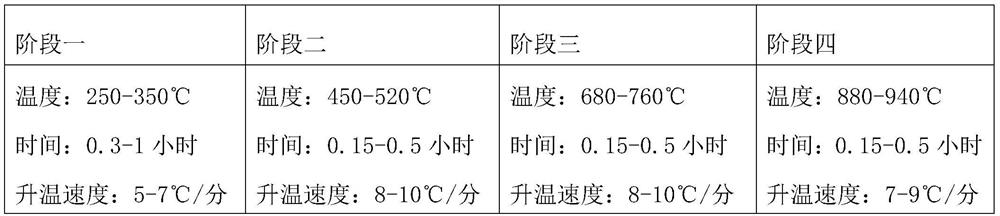

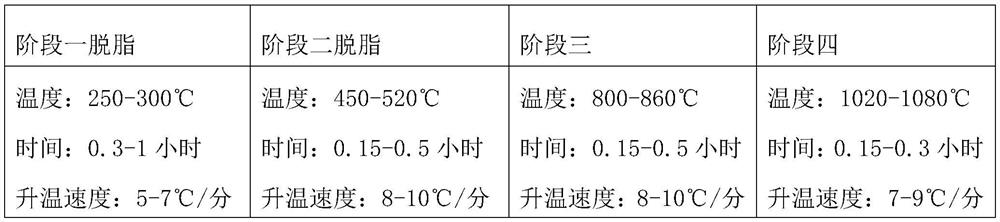

Method for preparing Kovar alloy electronic package box

InactiveCN1180908CHigh densityHigh dimensional accuracySemiconductor/solid-state device detailsSolid-state devicesHigh energyAdditive ingredient

The invention provides a method for preparing a Kovar alloy electronic packaging box body. Mixing iron, nickel and cobalt powder according to weight percentage Fe:Ni:Co=53~55:29~31:16~18, milling with high-energy ball mill for 2-8 hours to obtain alloy composite powder; adding binder to alloy composite powder , mixed into a uniform feed, the powder loading is 55-64%; the feed is injection-molded on the injection machine, the temperature is 150-170°C, and the pressure is 90-110MPa; the injection-molded blank is degreased by solvent degreasing + subsequent thermal degreasing Process, solvent degreasing the injection molding blank in trichlorethylene for 2 to 6 hours, and drying at a temperature of 40 to 60°C for 30 to 60 minutes; thermal degreasing is performed at room temperature to 600°C, and the time is 6 to 8 hours; injection After degreasing the formed body, it is sintered in a sintering furnace at 1250-1280° C. and kept for 1-3 hours. The sintered product is subjected to subsequent treatment to obtain a packaging box. The advantage lies in the high material utilization rate and the high dimensional accuracy of the product.

Owner:苏州创基精密制造有限公司

Positive electrode for zinc-air battery and its manufacturing method

InactiveCN100341179CChange structureChange granularityFuel and primary cellsCell electrodesElectrolysisEngineering

The invention relates to a positive electrode of zinc-air battery and its manufacturing method. Said positive electrode comprises a catalytic layer (2) mixed by polytetrafluoroethylene emulsion and the mixture which uses industrial alcohol to infiltrate carrier, conductor, and catalytic agent; a flow collector (3) and a waterproof layer (1), wherein, said catalytic agent is electrolytic manganese dioxide material. Since the conductor selects expansible graphite and the flow collector (3) selects nickel-plated iron net, the surface of material is increased more than 400 % to improve the ability of absorbing oxygen of electrode, and the conductivity of material is increased 40 % to improve the discharging current density and reduce the cost. The electrolytic manganese dioxide is processed into manganese dioxide powder, to change the crystal phase structure and its particle, so the manufacturing process is simplified.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Brazing mixture and method for preparing diamond brazing string beads from brazing mixture

PendingCN113880579AImprove wear resistanceImprove performanceWelding/cutting media/materialsSoldering mediaChromium carbideAcrylic resin

The invention discloses a brazing mixture which comprises brazing powder and / or fine-particle alloy powder, a modifier and a forming agent, wherein the modifier is high-hardness powder composed of dimolybdenum carbide and one or two of tungsten carbide, titanium diboride, titanium carbide or chromium carbide, and the use amount of the modifier is 5-20% (W / W) of the mass of the brazing powder or the fine-particle alloy powder; and the forming agent is one or two solutions of paraffin, PEG, PVA and acrylic resin which account for 2.5-4.5% of the mass of the brazing powder or the fine-particle alloy powder. Molybdenum carbide, tungsten carbide, titanium diboride, titanium carbide or chromium carbide and the like are added into the brazing mixture, so that the wear resistance of a matrix is adjusted, and meanwhile, the sintering effect can be improved; and the diamond concentration in the matrix can be conveniently and rapidly adjusted, and efficient cutting can be achieved. The invention further discloses a method for preparing the diamond brazing string beads, through efficient ball milling, destressing, deoxidizing, pelleting and the like, the granularity and morphology of brazing powder are changed, the pressing performance of the mixture is improved, and the brazing string beads are rapidly prepared in a cold pressing forming mode.

Owner:CHANGSHA BAICHUAN SUPERHARD MATERIAL TOOLS

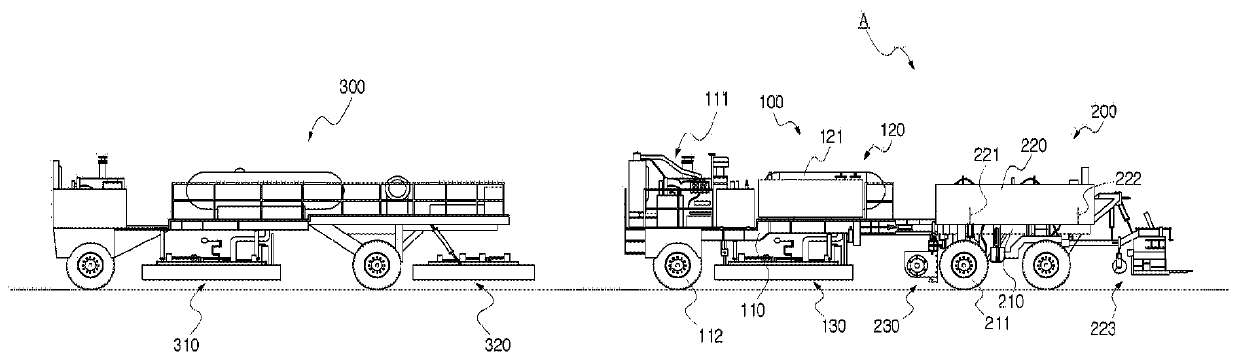

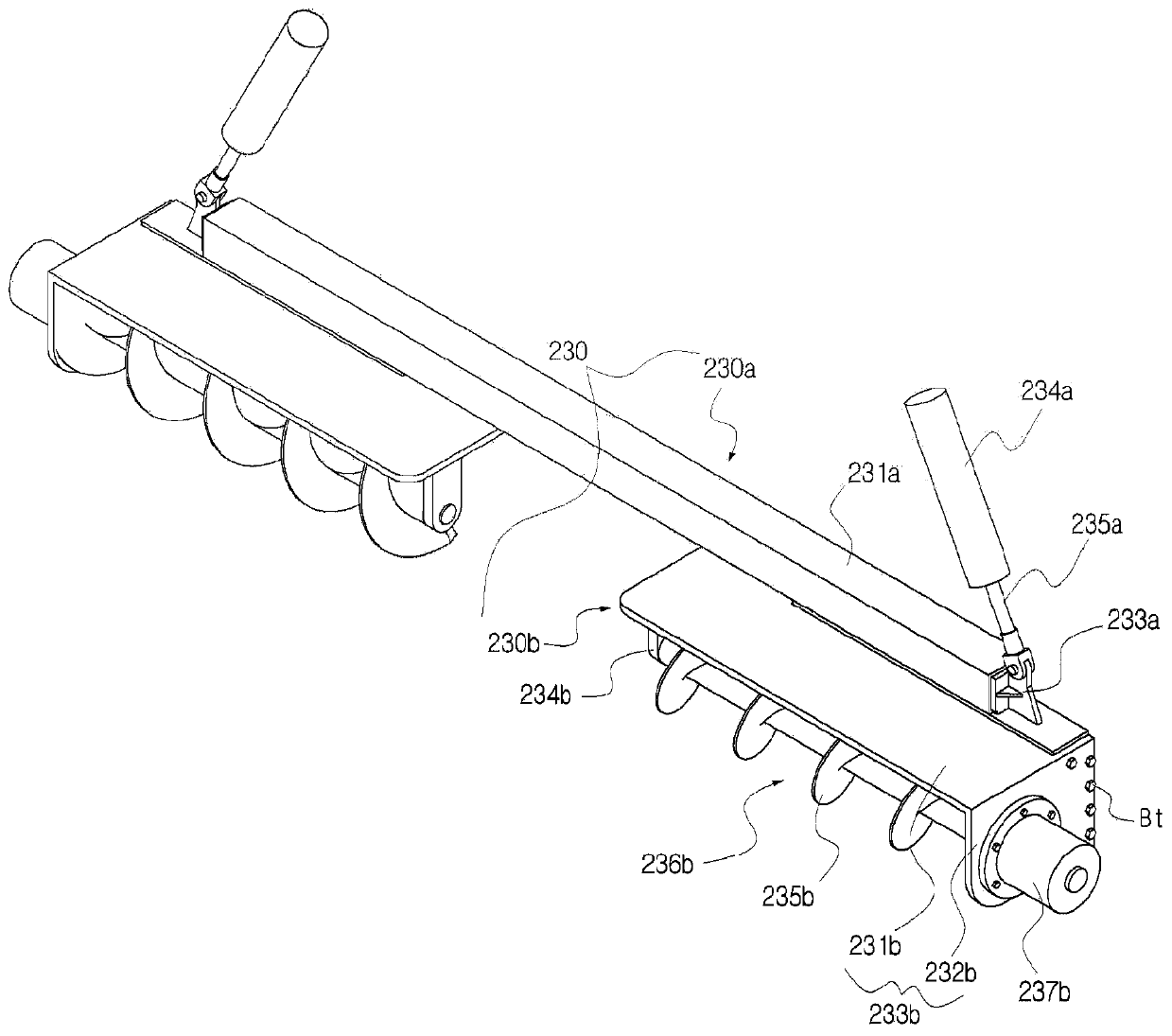

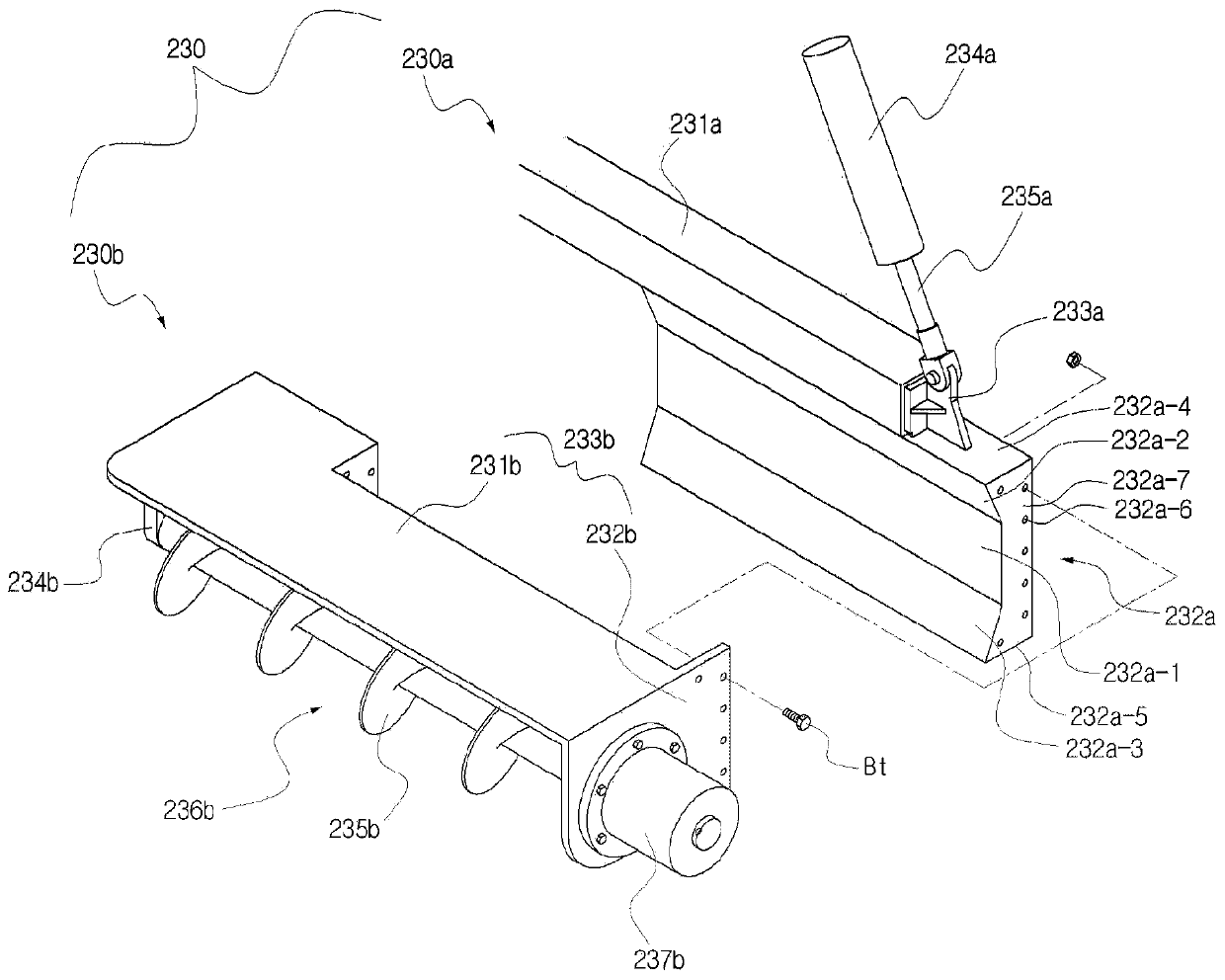

Hot in-place asphalt recycling apparatus and road paving method using same

The present invention relates to a hot in-place asphalt recycling apparatus and a road paving method using same. To this end, the hot in-place asphalt recycling apparatus provided with a preheater part and a recycling part, according to the present invention, is characterized in that: the preheater part comprises a support frame on one side, having driving wheels connected to a driving part, a fuel supply part having a fuel tank above the support frame on one side, and an ignition nozzle part provided below the support frame on one side, wherein fuel supplied from the fuel supply part to the ignition nozzle part is ignited so that an asphalt road surface is heated and softened; and the recycling part comprises a support frame on the other side, having driven wheels, a recycling tank provided above the support frame on the other side and to which a recycling additive is inputted, and a road surface removal part provided below the support frame on the other side located at the lower partof a side of the recycling tank, wherein the heated and softened road surface is scraped and fed into an inlet of the recycling tank so as to obtain recycled asphalt mixed with the recycling additive, and the recycled asphalt is outputted via an outlet provided on the other side of the recycling tank. Therefore, the present invention allows the heated and softened road surface to be scraped by the road surface removal part, thereby preventing aggregate inside the surface layer from which the road surface has been removed from breaking, while preventing a change in the gradation of the aggregate from occurring.

Owner:A ONE ROAD CO LTD

Low-cost magnesium-silicon based castable for tundish prefabricated component and preparation method thereof

The invention relates to a low-cost magnesium-silicon based castable for a tundish prefabricated component and a preparation method thereof. According to the invention, magnesium olivine sand, magnesia, silica powder, silicon carbide, sodium tripolyphosphate, sodium hexametaphosphate and organic fiber are used as raw materials. High content of the magnesium olivine sand raw-material is adopted, thus reducing the dosage of magnesia. The price of the magnesium olivine sand raw-material is low and is only 1 / 3-1 / 2 of the price of magnesia. Therefore, the cost of the castable product is reduced greatly. In addition, when the dosage of magnesium olivine sand and magnesia is adjusted, granularity of the raw materials magnesium olivine sand and magnesia is changed. Thus, a tundish prefabricated component prepared from the castable still can be endowed with advantages of high strength, anti-explosion performance and the like.

Owner:SHANGHAI LIER REFRACTORY MATERIAL

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com